Influence of Drying Methods on the Post-Harvest Quality of Coffee: Effects on Physicochemical, Sensory, and Microbiological Composition

Abstract

1. Introduction

2. Materials and Methods

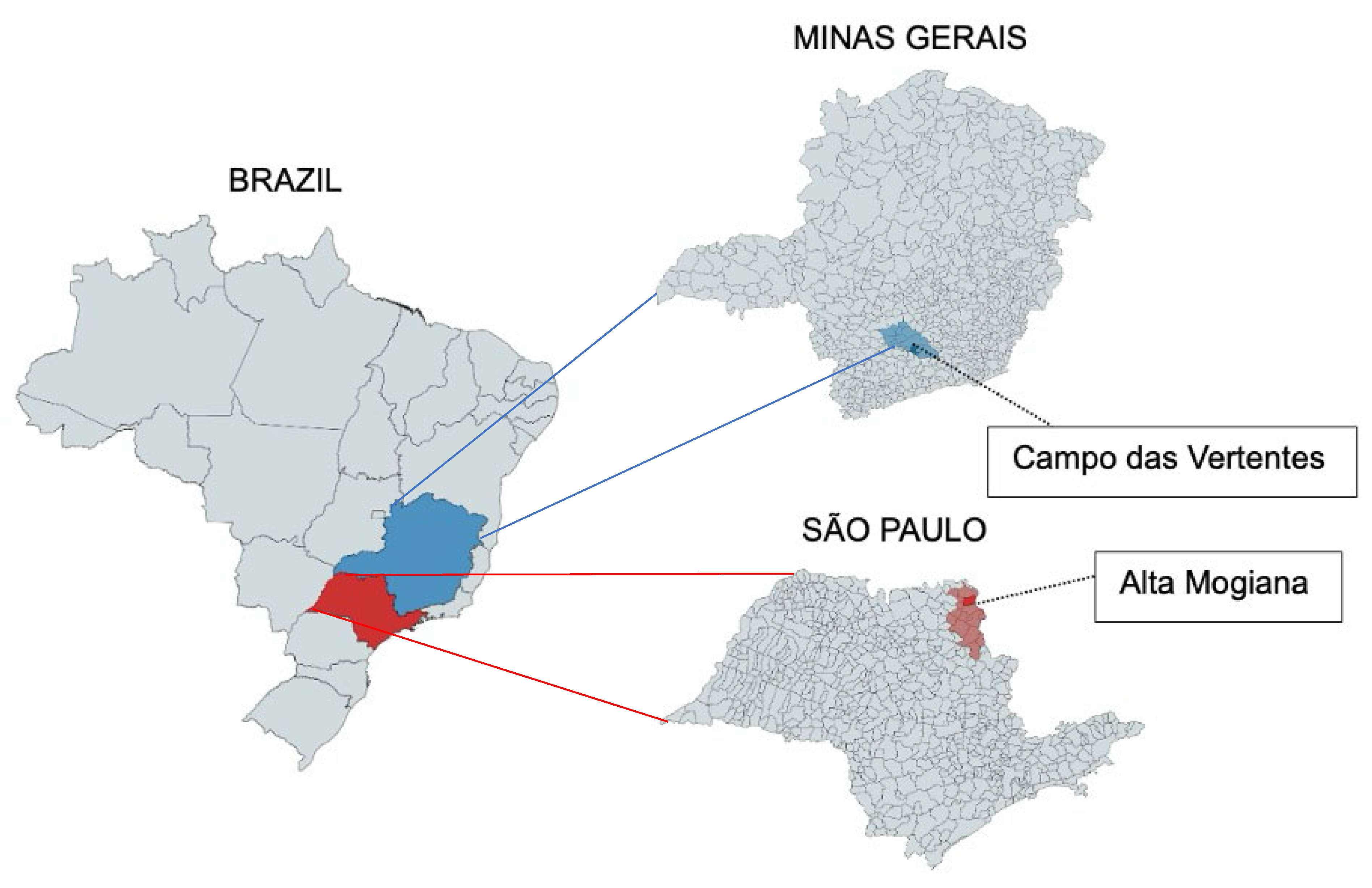

2.1. Plant Material and Study Region

2.2. Experimental Design for Drying Green Arabica Coffee Beans

