Microbial and Quality Changes of Seabream Fillets Processed with Cold Plasma During Refrigerated Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material Preparation

2.2. Plasma Treatment

2.3. Packaging and Storage

2.4. Analytical Determinations

2.4.1. Microbiological Analysis

2.4.2. Physico-Chemical Parameters

2.4.3. Sensory Evaluation

2.4.4. Oxidative Indices

2.4.5. Fatty Acids Profile

2.5. Statistical Analysis

3. Results and Discussion

3.1. Microbial Inactivation

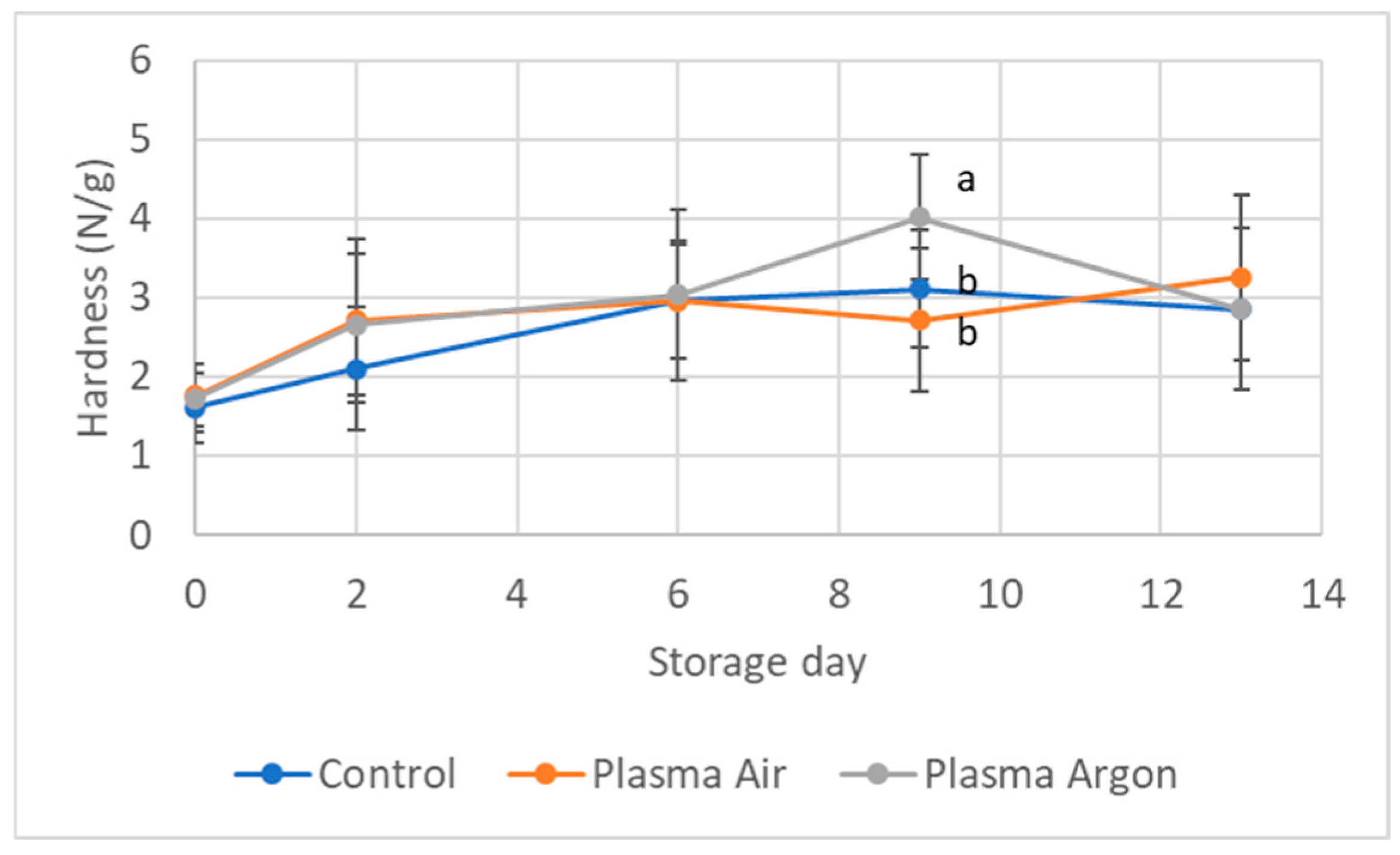

3.2. Quality Parameters

3.3. Fatty Acids Composition

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andoni, E.; Ozuni, E.; Bijo, B.; Shehu, F.; Branciari, R.; Miraglia, D.; Ranucci, D. Efficacy of Non-Thermal Processing Methods to Prevent Fish Spoilage. J. Aquat. Food Prod. Technol. 2021, 30, 228–245. [Google Scholar] [CrossRef]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making Sense of the “Clean Label” Trends: A Review of Consumer Food Choice Behavior and Discussion of Industry Implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- Bermudez-Aguirre, D. Advances in the Inactivation of Microorganisms and Viruses in Food and Model Systems Using Cold Plasma. In Advances in Cold Plasma Applications for Food Safety and Preservation; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2020; pp. 49–91. [Google Scholar]

- Bourke, P.; Ziuzina, D.; Boehm, D.; Cullen, P.J.; Keener, K. The Potential of Cold Plasma for Safe and Sustainable Food Production. Trends Biotechnol. 2018, 36, 615–626. [Google Scholar] [CrossRef] [PubMed]

- Albertos, I.; Martin-Diana, A.B.; Cullen, P.J.; Tiwari, B.K.; Ojha, K.S.; Bourke, P.; Rico, D. Shelf-Life Extension of Herring (Clupea harengus) Using in-Package Atmospheric Plasma Technology. Innov. Food Sci. Emerg. Technol. 2019, 53, 85–91. [Google Scholar] [CrossRef]

