Sustainable Utilization of Mushroom By-Products Processed with a Combined Osmotic Dehydration Pretreatment and a Hot-Air-Drying Step

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Osmotic Dehydration Process

2.3. Mass Transfer Calculations

2.4. Physicochemical Properties’ Determination during Osmotic Treatment

2.5. OD Experimental Design

2.6. Air-Drying Process

2.7. Air-Drying Kinetics’ Modeling

3. Results and Discussion

3.1. Effect of Osmotic Dehydration Process Parameters

3.1.1. Effect of Temperature and Time of Osmosis on Dependent Variables

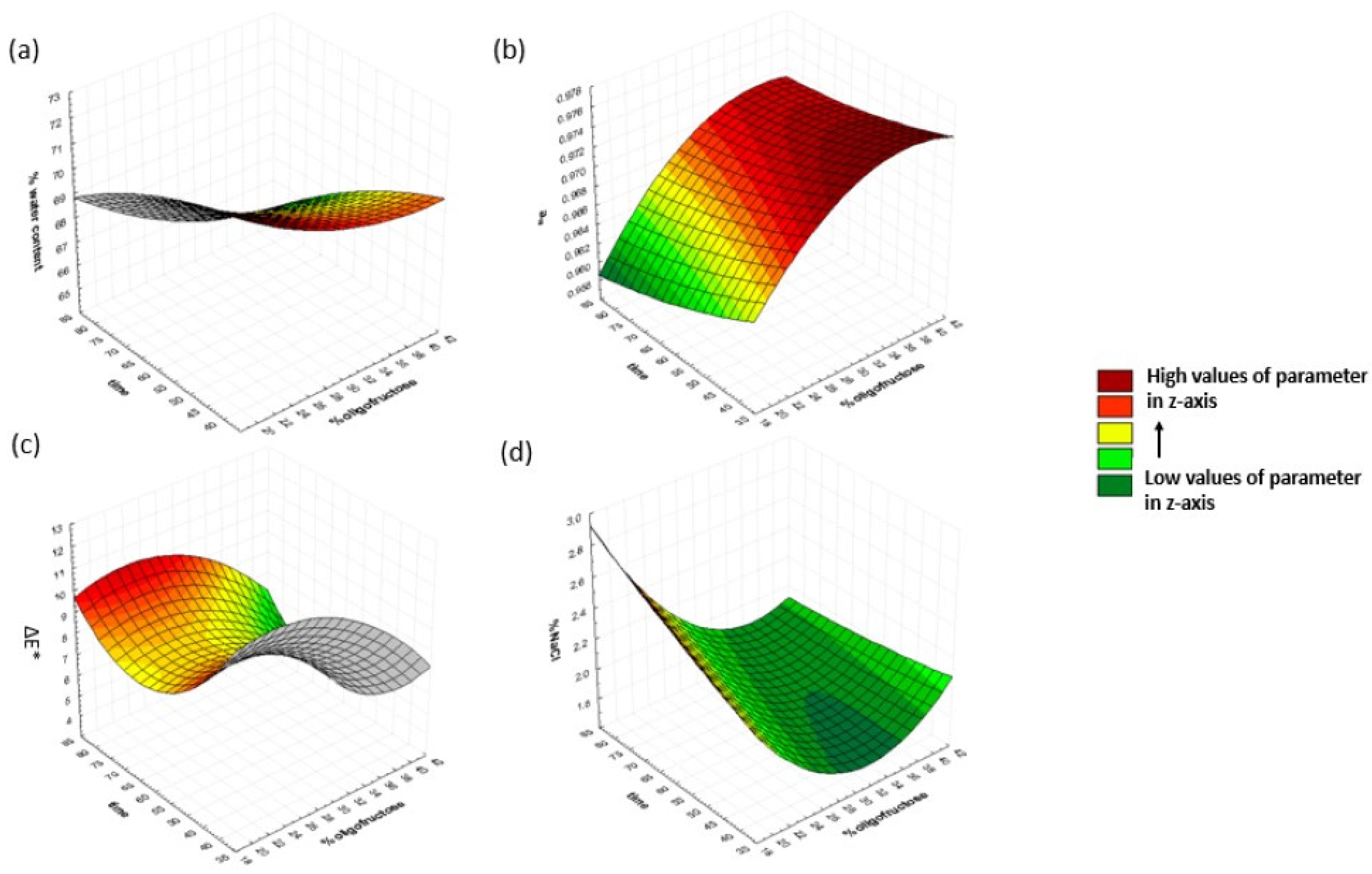

3.1.2. Effect of Dehydration Time and Oligofructose Concentration on Dependent Variables

