Improving the Sensory Quality of Black Tea by Blending Varieties During Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Sample Preparation

2.3. Sensory Evaluation

2.4. Quantification of Catechins, Gallic Acid, Caffeine, and Theaflavin

2.5. Amino Acids Analysis

2.6. Volatiles Analysis Based on GC-MS

2.7. Relative Odor Activity Value Analysis

2.8. Data Analysis and Statistics

3. Results and Discussion

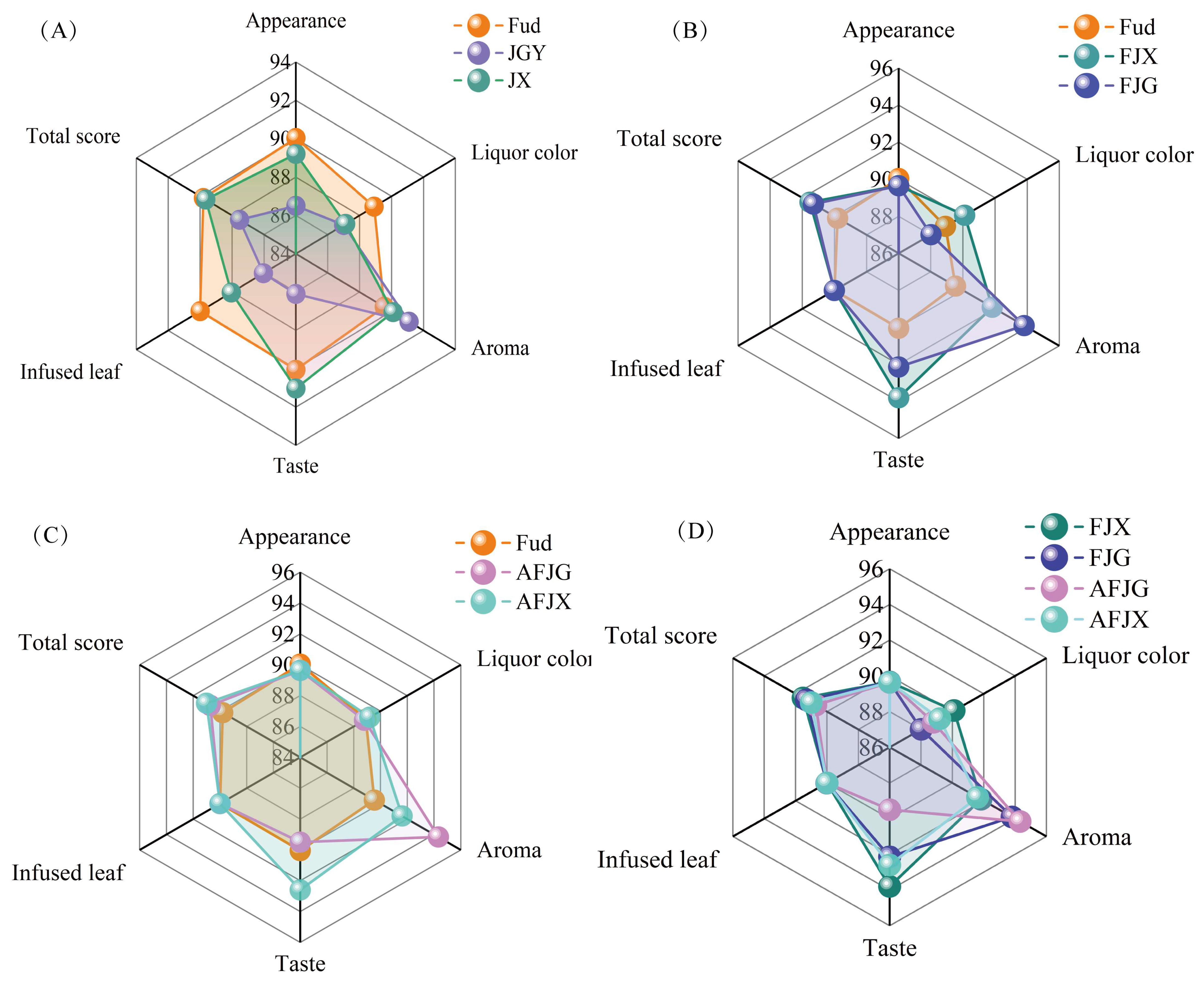

3.1. Sensory Evaluation of Black Tea

3.2. Analysis of the Main Taste Compounds

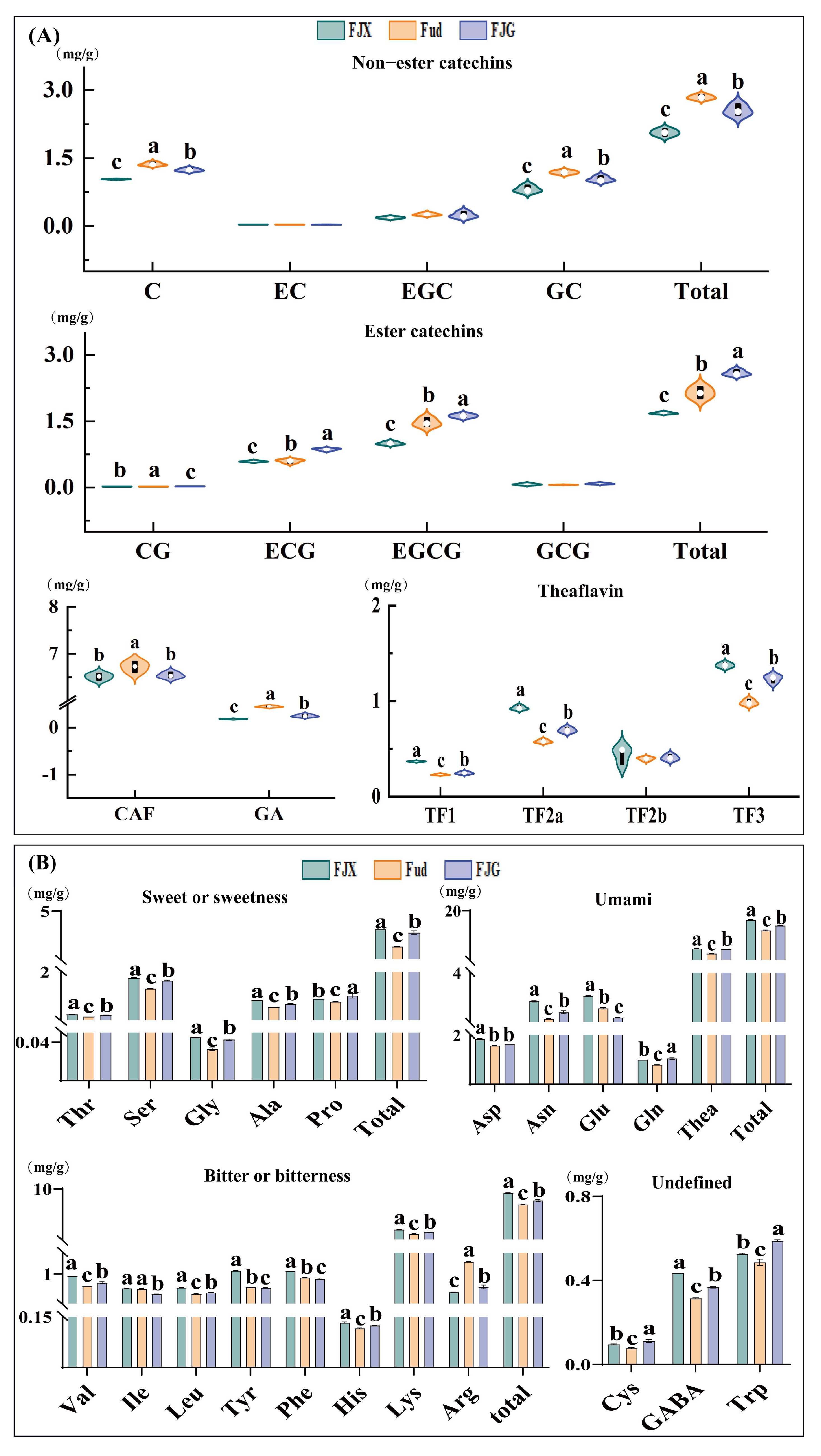

3.2.1. Analysis of Catechins and Relevant Compounds

3.2.2. Analysis of Amino Acids

3.3. Analysis of Volatile Components by GC-MS

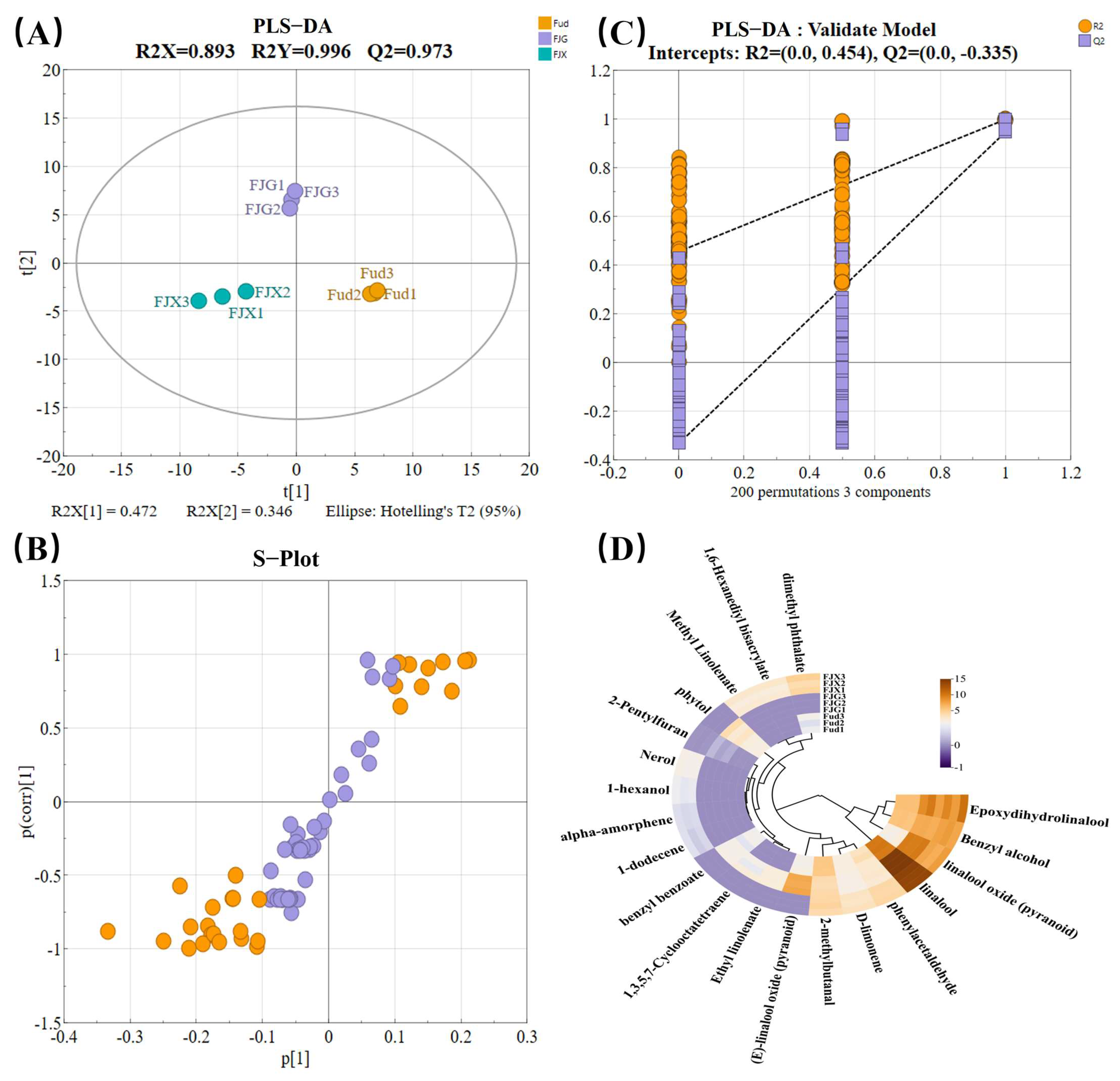

3.3.1. Multiple Statistics Analysis in Volatiles

3.3.2. Key Aroma-Active Volatiles in Different Blending Treatments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- An, T.; Li, Y.; Tian, X.; Fan, S.; Duan, D.; Zhao, C.; Huang, W.; Dong, C. Evaluation of Aroma Quality Using Multidimensional Olfactory Information During Black Tea Fermentation. Sens. Actuators B Chem. 2022, 371, 132518. [Google Scholar] [CrossRef]

