Effect of Artisanal Processing on Volatile Compounds and Sensory Characteristics of Traditional Soft-Ripened Cheeses Matured with Selected Lactic Acid Bacteria

Abstract

1. Introduction

2. Materials and Methods

2.1. Microbial Cultures

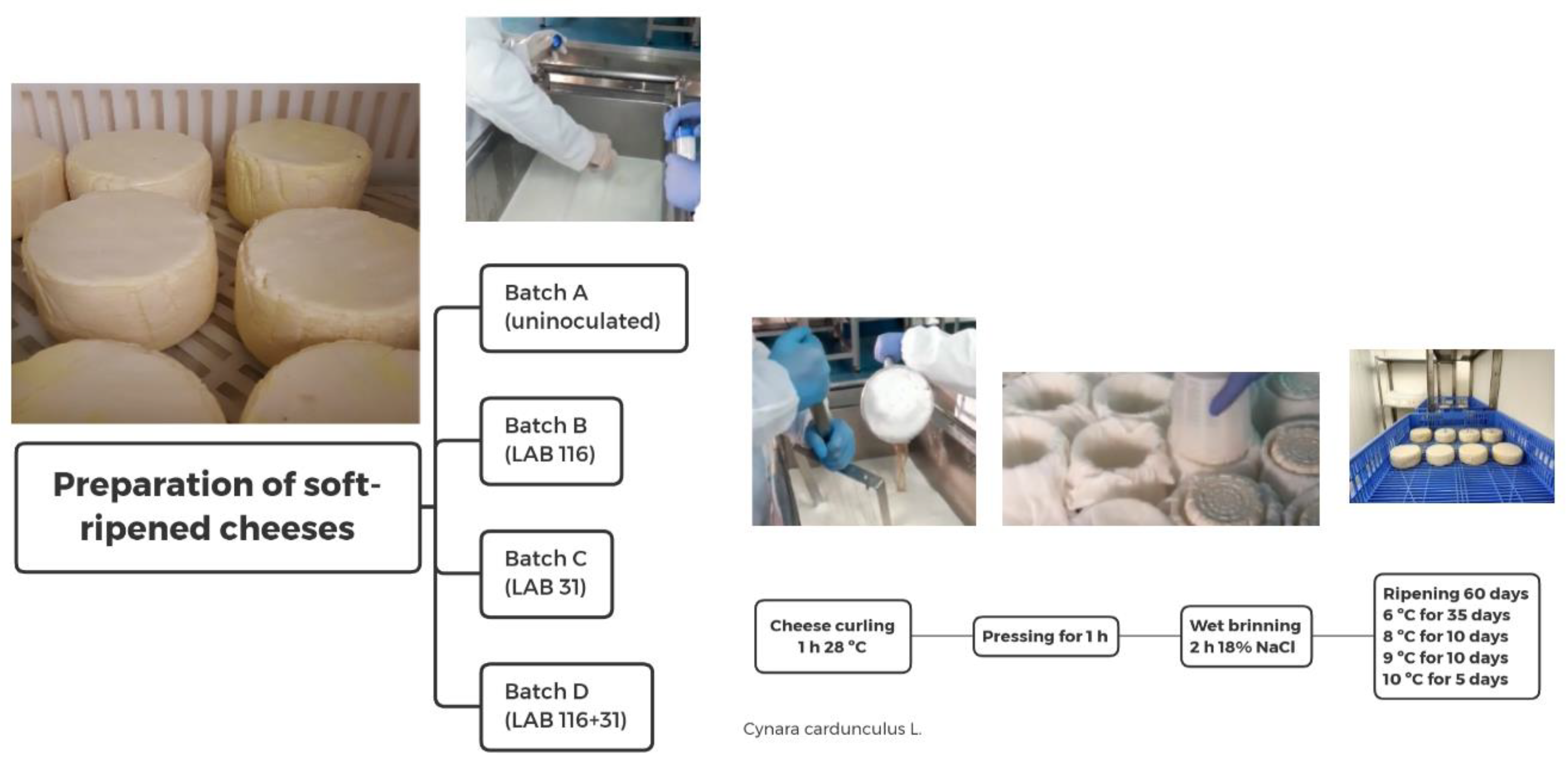

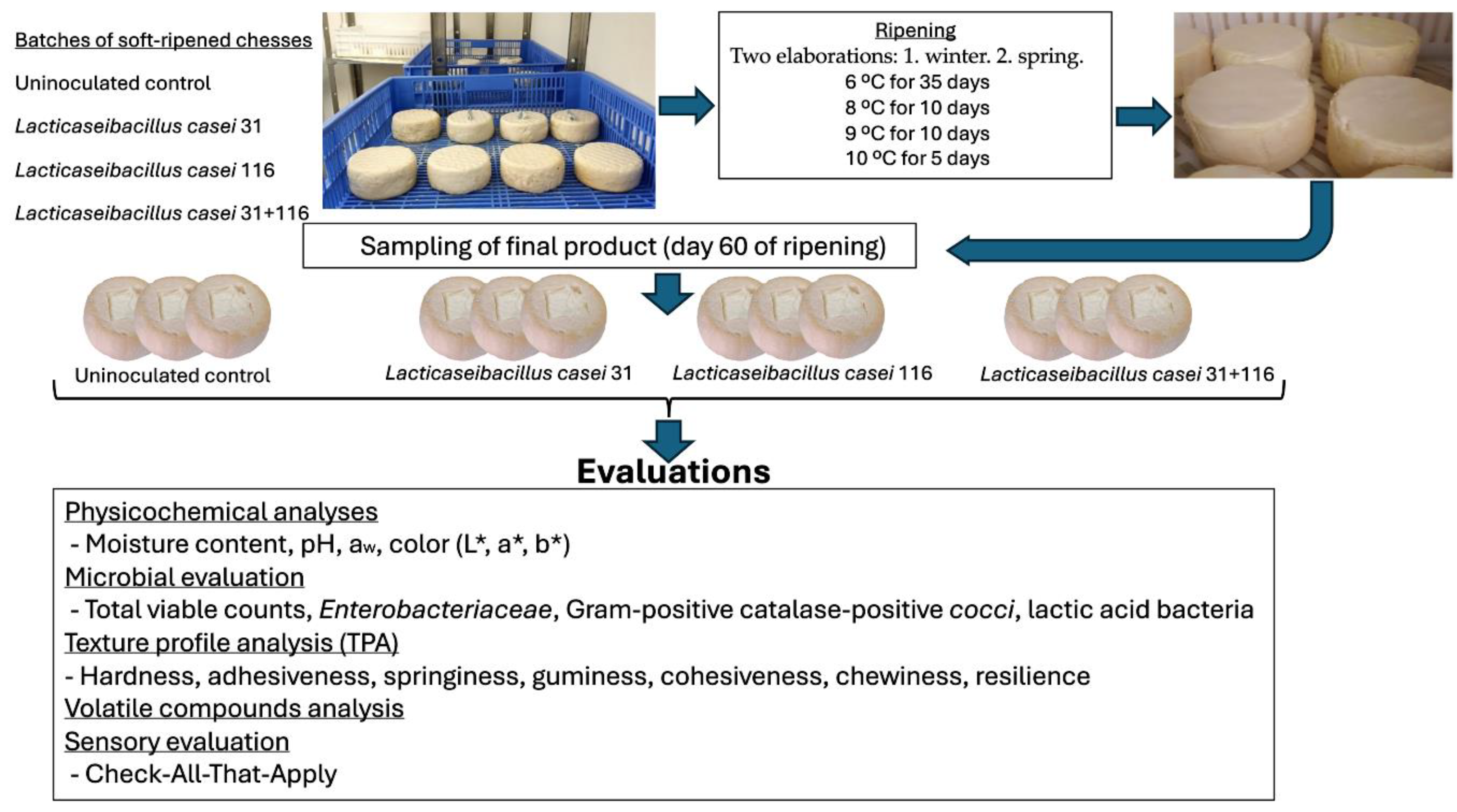

2.2. Preparation of Soft-Ripened Cheeses

2.3. Physicochemical Analyses

2.4. Microbial Analyses

2.5. Texture Profile Analysis

2.6. Volatile Compound Analysis

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results

3.1. Physicochemical Characteristics

3.2. Microbial Population

3.3. Texture Profile

3.4. Volatile Compound Identification

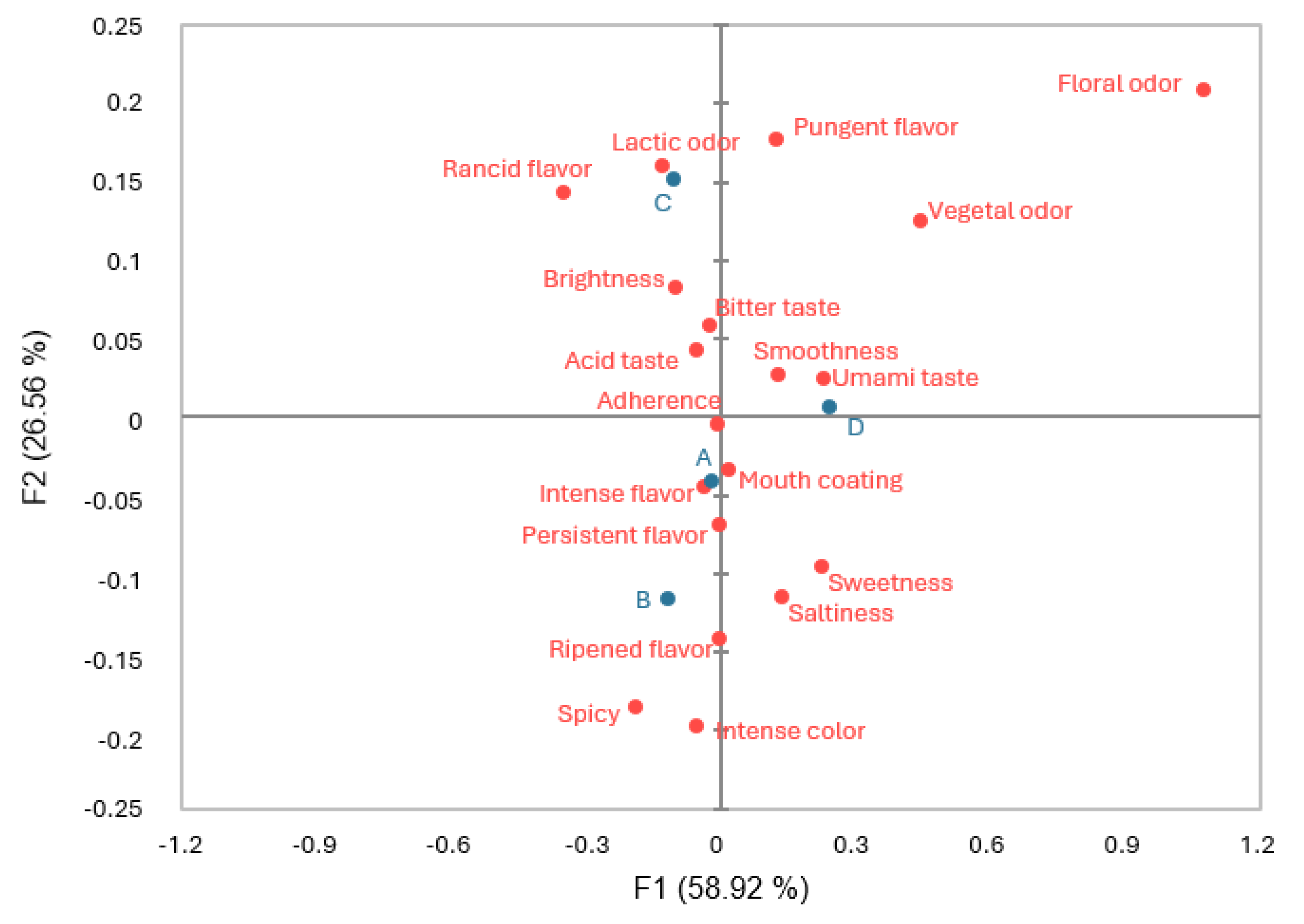

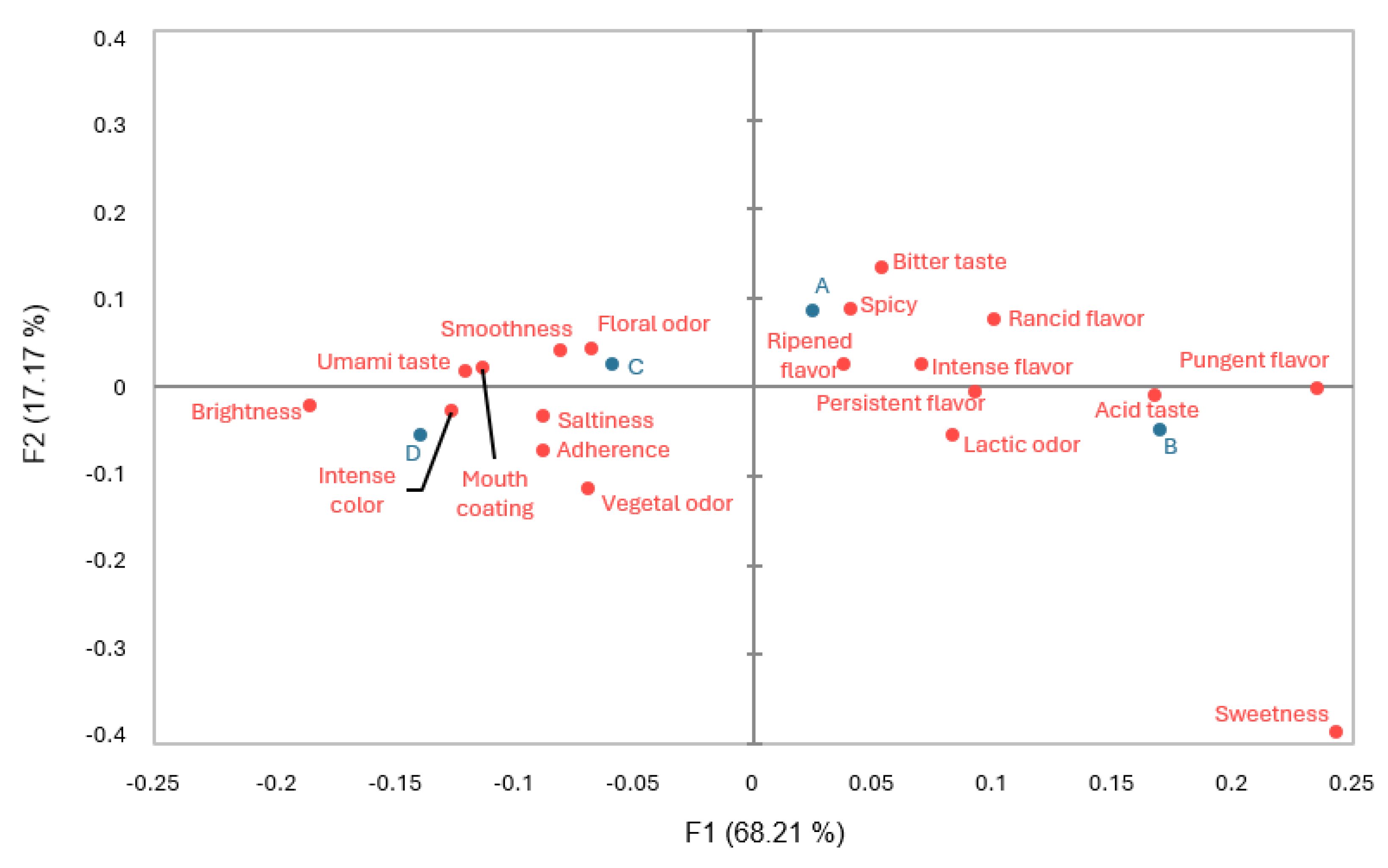

3.5. Sensory Evaluation

4. Discussion

4.1. Physicochemical Characteristics

4.2. Microbial Population

4.3. Texture Profile

4.4. Volatile Compounds

4.4.1. Acids

4.4.2. Aldehydes

4.4.3. Alcohols

4.4.4. Ketones

4.4.5. Esters

4.4.6. Other Molecules

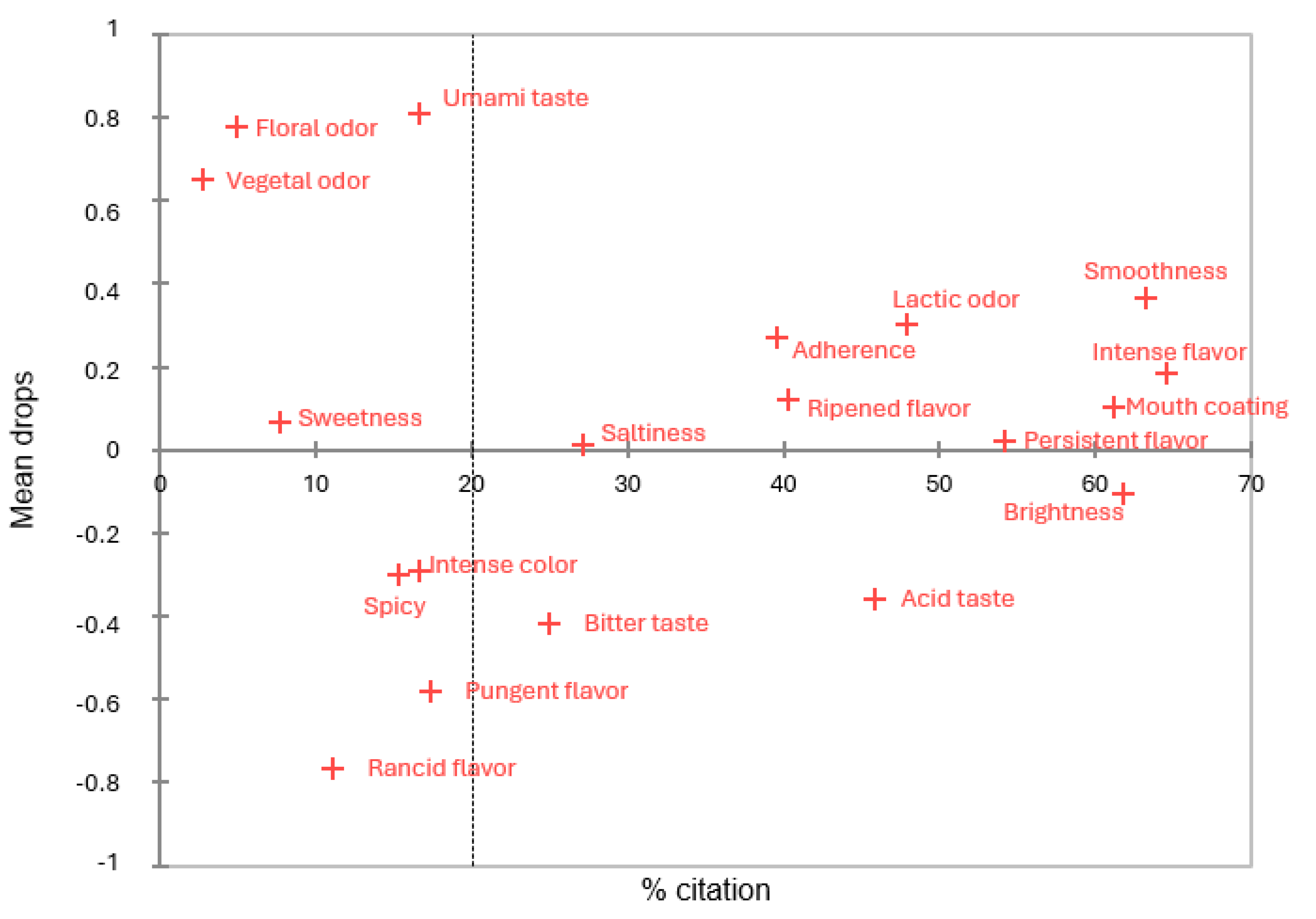