- Albertos, I.; Martín-Diana, A.B.; Cullen, P.J.; Tiwari, B.K.; Ojha, S.K.; Bourke, P.; Álvarez, C.; Rico, D. Effects of Dielectric Barrier Discharge (DBD) Generated Plasma on Microbial Reduction and Quality Parameters of Fresh Mackerel (Scomber scombrus) Fillets. Innov. Food Sci. Emerg. Technol. 2017, 44, 117–122. [Google Scholar] [CrossRef]

- Giannoglou, M.; Panagiotis, D.; Efthimiadou, A.; Gogolides, E.; Katsaros, G. Comparative Study on the Effect of Cold Atmospheric Plasma, Ozonation, Pulsed Electromagnetic Fields and High-Pressure Technologies on Sea Bream Fillet Quality Indices and Shelf Life. Food Eng. Rev. 2021, 13, 175–184. [Google Scholar] [CrossRef]

- Olatunde, O.O.; Benjakul, S.; Vongkamjan, K. High Voltage Cold Atmospheric Plasma: Antibacterial Properties and Its Effect on Quality of Asian Sea Bass Slices. Innov. Food Sci. Emerg. Technol. 2019, 52, 305–312. [Google Scholar] [CrossRef]

- Singh, A.; Benjakul, S. The Combined Effect of Squid Pen Chitooligosaccharides and High Voltage Cold Atmospheric Plasma on the Shelf-Life Extension of Asian Sea Bass Slices Stored at 4 °C. Innov. Food Sci. Emerg. Technol. 2020, 64, 102339. [Google Scholar] [CrossRef]

- Choi, S.; Puligundla, P.; Mok, C. Microbial Decontamination of Dried Alaska Pollock Shreds Using Corona Discharge Plasma Jet: Effects on Physicochemical and Sensory Characteristics. J. Food Sci. 2016, 81, M952–M957. [Google Scholar] [CrossRef]

- Choi, M.-S.; Jeon, E.B.; Kim, J.Y.; Choi, E.H.; Lim, J.S.; Choi, J.; Park, S.Y. Impact of Non-Thermal Dielectric Barrier Discharge Plasma on Staphylococcus Aureus and Bacillus Cereus and Quality of Dried Blackmouth Angler (Lophiomus setigerus). J. Food Eng. 2020, 278, 109952. [Google Scholar] [CrossRef]

- Colejo, S.; Alvarez-Ordóñez, A.; Prieto, M.; González-Raurich, M.; López, M. Evaluation of Ultraviolet Light (UV), Non-Thermal Atmospheric Plasma (NTAP) and Their Combination for the Control of Foodborne Pathogens in Smoked Salmon and Their Effect on Quality Attributes. Innov. Food Sci. Emerg. Technol. 2018, 50, 84–93. [Google Scholar] [CrossRef]