- Umeda, M.; Tominaga, T.; Kozuma, K.; Kitazawa, H.; Furushima, D.; Hibi, M.; Yamada, H. Preventive Effects of Tea and Tea Catechins against Influenza and Acute Upper Respiratory Tract Infections: A Systematic Review and Meta-Analysis. Eur. J. Nutr. 2021, 60, 4189–4202. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Yu, Q.; Shen, S.; Shan, X.; Hua, J.; Zhu, J.; Qiu, J.; Deng, Y.; Zhou, Q.; Jiang, Y.; et al. Non-Targeted Metabolomics and Electronic Tongue Analysis Reveal the Effect of Rolling Time on the Sensory Quality and Nonvolatile Metabolites of Congou Black Tea. LWT 2022, 169, 113971. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, H.; Liu, Y.; Wang, H.; Xu, Y.; Huang, J.; Lei, P. Chemical Constituents of Green Teas Processed from Albino Tea Cultivars with White and Yellow Shoots. Food Chem. Mol. Sci. 2022, 5, 100143. [Google Scholar]

- Qu, F.; Zhu, X.; Ai, Z.; Ai, Y.; Qiu, F.; Ni, D. Effect of Different Drying Methods on the Sensory Quality and Chemical Components of Black Tea. LWT 2019, 99, 112–118. [Google Scholar] [CrossRef]

- Liu, X.; Dong, F.; Li, Y.; Lu, F.; Wang, B.; Zhou, T.; Zhao, D.; Huang, M.; Wang, F. Impact of Mild Field Drought on the Aroma Profile and Metabolic Pathways of Fresh Tea (Camellia sinensis) Leaves Using Hs-Gc-Ims and Hs-Spme-Gc-Ms. Foods 2024, 13, 3412. [Google Scholar] [CrossRef]

- Qin, X.; Zhou, J.; He, C.; Qiu, L.; Zhang, D.; Yu, Z.; Wang, Y.; Ni, D.; Chen, Y. Non-Targeted Metabolomics Characterization of Flavor Formation of Lichuan Black Tea Processed from Different Cultivars in Enshi. Food Chem. X 2023, 19, 100809. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, Q.; Lou, Y.; Zhang, J.; Hu, X.; He, J.; Li, X. Comparative Analysis of the Chloroplast Genomes of a Novel Albino Tea “Huabai 1” and the Traditional Albino Tea “Huangjinya”. S. Afr. J. Bot. 2022, 149, 572–581. [Google Scholar] [CrossRef]

- Turgut, S.S.; Küçüköner, E.; Karacabey, E. Teapot: A Chemometric Tool for Tea Blend Recipe Estimation. Appl. Food Res. 2021, 1, 100006. [Google Scholar] [CrossRef]

- Gogoi, R.C. Blending of Tea–The Development. Two A Bud 2015, 61, 53–56. [Google Scholar]

- Tie, J.; Chen, W.; Sun, C.; Mao, T.; Xing, G. The Application of Agglomerative Hierarchical Spatial Clustering Algorithm in Tea Blending. Clust. Comput. 2019, 22, 6059–6068. [Google Scholar] [CrossRef]

- Fomeni, F.D. A Multi-Objective Optimization Approach for the Blending Problem in the Tea Industry. Int. J. Prod. Econ. 2018, 205, 179–192. [Google Scholar] [CrossRef]

- Zuo, H.; Lv, Z.; Guo, S.; Zhou, Y.; Shen, C. Mixed Processing Improved the Theaflavin, Theanine and Aroma Components of Congou Black Tea. Int. J. Food Sci. Technol. 2024, 59, 8011–8026. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, F.; Ye, Y.; Chen, L.; Liu, J.; Gui, A.; Zhang, J.; Dong, C. Application of Machine Learning Algorithms in Quality Assurance of Fermentation Process of Black Tea--Based on Electrical Properties. J. Food Eng. 2019, 263, 165–172. [Google Scholar] [CrossRef]

- GB/T 23776-2018; Methodology for Sensory Evaluation of Tea. Standards Press of China: Beijing, China, 2018.