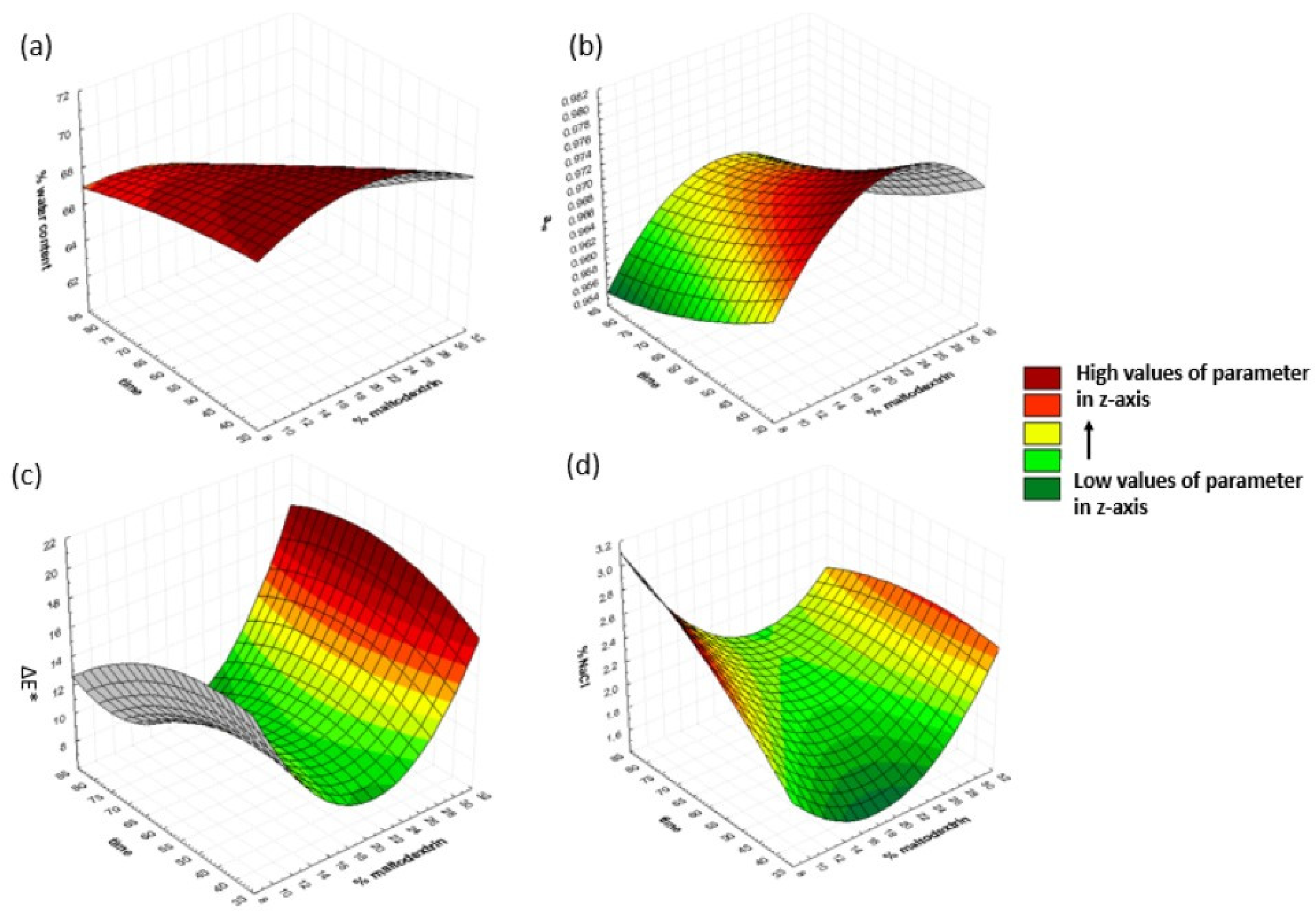

3.1.3. Effect of Dehydration Time and Maltodextrin Concentration on Dependent Variables

3.2. Optimization and Validation of the Process

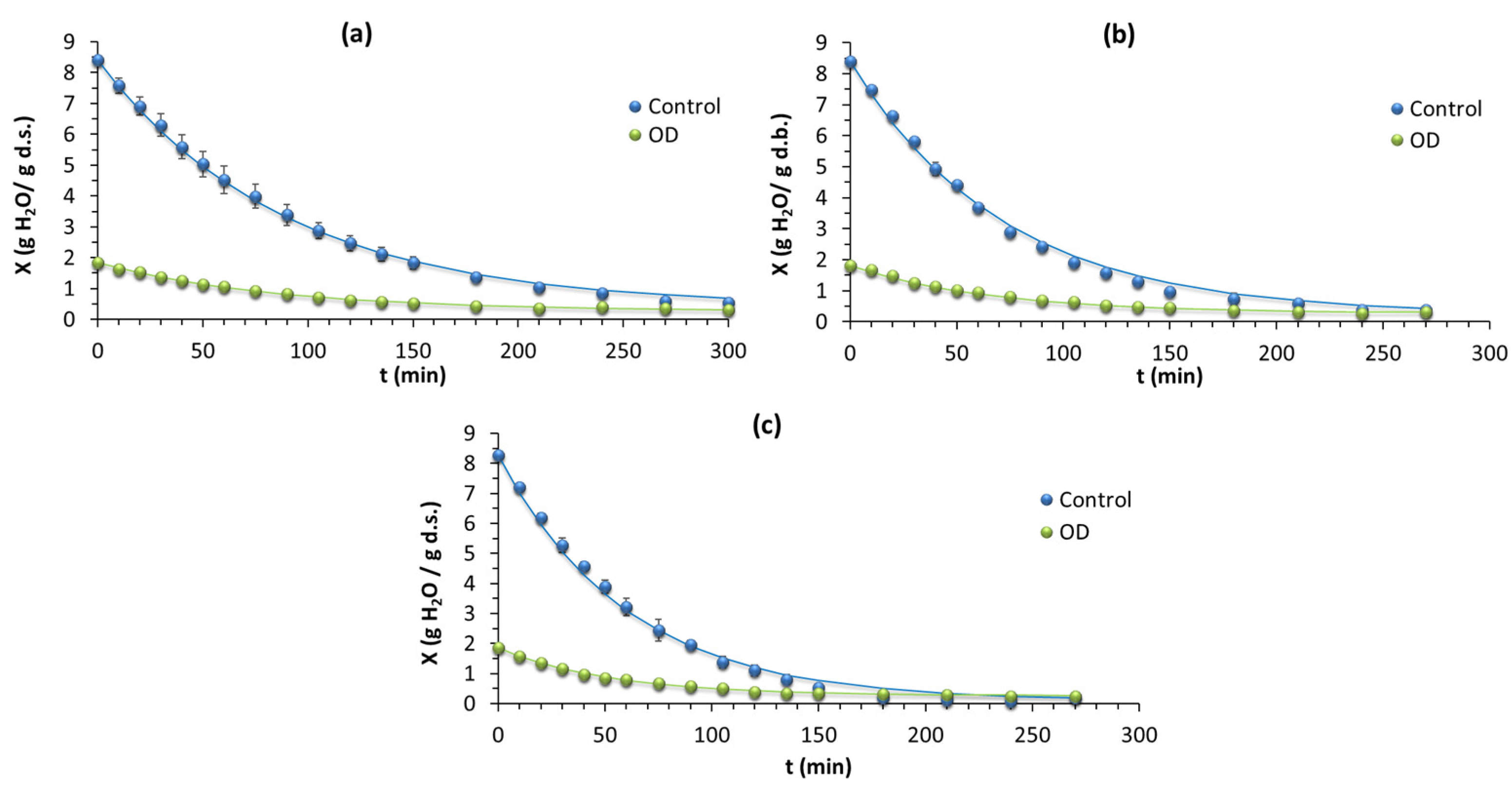

3.3. Hot-Air-Drying Kinetics

Effect of Air-Drying Temperature on Drying Kinetics of Optimal Osmodehydrated Mushroom Stems

