Plant-Based Burgers with Reduced Texture Additives: A Comparative Study of Methylcellulose and Sodium Alginate

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

Preparation of Plant-Based Burgers

2.2. Physicochemical Analyses

2.3. Sensory Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Analyses

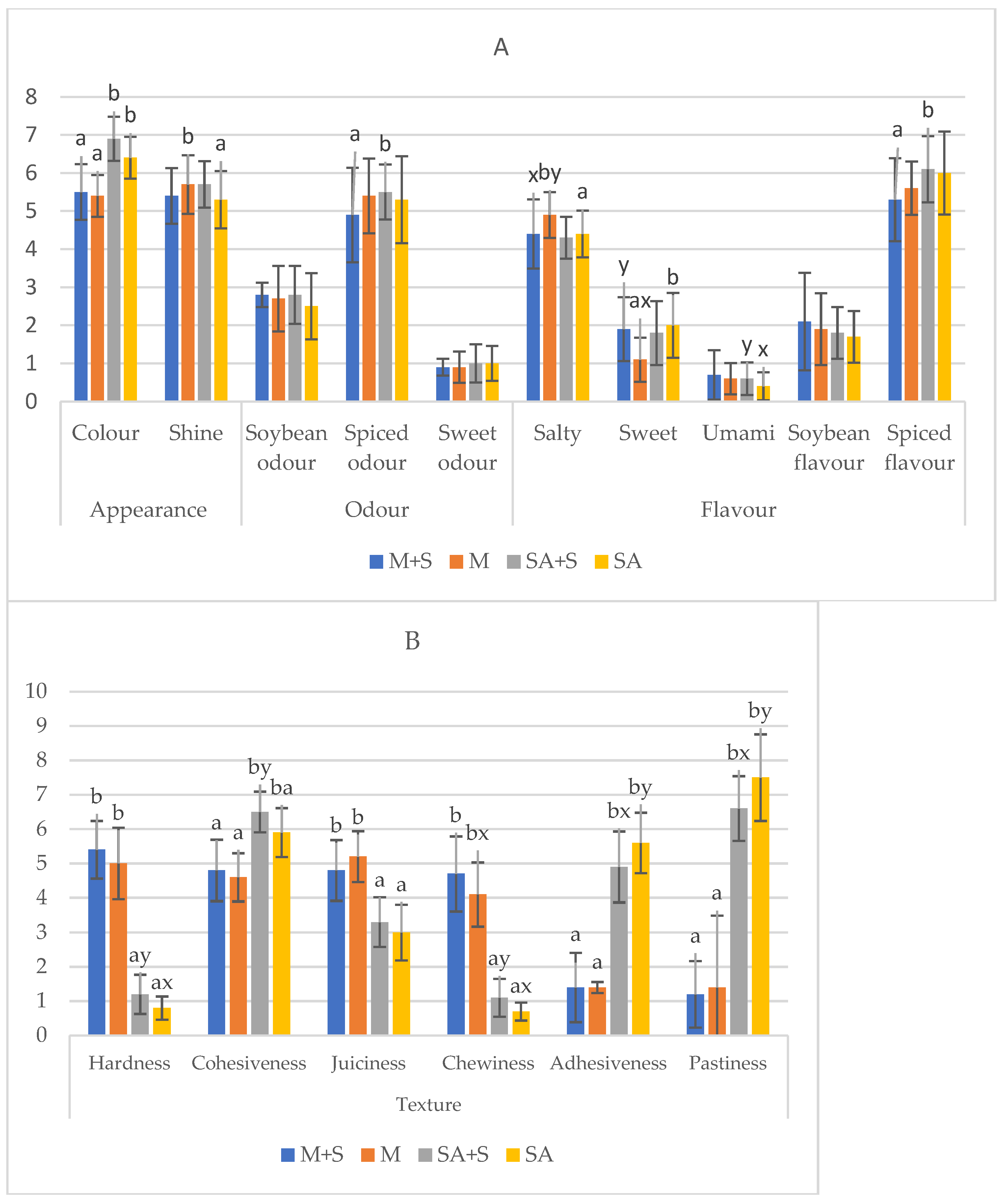

3.2. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WHC | Water holding capacity |

| M+S | Burgers made with methylcellulose as a binder with starch |

| M | Burgers made with methylcellulose as a binder without starch |

| SA+S | Burgers made with sodium alginate as a binder without starch |

| SA | Burgers made with sodium alginate as a binder without starch |

References

- Pereira, P.M.d.C.C.; Vicente, A.F.d.R.B. Meat Nutritional Composition and Nutritive Role in the Human Diet. Meat Sci. 2013, 93, 586–592. [Google Scholar] [CrossRef] [PubMed]

