Dietary Fibres in Processed Meat: A Review on Nutritional Enhancement, Technological Effects, Sensory Implications and Consumer Perception

Abstract

1. Introduction

2. Aspects Regarding the Necessity of Enriching Meat Products with Fibre Sources

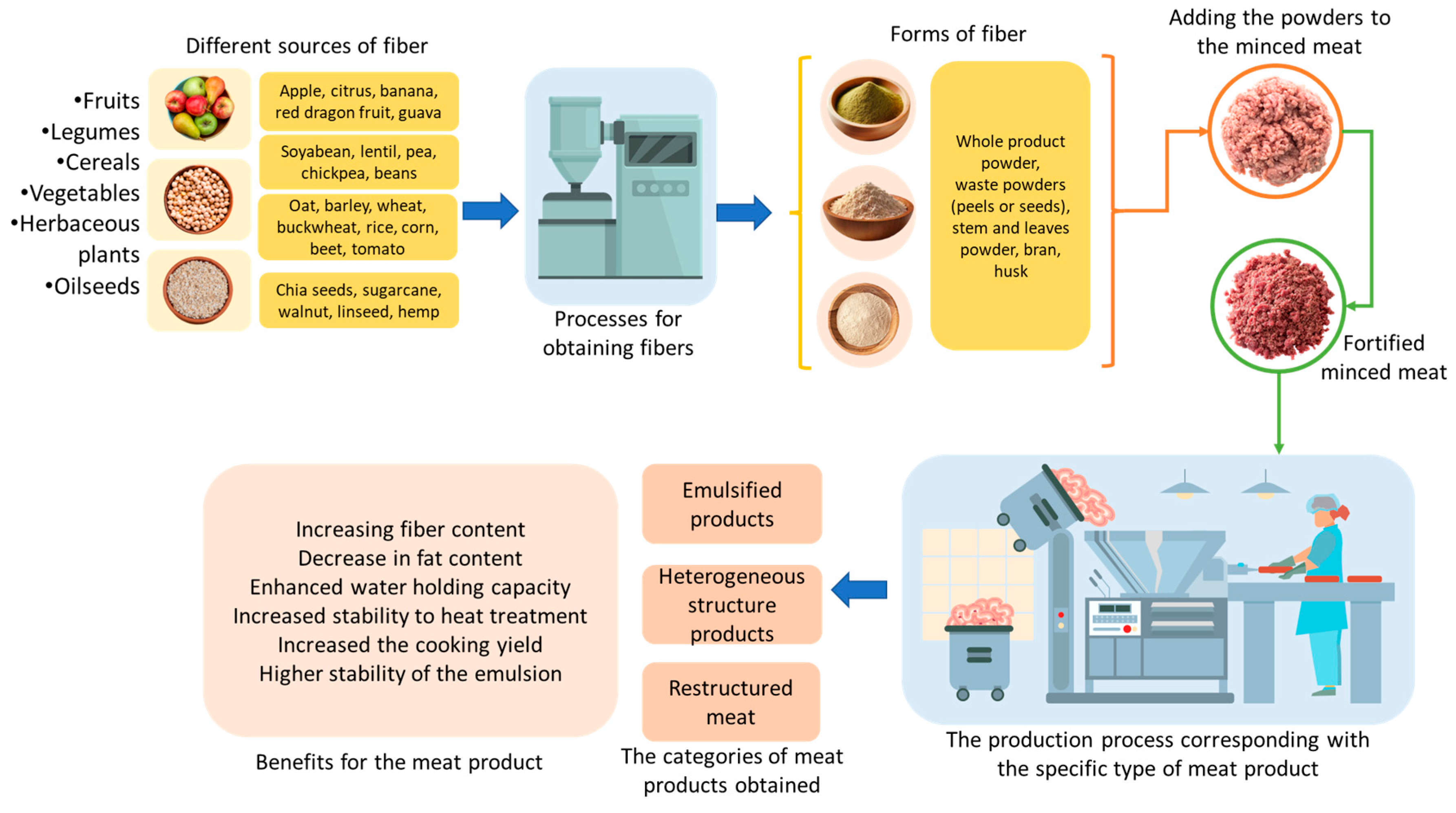

3. Meat Products Suitable for Fibre Addition

4. Dietary Fibres: Classification, Categorisation, and Application in Meat Products

5. Influence of Dietary Fibre Addition in Meat Products

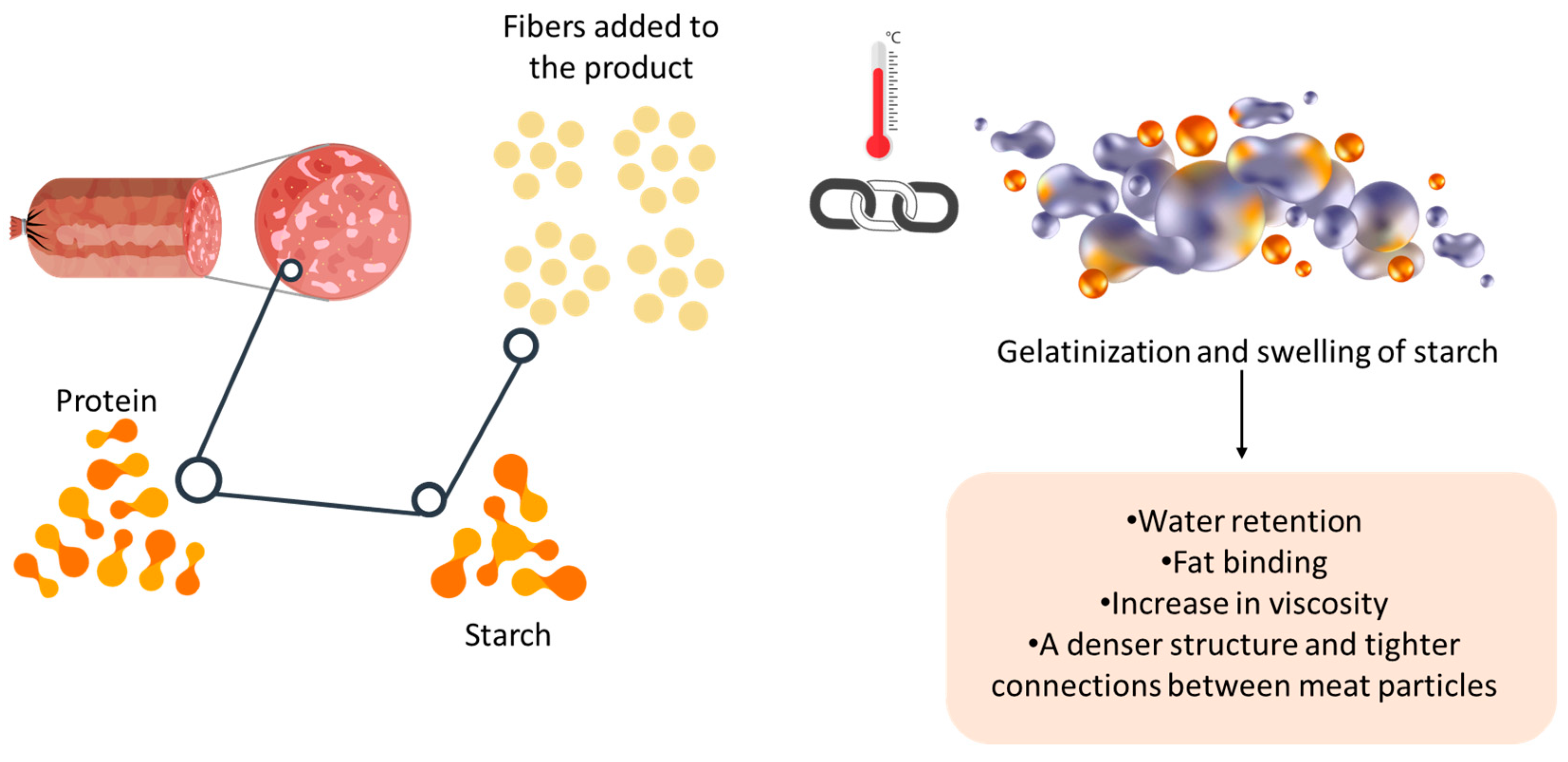

5.1. The Effect on Technological Properties

5.1.1. Influence on the Acidity of Meat Products

5.1.2. Influence on Water-Holding Capacity

5.1.3. Influence on Cooking Yield

5.1.4. Influence on Emulsion Stability

5.1.5. Influence on Diameter Reduction

5.1.6. Influence on Water Activity

5.2. The Effect on Physical Quality Attributes

5.2.1. Influence on Meat Product Texture

5.2.2. Influence on Meat Product Colour

5.3. The Effect on the Chemical Composition

5.3.1. The Impact of Cereal-Based Fibres

5.3.2. The Effect of Vegetable-Based Fibres

5.3.3. The Influence of Fruit-Derived Fibres

5.3.4. The Impact of Oilseed-Derived Fibres

5.4. The Effect on Sensory Characteristics and Consumer Perception

5.5. Functional Role of Dietary Fibres in Meat Product Stability

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Díaz-Rodríguez, M.A.; Salcedo Gastelum, L.A.; Félix Pablos, C.M.; Isela, F.; Santoyo, G.; Puente, M.L.; Bhattacharya, D.; Mukherjee, J. The Current and Future Role of Microbial Culture Collections in Food Security Worldwide. Front. Sustain. Food Syst. 2021, 4, 614739. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P.; Roser, M. Meat and Dairy Production. Our World in Data. 2017. Available online: https://ourworldindata.org/meat-production (accessed on 14 December 2024).