- Puligundla, P.; Choi, S.; Mok, C. Microbial Decontamination of Gwamegi (Semi-Dried Pacific Saury) Using Corona Discharge Plasma Jet, Including Physicochemical and Sensory Evaluation. J. Aquat. Food Prod. Technol. 2018, 27, 274–283. [Google Scholar] [CrossRef]

- Park, S.Y.; Ha, S. Application of Cold Oxygen Plasma for the Reduction of Cladosporium cladosporioides and Penicillium citrinum on the Surface of Dried Filefish (Stephanolepis cirrhifer) Fillets. Int. J. Food Sci. Technol. 2015, 50, 966–973. [Google Scholar] [CrossRef]

- Odeyemi, O.A.; Alegbeleye, O.O.; Strateva, M.; Stratev, D. Understanding Spoilage Microbial Community and Spoilage Mechanisms in Foods of Animal Origin. Compr. Rev. Food Sci. Food Saf. 2020, 19, 311–331. [Google Scholar] [CrossRef]

- Wu, J.; Cui, C.; Li, L. Effect of Cold Plasma on Lipid Oxidation of Fish and Fish-based Products: A Review. Int. J. Food Sci. Technol. 2024, 59, 1958–1967. [Google Scholar] [CrossRef]

- Tappi, S.; Nissen, L.; Casciano, F.; Antonelli, G.; Chiarello, E.; Picone, G.; Laurita, R.; Capelli, F.; Gherardi, M.; Maccaferri, C.; et al. Effect of Cold Plasma Generated with Different Gas Mixtures on Safety, Quality and Nutritional Aspects of Fresh Sea Bream Fillets. Innov. Food Sci. Emerg. Technol. 2023, 89, 103477. [Google Scholar] [CrossRef]

- Passi, S.; Cataudella, S.; Tiano, L.; Littarru, G.P. Dynamics of lipid oxidation and antioxidant depletion in Mediterranean fish stored at different temperatures. Biofactors 2005, 25, 241–254. [Google Scholar] [CrossRef]

- Capelli, F.; Tappi, S.; Gritti, T.; De Aguiar Saldanha Pinheiro, A.C.; Laurita, R.; Tylewicz, U.; Spataro, F.; Braschi, G.; Lanciotti, R.; Galindo, F.G.; et al. Decontamination of Food Packages from SARS-COV-2 RNA with a Cold Plasma-Assisted System. Appl. Sci. 2021, 11, 4177. [Google Scholar] [CrossRef]

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organisation for Standardisation: Geneva, Switzerland, 2013.

- ISO 21528-2:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 2: Colony-Count Technique. International Organisation for Standardisation: Geneva, Switzerland, 2017.

- SO 17410:2019; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Psychrotrophic Microorganisms. International Organisation for Standardisation: Geneva, Switzerland, 2019.

- Stamatis, N.; Arkoudelos, J.S. Effect of Modified Atmosphere and Vacuum Packaging on Microbial, Chemical and Sensory Quality Indicators of Fresh, Filleted Sardina Pilchardus at 3 °C. J. Sci. Food Agric. 2007, 87, 1164–1171. [Google Scholar] [CrossRef]

- Bao, Y.; Ertbjerg, P. Relationship between Oxygen Concentration, Shear Force and Protein Oxidation in Modified Atmosphere Packaged Pork. Meat Sci. 2015, 110, 174–179. [Google Scholar] [CrossRef]

- Soglia, F.; Petracci, M.; Ertbjerg, P. Novel DNPH-Based Method for Determination of Protein Carbonylation in Muscle and Meat. Food Chem. 2016, 197, 670–675. [Google Scholar] [CrossRef] [PubMed]

- Bligh, E.G.; Dyer, W.J. A Rapid Method of Total Lipid Extraction and Purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Di Nunzio, M.; Loffi, C.; Chiarello, E.; Dellafiora, L.; Picone, G.; Antonelli, G.; Di Gregorio, C.; Capozzi, F.; Tedeschi, T.; Galaverna, G.; et al. Impact of a Shorter Brine Soaking Time on Nutrient Bioaccessibility and Peptide Formation in 30-Months-Ripened Parmigiano Reggiano Cheese. Molecules 2022, 27, 664. [Google Scholar] [CrossRef]