- Serraj, R.; Krishnan, L.; Pingali, P. Agriculture and Food Systems to 2050: A Synthesis. In Agriculture & Food Systems to 2050; World Scientific Series in Grand Public Policy Challenges of the 21st Century; World Scientific: Singapore, 2018; Volume 2, pp. 3–45. ISBN 978-981-327-834-9. [Google Scholar]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of Sensory Evaluation in Consumer Acceptance of Plant-Based Meat Analogs and Meat Extenders: A Scoping Review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef] [PubMed]

- Dagevos, H. Finding Flexitarians: Current Studies on Meat Eaters and Meat Reducers. Trends Food Sci. Technol. 2021, 114, 530–539. [Google Scholar] [CrossRef]

- Zhang, T.; Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. The Development History and Recent Updates on Soy Protein-Based Meat Alternatives. Trends Food Sci. Technol. 2021, 109, 702–710. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Dekkers, B.; Van Der Goot, A.J. Plant-Based Meat Analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. ISBN 978-0-12-814874-7. [Google Scholar]

- Lee, H.J.; Yong, H.I.; Kim, M.; Choi, Y.-S.; Jo, C. Status of Meat Alternatives and Their Potential Role in the Future Meat Market—A Review. Asian-Australas. J. Anim. Sci. 2020, 33, 1533–1543. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Delgado-Pando, G. Sensory Analysis and Consumer Research in New Meat Products Development. Foods 2021, 10, 429. [Google Scholar] [CrossRef]

- Bohrer, B.M. An Investigation of the Formulation and Nutritional Composition of Modern Meat Analogue Products. Food Sci. Hum. Wellness 2019, 8, 320–329. [Google Scholar] [CrossRef]

- Sha, L.; Xiong, Y.L. Plant Protein-Based Alternatives of Reconstructed Meat: Science, Technology, and Challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Seisun, D.; Zalesny, N. Strides in Food Texture and Hydrocolloids. Food Hydrocoll. 2021, 117, 106575. [Google Scholar] [CrossRef]

- Birke Rune, C.J.; Song, Q.; Clausen, M.P.; Giacalone, D. Consumer Perception of Plant-Based Burger Recipes Studied by Projective Mapping. Future Foods 2022, 6, 100168. [Google Scholar] [CrossRef]

- Bühler, J.M.; Schlangen, M.; Möller, A.C.; Bruins, M.E.; Van Der Goot, A.J. Starch in Plant-Based Meat Replacers: A New Approach to Using Endogenous Starch from Cereals and Legumes. Starch Stärke 2022, 74, 2100157. [Google Scholar] [CrossRef]

- Campos, V.; Tappy, L.; Bally, L.; Sievenpiper, J.L.; Lê, K.-A. Importance of Carbohydrate Quality: What Does It Mean and How to Measure It? J. Nutr. 2022, 152, 1200–1206. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef] [PubMed]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration. Foods 2021, 10, 560. [Google Scholar] [CrossRef]

- Coughlin, M.L.; Liberman, L.; Ertem, S.P.; Edmund, J.; Bates, F.S.; Lodge, T.P. Methyl Cellulose Solutions and Gels: Fibril Formation and Gelation Properties. Prog. Polym. Sci. 2021, 112, 101324. [Google Scholar] [CrossRef]

- Borreani, J.; Espert, M.; Salvador, A.; Sanz, T.; Quiles, A.; Hernando, I. Oil-in-Water Emulsions Stabilised by Cellulose Ethers: Stability, Structure and in Vitro Digestion. Food Funct. 2017, 8, 1547–1557. [Google Scholar] [CrossRef]

- Avendaño-Romero, G.; López-Malo, A.; Palou, E. Propiedades Del Alginato y Aplicaciones En Alimentos. Temas Sel. Ing. Alimento 2013, 7, 87–96. [Google Scholar]

- Krog, N. Additives in Dairy Foods|Emulsifiers. In Encyclopedia of Dairy Sciences; Elsevier: Amsterdam, The Netherlands, 2011; pp. 61–71. ISBN 978-0-12-374407-4. [Google Scholar]