- Liu, D.; Wei, K.; Zhang, C.; Liu, H.; Gong, Y.; Ye, Y.; Chen, J.; Yao, M.; Chen, L.; Ma, C. The Potential Effects of Chlorophyll-Deficient Mutation and Tree_Age on the Accumulation of Amino Acid Components in Tea Plants. Food Chem. 2023, 411, 135527. [Google Scholar] [CrossRef]

- Yang, Y.; Xie, J.; Wang, Q.; Deng, Y.; Zhu, L.; Zhu, J.; Yuan, H.; Jiang, Y. Understanding the Dynamic Changes of Volatile and Non-Volatile Metabolites in Black Tea During Processing by Integrated Volatolomics and Uhplc-Hrms Analysis. Food Chem. 2024, 432, 137124. [Google Scholar] [CrossRef]

- Chen, J.L.; Tang, Q.; Shan, H.L.; Wang, Z.; Xu, Y.; Guo, X. Suitability of Introduced Cultivars in Sichuan for Processing Black Tea and Black Tea Quality Evaluation. Food Sci. 2015, 36, 83–88. [Google Scholar]

- Chen, S.; Li, X.; Liu, Y.; Chen, J.; Ma, J.; Chen, L. Identification of Qtl Controlling Volatile Terpene Contents in Tea Plant (Camellia sinensis) Using a High-Aroma ‘Huangdan’ X ‘Jinxuan’ F1 Population. Front. Plant Sci. 2023, 14, 1130582. [Google Scholar] [CrossRef]

- Fu, Z.; Hao, S.; Zhou, J.; Feng, W.; Zhu, M.; Wu, J.; Zhang, Y.; Yu, Y. Profiling Volatile Compounds in Fresh Leaves of 22 Major Oolong Tea Germplasm Cultivated in Fujian of China. Sci. Hortic. 2024, 327, 112849. [Google Scholar] [CrossRef]

- Li, Y.; Ran, W.; He, C.; Zhou, J.; Chen, Y.; Yu, Z.; Ni, D. Effects of Different Tea Tree Varieties on the Color, Aroma, and Taste of Chinese Enshi Green Tea. Food Chem. X 2022, 14, 100289. [Google Scholar] [CrossRef]

- Fan, F.Y.; Shi, M.; Nie, Y.; Zhao, Y.; Ye, J.H.; Liang, Y.R. Differential Behaviors of Tea Catechins under Thermal Processing: Formation of Non-Enzymatic Oligomers. Food Chem. 2016, 196, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Yang, J.; Cui, D.; Zhao, D.; Li, Y.; Wan, X.; Zhao, J. Transcriptome and Metabolic Profiling Unveiled Roles of Peroxidases in Theaflavin Production in Black Tea Processing and Determination of Tea Processing Suitability. J. Agric. Food Chem. 2020, 68, 3528–3538. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Hua, J.; Wang, B.; Yuan, H.; Ma, H. Effects of Variety, Season, and Region on Theaflavins Content of Fermented Chinese Congou Black Tea. J. Food Qual. 2018, 2018, 5427302. [Google Scholar] [CrossRef]

- Narukawa, M.; Kimata, H.; Noga, C.; Watanabe, T. Taste characterisation of green tea catechins. Int. J. Food Sci. Technol. 2010, 45, 1579–1585. [Google Scholar] [CrossRef]

- Lee, L.S.; Kim, Y.C.; Park, J.D.; Kim, Y.B.; Kim, S.H. Changes in Major Polyphenolic Compounds of Tea (Camellia sinensis) Leaves During the Production of Black Tea. Food Sci. Biotechnol. 2016, 25, 1523–1527. [Google Scholar] [CrossRef]

- Li, P.; Ye, Z.; Fu, J.; Xu, Y.; Shen, Y.; Zhang, Y.; Tang, D.; Li, P.; Zuo, H.; Tong, W.; et al. Csmyb184 Regulates Caffeine Biosynthesis in Tea Plants. Plant Biotechnol. J. 2022, 20, 1012–1014. [Google Scholar] [CrossRef]

- Lin, J.K.; Lin, C.L.; Liang, Y.C.; Lin-Shiau, S.Y.; Juan, I.M. Survey of Catechins, Gallic Acid, and Methylxanthines in Green, Oolong, Pu-Erh, and Black Teas. J. Agric. Food Chem. 1998, 46, 3635–3642. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, Q.Q.; Granato, D.; Xu, Y.Q.; Ho, C.T. Association between Chemistry and Taste of Tea: A Review. Trends Food Sci. Technol. 2020, 101, 139–149. [Google Scholar] [CrossRef]