- Chaijan, M.; Chaijan, S.; Panya, A.; Nisoa, M.; Cheong, L.-Z.; Panpipat, W. High Hydrogen Peroxide Concentration-Low Exposure Time of Plasma-Activated Water (PAW): A Novel Approach for Shelf-Life Extension of Asian Sea Bass (Lates calcarifer) Steak. Innov. Food Sci. Emerg. Technol. 2021, 74, 102861. [Google Scholar] [CrossRef]

- International Commission on Microbiological Specifications for Foods (ICMSF). Microbial Ecology of Food Commodities (Vol.6) Baltimore: Blackie Academic and Professional. In Microorganisms in Foods; Blackie Academic & Professional: Ada, MI, USA, 1998. [Google Scholar]

- Rodrigues, B.L.; da Silveira Alvares, T.; Sampaio, G.S.L.; Cabral, C.C.; Araujo, J.V.A.; Franco, R.M.; Mano, S.B.; Conte Junior, C.A. Influence of Vacuum and Modified Atmosphere Packaging in Combination with UV-C Radiation on the Shelf Life of Rainbow Trout (Oncorhynchus mykiss) Fillets. Food Cont. 2016, 60, 596–605. [Google Scholar] [CrossRef]

- Wang, Y.; Sang, X.; Cai, Z.; Zeng, L.; Deng, W.; Zhang, J.; Jiang, J.; Wang, J. Optimization of cold plasma combined treatment process and its effect on the quality of Asian sea bass (Lates calcarifer) during refrigerated storage. J. Sci. Food Agric. 2024, 104, 2750–2760. [Google Scholar] [CrossRef]

- Chanioti, S.; Giannoglou, M.; Stergiou, P.; Passaras, D.; Dimitrakellis, P.; Kokkoris, G.; Gogolides, E.; Katsaros, G. Cold-atmospheric-plasma activated-ice as a cooling medium with antimicrobial properties: Case study on fish fillet preservation. Food Res. Int. 2023, 167, 112639. [Google Scholar] [CrossRef]

- Rathod, N.B.; Ranveer, R.C.; Bhagwat, P.K.; Ozogul, F.; Benjakul, S.; Pillai, S.; Annapure, U.S. Cold Plasma for the Preservation of Aquatic Food Products: An Overview. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4407–4425. [Google Scholar] [CrossRef]

- Ozogul, Y.; Durmuş, M.; Balıkcı, E.; Ozogul, F.; Ayas, D.; Yazgan, H. The Effects of the Combination of Freezing and the Use of Natural Antioxidant Technology on the Quality of Frozen Sardine Fillets (Sardinella aurita). Int. J. Food Sci. Technol. 2011, 46, 236–242. [Google Scholar] [CrossRef]

- Ocaño-Higuera, V.M.; Maeda-Martínez, A.N.; Marquez-Ríos, E.; Canizales-Rodríguez, D.F.; Castillo-Yáñez, F.J.; Ruíz-Bustos, E.; Graciano-Verdugo, A.Z.; Plascencia-Jatomea, M. Freshness Assessment of Ray Fish Stored in Ice by Biochemical, Chemical and Physical Methods. Food Chem. 2011, 125, 49–54. [Google Scholar] [CrossRef]

- Segat, A.; Misra, N.N.; Cullen, P.J.; Innocente, N. Atmospheric Pressure Cold Plasma (ACP) Treatment of Whey Protein Isolate Model Solution. Innov. Food Sci. Emerg. Technol. 2015, 29, 247–254. [Google Scholar] [CrossRef]

- Hatab, S.; Koddy, J.K.; Miao, W.; Tang, L.; Xu, H.; Deng, S.; Zheng, B. Atmospheric Cold Plasma: A New Approach to Modify Protein and Lipid Properties of Myofibrillar Protein Isolate from Hairtail (Trichiurus lepturus) Fish. J. Sci. Food Agric. 2022, 102, 2041–2049. [Google Scholar] [CrossRef] [PubMed]