- FAO. Meat Market Review: Overview of Global Market Developments in 2023; FAO: Rome, Italy, 2024; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/ae4eb1ec-613d-478c-8361-c9bdba1df559/content (accessed on 14 December 2024).

- OECD. Meat Consumption. 2024. Available online: https://www.oecd.org/en/data/indicators/meat-consumption.html?oecdcontrol-106b3c3fe2-var3=2024 (accessed on 14 December 2024).

- Higgs, J.D. The Changing Nature of Red Meat: 20 Years of Improving Nutritional Quality. Trends Food Sci. Technol. 2000, 11, 85–95. [Google Scholar] [CrossRef]

- Scollan, N.; Price, E.; Morgan, S.; Huws, S.; Shingfield, K. Can We Improve the Nutritional Quality of Meat? Proc. Nutr. Soc. 2017, 76, 603–618. [Google Scholar] [CrossRef] [PubMed]

- Kausar, T.; Hanan, E.; Ayob, O.; Praween, B.; Azad, Z. A Review on Functional Ingredients in Red Meat Products. Bioinformation 2019, 15, 358–363. [Google Scholar] [CrossRef]

- Soren, N.M.; Biswas, A.K. Methods for Nutritional Quality Analysis of Meat. In Meat Quality Analysis; Elsevier: Amsterdam, The Netherlands, 2020; pp. 21–36. [Google Scholar] [CrossRef]

- Cordts, A.; Nitzko, S.; Spiller, A. Consumer Response to Negative Information on Meat Consumption in Germany. Int. Food Agribus. Manag. Rev. 2014, 17, 83–106. [Google Scholar] [CrossRef]

- Vandermoere, F.; Geerts, R.; De Backer, C.; Erreygers, S.; Van Doorslaer, E. Meat Consumption and Vegaphobia: An Exploration of the Characteristics of Meat Eaters, Vegaphobes, and Their Social Environment. Sustainability 2018, 11, 3936. [Google Scholar] [CrossRef]

- Liu, J.; Chriki, S.; Kombolo, M.; Santinello, M.; Pflanzer, S.B.; Hocquette, É.; Ellies-Oury, M.; Hocquette, J. Consumer Perception of the Challenges Facing Livestock Production and Meat Consumption. Meat Sci. 2023, 200, 109144. [Google Scholar] [CrossRef]

- McAfee, A.J.; McSorley, E.M.; Cuskelly, G.J.; Moss, B.W.; Wallace, J.M.; Bonham, M.P.; Fearon, A.M. Red Meat Consumption: An Overview of the Risks and Benefits. Meat Sci. 2009, 84, 1–13. [Google Scholar] [CrossRef]

- Clonan, A.; Wilson, P.; Swift, J.; Leibovici, D.; Holdsworth, M. Red and Processed Meat Consumption and Purchasing Behaviours and Attitudes: Impacts for Human Health, Animal Welfare and Environmental Sustainability. Public Health Nutr. 2015, 18, 2446–2456. [Google Scholar] [CrossRef]

- O’Grady, M.N.; Kerry, J.P. The Effect of Non-Meat Ingredients on Quality Parameters in Meat and Poultry. In Chemical Deterioration and Physical Instability of Food and Beverages; Woodhead Publishing: Cambridge, UK, 2010; pp. 701–725. [Google Scholar] [CrossRef]

- Verma, A.K.; Rajkumar, V.; Banerjee, R.; Biswas, S.; Das, A.K. Guava (Psidium guajava L.) Powder as an Antioxidant Dietary Fibre in Sheep Meat Nuggets. Asian-Australas. J. Anim. Sci. 2013, 26, 886–895. [Google Scholar] [CrossRef]

- Pame, K.; Daimary, B.; Sanjib, B. Utilization of Dietary Fibre in Meat Products as Functional Foods. Int. J. Agric. Environ. Biotechnol. 2022, 15, 147–151. [Google Scholar] [CrossRef]

- Calderón-Oliver, M.; López-Hernández, L.H. Food Vegetable and Fruit Waste Used in Meat Products. Food Rev. Int. 2020, 38, 628–654. [Google Scholar] [CrossRef]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Serna-Saldivar, S.O.; Welti-Chanes, J.; Garcia-Amezquita, L.E. Dietary Fiber Concentrates from Fruit and Vegetable By-Products: Processing, Modification, and Application as Functional Ingredients. Food Bioprocess. Technol. 2018, 11, 1439–1463. [Google Scholar] [CrossRef]

- Titov, E.I.; Sokolov, A.Y.; Litvinova, E.V.; Kidyaev, S.N.; Shishkina, D.I.; Baranov, B.A. Dietary Fibres in Preventative Meat Products. Foods Raw Mater. 2019, 7, 387–395. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Y.; Yang, Q.; Guo, J.; Zhou, S.; Zhong, T.; Wang, L. The Impact of Dietary Fiber on Cardiovascular Diseases: A Scoping Review. Nutrients 2025, 17, 444. [Google Scholar] [CrossRef] [PubMed]

- Barber, T.M.; Kabisch, S.; Pfeiffer, A.F.; Weickert, M.O. The Health Benefits of Dietary Fibre. Nutrients 2020, 12, 3209. [Google Scholar] [CrossRef]

- Das, A.K.; Nanda, P.K.; Madane, P.; Biswas, S.; Das, A.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Antioxidant Dietary Fibre Enriched Meat-Based Functional Foods. Trends Food Sci. Technol. 2020, 99, 323–336. [Google Scholar] [CrossRef]

- Scollan, N.D.; Dannenberger, D.; Nuernberg, K.; Richardson, I.; MacKintosh, S.; Hocquette, J.; Moloney, A.P. Enhancing the Nutritional and Health Value of Beef Lipids and Their Relationship with Meat Quality. Meat Sci. 2014, 97, 384–394. [Google Scholar] [CrossRef]

- Nikolic, D.; Jankovic, S.; Parunovic, N.; Djordjevic, V.; Petrovic, M.; Djordjevic, N. Nutrient Composition of Three Mangulica Pork Cuts from Serbia. Biol. Trace Elem. Res. 2018, 184, 369–377. [Google Scholar] [CrossRef]

- Das, A.; Biswas, S.; Nanda, P.K.; Chatterjee, N.; Pal, S.; Dhar, P.; Das, A.K. Moringa Pod Derived Antioxidant Dietary Fibre as a Quality Enhancer in Goat Meat Nuggets. Sustain. Food Technol. 2024, 2, 232–242. [Google Scholar] [CrossRef]

- Cobos, A.; Díaz, O. Chemical Composition of Meat and Meat Products. In Handbook of Food Chemistry; Cheung, P.C.K., Mehta, B.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; p. 484. [Google Scholar]

- Gawat, M.; Boland, M.; Singh, J.; Kaur, L. Goat Meat: Production and Quality Attributes. Foods 2022, 12, 3130. [Google Scholar] [CrossRef]

- Oh, M.; Kim, E.; Jeon, B.; Tang, Y.; Kim, M.S.; Seong, H.; Moon, S. Chemical Compositions, Free Amino Acid Contents and Antioxidant Activities of Hanwoo (Bos taurus coreanae) Beef by Cut. Meat Sci. 2016, 119, 16–21. [Google Scholar] [CrossRef] [PubMed]

- Vance, R.D.; Ockerman, H.W.; Cahill, V.R.; Plimpton, R.F. Chemical Composition as Related to Selected Measurements Used in Beef Carcass Evaluation. J. Anim. Sci. 1971, 33, 744–749. [Google Scholar] [CrossRef]

- Luchak, G.L.; Miller, R.K.; Belk, K.E.; Hale, D.S.; Michaelsen, S.A.; Johnson, D.D.; Savell, J.W. Determination of sensory, chemical and cooking characteristics of retail beef cuts differing in intramuscular and external Fat. Meat Sci. 1998, 50, 55–72. [Google Scholar] [CrossRef]

- Kim, M.; Choe, J.; Lee, H.J.; Yoon, Y.; Yoon, S.; Jo, C. Effects of Aging and Aging Method on Physicochemical and Sensory Traits of Different Beef Cuts. Food Sci. Anim. Resour. 2019, 39, 54–64. [Google Scholar] [CrossRef]

- Kim, C.; Lee, E. Effects of Quality Grade on the Chemical, Physical and Sensory Characteristics of Hanwoo (Korean Native Cattle) Beef. Meat Sci. 2003, 63, 397–405. [Google Scholar] [CrossRef] [PubMed]

- Patinho, I.; Cavalcante, C.L.; Saldaña, E.; Gagaoua, M.; Behrens, J.H.; Contreras-Castillo, C.J. Assessment of beef sensory attributes and physicochemical characteristics: A comparative study of intermediate versus normal ultimate ph striploin cuts. Food Res. Int. 2023, 175, 113778. [Google Scholar] [CrossRef]

- Greenfield, H.; Arcot, J.; Barnes, J.; Cunningham, J.; Adorno, P.; Stobaus, T.; Tume, R.; Beilken, S.; Muller, W. Nutrient composition of australian retail pork cuts 2005/2006. Food Chem. 2009, 117, 721–730. [Google Scholar] [CrossRef]

- Van Heerden, S.; Smith, M. The nutrient composition of three cuts obtained from P-Class South African pork carcasses. Food Chem. 2013, 140, 458–465. [Google Scholar] [CrossRef]

- Hamid, M.A.; Akhter, S.; Rahman, S.M.E.; Khan, M. Effect of Age and Wholesale Cuts on the Quality of Indigenous Sheep Carcass. Bangladesh J. Anim. Sci. 2008, 37, 32–38. [Google Scholar] [CrossRef]