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, J.; Zhang, M.; Fang, Z. Valorization of mushroom by-products: A review. J. Sci. Food Agric. 2022, 102, 5593–5605. [Google Scholar] [CrossRef] [PubMed]

- Prandi, B.; Cigognini, I.M.; Faccini, A.; Zurlini, C.; Rodríguez, Ó.; Tedeschi, T. Comparative Study of Different Protein Extraction Technologies Applied on Mushrooms By-products. Food Bioprocess Technol. 2023, 16, 1570–1581. [Google Scholar] [CrossRef]

- Antunes, F.; Marçal, S.; Taofiq, O.; MMB Morais, A.; Freitas, A.C.; CFR Ferreira, I.; Pintado, M. Valorization of mushroom by-products as a source of value-added compounds and potential applications. Molecules 2020, 25, 2672. [Google Scholar] [CrossRef]

- Guo, L.; Lan, N.; Li, H.; Xiang, P.; Kan, H. Effect of hot air drying temperature on the quality and antioxidant activity of Boletus edulis Bull. Fr. J. Food Process. Preserv. 2021, 45, e15540. [Google Scholar] [CrossRef]

- Kumar, H.; Bhardwaj, K.; Sharma, R.; Nepovimova, E.; Cruz-Martins, N.; Dhanjal, D.S.; Singh, R.; Chopra, C.; Verma, R.; Abd-Elsalam, K.A.; et al. Potential Usage of Edible Mushrooms and Their Residues to Retrieve Valuable Supplies for Industrial Applications. J. Fungi 2021, 7, 427. [Google Scholar] [CrossRef] [PubMed]

- Dermesonlouoglou, E.K.; Pantelaiaki, K.; Andreou, V.; Katsaros, G.J.; Taoukis, P.S. Osmotic pretreatment for the production of novel dehydrated tomatoes and cucumbers. J. Food Process. Preserv. 2019, 43, e13968. [Google Scholar] [CrossRef]

- González-Pérez, J.E.; Ramírez-Corona, N.; López-Malo, A. Mass transfer during osmotic dehydration of fruits and vegetables: Process factors and non-thermal methods. Food Eng. Rev. 2021, 13, 344–374. [Google Scholar] [CrossRef]

- Katsoufi, S.; Lazou, A.E.; Giannakourou, M.C.; Krokida, M.K. Air drying kinetics and quality characteristics of osmodehydrated-candied pumpkins using alternative sweeteners. Dry. Technol. 2021, 39, 2194–2205. [Google Scholar] [CrossRef]

- Biswas, R.; Hossain, M.A.; Zzaman, W. Thin layer modeling of drying kinetics, rehydration kinetics and color changes of osmotic pre-treated pineapple (Ananas comosus) slices during drying: Development of a mechanistic model for mass transfer. Innov. Food Sci. Emerg. Technol. 2022, 80, 103094. [Google Scholar] [CrossRef]

- Maleki, M.; Shahidi, F.; Varidi, M.J.; Azarpazhooh, E. Hot air drying kinetics of novel functional carrot snack: Impregnated using polyphenolic rich osmotic solution with ultrasound pretreatment. J. Food Process Eng. 2020, 43, e13331. [Google Scholar] [CrossRef]

- Pei, Y.P.; Sun, B.H.; Vidyarthi, S.K.; Zhu, Z.Q.; Yan, S.K.; Zhang, Y.; Wanga, J.; Xiao, H.W. Pulsed pressure enhances osmotic dehydration and subsequent hot air drying kinetics and quality attributes of red beetroot. Dry. Technol. 2020, 41, 262–276. [Google Scholar] [CrossRef]

- Md Salim, N.S.; Garièpy, Y.; Raghavan, V. Effects of processing on quality attributes of osmo-dried broccoli stalk slices. Food Bioprocess Technol. 2019, 12, 1174–1184. [Google Scholar] [CrossRef]

- Ashtiani, S.H.M.; Aghkhani, M.H.; Feizy, J.; Martynenko, A. Effect of Cold Plasma Pretreatment Coupled with Osmotic Dehydration on Drying Kinetics and Quality of Mushroom (Agaricus bisporus). Food Bioprocess Technol. 2023, 1–23. [Google Scholar] [CrossRef]

