Innovative Technologies Reshaping Meat Industrialization: Challenges and Opportunities in the Intelligent Era

Abstract

1. Introduction

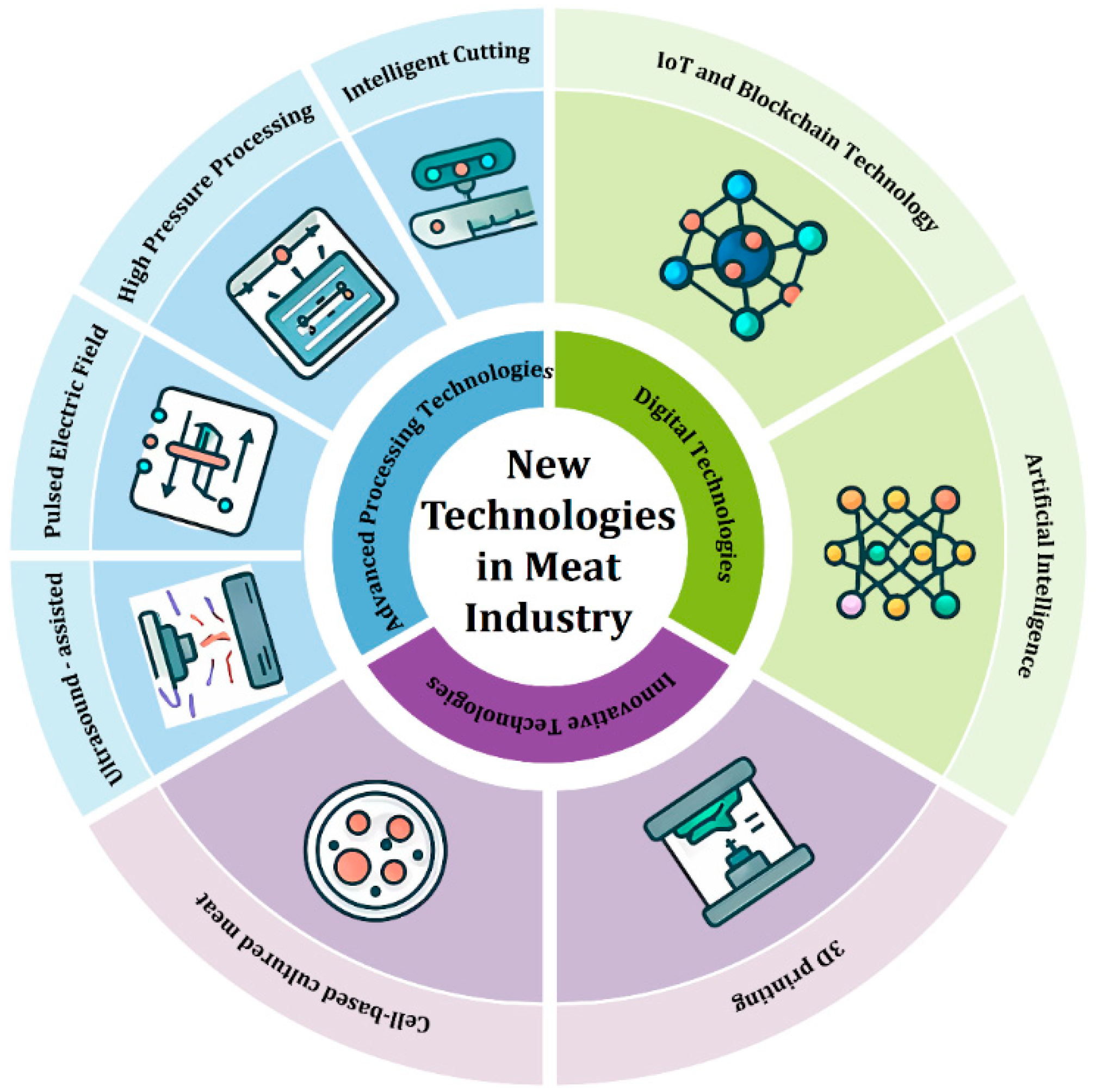

2. Technological Innovation Systems

2.1. Advanced Processing Innovations

2.1.1. Intelligent Cutting Technology

| References | Research Purpose | Research Methodology | Main Findings |

|---|---|---|---|

| [18] | Providing pig carcass cutting datasets to help develop intelligent systems for the meat industry | Acquisition of RGB-D data from 25 pigs with 6 cameras, stored as bag files and paired with JSON files | The dataset contains a variety of parameters, which can be used for multi-disciplinary research and promote the development of relevant robots and intelligent systems |

| [19] | Realizing real-time semantic segmentation of sheep carcass images | Acquisition, enhancement of sheep carcass images, labeling to construct the dataset, experimentation with ICNet models | ICNet model segmentation with high accuracy, good real-time performance, and good generalization ability |

| [20] | Enabling robots to recognize contact states for improved operational flexibility | Cutting with a robotic arm, TDNN recognizes objects and plans movement trajectories | TDNN can distinguish object characteristics and motion planning improves processing capability, but recognition accuracy needs to be improved |

| [21] | Developing smart knives with real-time feedback for robotic meat cutting | Design of smart tools, utilizing EM wave sensing technology, validated by simulation and experimentation | The tool can determine contact and depth more accurately, providing intelligent feedback for robotic cutting, with room for improvement |

| [36] | Development of localization and cutting point algorithms for trout processing systems | Trout images were acquired and cut points were extracted by preprocessing and segmentation steps | Algorithms accurately detect relevant parts and fins to determine the cutting point and automate the process |

| [37] | Exploring the use of haptic sensing in robotic red meat cutting | Cutting slices of beef tenderloin with a knife with a force sensor and analyzing the force signal | Force signals are recognizable, and tactile perception distinguishes between tissue and cutting phases, providing the basis for control strategies |

| [38] | Realization of automatic identification and classification of pork cut parts | Images are collected, preprocessed, and recognized based on a modified ResNet-50 model | The method has a recognition accuracy of 94.47% but is affected by the dataset and image environment |

| [39] | Development of a pHRI-based meat-cutting assistance strategy to reduce personnel illnesses | Develop an impedance control system, design two strategies and experiment with them | Determination of suitable sensors, advantages of both strategies, comfortable system operation |

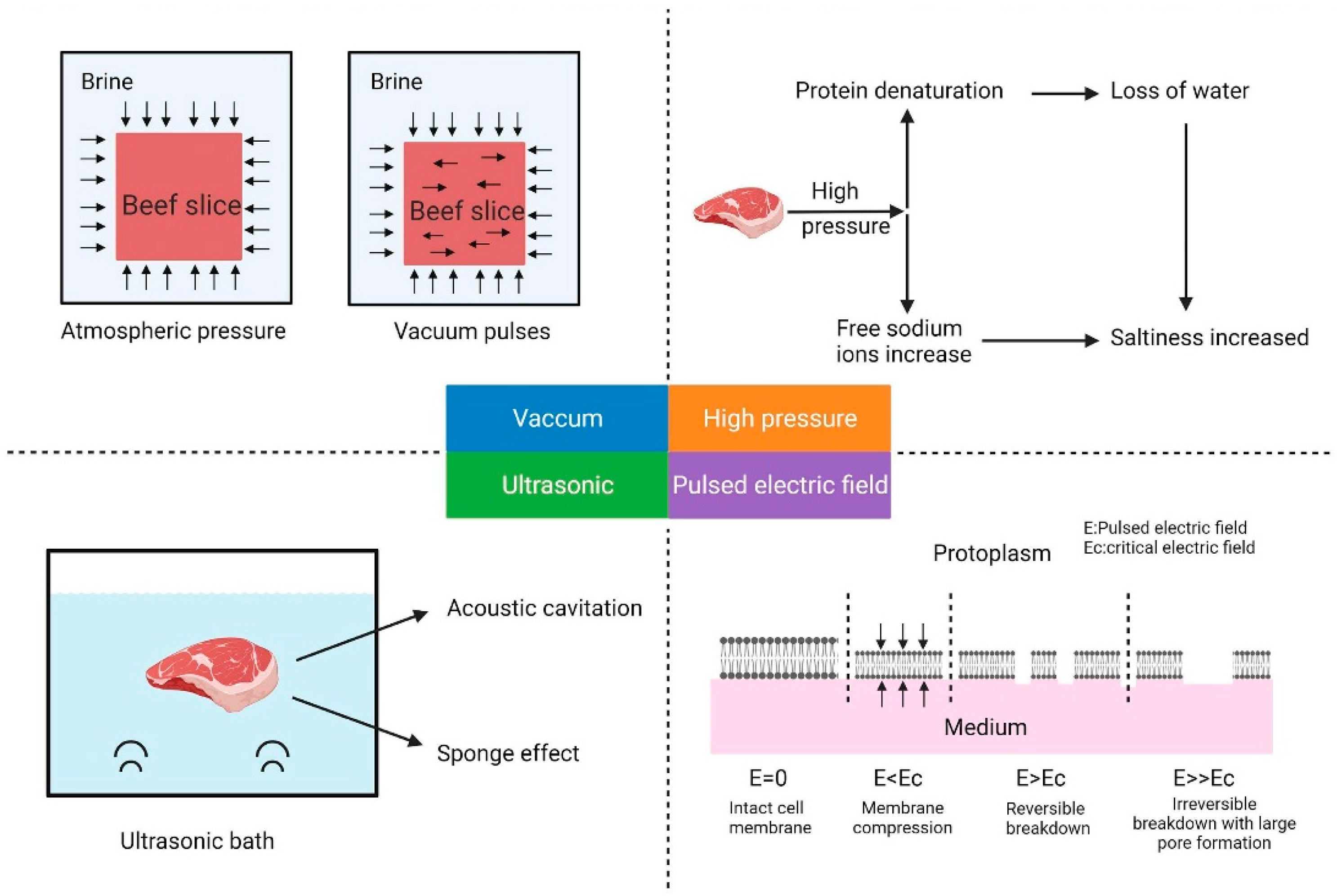

2.1.2. Pulsed Electric Field Technology

| References | Research Purpose | Research Methodology | Main Findings |

|---|---|---|---|

| [55] | Study of the effect of PEF parameters on beef curing and quality | Beef was marinated after treatment with different field strengths (2–4 kV/cm) and time (60–90 s) to analyze NaCl diffusion, moisture, texture, and structure | PEF accelerated NaCl penetration and shortened curing time by 66.7%, and the 4 kV/cm + 60 s treatment enhanced quality best |

| [56] | Investigating the role of PEF on the quality of freeze-thawed Atlantic salmon | PEF treatment of frozen–thawed salmon to analyze thawing time, fiber structure, and water holding capacity | PEF reduces thawing time by 20 min, reduces losses by 6%, and improves texture but slightly increases oxidation |

| [57] | Exploring the association between the conductivity of bovine calves and the effect of PEF treatment | Beef chops with different conductivities were analyzed for texture and color after PEF treatment combined with low-temperature slow cooking. | PEF improves tenderness, conductivity affects required processing time, and PEF reduces processing variability |

| [62] | Analyzing the effect of PEF on the quality and metabolites of wet/dry cured venison meat | High-and low-intensity PEF treatment of venison for tenderness, metabolites, and drying rates | High-intensity PEF increased tenderness by 9% and drying rate by 6%, with metabolite differences mainly caused by curing method |

| [63] | Evaluating the effect of PEF on the quality of fresh beef and frozen–thawed meat | PEF treatment of fresh and frozen–thawed beef for determination of color, oxidation, and sensory parameters | PEF improves tenderness and color but increases oxidation of freeze-thawed meat and affects sensory sensation when stored for 7 days |

| [64] | Exploring the effect of PEF-assisted thawing on duck meat quality | Determination of thawing rate, protein structure, and texture of duck meat thawed by PEF with different field strengths | 1–3 kV/cm PEF reduces thawing time by 50%, reduces losses and maintains meat quality, and stabilizes water holding capacity |

| [65] | Examining the effect of PEF pretreatment on pork curing efficiency | Needle electrode PEF treatment of pork after pickling system to analyze NaCl penetration, proteins, and microstructure | 3 kV/cm PEF shortens curing time 12 h and promotes salt penetration by widening the muscle gap |