- Fowler, S.M.; Morris, S.; Hopkins, D.L. Nutritional composition of lamb retail cuts from the carcases of extensively finished lambs. Meat Sci. 2019, 154, 126–132. [Google Scholar] [CrossRef]

- Campo, M.; Muela, E.; Resconi, V.; Barahona, M.; Sañudo, C. Influence of commercial cut on proximate composition and fatty acid profile of Rasa Aragonesa light lamb. J. Food Compos. Anal. 2016, 53, 7–12. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Jang, A. Nutritional and antioxidative properties of black goat meat cuts. Asian Australas. J. Anim. Sci. 2019, 32, 1423–1429. [Google Scholar] [CrossRef] [PubMed]

- Ayeb, N.; Ghrab, A.; Barmat, A.; Khorchani, T. Chemical and tissue composition of meat from carcass cuts of local goats affected by different feeding in Tunisian arid lands. Turk. J. Vet. Anim. Sci. 2016, 40, 95–101. [Google Scholar] [CrossRef]

- Soglia, F.; Mudalal, S.; Babini, E.; Di Nunzio, M.; Mazzoni, M.; Sirri, F.; Cavani, C.; Petracci, M. Histology, composition, and quality traits of chicken Pectoralis major muscle affected by wooden breast abnormality. Poult. Sci. 2016, 95, 651–659. [Google Scholar] [CrossRef]

- Jeon, H.J.; Choe, J.H.; Jung, Y.K.; Kruk, Z.A.; Lim, D.G.; Jo, C.R. Comparison of the chemical composition, textural characteristics, and sensory properties of North and South Korean native chickens and commercial broilers. Food Sci. Anim. Resour. 2010, 30, 171–178. [Google Scholar] [CrossRef]

- Ahmad, R.S.; Imran, A.; Hussain, M.B. Nutritional composition of meat. In Meat Science and Nutrition; Arshad, M.S., Ed.; IntechOpen: London, UK, 2018; pp. 61–75. [Google Scholar]

- Scanes, C.G. Carbohydrate metabolism. In Sturkie’s Avian Physiology, 7th ed.; Scanes, C.G., Dridi, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 613–645. [Google Scholar] [CrossRef]

- Buttriss, J.L.; Stokes, C.S. Dietary fibre and health: An overview. Nutr. Bull. 2008, 33, 186–200. [Google Scholar] [CrossRef]

- Rodríguez, R.; Jiménez, A.; Fernández-Bolaños, J.; Guillén, R.; Heredia, A. Dietary fibre from vegetable products as a source of functional ingredients. Trends Food Sci. Technol. 2005, 17, 3–15. [Google Scholar] [CrossRef]

- McRae, M.P. Dietary Fiber is Beneficial for the Prevention of Cardiovascular Disease: An Umbrella Review of Meta-analyses. J. Chiropr. Med. 2017, 16, 289–299. [Google Scholar] [CrossRef]

- Raman, M.; Nilsson, U.; Skog, K.; Lawther, M.; Nair, B.; Nyman, M. Physicochemical characterisation of dietary fibre components and their ability to bind some process-induced mutagenic heterocyclic amines, Trp-P-1, Trp-P-2, AαC and MeAαC. Food Chem. 2013, 138, 2219–2224. [Google Scholar] [CrossRef]

- Haque, A.; Ahmad, S.; Azad, Z.R.A.A.; Adnan, M.; Ashraf, S.A. Incorporating dietary fiber from fruit and vegetable waste in meat products: A systematic approach for sustainable meat processing and improving the functional, nutritional and health attributes. PeerJ 2023, 11, e14977. [Google Scholar] [CrossRef]

- Maćkowiak, K.; Torlińska-Walkowiak, N.; Torlińska, B. Dietary fibre as an important constituent of the diet. Adv. Hyg. Exp. Med. 2016, 70, 104–109. [Google Scholar] [CrossRef]

- Edwards, C.A.; Xie, C.; Garcia, A.L. Dietary fibre and health in children and adolescents. Proc. Nutr. Soc. 2015, 74, 292–302. [Google Scholar] [CrossRef]

- Stephen, A.M.; Champ, M.M.-J.; Cloran, S.J.; Fleith, M.; van Lieshout, L.; Mejborn, H.; Burley, V.J. Dietary fibre in Europe: Current state of knowledge on definitions, sources, recommendations, intakes and relationships to health. Nutr. Res. Rev. 2017, 30, 149–190. [Google Scholar] [CrossRef] [PubMed]

- Hervik, A.K.; Svihus, B. The role of fiber in energy balance. J. Nutr. Metab. 2019, 2019, 4983657. [Google Scholar] [CrossRef] [PubMed]

- Ozyurt, V.H.; Ötles, S. Effect of food processing on the physicochemical properties of dietary fibre. Acta Sci. Pol. Technol. Aliment. 2016, 15, 233–245. [Google Scholar] [CrossRef]

- Olmedilla-Alonso, B.; Jiménez-Colmenero, F.; Sánchez-Muniz, F.J. Development and assessment of healthy properties of meat and meat products designed as functional foods. Meat Sci. 2013, 95, 919–930. [Google Scholar] [CrossRef] [PubMed]

- Ragaee, S.; Abdel-Aal, E.M.; Noaman, M. Antioxidant activity and nutrient composition of selected cereals for food use. Food Chem. 2005, 98, 32–38. [Google Scholar] [CrossRef]

- Martínez, R.; Torres, P.; Meneses, M.A.; Figueroa, J.G.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, technological, and in vitro antioxidant properties of mango, guava, pineapple, and passion fruit dietary fibre concentrate. Food Chem. 2012, 135, 1520–1526. [Google Scholar] [CrossRef]

- López-Vargas, J.H.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, physico-chemical, technological, antibacterial, and antioxidant properties of dietary fiber powder obtained from yellow passion fruit (Passiflora edulis var. Flavicarpa) co-products. Food Res. Int. 2013, 51, 756–763. [Google Scholar] [CrossRef]

- Nandi, I.; Ghosh, M. Studies on functional and antioxidant property of dietary fibre extracted from defatted sesame husk, rice bran, and flaxseed. Bioact. Carbohydr. Diet. Fibre 2015, 5, 129–136. [Google Scholar] [CrossRef]

- Iftikhar, M.; Zhang, H.; Iftikhar, A.; Raza, A.; Khan, M.; Sui, M.; Wang, J. Comparative assessment of functional properties, free and bound phenolic profile, antioxidant activity, and in vitro bioaccessibility of rye bran and its insoluble dietary fiber. J. Food Biochem. 2020, 44, e13388. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Ospina, J.; Martuscelli, M.; Grande-Tovar, C.D.; Lucas-González, R.; Molina-Hernandez, J.B.; Viuda-Martos, M.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Chaves-López, C. Cacao Pod Husk Flour as an Ingredient for Reformulating Frankfurters: Effects on Quality Properties. Foods 2021, 10, 1243. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Paik, H.D. Functionality and application of dietary fiber in meat products. Food Sci. Anim. Resour. 2012, 32, 695–705. [Google Scholar] [CrossRef]

- Pathiraje, D.; Carlin, J.; Der, T.; Wanasundara, J.P.; Shand, P.J. Generating multi-functional pulse ingredients for processed meat products—Scientific evaluation of infrared-treated lentils. Foods 2022, 12, 1722. [Google Scholar] [CrossRef]

- Bolger, Z.; Brunton, N.P.; Lyng, J.G.; Monahan, F.J. Comminuted meat products—Consumption, composition, and approaches to healthier formulations. Food Rev. Int. 2016, 33, 143–166. [Google Scholar] [CrossRef]

- Corimayhua-Silva, A.A.; Elías-Peñafiel, C.; Rojas-Ayerve, T.; Guevara-Pérez, A.; Farfán-Rodríguez, L.; Encina-Zelada, C.R. Red dragon fruit peels: Effect of two species ratio and particle size on fibre quality and its application in reduced-fat alpaca-based sausages. Foods 2024, 13, 386. [Google Scholar] [CrossRef]

- Zhao, Y.; Hou, Q.; Zhuang, X.; Wang, Y.; Zhou, G.; Zhang, W. Effect of regenerated cellulose fiber on the physicochemical properties and sensory characteristics of fat-reduced emulsified sausage. LWT 2018, 97, 157–163. [Google Scholar] [CrossRef]

- Alves, L.A.A.S.; Lorenzo, J.M.; Gonçalves, C.A.A.; Santos, B.A.D.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna-type sausages using pork skin and green banana flour as fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef]

- Salazar, D.; Arancibia, M.; Calderón, L.; Elvira, M.; Montero, M.P. Underutilized Green Banana (Musa acuminata AAA) Flours to Develop Fiber Enriched Frankfurter-Type Sausages. Foods 2021, 10, 1142. [Google Scholar] [CrossRef]

- Schmiele, M.; Nucci Mascarenhas, M.C.C.; Da Silva Barretto, A.C.; Rodrigues Pollonio, M.A. Dietary fiber as fat substitute in emulsified and cooked meat model system. LWT 2015, 61, 105–111. [Google Scholar] [CrossRef]

- Choi, Y.; Choi, J.; Han, D.; Kim, H.; Lee, M.; Kim, H.; Jeong, J.; Kim, C. Characteristics of low-fat meat emulsion systems with pork fat replaced by vegetable oils and rice bran fiber. Meat Sci. 2009, 82, 266–271. [Google Scholar] [CrossRef] [PubMed]