- González-Pérez, J.E.; López-Méndez, E.M.; Ochoa-Velasco, C.E.; Ruiz-López, I.I. Mass transfer and morphometric characteristics of fresh and osmodehydrated white mushroom pilei during convective drying. J. Food Eng. 2019, 262, 181–188. [Google Scholar] [CrossRef]

- Kurozawa, L.E.; Azoubel, P.M.; Murr, F.E.X.; Park, K.J. Drying kinetic of fresh and osmotically dehydrated mushroom (Agaricus blazei). J. Food Process Eng. 2012, 35, 295–313. [Google Scholar] [CrossRef]

- Singla, R.; Ganguli, A.; Ghosh, M. Antioxidant Activities and Polyphenolic Properties of Raw and Osmotically Dehydrated Dried Mushroom (Agaricus bisporous) Snack Food. Int. J. Food Prop. 2010, 13, 1290–1299. [Google Scholar] [CrossRef]

- Niness, K.R. Inulin and oligofructose: What are they? J. Nutr. 1999, 129, 1402S–1406S. [Google Scholar] [CrossRef] [PubMed]

- Van Loo, J.; Coussement, P.; De Leenheer, L.; Hoebregs, H.; Smits, G. On the presence of inulin and oligofructose as natural ingredients in the western diet. Crit. Rev. Food Sci. Nutr. 1995, 35, 525–552. [Google Scholar] [CrossRef] [PubMed]

- Pantelidou, D.; Gerogiannis, K.; Goula, A.M.; Gonas, C. Ultrasound-Assisted Osmotic Dehydration as a Method for Supplementing Potato with Unused Chokeberries Phenolics. Food Bioprocess Technol. 2021, 14, 2231–2247. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, M.; Devahastin, S.; Yu, D. Effect of ultrasound-assisted osmotic dehydration pretreatments on drying and quality characteristics of pulsed fluidized bed microwave freeze-dried strawberries. LWT 2021, 145, 111300. [Google Scholar] [CrossRef]

- Kumari, V.; Yadav, B.S.; Yadav, R.; Nema, P.K. Effect of osmotic agents and ultasonication on osmo-convective drying of sweet lime (Citrus limetta) peel. J. Food Process Eng. 2020, 43, e13371. [Google Scholar] [CrossRef]

- Shinde, B.; Ramaswamy, H.S. Maltodextrin Moderated Microwave Osmotic Dehydration of Mango Cubes with Finish Air-Drying: Optimum Considerations. J. Compos. Sci. 2022, 6, 56. [Google Scholar] [CrossRef]

- Shinde, B.; Ramaswamy, H.S. Microwave–osmotic–vacuum combination drying of mango cubes with maltodextrin moderated sucrose solution. Dry. Technol. 2023, 41, 1046–1059. [Google Scholar] [CrossRef]

- Sobotka, O.; Ticha, M.; Kubickova, M.; Adamek, P.; Polakova, L.; Mezera, V.; Sobotka, L. Should Carbohydrate Intake Be More Liberal during Oral and Enteral Nutrition in Type 2 Diabetic Patients? Nutrients 2023, 15, 439. [Google Scholar] [CrossRef] [PubMed]

- Kumari, B.; Tiwari, B.K.; Hossain, M.B.; Brunton, N.P.; Rai, D.K. Recent advances on application of ultrasound and pulsed electric field technologies in the extraction of bioactives from agro-industrial by-products. Food Bioprocess Technol. 2018, 11, 223–241. [Google Scholar] [CrossRef]

- Messinese, E.; Pitirollo, O.; Grimaldi, M.; Milanese, D.; Sciancalepore, C.; Cavazza, A. By-Products as Sustainable Source of Bioactive Compounds for Potential Application in the Field of Food and New Materials for Packaging Development. Food Bioprocess Technol. 2023, 17, 606–627. [Google Scholar] [CrossRef]

- Wang, C.Y. A Review on the Potential Reuse of Functional Polysaccharides Extracted from the By-Products of Mushroom Processing. Food Bioprocess Technol. 2020, 13, 217–228. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Lazou, A.Ε.; Dermesonlouoglou, E.K.; Giannakourou, M.C. Modeling and evaluation of the osmotic pretreatment of tomatoes (S. lycopersicum) with alternative sweeteners for the production of candied products. Food Bioprocess Technol. 2020, 13, 948–961. [Google Scholar] [CrossRef]