- Kulawik, P.; Alvarez, C.; Cullen, P.J.; Aznar-Roca, R.; Mullen, A.M.; Tiwari, B. The Effect of Non-Thermal Plasma on the Lipid Oxidation and Microbiological Quality of Sushi. Innov. Food Sci. Emerg. Technol. 2018, 45, 412–417. [Google Scholar] [CrossRef]

- Pérez-Andrés, J.M.; de Alba, M.; Harrison, S.M.; Brunton, N.P.; Cullen, P.J.; Tiwari, B.K. Effects of Cold Atmospheric Plasma on Mackerel Lipid and Protein Oxidation during Storage. LWT 2020, 118, 108697. [Google Scholar] [CrossRef]

- Olatunde, O.O.; Singh, A.; Shiekh, K.A.; Nuthong, P.; Benjakul, S. Effect of High Voltage Cold Plasma on Oxidation, Physiochemical, and Gelling Properties of Myofibrillar Protein Isolate from Asian Sea Bass (Lates calcarifer). Foods 2021, 10, 326. [Google Scholar] [CrossRef]

- Ozogul, Y.; Ayas, D.; Yazgan, H.; Ozogul, F.; Boga, E.K.; Ozyurt, G. The capability of rosemary extract in preventing oxidation of fish lipid. Int. J. Food Sci. Technol. 2010, 45, 1717–1723. [Google Scholar] [CrossRef]

- Uçak, İ.; Özogul, Y.; Durmuş, M. The effects of rosemary extract combination with vacuum packing on the quality changes of Atlantic mackerel fish burgers. Int. J. Food Sci. Technol. 2011, 46, 1157–1163. [Google Scholar] [CrossRef]

- Bahrami, N.; Bayliss, D.; Chope, G.; Penson, S.; Perehinec, T.; Fisk, I.D. Cold Plasma: A New Technology to Modify Wheat Flour Functionality. Food Chem. 2016, 202, 247–253. [Google Scholar] [CrossRef]

- Sarangapani, C.; Ryan Keogh, D.; Dunne, J.; Bourke, P.; Cullen, P.J. Characterisation of Cold Plasma Treated Beef and Dairy Lipids Using Spectroscopic and Chromatographic Methods. Food Chem. 2017, 235, 324–333. [Google Scholar] [CrossRef]

- Kopuk, B.; Gunes, R.; Palabiyik, I. Cold Plasma Modification of Food Macromolecules and Effects on Related Products. Food Chem. 2022, 382, 132356. [Google Scholar] [CrossRef]