- García, M.L.; Cáceres, E.; Selgas, M.D. Utilisation of fruit fibres in conventional and reduced-fat cooked-meat sausages. J. Sci. Food Agric. 2007, 87, 624–631. [Google Scholar] [CrossRef]

- Reddy, G.B.; Reddy, K.V.N.; Amaravathi, P. Quality characteristics and ultra-structural changes of restructured buffalo meat slices with flaxseed flour as binder: A novel value-added technology. Emir. J. Food Agric. 2023, 35, 342–350. [Google Scholar] [CrossRef]

- Ribeiro, W.O.; Ozaki, M.M.; Dos Santos, M.; Rodríguez, A.P.; De Castro, R.J.S.; Sato, H.H.; Campagnol, P.C.B.; Pollonio, M.A.R. Improving the textural and nutritional properties in restructured meat loaf by adding fibers and papain designed for elderly. Food Res. Int. 2023, 165, 112539. [Google Scholar] [CrossRef]

- Piñero, M.; Parra, K.; Huerta-Leidenz, N.; Arenas de Moreno, L.; Ferrer, M.; Araujo, S.; Barboza, Y. Effect of oat’s soluble fibre (β-glucan) as a fat replacer on physical, chemical, microbiological, and sensory properties of low-fat beef patties. Meat Sci. 2008, 80, 675–680. [Google Scholar] [CrossRef]

- Sakr, M.S.; Rahma, E.; Aly-Aldin, M.; Said, M. Utilization of fruits and vegetables by-products in the manufacture of beef burger. Menoufia J. Food Dairy. Sci. 2023, 8, 121–136. [Google Scholar] [CrossRef]

- Banerjee, D.K.; Das, A.K.; Banerjee, R.; Pateiro, M.; Nanda, P.K.; Gadekar, Y.P.; Biswas, S.; McClements, D.J.; Lorenzo, J.M. Application of Enoki mushroom (Flammulina velutipes) stem wastes as functional ingredients in goat meat nuggets. Foods 2020, 9, 432. [Google Scholar] [CrossRef]

- Verma, S.; Verma, A.K.; Umaraw, P.; Singh, V.P.; Vihan, V.; Singh, C. Development and evaluation of quality characteristics of meat nuggets prepared with inclusion of Nelumbo nucifera root powder. J. Anim. Res. 2022, 12, 205–214. [Google Scholar] [CrossRef]

- Haque, M.E.; Mollah, M.B.R.; Habib, M.; Hashem, M.A.; Azad, M.A.K.; Ali, M.S. Development of dietary fiber enriched chicken nugget using rice bran. Meat Res. 2024, 4, 1–6. [Google Scholar] [CrossRef]

- Biswas, O.; Kandasamy, P.; Das, S.K. Effect of dragon fruit peel powder on quality and acceptability of fish nuggets stored in a solar cooler (5 ± 1 °C). J. Food Sci. Technol. 2022, 59, 3647–3658. [Google Scholar] [CrossRef]

- Jandyal, M.; Malav, O.P.; Mehta, N.; Wagh, R.V. Quality Characteristics of Functional Pork Sausages Incorporated with Oat Bran Powder. J. Meat Sci. 2022, 17, 1–7. [Google Scholar] [CrossRef]

- Aminzare, M.; Hashemi, M.; Afshari, A.; Noori, S.M.A.; Rezaeigolestani, M. Comparative Evaluation of the Effects of Different Dietary Fibers as Natural Additives on the Shelf Life of Cooked Sausages. SSRN 2022, 17, e121624. [Google Scholar] [CrossRef]

- Yuan, D.; Xu, Y.; Kong, B.; Cao, C.; Zhang, F.; Xia, X.; Zhao, J. Application of seaweed dietary fiber as a potential alternative to phosphates in frankfurters with healthier profiles. Meat Sci. 2023, 196, 109044. [Google Scholar] [CrossRef]

- Salejda, A.M.; Olender, K.; Zielińska-Dawidziak, M.; Mazur, M.; Szperlik, J.; Miedzianka, J.; Szmaja, A. Frankfurter-Type Sausage Enriched with Buckwheat By-Product as a Source of Bioactive Compounds. Foods 2022, 11, 674. [Google Scholar] [CrossRef] [PubMed]

- Câmara, A.K.F.I.; Okuro, P.K.; Cunha, R.L.D.; Herrero, A.M.; Ruiz-Capillas, C.; Pollonio, M.A.R. Chia (Salvia hispanica L.) mucilage as a new fat substitute in emulsified meat products: Technological, physicochemical, and rheological characterization. LWT 2020, 125, 109193. [Google Scholar] [CrossRef]

- Kim, J.; Shand, P.J. Combined Effect of beet powder and lentil flour as a partial nitrite substitute on physicochemical, texture and sensory characteristics, color, and oxidative stability of pork bologna. J. Food Sci. 2022, 87, 4379–4393. [Google Scholar] [CrossRef]

- Ferjančič, B.; Kugler, S.; Korošec, M.; Polak, T.; Bertoncelj, J. Development of low-fat chicken bologna sausages enriched with inulin, oat fibre or psyllium. Int. J. Food Sci. Technol. 2021, 56, 1818–1828. [Google Scholar] [CrossRef]

- Aminzare, M.; Hashemi, M.; Afshari, A.; Noori, S.M.A.; Rezaeigolestani, M. Development of Functional Sausages: A Comparative Study of the Impact of Four Dietary Fibers on the Physico-Chemical Properties of Mortadella Sausages. J. Hum. Environ. Health Promot. 2024, 10, 83–88. [Google Scholar] [CrossRef]

- Kambarova, A.; Nurgazezova, A.; Nurymkhan, G.; Atambayeva, Z.; Smolnikova, F.; Rebezov, M.; Moldabaeva, Z. Improvement of Quality Characteristics of Turkey Pâté through Optimization of a Protein Rich Ingredient: Physicochemical Analysis and Sensory Evaluation. Food Sci. Technol. 2020, 41, 203–209. [Google Scholar] [CrossRef]

- Fang, Z.; Lin, P.; Ha, M.; Warner, R.D. Effects of incorporation of sugarcane fibre on the physicochemical and sensory properties of chicken sausage. Int. J. Food Sci. Technol. 2018, 54, 1036–1044. [Google Scholar] [CrossRef]

- Zaini, H.B.M.; Sintang, M.D.B.; Pindi, W. The roles of banana peel powders to alter technological functionality, sensory and nutritional quality of chicken sausage. Food Sci. Nutr. 2020, 8, 5497–5507. [Google Scholar] [CrossRef]

- Weigel, I.; Nistler, S.; Pichner, R.; Budday, S.; Gensberger-Reigl, S. Dried Vegetables as Potential Clean-Label Phosphate Substitutes in Cooked Sausage Meat. Foods 2023, 12, 1960. [Google Scholar] [CrossRef]

- Florowski, T.; Florowska, A.; Chmiel, M.; Adamczak, L.; Pietrzak, D.; Ostrowska, A.; Szymańska, I. Quality Aspects of Designing Prohealth Liver Sausages Enriched with Walnut Paste. Foods 2022, 11, 3946. [Google Scholar] [CrossRef] [PubMed]

- Grispoldi, L.; Ianni, F.; Blasi, F.; Pollini, L.; Crotti, S.; Cruciani, D.; Cenci-Goga, B.T.; Cossignani, L. Apple Pomace as Valuable Food Ingredient for Enhancing Nutritional and Antioxidant Properties of Italian Salami. Antioxidants 2022, 11, 1221. [Google Scholar] [CrossRef] [PubMed]

- Bis-Souza, C.V.; Ozaki, M.M.; Vidal, V.A.S.; Pollonio, M.A.R.; Penna, A.L.B.; Barretto, A.C.S. Can dietary fiber improve the technological characteristics and sensory acceptance of low-fat italian type salami? J. Food Sci. Technol. 2020, 57, 1003–1012. [Google Scholar] [CrossRef]

- Słowiński, M.; Miazek, J.; Dasiewicz, K.; Chmiel, M. The Effect of the Addition of Fiber Preparations on the Color of Medium-Grounded Pasteurized and Sterilized Model Canned Meat Products. Molecules 2021, 26, 2247. [Google Scholar] [CrossRef]

- Zhao, D.; Guo, C.; Liu, X.; Xiao, C. Effects of insoluble dietary fiber from kiwi fruit pomace on the physicochemical properties and sensory characteristics of low-fat pork meatballs. J. Food Sci. Technol. 2021, 58, 1524–1537. [Google Scholar] [CrossRef]

- Carballo, D.E.; Caro, I.; Gallego, C.; González, A.R.; Giráldez, F.J.; Andrés, S.; Mateo, J. Banana Pseudo-Stem Increases the Water-Holding Capacity of Minced Pork Batter and the Oxidative Stability of Pork Patties. Foods 2021, 10, 2173. [Google Scholar] [CrossRef]

- Barbut, S. Research Note: Effects of fiber source on the physicochemical properties of lean poultry meat products. Poult. Sci. 2023, 102, 102423. [Google Scholar] [CrossRef]

- Swastike, W.; Kartikasari, L.R.; Nuhriawangsa, A.M.P.; Barido, F.H.; Hertanto, B.S. The Effectiveness of Enhanced Moringa oleifera Leaves Extract Powder (MOLEP) in Beef Patties as a Fortification on a Well-Done Cooking Method. IOP Conf. Ser. Earth Environ. Sci. 2024, 1292, 012024. [Google Scholar] [CrossRef]

- Boișteanu, P.C.; Manoliu, D.R.; Ciobanu, M.M. The Effect of Red Lentil Flour on the Quality Characteristics of Beef Burgers Obtained from Two Different Anatomical Regions. Sci. Pap. Ser. D Anim. Sci. 2023, 66, 385–390. [Google Scholar]

