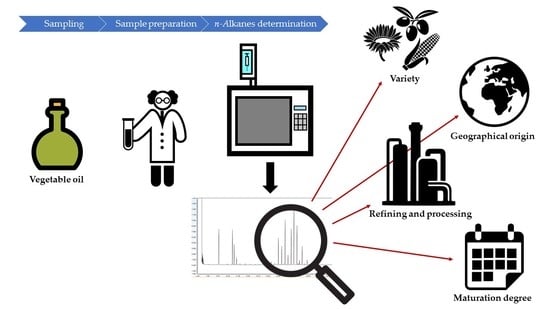

Occurrence of n-Alkanes in Vegetable Oils and Their Analytical Determination

Abstract

:1. Introduction

2. Occurrence in Vegetable Oils

2.1. Olive Oils

2.2. Other Vegetable Oils

2.3. Parameters Affecting n-Alkane Content and Qualitative Profile

2.3.1. Influence of the Variety

2.3.2. Influence of the Geographical Origin

2.3.3. Influence of Maturation Degree and Presence of Leaves

2.3.4. Influence of Oil Refining

3. Analytical Determination

3.1. Methods Specifically Designed for n-Alkane Determination in Vegetable Oils

3.2. Official Method for the Determination of Aliphatic Hydrocarbons in Vegetable Oils

3.3. Methods Developed for Mineral Oil Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EVOO | extra virgin olive oil |

| FID | flame ionization detection |

| GC | gas chromatography |

| HPLC | high-performance liquid chromatography |

| LOD | limit of detection |

| MOAH | mineral oil aromatic hydrocarbon |

| MOSH | saturated mineral oil hydrocarbon |

| MS | mass spectrometry |

| PCA | principal component analysis |

| SPE | solid-phase extraction |

| TLC | thin-layer chromatography |

| UCM | unresolved complex mixture |

References

- Giuffrè, A.M.; Capocasale, M. N-Alkanes in tomato (Solanum lycopersicum L.) seed oil: The cultivar effect. Int. Food Res. J. 2016, 23, 979–985. [Google Scholar]

- Bortolomeazzi, R.; Berno, P.; Pizzale, L.; Conte, L.S. Sesquiterpene, alkene, and alkane hydrocarbons in virgin olive oils of different varieties and geographical origins. J. Agric. Food Chem. 2001, 49, 3278–3283. [Google Scholar] [CrossRef] [PubMed]

- Troya, F.; Lerma-García, M.J.; Herrero-Martínez, J.M.; Simó-Alfonso, E.F. Classification of vegetable oils according to their botanical origin using n-alkane profiles established by GC-MS. Food Chem. 2015, 167, 36–39. [Google Scholar] [CrossRef] [PubMed]

- Moreda, W.; Pérez-Camino, M.C.; Cert, A. Gas and liquid chromatography of hydrocarbons in edible vegetable oils. J. Chromatogr. A 2001, 936, 159–171. [Google Scholar] [CrossRef]

- Webster, L.; Simpson, P.; Shanks, A.M.; Moffat, C.F. The authentication of olive oil on the basis of hydrocarbon concentration and composition. Analyst 2000, 125, 97–104. [Google Scholar] [CrossRef]

- Pèrez-Camino, M.C.; Gòmez-Coca, R.B.; Moreda, W. Update on aliphatic aldehydes in lipid foods. In New Developments in Aldehydes Research, 3rd ed.; Torriani, L., Pescasseroli, E., Eds.; Nova Science Publishers: London, UK, 2013; Volume 3, pp. 81–100. [Google Scholar]

- Nartea, A. A Study on Possible Sources of Mineral Oil Contamination in Olive and Extra Virgin Olive Oil. Master’s Thesis, University of Udine, Udine, Italy, 2017. [Google Scholar]

- Bognar, A.L.; Paliyath, G.; Rogers, L.; Kolattukudy, P.E. Biosynthesis of alkanes by particulate and solubilized enzyme preparations from pea leaves (Pisum sativum). Arch. Biochem. Biophys. 1984, 235, 8–17. [Google Scholar] [CrossRef]

- Samuels, L.; Kunst, L.; Jetter, R. Sealing plant surface: Cultivar wax formation by epidermal cells. Annu. Rev. Plant. Biol. 2008, 59, 683–707. [Google Scholar] [CrossRef] [Green Version]

- Firestone, D.; Carson, K.L.; Reina, R.J. Update on control of olive oil adulteration and misbranding in the United States. J. Am. Oil Chem. Soc. 1988, 65, 788–792. [Google Scholar] [CrossRef]