- Cao, Q.Q.; Zou, C.; Zhang, Y.H.; Du, Q.Z.; Yin, J.F.; Shi, J.; Xue, S.; Xu, Y.-Q. Improving the Taste of Autumn Green Tea with Tannase. Food Chem. 2019, 277, 432–437. [Google Scholar] [CrossRef]

- Chen, Y.; Zeng, L.; Liao, Y.; Li, J.; Zhou, B.; Yang, Z.; Tang, J. Enzymatic Reaction-Related Protein Degradation and Proteinaceous Amino Acid Metabolism During the Black Tea (Camellia sinensis) Manufacturing Process. Foods 2020, 9, 66. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, Z. Understanding Different Regulatory Mechanisms of Proteinaceous and Non-Proteinaceous Amino Acid Formation in Tea (Camellia sinensis) Provides New Insights into the Safe and Effective Alteration of Tea Flavor and Function. Crit. Rev. Food Sci. Nutr. 2020, 60, 844–858. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wu, S.; Yu, Q.; Shan, X.; Chen, L.; Deng, Y.; Hua, Y.; Zhu, J.; Zhou, Q.; Jiang, Y.; et al. The Influence of Rolling Pressure on the Changes in Non-Volatile Compounds and Sensory Quality of Congou Black Tea: The Combination of Metabolomics, E-Tongue, and Chromatic Differences Analyses. Food Chem. X 2023, 20, 100989. [Google Scholar] [CrossRef]

- Ting, G.; Hou, B.-h.; Shao, S.-x.; Xu, M.-t.; Zheng, Y.-c.; Shan, J.; Wang, P.-j.; Ye, N.-x. Differential Metabolites and Their Transcriptional Regulation in Seven Major Tea Cultivars (Camellia sinensis) in China. J. Integr. Agric. 2023, 22, 3346–3363. [Google Scholar]

- Yu, P.; Huang, H.; Zhao, X.; Zhong, N.; Zheng, H. Dynamic Variation of Amino Acid Content During Black Tea Processing: A Review. Food Rev. Int. 2023, 39, 3970–3983. [Google Scholar] [CrossRef]

- Scharbert, S.; Hofmann, T. Molecular Definition of Black Tea Taste by Means of Quantitative Studies, Taste Reconstitution, and Omission Experiments. J. Agric. Food Chem. 2005, 53, 5377–5384. [Google Scholar] [CrossRef]

- Ho, C.T.; Zheng, X.; Li, S. Tea Aroma Formation. Food Sci. Hum. Wellness 2015, 4, 9–27. [Google Scholar] [CrossRef]

- Van Gemert, L.J. Compilations of Odour Thershold Values in Air, Water and Other Media; Leffingwell & Associates: Canton, GA, USA, 2011. [Google Scholar]

- Xie, J.; Wang, L.; Deng, Y.; Yuan, H.; Zhu, J.; Jiang, Y.; Yang, Y. Characterization of the Key Odorants in Floral Aroma Green Tea Based on Gc-E-Nose, Gc-Ims, Gc-Ms and Aroma Recombination and Investigation of the Dynamic Changes and Aroma Formation During Processing. Food Chem. 2023, 427, 136641. [Google Scholar] [CrossRef]

- Guo, X.; Schwab, W.; Ho, C.T.; Song, C.; Wan, X. Characterization of the Aroma Profiles of Oolong Tea Made from Three Tea Cultivars by Both Gc–Ms and Gc-Ims. Food Chem. 2022, 376, 131933. [Google Scholar] [CrossRef]

- Zhai, X.; Zhang, L.; Granvogl, M.; Ho, C.T.; Wan, X. Flavor of Tea (Camellia sinensis): A Review on Odorants and Analytical Techniques. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3867–3909. [Google Scholar] [CrossRef]

- Chen, X.; Sun, H.; Qu, D.; Yan, F.; Jin, W.; Jiang, H.; Chen, C.; Zhang, Y.; Li, C.; Xu, Z. Identification and Characterization of Key Aroma Compounds in Chinese High Altitude and Northernmost Black Tea (Camellia sinensis) Using Distillation Extraction and Sensory Analysis Methods. Flavour Fragr. J. 2020, 35, 666–673. [Google Scholar] [CrossRef]