- Basiri, S.; Yousefi, M.H.; Shekarforoush, S.S. Functional and Quality Attributes of Beef Burgers Fortified by Brown Linseed Powder. Funct. Foods Health Dis. 2022, 12, 1–11. [Google Scholar] [CrossRef]

- Chandler, S.L.; McSweeney, M.B. Characterizing the properties of hybrid meat burgers made with pulses and chicken. Int. J. Gastron. Food Sci. 2022, 27, 100492. [Google Scholar] [CrossRef]

- Asp, N. Dietary carbohydrates: Classification by chemistry and physiology. Food Chem. 1996, 57, 9–14. [Google Scholar] [CrossRef]

- Dai, F.; Chau, C. Classification and regulatory perspectives of dietary fiber. J. Food Drug Anal. 2016, 25, 37–42. [Google Scholar] [CrossRef]

- Guan, Z.; Yu, E.; Feng, Q. Soluble Dietary Fiber, One of the Most Important Nutrients for the Gut Microbiota. Molecules 2020, 26, 6802. [Google Scholar] [CrossRef]

- McCleary, B.V. Development of an Integrated Total Dietary Fiber Method Consistent with the Codex Alimentarius Definition. Cereal Foods World 2010, 55, 24–28. [Google Scholar] [CrossRef]

- Biswas, A.K.; Kumar, V.; Bhosle, S.; Sahoo, J.; Chatli, M.K. Dietary Fibers as Functional Ingredients in Meat Products and Their Role in Human Health. Int. J. Livest. Prod. 2011, 2, 45–54. Available online: http://www.academicjournals.org/IJLP (accessed on 16 January 2025).

- Mehta, N.; Ahlawat, S.S.; Sharma, D.P.; Dabur, R.S. Novel trends in development of dietary fiber rich meat products—A critical review. J. Food Sci. Technol. 2015, 52, 633–647. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Kim, S.; Chung, I. Comparison of Lignin, Cellulose, and Hemicellulose Contents for Biofuels Utilization among Four Types of Lignocellulosic Crops. Biomass Bioenergy 2015, 83, 322–327. [Google Scholar] [CrossRef]

- Yang, Y.Y.; Ma, S.; Wang, X.X.; Zheng, X.L. Modification and Application of Dietary Fiber in Foods. J. Chem. 2017, 2017, 9340427. [Google Scholar] [CrossRef]

- Tudu, M.; Samanta, A. Natural Polysaccharides: Chemical Properties and Application in Pharmaceutical Formulations. Eur. Polym. J. 2023, 184, 111801. [Google Scholar] [CrossRef]

- He, Y.; Wang, B.; Wen, L.; Wang, F.; Yu, H.; Chen, D.; Su, X.; Zhang, C. Effects of Dietary Fiber on Human Health. Food Sci. Hum. Wellness 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Manoliu, D.R.; Ciobanu, M.M.; Ciobotaru, M.C.; Anchidin, B.G.; Boișteanu, P.C. The Impact of Fruit Fiber on Meat Products: A Mini Review. Sci. Pap. Ser. D Anim. Sci. 2024, 67, 481–489. [Google Scholar]

- Guillon, F.; Champ, M. Structural and Physical Properties of Dietary Fibres, and Consequences of Processing on Human Physiology. Food Res. Int. 2000, 33, 233–245. [Google Scholar] [CrossRef]

- O’Shea, N.; Ktenioudaki, A.; Smyth, T.; McLoughlin, P.; Doran, L.; Auty, M.; Arendt, E.; Gallagher, E. Physicochemical Assessment of Two Fruit By-Products as Functional Ingredients: Apple and Orange Pomace. J. Food Eng. 2015, 153, 89–95. [Google Scholar] [CrossRef]

- Polizer-Rocha, Y.J.; Lorenzo, J.M.; Pompeu, D.; Rodrigues, I.; Baldin, J.C.; Pires, M.A.; Trindade, M.A. Physicochemical and technological properties of beef burger as influenced by the addition of pea fibre. Int. J. Food Sci. Technol. 2020, 55, 1018–1024. [Google Scholar] [CrossRef]

- Karaman, E.; Yılmaz, E.; Tuncel, N.B. Physicochemical, microstructural and functional characterization of dietary fibers extracted from lemon, orange and grapefruit seeds press meals. Bioact. Carbohydr. Diet. Fibre 2017, 11, 9–17. [Google Scholar] [CrossRef]

- Kehlet, U.; Christensen, L.B.; Raben, A.; Aaslyng, M.D. Physico-chemical, orosensory and microstructural properties of meat products containing rye bran, pea fibre or a combination of the two. Int. J. Food Sci. Technol. 2020, 55, 1010–1017. [Google Scholar] [CrossRef]

- Silva, H.L.; da Silva Pires, P.G.; Lima, A.L.F.; Cristofolini, A.C.; Netto, D.P.; Miotto, M.; de Oliveira Moraes, P. Effect of oat bran fiber on physicochemical properties and acceptance of enriched rabbit meat burgers. Acta Sci. Anim. Sci. 2024, 46, e64264. [Google Scholar] [CrossRef]

- Hu, G.; Yu, W. Effect of hemicellulose from rice bran on low-fat meatballs chemical and functional properties. Food Chem. 2015, 186, 239–243. [Google Scholar] [CrossRef] [PubMed]

- Abiala, O.; Abiala, M.; Omojola, B. Quality attributes of chicken nuggets extended with different legume flours. Food Prod. Process. Nutr. 2022, 4, 20. [Google Scholar] [CrossRef]

- de Souza Paglarini, C.; Vidal, V.A.S.; Ribeiro, W.; Badan Ribeiro, A.P.; Bernardinelli, O.D.; Herrero, A.M.; Ruiz-Capillas, C.; Sabadini, E.; Rodrigues Pollonio, M.A. Using inulin-based emulsion gels as fat substitute in salt-reduced Bologna sausage. J. Sci. Food Agric. 2021, 101, 505–517. [Google Scholar] [CrossRef]

- Özer, C. Utilization of Jerusalem artichoke powder in production of low-fat and fat-free fermented sausage. Ital. J. Food Sci. 2019, 31, 301–310. [Google Scholar] [CrossRef]

- Mahmoud, M.H.; Abou-Arab, A.A.; Abu-Salem, F.M. Quality Characteristics of Beef Burger as Influenced by Different Levels of Orange Peel Powder. Am. J. Food Technol. 2017, 12, 262–270. [Google Scholar] [CrossRef]

- Argel, N.S.; Ranalli, N.; Califano, A.N.; Andrés, S.C. Influence of partial pork meat replacement by pulse flour on physicochemical and sensory characteristics of low-fat burgers. J. Sci. Food Agric. 2020, 100, 3932–3941. [Google Scholar] [CrossRef]

- Bingley, C. The technological challenges of reformulating with different dietary fibres. Nutr. Bull. 2020, 45, 328–331. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, R.; Dong, L.; Huang, F.; Tang, X.; Wei, Z.; Zhang, M. Particle size of insoluble dietary fiber from rice bran affects its phenolic profile, bioaccessibility and functional properties. LWT 2018, 87, 450–456. [Google Scholar] [CrossRef]

- Ma, M.; Mu, T. Effects of extraction methods and particle size distribution on the structural, physicochemical, and functional properties of dietary fiber from deoiled cumin. Food Chem. 2016, 194, 237–246. [Google Scholar] [CrossRef]

- Xie, J.; Peng, G.; Hu, X.; Xie, J.; Chen, Y.; Dong, R.; Si, J.; Yang, C.; Yu, Q. Physicochemical Characteristics of Soluble Dietary Fiber Obtained from Grapefruit Peel Insoluble Dietary Fiber and Its Effects on Blueberry Jam. Foods 2021, 11, 3735. [Google Scholar] [CrossRef] [PubMed]

- Ralet, M.; Axelos, M.A.; Thibault, J. Gelation properties of extruded lemon cell walls and their water-soluble pectins. Carbohydr. Res. 1994, 260, 271–282. [Google Scholar] [CrossRef]

- Núñez-Gómez, V.; San Mateo, M.; González-Barrio, R.; Periago, M.J. Chemical Composition, Functional and Antioxidant Properties of Dietary Fibre Extracted from Lemon Peel after Enzymatic Treatment. Molecules 2024, 29, 269. [Google Scholar] [CrossRef] [PubMed]

- Schalow, S.; Baloufaud, M.; Cottancin, T.; Fischer, J.; Drusch, S. Orange pulp and peel fibres: Pectin-rich by-products from citrus processing for water binding and gelling in foods. Eur. Food Res. Technol. 2018, 244, 235–244. [Google Scholar] [CrossRef]

- Wang, K.; Li, M.; Wang, Y.; Liu, Z.; Ni, Y. Effects of extraction methods on the structural characteristics and functional properties of dietary fiber extracted from kiwifruit (Actinidia deliciosa). Food Hydrocoll. 2020, 110, 106162. [Google Scholar] [CrossRef]

- Bchir, B.; Rabetafika, H.N.; Paquot, M.; Blecker, C. Effect of pear, apple and date fibres from cooked fruit by-products on dough performance and bread quality. Food Bioproc. Technol. 2014, 7, 1114–1127. [Google Scholar] [CrossRef]

- Yan, L.; Li, T.; Liu, C.; Zheng, L. Effects of high hydrostatic pressure and superfine grinding treatment on physicochemical/functional properties of pear pomace and chemical composition of its soluble dietary fibre. LWT 2019, 107, 171–177. [Google Scholar] [CrossRef]