- Koprivnjak, O.; Moret, S.; Populin, T.; Lagazio, C.; Conte, L.S. Variety differentiation of virgin olive oil based on n-alkane profile. Food Chem. 2005, 90, 603–608. [Google Scholar] [CrossRef]

- Mihailova, A.; Abbado, D.; Kelly, S.D.; Pedentchouk, N. The impact of environmental factors on molecular and stable isotope compositions of n-alkanes in Mediterranean extra virgin olive oils. Food Chem. 2015, 173, 114–121. [Google Scholar] [CrossRef]

- Biedermann, M.; Fiselier, K.; Grob, K. Aromatic hydrocarbons of mineral origin in foods: Method for determining the total concentration and first results. J. Agric. Food Chem. 2009, 57, 8711–8721. [Google Scholar] [CrossRef] [PubMed]

- Moret, S.; Populin, T.; Conte, L.S. La contaminazione degli oli vegetali con oli minerali. Riv. Ital. Sostanze Grasse 2009, 86, 3–14. [Google Scholar]

- Moret, S.; Barp, L.; Grob, K.; Conte, L.S. Optimised off-line SPE-GC-FID method for the determination of mineral oil saturated hydrocarbons (MOSH) in vegetable oils. Food Chem. 2011, 129, 1898–1903. [Google Scholar] [CrossRef]

- Gòmez-Coca, R.B.; Pèrez-Camino, M.C.; Moreda, W. Saturated hydrocarbon content in olive fruits and crude olive pomace oils. Food Addit. Contam. Part. A Chem. Anal. Control. Expo. Risk Assess. 2016, 33, 391–402. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Coca, R.B.; Cert, R.; Pérez-Camino, M.D.C.; Moreda, W. Determination of saturated aliphatic hydrocarbons in vegetable oils. Grasas y Aceites 2016, 67, 127. [Google Scholar] [CrossRef] [Green Version]

- Lacoste, F. International validation of the determination of saturated hydrocarbon mineral oil in vegetable oils. Eur. J. Lipid Sci. Technol. 2016, 118, 373–381. [Google Scholar] [CrossRef]

- Liu, L.; Huang, H.; Wu, Y.; Li, B.; Ouyang, J. Offline solid-phase extraction large-volume injection-gas chromatography for the analysis of mineral oil-saturated hydrocarbons in commercial vegetable oils. J. Oleo Sci. 2017, 66, 981–990. [Google Scholar] [CrossRef] [Green Version]

- Barp, L.; Purcaro, G.; Moret, S.; Conte, L.S. A high-sample-throughput LC-GC method for mineral oil determination. J. Sep. Sci. 2013, 36, 3135–3139. [Google Scholar] [CrossRef]

- Fiorini, D.; Paciaroni, A.; Gigli, F.; Ballini, R. A versatile splitless injection GC-FID method for the determination of mineral oil paraffins in vegetable oils and dried fruit. Food Control 2010, 21, 1155–1160. [Google Scholar] [CrossRef]

- Biedermann, M.; Grob, K. On-line coupled high performance liquid chromatography-gas chromatography for the analysis of contamination by mineral oil. Part 1: Method of analysis. J. Chromatogr. A. 2012, 1255, 56–75. [Google Scholar] [CrossRef]

- Sakouhi, F.; Herchi, W.; Sbei, K.; Absalon, C.; Boukhchina, S. Characterisation and accumulation of squalene and n-alkanes in developing Tunisian Olea europaea L. fruits. Int. J. Food Sci. Technol. 2011, 46, 2281–2286. [Google Scholar] [CrossRef]

- McGill, A.S.; Moffat, C.F.; Mackie, P.R.; Cruickshank, P. The composition and concentration of n-alkanes in retail samples of edible oils. J. Sci. Food Agric. 1993, 61, 357–362. [Google Scholar] [CrossRef]

- Lanzón, A.; Albi, T.; Cert, A.; Gracián, J. The hydrocarbon fraction of virgin olive oil and changes resulting from refining. J. Am. Oil Chem. Soc. 1994, 71, 285–291. [Google Scholar] [CrossRef]

- Guinda, A.; Lanzón, A.; Albi, T. Differences in hydrocarbons of virgin olive oils obtained from several olive varieties. J. Agric. Food Chem. 1996, 44, 1723–1726. [Google Scholar] [CrossRef]

- Koprivnjak, O.; Procida, G.; Favretto, L. Determination of endogenous aliphatic hydrocarbons of virgin olive oils of four autochthonous cultivars from Krk Island (Croatia). Food Technol. Biotechnol. 1997, 35, 125–131. [Google Scholar]