- Kang, S.; Yan, H.; Zhu, Y.; Liu, X.; Lv, H.P.; Zhang, Y.; Dai, W.-D.; Guo, L.; Tan, J.-F.; Peng, Q.-H.; et al. Identification and Quantification of Key Odorants in the World’s Four Most Famous Black Teas. Food Res. Int. 2019, 121, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Zhu, Y.; Liu, Y.; Liu, Y.; Dong, C.; Lin, Z.; Teng, J. Black Tea Aroma Formation During the Fermentation Period. Food Chem. 2022, 374, 131640. [Google Scholar] [CrossRef] [PubMed]

- Qi, D.; Miao, A.; Chen, W.; Wang, W.; He, X.; Ma, C. Characterization of the Volatile Compounds Profile of the Innovative Broken Oolong-Black Tea in Comparison with Broken Oolong and Broken Black Tea. Food Control. 2021, 129, 108197. [Google Scholar] [CrossRef]

- Yang, Z.; Baldermann, S.; Watanabe, N. Recent Studies of the Volatile Compounds in Tea. Food Res. Int. 2013, 53, 585–599. [Google Scholar] [CrossRef]

- Wang, X.; Zeng, L.; Liao, Y.; Zhou, Y.; Xu, X.; Dong, F.; Yang, Z. An Alternative Pathway for the Formation of Aromatic Aroma Compounds Derived from L-Phenylalanine Via Phenylpyruvic Acid in Tea (Camellia sinensis (L.) O. Kuntze) Leaves. Food Chem. 2019, 270, 17–24. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Y.; Wen, J.; An, K.; Yu, Y.; Zou, B.; Guo, M. A Comparative Study of Aromatic Characterization of Yingde Black Tea Infusions in Different Steeping Temperatures. LWT Food Sci. Technol. 2021, 143, 110860. [Google Scholar] [CrossRef]

- Yang, P.; Song, H.; Lin, Y.; Guo, T.; Wang, L.; Granvogl, M.; Xu, Y. Differences of Characteristic Aroma Compounds in Rougui Tea Leaves with Different Roasting Temperatures Analyzed by Switchable Gc-O-Ms and Gc × Gc-O-Ms and Sensory Evaluation. Food Funct. 2021, 12, 4797–4807. [Google Scholar] [CrossRef]

- Su, D.; He, J.J.; Zhou, Y.Z.; Li, Y.L.; Zhou, H.J. Aroma Effects of Key Volatile Compounds in Keemun Black Tea at Different Grades: Hs-Spme-Gc-Ms, Sensory Evaluation, and Chemometrics. Food Chem. 2022, 373, 131587. [Google Scholar] [CrossRef]

- Alasalvar, C.; Topal, B.; Serpen, A.; Bahar, B.; Pelvan, E.; Gokmen, V. Flavor Characteristics of Seven Grades of Black Tea Produced in Turkey. J. Agric. Food Chem. 2012, 60, 6323–6332. [Google Scholar] [CrossRef]

- Ramaswamy, R. Carotenoid Composition, Distribution and Degradation to Flavour Volatiles During Black Tea Manufacture and the Effect of Carotenoid Supplementation on Tea Quality and Aroma. Food Chem. 2002, 78, 23–28. [Google Scholar]

| No. | Name | Treatments | Manufacture Methods |

|---|---|---|---|

| 1 | Fud | Single variety, without blending | Using the variety of Fudingdabai manufactured black tea. |

| 2 | JGY | Single variety, without blending | Using the variety of Jinguanyin (oolong tea variety) manufactured black tea. |

| 3 | JX | Single variety, without blending | Using the variety of Jinxuan (oolong tea variety) manufactured black tea. |

| 4 | FJG | Mixed varieties, fresh leaf blending | Fresh leaves were blended with a ratio of 85% Fudingdabai and 15% Jinguanyin. |

| 5 | FJX | Mixed varieties, fresh leaf blending | Fresh leaves were blended with a ratio of 85% Fudingdabai and 15% Jinxuan. |

| 6 | AFJG | Mixed varieties, finished tea blending | Fresh leaves were not blended; samples manufactured by blending with the ratio of 85% Fud and 15% JGY. |