4.5. Sensory Evaluation

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delgado, J.; Álvarez, M.; Cebrián, E.; Martín, I.; Roncero, E.; Rodríguez, M. Biocontrol of Pathogen Microorganisms in Ripened Foods of Animal Origin. Microorganisms 2023, 11, 1578. [Google Scholar] [CrossRef] [PubMed]

- Szűcs, V.; Szabó, E.; Guerrero, L.; Tarcea, M.; Bánáti, D. Modelling of Avoidance of Food Additives: A Cross Country Study. Int. J. Food Sci. Nutr. 2019, 70, 1020–1032. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Wu, L.; Chen, X.; Huang, Z.; Hu, W. Effects of Food-Additive-Information on Consumers’ Willingness to Accept Food with Additives. Int. J. Environ. Res. Public. Health 2018, 15, 2394. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; He, M.; Wu, C. Cross Protection of Lactic Acid Bacteria during Environmental Stresses: Stress Responses and Underlying Mechanisms. LWT 2021, 144, 111203. [Google Scholar] [CrossRef]

- Xia, L.; Qian, M.; Cheng, F.; Wang, Y.; Han, J.; Xu, Y.; Zhang, K.; Tian, J.; Jin, Y. The Effect of Lactic Acid Bacteria on Lipid Metabolism and Flavor of Fermented Sausages. Food Biosci. 2023, 56, 103172. [Google Scholar] [CrossRef]

- Martín, I.; Rodríguez, A.; Alía, A.; Martínez, R.; Córdoba, J.J. Selection and Characterization of Lactic Acid Bacteria with Activity against Listeria monocytogenes from Traditional RTE Ripened Foods. LWT 2022, 163, 113579. [Google Scholar] [CrossRef]

- Fusco, V.; Quero, G.M.; Poltronieri, P.; Morea, M.; Baruzzi, F. Autochthonous and Probiotic Lactic Acid Bacteria Employed for Production of “Advanced Traditional Cheeses”. Foods 2019, 8, 412. [Google Scholar] [CrossRef]

- Official Journal of the European Union. Publication of an Amendment Application Pursuant to Article 50(2)(a) of Regulation (EU) No 1151/2012 of the European Parliament and of the Council on Quality Schemes for Agricultural Products and Foodstuffs. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=uriserv%3AOJ.C_.2015.235.01.0005.01.SPA&toc=OJ%3AC%3A2015%3A235%3ATOC (accessed on 30 September 2023).