- Wachirasiri, P.; Julakarangka, S.; Wanlapa, S. The effects of banana peel preparations on the properties of banana peel dietary fibre concentrate. Songklanakarin J. Sci. Technol. 2009, 31, 605–611. [Google Scholar]

- Zhang, J.W.; Wang, J.H.; Wang, G.H.; Wang, C.C.; Huang, R.Q. Extraction and characterization of phenolic compounds and dietary fibres from banana peel. Acta Aliment. 2019, 48, 525–537. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Yi, C.; Quan, K.; Lin, B. Chemical composition, structure, physicochemical and functional properties of rice bran dietary fiber modified by cellulase treatment. Food Chem. 2021, 342, 128352. [Google Scholar] [CrossRef] [PubMed]

- Nikolina, A.; Zinina, O.; Neverova, O.; Sharaviev, P.; Pavlova, Y.; Lopayeva, N. Preparation of dietary fiber from oats. BIO Web Conf. 2024, 108, 02011. [Google Scholar] [CrossRef]

- Ursachi, C.Ș.; Perța-Crișan, S.; Munteanu, F.-D. Strategies to Improve Meat Products’ Quality. Foods 2020, 9, 1883. [Google Scholar] [CrossRef] [PubMed]

- Grasso, S.; Estévez, M.; Lorenzo, J.M.; Pateiro, M.; Ponnampalam, E.N. The utilisation of agricultural by-products in processed meat products: Effects on physicochemical, nutritional and sensory quality—Invited Review. Meat Sci. 2024, 211, 109451. [Google Scholar] [CrossRef]

- Mishra, B.P.; Mishra, J.; Paital, B.; Rath, P.K.; Jena, M.K.; Reddy, B.V.V.; Pati, P.K.; Panda, S.K.; Sahoo, D.K. Properties and physiological effects of dietary fiber-enriched meat products: A review. Front. Nutr. 2023, 10, 1275341. [Google Scholar] [CrossRef]

- Kerner, K.; Jõudu, I.; Tänavots, A.; Venskutonis, P.R. Application of raw and defatted by supercritical CO2 hemp seed press-cake and sweet grass antioxidant extract in pork burger patties. Foods 2021, 10, 1904. [Google Scholar] [CrossRef]

- Augustyńska-Prejsnar, A.; Topczewska, J.; Ormian, M.; Sokołowicz, Z. Quality of Poultry Roast Enriched with Hemp Seeds, Hemp Oil, and Hemp Flour. Foods 2022, 11, 3907. [Google Scholar] [CrossRef]

- Choi, J.H.; Bae, S.M.; Jeong, J.Y. Effects of the addition levels of white kimchi powder and acerola juice powder on the qualities of indirectly cured meat products. Food Sci. Anim. Resour. 2020, 40, 636–648. [Google Scholar] [CrossRef]

- Tomar, S.; Chauhan, G.; Das, A.; Meshram, S. Optimization of Ready-to-Cook Chicken Cutlet Mix Using Different Levels of Antioxidant Dietary Fiber Enriched Dehydrated Vegetable Mix. Int. J. Bio Resour. Stress. Manag. 2023, 14, 1196–1203. [Google Scholar] [CrossRef]

- Madane, P.; Das, A.K.; Nanda, P.K.; Bandyopadhyay, S.; Jagtap, P.; Shewalkar, A.; Maity, B. Dragon fruit peel as antioxidant dietary fibre on quality and lipid oxidation of chicken nuggets. J. Food Sci. Technol. 2020, 57, 1449–1461. [Google Scholar] [CrossRef]

- Araujo-Chapa, A.P.; Urías-Orona, V.; Niño-Medina, G.; Muy-Rangel, D.; de la Garza, A.L.; Castro, H. Dietary Fiber from Soybean (Glycine max) Husk as Fat and Phosphate Replacer in Frankfurter Sausage: Effect on the Nutritional, Physicochemical, and Nutraceutical Quality. Molecules 2023, 28, 4997. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Yan, H.; Xu, W.; Jia, C.; Peng, Y.; Zhuang, X.; Qi, J.; Xiong, G.; Mei, L.; Xu, X. The effect of water-insoluble dietary fiber from star anise on water retention of minced meat gels. Food Res. Int. 2022, 157, 111425. [Google Scholar] [CrossRef]

- Jovanovichs, M.R.C.; Pinton, M.B.; Correa, L.P.; Pedro, D.; Mallmann, C.A.; Wagner, R.; Cichoski, A.J.; Lorenzo, J.M.; Teixeira, A.J.C.; Campagnol, P.C.B.; et al. Replacing Animal Fat with Gels of Psyllium Fiber and Combined Linseed Oil–Psyllium Fiber in Salamis: Impacts on Technological, Nutritional, Oxidative, and Sensory Properties. Foods 2023, 12, 2439. [Google Scholar] [CrossRef]

- Choe, J.; Kim, H.Y. Quality characteristics of reduced fat emulsion-type chicken sausages using chicken skin and wheat fiber mixture as fat replacer. Poult. Sci. 2019, 98, 2662–2669. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, G.-W.; Choe, J.; Kim, H.-Y. Effect of Buckwheat Powder on the Physicochemical and Sensory Properties of Emulsion-type Sausage. Korean J. Food Sci. Anim. Resour. 2018, 38, 927–935. [Google Scholar] [CrossRef] [PubMed]

- Pathania, S.; Kaur, N. Utilization of fruits and vegetable by-products for isolation of dietary fibres and its potential application as functional ingredients. Bioact. Carbohydr. Diet. Fibre 2022, 27, 100295. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Sigvaldson, M.; Soladoye, O.P.; Gaudette, N.J. Utilization of pea starch and fibre fractions for replacement of wheat crumb in beef burgers. Meat Sci. 2020, 161, 107974. [Google Scholar] [CrossRef] [PubMed]

- Momchilova, M.; Gradinarska-Ivanova, D.; Zsivanovits, G.; Yordanov, D. Effect of Pork Back Fat Replacement with Inulin Gel and Oat Bran Flour on the Physicochemical and Sensory Evaluation of a Leberkäse Meat Product. Lett. Appl. NanoBioScience 2023, 12, 116. [Google Scholar] [CrossRef]

- Rekola, S.M.; Kårlund, A.; Mikkonen, S.; Kolehmainen, M.; Pomponio, L.; Sozer, N. Structure, texture and protein digestibility of high moisture extruded meat alternatives enriched with cereal brans. Appl. Food Res. 2023, 3, 100262. [Google Scholar] [CrossRef]

- Kaur, S.; Goswami, M.; Kumar, P.; Mehta, N.; Sharma, A. Utilization of Cauliflower Stems and Leaves Powder in the Development of High Fibre Spent Hen Meat Cutlets. J. Meat Sci. 2022, 17, 17–24. [Google Scholar] [CrossRef]

- Choe, J.; Lee, J.; Jo, K.; Jo, C.; Song, M.; Jung, S. Application of winter mushroom powder as an alternative to phosphates in emulsion-type sausages. Meat Sci. 2018, 143, 114–118. [Google Scholar] [CrossRef]

- Balestra, F.; Bianchi, M.; Petracci, M. Applications in meat products. In Dietary Fiber: Properties, Recovery, and Applications; Galanakis, C.M., Ed.; Academic Press: New York, NY, USA, 2019; pp. 313–344. [Google Scholar] [CrossRef]

- Słowinski, M.; Miazek, J.; Chmiel, M. Influence of the dose and length of wheat fiber on the quality of model sterilized canned meat products. Foods 2020, 9, 1001. [Google Scholar] [CrossRef]

- Drachuk, U.; Simonova, I.; Halukh, B.; Basarab, I.; Romashko, I. The study of lentil flour as a raw material for production of semi-smoked sausages. East. Eur. J. Enterp. Technol. 2018, 6, 44–50. [Google Scholar] [CrossRef]

- Soria-Hernández, C.; Serna-Saldívar, S.; Chuck-Hernández, C. Physicochemical and Functional Properties of Vegetable and Cereal Proteins as Potential Sources of Novel Food Ingredients. Food Technol. Biotechnol. 2015, 53, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Shoaib, A.; Sahar, A.; Sameen, A.; Saleem, A.; Tahir, A.T. Use of pea and rice protein isolates as source of meat extenders in the development of chicken nuggets. J. Food Process. Preserv. 2018, 42, e13763. [Google Scholar] [CrossRef]

- Younis, K.; Ahmad, S. Waste utilization of apple pomace as a source of functional ingredient in buffalo meat sausage. Cogent Food Agric. 2015, 1, 1119397. [Google Scholar] [CrossRef]

- Kurt, S. The effects of grape seed flour on the quality of Turkish dry fermented sausage (Sucuk) during ripening and refrigerated storage. Korean J. Food Sci. Anim. Resour. 2016, 36, 300–308. [Google Scholar] [CrossRef]

- Essa, R.Y.; Elsebaie, E.M. New fat replacement agent comprised of gelatin and soluble dietary fibers derived from date seed powder in beef burger preparation. LWT-Food Sci. Technol. 2022, 156, 113051. [Google Scholar] [CrossRef]

- Younis, K.; Ahmad, S.; Malik, M.A. Mosambi peel powder incorporation in meat products: Effect on physicochemical properties and shelf life stability. Appl. Food Res. 2021, 1, 100015. [Google Scholar] [CrossRef]

- FAO. Banana Market Review—Preliminary Results 2024; FAO: Rome, Italy, 2025; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/a2c47975-b6eb-4088-acdb-b2b7415b076a/content (accessed on 12 January 2025).