- El Khoury, D.; Goff, H.D.; Anderson, G.H. The Role of Alginates in Regulation of Food Intake and Glycemia: A Gastroenterological Perspective. Crit. Rev. Food Sci. Nutr. 2015, 55, 1406–1424. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Viuda-Martos, M.; Fernández-López, J.A.; Pérez-Alvarez, J.A.; Fernández-López, J. Development of Plant-Based Burgers Using Gelled Emulsions as Fat Source and Beetroot Juice as Colorant: Effects on Chemical, Physicochemical, Appearance and Sensory Characteristics. LWT 2022, 172, 114193. [Google Scholar] [CrossRef]

- Peñaranda, I.; Garrido, M.D.; García-Segovia, P.; Martínez-Monzó, J.; Igual, M. Enriched Pea Protein Texturing: Physicochemical Characteristics and Application as a Substitute for Meat in Hamburgers. Foods 2023, 12, 1303. [Google Scholar] [CrossRef]

- Grau, R.; Hamm, R. A simple method for the determination of water binding in muscles. Naturwissenschaften 1953, 40(1), 29–30. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Lee, E.J.; Hong, G.P. Effects of microbial transglutaminase and alginate on the water-binding, textural and oil absorption properties of soy patties. Food Sci. Technol. Int. 2020, 29, 777–782. [Google Scholar] [CrossRef] [PubMed]

- ISO 8586:2023; Sensory Analysis—Selection and Training of Sensory Assessors. ISO: Geneva, Switzerland, 2023.

- ISO 4121; Meat and Meat Products. Evaluation of Food Products by Methods Using Scales. ISO: Geneva, Switzerland, 2003.

- Peñaranda, I.; Garrido, M.D.; Egea, M.; Díaz, P.; Álvarez, D.; Oliver, M.A.; Linares, M.B. Sensory Perception of Meat from Entire Male Pigs Processed by Different Heating Methods. Meat Sci. 2017, 134, 98–102. [Google Scholar] [CrossRef] [PubMed]

- Macfie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L.V. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- ISO 8589; General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland,, 2007.

- Sahu, D.; Bharti, D.; Kim, D.; Sarkar, P.; Pal, K. Variations in Microstructural and Physicochemical Properties of Candelilla Wax/Rice Bran Oil–Derived Oleogels Using Sunflower Lecithin and Soya Lecithin. Gels 2021, 7, 226. [Google Scholar] [CrossRef]

- Galus, S.; Lenart, A. Development and Characterization of Composite Edible Films Based on Sodium Alginate and Pectin. J. Food Eng. 2013, 115, 459–465. [Google Scholar] [CrossRef]

- Von Atzingen, M.C.; Machado Pinto E Silva, M.E. evaluación de la textura y color de almidones y harinas en preparaciones sin gluten evaluation of texture and color of starches and flours in preparations without gluten avaliación da textura e cor de almidóns e fariñas en preparacións sen gluten. Cienc. Tecnol. Aliment. 2005, 4, 319–323. [Google Scholar] [CrossRef]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef]

- Zhou, H.; Vu, G.; Gong, X.; McClements, D.J. Comparison of the Cooking Behaviors of Meat and Plant-Based Meat Analogues: Appearance, Texture, and Fluid Holding Properties. ACS Food Sci. Technol. 2022, 2, 844–851. [Google Scholar] [CrossRef]

- Yao, J.; Zhou, Y.; Chen, X.; Ma, F.; Li, P.; Chen, C. Effect of Sodium Alginate with Three Molecular Weight Forms on the Water Holding Capacity of Chicken Breast Myosin Gel. Food Chem. 2018, 239, 1134–1142. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wu, Y.; He, J.; Huang, Y. A New Insight to the Effect of Calcium Concentration on Gelation Process and Physical Properties of Alginate Films. J. Mater. Sci. 2016, 51, 5791–5801. [Google Scholar] [CrossRef]

- Larrosa, V.J.; Lorenzo, G.; Zaritzky, N.E.; Califano, A.N. Response Surface Methodology to Assay the Effect of the Addition of Proteins and Hydrocolloids on the Water Mobility of Gluten-Free Pasta Formulations. In Water Stress in Biological, Chemical, Pharmaceutical and Food Systems; Gutiérrez-López, G.F., Alamilla-Beltrán, L., Del Pilar Buera, M., Welti-Chanes, J., Parada-Arias, E., Barbosa-Cánovas, G.V., Eds.; Food Engineering Series; Springer New York: New York, NY, USA, 2015; pp. 367–374. ISBN 978-1-4939-2577-3. [Google Scholar]