- West, H.G. Crafting Innovation: Continuity and Change in the “Living Traditions” of Contemporary Artisan Cheesemakers. Food Foodways 2020, 28, 91–116. [Google Scholar] [CrossRef]

- Costanzo, N.; Ceniti, C.; Santoro, A.; Clausi, M.T.; Casalinuovo, F. Foodborne Pathogen Assessment in Raw Milk Cheeses. Int. J. Food Sci. 2020, 2020, 3616713. [Google Scholar] [CrossRef]

- Campagnollo, F.B.; Margalho, L.P.; Kamimura, B.A.; Feliciano, M.D.; Freire, L.; Lopes, L.S.; Alvarenga, V.O.; Cadavez, V.A.P.; Gonzales-Barron, U.; Schaffner, D.W.; et al. Selection of Indigenous Lactic Acid Bacteria Presenting Anti-Listerial Activity, and Their Role in Reducing the Maturation Period and Assuring the Safety of Traditional Brazilian Cheeses. Food Microbiol. 2018, 73, 288–297. [Google Scholar] [CrossRef]

- Martín-Miguélez, J.M.; Robledo, J.; Martín, I.; Castaño, C.; Delgado, J.; Córdoba, J.J. Biocontrol of L. monocytogenes with Selected Autochthonous Lactic Acid Bacteria in Raw Milk Soft-Ripened Cheese under Different Water Activity Conditions. Foods 2024, 13, 172. [Google Scholar] [CrossRef] [PubMed]

- AOAC Association of Official Analytical Chemists. Official Methods of Analysis of the AOAC International; AOAC: Washington, DC, USA, 2000. [Google Scholar]

- Commission Internationale de L’Éclairage Colorimetry. Color Research & Application, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 1988; Volume 13, pp. 64–65. [Google Scholar]

- ISO 11290-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 1: Detection Method. International Organization for Standardization: Geneva, Switzerland, 2017.

- Jiménez, A.; González-Mohino, A.; Rufo, M.; Paniagua, J.M.; Antequera, T.; Perez-Palacios, T. Dry-Cured Loin Characterization by Ultrasound Physicochemical and Sensory Parameters. Eur. Food Res. Technol. 2022, 248, 2603–2613. [Google Scholar] [CrossRef]

- González-Mohino, A.; Jiménez, A.; Rufo, M.; Paniagua, J.M.; Antequera, T.; Perez-Palacios, T. Ultrasound Parameters Used to Characterize Iberian Fresh Pork Loins of Different Feeding Systems. J. Food Eng. 2022, 314, 110795. [Google Scholar] [CrossRef]

- Ventanas, S.; González-Mohino, A.; Estévez, M.; Carvalho, L. Innovation in Sensory Assessment of Meat and Meat Products. In Meat Quality Analysis: Advanced Evaluation Methods, Techniques, and Technologies; Academic Press: Cambridge, MA, USA, 2020; pp. 393–418. [Google Scholar] [CrossRef]

- Pérez Elortondo, F.J.; Torre, P. Queso. In Análisis Sensorial de Alimentos y Respuesta del Consumidor; Pérez Elortondo, F.J., Salvador Moya, M.a.D., Eds.; Editorial Acribia, S.A.: Zaragoza, Spain, 2022; pp. 209–229. ISBN 978-84-200-1279-7. [Google Scholar]

- Torres, F.R.; Esmerino, E.A.; Carr, B.T.; Ferrão, L.L.; Granato, D.; Pimentel, T.C.; Bolini, H.M.A.; Freitas, M.Q.; Cruz, A.G. Rapid Consumer-Based Sensory Characterization of Requeijão Cremoso, a Spreadable Processed Cheese: Performance of New Statistical Approaches to Evaluate Check-All-That-Apply Data. J. Dairy Sci. 2017, 100, 6100–6110. [Google Scholar] [CrossRef]

- Meals, S.E.; Schiano, A.N.; Drake, M.A. Drivers of Liking for Cheddar Cheese Shreds. J. Dairy Sci. 2020, 103, 2167–2185. [Google Scholar] [CrossRef] [PubMed]

- Martín, I.; Rodríguez, A.; García, C.; Córdoba, J.J. Evolution of Volatile Compounds during Ripening and Final Sensory Changes of Traditional Raw Ewe’s Milk Cheese “Torta Del Casar” Maturated with Selected Protective Lactic Acid Bacteria. Foods 2022, 11, 2658. [Google Scholar] [CrossRef]

- Fu, W.; Nakamura, T. Moisture Content Impact Creaming Effect and Microstructure of Processed Cheese Containing Different Textural Starches. Int. Dairy J. 2020, 105, 104685. [Google Scholar] [CrossRef]

- Ordiales, E.; Benito, M.J.; Martin, A.; Fernández, M.; Hernández, A.; De Guia Córdoba, M. Proteolytic Effect of Cynara cardunculus Rennet for Use in the Elaboration of ‘Torta Del Casar’ Cheese. J. Dairy Res. 2013, 80, 429–438. [Google Scholar] [CrossRef]

- Crespo, A.; Martín, A.; Ruiz-Moyano, S.; Benito, M.J.; Rufo, M.; Paniagua, J.M.; Jiménez, A. Application of Ultrasound for Quality Control of “Torta Del Casar” Cheese Ripening. J. Dairy Sci. 2020, 103, 8808–8821. [Google Scholar] [CrossRef]

- Martín, I.; Rodríguez, A.; Córdoba, J.J. Application of Selected Lactic-Acid Bacteria to Control Listeria monocytogenes in Soft-Ripened “Torta Del Casar” Cheese. LWT 2022, 168, 113873. [Google Scholar] [CrossRef]

- Sanahuja, A.B.; de Almeida, R.P.; Marí, K.-A.I.; Lamadrid, M.C.; García, A.V.; Nadal, E.S. Sensory Attributes and Instrumental Chemical Parameters of Commercial Spanish Cured Ewes’ Milk Cheeses: Insights into Cheese Quality Figures. Foods 2023, 13, 127. [Google Scholar] [CrossRef] [PubMed]

- Tabla, R.; Roa, I. Use of Gaseous Ozone in Soft Cheese Ripening: Effect on the Rind Microorganisms and the Sensorial Quality. LWT 2022, 170, 114066. [Google Scholar] [CrossRef]

- Bintsis, T. Yeasts in Different Types of Cheese. AIMS Microbiol. 2021, 7, 447. [Google Scholar] [CrossRef] [PubMed]

- Merchán, A.V.; Ruiz-Moyano, S.; Hernández, M.V.; Martín, A.; Lorenzo, M.J.; Benito, M.J. Characterization of Autochthonal Hafnia spp. Strains Isolated from Spanish Soft Raw Ewe’s Milk PDO Cheeses to Be Used as Adjunct Culture. Int. J. Food Microbiol. 2022, 373, 109703. [Google Scholar] [CrossRef]