| Storage Day | Control | Plasma-Air | Plasma-Argon | p Value Treatment |

|---|---|---|---|---|

| Mesophiles | ||||

| 0 | 3.08 ± 0.03 C | 3.05 ± 0.03 B | 2.81 ± 0.05 C | 0.066001 |

| 2 | 3.11 ± 0.04 C | 3.09 ± 0.06 B | 3.06 ± 0.04 C | 0.422850 |

| 6 | 3.88 ± 0.01 C | 3.91 ± 0.02 B | 3.73 ± 0.03 C | 0.056304 |

| 9 | 5.10 ± 0.05 Bb | 5.56 ± 0.02 Aab | 5.90 ± 0.02 Ba | <0.000001 |

| 13 | 7.29 ± 0.06 Aa | 6.61 ± 0.11 Ab | 7.08 ± 0.04 Aab | 0.000004 |

| p value time | 0.000036 | 0.000454 | 0.000322 | |

| Enterobacteriaceae | ||||

| 0 | 2.03 ± 0.09 C | 1.71 ± 0.23 C | 2.02 ± 0.09 B | 0.069549 |

| 2 | 3.27 ± 0.69 Ba | 2.00 ± 0.15 Cb | 1.82 ± 0.10 Bb | 0.021316 |

| 6 | 4.41 ± 0.08 Ba | 3.43 ± 0.17 Bb | 3.10 ± 0.07 Ab | 0.000011 |

| 9 | 4.42 ± 0.06 Ba | 4.42 ± 0.09 Aa | 3.14 ± 0.08 Ab | 0.000011 |

| 13 | 5.54 ± 0.33 Aa | 4.25 ± 0.07 Ab | 3.23 ± 0.04 Ac | 0.002928 |

| p value time | 0.000772 | 0.003423 | 0.000062 | |

| Psychrophiles | ||||

| 0 | 2.89 ± 0.09 C | 2.73 ± 0.08 C | 2.86 ± 0.15 C | 0.207807 |

| 2 | 4.94 ± 0.32 B | 4.76 ± 0.15 B | 4.83 ± 0.16 B | 0.443364 |

| 6 | 6.58 ± 0.06 Aa | 5.52 ± 0.08 Ab | 5.04 ± 0.05 Bb | <0.000001 |

| 9 | 7.08 ± 0.05 Aa | 5.99 ± 0.10 Ab | 5.33 ± 0.05 Bb | <0.000001 |

| 13 | 7.66 ± 0.06 Aa | 6.74 ± 0.59 Ab | 6.73 ± 0.06 Ab | 0.000001 |

| p value time | 0.0000052 | 0.000001 | <0.000001 | |

| Storage Day | Control | Plasma-Air | Plasma-Argon | p Value Treatment |

|---|---|---|---|---|

| Moisture content (%) | ||||

| 0 | 73.0 ± 1.0 aA | 73.6 ± 1.7 aA | 73.9 ± 0.6 aA | 0.234 |

| 2 | 73.3 ± 1.3 aA | 73.7 ± 0.4 aA | 74.2 ± 1.5 aA | 0.123 |

| 6 | 71.3 ± 1.2 aA | 72.2 ± 0.6 aA | 72.4 ± 0.9 aA | 0.342 |

| 9 | 72.4 ± 0.5 aA | 74.0 ± 0.3 aA | 72.1 ± 1.4 aA | 0.112 |

| 13 | 72.4 ± 2.1 aA | 74.1 ± 0.4 aA | 72.4 ± 2.1 aA | 0.254 |

| p value time | 0.114 | 0.210 | 0.301 | |

| pH | ||||

| 0 | 6.5 ± 0.1 aA | 6.5 ± 0.2 aA | 6.4 ± 0.2 aA | 0.213 |

| 2 | 6.4 ± 0.2 aA | 6.5 ± 0.1 aA | 6.5 ± 0.1 aA | 0.114 |

| 6 | 6.5 ± 0.1 aA | 6.5 ± 0.1 aA | 6.4 ± 0.2 aA | 0.126 |

| 9 | 6.5 ± 0.1 aA | 6.5 ± 0.2 aA | 6.4 ± 0.2 aA | 0.172 |

| 13 | 6.5 ± 0.2 aA | 6.5 ± 0.1 aA | 6.5 ± 0.1 aA | 0.138 |

| p value time | 0.154 | 0.134 | 0.08 | |

| L* | ||||

| 0 | 44.0 ± 1.4 bB | 47.7 ± 2.2 aA | 46.8 ± 1.5 aA | <0.0001 |

| 2 | 43.9 ± 1.8 aB | 45.5 ± 2.9 aAB | 45.3 ± 1.6 aA | 0.158 |

| 6 | 44.5 ± 1.8 bB | 45.9 ± 1.7 abAB | 46.7 ± 2.1 aA | 0.025 |

| 9 | 44.6 ± 1.5 bB | 47.0 ± 2.1 aA | 46.7 ± 1.7 aA | 0.005 |

| 13 | 46.9 ± 1.6 aA | 44.4 ± 4.1 aB | 46.9 ± 1.6 aA | 0.110 |

| p value time | 0.004 | 0.002 | 0.008 | |

| a* | ||||

| 0 | −4.0 ± 0.3 aA | −3.8 ± 0.3 aA | −3.9 ± 0.2 aA | 0.364 |

| 2 | −3.4 ± 0.4 aA | −3.2 ± 0.3 aA | −3.4 ± 0.3 aA | 0.159 |