- Samard, S.; Maung, T.-T.; Gu, B.-Y.; Kim, M.-H.; Ryu, G.-H. Influences of Extrusion Parameters on Physicochemical Properties of Textured Vegetable Proteins and Its Meatless Burger Patty. Food Sci. Biotechnol. 2021, 30, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Linares, M.B.; Peñaranda, I.; Iniesta, C.M.; Egea, M.; Garrido, M.D. Development of Edible Gels and Films as Potential Strategy to Revalorize Entire Male Pork. Food Hydrocoll. 2022, 123, 107182. [Google Scholar] [CrossRef]

- Huang, M.; Kennedy, J.F.; Li, B.; Xu, X.; Xie, B.J. Characters of Rice Starch Gel Modified by Gellan, Carrageenan, and Glucomannan: A Texture Profile Analysis Study. Carbohydr. Polym. 2007, 69, 411–418. [Google Scholar] [CrossRef]

- Sow, L.C.; Toh, N.Z.Y.; Wong, C.W.; Yang, H. Combination of Sodium Alginate with Tilapia Fish Gelatin for Improved Texture Properties and Nanostructure Modification. Food Hydrocoll. 2019, 94, 459–467. [Google Scholar] [CrossRef]

- Al-Hinai, K.Z.; Guizani, N.; Singh, V.; Rahman, M.S.; Al-Subhi, L. Instrumental Texture Profile Analysis of Date-Tamarind Fruit Leather with Different Types of Hydrocolloids. Food Sci. Technol. Res. 2013, 19, 531–538. [Google Scholar] [CrossRef]

- King, A.H. Brown Seaweed Extracts (Alginates). In Food Hydrocolloids; CRC Press: Boca Raton, FL, USA, 1983; ISBN 978-0-429-29037-4. [Google Scholar]

- Cornet, S.H.V.; Snel, S.J.E.; Lesschen, J.; Van Der Goot, A.J.; Van Der Sman, R.G.M. Enhancing the Water Holding Capacity of Model Meat Analogues through Marinade Composition. J. Food Eng. 2021, 290, 110283. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Zhu, S.; Wang, Q. Texturisation Behaviour of Peanut–Soy Bean/Wheat Protein Mixtures during High Moisture Extrusion Cooking. Int. J. Food Sci. Technol. 2018, 53, 2535–2541. [Google Scholar] [CrossRef]

- McClements, D.J. Ultraprocessed Plant-based Foods: Designing the next Generation of Healthy and Sustainable Alternatives to Animal-based Foods. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3531–3559. [Google Scholar] [CrossRef]

- Guriqbal, S. (Ed.) The Soybean: Botany, Production and Uses; CABI: Wallingford, UK, 2010; ISBN 978-1-84593-644-0. [Google Scholar]

- Kaleda, A.; Talvistu, K.; Vaikma, H.; Tammik, M.-L.; Rosenvald, S.; Vilu, R. Physicochemical, Textural, and Sensorial Properties of Fibrous Meat Analogs from Oat-Pea Protein Blends Extruded at Different Moistures, Temperatures, and Screw Speeds. Future Foods 2021, 4, 100092. [Google Scholar] [CrossRef]

- Sothornvit, R. Relationship Between Solution Rheology and Properties of Hydroxypropyl Methylcellulose Films.|EBSCOhost. Available online: https://openurl.ebsco.com/contentitem/gcd:151716479?sid=ebsco:plink:crawler&id=ebsco:gcd:151716479 (accessed on 5 March 2025).

- Bourne, M.C. Chapter 8—Correlation Between Physical Measurements and Sensory Assessments of Texture and Viscosity. In Food Texture and Viscosity, 2nd ed.; Bourne, M.C., Ed.; Food Science and Technology; Academic Press: London, UK, 2002; pp. 293–323. ISBN 978-0-12-119062-0. [Google Scholar]

- Wang, W.; Zhou, X.; Liu, Y. Characterization and Evaluation of Umami Taste: A Review. TrAC Trends Anal. Chem. 2020, 127, 115876. [Google Scholar] [CrossRef]