- Mihailova, A.; Abbado, D.; Pedentchouk, N. Differences in n-alkane profiles between olives and olive leaves as potential indicators for the assessment of olive leaf presence in virgin olive oils. Eur. J. Lipid Sci. Technol. 2015, 117, 1480–1485. [Google Scholar] [CrossRef]

- Benitez-Sánchez, P.L.; León-Camacho, M.; Aparicio, R. A comprehensive study of hazelnut oil composition with comparisons to other vegetable oils, particularly olive oil. Eur. Food Res. Technol. 2003, 218, 13–19. [Google Scholar] [CrossRef]

- Giuffrè, A.M. Changes in the n-alkane composition of avocado pulp oil (Persea americana, Mill.) during fruit ripening. Grasas y Aceites 2005, 56, 75–78. [Google Scholar] [CrossRef] [Green Version]

- Bianchi, G.; Murelli, C.; Vlahov, G. Surface waxes from olive fruits. Phytochemistry 1992, 31, 3503–3506. [Google Scholar] [CrossRef]

- Srbinovska, A. Validation of an Off-Line SPE-GC-FID Method for the Determination of n-Alkanes in Vegetable Oils and Comparison with the On-Line LC-GC-FID Method. Master’s Thesis, University of Udine, Udine, Italy, 2018. [Google Scholar]

- Pineda, M.; Rojas, M.; Gàlvez-Valdivieso, G.; Aguilar, M. The origin of aliphatic hydrocarbons in olive oil. J. Sci. Food Agric. 2017, 4827–4834. [Google Scholar] [CrossRef]

- Bastic, M.; Bastic, L.; Jovanovic, J.A.; Spiteller, G. Hydrocarbons and Other Weakly Polar Unsaponifiables in Some Vegetable Oils. J. Am. Oil Chem. Soc. 1978, 55, 886–891. [Google Scholar] [CrossRef]

- European Union. Commission Regulation (EC) No 656/95. Off. J. Eur. Communities 1995, 69, 1–2. [Google Scholar]

- Moret, S.; Popilin, T.; Conte, L.S.; Grob, K.; Neukom, H.P. Occurrence of C15-C45 mineral paraffins in olives and olive oils. Food Addit. Contam. 2003, 20, 417–426. [Google Scholar] [CrossRef] [PubMed]

- International Standard ISO/DIS 17780:2015-Animal and Vegetable Fats and Oils-Determination of Aliphatic Hydrocarbons in Vegetable Oils; ISO: Geneva, Switzerland, 2015.

- Brühl, L. Occurrence, determination, and assessment of mineral oils in oilseeds and vegetable oils. Eur. J. Lipid Sci. Technol. 2016, 118, 361–372. [Google Scholar] [CrossRef]

- Purcaro, G.; Barp, L.; Moret, S. Determination of hydrocarbon contamination in foods. A review. Anal. Methods 2016, 8, 5755–5772. [Google Scholar] [CrossRef]

- Weber, S.; Schrag, K.; Mildau, G.; Kuballa, T.; Walch, S.G.; Lachenmeier, D.W. Analytical Methods for the Determination of Mineral Oil Saturated Hydrocarbons (MOSH) and Mineral Oil Aromatic Hydrocarbons (MOAH)—A Short Review. Anal. Chem. Insights 2018, 13, 1–16. [Google Scholar] [CrossRef] [Green Version]

- DI NEN 16995:2017-08. Foodstuffs-Vegetable Oils and Foodstuff on Basis of Vegetable Oils-Determination of Mineral Oil Saturated Hydrocarbons (MOSH) and Mineral Oil Aromatic Hydrocarbons (MOAH) with On-Line HPLC-GC-FID Analysis; Beuth Verlag: Berlin, Germany, 2017. [Google Scholar]

- Purcaro, G.; Moret, S.; Conte, L. Hyphenated liquid chromatography-gas chromatography technique: Recent evolution and applications. J. Chromatogr. A 2012, 1255, 100–111. [Google Scholar] [CrossRef]

- Purcaro, G.; Moret, S.; Conte, L. Sample pre-fractionation of environmental and food samples using LC-GC multidimensional techniques. TrAC–Trends Anal. Chem. 2013, 43, 146–160. [Google Scholar] [CrossRef]

| Sample | Variety | Geographical Origin | Sample Number | Tot. n-Alkane (mg/kg) | Major n-Alkanes | Ref. |

|---|---|---|---|---|---|---|

| Olive oil and Extra virgin olive oil | 6 | 28–99 | n-C23, n-C25, n-C27 | [24] | ||

| Virgin olive oil | Arbequina, Cornicabra, Empeltre, Farga, Hojiblanca, Lechin, Picual, Picudo, Verdial | Various Spanish regions | 250 | 15.3–115.8 | n-C25, n-C23, n-C27 | [25] |