- Amiripour, M.; Habibi-Najafi, M.B.; Mohebbi, M.; Emadi, B. Optimization of osmo-vacuum drying of pear (Pyrus communis L.) using response surface methodology. J. Food Meas. Charact. 2015, 9, 269–280. [Google Scholar] [CrossRef]

- Ghellam, M.; Zannou, O.; Pashazadeh, H.; Galanakis, C.M.; Aldawoud, T.M.; Ibrahim, S.A.; Koca, I. Optimization of osmotic dehydration of autumn olive berries using response surface methodology. Foods 2021, 10, 1075. [Google Scholar] [CrossRef]

- Romero, I.P.; Gómez, M.J.R.; Iñiguez, F.M.S.; Magro, P.C. Optimization of the osmotic dehydration process of plums (Prunus Salicina Lindl.) in solutions enriched with inulin, using response surface methodology. LWT 2022, 157, 113092. [Google Scholar] [CrossRef]

- Macedo, L.L.; Corrêa, J.L.G.; Araújo, C.D.S.; Oliveira, D.D.S.; Teixeira, L.J.Q. Use of coconut sugar as an alternative agent in osmotic dehydration of strawberries. J. Food Sci. 2023, 88, 3786–3806. [Google Scholar] [CrossRef] [PubMed]

- Stavropoulou, N.A.; Pavlidis, V.A.; Giannakourou, M.C. Optimization of Osmotic Dehydration of White Mushrooms by Response Surface Methodology for Shelf-Life Extension and Quality Improvement of Frozen End-Products. Foods 2022, 11, 2354. [Google Scholar] [CrossRef] [PubMed]

- Dermesonlouoglou, E.K.; Pourgouri, S.; Taoukis, P.S. Kinetic study of the effect of the osmotic dehydration pre-treatment to the shelf life of frozen cucumber. Innov. Food Sci. Emerg. Technol. 2008, 9, 542–549. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.K.; Giannakourou, M.C.; Taoukis, P.S. Stability of dehydrofrozen tomatoes pre-treated with alternative osmotic solutes. J. Food Eng. 2007, 78, 272–280. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.K.; Giannakourou, M.; Taoukis, P.S. Kinetic study of the effect of the osmotic dehydration pre-treatment with alternative osmotic solutes to the shelf life of frozen strawberry. Food Bioprod. Process. 2016, 99, 212–221. [Google Scholar] [CrossRef]

- Ramya, H.G.; Kumar, S.; Kapoor, S. Optimization of osmotic dehydration process for Oyster mushrooms (Pleurotus sajor-caju) in sodium chloride solution using RSM. J. Appl. Nat. Sci. 2014, 6, 152–158. [Google Scholar] [CrossRef]

- Shinde, B.; Ramaswamy, H.S. Optimization of maltodextrin (10DE)—Sucrose moderated microwave osmotic dehydration of mango cubes under continuous flow spray mode (MWODS) conditions. J. Food Process Eng. 2021, 44, e13835. [Google Scholar] [CrossRef]

- Avaltroni, F.; Bouquerand, P.-E.; Normand, V. Maltodextrin molecular weight distribution influence on the glass transition temperature and viscosity in aqueous solutions. Carbohydr. Polym. 2004, 58, 323–334. [Google Scholar] [CrossRef]

- Schaller-Povolny, L.A.; Smith, D.E.; Labuza, T.P. Effect of water content and molecular weight on the moisture isotherms and glass transition properties of inulin. Int. J. Food Prop. 2000, 3, 173–192. [Google Scholar] [CrossRef]

- González-Pérez, J.E.; Romo-Hernández, A.; Ramírez-Corona, N.; López-Malo, A. Modeling mass transfer during osmodehydration of apple cubes with sucrose or apple juice concentrate solutions: Equilibrium estimation, diffusion model, and state observer-based approach. J. Food Process Eng. 2022, 45, e14125. [Google Scholar] [CrossRef]

- Seth, D.; Sen, D.; Kumar Dash, K. Optimization of osmotic dehydration process of carambola (Averrhoacarambola L.) fruit in binary solution of salt and sucrose. J. Microbiol. Biotechnol. Food Sci. 2021, 10, e3307. [Google Scholar] [CrossRef]