2.1.3. Ultrasound-Assisted Processing Technology

2.1.4. High-Pressure Treatment Technology

2.1.5. Regulatory Landscape and Challenges for Non-Thermal Technologies in Meat Applications

| References | Research Purpose | Research Methodology | Main Findings |

|---|---|---|---|

| [79] | Ultrasound + effect of sodium bicarbonate marinade on chicken breasts | WC/SC/USC Comparison | USC pickling had the highest uptake (11.1%), the lowest shear (6.99 N), significant muscle fiber breakage (MFI = 61.65), and the best overall results |

| [83] | Effect of ultrasound-assisted dry curing on beef protein and flavor | Beef was ultrasonicated for 90 min and then statically marinated to measure protease and free amino acids | Ultrasound accelerates protein degradation, and 90 min ultrasound + 12 h curing is equivalent to the traditional 24 h curing |

| [84] | Effect of ultrasound probe parameters on salt diffusion in cured meat | Different sizes of probes and distances were used to treat pork and analyze the distribution of NaCl | 0.3 cm distance diffuses fastest, 0.5 cm balances efficiency and quality, and distance is the key parameter |

| [85] | Effect of ultrasound frequency on moisture migration and structure of pork meat | 23.6–55 kHz ultrasonication of pork for analysis of moisture and muscle fiber structure | 26.8 kHz sound field homogeneity, promotion of salt penetration, ultrasound disruption of muscle fiber interstitial space, and amplification test for home refrigerators |

| [92] | Single-frequency ultrasonic defrosting of goose meat | 28/50 kHz + multi-temperature combinations | 50 kHz ultrasound shortens thawing time by 57.58%, achieving hardness 173.2 N at 25 °C, protein structure stabilization, and best results |

| [93] | Effect of ultrasonic thawing at different frequencies on beef quality | Single/dual/triple frequency ultrasonic defrosting, determination of defrosting time, loss rate, tenderness, etc. | 22 kHz single-frequency and 22/33 kHz dual-frequency defrosting with high efficiency, good tenderness, and uniform moisture distribution |

| [96] | Comparison of physical field thawing of livestock and poultry meat | RTT/SWT/MT/UT/IT vs | Ultrasonic thawing loss is the lowest (43% for pigs), TBARS value is reduced by 14.58% to 15.87%, and water retention and antioxidant properties are optimized |

| [105] | Effect of ultrasound on beef tenderness and sensory after storage | Beef was ultrasonicated at 40 kHz after storage to measure shear force and sensory characteristics | HIU reduces shear, improves tenderness, achieves better results after storage, and improved sensory odor but with slight color change |

| [130] | Effect of high-pressure thawing on water holding capacity and ultrastructure of pork meat | High-pressure thawing at 70–210 MPa to analyze thawing loss, protein denaturation, and electron microscopic structure | Minimal thawing losses at 140 MPa, denaturation of myosin due to high pressure, and significant contraction of muscle segments at 210 MPa |

| [143] | Investigating the effect and mechanism of myostatin + ultrahigh pressure to inhibit fishy odor in snakehead fish | 300 MPa UHP + 25 mM carnosine treatment to analyze VOCs, TMA-N, lipid oxidation, etc. | The combination effectively inhibits the generation of fishy substances and extends the shelf life by 6 days, which is achieved through antioxidant and enzyme inactivation mechanisms |

| [144] | Comparison of the effects of sequential and simultaneous ultrasonic thawing on the quality of small yellow croaker (Lepomis macrocephalus) | Three-frequency sequential (TSEU)/simultaneous (TSIU) ultrasonic thawing, analysis of protein structure, texture, etc. | TSEU thawing quality is better, preserves alpha-helix structure, reduces oxidation, and is superior to TSIU and running water thawing |

| [145] | Ultrasound + effect of low-temperature short-term heating on protease and texture of yellow feather chicken meat | Determination of protease activity and texture by sonication at 40 kHz and heating at 55 °C | Inactivation of proteases to reduce protein degradation, improve texture, and extend shelf life |

| [146] | Effect of triple-frequency synchronized ultrasound on the efficiency and quality of pork curing | 20 + 40 + 60 kHz ultrasound (85–150 W/L) treatment to analyze NaCl permeation, moisture, etc. | 101.3 W/L sonication significantly increased NaCl content by 59.95% and improved water retention and texture |

| [147] | Effect of high-pressure preconditioning on the stability of pork in supercooled preservation | 50–200 MPa high-pressure treatment followed by ultra-cold storage to analyze ice nucleus inhibition and protein structure | 200 MPa inhibits ice nucleation, stabilizes protein structure, and prolongs freshness with ultra-cold storage |

| [148] | Effect of high-pressure treatment on protein and moisture in frozen storage of pork | 200–400 MPa high-pressure treatment followed by freezing at for 84 days to analyze protein structure and drip loss | 300–400 MPa reduces drip loss 35% and protein-water interaction dynamics affect water holding capacity |

| [149] | Effect of high-pressure treatment on the sodium water dynamics and structure of dry-cured hams | 0.1–900 MPa treated hams analyzed by 23Na-NMR and TEM | 600 MPa disrupts myofibrils and promotes sodium binding and release, explaining the increased saltiness of HPP hams and providing a rationale for low-sodium products |

| [150] | An overview of the application of HPP in salt-reduced meat products | Analyzing the effect of HPP on the functional and sensory properties and safety of salt-reduced meat | HPP improves texture and water retention and extends shelf life for salt-reduced meat products |

| [151] | Effect of ultrasound-assisted dry curing on the color of pork meat | Pork with different salt content was QDS dried and autoclaved to measure color parameters | High-moisture samples show increased brightness with HPP, low-moisture samples show no change, and salt substitution does not affect color |

| [152] | Effect of HPP and storage temperature on microbiology and oxidation of dry cured meat | 600 MPa treatment of dry cured meat inoculated with Listeria monocytogenes, stored at 4/18 °C | 600 MPa effective sterilization, storage temperature affects microbial growth, and HPP promotes oxidation with little color effect |

| [153] | Ultrasonic combined thawing quality of red drum fish | UT/MT/IT/UMT/UIT vs | The UMT/UIT group had intact muscle fibers and good retention of fixed water, making UMT/UIT superior to single sonication or conventional thawing |

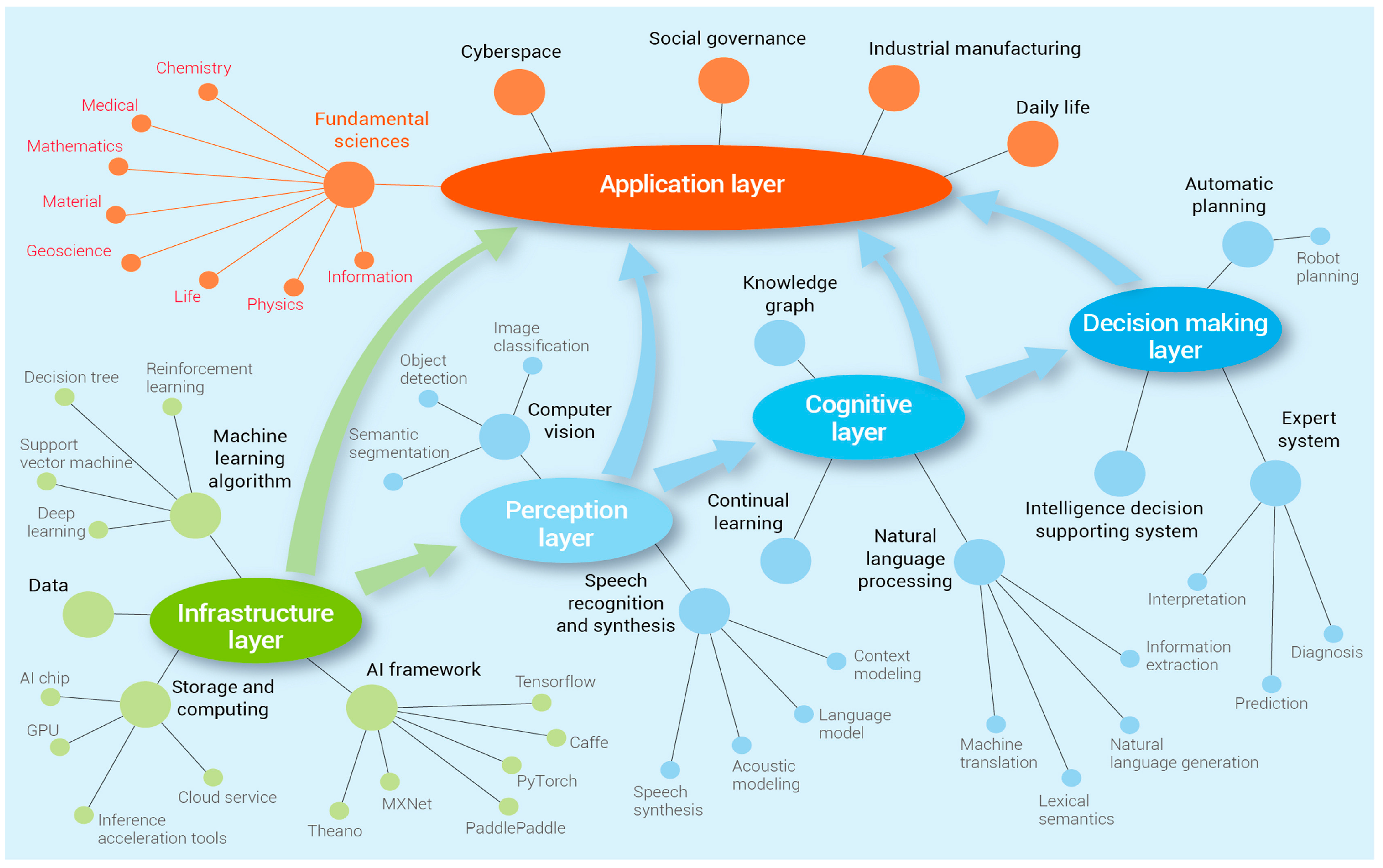

2.2. Intelligent Digital Integration Advancements

2.2.1. IoT-Enabled Blockchain Traceability Technology

2.2.2. AI-Driven Quality Prediction Technology

2.3. Emerging Resource Utilization Breakthroughs

2.3.1. Cell-Based Cultured Meat Production Technology

2.3.2. Three-Dimensional Bioprinted Tissue Fabrication Technology

3. Industrial Application Pathways

3.1. Application in Intelligent Centralized Food Processing System Development

3.1.1. Industrial Deployment of Intelligent Cutting Systems

3.1.2. PEF Integration in Commercial Meat Processing Lines

3.1.3. Ultrasonic Processing Solutions for Industrial-Scale Production

3.1.4. HPP Implementation in Modern Meat Facilities

3.1.5. Sustainability Challenges for Central Kitchens Enabled by Technology

3.2. Application in Intelligent Cold Chain Logistics System Optimization

3.3. Application in Multi-Source Data Fusion Based Freshness Monitoring

3.3.1. Smart Tag-Based Freshness Monitoring System Deployment

3.3.2. IoT-Integrated Sensor Network for Real-Time Freshness Assessment

3.3.3. Multimodal Data Fusion Platform Implementation

3.3.4. AI-Driven Freshness Prediction Model Application

3.4. Application in Personalized Nutritional Solution Development

4. Techno-Economic Assessment and Outlook

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amorim, A.; Laurindo, J.B.; Sobral, P.J.D.A. On how people deal with industrialized and non-industrialized food: A theoretical analysis. Front. Nutr. 2022, 9, 948262. [Google Scholar] [CrossRef] [PubMed]

- Steele, J.H. History, trends, and extent of pasteurization. J. Am. Vet. Med. Assoc. 2000, 217, 175–178. [Google Scholar] [CrossRef]

- Goody, J. Cooking, Cuisine and Class: A Study in Comparative Sociology, 1st ed.; Cambridge University Press: Cambridge, UK, 1982. [Google Scholar]

- Barbut, S. Meat Industry 4.0: A Distant Future? Anim. Front. 2020, 10, 38–47. [Google Scholar] [CrossRef]

- Altekruse, S.F.; Cohen, M.L.; Swerdlow, D.L. Emerging Foodborne Diseases. Emerg. Infect. Dis. 1997, 3, 285. [Google Scholar] [CrossRef]

- Hulebak, K.L.; Schlosser, W. Hazard Analysis and Critical Control Point (HACCP) History and Conceptual Overview. Risk Anal. 2002, 22, 547–552. [Google Scholar] [CrossRef]

- Ehiri, J.E.; Morris, G.P.; McEwen, J. Implementation of HACCP in food businesses: The way ahead. Food Control 1995, 6, 341–345. [Google Scholar] [CrossRef]