2.3. Physicochemical Analysis

2.4. Colorimetric Parameters

2.5. Phenolic Compounds and Antioxidant Capacity

2.6. Hygienic and Sanitary Qualities of Dried Coffee Beans

2.7. Isolation and Morphological Identification of Fungi

2.8. Ochratoxin A Detection

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Results and Discussion

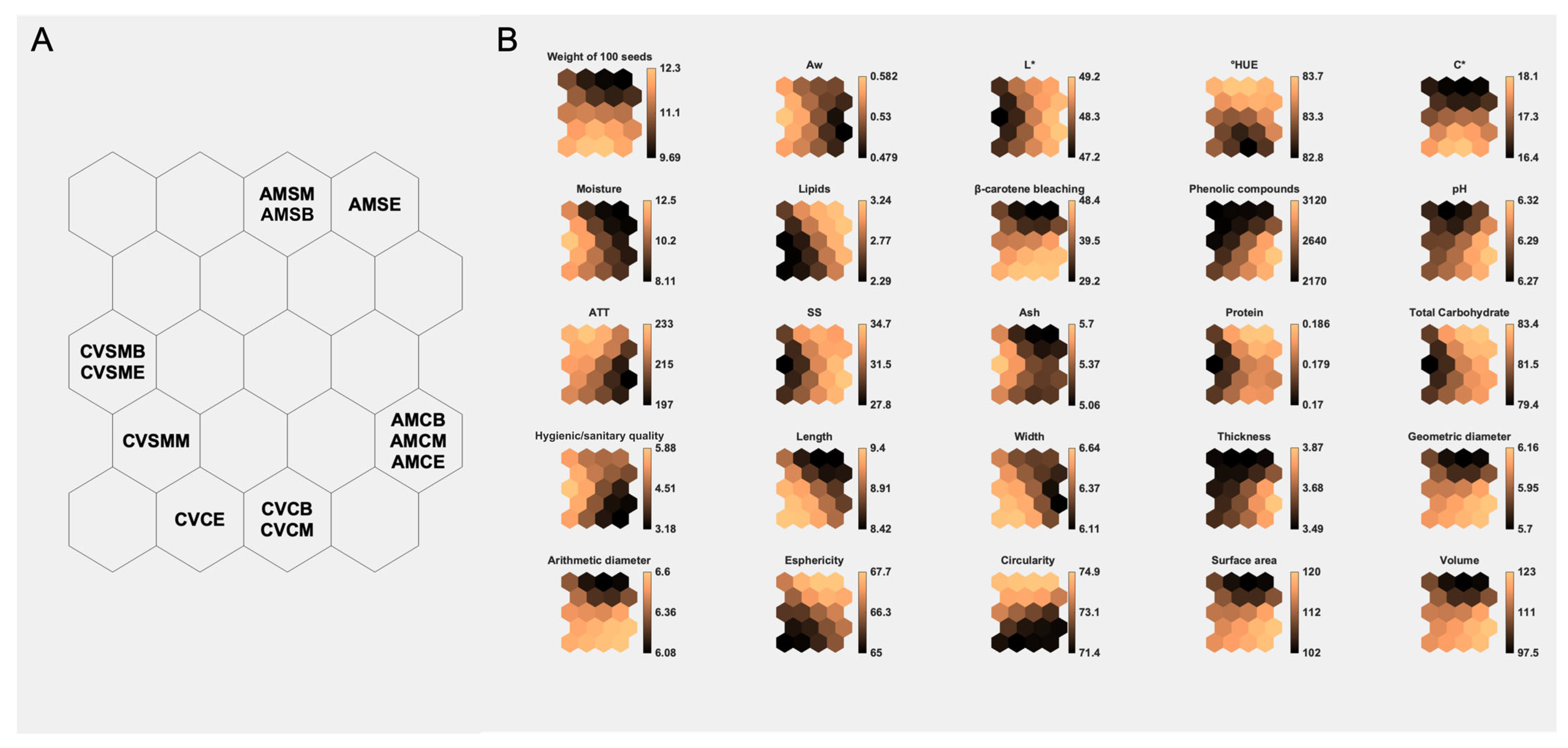

3.1. Evaluation of the Physicochemical Parameters of SOMs

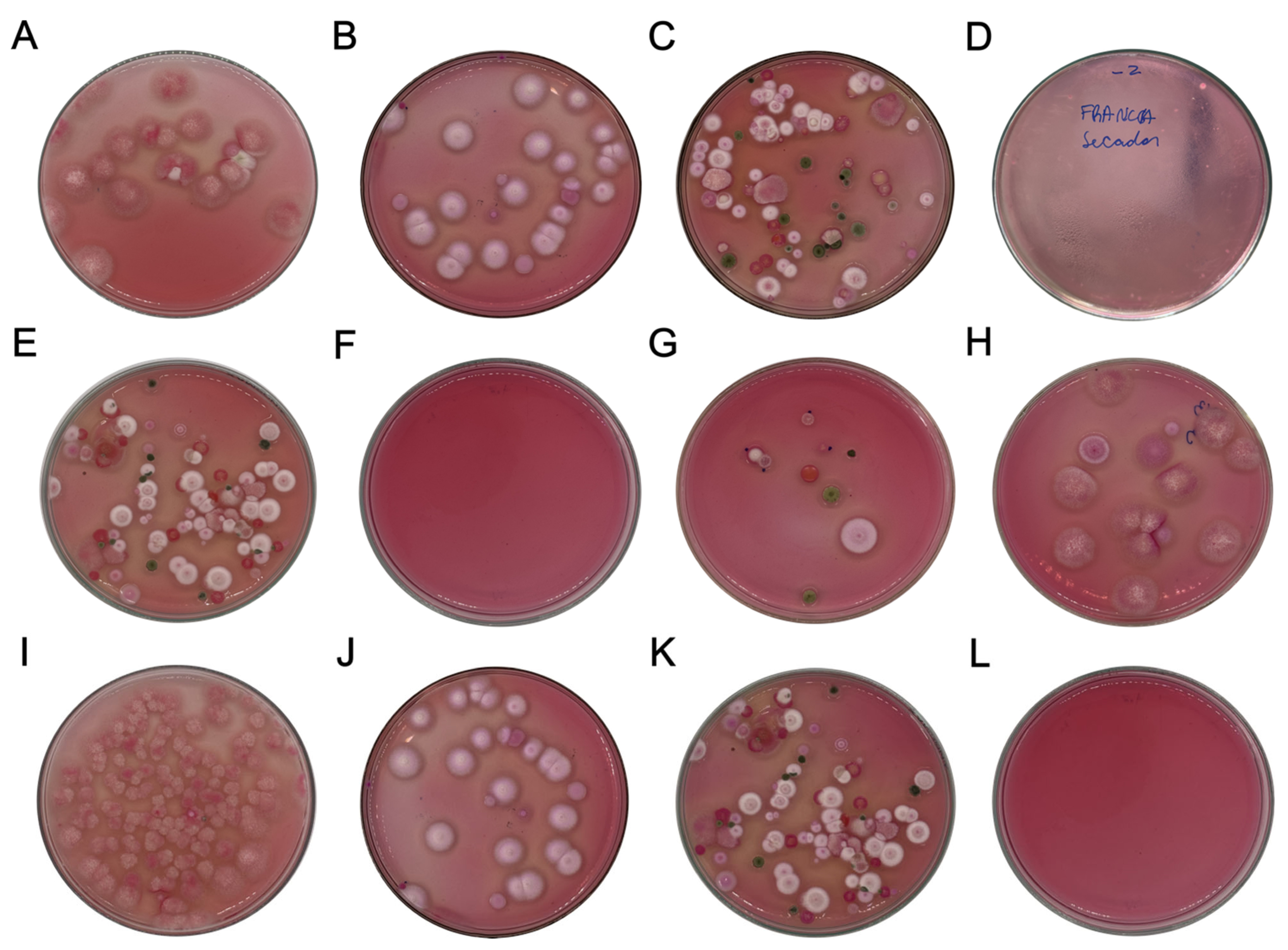

3.2. Microbiological Analysis by SOM, Presence/Absence of Ochratoxin A, and Morphological Identification of Filamentous Fungi