- Kaur Dhillon, G.; Kour, A.; Gupta, N. Optimization of low-cost drying technology for preservation of peach (Prunus Persica) using RSM. Int. J. Fruit Sci. 2022, 22, 525–538. [Google Scholar] [CrossRef]

- Kaur, B.; Rana, P.; Sridhar, K. Mass transfer kinetics and process optimization of osmotic dehydration of Kinnow mandarin (Citrus reticulata) peel. J. Food Process. Preserv. 2022, 46, e16318. [Google Scholar] [CrossRef]

- Rai, R.; Rani, P.; Tripathy, P.P. Osmo-air drying of banana slices: Multivariate analysis, process optimization and product quality characterization. J. Food Sci. Technol. 2022, 1–18. [Google Scholar] [CrossRef]

- Giraldo, G.; Talens, P.; Fito, P.; Chiralt, A. Influence of sucrose solution concentration on kinetics and yield during osmotic dehydration of mango. J. Food Eng. 2003, 58, 33–43. [Google Scholar] [CrossRef]

- Haque, M.R.; Hosain, M.M.; Kamal, M.M.; Islam, M.R.; Mondal, S.C. Optimization of osmotic dehydration parameters of banana under pulsed microwave conditions by response surface methodology. J. Microbiol. Biotechnol. Food Sci. 2020, 9, 1053–1059. [Google Scholar] [CrossRef]

- Mang, D.Y.; Abdou, A.B.; Njintang, N.Y.; Djiogue, E.M.; Loura, B.B.; Mbofung, M.C. Application of desirability-function and RSM to optimize antioxidant properties of mucuna milk. J. Food Meas. Charact. 2015, 9, 495–507. [Google Scholar] [CrossRef]

| Process Factors | Temperature (°C) | Oligofructose Concentration (%) | Maltodextrin Concentration (%) | Duration of Osmosis (min) | |||

|---|---|---|---|---|---|---|---|

| High | 50 | 30 | 40 | 80 | +1 | +1 | +1 |

| Center | 40 | 20 | 30 | 60 | 0 | 0 | 0 |

| Low | 30 | 10 | 20 | 40 | −1 | −1 | −1 |

| Standard order | X1 | X2 | X3 | X4 |

| Constant Regression Coefficients | % MC | aw | °Brix | WL | SG | L/L0 | ΔΕ* | NaCl (%) | C* | Fmax/Fmax0 |

|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | 115.0311 * | 0.948488 * | 22.92045 * | 6.423953 | 12.17969 * | −0.121860 | 61.42830 * | −1.53541 | 11.96114 * | −5.30788 |

| X1 | −1.0140 | 0.000287 | −0.22931 | −0.232524 * | −0.31859 * | 0.033076 * | −1.48643 * | 0.18600 * | 0.19815 | 0.08266 |

| X11 | 0.0157 * | 0.000002 | −0.00011 | 0.003764 * | 0.00283 * | −0.000221 | 0.01128 | −0.00249 * | −0.00263 | −0.00141 |

| X2 | −0.6042 | 0.002043 | 0.69079 * | −0.030746 | −0.17630 * | 0.002328 | −0.45083 | −0.00745 | −0.2185 * | 0.12323 |

| X22 | 0.0117 | −0.000026 | 0.00110 | 0.000497 | 0.00201 * | 0.000010 | 0.00071 | 0.00001 | 0.00190 | −0.00329 * |

| X3 | −0.3165 | 0.001547 | 0.30553 | 0.090251 | −0.27120 * | 0.029644 * | −1.32513 * | −0.03631 | −0.7937 * | 0.32601 * |

| X33 | −0.0053 | −0.000051 * | 0.01082 * | 0.001125 | 0.00095 | −0.000560 * | 0.02026 * | 0.00209 * | 0.0129 * | −0.00422 * |

| X4 | −0.0067 | −0.000372 | −0.01658 | −0.003637 | 0.00025 | 0.002970 | −0.06856 | 0.01040 | 0.02313 | −0.01646 |

| X44 | 0.0006 | 0.000002 | 0.00003 | 0.000046 | 0.00001 | −0.000010 | −0.00003 | 0.00002 | −0.00061 | −0.00002 |

| X12 | −0.0138 * | −0.000031 * | 0.00458 | −0.000101 | 0.00021 | −0.000248 | 0.00956 | 0.00129 | 0.00191 | 0.00183 |

| X13 | 0.0066 | 0.000007 | 0.00333 | −0.003618 * | 0.00447 * | −0.000392 * | 0.01237 * | −0.00085 | −0.00567 | −0.00211 |