| 6 | −3.3 ± 0.3 aA | −3.3 ± 0.2 aA | −3.5 ± 0.2 aA | 0.248 |

| 9 | −3.3 ± 0.4 aA | −3.3 ± 0.2 aA | −3.4 ± 0.3 aA | 0.681 |

| 13 | −2.8 ± 0.3 aB | −2.7 ± 0.5 aB | −2.8 ± 0.3 aB | 0.629 |

| p value time | 0.002 | 0.003 | 0.002 | |

| b* | ||||

| 0 | −0.5 ± 1.7 aA | −2.1 ± 1.0 bA | −1.9 ± 0.6 bA | 0.008 |

| 2 | −2.1 ± 1.2 aA | −1.3 ± 0.8 aA | −2.3 ± 1.1 aA | 0.074 |

| 6 | −2.0 ± 1.1 aA | −2.0 ± 0.9 aA | −2.1 ± 0.9 aA | 0.984 |

| 9 | −1.3 ± 1.0 aA | −1.2 ± 1.0 aA | −0.9 ± 1.3 aA | 0.603 |

| 13 | −1.4 ± 1.1 aA | −0.8 ± 0.9 aA | −1.4 ± 1.1 aA | 0.193 |

| p value time | 0.007 | 0.121 | 0.007 | |

| Storage Day | Control | Plasma-Air | Plasma-Argon |

|---|---|---|---|

| 0 | E | E | E |

| 2 | E | E | E |

| 6 | A | A | A |

| 9 | B | A | A |

| 13 | C | B | B |

| Storage Day | Control | Plasma-Air | Plasma-Argon | p Value |

|---|---|---|---|---|

| TBARS (mg MDA/kg of sample) | ||||

| 0 | 1.56 ± 0.52 a | 2.09 ± 0.14 a | 1.97 ± 0.69 a | 0.052 |

| 9 | 1.63 ± 0.19 b | 4.29 ± 0.34 a | 5.20 ± 1.06 a | 0.005 |

| Carbonyl content (nmol/mg of protein) | ||||

| 0 | 3.33 ± 0.81 a | 4.16 ± 1.36 a | 3.37 ± 0.82 a | 0.391 |

| 9 | 2.06 ± 0.62 a | 3.82 ± 0.54 b | 3.07 ± 1.28 b | 0.012 |

| Control | Plasma-Air | Plasma-Argon | |||||

|---|---|---|---|---|---|---|---|

| Storage Day | p Value | ||||||

| 0 | 9 | 0 | 9 | 0 | 9 | ||

| 14:0 | 121.04 ± 14.01 a | 143.40 ± 49.58 a | 90.74 ± 8.48 a | 92.80 ± 43.22 a | 158.25 ± 115.17 a | 132.17 ± 79.40 a | 0.735 |

| 16:0 | 586.00 ± 61.00 a | 662.87 ± 202.81 a | 446.92 ± 32.18 a | 469.18 ± 191.84 a | 729.84 ± 478.17 a | 585.62 ± 300.03 a | 0.748 |

| 16:1 n-7 | 191.05 ± 18.12 a | 216.81 ± 71.16 a | 146.52 ± 27.14 a | 153.19 ± 73.00 a | 239.99 ± 168.23 a | 195.75 ± 111.69 a | 0.807 |

| 18:0 | 117.74 ± 11.77 a | 135.71 ± 34.80 a | 86.35 ± 3.17 a | 101.10 ± 33.98 a | 143.87 ± 90.73 a | 126.64 ± 61.09 a | 0.713 |

| 18:1 n-9 | 1046.92 ± 120.48 a | 1161.90 ± 373.91 a | 784.42 ± 109.14 a | 832.46 ± 353.32 a | 1358.82 ± 948.91 a | 1084.62 ± 614.09 a | 0.757 |

| 18:2 n-6 | 382.51 ± 41.61 a | 450.31 ± 144.80 a | 295.09 ± 32.43 a | 306.37 ± 110.39 a | 495.96 ± 334.64 a | 432.05 ± 235.71 a | 0.717 |

| 18:3 n-3 | 92.02 ± 10.09 a | 106.41 ± 36.52 a | 71.11 ± 9.93 a | 71.87 ± 25.31 a | 121.77 ± 84.53 a | 102.39 ± 57.51 a | 0.719 |

| 20:1 | 149.86 ± 16.72 a | 171.90 ± 53.77 a | 112.67 ± 11.28 a | 115.22 ± 53.49 a | 192.79 ± 136.74 a | 164.47 ± 96.64 a | 0.744 |

| 20:4 | 28.68 ± 2.55 a | 35.09 ± 8.37 a | 24.40 ± 2.89 a | 26.83 ± 6.55 a | 36.07 ± 19.62 a | 34.57 ± 12.88 a | 0.671 |

| 20:5 n-3 | 170.80 ± 13.96 a | 194.98 ± 60.42 a | 132.19 ± 13.20 a | 137.34 ± 25.54 a | 205.19 ± 117.02 a | 134.62 ± 1.30 a | 0.441 |