| 7 | AFJX | Mixed varieties, finished tea blending | Fresh leaves were not blended; samples manufactured by blending with the ratio of 85% Fud and 15% JX. |

| Compounds | OT (mg/kg) | Odor Descriptor | ROAV | p | ||

|---|---|---|---|---|---|---|

| Fud | FJG | FJX | ||||

| 2-methylbutanal | cocoa, almond (*) | 43.28 | 31.76 | 34.24 | <0.05 | |

| D-limonene | 0.004 | mint, lemon, citrus, orange, fresh, sweet (*, #) | 46.25 | 37.75 | 80.25 | <0.05 |

| linalool | 0.028 | lemon, citrus, orange, floral, sweet, woody, blueberry, lavender, flower, green (*, #) | 35.99 | 54.07 | 50.05 | <0.05 |

| phenylacetaldehyde | 0.002 | hyacinth, honey, clover, sweet, cocoa, grapefruit, green, peanut, floral, bitter (*, #) | 162.50 | 131.50 | 213.00 | <0.05 |

| linalool oxide (pyranoid) | 0.19 | flower (*) | 0.93 | 5.19 | 3.95 | <0.05 |

| benzyl alcohol | 0.62 | berry, balsamic, rose, floral, walnut, sweet, cherry, phenolic, flower, grapefruit (*, #) | 0.92 | 1.15 | 1.25 | <0.05 |

| 1-hexanol | 0.0056 | oil, ethereal, resin, fusel, sweet, fruity, flower, green (*, #) | 0.00 | 0.00 | 15.00 | <0.05 |

| 2-Pentylfuran | 0.0058 | fruity (#) | 0.57 | 4.14 | 0.86 | <0.05 |

| Epoxydihydrolinalool | n. f. | flower, wood (*) | - | - | - | <0.05 |

| dimethyl phthalate | n. f. | n. f. | - | - | - | <0.05 |

| 1,3,5,7-cyclooctatetraene | n. f. | n. f. | - | - | - | <0.05 |

| ethyl linolenate | n. f. | fruit (*) | - | - | - | <0.05 |

| α-amorphene | n. f. | n. f. | - | - | - | <0.05 |

| 1-dodecene | n. f. | n. f. | - | - | - | <0.05 |

| 1,6-Hexanediyl bisacrylate | n. f. | n. f. | - | - | - | <0.05 |

| methyl Linolenate | 450 | oily, fatty, woody (*) | 0.00 | 0.00 | 0.00 | <0.05 |

| (E)-linalool oxide (pyranoid) | 3 | woody, tea-like (#) | 0.05 | 0.25 | 0.00 | <0.05 |

| phytol | 0.64 | powdery, delicate, waxy, balsam, flower (*, #) | 0.28 | 0.49 | 0.00 | <0.05 |

| benzyl benzoate | 0.341 | oil, pineapple, balsamic, herbal, strawberry, oily, faint, sweet, balsam, cherry, almond, herb, cheese (*, #) | 0.28 | 0.37 | 0.00 | <0.05 |

| nerol | 0.29 | sweet (*) | 0.00 | 0.00 | 0.43 | <0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Zan, J.; Yan, L.; Yuan, H.; Wang, P.; Jiang, Y.; Zhu, H. Improving the Sensory Quality of Black Tea by Blending Varieties During Processing. Foods 2025, 14, 941. https://doi.org/10.3390/foods14060941

Chen W, Zan J, Yan L, Yuan H, Wang P, Jiang Y, Zhu H. Improving the Sensory Quality of Black Tea by Blending Varieties During Processing. Foods. 2025; 14(6):941. https://doi.org/10.3390/foods14060941

Chicago/Turabian StyleChen, Wenxue, Jiezhong Zan, Linfeng Yan, Haibo Yuan, Peiqiang Wang, Yongwen Jiang, and Hongkai Zhu. 2025. "Improving the Sensory Quality of Black Tea by Blending Varieties During Processing" Foods 14, no. 6: 941. https://doi.org/10.3390/foods14060941

APA StyleChen, W., Zan, J., Yan, L., Yuan, H., Wang, P., Jiang, Y., & Zhu, H. (2025). Improving the Sensory Quality of Black Tea by Blending Varieties During Processing. Foods, 14(6), 941. https://doi.org/10.3390/foods14060941