| X23 | 0.0053 | 0.000008 | 0.00250 | −0.000200 | 0.00259 * | 0.000350 * | −0.00074 | −0.00147 | 0.00830 | −0.00125 |

| X14 | −0.0030 | −0.000001 | 0.00071 | 0.000198 | 0.00001 | −0.000028 | 0.00169 | 0.00017 | 0.00162 | 0.00056 |

| X24 | −0.0009 | 0.000000 | −0.00075 | −0.000200 | 0.00013 | 0.000001 | −0.00034 | −0.00035 | −0.00270 | 0.00029 |

| X34 | −0.0002 | 0.000002 | −0.00000 | 0.000270 | −0.00001 | −0.000040 | 0.00005 | −0.00012 | 0.00337 | −0.00055 |

| R2 | 0.922661 | 0.902627 | 0.995198 | 0.862179 | 0.871397 | 0.780621 | 0.797130 | 0.862261 | 0.8178 | 0.705193 |

| R2adj | 0.797926 | 0.653159 | 0.986981 | 0.620296 | 0.669390 | 0.516289 | 0.620557 | 0.614023 | 0.6078 | 0.490638 |

| R2predict | 0.851304 | 0.763268 | 0.990420 | 0.717199 | 0.742004 | 0.603307 | 0.730032 | 0.717677 | 0.7037 | 0.530847 |

| Predicted Values | Experimental Values | Error (%) | |

|---|---|---|---|

| aw | 0.9768 | 0.9705 ± 0.01 | −0.64 |

| WL | 2.15 | 2.38 ± 0.16 | 9.66 |

| SG | 1.57 | 1.60 ± 0.22 | 1.88 |

| ΔE* | 8.18 | 8.44 ± 0.97 | 3.05 |

| L/L0 | 0.95 | 0.92 ± 0.02 | −3.35 |

| %NaCl | 2.10 | 2.01 ± 0.38 | −4.57 |

| °Brix | 61.30 | 61.50 ± 0.87 | 0.29 |

| %MC | 63.57 | 64.55 ± 1.37 | 1.51 |

| C* | 4.09 | 4.71 ± 0.88 | 13.16 |

| Fmax/Fmax0 | 0.67 | 0.58 ± 0.28 | −15.07 |

| Fresh Mushroom Stems | R2 | |

|---|---|---|

| K0 | 0.0140 ± 0.0001 | 0.997 |

| K1 | 1.1552 ± 0.0673 | |

| Osmodehydrated Mushroom Stems | R2 | |

| K0 | 0.0152 ± 0.0001 | 0.996 |

| K1 | 1.3228 ± 0.0709 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stavropoulou, N.A.; Lazou, A.E.; Giannakourou, M.C. Sustainable Utilization of Mushroom By-Products Processed with a Combined Osmotic Dehydration Pretreatment and a Hot-Air-Drying Step. Foods 2024, 13, 1339. https://doi.org/10.3390/foods13091339

Stavropoulou NA, Lazou AE, Giannakourou MC. Sustainable Utilization of Mushroom By-Products Processed with a Combined Osmotic Dehydration Pretreatment and a Hot-Air-Drying Step. Foods. 2024; 13(9):1339. https://doi.org/10.3390/foods13091339

Chicago/Turabian StyleStavropoulou, Natalia A., Andriana E. Lazou, and Maria C. Giannakourou. 2024. "Sustainable Utilization of Mushroom By-Products Processed with a Combined Osmotic Dehydration Pretreatment and a Hot-Air-Drying Step" Foods 13, no. 9: 1339. https://doi.org/10.3390/foods13091339

APA StyleStavropoulou, N. A., Lazou, A. E., & Giannakourou, M. C. (2024). Sustainable Utilization of Mushroom By-Products Processed with a Combined Osmotic Dehydration Pretreatment and a Hot-Air-Drying Step. Foods, 13(9), 1339. https://doi.org/10.3390/foods13091339