- Al-Gamal, M.S.; Ibrahim, G.A.; Sharaf, O.M.; Radwan, A.A.; Dabiza, N.M.; Youssef, A.M.; El-Ssayad, M.F.; El, M.F. The Protective Potential of Selected Lactic Acid Bacteria against the Most Common Contaminants in Various Types of Cheese in Egypt. Heliyon 2019, 5, e01362. [Google Scholar] [CrossRef]

- Ordiales, E.; Martín, A.; Benito, M.J.; Fernández, M.; Casquete, R.; de Guía Córdoba, M. Influence of the Technological Properties of Vegetable Rennet (Cynara cardunculus) on the Physicochemical, Sensory and Rheological Characteristics of ‘Torta Del Casar’ Cheese. Int. J. Dairy Technol. 2014, 67, 402–409. [Google Scholar] [CrossRef]

- Yates, M.D.; Drake, M.A. Texture Properties of Gouda Cheese. J. Sens. Stud. 2007, 22, 493–506. [Google Scholar] [CrossRef]

- Urbach, G. Contribution of Lactic Acid Bacteria to Flavour Compound Formation in Dairy Products. Int. Dairy J. 1995, 5, 877–903. [Google Scholar] [CrossRef]

- Delgado-Martínez, F.J.; Carrapiso, A.I.; Contador, R.; Ramírez, M.R. Volatile Compounds and Sensory Changes after High Pressure Processing of Mature “Torta Del Casar” (Raw Ewe’s Milk Cheese) during Refrigerated Storage. Innov. Food Sci. Emerg. Technol. 2019, 52, 34–41. [Google Scholar] [CrossRef]

- Sousa, M.J.; Malcata, F.X. Ripening of Ovine Milk Cheeses: Effects of Plant Rennet, Pasteurization, and Addition of Starter on Lipolysis. Food Chem. 1997, 59, 427–432. [Google Scholar] [CrossRef]

- Ferreira, I.M.P.L.V.O.; Pinho, O.; Sampaio, P. Volatile Fraction of DOP “Castelo Branco” Cheese: Influence of Breed. Food Chem. 2009, 112, 1053–1059. [Google Scholar] [CrossRef]

- Fröhlich-Wyder, M.T.; Bachmann, H.P.; Schmidt, R.S. Classification of Cheese Varieties from Switzerland Using Machine Learning Methods: Free Volatile Carboxylic Acids. LWT 2023, 184, 115095. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.J.; Wang, Y.D.; Cao, Y.P.; Wang, B.; Liu, Y. The Key Aroma Compounds and Sensory Characteristics of Commercial Cheddar Cheeses. J. Dairy Sci. 2021, 104, 7555–7571. [Google Scholar] [CrossRef] [PubMed]

- Gan, H.H.; Yan, B.; Linforth, R.S.T.; Fisk, I.D. Development and Validation of an APCI-MS/GC–MS Approach for the Classification and Prediction of Cheddar Cheese Maturity. Food Chem. 2016, 190, 442–447. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, W.; Yu, H.; Yuan, J.; Tian, H. Characterization of Major Odor-Active Compounds Responsible for Nutty Flavor in Cheddar Cheese According to Chinese Taste. Flavour. Fragr. J. 2021, 36, 171–181. [Google Scholar] [CrossRef]

- Curtin, Á.C.; McSweeney, P.L.H. Catabolism of Amino Acids in Cheese during Ripening. Cheese Chem. Phys. Microbiol. 2004, 1, 435–454. [Google Scholar] [CrossRef]

- Jiao, J.; Zheng, Z.; Liu, Z.; You, C. Study of the Compositional, Microbiological, Biochemical, and Volatile Profile of Red-Veined Cheese, an Internal Monascus-Ripened Variety. Front. Nutr. 2021, 8, 649611. [Google Scholar] [CrossRef]

- Curioni, P.M.G.; Bosset, J.O. Key Odorants in Various Cheese Types as Determined by Gas Chromatography-Olfactometry. Int. Dairy J. 2002, 12, 959–984. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, J.; Shi, X.; Wang, B.; Zheng, X.; Zheng, X. Characteristic Physicochemical Indexes and Flavor Compounds in Xinjiang Kazak Cheese during Ripening. Food Biosci. 2020, 35, 100586. [Google Scholar] [CrossRef]

- Tekin, A.; Hayaloglu, A.A. Understanding the Mechanism of Ripening Biochemistry and Flavour Development in Brine Ripened Cheeses. Int. Dairy J. 2023, 137, 105508. [Google Scholar] [CrossRef]

- Dahl, S.; Tavaria, F.K.; Xavier Malcata, F. Relationships between Flavour and Microbiological Profiles in Serra Da Estrela Cheese throughout Ripening. Int. Dairy J. 2000, 10, 255–262. [Google Scholar] [CrossRef]

- Ordiales, E.; Martín, A.; Benito, M.J.; Hernández, A.; Ruiz-Moyano, S.; de Guía Córdoba, M. Role of the Microbial Population on the Flavor of the Soft-Bodied Cheese Torta Del Casar. J. Dairy Sci. 2013, 96, 5477–5486. [Google Scholar] [CrossRef] [PubMed]

- Unno, R.; Suzuki, T.; Osaki, Y.; Matsutani, M.; Ishikawa, M. Causality Verification for the Correlation between the Presence of Nonstarter Bacteria and Flavor Characteristics in Soft-Type Ripened Cheeses. Microbiol. Spectr. 2022, 10, e02894-22. [Google Scholar] [CrossRef] [PubMed]

- Delgado, F.J.; González-Crespo, J.; Cava, R.; García-Parra, J.; Ramírez, R. Characterisation by SPME–GC–MS of the Volatile Profile of a Spanish Soft Cheese P.D.O. Torta Del Casar during Ripening. Food Chem. 2010, 118, 182–189. [Google Scholar] [CrossRef]

- Jia, R.; Zhang, F.; Song, Y.; Lou, Y.; Zhao, A.; Liu, Y.; Peng, H.; Hui, Y.; Ren, R.; Wang, B. Physicochemical and Textural Characteristics and Volatile Compounds of Semihard Goat Cheese as Affected by Starter Cultures. J. Dairy Sci. 2021, 104, 270–280. [Google Scholar] [CrossRef]

- Cakmakci, S.; Gundogdu, E.; Hayaloglu, A.A.; Dagdemir, E.; Gurses, M.; Cetin, B.; Tahmas-Kahyaoglu, D. Chemical and Microbiological Status and Volatile Profiles of Mouldy Civil Cheese, a Turkish Mould-Ripened Variety. Int. J. Food Sci. Technol. 2012, 47, 2405–2412. [Google Scholar] [CrossRef]

- Boltar, I.; Čanžek Majhenič, A.; Jarni, K.; Jug, T.; Bavcon Kralj, M. Volatile Compounds in Nanos Cheese: Their Formation during Ripening and Sesonal Variation. J. Food Sci. Technol. 2015, 52, 608–623. [Google Scholar] [CrossRef]

- Teter, A.; Barłowska, J.; Król, J.; Brodziak, A.; Rutkowska, J.; Litwińczuk, Z. Volatile Compounds and Amino Acid Profile of Short-Ripened Farmhouse Cheese Manufactured from the Milk of the White-Backed Native Cow Breed. LWT 2020, 129, 109602. [Google Scholar] [CrossRef]