- Welch, R.W.; Mitchell, P.C. Food processing: A century of change. Br. Med. Bull. 2000, 56, 1–17. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Huang, X.; He, W.; Qin, Z.; Kong, J.; Zhou, X.; Shi, J.; Zou, X. Progress and future prospects of cooking robots for Chinese dishes. J. Agric. Food Res. 2025, 21, 101959. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wang, L.H.; Zeng, X.A.; Han, Z.; Brennan, C.S. Non-thermal technologies and its current and future application in the food industry: A review. Int. J. Food Sci. Technol. 2019, 54, 1–13. [Google Scholar] [CrossRef]

- Zhang, W.; Naveena, B.M.; Jo, C.; Sakata, R.; Zhou, G.; Banerjee, R.; Nishiumi, T. Technological demands of meat processing–An Asian perspective. Meat Sci. 2017, 132, 35–44. [Google Scholar] [CrossRef] [PubMed]

- De Medeiros Esper, I.; Cordova-Lopez, L.E.; From, P.J.; Mason, A. 3D Registration of Multiple RGB-D Cameras on Arbitrary Position of a Symmetric Object with No Overlapping in a Meat Factory Environment. In Proceedings of the 2021 IEEE 21st International Symposium on Computational Intelligence and Informatics (CINTI), Budapest, Hungary, 18 November 2021; IEEE: New York, NY, USA, 2021; pp. 85–90. [Google Scholar]

- Einarsdóttir, H.; Guðmundsson, B.; Ómarsson, V. Automation in the fish industry. Anim. Front. 2022, 12, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Aly, B.A.; Low, T.; Long, D.; Baillie, C.; Brett, P. Robotics and sensing technologies in red meat processing: A review. Trends Food Sci. Technol. 2023, 137, 142–155. [Google Scholar] [CrossRef]

- Ross, S.; Korostynska, O.; Cordova-Lopez, L.E.; Mason, A. A review of unilateral grippers for meat industry automation. Trends Food Sci. Technol. 2022, 119, 309–319. [Google Scholar] [CrossRef]

- De Medeiros Esper, I.; Cordova-Lopez, L.E.; Romanov, D.; Alvseike, O.; From, P.J.; Mason, A. Pigs: A stepwise RGB-D novel pig carcass cutting dataset. Data Brief. 2022, 41, 107945. [Google Scholar] [CrossRef]

- Zhao, S.; Hao, G.; Zhang, Y.; Wang, S. A Real-Time Semantic Segmentation Method of Sheep Carcass Images Based on ICNet. J. Robot. 2021, 2021, 8847984. [Google Scholar] [CrossRef]

- Kato, Y.; Sakaino, S.; Tsuji, T. Motion Planning for Cutting Flexible Objects Based on Contact State Recognition. IEEJ J. Ind. Appl. 2023, 12, 786–792. [Google Scholar] [CrossRef]

- Mason, A.; Romanov, D.; Cordova-Lopez, L.E.; Korostynska, O. Smart Knife: Integrated Intelligence for Robotic Meat Cutting. IEEE Sens. J. 2022, 22, 20475–20483. [Google Scholar] [CrossRef]

- Kim, J.; Kwon, Y.-K.; Kim, H.-W.; Seol, K.-H.; Cho, B.-K. Robot Technology for Pork and Beef Meat Slaughtering Process: A Review. Animals 2023, 13, 651. [Google Scholar] [CrossRef]

- Alves, V.F.; Tadielo, L.E.; Pires, A.C.M.D.S.; Pereira, M.G.; Bersot, L.D.S.; De Martinis, E.C.P. Hidden Places for Foodborne Bacterial Pathogens and Novel Approaches to Control Biofilms in the Meat Industry. Foods 2024, 13, 3994. [Google Scholar] [CrossRef] [PubMed]

- Sofos, J.N.; Geornaras, I. Overview of current meat hygiene and safety risks and summary of recent studies on biofilms, and control of Escherichia coli O157:H7 in nonintact, and Listeria monocytogenes in ready-to-eat, meat products. Meat Sci. 2010, 86, 2–14. [Google Scholar] [CrossRef] [PubMed]

- Ravensdale, J.T.; Coorey, R.; Dykes, G.A. Integration of Emerging Biomedical Technologies in Meat Processing to Improve Meat Safety and Quality. Compr. Rev. Food Sci. Food Saf. 2018, 17, 615–632. [Google Scholar] [CrossRef] [PubMed]

- Rebezov, M.; Khayrullin, M.; Assenova, B.; Farida, S.; Baydan, D.; Garipova, L.; Savkina, R.; Rodionova, S. Improving meat quality and safety: Innovative strategies. Potravin. Slovak. J. Food Sci. 2024, 18, 523–546. [Google Scholar] [CrossRef]

- Bai, Y.-r.; Wang, W.; Zha, J.; Ge, L.; Han, Q.-l.; Zheng, L.; Ma, F. Identification of bone fragments embedded in lean pork slices by comparing the pixel areas of bone regions segmented from single-band images. Infrared Phys. Technol. 2024, 138, 105250. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Zhang, S.; Zhang, Y.; Zhou, J.; Wang, Z.; Huang, B.; Huang, R. A novel method based on deep reinforcement learning for machining process route planning. Robot. Comput.-Integr. Manuf. 2024, 86, 102688. [Google Scholar] [CrossRef]

- Xu, W.; He, Y.; Li, J.; Zhou, J.; Xu, E.; Wang, W.; Liu, D. Robotization and intelligent digital systems in the meat cutting industry: From the perspectives of robotic cutting, perception, and digital development. Trends Food Sci. Technol. 2023, 135, 234–251. [Google Scholar] [CrossRef]

- Sinha, S.; Lee, Y.M. Challenges with developing and deploying AI models and applications in industrial systems. Discov. Artif. Intell. 2024, 4, 55. [Google Scholar] [CrossRef]

- Defraeye, T.; Shrivastava, C.; Berry, T.; Verboven, P.; Onwude, D.; Schudel, S.; Bühlmann, A.; Cronje, P.; Rossi, R.M. Digital twins are coming: Will we need them in supply chains of fresh horticultural produce? Trends Food Sci. Technol. 2021, 109, 245–258. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Marvin, H.J.P.; Bouzembrak, Y.; Van Der Fels-Klerx, H.J.; Kempenaar, C.; Veerkamp, R.; Chauhan, A.; Stroosnijder, S.; Top, J.; Simsek-Senel, G.; Vrolijk, H.; et al. Digitalisation and Artificial Intelligence for sustainable food systems. Trends Food Sci. Technol. 2022, 120, 344–348. [Google Scholar] [CrossRef]

- Jagtap, S.; Garcia-Garcia, G.; Rahimifard, S. Optimisation of the resource efficiency of food manufacturing via the Internet of Things. Comput. Ind. 2021, 127, 103397. [Google Scholar] [CrossRef]

- Ren, Q.-S.; Fang, K.; Yang, X.-T.; Han, J.-W. Ensuring the quality of meat in cold chain logistics: A comprehensive review. Trends Food Sci. Technol. 2022, 119, 133–151. [Google Scholar] [CrossRef]

- Azarmdel, H.; Mohtasebi, S.S.; Jafari, A.; Rosado Muñoz, A. Developing an orientation and cutting point determination algorithm for a trout fish processing system using machine vision. Comput. Electron. Agric. 2019, 162, 613–629. [Google Scholar] [CrossRef]

- Aly, B.A.; Low, T.; Long, D.; Brett, P.; Baillie, C. Tactile sensing for tissue discrimination in robotic meat cutting: A feasibility study. J. Food Eng. 2024, 363, 111754. [Google Scholar] [CrossRef]

- Huang, H.; Zhan, W.; Du, Z.; Hong, S.; Dong, T.; She, J.; Min, C. Pork primal cuts recognition method via computer vision. Meat Sci. 2022, 192, 108898. [Google Scholar] [CrossRef]

- Maithani, H.; Corrales Ramon, J.A.; Lequievre, L.; Mezouar, Y.; Alric, M. Exoscarne: Assistive Strategies for an Industrial Meat Cutting System Based on Physical Human-Robot Interaction. Appl. Sci. 2021, 11, 3907. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Morton, J.D.; Mason, S.L.; Bekhit, A.E.-D.A. Current and future prospects for the use of pulsed electric field in the meat industry. Crit. Rev. Food Sci. 2019, 59, 1660–1674. [Google Scholar] [CrossRef]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Mannozzi, C.; Fauster, T.; Haas, K.; Tylewicz, U.; Romani, S.; Dalla Rosa, M.; Jaeger, H. Role of thermal and electric field effects during the pre-treatment of fruit and vegetable mash by pulsed electric fields (PEF) and ohmic heating (OH). Innov. Food Sci. Emerg. Technol. 2018, 48, 131–137. [Google Scholar] [CrossRef]

- Dellarosa, N.; Ragni, L.; Laghi, L.; Tylewicz, U.; Rocculi, P.; Dalla Rosa, M. Time domain nuclear magnetic resonance to monitor mass transfer mechanisms in apple tissue promoted by osmotic dehydration combined with pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2016, 37, 345–351. [Google Scholar] [CrossRef]

- Walkling-Ribeiro, M.; Rodríguez-González, O.; Jayaram, S.H.; Griffiths, M.W. Processing temperature, alcohol and carbonation levels and their impact on pulsed electric fields (PEF) mitigation of selected characteristic microorganisms in beer. Food Res. Int. 2011, 44, 2524–2533. [Google Scholar] [CrossRef]

- Afraz, M.T.; Khan, M.R.; Roobab, U.; Noranizan, M.A.; Tiwari, B.K.; Rashid, M.T.; Inam-ur-Raheem, M.; Hashemi, S.M.B.; Aadil, R.M. Impact of novel processing techniques on the functional properties of egg products and derivatives: A review. J. Food Process Eng. 2020, 43, e13568. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Arnal, Á.J.; Royo, P.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Energy and resource efficiency of electroporation-assisted extraction as an emerging technology towards a sustainable bio-economy in the agri-food sector. J. Clean. Prod. 2019, 233, 1123–1132. [Google Scholar] [CrossRef]

- Milani, E.A.; Alkhafaji, S.; Silva, F.V.M. Pulsed Electric Field continuous pasteurization of different types of beers. Food Control 2015, 50, 223–229. [Google Scholar] [CrossRef]

- Sharma, P.; Oey, I.; Bremer, P.; Everett, D.W. Microbiological and enzymatic activity of bovine whole milk treated by pulsed electric fields. Int. J. Dairy. Technol. 2018, 71, 10–19. [Google Scholar] [CrossRef]

- Timmermans, R.A.H.; Mastwijk, H.C.; Berendsen, L.B.J.M.; Nederhoff, A.L.; Matser, A.M.; Van Boekel, M.A.J.S.; Nierop Groot, M.N. Moderate intensity Pulsed Electric Fields (PEF) as alternative mild preservation technology for fruit juice. Int. J. Food Microbiol. 2019, 298, 63–73. [Google Scholar] [CrossRef]

- Manzoor, M.F.; Ahmed, Z.; Ahmad, N.; Karrar, E.; Rehman, A.; Aadil, R.M.; Al-Farga, A.; Iqbal, M.W.; Rahaman, A.; Zeng, X.A. Probing the combined impact of pulsed electric field and ultra-sonication on the quality of spinach juice. J. Food Process. Preserv. 2021, 45, e15475. [Google Scholar]

- Qian, J.Y.; Yan, G.M.; Huo, S.H.; Dai, C.H.; Ma, H.L.; Kan, J. Effects of pulsed magnetic field on microbial and enzymic inactivation and quality attributes of orange juice. J. Food Process. Preserv. 2021, 45, e15533. [Google Scholar] [CrossRef]

- Zhu, M.; Xing, Y.; Zhang, J.; Li, H.; Kang, Z.; Ma, H.; Zhao, S.; Jiao, L. Low-frequency alternating magnetic field thawing of frozen pork meat: Effects of intensity on quality properties and microstructure of meat and structure of myofibrillar proteins. Meat Sci. 2023, 204, 109241. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, Y.; Shen, Q.; Xu, T.; Dong, Z.; Lou, A. Optimization of pulsed electric fields-assisted thawing process conditions and its effect on the quality of Zhijiang duck meat. Food Chem X 2024, 24, 101812. [Google Scholar] [CrossRef] [PubMed]

- Gudmundsson, M.; Hafsteinsson, H. Effect of electric field pulses on microstructure of muscle foods and roes. Trends Food Sci. Technol. 2001, 12, 122–128. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, J.; Bai, Y.; Wang, X.; Xu, X.; Lu, X.; Yue, J.; Han, M. Effect of pulsed electric field (PEF) on NaCl diffusion in beef and consequence on meat quality. Meat Sci. 2024, 213, 109507. [Google Scholar] [CrossRef]