| 22:5 n-3 | 85.42 ± 8.12 a | 105.27 ± 36.94 a | 69.60 ± 8.88 a | 79.36 ± 26.90 a | 108.46 ± 66.37 a | 309.67 ± 347.85 a | 0.379 |

| 22:6 n-3 | 364.45 ± 33.17 a | 443.50 ± 90.23 a | 303.96 ± 26.21 a | 356.27 ± 83.16 a | 441.62 ± 232.82 a | 162.42 ± 229.70 a | 0.237 |

| Total | 3336.49 ± 348.00 a | 3828.13 ± 1163.13 a | 2563.98 ± 280.73 a | 2741.96 ± 1026.70 a | 4232.61 ± 2790.97 a | 3464.94 ± 1688.80 a | 0.739 |

| SFA (%) | 24.72 ± 0.18 a | 24.60 ± 0.03 a | 24.41 ± 1.00 a | 24.03 ± 0.81 a | 24.46 ± 0.61 a | 24.14 ±0.95 a | 0.822 |

| MUFA (%) | 41.57 ± 0.46 a | 40.39 ± 0.76 a | 40.61 ± 1.21 a | 39.65 ± 2.65 a | 40.59 ± 3.50 a | 40.75 ± 3.88 a | 0.962 |

| PUFA (%) | 33.71 ± 0.35 a | 35.01 ± 0.78 a | 34.98 ± 0.37 a | 36.32 ± 3.47 a | 34.94 ± 3.16 a | 35.11 ± 4.83 a | 0.923 |

| n-3 PUFA (%) | 21.38 ± 0.43 a | 22.35 ± 0.94 a | 22.52 ± 0.43 a | 24.11 ± 3.16 a | 22.54 ± 3.56 a | 21.81 ± 5.52 a | 0.911 |

| n-6 PUFA (%) | 12.32 ± 0.09 ab | 12.66 ± 0.16 ab | 12.46 ± 0.07 ab | 12.21 ± 0.31 b | 12.40 ± 0.50 ab | 13.30 ± 0.69 a | 0.044 |

| Σ n-6/Σ n-3 | 0.57 ± 0.02 a | 0.57 ± 0.03 a | 0.55 ± 0.01 a | 0.51 ± 0.06 a | 0.56 ± 0.10 a | 0.64 ± 0.19 a | 0.6812 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tappi, S.; Nissen, L.; Pinheiro, A.C.D.A.S.; D’Elia, F.; Casciano, F.; Antonelli, G.; Chiarello, E.; Soglia, F.; Baldi, G.; Capelli, F.; et al. Microbial and Quality Changes of Seabream Fillets Processed with Cold Plasma During Refrigerated Storage. Foods 2025, 14, 1443. https://doi.org/10.3390/foods14091443

Tappi S, Nissen L, Pinheiro ACDAS, D’Elia F, Casciano F, Antonelli G, Chiarello E, Soglia F, Baldi G, Capelli F, et al. Microbial and Quality Changes of Seabream Fillets Processed with Cold Plasma During Refrigerated Storage. Foods. 2025; 14(9):1443. https://doi.org/10.3390/foods14091443

Chicago/Turabian StyleTappi, Silvia, Lorenzo Nissen, Ana Cristina De Aguiar Saldanha Pinheiro, Fabio D’Elia, Flavia Casciano, Giorgia Antonelli, Elena Chiarello, Francesca Soglia, Giulia Baldi, Filippo Capelli, and et al. 2025. "Microbial and Quality Changes of Seabream Fillets Processed with Cold Plasma During Refrigerated Storage" Foods 14, no. 9: 1443. https://doi.org/10.3390/foods14091443

APA StyleTappi, S., Nissen, L., Pinheiro, A. C. D. A. S., D’Elia, F., Casciano, F., Antonelli, G., Chiarello, E., Soglia, F., Baldi, G., Capelli, F., Gianotti, A., Bordoni, A., Petracci, M., Capozzi, F., Dalla Rosa, M., & Rocculi, P. (2025). Microbial and Quality Changes of Seabream Fillets Processed with Cold Plasma During Refrigerated Storage. Foods, 14(9), 1443. https://doi.org/10.3390/foods14091443