- Niimi, J.; Eddy, A.I.; Overington, A.R.; Silcock, P.; Bremer, P.J.; Delahunty, C.M. Sensory Interactions between Cheese Aroma and Taste. J. Sens. Stud. 2015, 30, 247–257. [Google Scholar] [CrossRef]

| Attribute | Description |

|---|---|

| Brightness a | Reflection of light |

| Intense color a | Strength perceived of a color |

| Vegetal odor o | Odor perception characteristic of vegetables |

| Lactic odor o | Odor perception characteristic of milk |

| Floral odor o | Odor perception characteristic of flowers |

| Spicy t | Spicy mouth sensation |

| Smoothness te | Lack of gritty or grainy particles perceived in the mass while chewing |

| Adherence te | Adherence to the palate when pressed against the roof of the mouth by the tongue |

| Mouth coating te | Impression of lubricated food during chewing |

| Acid taste ta | Primary acid taste |

| Saltiness ta | Primary salty taste |

| Bitter taste ta | Primary bitter taste |

| Sweetness ta | Primary sweet taste |

| Umami taste ta | Primary umami taste |

| Intense flavor f | Intensity of flavor as a whole |

| Persistent flavor f | Continued flavor perception after swallowing the sample |

| Ripened flavor f | Flavor perception characteristic of ripened products |

| Rancid flavor f | Flavor perception characteristic of oxidized products |

| Pungent flavor f | Flavor perception characteristic of traditional spices |

| Batches | A | B | C | D |

|---|---|---|---|---|

| First elaboration | ||||

| Moisture content (%) | 40.87 ± 0.58 * | 40.89 ± 0.46 * | 40.07 ± 0.47 * | 41.06 ± 0.20 * |

| pH | 5.70 ± 0.08 * | 5.74 ± 0.04 * | 5.62 ± 0.06 * | 5.51 ± 0.14 |

| aw | 0.939 ± 0.005 | 0.935 ± 0.001 * | 0.947 ± 0.004 | 0.948 ± 0.001 |

| L* | 78.11 ± 0.59 * | 79.51 ± 3.90 | 77.97 ± 0.97 * | 82.92 ± 2.19 * |

| a* | −1.46 ± 0.07 b* | −1.54 ± 0.07 b* | −1.83 ± 0.02 a* | −1.87 ± 0.02 a* |

| b* | 19.85 ± 0.24 * | 20.39 ± 0.62 * | 21.37 ± 0.63 * | 20.59 ± 0.63 * |

| Second elaboration | ||||

| Moisture content (%) | 47.24 ± 1.72 * | 47.13 ± 1.44 * | 45.61 ± 0.00 * | 44.86 ± 1.08 * |

| pH | 5.26 ± 0.03 ab* | 5.25 ± 0.09 a* | 5.16 ± 0.02 a* | 5.49 ± 0.01 b |

| aw | 0.948 ± 0.002 | 0.948 ± 0.003 * | 0.952 ± 0.002 | 0.951 ± 0.001 |

| L* | 89.53 ± 0.70 b* | 83.85 ± 0.28 a | 90.37 ± 1.15 b* | 89.58 ± 0.45 b* |

| a* | −0.70 ± 0.05 a* | −0.24 ± 0.03 b* | −0.79 ± 0.04 a* | −0.712 ± 0.07 a* |

| b* | 16.83 ± 0.20 a* | 17.84 ± 0.25 ab* | 18.00 ± 0.21 ab* | 18.36 ± 0.33 b* |

| Batches | A | B | C | D |

|---|---|---|---|---|

| First elaboration (log CFU/g) | ||||

| TVC | 9.09 ± 0.14 | 8.74 ± 0.07 * | 9.25 ± 0.03 | 9.10 ± 0.14 |

| EB | 5.45 ± 0.46 ab | 6.72 ± 0.13 b* | 4.83 ± 0.29 a | 5.06 ± 0.18 a |

| GC+ | 5.96 ± 0.34 | 6.24 ± 0.09 * | 6.28 ± 0.49 | 6.15 ± 0.27 * |

| LAB | 9.06 ± 0.20 ab | 8.67 ± 0.06 a* | 9.20 ± 0.03 b | 9.08 ± 0.12 ab* |

| Second elaboration (log CFU/g) | ||||

| TVC | 9.06 ± 0.14 ab | 9.27 ± 0.05 b* | 9.25 ± 0.08 b | 8.62 ± 0.15 a |

| EB | 5.46 ± 0.29 | 5.02 ± 0.28 * | 4.99 ± 0.16 | 5.26 ± 0.19 |

| GC+ | 5.36 ± 0.20 | 4.79 ± 0.11 * | 5.01 ± 0.30 | 4.68 ± 0.16 * |

| LAB | 9.10 ± 0.13 b | 9.10 ± 0.05 b* | 9.09 ± 0.10 b | 8.32 ± 0.10 a* |

| Batches | A | B | C | D |

|---|---|---|---|---|

| First elaboration | ||||

| Hardness (g) | 828.23 ± 120.71 * | 1083.47 ± 157.91 * | 1029.99 ± 135.91 * | 675.90 ± 105.12 * |

| Adhesiveness (g × s) | −15.74 ± 7.21 | −4.07 ± 1.69 | −2.68 ± 1.20 | −7.57 ± 3.57 |

| Springiness (g) | 0.69 ± 0.02 | 0.67 ± 0.04 | 0.60 ± 0.04 | 0.62 ± 0.03 |

| Cohesiveness | 0.51 ± 0.05 * | 0.43 ± 0.02 | 0.38 ± 0.03 * | 0.45 ± 0.04 |

| Gumminess (g) | 397.85 ± 20.80 b* | 451.84 ± 44.30 b* | 382.50 ± 30.60 ab* | 293.42 ± 18.90 a* |

| Chewiness (g) | 276.94 ± 15.14 b | 302.00 ± 30.21 ab* | 228.15 ± 18.39 ab* | 182.71 ± 7.31 a* |

| Resilience (J x m−3) | 0.14 ± 0.02 | 0.11 ± 0.01 | 0.11 ± 0.01 * | 0.12 ± 0.01 |

| Second elaboration | ||||

| Hardness (g) | 225.13 ± 102.57 * | 290.84 ± 66.89 * | 260.24 ± 92.00 * | 194.53 ± 79.04 * |

| Adhesiveness (g × s) | −28.60 ± 14.02 | −9.81 ± 5.42 | −6.76 ± 3.17 | −7.85 ± 2.94 |

| Springiness (g) | 0.79 ± 0.10 | 0.65 ± 0.03 | 0.67 ± 0.03 | 0.62 ± 0.06 |

| Cohesiveness | 0.72 ± 0.04 b* | 0.47 ± 0.04 a | 0.53 ± 0.01 a* | 0.51 ± 0.02 a |

| Gumminess (g) | 162.20 ± 70.86 * | 125.63 ± 21.77 * | 138.12 ± 47.63 * | 96.42 ± 38.72 * |

| Chewiness (g) | 142.64 ± 65.68 | 81.83 ± 15.69 * | 95.63 ± 35.43 * | 64.64 ± 27.84 * |

| Resilience (J x m−3) | 0.19 ± 0.04 | 0.12 ± 0.01 | 0.15 ± 0.01 * | 0.13 ± 0.01 |