3.3. Bioactive Compounds Produced by SOM

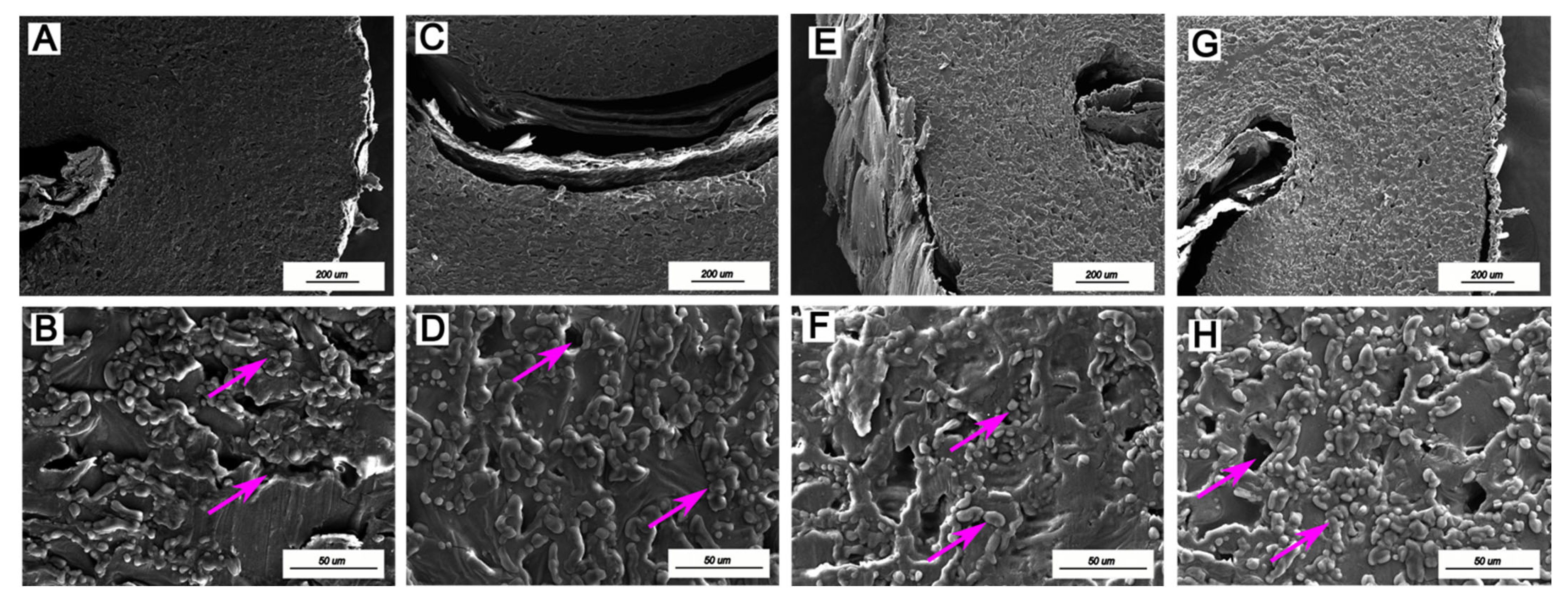

3.4. Scanning Electron Microscopy (SEM)

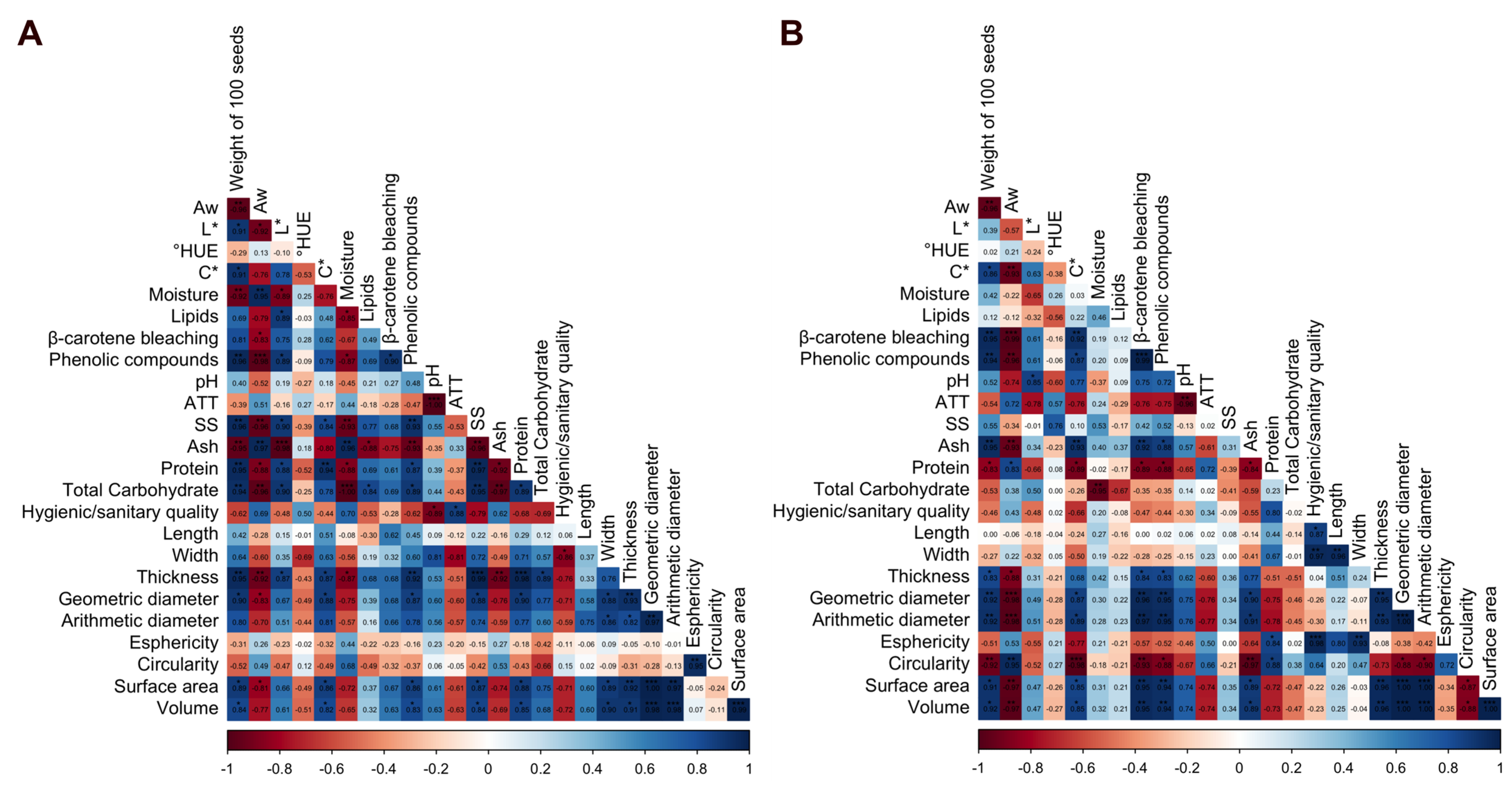

3.5. Pearson’s Correlation

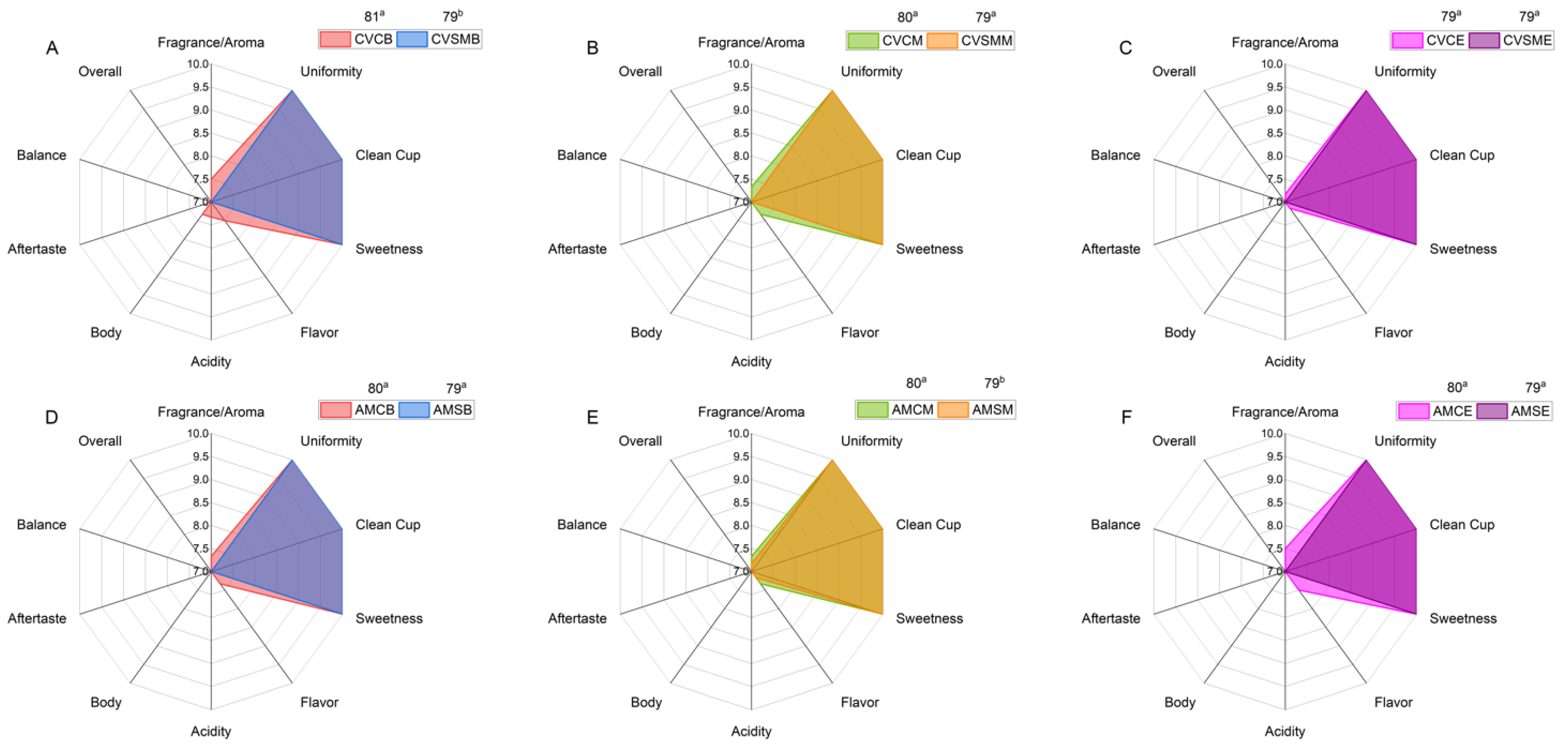

3.6. Sensory Analysis of the Coffee Beverages

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CONAB. Companhia Nacional de Abastecimento. Acompanhamento da Safra Brasileira. 2025. Vol. 11. Available online: https://www.conab.gov.br/info-agro/safras/cafe/boletim-da-safra-de-cafe#:~:text=Boletim%20Caf%C3%A9%20janeiro%202025%0A(3065%20Downloads) (accessed on 2 April 2025).

- ICO—International Coffee Association. World Coffee Consumption. 2024. Available online: https://www.icocoffee.org/documents/cy2023-24/cmr-0124-e.pdf (accessed on 2 April 2025).

- Freitas, V.V.; Borges, L.L.R.; Vidigal, M.C.T.R.; dos Santos, M.H.; Stringheta, P.C. Coffee: A comprehensive overview of origin, market, and the quality process. Trends Food Sci. Technol. 2024, 146, 104411. [Google Scholar] [CrossRef]

- United States Department of Agriculture (USDA). Coffee: World Markets and Trade. Foreign Agricultural Service. 2023. Available online: https://apps.fas.usda.gov/psdonline/circulars/coffee.pdf (accessed on 2 April 2025).