- Li, J.; Shi, J.; Huang, X.; Zou, X.; Li, Z.; Zhang, D.; Zhang, W.; Xu, Y. Effects of pulsed electric field on freeze-thaw quality of Atlantic salmon. Innov. Food Sci. Emerg. Technol. 2020, 65, 102454. [Google Scholar] [CrossRef]

- Karki, R.; Oey, I.; Bremer, P.; Silcock, P. Understanding the effect of meat electrical conductivity on Pulsed Electric Field (PEF) process parameters and the ability of PEF to enhance the quality and shorten sous vide processing for beef short ribs. Food Res. Int. 2023, 163, 112251. [Google Scholar] [CrossRef]

- Ahmed, M.; Ranjan, H.; Roy, S. Pulsed electric fields for sustainable meat, poultry, and fish processing: Recent advances, prospects, and industry challenges. Innov. Food Sci. Emerg. Technol. 2025, 102, 104008. [Google Scholar] [CrossRef]

- Ghosh, S.; Gillis, A.; Levkov, K.; Vitkin, E.; Golberg, A. Saving energy on meat air convection drying with pulsed electric field coupled to mechanical press water removal. Innov. Food Sci. Emerg. Technol. 2020, 66, 102509. [Google Scholar] [CrossRef]

- Yang, R.W.; Wang, J.; Jin, Y.; Lin, S.Y. Research Status of High-Intensity Pulsed Electric Field (PEF) Equipment and its Application on Food Processing. Adv. Mater. Res. 2014, 915, 331–335. [Google Scholar] [CrossRef]

- Roobab, U.; Chen, B.-R.; Madni, G.M.; Tong, Z.G.; Zeng, X.-A.; Abdi, G.; Hussain, S.; Aadil, R.M. Evaluation of ultrasound and pulsed electric field combinations on the cooking Losses, texture Profile, and Taste-Related amino acids of chicken breast meat. Ultrason. Sonochem. 2024, 107, 106919. [Google Scholar] [CrossRef]

- Mungure, T.E.; Farouk, M.M.; Birch, E.J.; Carne, A.; Staincliffe, M.; Stewart, I.; Bekhit, A.E.-D.A. Effect of PEF treatment on meat quality attributes, ultrastructure and metabolite profiles of wet and dry aged venison Longissimus dorsi muscle. Innov. Food Sci. Emerg. Technol. 2020, 65, 102457. [Google Scholar] [CrossRef]

- Kantono, K.; Hamid, N.; Oey, I.; Wang, S.; Xu, Y.; Ma, Q.; Faridnia, F.; Farouk, M. Physicochemical and sensory properties of beef muscles after Pulsed Electric Field processing. Food Res. Int. 2019, 121, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Lung, C.-T.; Chang, C.-K.; Cheng, F.-C.; Hou, C.-Y.; Chen, M.-H.; Santoso, S.P.; Yudhistira, B.; Hsieh, C.-W. Effects of pulsed electric field-assisted thawing on the characteristics and quality of Pekin duck meat. Food Chem. 2022, 390, 133137. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, Y.; Chen, Q.; Dong, Z.; Xiong, Q.; Li, X. Accelerated pork salting using needle electrode-derived pulsed electric fields. Food Biosci. 2024, 59, 103994. [Google Scholar] [CrossRef]

- Li, M.G.; Zhou, C.S.; Wang, B.; Zeng, S.Y.; Mu, R.Y.; Li, G.H.; Li, B.Z.; Lv, W.Q. Research progress and application of ultrasonic- and microwave-assisted food processing technology. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3707–3731. [Google Scholar] [CrossRef]

- Xu, B.G.; Feng, M.; Chitrakar, B.; Cheng, J.A.; Wei, B.X.; Wang, B.; Zhou, C.S.; Ma, H.L. Multi-frequency power thermosonication treatments of clear strawberry juice: Impact on color, bioactive compounds, flavor volatiles, microbial and polyphenol oxidase inactivation. Innov. Food Sci. Emerg. Technol. 2023, 84, 103295. [Google Scholar] [CrossRef]

- Hu, H.; Li-Chan, E.C.Y.; Wan, L.; Tian, M.; Pan, S. The effect of high intensity ultrasonic pre-treatment on the properties of soybean protein isolate gel induced by calcium sulfate. Food Hydrocoll. 2013, 32, 303–311. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Chen, L.; Wang, Y.; Okonkwo, C.E.; Yagoub, A.A.; Wahia, H.; Zhou, C.S. Application of ultrasound and its real-time monitoring of the acoustic field during processing of tofu: Parameter optimization, protein modification, and potential mechanism. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2747–2772. [Google Scholar] [CrossRef] [PubMed]

- Soria, A.C.; Villamiel, M. Effect of ultrasound on the technological properties and bioactivity of food: A review. Trends Food Sci. Technol. 2010, 21, 323–331. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Morton, J.D.; Bekhit, A.E.-D.A.; Kumar, S.; Bhat, H.F. Emerging processing technologies for improved digestibility of muscle proteins. Trends Food Sci. Technol. 2021, 110, 226–239. [Google Scholar] [CrossRef]

- Xu, W.J.; Bao, Y.L.; Gou, H.; Xu, B.G.; Hong, H.; Gao, R.C. Mitigation of mechanical damage and protein deterioration in giant river prawn by multi-frequency ultrasound-assisted immersion freezing. Food Chem. 2024, 458, 140324. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Wang, H.O.; Zhou, F.; Wu, Y.L.; Ma, H.L.; Zhao, R.; He, J.; Gu, Z.J. Effect of ultrasonic thawing temperature on the quality of quick-frozen small yellow croaker (Larimichthys polyactis) and its possible mechanisms. LWT-Food Sci. Technol. 2023, 179, 114620. [Google Scholar] [CrossRef]

- Wang, H.P.; Gao, Z.W.; Guo, X.Y.; Gao, S.M.; Wu, D.X.; Liu, Z.Z.; Wu, P.; Xu, Z.C.; Zou, X.B.; Meng, X.R. Changes in Textural Quality and Water Retention of Spiced Beef under Ultrasound-Assisted Sous-Vide Cooking and Its Possible Mechanisms. Foods 2022, 11, 2251. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Cheung, I.W.Y.; Pan, S.; Li-Chan, E.C.Y. Effect of high intensity ultrasound on physicochemical and functional properties of aggregated soybean β-conglycinin and glycinin. Food Hydrocoll. 2015, 45, 102–110. [Google Scholar] [CrossRef]

- Pan, J.; Zhang, Z.; Mintah, B.K.; Xu, H.; Dabbour, M.; Cheng, Y.; Dai, C.; He, R.; Ma, H. Effects of nonthermal physical processing technologies on functional, structural properties and digestibility of food protein: A review. J. Food Process Eng. 2022, 45, e14010. [Google Scholar] [CrossRef]

- Chen, X.; Zou, Y.; Wang, D.Y.; Xiong, G.Y.; Xu, W.M. Effects of ultrasound pretreatment on the extent of Maillard reaction and the structure, taste and volatile compounds of chicken liver protein. Food Chem. 2020, 331, 127369. [Google Scholar] [CrossRef]

- Zou, B.; Zhao, D.; He, G.; Nian, Y.; Da, D.; Yan, J.; Li, C. Acetylation and Phosphorylation of Proteins Affect Energy Metabolism and Pork Quality. J. Agr. Food Chem. 2020, 68, 7259–7268. [Google Scholar] [CrossRef]

- Xiong, G.; Fu, X.; Pan, D.; Qi, J.; Xu, X.; Jiang, X. Influence of ultrasound-assisted sodium bicarbonate marination on the curing efficiency of chicken breast meat. Ultrason. Sonochem. 2020, 60, 104808. [Google Scholar] [CrossRef]

- Cárcel, J.A.; Benedito, J.; Bon, J.; Mulet, A. High intensity ultrasound effects on meat brining. Meat Sci. 2007, 76, 611–619. [Google Scholar] [CrossRef]

- Gou, P.; Comaposada, J.; Arnau, J. NaCl content and temperature effects on moisture diffusivity in the Gluteus medius muscle of pork ham. Meat Sci. 2003, 63, 29–34. [Google Scholar] [CrossRef]

- Alarcon-Rojo, A.D.; Carrillo-Lopez, L.M.; Reyes-Villagrana, R.; Huerta-Jiménez, M.; Garcia-Galicia, I.A. Ultrasound and meat quality: A review. Ultrason. Sonochem. 2019, 55, 369–382. [Google Scholar] [CrossRef]

- Lin, W.; Zhu, J.; Sun, Y.; Pan, D.; Xia, Q.; Zhou, C.; He, J.; Dang, Y. Effects of ultrasonic-assisted marinating on degradation of beef protein and formation of flavor precursors. J. Food Compos. Anal. 2024, 133, 106407. [Google Scholar] [CrossRef]

- Inguglia, E.S.; Zhang, Z.; Burgess, C.; Kerry, J.P.; Tiwari, B.K. Influence of extrinsic operational parameters on salt diffusion during ultrasound assisted meat curing. Ultrasonics 2018, 83, 164–170. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, X.; Hong, C.; Liu, N.; Ouyang, N.; Chen, J.; Ashokkumar, M.; Ma, H. Application of ultrasound treatment in pork marination: Effects on moisture migration and microstructure. Food Chem. 2024, 447, 138950. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, X.; Guo, Y.; Chen, Z.; Ma, H. Evaluation of ultrasonic-assisted pickling with different frequencies on NaCl transport, impedance properties, and microstructure in pork. Food Chem. 2024, 430, 137003. [Google Scholar] [CrossRef]

- Leygonie, C.; Britz, T.J.; Hoffman, L.C. Impact of freezing and thawing on the quality of meat: Review. Meat Sci. 2012, 91, 93–98. [Google Scholar] [CrossRef]

- Nakazawa, N.; Okazaki, E. Recent research on factors influencing the quality of frozen seafood. Fish. Sci. 2020, 86, 231–244. [Google Scholar] [CrossRef]

- Kim, H.N.; Suslick, K.S. The Effects of Ultrasound on Crystals: Sonocrystallization and Sonofragmentation. Crystals 2018, 8, 280. [Google Scholar] [CrossRef]

- Sánchez-García, Y.I.; Ashokkumar, M.; Mason, T.J.; Gutiérrez-Méndez, N. Influence of ultrasound frequency and power on lactose nucleation. J. Food Eng. 2019, 249, 34–39. [Google Scholar] [CrossRef]

- Yu, H.; Mei, J.; Xie, J. New ultrasonic assisted technology of freezing, cooling and thawing in solid food processing: A review. Ultrason. Sonochem. 2022, 90, 106185. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, W.; Wang, Y.; Meng, X.; Dabbour, M.; Kumah Mintah, B.; Chen, X.; Chen, X.; He, R.; Ma, H. Mono-frequency ultrasonic-assisted thawing of frozen goose meat: Influence on thawing efficiency, product quality and microstructure. Ultrason. Sonochem. 2023, 98, 106489. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, C.; Guo, Y.; Zhang, C.; Guo, X.; Bouhile, Y.; Ma, H. Ultrasonic-assisted flowing water thawing of frozen beef with different frequency modes: Effects on thawing efficiency, quality characteristics and microstructure. Food Res. Int. 2022, 157, 111484. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, N.; Guo, L.; Wang, Y.; Wang, Y.; Lu, F.; Tuly, J.; Ma, H. Effect of ultrasonic rapid thawing on the quality of frozen pork and numerical simulation. J. Food Eng. 2025, 387, 112344. [Google Scholar] [CrossRef]

- Shi, W.; Wang, Y.; Chen, X.; Hu, H.; Chen, X.; Mintah, B.K.; Dabbour, M.; Meng, X.; Zhang, Z.; He, R.; et al. Thawing of goose meat by simultaneous dual frequency ultrasound for process efficiency: Thawing rate, quality attributes, structural characteristics. Innov. Food Sci. Emerg. Technol. 2024, 92, 103588. [Google Scholar] [CrossRef]

- Gan, S.; Zhang, M.; Mujumdar, A.S.; Jiang, Q. Effects of different thawing methods on quality of unfrozen meats. Int. J. Refrig. 2022, 134, 168–175. [Google Scholar] [CrossRef]