- Stragliotto, L.K.; Ferrari, G.T.; Campagnol, P.C.B.; Strasburg, V.J.; Zandonadi, R.P.; Oliveira, V.R. Green banana by-products on the chemical, technological and sensory quality of meat products. Int. J. Gastr. Food Sci. 2022, 30, 100614. [Google Scholar] [CrossRef]

- Begum, Y.A.; Deka, S.C. Chemical profiling and functional properties of dietary fibre rich inner and outer bracts of culinary banana flower. J. Food Sci. Technol. 2019, 56, 5298–5308. [Google Scholar] [CrossRef]

- Florowski, T.; Florowska, A.; Chmiel, M.; Dasiewicz, K.; Adamczak, L.; Pietrzak, D. The effect of nuts and oilseeds enriching on the quality of restructured beef steaks. LWT 2019, 104, 128–133. [Google Scholar] [CrossRef]

- Ciobanu, M.; Manoliu, D.; Ciobotaru, M.; Anchidin, B.; Matei, M.; Munteanu, M.; Frunză, G.; Murariu, O.C.; Flocea, E.; Boișteanu, P. The Influence of Sensory Characteristics of Game Meat on Consumer Neuroperception: A Narrative Review. Foods 2022, 12, 1341. [Google Scholar] [CrossRef]

- Kehlet, U.; Pagter, M.; Aaslyng, M.D.; Raben, A. Meatballs with 3% and 6% dietary fibre from rye bran or pea fibre—Effects on sensory quality and subjective appetite sensations. Meat Sci. 2017, 125, 66–75. [Google Scholar] [CrossRef] [PubMed]

- Boișteanu, P.; Anchidin, B.; Ciobanu, M. Exploring Sensory Attributes in Spinach- and Offals-Filled Chicken Roulades: An Empirical Analysis. Foods 2025, 14, 303. [Google Scholar] [CrossRef] [PubMed]

- Predanócyová, K.; Kubicová, Ľ.; Pindešová, D. Functional meat products: Examining attitudes and preferences of Slovak consumers. J. Cent. Eur. Agric. 2023, 24, 953–967. [Google Scholar] [CrossRef]

- Curutchet, A.; Arcia, P.; Prisco, F.; Tarrega, A. Brewer’s Spent Grain Used in Fiber-Enriched Burgers—Influence of Sustainability Information on Consumer Responses. Sustainability 2022, 15, 3873. [Google Scholar] [CrossRef]

- Ahmad, S.R.; Sharma, B.D.; Irshad, A.; Kumar, R.R.; Malav, O.P.; Talukder, S. Effect of aerobic storage conditions on the quality of functional restructured buffalo meat fillets enriched with natural sources of dietary fibers and antioxidant components. J. Food Process. Preserv. 2021, 45, e15072. [Google Scholar] [CrossRef]

- Zargar, F.A.; Kumar, S.; Bhat, Z.F.; Kumar, P. Effect of pumpkin on the quality characteristics and storage quality of aerobically packaged chicken sausages. SpringerPlus 2014, 3, 39. [Google Scholar] [CrossRef]

- Diao, X.; Zhu, J.; Huang, L.; Li, S.; Mao, X.; Li, C.; Ke, W. Effect of citrus fiber on physicochemical quality of Frankfurter sausages: A study on lipid oxidation and protein gel characteristics. LWT 2024, 209, 116778. [Google Scholar] [CrossRef]

- Mushtruk, M.; Palamarchuk, I.; Palamarchuk, V.; Gudzenko, M.; Slobodyanyuk, N.; Zhuravel, D.; Petrychenko, I.; Pylypchuk, O. Mathematical modelling of quality assessment of cooked sausages with the addition of vegetable additives. Potrav. Slovak. J. Food Sci. 2023, 17, 242–255. [Google Scholar] [CrossRef] [PubMed]

| Species | Cut | Chemical Composition (%) | Ref. | ||||

|---|---|---|---|---|---|---|---|

| Moisture | Dry Matter | Protein | Lipids | Ash | |||

| Beef | Loin | 36.28 ± 1.42 | 19.30 | 8.03 | 0.35 | [28] | |

| 48.92 ± 3.42 | 15.69 ± 1.04 | 2.58 ± 0.41 | [29] | ||||

| Tenderloin | 41.18 ± 2.51 | 16.48 | 9.17 | 0.29 | [28] | ||

| Top loin | 59.4 | 27.9 | 11.2 | 1.03 | [30] | ||

| Sirloin | 67.13 | 21.18 | 9.90 | [31] | |||

| Longissimus dorsi | 67.7 | 32.3 | 19.77 | 9.87 | 1.67 | [32] | |

| Longissimus thoracis et lumborum | 73.49 | 24.02 | 1.40 | 1.06 | [33] | ||

| Rib | 35.97 ± 1.51 | 16.88 | 8.06 | 0.24 | [28] | ||

| 45.39 ± 3.41 | 14.75 ± 1.09 | 3.02 ± 0.48 | [29] | ||||

| Chuck | 53.27 ± 2.94 | 16.78 ± 0.82 | 2.82 ± 0.74 | [29] | |||

| Round | 53.99 ± 2.63 | 17.58 ± 0.71 | 3.10 ± 0.36 | [29] | |||

| Rump | 69.85 | 21.67 | 6.59 | [31] | |||

| Butt | 70.71 | 21.46 | 5.99 | [31] | |||

| Brisket | 30.00 ± 1.01 | 19.40 | 5.97 | 0.38 | [28] | ||

| Shank | 29.00 ± 1.36 | 18.88 | 5.57 | 0.39 | [28] | ||

| Pork | Loin chop | 74.1 ± 0.7 | 23.2 ± 0.8 | 1.75 ± 0.21 | 1.22 ± 0.04 | [34] | |

| Loin | 73.5 | 21.1 | 3.9 | 1.14 | [35] | ||

| 67.38 ± 0.63 | 21.15 ± 0.38 | 10.60 ± 0.95 | 0.95 ± 0.03 | [24] | |||

| Shoulder | 73.3 | 18.0 | 7.5 | 1.02 | [35] | ||

| 72.02 ± 0.38 | 19.35 ± 0.26 | 7.52 ± 0.50 | 0.94 ± 0.01 | [24] | |||

| Leg | 74.4 | 19.8 | 4.3 | 1.12 | [35] | ||

| Hind leg | 70.28 ± 0.42 | 20.48 ± 0.22 | 8.33 ± 0.48 | 0.93 ± 0.01 | [24] | ||

| Sheep | Shoulder | 25.689 | 21.682 | 11.694 * | 0.963 | [36] | |

| Rack | 25.989 | 22.499 | 10.694 * | 0.924 | [36] | ||

| Loin | 26.750 | 22.526 | 10.718 * | 0.992 | [36] | ||

| Leg | 26.917 | 21.953 | 10.553 * | 0.929 | [36] | ||

| Lamb | Loin | 22.9 | 4.5 | [37] | |||

| Loin + rack | 66.2 | 13.3 | 19.0 | 0.90 | [38] | ||

| Eye of shoulder | 17.1 | 15.3 | [37] | ||||

| Shoulder-ribs | 68.2 | 16.1 | 14.6 | 1.06 | [38] | ||

| Shoulder | 70.3 | 16.1 | 12.7 | 0.95 | [38] | ||

| Knuckle | 20.5 | 6.8 | [37] | ||||

| Leg | 71.7 | 15.8 | 11.5 | 0.94 | [38] | ||

| Topside | 22.5 | 6.6 | [37] | ||||

| Goat | Loin | 75.00 | 21.60 | 1.48 | 1.41 | [39] | |

| Leg | 23.12 | 20.19 | 2.18 | 4.79 | [40] | ||

| Rump | 75.49 | 21.30 | 1.40 | 1.25 | [39] | ||

| Shoulder | 22.61 | 21.36 | 3.95 | 4.70 | [40] | ||

| Chest | 24.26 | 20.20 | 2.29 | 4.98 | [40] | ||

| Chicken | Breast | 74.1 | 22.8 | 0.87 | 1.37 | [41] | |

| 74.71 | 23.04 | 1.48 | 0.86 | [42] | |||

| Thigh | 74.50 | 19.02 | 3.58 | 0.76 | [42] | ||

| Meat Product Formulation | Dietary Fibre | Levels Used | Objective for Use | Ref. |

|---|---|---|---|---|

| Goat meat nuggets | Moringa pod powder | 1.5% and 3.0% (w/w) | Antioxidant capacities | [25] |

| Enoki mushroom (Flammulina velutipes) stem wastes | 2.0%, 4.0%, and 6.0% (w/w) | Value-added functional ingredient | [77] | |

| Chicken meat nuggets | Lotus (Nelumbo nucifera) root powder | 1.5%, 3.0%, and 4.5% (w/w) | Fibre fortification | [78] |

| Rice bran | 5.0% and 10% (w/w) | Increase the fibre content of meat products | [79] | |

| Fish nuggets | Dragon fruit peel powder | 1.0%, 1.5%, and 2.0% (w/w) | Quality and shelf-life improvement | [80] |

| Emulsion-type pork sausages | Oat bran powder | 3.0%, 6.0%, and 9.0% (w/w) | Improving physico-chemical quality | [81] |

| Emulsion-type chicken sausage | Orange fibre, wheat fibre, bamboo fibre, carrot fibre | 1.0% (w/w) | Quality maintenance during storage | [82] |

| Frankfurters | Cacao pod husk flour | 1.5% and 3.0% (w/w) | As starch replacement for reformulated frankfurters | [61] |