- Worku, M.; Astatkie, T.; Boeckx, P. Quality and biochemical composition of Ethiopian coffee varied with growing region and locality. J. Food Compos. Anal. 2023, 115, 105015. [Google Scholar] [CrossRef]

- da Silva Oliveira, E.C.; da Luz, J.M.R.; de Castro, M.G.; Filgueiras, P.R.; Guarçoni, R.C.; de Castro, E.V.R.; de Cássia Soares da Silva, M.; Pereira, L.L. Chemical and sensory discrimination of coffee: Impacts of the planting altitude and fermentation. Eur. Food Res. Technol. 2022, 248, 659–669. [Google Scholar] [CrossRef]

- Jakkaew, P.; Yingchutrakul, Y.; Aunsri, N. A data-driven approach to improve coffee drying: Combining environmental sensors and chemical analysis. PLoS ONE 2024, 19, e0296526. [Google Scholar] [CrossRef]

- de Andrade, P.S.; Duarte, C.R.; de Souza Barrozo, M.A. Improving the quality of Arabica coffee (Coffea arabica L.) through innovative optimization of roto-aerated drying. Innov. Food Sci. Emerg. Technol. 2024, 96, 103770. [Google Scholar] [CrossRef]

- Dong, W.; Hu, R.; Chu, Z.; Zhao, J.; Tan, L. Effect of different drying techniques on bioactive components, fatty acid composition, and volatile profile of robusta coffee beans. Food Chem. 2017, 234, 121–130. [Google Scholar] [CrossRef]

- Hii, C.L.; Borém, F.M. Drying and Roasting of Cocoa and Coffee, 1st ed.; CRC Press: Boca Raton, FL, USA, 2020; Volume 1. [Google Scholar]

- Konopatzki, E.A.; Christ, D.; Coelho, S.R.M.; Demito, A.; Werncke, I.; Rafaela, R.G. COFFEE DRYER WITH DEHYDRATED AIR: A TECHNICAL AND ECONOMIC VIABILITY ANALYSIS. Eng. Agric. 2022, 42, e20210003. [Google Scholar] [CrossRef]

- Dryeration. Secador de Café DRYERATION—COFFEE DRYER. 2025. Available online: https://www.dryeration.com.br/secador-de-cafe/ (accessed on 2 April 2025).

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials, 2nd ed.; Gordon and Breach: New York, NY, USA, 1986; Volume 1, Available online: http://www.sidalc.net/cgi-bin/wxis.exe/?IsisScript=UACHBC.xis&method=post&formato=2&cantidad=1&expresion=mfn=005902 (accessed on 2 April 2025).

- AOAC. Association of Official Analytical Chemists, 20th ed.; Horwits, W., Latimer, G.W., Eds.; AOAC International: Rockville, MD, USA, 2016; Available online: http://sutlib2.sut.ac.th/sut_contents/H125800.pdf (accessed on 2 April 2025).

- Rufino, M.d.S.M.; Alves, R.E.; de Brito, E.S.; Pérez-Jiménez, J.; Saura-Calixto, F.; Mancini-Filho, J. Bioactive compounds and antioxidant capacities of 18 nontraditional tropical fruits from Brazil. Food Chem. 2010, 121, 996–1002. [Google Scholar] [CrossRef]

- Waterhouse, A.L. Determination of total phenolics. Curr. Protoc. Food Anal. Chem. 2002, 6, I1.1.1–I1.1.8. [Google Scholar]

- Ryu, D.; Wolf-Hall, C. Yeasts and molds. In Compendium of Methods for The Microbiological Examination of Foods; American Public Health Association: Washington, DC, USA, 2015. [Google Scholar]

- Klich, M.A. Identification of Common Aspergillus Species; Centraal Bureau Voor Schimmelcultures: Utrecht, The Netherlands, 2002. [Google Scholar]

- Pitt, J.I. A Laboratory Guide to Common Penicillium Species; CSIRO, Division of Food Research: North Ryde, NSW, Australia, 1985. [Google Scholar]

- Pitt, J.I.; Hocking, A.D. Fungi and Food Spoilage; Springer: New York, NY, USA, 2009; Volume 519. [Google Scholar]

- Samson, R.A. Introduction to Food and Airborne Fungi; American Society Microbiology: Washington, DC, USA, 2002. [Google Scholar]

- Lingle, T.R. The Coffee Brewing Handbook: A Systematic Guide to Coffee Preparation; Specialty Coffee Association of America: Irvine, CA, USA, 2011. [Google Scholar]

- Agnoletti, B.Z.; Pereira, L.L.; Alves, E.A.; Rocha, R.B.; Debona, D.G.; Lyrio, M.V.V.; Moreira, T.R.; de Castro, E.V.R.; Oliveira, E.C.d.S.; Filgueiras, P.R. The terroir of Brazilian Coffea canephora: Characterization of the chemical composition. Food Res. Int. 2024, 176, 113814. [Google Scholar] [CrossRef]