- Guyon, C.; Meynier, A.; de Lamballerie, M. Protein and lipid oxidation in meat: A review with emphasis on high-pressure treatments. Trends Food Sci. Technol. 2016, 50, 131–143. [Google Scholar] [CrossRef]

- Duan, X.; Feng, X.; Song, L.; Zhang, B.; Cai, X.; Li, M.; Yang, F.; Fan, L. Advances on development of fruit and vegetable drying by MVD technology. Food Fermentiin Ind. 2013, 39, 156–164. [Google Scholar]

- Turantaş, F.; Kılıç, G.B.; Kılıç, B. Ultrasound in the meat industry: General applications and decontamination efficiency. Int. J. Food Microbiol. 2015, 198, 59–69. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Sardari, H.; Alikhani Chamgordani, P.; Behjati, M. Power ultrasound in the meat industry (freezing, cooking and fermentation): Mechanisms, advances and challenges. Ultrason. Sonochem. 2022, 86, 106027. [Google Scholar] [CrossRef]

- Barretto, T.L.; Sanches, M.A.R.; Pateiro, M.; Lorenzo, J.M.; Telis-Romero, J.; da Silva Barretto, A.C. Recent advances in the application of ultrasound to meat and meat products: Physicochemical and sensory aspects. Food Rev. Int. 2022, 39, 4529–4544. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, J.; Du, J.; He, G. Food Processing and Nutrition Strategies for Improving the Health of Elderly People with Dysphagia: A Review of Recent Developments. Foods 2024, 13, 215. [Google Scholar] [CrossRef]

- Cheng, Y.; Meng, Y.; Liu, S. Diversified Techniques for Restructuring Meat Protein-Derived Products and Analogues. Foods 2024, 13, 1950. [Google Scholar] [CrossRef] [PubMed]

- Siró, I.; Vén, C.; Balla, C.; Jónás, G.; Zeke, I.; Friedrich, L. Application of an ultrasonic assisted curing technique for improving the diffusion of sodium chloride in porcine meat. J. Food Eng. 2009, 91, 353–362. [Google Scholar] [CrossRef]

- Peña-Gonzalez, E.; Alarcon-Rojo, A.D.; Garcia-Galicia, I.; Carrillo-Lopez, L.; Huerta-Jimenez, M. Ultrasound as a potential process to tenderize beef: Sensory and technological parameters. Ultrason. Sonochem. 2019, 53, 134–141. [Google Scholar] [CrossRef]

- Zheng, L.; Sun, D.-W. Innovative applications of power ultrasound during food freezing processes—A review. Trends Food Sci. Technol. 2006, 17, 16–23. [Google Scholar] [CrossRef]

- Li, Z.H.; He, W.T.; Huang, X.W.; Hu, X.Y.; Chen, H.Z.; Zhang, Y.; Shi, J.Y.; Zou, X.B. Contactless printing of food micro-particles controlled by ultrasound. J. Food Eng. 2025, 388, 112375. [Google Scholar] [CrossRef]

- Xu, B.G.; Ren, A.Q.; Chen, J.N.; Li, H.Y.; Wei, B.X.; Wang, J.; Azam, S.M.R.; Bhandari, B.; Zhou, C.S.; Ma, H.L. Effect of multi-mode dual-frequency ultrasound irradiation on the degradation of waxy corn starch in a gelatinized state. Food Hydrocoll. 2021, 113, 106440. [Google Scholar] [CrossRef]

- Shikha Ojha, K.; Granato, D.; Rajuria, G.; Barba, F.J.; Kerry, J.P.; Tiwari, B.K. Application of chemometrics to assess the influence of ultrasound frequency, Lactobacillus sakei culture and drying on beef jerky manufacture: Impact on amino acid profile, organic acids, texture and colour. Food Chem. 2018, 239, 544–550. [Google Scholar] [CrossRef]

- Gao, K.; Liu, B.; Wu, B.A.; Guo, Y.T.; Song, C.Y.; Nan, S.A.; Dai, J.J.; Shen, Y.; Ma, H.L. A Study on the Effect Mechanism of Pectin Modification on the Carrot Cell Wall’s Texture Formation under Ultrasonic and Infrared Drying. Agriculture 2024, 14, 803. [Google Scholar] [CrossRef]

- Xu, B.G.; Tiliwa, E.S.; Yan, W.Q.; Azam, S.M.R.; Wei, B.X.; Zhou, C.S.; Ma, H.L.; Bhandari, B. Recent development in high quality drying of fruits and vegetables assisted by ultrasound: A review. Food Res. Int. 2022, 152, 110744. [Google Scholar] [CrossRef]

- Dong, X.; Wang, J.; Raghavan, V. Critical reviews and recent advances of novel non-thermal processing techniques on the modification of food allergens. Crit. Rev. Food Sci. 2021, 61, 196–210. [Google Scholar] [CrossRef]

- Qian, J.Y.; Chen, S.B.; Huo, S.H.; Wang, F.; Zou, B.; Zhou, C.S.; Zhang, L.; Ma, H.L. Inactivation of Pichia membranaefaciens in Soybean Paste by Dual-Frequency and Moderate Thermosonication. Foods 2024, 13, 3600. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.X.; Wang, Y.; Zhou, C.S.; Sun, Q.L.; Zhang, L.; Niu, Y.W.; Yao, D.Y.; Song, L.L.; Okonkwo, C.E.; Phyllis, O.; et al. Ultrasonic vacuum synergistic assisted ethanol extraction of steviol glycosides and kinetic studies. Ind. Crop Prod. 2024, 221, 119385. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Y.; Okonkwo, C.E.; Chen, L.; Zhou, C. Multimode ultrasonic-assisted decontamination of fruits and vegetables: A review. Food Chem. 2024, 450, 139356. [Google Scholar] [CrossRef]

- Bolumar, T.; Orlien, V.; Sikes, A.; Aganovic, K.; Bak, K.H.; Guyon, C.; Stübler, A.S.; De Lamballerie, M.; Hertel, C.; Brüggemann, D.A. High-pressure processing of meat: Molecular impacts and industrial applications. Compr. Rev. Food Sci. Food Saf. 2021, 20, 332–368. [Google Scholar] [CrossRef]

- Rajendran, S.; Mallikarjunan, P.K.; O’Neill, E. High pressure processing for raw meat in combination with other treatments: A review. J. Food Process. Preserv. 2022, 46, e16049. [Google Scholar] [CrossRef]

- Hygreeva, D.; Pandey, M.C. Novel approaches in improving the quality and safety aspects of processed meat products through high pressure processing technology A review. Trends Food Sci. Technol. 2016, 54, 175–185. [Google Scholar] [CrossRef]

- Chacha, J.S.; Zhang, L.; Ofoedu, C.E.; Suleiman, R.A.; Dotto, J.M.; Roobab, U.; Agunbiade, A.O.; Duguma, H.T.; Mkojera, B.T.; Hossaini, S.M.; et al. Revisiting Non-Thermal Food Processing and Preservation Methods—Action Mechanisms, Pros and Cons: A Technological Update (2016–2021). Foods 2021, 10, 1430. [Google Scholar] [CrossRef]

- Simonin, H.; Duranton, F.; De Lamballerie, M. New Insights into the High-Pressure Processing of Meat and Meat Products. Compr. Rev. Food Sci. Food Saf. 2012, 11, 285–306. [Google Scholar] [CrossRef]

- Morton, J.D.; Pearson, R.G.; Lee, H.Y.-Y.; Smithson, S.; Mason, S.L.; Bickerstaffe, R. High pressure processing improves the tenderness and quality of hot-boned beef. Meat Sci. 2017, 133, 69–74. [Google Scholar] [CrossRef]

- Kaur, L.; Astruc, T.; Vénien, A.; Loison, O.; Cui, J.; Irastorza, M.; Boland, M. High pressure processing of meat: Effects on ultrastructure and protein digestibility. Food Funct. 2016, 7, 2389–2397. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Nishiumi, T.; Fujimura, S.; Ogoshi, H.; Suzuki, A. Combined effects of high pressure and sodium hydrogen carbonate treatment on pork ham: Improvement of texture and palatability. High. Press. Res. 2013, 33, 354–361. [Google Scholar]

- Subhashini, M.S.; Meenatchi, C.R.; Radhakrishnan, M. Pressure Shift Freezing: An Alternate Method of Freezing for Meat and Marine Products and Their Quality Characteristics. J. Food Process. Preserv. 2024, 2024, 1720752. [Google Scholar] [CrossRef]

- Şayin Sert, T.; Coşkun, F. The Effects of High-Pressure Processing on pH, Thiobarbituric Acid Value, Color and Texture Properties of Frozen and Unfrozen Beef Mince. Molecules 2022, 27, 3974. [Google Scholar] [CrossRef]

- Döner, D.; Çokgezme, Ö.F.; Çevik, M.; Engin, M.; İçier, F. Thermal Image Processing Technique for Determination of Temperature Distributions of Minced Beef Thawed by Ohmic and Conventional Methods. Food Bioprocess. Tech. 2020, 13, 1878–1892. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Gaudette, N.J.; Johnston, S.P. The impact of high hydrostatic pressure on the functionality and consumer acceptability of reduced sodium naturally cured wieners. Meat Sci. 2017, 129, 127–134. [Google Scholar] [CrossRef]

- Bolumar, T.; Lohmayer, R.; Peukert, M.; Thiemann, K.; Münch, S.; Brüggemann, D.A. High-pressure processing enhances saltiness perception and sensory acceptability of raw but not of cooked cured pork loins—Leveraging salty and umami taste. Front. Nutr. 2024, 11, 1352550. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Gaudette, N.J.; Johnston, S.P. The use of high pressure processing to enhance the quality and shelf life of reduced sodium naturally cured restructured cooked hams. Meat Sci. 2016, 116, 102–109. [Google Scholar] [CrossRef]

- Jia, F.; Jing, Y.; Dai, R.; Li, X.; Xu, B. High-pressure thawing of pork: Water holding capacity, protein denaturation and ultrastructure. Food Biosci. 2020, 38, 100688. [Google Scholar] [CrossRef]

- Tikhonov, S.; Tikhonova, N.; Lazarev, V.; Samokhvalova, E.; Minukhin, L.; Pischikov, G. Ultra-High Pressure Chilled Meat Processing: A Promising Storage Method. E3S Web Conf. 2020, 176, 03022. [Google Scholar] [CrossRef]

- Huang, H.-W.; Wu, S.-J.; Lu, J.-K.; Shyu, Y.-T.; Wang, C.-Y. Current status and future trends of high-pressure processing in food industry. Food Control 2017, 72, 1–8. [Google Scholar] [CrossRef]

- Banerjee, R.; Jayathilakan, K.; Chauhan, O.P.; Naveena, B.M.; Devatkal, S.; Kulkarni, V.V. Vacuum Packaged Mutton Patties: Comparative Effects of High Pressure Processing and Irradiation. J. Food Process. Preserv. 2017, 41, e12880. [Google Scholar] [CrossRef]

- Chuang, S.; Sheen, S. High pressure processing of raw meat with essential oils-microbial survival, meat quality, and models: A review. Food Control 2022, 132, 108529. [Google Scholar] [CrossRef]

- Reesman, C.; Sullivan, G.; Danao, M.-G.; Mafi, G.G.; Pfeiffer, M.; Ramanathan, R. Effects of high-pressure processing on cooked color and eating qualities of dark-cutting beef. Appl. Food Res. 2023, 3, 100260. [Google Scholar] [CrossRef]

- Nema, P.K.; Sehrawat, R.; Ravichandran, C.; Kaur, B.P.; Kumar, A.; Tarafdar, A.; Aadil, R.M. Inactivating Food Microbes by High-Pressure Processing and Combined Nonthermal and Thermal Treatment: A Review. J. Food Qual. 2022, 2022, 5797843. [Google Scholar] [CrossRef]

- Arokiyaraj, S.; Dinakarkumar, Y.; Shin, H. A comprehensive overview on the preservation techniques and packaging of processed meat products: Emphasis on natural derivatives. J. King Saud. Univ. Sci. 2024, 36, 103032. [Google Scholar] [CrossRef]

- Iqbal, A.; Murtaza, A.; Pinto, C.A.; Saraiva, J.A.; Liu, X.; Zhu, Z.; Lorenzo, J.M.; Marszałek, K. High-pressure processing for food preservation. In Innovative and Emerging Technologies in the Bio-Marine Food Sector; Academic Press: Cambridge, MA, USA, 2022; pp. 495–518. [Google Scholar]