| First Elaboration | Second Elaboration | |||||||

|---|---|---|---|---|---|---|---|---|

| Batches | A | B | C | D | A | B | C | D |

| Acids | ||||||||

| Acetic acid | n.d. * | n.d. | n.d. * | n.d. * | 3.72 ± 0.77 * | 6.76 ± 1.64 | 4.57 ± 1.12 * | 8.18 ± 0.80 * |

| Propanoic acid | n.d. | n.d. | n.d. | n.d. | 0.09 ± 0.04 | 0.05 ± 0.01 | n.d. | n.d. |

| Butanoic acid | 1.63 ± 0.05 | 1.24 ± 0.05 * | 1.18 ± 0.07 | 1.18 ± 0.18 | 1.19 ± 0.25 ab | 1.83 ± 0.09 b* | 0.89 ± 0.24 a | 1.21 ± 0.06 ab |

| Hexanoic acid | 2.38 ± 0.09 b | 1.32 ± 0.14 a* | 1.22 ± 0.06 a | 0.99 ± 0.26 a* | 1.84 ± 0.33 | 2.20 ± 0.11 * | 1.76 ± 0.53 | 2.07 ± 0.05 * |

| Octanoic acid | 0.32 ± 0.04 b* | 0.17 ± 0.01 a* | 0.16 ± 0.02 a | 0.14 ± 0.04 a | 0.11 ± 0.05 * | 0.09 ± 0.02 * | 0.10 ± 0.02 | 0.10 ± 0.00 |

| 2-methylpropanoic acid | 0.74 ± 0.11 a | 1.75 ± 0.25 ab* | 2.20 ± 0.04 b* | 0.84 ± 0.06 a* | 0.44 ± 0.13 | 0.34 ± 0.02 * | 0.66 ± 0.09 * | 0.29 ± 0.01 * |

| 3-methylbutanoic acid | 6.37 ± 0.22 a | 9.79 ± 0.45 b* | 12.21 ± 0.82 b* | 6.39 ± 0.22 a* | 3.82 ± 1.13 | 3.47 ± 0.32 * | 4.68 ± 0.61 * | 2.77 ± 0.08 * |

| 2-methylbutanoic acid | 0.58 ± 0.05 ab | 0.86 ± 0.05 b* | 1.09 ± 0.12 b* | 0.46 ± 0.02 a* | 0.33 ± 0.11 | 0.16 ± 0.02 * | 0.40 ± 0.07 * | 0.14 ± 0.00 * |

| Aldehydes | ||||||||

| 3-methylbutanal | 0.08 ± 0.01 | 0.06 ± 0.01 * | 0.06 ± 0.02 | 0.12 ± 0.02 | 0.21 ± 0.03 | 0.17 ± 0.03 * | 0.25 ± 0.09 | 0.15 ± 0.02 |

| Nonanal | 0.11 ± 0.01 b | 0.08 ± 0.01 ab | n.d. a* | 0.08 ± 0.01 ab | 0.11 ± 0.02 | 0.15 ± 0.02 | 0.09 ± 0.00 * | 0.11 ± 0.02 |

| 2-Decenal, (E)- | 0.06 ± 0.01 | n.d. * | n.d. * | n.d. | 0.08 ± 0.00 | 0.07 ± 0.00 * | 0.07 ± 0.00 * | 0.07 ± 0.00 |

| Benzaldehyde | 0.12 ± 0.01 ab* | 0.07 ± 0.01 a | 0.07 ± 0.01 ab | 0.14 ± 0.02 b* | 0.06 ± 0.00 b* | 0.06 ± 0.01 ab | 0.09 ± 0.04 ab | n.d. a* |

| Benzeneacetaldehyde | n.d. a* | 0.06 ± 0.01 b | 0.06 ± 0.01 b* | 0.05 ± 0.00 b* | 0.08 ± 0.01 * | 0.07 ± 0.01 | 0.11 ± 0.01 * | 0.10 ± 0.01 * |

| Alcohols | ||||||||

| 2,3-Butanediol [R-(R*,R*)]- | 2.59 ± 0.14 | 3.51 ± 0.70 | 3.17 ± 0.43 | 2.64 ± 0.09 | 1.58 ± 0.52 | 1.55 ± 0.07 | 2.68 ± 0.27 | 2.37 ± 0.22 |

| 3-methyl-1-butanol | 0.77 ± 0.06 | 0.72 ± 0.01 * | 0.74 ± 0.04 | 0.68 ± 0.01 * | 1.28 ± 0.22 | 0.89 ± 0.02 * | 0.82 ± 0.05 | 0.79 ± 0.04 * |

| 2-Heptanol | n.d. | n.d. * | n.d. | n.d. | 0.08 ± 0.03 | 0.07 ± 0.02 * | 0.05 ± 0.00 | 0.06 ± 0.01 |

| Phenylethyl Alcohol | 0.82 ± 0.06 | 0.54 ± 0.08 | 0.82 ± 0.26 | 0.57 ± 0.08 * | 1.12 ± 0.08 | 0.60 ± 0.01 | 1.58 ± 0.43 | 0.96 ± 0.07 * |

| Ketones | ||||||||

| 2-Propanone | n.d. * | n.d. * | n.d. * | n.d. * | 0.12 ± 0.00 * | 0.08 ± 0.01 * | 0.12 ± 0.03 * | 0.10 ± 0.01 * |

| 2-Butanone | 0.13 ± 0.06 | n.d. | n.d. | n.d. | 0.42 ± 0.22 | n.d. | 0.06 ± 0.02 | n.d. |

| 2-Pentanone | n.d. | n.d. | n.d. * | n.d. * | 0.08 ± 0.03 | 0.10 ± 0.03 | 0.10 ± 0.02 * | 0.11 ± 0.04 * |

| 2-Heptanone | 0.08 ± 0.01 b* | n.d. a | n.d. a | 0.10 ± 0.03 ab | 0.38 ± 0.08 * | 0.51 ± 0.20 | 1.11 ± 0.74 | 0.41 ± 0.20 |

| 2-Nonanone | 0.22 ± 0.04 | n.d. * | n.d. | n.d. | 0.19 ± 0.08 | 0.37 ± 0.11 * | 1.50 ± 1.32 | 0.14 ± 0.05 |

| Esters | ||||||||

| Butanoic acid, ethyl ester | 0.09 ± 0.01 b | n.d. a* | n.d. a | n.d. a | 0.06 ± 0.01 ab | 0.11 ± 0.01 b* | n.d. a | n.d. a |

| 1-Butanol, 3-methyl-. acetate | 0.17 ± 0.01 | 0.15 ± 0.00 * | 0.15 ± 0.01 | 0.17 ± 0.01 | 0.18 ± 0.00 | 0.21 ± 0.02 * | 0.15 ± 0.01 | 0.20 ± 0.01 |

| Hexanoic acid, ethyl ester | 0.22 ± 0.04 | 0.06 ± 0.01 * | 0.05 ± 0.00 | 0.07 ± 0.00 | 0.13 ± 0.01 bc | 0.18 ± 0.01 c* | 0.06 ± 0.00 ab | 0.07 ± 0.00 a |

| Octanoic acid, ethyl ester | 0.25 ± 0.04 b* | n.d. a* | n.d. a* | 0.06 ± 0.00 a | 0.11 ± 0.02 bc* | 0.14 ± 0.01 c* | 0.05 ± 0.00 ab* | 0.06 ± 0.00 a |