- Brige, F.A.A.; Celestino, S.M.C.; Amabile, R.F.; Fagioli, M.; Delvico, F.M.d.S.; Montalvão, A.P.L.; Sala, P.I.A.L. Genetic variability in conilon coffee related to grain attributes in an irrigated crop in the Cerrado. Pesqui. Agropecuária Bras. 2019, 54, e00358. [Google Scholar] [CrossRef]

- Celestino, S.M.C.; Veiga, A.D. Caracterização físico-química e produtividade de grãos de cafeeiros do banco de germoplasma da Embrapa Cerrados. In Proceedings of the X Simpósio de Pesquisa Dos Cafés Do Brasil, Vitória, ES, Brazil, 8–11 October 2019. [Google Scholar]

- Silva, S.d.A.; de Queiroz, D.M.; Pinto, F.d.A.C.; Santos, N.T. Coffee quality and its relationship with Brix degree and colorimetric information of coffee cherries. Precis. Agric. 2014, 15, 543–554. [Google Scholar] [CrossRef]

- Ministério da Agricultura, Pecuária e Abastecimento. Instrução Normativa no. 8, de 11 DE Junho de 2003. Brasil. 2003. Available online: https://sistemasweb.agricultura.gov.br/sislegis/action/detalhaAto.do?method=recuperarTextoAtoTematicaPortal&codigoTematica=1229303#:~:text=5.1.,doze%20e%20meio%20por%20cento).&text=6.1.,%25%20(um%20por%20cento) (accessed on 2 April 2025).

- de Abreu, D.J.M.; Carvalho, E.E.N.; Vilas Boas, E.V.d.B.; Asquieri, E.R.; Damiani, C. Antioxidant Capacity of Bioactive Compounds from Undervaluated Red Mombin Seed (Spondias purpurea L.) Affected by Different Drying Stages. ACS Food Sci. Technol. 2021, 1, 707–716. [Google Scholar] [CrossRef]

- Rocha, H.A.; Correa, J.L.G.; Borém, F.M. Vacuum drying of peeled coffee cherry beans: Drying kinetics and physiological effects. Coffee Sci. 2021, 16, e161921. [Google Scholar] [CrossRef]

- Tran, H.T.M.; Vargas, C.A.C.; Slade Lee, L.; Furtado, A.; Smyth, H.; Henry, R. Variation in bean morphology and biochemical composition measured in different genetic groups of arabica coffee (Coffea arabica L.). Tree Genet. Genomes 2017, 13, 54. [Google Scholar] [CrossRef]

- do Amaral, A.D.; Medeiros, S.L.P.; de Menezes, N.L.; da Luz, G.L.; Pivoto, D.; Bialozor, A. Qualidade de sementes de canola classificadas por densidade. Rev. Bras. Sementes 2012, 34, 302–309. [Google Scholar] [CrossRef]

- Sharma, V.; Das, L.; Pradhan, R.C.; Naik, S.N.; Bhatnagar, N.; Kureel, R.S. Physical properties of tung seed: An industrial oil yielding crop. Ind. Crops Prod. 2011, 33, 440–444. [Google Scholar] [CrossRef]

- Araujo, M.E.V.; Corrêa, P.C.; Barbosa, E.G.; Martins, M.A. Determination and modeling of physical and aerodynamic properties of coffee beans (Coffea arabica) during the drying process. J. Food Process. Preserv. 2021, 45, e15698. [Google Scholar] [CrossRef]

- Hu, D.; Yang, G.; Liu, X.; Qin, Y.; Zhang, F.; Sun, Z.; Wang, X. Comparison of different drying technologies for coffee pulp tea: Changes in color, taste, bioactive and aroma components. LWT 2024, 200, 116193. [Google Scholar] [CrossRef]

- Coelho, E.G.; Bertarini, P.L.L.; Gomes, M.S.; Amaral, L.R.; Zotarelli, M.F.; Santos, L.D.; Santana, R.C. Physicochemical and Sensory Properties of Arabica Coffee Beans of Arara cv. Dried Using Different Methods. Foods 2024, 13, 642. [Google Scholar] [CrossRef]

- Hu, D.; Liu, X.; Qin, Y.; Yan, J.; Li, R.; Yang, Q. The impact of different drying methods on the physical properties, bioactive components, antioxidant capacity, volatile components and industrial application of coffee peel. Food Chem. X 2023, 19, 100807. [Google Scholar] [CrossRef] [PubMed]

- Kulapichitr, F.; Borompichaichartkul, C.; Fang, M.; Suppavorasatit, I.; Cadwallader, K.R. Effect of postharvest drying process on chlorogenic acids, antioxidant activities and CIE-Lab color of Thai Arabica green coffee beans. Food Chem. 2022, 366, 130504. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.F.; Batista, L.R.; Schwan, R.F. Incidence and distribution of filamentous fungi during fermentation, drying and storage of coffee (Coffea arabica L.) beans. Braz. J. Microbiol. 2008, 39, 521–526. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Tibpromma, S.; Karunarathna, S.C.; Jayawardena, R.S.; Lumyong, S.; Xu, J.; Hyde, K.D. Comprehensive Review of Fungi on Coffee. Pathogens 2022, 11, 411. [Google Scholar] [CrossRef]

- Brasil. Agência Nacional de Vigilância Sanitária (ANVISA). Intrução normativa no 160, de 1° de julho de 2022. Available online: https://www.in.gov.br/en/web/dou/-/instrucao-normativa-in-n-160-de-1-de-julho-de-2022-413367081 (accessed on 2 April 2025).