- Walayat, N.; Campagnol, P.C.B.; Zhang, W.; Su, Z.; Lorenzo, J.M. Films with antimicrobial activity for meat products. Curr. Opin. Food Sci. 2024, 56, 101127. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Huang, H.-W.; Hsu, C.-P.; Yang, B.B. Recent Advances in Food Processing Using High Hydrostatic Pressure Technology. Crit. Rev. Food Sci. Nutr. 2015, 56, 527–540. [Google Scholar] [CrossRef]

- Rusconi, G. Food Safety and Policy in the European Union. In International Food Law and Policy; Springer: Berlin/Heidelberg, Germany, 2016; pp. 451–483. [Google Scholar]

- Toy, J.Y.H.; Chin, F.W.L.; Zhang, L.; Jing, L.; Yang, X.; Huang, D. Novel food processing technologies for retaining nutrition of horticultural food products. Future Postharvest Food 2024, 1, 198–212. [Google Scholar] [CrossRef]

- Sun, L.; Lv, J.; Liu, Y.; Zang, M.; Li, P.; Wang, D.; Zhu, Y.; Xu, W. Effects of combined carnosine and ultra-high pressure on the inhibition of fishy off-odor of snakehead fillets and the possible mechanism. Food Chem. 2022, 395, 133615. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Wang, H.; Zhou, F.; Ma, H.; Ding, Y.; Hu, Y. Possible mechanisms of sequential and simultaneous ultrasonic thawing modes affecting the quality of small yellow croaker. LWT 2024, 198, 116046. [Google Scholar] [CrossRef]

- Li, P.; Sun, L.; Wang, J.; Wang, Y.; Zou, Y.; Yan, Z.; Zhang, M.; Wang, D.; Xu, W. Effects of combined ultrasound and low-temperature short-time heating pretreatment on proteases inactivation and textural quality of meat of yellow-feathered chickens. Food Chem. 2021, 355, 129645. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Guo, L.; Chen, Z.; Ma, H. Tri-frequency simultaneous ultrasound pickling for the acceleration of the NaCl content and quality improvement of pork (Longissimus dorsi). J. Sci. Food Agric. 2024, 104, 6242–6251. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Lee, J.; Jeong, S.; Lee, S.; Hong, G.-P. Effect of high pressure pretreatment on the inhibition of ice nucleation and biochemical changes in pork loins during supercooling preservation. Meat Sci. 2024, 208, 109393. [Google Scholar] [CrossRef] [PubMed]

- Jia, G.; Orlien, V.; Liu, H.; Sun, A. Effect of high pressure processing of pork (Longissimus dorsi) on changes of protein structure and water loss during frozen storage. LWT-Food Sci. Technol. 2021, 135, 110084. [Google Scholar] [CrossRef]

- Picouet, P.A.; Sala, X.; Garcia-Gil, N.; Nolis, P.; Colleo, M.; Parella, T.; Arnau, J. High pressure processing of dry-cured ham: Ultrastructural and molecular changes affecting sodium and water dynamics. Innov. Food Sci. Emerg. Technol. 2012, 16, 335–340. [Google Scholar] [CrossRef]

- Nuygen, M.; Arvaj, L.; Balamurugan, S. The use of high pressure processing to compensate for the effects of salt reduction in ready-to-eat meat products. Crit. Rev. Food Sci. 2024, 64, 2533–2547. [Google Scholar] [CrossRef]

- Ferrini, G.; Comaposada, J.; Arnau, J.; Gou, P. Colour modification in a cured meat model dried by Quick-Dry-Slice process® and high pressure processed as a function of NaCl, KCl, K-lactate and water contents. Innov. Food Sci. Emerg. Technol. 2012, 13, 69–74. [Google Scholar] [CrossRef]

- Cava, R.; Higuero, N.; Ladero, L. High-pressure processing and storage temperature on Listeria monocytogenes, microbial counts and oxidative changes of two traditional dry-cured meat products. Meat Sci. 2021, 171, 108273. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, W.; Cao, A.; Cao, M.; Li, J. Effects of ultrasonics combined with far infrared or microwave thawing on protein denaturation and moisture migration of Sciaenops ocellatus (red drum). Ultrason. Sonochem. 2019, 55, 96–104. [Google Scholar] [CrossRef]

- Jia, S.; Shen, H.; Wang, D.; Liu, S.; Ding, Y.; Zhou, X. Novel NaCl reduction technologies for dry-cured meat products and their mechanisms: A comprehensive review. Food Chem. 2024, 431, 137142. [Google Scholar] [CrossRef]

- Dadhaneeya, H.; Nema, P.K.; Arora, V.K. Internet of Things in food processing and its potential in Industry 4.0 era: A review. Trends Food Sci. Technol. 2023, 139, 104109. [Google Scholar] [CrossRef]

- Mohamed, T.M.K.; Gao, J.M.; Tunio, M. Development and experiment of the intelligent control system for rhizosphere temperature of aeroponic lettuce via the Internet of Things. Int. J. Agr. Biol. Eng. 2022, 15, 225–233. [Google Scholar]

- Bouzembrak, Y.; Klüche, M.; Gavai, A.; Marvin, H.J.P. Internet of Things in food safety: Literature review and a bibliometric analysis. Trends Food Sci. Technol. 2019, 94, 54–64. [Google Scholar] [CrossRef]

- Wang, C.Q.; Gu, C.D.; Zhao, X.; Yu, S.S.; Zhang, X.R.; Xu, F.Y.; Ding, L.J.; Huang, X.Y.; Qian, J. Self-designed portable dual-mode fluorescence device with custom python-based analysis software for rapid detection via dual-color FRET aptasensor with IoT capabilities. Food Chem. 2024, 457, 140190. [Google Scholar] [CrossRef]

- Kodan, R.; Parmar, P.; Pathania, S. Internet of Things for Food Sector: Status Quo and Projected Potential. Food Rev. Int. 2020, 36, 584–600. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Chen, L.Y.; Battino, M.; Farag, M.A.; Xiao, J.B.; Simal-Gandara, J.; Gao, H.Y.; Jiang, W.B. Blockchain: An emerging novel technology to upgrade the current fresh fruit supply chain. Trends Food Sci. Technol. 2022, 124, 1–12. [Google Scholar] [CrossRef]

- Bakalis, S.; Gerogiorgis, D.; Argyropoulos, D.; Emmanoulidis, C. Food Industry 4.0: Opportunities for a digital future. In Food Engineering Innovations Across the Food Supply Chain; Elsevier: Amsterdam, The Netherlands, 2022; pp. 357–368. [Google Scholar]

- Arvana, M.; Rocha, A.D.; Barata, J. Agri-Food Value Chain Traceability Using Blockchain Technology: Portuguese Hams’ Production Scenario. Foods 2023, 12, 4246. [Google Scholar] [CrossRef]

- Kechagias, E.P.; Gayialis, S.P.; Papadopoulos, G.A.; Papoutsis, G. An Ethereum-Based Distributed Application for Enhancing Food Supply Chain Traceability. Foods 2023, 12, 1220. [Google Scholar] [CrossRef]

- Kailaku, S.I.; Djatna, T. Traceability and Quality Monitoring Improvement Throughout Carrot Supply Chain with the Implementation of Internet-Of-Things. IOP Conf. Ser. Earth Environ. Sci. 2022, 1024, 012079. [Google Scholar] [CrossRef]

- Hu, X. Cold chain logistics model of agricultural products based on embedded system and blockchain. Prod. Plan. Control 2022, 1–12. [Google Scholar] [CrossRef]

- Patel, A.S.; Brahmbhatt, M.N.; Bariya, A.R.; Nayak, J.B.; Singh, V.K. Blockchain technology in food safety and traceability concern to livestock products. Heliyon 2023, 9, e16526. [Google Scholar] [CrossRef] [PubMed]

- Echegaray, N.; Hassoun, A.; Jagtap, S.; Tetteh-Caesar, M.; Kumar, M.; Tomasevic, I.; Goksen, G.; Lorenzo, J.M. Meat 4.0: Principles and Applications of Industry 4.0 Technologies in the Meat Industry. Appl. Sci. 2022, 12, 6986. [Google Scholar] [CrossRef]

- Režek Jambrak, A.; Nutrizio, M.; Djekić, I.; Pleslić, S.; Chemat, F. Internet of Nonthermal Food Processing Technologies (IoNTP): Food Industry 4.0 and Sustainability. Appl. Sci. 2021, 11, 686. [Google Scholar] [CrossRef]

- Vern, P.; Panghal, A.; Mor, R.S.; Kamble, S.S. Blockchain technology in the agri-food supply chain: A systematic literature review of opportunities and challenges. Manag. Rev. Q. 2024, 75, 643–675. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, Y. Study on artificial intelligence: The state of the art and future prospects. J. Ind. Inf. Integr. 2021, 23, 100224. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, X.; Cao, X.; Huang, C.; Liu, E.; Qian, S.; Liu, X.; Wu, Y.; Dong, F.; Qiu, C.-W.; et al. Artificial intelligence: A powerful paradigm for scientific research. Innovation 2021, 2, 100179. [Google Scholar] [CrossRef]

- Nunekpeku, X.; Zhang, W.; Gao, J.Y.; Adade, S.Y.S.S.; Li, H.H.; Chen, Q.S. Gel strength prediction in ultrasonicated chicken mince: Fusing near-infrared and Raman spectroscopy coupled with deep learning LSTM algorithm. Food Control 2025, 168, 110916. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, C. Design and Implementation of an Android-based Broiler Production Environment Monitoring System. In Proceedings of the 2020 IEEE 3rd International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), Shenyang, China, 20 November 2020; IEEE: New York, NY, USA, 2020; pp. 125–128. [Google Scholar]

- Mason, A.; De Medeiros Esper, I.; Korostynska, O.; Cordova-Lopez, L.E.; Romanov, D.; Pinceková, M.; Bjørnstad, P.H.; Alvseike, O.; Popov, A.; Smolkin, O.; et al. RoBUTCHER: A novel robotic meat factory cell platform. Int. J. Robot. Res. 2024, 43, 1711–1730. [Google Scholar] [CrossRef]

- Wright, R.; Parekh, S.; White, R.; Losey, D.P. Safely and autonomously cutting meat with a collaborative robot arm. Sci. Rep. 2024, 14, 299. [Google Scholar] [CrossRef]

- Bzdok, D.; Krzywinski, M.; Altman, N. Machine learning: A primer. Nat. Methods 2017, 14, 1119–1120. [Google Scholar] [CrossRef]

- Nturambirwe, J.F.I.; Opara, U.L. Machine learning applications to non-destructive defect detection in horticultural products. Biosyst. Eng. 2020, 189, 60–83. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.R.; Qi, J.T.; Gao, J.P.; Chen, W.H.; Fei, J.M.; Meng, H.W.; Ma, Z. Research on the Control System for the Conveying and Separation Experimental Platform of Tiger Nut Harvester Based on Sensing Technology and Control Algorithms. Agriculture 2025, 15, 1–26. [Google Scholar] [CrossRef]

- Zhao, S.G.; Jiao, T.H.; Adade, S.Y.S.S.; Wang, Z.; Wu, X.X.; Li, H.H.; Chen, Q.S. Based on vis-NIR combined with ANN for on-line detection of bacterial concentration during kombucha fermentation. Food Biosci. 2024, 60, 104346. [Google Scholar] [CrossRef]

- You, J.; Li, D.S.; Wang, Z.; Chen, Q.S.; Ouyang, Q. Prediction and visualization of moisture content in Tencha drying processes by computer vision and deep learning. J. Sci. Food Agric. 2024, 104, 5486–5494. [Google Scholar] [CrossRef]

- Umer, F.; Adnan, N. Generative artificial intelligence: Synthetic datasets in dentistry. BDJ Open 2024, 10, 13. [Google Scholar] [CrossRef]

- Pushparaj, K.; Balasubramanian, B.; Meyyazhagan, A.; Park, S.; Arumugam, V.A.; Pappuswamy, M.; Bhotla, H.K.; Liu, W.-C.; Mousavi Khaneghah, A. Advancements in Sustainable Techniques for Dried Meat Production: An Updated Review. Food Bioprocess. Tech. 2025, 18, 2170–2194. [Google Scholar] [CrossRef]

- Mahanti, N.K.; Shivashankar, S.; Chhetri, K.B.; Kumar, A.; Rao, B.B.; Aravind, J.; Swami, D.V. Enhancing food authentication through E-nose and E-tongue technologies: Current trends and future directions. Trends Food Sci. Technol. 2024, 150, 104574. [Google Scholar] [CrossRef]