- De Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; Squeo, G.; Summo, C. Physicochemical and Sensorial Evaluation of Meat Analogues Produced from Dry-Fractionated Pea and Oat Proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef] [PubMed]

| Scheme | M+S * | M * | SA+S * | SA * |

|---|---|---|---|---|

| Hydrated soybean protein 1 | 50 | 50 | 50 | 50 |

| Methylcellulose 2 | 50 | 50 | - | - |

| Sodium alginate 3 | - | - | 50 | 50 |

| Starch 4 | 5 | - | 5 | - |

| Spice mixture 1, * | 2.5 | 2.5 | 2.5 | 2.5 |

| Olive oil 1 | 9 | 9 | 9 | 9 |

| TOTAL (g) | 117 | 112 | 117 | 112 |

| * Spice mixture | ||||

| Salt | 1.16 | |||

| Pepper | 0.20 | |||

| Garlic Powder | 0.57 | |||

| Brewer’s Yeast | 0.57 | |||

| TOTAL | 2.5 | |||

| Attributes | Definition | Scale | |

|---|---|---|---|

| Appearance | Colour | Similarity of the colour tone of the sample to the characteristic colour of a soybean (light brown). Looking at the colour in the cut surface. |  0—light; 5—light brown (characteristic of this product); 10—dark |

| Shine | Amount of reflected light on the surface of burger. |  0—dull; 10—very shiny | |

| Odour | Soybean odour | Overall intensity of the soybean or legume odour of the sample. | 0—not perceptible; 10—very intense |

| Spiced odour | Odour associated with the olfactory perception of a number of spices in the burger. | ||

| Sweet odour | Odour associated with sucrose. | ||

| Flavour | Salty | Taste sensation associated with the presence of sodium chloride in the food. | 0—not perceived; 5—normal salty; 10—very intense |

| Sweet | Taste sensation associated with sucrose. | 0—not perceived; 10—very intense | |

| Umami | Taste sensation produced by monosodium glutamate. Induces salivation and a velvety sensation on the tongue. | ||

| Soybean flavour | Overall intensity of the soybean or legume flavour of the sample. | ||

| Spiced flavour | Flavour associated with the olfactory–gustatory perception of a number of spices in the burger. | ||

| Texture | Hardness | Force required to deform or compress a substance between the teeth. |  0—easily compressible; 5—characteristic of minced meat; 10—not compressible |

| Cohesiveness | Degree of deformation of a foodstuff before it breaks down. |  0—little; 10—very much | |

| Juiciness | Associated with the amount of water and/or fat released from a bite of food during mastication. |  0—completely dry; 10—very moist | |

| Adhesiveness | Work required by the tongue to dislodge a product stuck on the palate or teeth. |  0—little; 10—very much | |

| Chewiness | Time required to reduce the size of a food until it is swallowed. |  0—no chewing required for swallowing; 10—requires a large amount of chewing for swallowing | |

| Pastiness | Sensation of paste in the mouth detected. It is an adhesive sample, not very hard and not very elastic. |  0—little; 10—very much |

| CIELab Colour | M+S | M | SA+S | SA |

|---|---|---|---|---|

| L* | 63.55 ± 0.34 y | 58.48 ± 0.99x | 62.31 ± 1.53 y | 57.98 ± 0.58 x |

| a* | 7.25 ± 0.17 b | 7.68 ± 0.22b | 6.41 ± 0.26 a | 6.78 ± 0.17 a |

| b* | 13.85 ± 0.17 x | 14.73 ± 0.31 b,y | 12.97 ± 0.41 | 13.39 ± 0.21 a |

| C* | 15.64 ± 0.21 b,x | 16.61 ± 0.37 b,y | 14.47 ± 0.47 a | 15.02 ± 0.24 a |

| h* | 62.41 ± 0.42 | 62.52 ± 0.35 | 63.75 ± 0.50 | 63.19 ± 0.53 |

| Parameters | ||||

| WHC (%) | 85.98 ± 0.75 a | 84.05 ± 0.66 a | 89.21 ± 0.78 b | 90.25 ± 1.43 b |

| CL (%) | 14.40 ± 1.70 b | 16.52 ± 1.55 | 9.72 ± 1.20 a,x | 14.06 ± 1.26 y |

| Properties | M+S | M | SA+S | SA |

|---|---|---|---|---|

| Hardness 1 (g) | 214.0 ± 16.40 | 251.4 ± 20.10 | 216.8 ± 23.60 | 211.9 ± 24.70 |

| Hardness 2 (g) | 185.8 ± 12.90 | 215.6 ± 16.30 | 193.8 ± 21.10 | 184.0 ± 20.90 |

| Adhesiveness (mJ) | 0.09 ± 0.03 | 0.19 ± 0.04 | 0.04 ± 0.03 x | 0.21 ± 0.06 y |

| Resilience (J/m3) | 0.19 ± 0.01 a,y | 0.16 ± 0.01 a,x | 0.26 ± 0.02 b | 0.22 ± 0.01 b |