- European Union. REGLAMENTO (UE) 2023/915 DE LA COMISIÓN, 2023. Available online: http://data.europa.eu/eli/reg/2023/915/oj (accessed on 2 April 2025).

- Kim, J.; Nedwidek-Moore, M.; Kim, K. Safest Roasting Times of Coffee To Reduce Carcinogenicity. J. Food Prot. 2022, 85, 918–923. [Google Scholar] [CrossRef]

- Yusibani, E.; Woodfield, P.L.; Rahwanto, A.; Surbakti, M.S.; Rajibussalim, R.; Rahmi, R. Physical and Chemical Properties of Indonesian Coffee Beans for Different Postharvest Processing Methods. J. Eng. Technol. Sci. 2023, 55, 1–11. [Google Scholar] [CrossRef]

- SCA. Protocols Best Practices. Cupping Protocols. 2004. Available online: https://sca.coffee/research/protocols-best-practices (accessed on 2 April 2025).

- Osorio Pérez, V.; Matallana Pérez, L.G.; Fernandez-Alduenda, M.R.; Alvarez Barreto, C.I.; Gallego Agudelo, C.P.; Montoya Restrepo, E.C. Chemical Composition and Sensory Quality of Coffee Fruits at Different Stages of Maturity. Agronomy 2023, 13, 341. [Google Scholar] [CrossRef]

- Borém, F.M.; Coradi, P.C.; Saath, R.; Oliveira, J.A. Qualidade do café natural e despolpado após secagem em terreiro e com altas temperaturas. Ciênc. Agrotecnol. 2008, 32, 1609–1615. [Google Scholar] [CrossRef]

| Region | Drying Method | Genus/Species |

|---|---|---|

| Alta Mogiana | CoffeeDryer® | Fusarium sp. Penicillium implicatum |

| Alta Mogiana | Sun Dryer | Penicillium sp. Fusarium sp. |

| Campo das Vertentes | CoffeeDryer® | Rhizopus sp. Penicillium citrinum Cladosporium cladosporioides |

| Campo das Vertentes | Sun + Mechanical dryer | Aspergillus ochraceus Penicillium brevicompactum |

| Parameter | Campo das Vertentes | Alta Mogiana | Detection Limit (μg.kg−1) | |||||

|---|---|---|---|---|---|---|---|---|

| Begin | Middle | End | Begin | Middle | End | Brazil 1 | European Union 2 | |

| Ochratoxin A (μg.kg−1) | <2.5 | <2.5 | <2.5 | <2.5 | <2.5 | <2.5 | ≤10.0 | ≤5.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abreu, D.J.M.d.; Lorenço, M.S.; Machado, G.G.L.; Silva, J.M.; Azevedo, E.C.d.; Carvalho, E.E.N. Influence of Drying Methods on the Post-Harvest Quality of Coffee: Effects on Physicochemical, Sensory, and Microbiological Composition. Foods 2025, 14, 1463. https://doi.org/10.3390/foods14091463

Abreu DJMd, Lorenço MS, Machado GGL, Silva JM, Azevedo ECd, Carvalho EEN. Influence of Drying Methods on the Post-Harvest Quality of Coffee: Effects on Physicochemical, Sensory, and Microbiological Composition. Foods. 2025; 14(9):1463. https://doi.org/10.3390/foods14091463

Chicago/Turabian StyleAbreu, Danilo José Machado de, Mário Sérgio Lorenço, Gilson Gustavo Lucinda Machado, Joana Moratto Silva, Estela Corrêa de Azevedo, and Elisângela Elena Nunes Carvalho. 2025. "Influence of Drying Methods on the Post-Harvest Quality of Coffee: Effects on Physicochemical, Sensory, and Microbiological Composition" Foods 14, no. 9: 1463. https://doi.org/10.3390/foods14091463

APA StyleAbreu, D. J. M. d., Lorenço, M. S., Machado, G. G. L., Silva, J. M., Azevedo, E. C. d., & Carvalho, E. E. N. (2025). Influence of Drying Methods on the Post-Harvest Quality of Coffee: Effects on Physicochemical, Sensory, and Microbiological Composition. Foods, 14(9), 1463. https://doi.org/10.3390/foods14091463