- Rady, A.M.; Adedeji, A.; Watson, N.J. Feasibility of utilizing color imaging and machine learning for adulteration detection in minced meat. J. Agric. Food Res. 2021, 6, 100251. [Google Scholar] [CrossRef]

- Ng, F.Y.C.; Thirunavukarasu, A.J.; Cheng, H.; Tan, T.F.; Gutierrez, L.; Lan, Y.; Ong, J.C.L.; Chong, Y.S.; Ngiam, K.Y.; Ho, D.; et al. Artificial intelligence education: An evidence-based medicine approach for consumers, translators, and developers. Cell Rep. Med. 2023, 4, 101230. [Google Scholar] [CrossRef]

- Zhu, L.; Spachos, P.; Pensini, E.; Plataniotis, K.N. Deep learning and machine vision for food processing: A survey. Curr. Res. Food Sci. 2021, 4, 233–249. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Q.; Liu, L.H.; Zareef, M.; Wang, L.; Chen, Q.S. Application of portable visible and near-infrared spectroscopy for rapid detection of cooking loss rate in pork: Comparing spectra from frozen and thawed pork. LWT-Food Sci. Technol. 2022, 160, 113304. [Google Scholar] [CrossRef]

- Cheng, J.H.; Sun, J.; Yao, K.S.; Xu, M.; Dai, C.X. Multi-task convolutional neural network for simultaneous monitoring of lipid and protein oxidative damage in frozen-thawed pork using hyperspectral imaging. Meat Sci. 2023, 201, 109196. [Google Scholar] [CrossRef]

- Lu, B.; Han, F.K.; Aheto, J.H.; Rashed, M.M.A.; Pan, Z.G. Artificial bionic taste sensors coupled with chemometrics for rapid detection of beef adulteration. Food Sci. Nutr. 2021, 9, 5220–5228. [Google Scholar] [CrossRef]

- Dixit, Y.; Al-Sarayreh, M.; Craigie, C.R.; Reis, M.M. A global calibration model for prediction of intramuscular fat and pH in red meat using hyperspectral imaging. Meat Sci. 2021, 181, 108405. [Google Scholar] [CrossRef]

- Kolosov, D.; Fengou, L.-C.; Carstensen, J.M.; Schultz, N.; Nychas, G.-J.; Mporas, I. Microbiological Quality Estimation of Meat Using Deep CNNs on Embedded Hardware Systems. Sensors 2023, 23, 4233. [Google Scholar] [CrossRef]

- Ahmed, M.R.; Reed, D.D.; Young, J.M.; Eshkabilov, S.; Berg, E.P.; Sun, X. Beef Quality Grade Classification Based on Intramuscular Fat Content Using Hyperspectral Imaging Technology. Appl. Sci. 2021, 11, 4588. [Google Scholar] [CrossRef]

- Wang, M.; Li, X. Application of artificial intelligence techniques in meat processing: A review. J. Food Process Eng. 2024, 47, e14590. [Google Scholar] [CrossRef]

- Vainio-Pekka, H.; Agbese, M.O.-O.; Jantunen, M.; Vakkuri, V.; Mikkonen, T.; Rousi, R.; Abrahamsson, P. The Role of Explainable AI in the Research Field of AI Ethics. ACM Trans. Interact. Intell. Syst. 2023, 13, 1–39. [Google Scholar] [CrossRef]

- Morchhale, Y. Ethical Considerations in Artificial Intelligence: Addressing Bias and Fairness in Algorithmic Decision-Making. Interantional J. Sci. Res. Eng. Manag. 2024, 8, 1–5. [Google Scholar] [CrossRef]

- Androutsopoulou, M.; Askounis, D.; Carayannis, E.G.; Zotas, N. Leveraging AI for Enhanced eGovernment: Optimizing the Use of Open Governmental Data. J. Knowl. Econ. 2024, 1–36. [Google Scholar] [CrossRef]

- Rawas, S. AI: The future of humanity. Discov. Artif. Intell. 2024, 4, 25. [Google Scholar] [CrossRef]

- Hu, X.; Sui, H.; Geng, X.; Zhao, L. Constructing a teacher portrait for the artificial intelligence age based on the micro ecological system theory: A systematic review. Educ. Inf. Technol. 2024, 29, 16679–16715. [Google Scholar] [CrossRef]

- Treich, N. Cultured Meat: Promises and Challenges. Environ. Resour. Econ. 2021, 79, 33–61. [Google Scholar] [CrossRef]

- Nyika, J.; Mackolil, J.; Workie, E.; Adhav, C.; Ramadas, S. Cellular agriculture research progress and prospects: Insights from bibliometric analysis. Curr. Res. Biotechnol. 2021, 3, 215–224. [Google Scholar] [CrossRef]

- Jahir, N.R.; Ramakrishna, S.; Abdullah, A.A.A.; Vigneswari, S. Cultured meat in cellular agriculture: Advantages, applications and challenges. Food Biosci. 2023, 53, 102614. [Google Scholar] [CrossRef]

- Boland, M.J.; Rae, A.N.; Vereijken, J.M.; Meuwissen, M.P.M.; Fischer, A.R.H.; Van Boekel, M.A.J.S.; Rutherfurd, S.M.; Gruppen, H.; Moughan, P.J.; Hendriks, W.H. The future supply of animal-derived protein for human consumption. Trends Food Sci. Technol. 2013, 29, 62–73. [Google Scholar] [CrossRef]

- Post, M.J.; Levenberg, S.; Kaplan, D.L.; Genovese, N.; Fu, J.; Bryant, C.J.; Negowetti, N.; Verzijden, K.; Moutsatsou, P. Scientific, sustainability and regulatory challenges of cultured meat. Nat. Food 2020, 1, 403–415. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, Z.; Ding, X.; Post, M.J.; Guo, R.; Wang, J.; Wu, J.; Tang, W.; Ding, S.; Zhou, G. Production of cultured meat from pig muscle stem cells. Biomaterials 2022, 287, 121650. [Google Scholar] [CrossRef]

- Zheng, Y.-Y.; Hu, Z.-N.; Zhou, G.-H. A review: Analysis of technical challenges in cultured meat production and its commercialization. Crit. Rev. Food Sci. Nutr. 2024, 65, 1911–1928. [Google Scholar] [CrossRef]

- Guan, X.; Pan, Z.; Li, M.; Shen, J.; Sun, Y.; Yu, C.; Fei, Z.; Ma, Z.; Zhou, J.; Chen, J. Production of cultivated meat with stably proliferated porcine muscle stem cells and edible scaffolds. Future Foods 2025, 11, 100618. [Google Scholar] [CrossRef]

- Guo, Y.; Ding, S.-J.; Ding, X.; Liu, Z.; Wang, J.-L.; Chen, Y.; Liu, P.-P.; Li, H.-X.; Zhou, G.-H.; Tang, C.-B. Effects of selected flavonoids on cell proliferation and differentiation of porcine muscle stem cells for cultured meat production. Food Res. Int. 2022, 160, 111459. [Google Scholar] [CrossRef] [PubMed]

- Louis, F.; Furuhashi, M.; Yoshinuma, H.; Takeuchi, S.; Matsusaki, M. Mimicking Wagyu beef fat in cultured meat: Progress in edible bovine adipose tissue production with controllable fatty acid composition. Mater. Today Bio 2023, 21, 100720. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Wang, Q.; Zhu, Y.; Sheng, K.; Xiang, N.; Zhang, X. Cell culture medium cycling in cultured meat: Key factors and potential strategies. Trends Food Sci. Technol. 2023, 138, 564–576. [Google Scholar] [CrossRef]

- Warner, R.D. Review: Analysis of the process and drivers for cellular meat production. Animal 2019, 13, 3041–3058. [Google Scholar] [CrossRef]

- Kouarfaté, B.B.; Durif, F. Understanding Consumer Attitudes toward Cultured Meat: The Role of Online Media Framing. Sustainability 2023, 15, 16879. [Google Scholar] [CrossRef]

- Stephens, N.; Di Silvio, L.; Dunsford, I.; Ellis, M.; Glencross, A.; Sexton, A. Bringing cultured meat to market: Technical, socio-political, and regulatory challenges in cellular agriculture. Trends Food Sci. Technol. 2018, 78, 155–166. [Google Scholar] [CrossRef]

- Bekker, G.A.; Fischer, A.R.H.; Tobi, H.; Van Trijp, H.C.M. Explicit and implicit attitude toward an emerging food technology: The case of cultured meat. Appetite 2017, 108, 245–254. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Caron, E.; Van De Walle, D.; Dewettinck, K.; Marchesini, F.H. State of the art, challenges, and future prospects for the multi-material 3D printing of plant-based meat. Food Res. Int. 2024, 192, 114712. [Google Scholar] [CrossRef]

- Wen, Y.; Chao, C.; Che, Q.T.; Kim, H.W.; Park, H.J. Development of plant-based meat analogs using 3D printing: Status and opportunities. Trends Food Sci. Technol. 2023, 132, 76–92. [Google Scholar] [CrossRef]

- Jeong, D.; Seo, J.W.; Lee, H.G.; Jung, W.K.; Park, Y.H.; Bae, H. Efficient Myogenic/Adipogenic Transdifferentiation of Bovine Fibroblasts in a 3D Bioprinting System for Steak-Type Cultured Meat Production. Adv. Sci. 2022, 9, 2202877. [Google Scholar] [CrossRef] [PubMed]

- Bisht, B.; Begum, J.P.S.; Dmitriev, A.A.; Kurbatova, A.; Singh, N.; Nishinari, K.; Nanda, M.; Kumar, S.; Vlaskin, M.S.; Kumar, V. Unlocking the potential of future version 3D food products with next generation microalgae blue protein integration: A review. Trends Food Sci. Technol. 2024, 147, 104471. [Google Scholar] [CrossRef]

- Mittal, S.; Bhuiyan, M.H.R.; Ngadi, M.O. Challenges and Prospects of Plant-Protein-Based 3D Printing. Foods 2023, 12, 4490. [Google Scholar] [CrossRef]

- Dong, H.; Wang, P.; Yang, Z.; Xu, X. 3D printing based on meat materials: Challenges and opportunities. Curr. Res. Food Sci. 2023, 6, 100423. [Google Scholar] [CrossRef]

- Imran, M.; Liyan, Z. Production of plant-based meat: Functionality, limitations and future prospects. Eur. Food Res. Technol. 2023, 249, 2189–2213. [Google Scholar] [CrossRef]

- Tong, Q.; Jiang, Y.; Xiao, S.; Meng, Y.; Dong, X. Research on improving the structural stability of surimi 3D printing through laser cooking techniques. J. Food Eng. 2024, 375, 112075. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, Q.; Liu, Y.; Wei, S.; Han, Z.; Zheng, O.; Ji, H.; Zhang, B.; Liu, S. Optimization of 3D printing formulation of shrimp surimi based on response surface method. LWT-Food Sci. Technol. 2024, 199, 116126. [Google Scholar] [CrossRef]

- Li, Q.; Chen, S.; You, J.; Hu, Y.; Yin, T.; Liu, R. A comprehensive unraveling of the mystery of reduced-salt surimi gels: From molecular mechanism to future prospects. Trends Food Sci. Technol. 2024, 154, 104783. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, M.; Fan, K.; Mujumdar, A.S. Non-thermal Technology and Heating Technology for Fresh Food Cooking in the Central Kitchen Processing: A Review. Food Rev. Int. 2022, 38, 608–627. [Google Scholar] [CrossRef]

- Luan, C.; Zhang, M.; Fan, K.; Devahastin, S. Effective pretreatment technologies for fresh foods aimed for use in central kitchen processing. J. Sci. Food Agric. 2021, 101, 347–363. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Zhang, M.; Sun, Y.; Wang, Y.C. Current intelligent segmentation and cooking technology in the central kitchen food processing. J. Food Process Eng. 2019, 42, e13149. [Google Scholar] [CrossRef]

- Khodabandehloo, K. Achieving robotic meat cutting. Anim. Front. 2022, 12, 7–17. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, C.; Er, M.J. Robotic 3-D Laser-Guided Approach for Efficient Cutting of Porcine Belly. IEEE/ASME Trans. Mechatron. 2022, 27, 2963–2972. [Google Scholar] [CrossRef]

- Saeidi, H.; Opfermann, J.D.; Kam, M.; Wei, S.; Leonard, S.; Hsieh, M.H.; Kang, J.U.; Krieger, A. Autonomous robotic laparoscopic surgery for intestinal anastomosis. Sci. Robot. 2022, 7, eabj2908. [Google Scholar] [CrossRef]