| Cohesiveness | 0.53 ± 0.03 a | 0.47 ± 0.01 a | 0.65 ± 0.03 b,y | 0.53 ± 0.00 b,x |

| Elasticity (mm) | 3.29 ± 0.11 | 3.19 ± 0.07 | 3.80 ± 0.22 | 3.33 ± 0.08 |

| Chewiness (mJ) | 3.76 ± 0.36 | 3.74 ± 0.19 | 5.58 ± 0.95 | 3.76 ± 0.54 |

| Attributes | M+S | M | SA+S | SA | |

|---|---|---|---|---|---|

| Appearance | Colour | 5.5 ± 0.73 a | 5.4 ± 0.55 a | 6.9 ± 0.58 b | 6.4 ± 0.55 b |

| Shine | 5.4 ± 0.73 | 5.7 ± 0.77 b | 5.7 ± 0.61 | 5.3 ± 0.75 a | |

| Odour | Soybean odour | 2.8 ± 0.32 | 2.7 ± 0.86 | 2.8 ± 0.76 | 2.5 ± 0.87 |

| Spiced odour | 4.9 ± 1.24 a | 5.4 ± 0.98 | 5.5 ± 0.72 b | 5.3 ± 1.14 | |

| Sweet odour | 0.9 ± 0.22 | 0.9 ± 0.41 | 1.0 ± 0.50 | 1.0 ± 0.46 | |

| Flavour | Salty | 4.4 ± 0.91 x | 4.9 ± 0.60 b,y | 4.3 ± 0.55 | 4.4 ± 0.61 a |

| Sweet | 1.9 ± 0.84 y | 1.1 ± 0.58 a,x | 1.8 ± 0.84 | 2.0. ± 0.85 b | |

| Umami | 0.7 ± 0.65 | 0.6 ± 0.41 | 0.6 ± 0.43 y | 0.4 ± 0.37 x | |

| Soybean flavour | 2.1 ± 1.28 | 1.9 ± 0.94 | 1.8 ± 0.68 | 1.7 ± 0.68 | |

| Spiced flavour | 5.3 ± 1.09 a | 5.6 ± 0.70 | 6.1 ± 0.87 b | 6.0 ± 1.09 | |

| Texture | Hardness | 5.4 ± 0.84 b | 5.0 ± 1.04 b | 1.2 ± 0.57 a,y | 0.8 ± 0.34 a,x |

| Cohesiveness | 4.8 ± 0.89 a | 4.6 ± 0.70 a | 6.5 ± 0.59 b,y | 5.9 ± 0.71 b,a | |

| Juiciness | 4.8 ± 0.88 b | 5.2 ± 0.74 b | 3.3 ± 0.72 a | 3.0 ± 0.81 a | |

| Chewiness | 4.7 ± 1.09 b,y | 4.1 ± 0.93 b,x | 1.1 ± 0.55 a,y | 0.7 ± 0.26 a,x | |

| Adhesiveness | 1.4 ± 1.01 a | 1.4 ± 0.16 a | 4.9 ± 1.03 b,x | 5.6 ± 0.88 b,y | |

| Pastiness | 1.2 ± 0.97 a | 1.4 ± 2.09 a | 6.6 ± 0.94 b,x | 7.5 ± 1.26 b,y |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peñaranda, I.; López Morales, M.B.; Garrido, M.D.; Egea, M. Plant-Based Burgers with Reduced Texture Additives: A Comparative Study of Methylcellulose and Sodium Alginate. Foods 2025, 14, 1373. https://doi.org/10.3390/foods14081373

Peñaranda I, López Morales MB, Garrido MD, Egea M. Plant-Based Burgers with Reduced Texture Additives: A Comparative Study of Methylcellulose and Sodium Alginate. Foods. 2025; 14(8):1373. https://doi.org/10.3390/foods14081373

Chicago/Turabian StylePeñaranda, Irene, María Belén López Morales, María Dolores Garrido, and Macarena Egea. 2025. "Plant-Based Burgers with Reduced Texture Additives: A Comparative Study of Methylcellulose and Sodium Alginate" Foods 14, no. 8: 1373. https://doi.org/10.3390/foods14081373

APA StylePeñaranda, I., López Morales, M. B., Garrido, M. D., & Egea, M. (2025). Plant-Based Burgers with Reduced Texture Additives: A Comparative Study of Methylcellulose and Sodium Alginate. Foods, 14(8), 1373. https://doi.org/10.3390/foods14081373