| Decanoic acid, ethyl ester | 0.33 ± 0.04 b* | n.d. a* | n.d. a* | n.d. a* | 0.12 ± 0.02 bc* | 0.15 ± 0.02 c* | 0.07 ± 0.00 a* | 0.07 ± 0.01 ab* |

| Others | ||||||||

| Acetoin | 4.72 ± 0.38 | 6.37 ± 0.63 * | 5.50 ± 0.67 | 9.88 ± 1.84 | 5.20 ± 1.16 | 4.13 ± 0.29 * | 5.57 ± 0.50 | 5.78 ± 0.06 |

| 2,3-Butanedione | 1.37 ± 0.18 a* | 3.13 ± 0.40 b* | 3.44 ± 0.16 b | 2.74 ± 0.20 b* | 2.49 ± 0.34 a* | 4.61 ± 0.31 b* | 3.91 ± 0.34 b | 4.64 ± 0.15 b* |

| Dimethyl disulfide | 1.25 ± 0.30 a* | 0.85 ± 0.34 a* | 1.29 ± 0.50 a | 3.62 ± 0.18 b* | 3.52 ± 0.24 * | 3.37 ± 0.66 * | 3.43 ± 0.75 | 2.33 ± 0.31 * |

| Dimethyl sulfone | 0.08 ± 0.00 | 0.07 ± 0.00 | 0.10 ± 0.04 | 0.06 ± 0.00 * | 0.04 ± 0.00 | 0.05 ± 0.00 | 0.04 ± 0.00 | 0.04 ± 0.00 * |

| Attributes | p-Values | |

|---|---|---|

| First Elaboration | Second Elaboration | |

| Adherence | 0.991 | 0.439 |

| Brightness | 0.110 | 0.050 * |

| Ripened flavor | 0.140 | 0.910 |

| Intense flavor | 0.782 | 0.555 |

| Persistent flavor | 0.603 | 0.218 |

| Pungent flavor | 0.359 | 0.252 |

| Rancid flavor | 0.083 | 0.543 |

| Intense color | 0.623 | 0.815 |

| Floral odor | 0.015 * | 0.912 |

| Lactic odor | 0.048 * | 0.364 |

| Vegetal odor | 0.494 | 0.753 |

| Spicy | 0.317 | 0.889 |

| Acid taste | 0.841 | 0.140 |

| Bitter taste | 0.914 | 0.576 |

| Sweetness | 0.697 | 0.468 |

| Umami taste | 0.456 | 0.699 |

| Saltiness | 0.409 | 0.682 |

| Mouth coating | 0.494 | 0.227 |

| Smoothness | 0.116 | 0.392 |

| First Elaboration | Second Elaboration | |||||||

|---|---|---|---|---|---|---|---|---|

| Attributes | A | B | C | D | A | B | C | D |

| Adherence | 41.67 | 38.89 | 38.89 | 38.89 | 44.44 | 47.22 | 50.00 | 58.33 |

| Brightness | 69.44 | 55.56 | 72.22 | 50.00 | 50.00 | 41.67 | 61.11 | 66.67 |

| Ripened flavor | 47.22 | 44.44 | 30.56 | 38.89 | 44.44 | 44.44 | 41.67 | 38.89 |

| Intense flavor | 66.67 | 69.44 | 61.11 | 61.11 | 66.67 | 69.44 | 61.11 | 55.56 |

| Persistent flavor | 61.11 | 55.56 | 47.22 | 52.78 | 63.89 | 75.00 | 63.89 | 55.56 |

| Pungent flavor | 22.22 | 8.33 | 19.44 | 19.44 | 25.00 | 33.33 | 22.22 | 16.67 |

| Rancid flavor | 8.33 | 13.89 | 16.67 | 5.56 | 19.44 | 16.67 | 11.11 | 13.89 |

| Intense color | 16.67 | 19.44 | 11.11 | 13.89 | 13.89 | 11.11 | 11.11 | 16.67 |

| Floral odor | 2.78 | 0.00 | 2.8 | 13.89 | 5.56 | 5.56 | 8.33 | 5.56 |

| Lactic odor | 44.44 | 44.44 | 63.89 | 38.89 | 47.22 | 61.11 | 50.00 | 47.22 |

| Vegetal odor | 0.00 | 2.78 | 2.78 | 5.56 | 8.33 | 8.33 | 5.56 | 11.11 |

| Spicy | 19.44 | 22.22 | 13.89 | 11.11 | 22.22 | 19.44 | 19.44 | 16.67 |

| Acid taste | 47.22 | 44.44 | 50.00 | 41.67 | 50.00 | 63.89 | 47.22 | 38.89 |

| Bitter taste | 22.22 | 25.00 | 27.78 | 25.00 | 33.33 | 25.00 | 22.22 | 22.22 |

| Sweetness | 5.56 | 8.33 | 5.56 | 11.11 | 2.78 | 8.33 | 2.78 | 5.56 |

| Umami taste | 19.44 | 11.11 | 13.89 | 22.22 | 22.22 | 19.44 | 27.78 | 25.00 |

| Saltiness | 27.78 | 27.78 | 19.44 | 33.33 | 30.56 | 27.78 | 27.78 | 36.11 |

| Mouth coating | 69.44 | 58.33 | 55.56 | 61.11 | 55.56 | 47.22 | 63.89 | 61.11 |

| Smoothness | 69.44 | 50.00 | 58.33 | 75.00 | 77.78 | 63.89 | 77.78 | 77.78 |

| Acceptability | 4.97 ± 1.30 | 5.14 ± 1.33 | 5.05 ± 1.28 | 5.30 ± 1.21 | 4.55 ± 1.50 | 4.36 ± 1.39 | 4.69 ± 1.30 | 5.11 ± 1.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín Miguélez, J.M.; Martín, I.; Robledo, J.; Ventanas, S.; Córdoba, J.J. Effect of Artisanal Processing on Volatile Compounds and Sensory Characteristics of Traditional Soft-Ripened Cheeses Matured with Selected Lactic Acid Bacteria. Foods 2025, 14, 231. https://doi.org/10.3390/foods14020231

Martín Miguélez JM, Martín I, Robledo J, Ventanas S, Córdoba JJ. Effect of Artisanal Processing on Volatile Compounds and Sensory Characteristics of Traditional Soft-Ripened Cheeses Matured with Selected Lactic Acid Bacteria. Foods. 2025; 14(2):231. https://doi.org/10.3390/foods14020231

Chicago/Turabian StyleMartín Miguélez, José M., Irene Martín, Jurgen Robledo, Sonia Ventanas, and Juan J. Córdoba. 2025. "Effect of Artisanal Processing on Volatile Compounds and Sensory Characteristics of Traditional Soft-Ripened Cheeses Matured with Selected Lactic Acid Bacteria" Foods 14, no. 2: 231. https://doi.org/10.3390/foods14020231

APA StyleMartín Miguélez, J. M., Martín, I., Robledo, J., Ventanas, S., & Córdoba, J. J. (2025). Effect of Artisanal Processing on Volatile Compounds and Sensory Characteristics of Traditional Soft-Ripened Cheeses Matured with Selected Lactic Acid Bacteria. Foods, 14(2), 231. https://doi.org/10.3390/foods14020231