- Mu, X.; Jia, Y.-B. Physical Property Estimation and Knife Trajectory Optimization During Robotic Cutting. In Proceedings of the 2022 IEEE International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23 May 2022; IEEE: New York, NY, USA, 2022; pp. 2700–2706. [Google Scholar]

- Wu, J.; Tang, X.; Xin, S.; Wang, C.; Peng, F.; Yan, R. Research on the directionality of end dynamic compliance dominated by milling robot body structure and milling vibration suppression. Robot. Comput. -Integr. Manuf. 2024, 85, 102631. [Google Scholar] [CrossRef]

- Takacs, K.; Takacs, B.; Tarsoly, S.; Garamvolgyi, T.; Galambos, P.; Rudas, I.; Haidegger, T. Analysis of Intelligent Force Control Methods for Red-Meat Gripping Applications. In Proceedings of the International Conference on Computational Cybernetics (ICCC), Reykjavík, Iceland, 6–9 July 2022. [Google Scholar]

- Spagnoli, A.; Brighenti, R.; Terzano, M.; Artoni, F. Cutting resistance of soft materials: Effects of blade inclination and friction. Theor. Appl. Fract. Mech. 2019, 101, 200–206. [Google Scholar] [CrossRef]

- Røer, H.; Korostynska, O.; Bjerke, F.; Romanov, D.; Cordova-Lopez, L.E.; Mason, A.; Bjørnstad, P.H.; Håseth, T.T.; Alvseike, O. Quality assessment of fresh meat cuts as a performance indicator of knives specifically adapted for robot-assisted operations. Manag. Sci. Lett. 2023, 13, 108–117. [Google Scholar] [CrossRef]

- Faridnia, F.; Ma, Q.L.; Bremer, P.J.; Burritt, D.J.; Hamid, N.; Oey, I. Effect of freezing as pre-treatment prior to pulsed electric field processing on quality traits of beef muscles. Innov. Food Sci. Emerg. Technol. 2015, 29, 31–40. [Google Scholar] [CrossRef]

- Iglesias, I.; Sanchez, A.; Silva, F.J.G. Robotic path compensation training method for optimizing face milling operations based on non-contact CMM techniques. Robot. Comput. Integr. Manuf. 2024, 85, 102623. [Google Scholar] [CrossRef]

- Cardoso, A.; Colim, A.; Bicho, E.; Braga, A.C.; Arezes, P. A novel human-centered methodology for assessing manual-to-collaborative safe conversion of workstations. Saf. Sci. 2025, 181, 106685. [Google Scholar] [CrossRef]

- Al-Hilphy, A.R.; Al-Asadi, M.H.; Al-Hmedawy, N.K.; Khalil, A.A.; Roobab, U.; Ranjha, M.M.A.N.; Manzoor, M.F. Effects of electrical field stimulation on the physicochemical and sensory attributes of aged chicken meat. J. Food Process Eng. 2022, 45, e14032. [Google Scholar] [CrossRef]

- Pan, J.J.; Li, C.L.; Liu, X.J.; He, L.C.; Zhang, M.; Huang, S.J.; Huang, S.F.; Liu, Y.Y.; Zhang, Y.; Jin, G.F. A multivariate insight into the organoleptic properties of porcine muscle by ultrasound-assisted brining: Protein oxidation, water state and microstructure. LWT-Food Sci. Technol. 2022, 159, 113136. [Google Scholar] [CrossRef]

- Guo, Z. Ultrasound-assisted thawing of frozen white yak meat Effects on thawing rate, meat quality, nutrients, and microstructure. Ultrason. Sonochem. 2021, 70, 105345. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Q.; Xuan, L.; Lin, Z.; Yang, Z.; Huang, X.; Li, Z.; Gao, W.; Ren, J.; Shi, J.; et al. Ultrasonic technology for predicting beef thawing degree and endpoint. J. Food Eng. 2024, 383, 112236. [Google Scholar] [CrossRef]

- Li, C.; Sun, Y.; Pan, D.; Zhou, C.; He, J.; Du, L. Contribution of ultrasound-assisted protein structural changes in marinated beef to the improved binding ability of spices and flavor enhancement. J. Sci. Food Agric. 2025, 105, 1239–1250. [Google Scholar] [CrossRef]

- Li, C.; Shi, J.; Zhai, X.; Yang, Z.; Huang, X.; Li, Z.; Li, Y.; Zou, X. Effects of Pulsed Pressure Curing on Beef Quality. Foods 2023, 12, 656. [Google Scholar] [CrossRef]

- Zhu, Y.; Yan, Y.; Yu, Z.; Wu, T.; Bennett, L.E. Effects of high pressure processing on microbial, textural and sensory properties of low-salt emulsified beef sausage. Food Control 2022, 133, 108596. [Google Scholar] [CrossRef]

- Fernández, P.P.; Sanz, P.D.; Molina-García, A.D.; Otero, L.; Guignon, B.; Vaudagna, S.R. Conventional freezing plus high pressure–low temperature treatment: Physical properties, microbial quality and storage stability of beef meat. Meat Sci. 2007, 77, 616–625. [Google Scholar] [CrossRef]

- Zhu, Y.; Xia, T.; Chen, Z.; Zheng, M.; Pan, E.; Xi, L. Joint optimization of price, warranty and service investment for capital-intensive equipment considering maintenance capacity limits. Comput. Ind. Eng. 2022, 169, 108152. [Google Scholar] [CrossRef]

- Deniz, Y.; Ekmen, S.; Dogan, E.; Calıs, S.O. Clinical and Laboratory Effects of Foodborne Illness in Children. Foodborne Pathog. Dis. 2024, 21, 366–369. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.Z.; Zhang, M.; Xu, B.G.; Guo, Z.M. Intelligent quality control of gelatinous polysaccharide-based fresh products during cold chain logistics: A review. Food Biosci. 2024, 62, 105081. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, D.; Xie, F.; Li, X.; Schroyen, M.; Chen, L.; Hou, C. Changes in water holding capacity of chilled fresh pork in controlled freezing-point storage assisted by different modes of electrostatic field action. Meat Sci. 2023, 204, 109269. [Google Scholar] [CrossRef]

- Xu, Y.; Leng, D.; Li, X.; Wang, D.; Chai, X.; Schroyen, M.; Zhang, D.; Hou, C. Effects of different electrostatic field intensities assisted controlled freezing point storage on water holding capacity of fresh meat during the early postmortem period. Food Chem. 2024, 439, 138096. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Y.; Pu, A.; Tian, J.; Yang, Z.; Feng, Y.; Zhang, Y.; Liu, G. A preliminary exploration of the synergistic preservation effect of electrostatic field and superchilling on muscle foods: Mechanisms, influencing factors, applications, and challenges. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70066. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, M.; Mujumdar, A.S.; Rui, L. Extending shelf life of chilled pork pretreated with high-voltage electrostatic field in modified atmosphere packaging by cinnamaldehyde nanoemulsion at non-contact mode. Meat Sci. 2025, 225, 109802. [Google Scholar] [CrossRef]

- Kour, K.; Deep Singh, S.K.; Singh Bali, M.; Pradeep Ghantasala, G.S.; Sharma, R.R.; Ananthanagu, U. Supply Chain Management Using Internet of Things and Blockchain for Smart Meat Packaging. In Proceedings of the 2024 5th International Conference on Data Intelligence and Cognitive Informatics (ICDICI), Tirunelveli, India, 18 November 2024; IEEE: New York, NY, USA, 2024; pp. 284–288. [Google Scholar]

- Kalimuthu, T.; Kalpana, P.; Kuppusamy, S.; Raja Sreedharan, V. Intelligent decision-making framework for agriculture supply chain in emerging economies: Research opportunities and challenges. Comput. Electron. Agric. 2024, 219, 108766. [Google Scholar] [CrossRef]

- Wu, X.; Liang, X.; Wang, Y.; Wu, B.; Sun, J. Non-Destructive Techniques for the Analysis and Evaluation of Meat Quality and Safety: A Review. Foods 2022, 11, 3713. [Google Scholar] [CrossRef]

- Mery, D.; Lillo, I.; Loebel, H.; Riffo, V.; Soto, A.; Cipriano, A.; Aguilera, J.M. Automated fish bone detection using X-ray imaging. J. Food Eng. 2011, 105, 485–492. [Google Scholar] [CrossRef]

- Campos, R.L.; Yoon, S.-C.; Chung, S.; Bhandarkar, S.M. Semisupervised Deep Learning for the Detection of Foreign Materials on Poultry Meat with Near-Infrared Hyperspectral Imaging. Sensors 2023, 23, 7014. [Google Scholar] [CrossRef]

- Zaytsev, V.; Tutukina, M.N.; Chetyrkina, M.R.; Shelyakin, P.V.; Ovchinnikov, G.; Satybaldina, D.; Kondrashov, V.A.; Bandurist, M.S.; Seilov, S.; Gorin, D.A.; et al. Monitoring of meat quality and change-point detection by a sensor array and profiling of bacterial communities. Anal. Chim. Acta 2024, 1320, 343022. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.H.; Jiao, L.Z.; Wu, J.W.; Zhang, Y.H.; Zhu, Q.Z.; Dong, D.M. Non-destructive and in-situ detection of shrimp freshness using mid-infrared fiber-optic evanescent wave spectroscopy. Food Chem. 2023, 422, 136189. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh Sani, M.; Zhang, W.; Abedini, A.; Khezerlou, A.; Shariatifar, N.; Assadpour, E.; Zhang, F.; Jafari, S.M. Intelligent packaging systems for the quality and safety monitoring of meat products: From lab scale to industrialization. Food Control 2024, 160, 110359. [Google Scholar] [CrossRef]

- Ding, H.; Li, R.; Li, S.; Han, J.; Zhao, J. MISS: Multi-dimensional Information Sensing Surveillance for Cold Chain Logistics. In Proceedings of the 2013 IEEE 10th International Conference on Mobile Ad-Hoc and Sensor Systems (MASS), Hangzhou, China, 14–16 October 2013; IEEE: New York, NY, USA, 2013; pp. 519–523. [Google Scholar]

- Zhang, X.; Sun, Y.; Sun, Y.; Chen, H. Research on Cold Chain Logistics Traceability System of Fresh Agricultural Products Based on Blockchain. Comput. Intell. Neurosci. 2022, 2022, 1957957. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, M.; Yu, Q.; Mujumdar, A.S.; Rui, L. Intelligent control for improving the quality of fresh meat products with rich lipid in cold chain logistics: Research status, challenge, and potential applications. Crit. Rev. Food Sci. Nutr. 2025, 1–28. [Google Scholar] [CrossRef]

- Dai, J.M.; Hu, W.; Yang, H.Y.; Li, C.Z.; Cui, H.Y.; Li, X.Z.; Lin, L. Controlled release and antibacterial properties of PEO/casein nanofibers loaded with Thymol/β-cyclodextrin inclusion complexes in beef preservation. Food Chem. 2022, 382, 132369. [Google Scholar] [CrossRef]

- Tahir, H.E.; Hashim, S.B.H.; Mahunu, G.K.; Arslan, M.; Shi, J.Y.; Mariod, A.A.; Zhang, J.J.; El-Seedi, H.R.; Zhai, X.D.; Musa, T.H.; et al. Smart films fabricated from natural pigments for measurement of total volatile basic nitrogen (TVB-N) content of meat for freshness evaluation: A systematic review. Food Chem. 2022, 396, 133674. [Google Scholar] [CrossRef]

- Lin, L.; Wu, J.J.; Li, C.Z.; Chen, X.C.; Cui, H.Y. Fabrication of a dual-response intelligent antibacterial nanofiber and its application in beef preservation. LWT-Food Sci. Technol. 2022, 154, 112606. [Google Scholar] [CrossRef]

- Lin, L.; Mei, C.C.; Shi, C.; Li, C.Z.; Abdel-Samie, M.A.; Cui, H.Y. Preparation and characterization of gelatin active packaging film loaded with eugenol nanoparticles and its application in chicken preservation. Food Biosci. 2023, 53, 102778. [Google Scholar] [CrossRef]

- Zhang, X.L.; Chen, X.C.; Dai, J.M.; Cui, H.Y.; Lin, L. A pH indicator film based on dragon fruit peel pectin/cassava starch and cyanidin/alizarin for monitoring the freshness of pork. Food Packag. Shelf 2023, 40, 101215. [Google Scholar] [CrossRef]