| Seaweed dietary fibre | 2.5%, 5.0%, 7.5%, 10%, and 12.5% (w/w) | Phosphates alternative | [83] | |

| Frankfurter-type sausage | Buckwheat husk | 1.0%, 2.0%, and 3.0% (w/w) | Source of bioactive compounds | [84] |

| Emulsified meat products | Chia (Salvia hispanica L.) mucilage powder | 2.5% and 5.0% (w/w) | Fat substituent | [85] |

| Bologna pork sausages | Beet powder | 0.1%, 0.3%, and 0.5% (w/w) | Nitrite substitute | [86] |

| Bologna chicken sausages | Inulin, oat fibre, psyllium | 3.0% and 6.0% (w/w) | Reducing fat content | [87] |

| Mortadella | Orange fibre, wheat fibre, bamboo fibre, carrot fibre | 1.0% (w/w) | Development of functional meat products | [88] |

| Turkey pâté | Grain mix supplement (with oat, rice, corn, and buckwheat) | 18.0% (w/w) | Protein-herbal supplement | [89] |

| Chicken sausage | Sugarcane fibre | 2.0% and 3.0% (w/w) | Improving functional and eating qualities | [90] |

| Banana peel powder | 2.0%, 4.0%, and 6.0% (dry matter) | Enriching meat products with fibres | [91] | |

| Sausage meat | Freeze-dried vegetables | 1.0%, 1.6%, 2.2%, 2.8%, 3.4%, and 4.0% (w/w) | Phosphate substitutes | [92] |

| Liver sausages | Walnut paste | 5.0%, 10.0%, 15.0%, 20.0%, and 25.0% (w/w) | Nutritional enrichment and functional value | [93] |

| Italian salami | Apple pomace (rehydrated, from dried powder) | 7.0% and 14.0% (w/w) | Enhancing nutritional and antioxidant properties | [94] |

| Italian type salami | Inulin, fructo-oligosaccharide, α-cyclodextrin | 2.0% (w/w) | Pork fat substitute | [95] |

| Canned meat products | Preparations of barley, wheat and oat fibre | 3.0% and 6.0% (w/w) | Colour improvement | [96] |

| Comminuted meat products | Inulin, chitosan, carboxymethyl cellulose, pectin, cellulose | 2.0% (w/w) | Fibre enrichment/fat substitutes | [62] |

| Pork meatballs | Kiwi fruit pomace dietary fibre | 0.5%, 1.0%, 3.0%, 5.0%, and 7.0% (w/w) | Fat substitute | [97] |

| Minced pork batter | Banana pseudo-stem powder | 1.5, 3.0, and 4.5 (g/kg) | Improve oxidative stability | [98] |

| Turkey meat batters | Citrus, apple, pea, bamboo, sugar cane fibre | 2.0% (w/w) | Texture and microstructure improvement | [99] |

| Beef loaves | Apple, oat, pea, inulin | 6.0% (w/w) | Improving the textural and nutritional properties | [74] |

| Buffalo meat slices | Flaxseed flour | 2.0%, 4.0%, and 6.0% (w/w) | Binding properties | [73] |

| Beef patties | Moringa oleifera leaves extract powder | 1.0%, 2.0%, 3.0%, and 4.0% (w/w) | Minimise shrinkage during well-done cooking methods | [100] |

| Beef burger | Red lentil | 5.0% and 10.0% (w/w) | Quality improvement and fat reduction | [101] |

| Brown linseed powder | 3.0%, 4.0%, and 5.0% (w/w) | Quality attributes improvement | [102] | |

| Guava and tomato waste powders (peels and seeds) | 5.0%, 10.0%, and 15.0% (w/w) | Enhance and improve shelf-life | [76] | |

| Hybrid chicken meat burger | Pulse flours: yellow pea, chickpea, lentil | 25%, 50%, and 75% (w/w meat replacement) | Sustainable protein source | [103] |

| Principal Groupings | Dietary Fibre Components | Fibre Sources | Specific Ingredient Added | Meat Product | Technological Effect in the Meat Product | Ref. |

|---|---|---|---|---|---|---|

| Non starch polysaccharides and oligosaccharides | Cellulose, hemicellulose | Cereal grains and bran | Oat bran | Rabbit meat burgers | Increased water-holding capacity, cooking yield, and firmness; reduced moisture content. | [120] |

| Rice bran | Meatballs | Reduced total fat and trans fatty acids; increased firmness and reduced chewiness. | [121] | |||

| Herbaceous plant | Sugarcane fibre | Chicken sausages | Improved cooking yield; higher phenolic content and antioxidant activity; reduced TBARS values. | [90] | ||

| Cereal and legume flours | Soybean, cowpea and groundnut | Chicken nuggets | Reduced moisture content; improved texture, binding ability, and firmness; increased cooking yield. | [122] | ||

| Cellulose, hemicellulose, pectin | Fruits and vegetables | Moringa pod powder | Goat nuggets | Improved emulsion stability, cooking yield, and moisture retention; reduced expressible water and hardness. | [25] | |

| Dragon fruit peel powder | Alpaca sausages | Increased water retention and activity; reduced fat content and chewiness. | [66] | |||

| Inulin, fructo-oligosaccharides | Chicory root, jerusalem artichoke (inulin extracted from simple carbohydrates) | Emulsion gel (with 16.5% inulin) | Bologna sausages | Improved heat stability; reduced hardness. | [123] | |

| Jerusalem artichoke powder | Sausages | Reduced TBARS values; increased moisture and adhesiveness; reduced hardness. | [124] | |||

| Gums and mucilages, psyllium | Plantago ovata plant | Psyllium powder | Chicken bologna sausages | Improved adhesiveness and hardness; reduced gumminess and cohesiveness. | [87] | |

| Gums and mucilages | Oilseeds | Flaxseed flour | Restructured buffalo meat fillets | Formed a gel network with increased cohesiveness and reduced hardness, gumminess, and springiness. | [73] | |

| Herbaceous plant | Chia seeds | Meat emulsion | Increased emulsion stability; improved hardness and cohesiveness. | [85] | ||

| Carbohydrate analogues | Pectin | Fruits and vegetables | Guava and tomato waste powders | Beef burgers | Reduced shrinkage and cooking loss; enhanced water-holding capacity | [76] |

| Orange peel powder | Beef burgers | Improved texture and cooking yield; increased phenolic content; delayed lipid oxidation. | [125] | |||

| Resistant starch | Legumes, unripe banana | Pulse flours (lentil, pea, chickpea, bean) | Burgers | Increased cooking yield, decreased diameter reduction and expressible liquid. | [126] | |

| Green banana flours (pulp, peel and whole banana) | Frankfurters | Increased moisture retention; higher cooking yield; reduced shrinkage. | [69] | |||

| Lignin | Lignin | Woody plant | Cacao pod husk flour | Frankfurters | Enhanced emulsion stability; increased hardness and reduced cohesiveness. | [61] |

| Non starch polysaccharides and oligosaccharides | Cellulose, hemicellulose |

| Dietary Fibre Source | Water Retention Capacity (g/g) | Oil-Holding Capacity (g/g) | Gel-Forming Ability (Swelling Capacity, SWC—mL Water/g) | Ref. |

|---|---|---|---|---|

| Grapefruit peel | 13.43 | 22.10 | High | [130] |

| Lemon | 1.1 | 9.3 | High (SWC = 9.9) | [131,132] |

| Orange | 7.1–12.6 | 0.86–1.28 | High | [118,133] |

| Kiwifruit | 2.02–13.34 | 22.79–23.00 | - | [134] |

| Apple pomace | 7.5 | 2.2 | High (SWC = 7) | [135] |

| Pear pomace | 3.44–4.9 | 1.09–2.77 | Moderate (SWC = 5.9) | [135,136] |

| Date | 5.7 | 2.3 | Low (SWC = 3.9) | [135] |

| Banana peel | 6.57 | 4.75 | Low to moderate (4.3–4.8) | [137,138] |

| Rice bran | 4.75–5.06 | 4.58–5.64 | Low (SWC = 2.02–2.72) | [139] |

| Oat fibre | 3.42 | 3.95 | Moderate to high | [140] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciobanu, M.-M.; Manoliu, D.-R.; Ciobotaru, M.C.; Flocea, E.-I.; Boișteanu, P.-C. Dietary Fibres in Processed Meat: A Review on Nutritional Enhancement, Technological Effects, Sensory Implications and Consumer Perception. Foods 2025, 14, 1459. https://doi.org/10.3390/foods14091459

Ciobanu M-M, Manoliu D-R, Ciobotaru MC, Flocea E-I, Boișteanu P-C. Dietary Fibres in Processed Meat: A Review on Nutritional Enhancement, Technological Effects, Sensory Implications and Consumer Perception. Foods. 2025; 14(9):1459. https://doi.org/10.3390/foods14091459

Chicago/Turabian StyleCiobanu, Marius-Mihai, Diana-Remina Manoliu, Mihai Cătălin Ciobotaru, Elena-Iuliana Flocea, and Paul-Corneliu Boișteanu. 2025. "Dietary Fibres in Processed Meat: A Review on Nutritional Enhancement, Technological Effects, Sensory Implications and Consumer Perception" Foods 14, no. 9: 1459. https://doi.org/10.3390/foods14091459

APA StyleCiobanu, M.-M., Manoliu, D.-R., Ciobotaru, M. C., Flocea, E.-I., & Boișteanu, P.-C. (2025). Dietary Fibres in Processed Meat: A Review on Nutritional Enhancement, Technological Effects, Sensory Implications and Consumer Perception. Foods, 14(9), 1459. https://doi.org/10.3390/foods14091459