| Refined virgin olive oil | 2 | 20.9 | n-C27, n-C29, n-C31 | |||

| 14.7 | n-C29, n-C27, n-C31 | |||||

| Virgin olive oil | Arbequina | Lèrida | 50 | 36–60 | n-C27, n-C25, n-C29 | [26] |

| Carnicabra | Toledo | 26–43 | n-C29, n-C27, n-C31 | |||

| Empeltre | Teruel | 72–92 | n-C25, n-C23, n-C29 | |||

| Hojiblanca | Màlaga/Còrdoba | 20–53 | n-C27, n-C29, n-C25 | |||

| Picual | Jaen | 18–31 | n-C27, n-C29, n-C25 | |||

| Virgin olive oil | Debela | Krk island (Croatia) | 31 | n-C29, n-C27, n-C31 | [27] | |

| Naska | 104 | n-C25, n-C23, n-C24 | ||||

| Rosulja | 42 | n-C29, n-C25, n-C27 | ||||

| Slatka | 40 | n-C29, n-C27, n-C25 | ||||

| Extra virgin olive oil | Various origin | 20 | 71.6 | [5] | ||

| Refined olive oil | Various origin | 20 | 36.2 | |||

| Virgin olive oil | Various origin | 30 | 30.5–176.2 | n-C23, n-C25, n-C27, n-C29 | [2] | |

| Virgin olive oil | Bjelica | Istria (Croatia) | 40 | 13.7−26.4 | n-C29, n-C25, n-C27 | [11] |

| Buza | 28.0−62.3 | n-C25, n-C23, n-C24 | ||||

| Leccino | 27.0− 80.4 | n-C25, n-C23, n-C24 | ||||

| Olive oil | Meski | Bzerte (North-East Tunisia) | 90.9 ± 22.7 | n-C25, n-C27, n-C23 | [23] | |

| Virgin olive oil | Frantoio, Leccino, Maraiolo | Ciggiano, Italia | 8 | At early ripening n-C29 and n-C31;At late ripening n-C25, n-C27, n-C29 | [28] | |

| Olive oil | 4 | n-C27, n-C25, n-C29 | [3] | |||

| Extra virgin olive oil | Bianchera istriana, Leccino, Frantoio | Koper (Slovenia) | 3 | 62.7 ± 4.5 | n-C29, n-C25, n-C27 | [12] |

| Buza | Vodnjan (Croatia) | 4 | 96.7 ± 12.8 | n-C25, n-C23, n-C29 | ||

| Salonenque, Aglandau, Grossane, Verdale, Altre, Calian, Petit ribier, Coratina | Provence-Alpes-Côte d’Azur (France) | 15 | 66.8 ± 10.6 | n-C25, n-C29, n-C27 | ||

| Leccino, Frantoio, Grignano, Perlarola | Veneto (North Italy) | 4 | 81.3 ± 13.3 | n-C25, n-C27, n-C23 | ||

| Frantoio, Moraiolo, Leccino, San Felice, Caninese, Itrana | Tuscany, Laizo, Umbria (Central Italy) | 14 | 115.6 ± 12.1 | n-C25, n-C29, n-C27 | ||

| Ogliarola Precoce, Nocellara del Belice, Biancolilla, Tonda Iblea | Apulia (South Italy) | 7 | 96.2 ± 22.0 | n-C25, n-C23, n-C29 | ||

| Cobrancosa, Madural, Arbequina, Verdeal transmontana, Galega vulgar | Portugal | 5 | 73.9 ± 12.5 | n-C29, n-C27, n-C25 | ||

| Chalkidiki | Central Macedonia (North Greece) | 8 | 35.6 ± 3.5 | n-C25, n-C27, n-C29 | ||

| Koroneiki | Peloponnese (South Greece) | 6 | 67.8 ± 5.2 | n-C23, n-C25, n-C27 | ||

| Picual | Jean (Spain) | 6 | 40.1 ± 7.1 | n-C29, n-C27, n-C25 | ||

| Picholine marocaine | Meknes, El Hajeb (Marocco) | 4 | 78.0 ± 11.6 | n-C23, n-C25, n-C27 |

| Sample | Variety | Geographical Origin | Sample Number | Tot. n-Alkane (mg/kg) | Major n-Alkanes | Ref. |

|---|---|---|---|---|---|---|

| Sunflower oil | 5 | 105–166 | n-C27, n-C29, n-C31 | [24] | ||

| Sesame oil | 4 | 7–30 | n-C29, n-C31, n-C27 | |||

| Corn oil | 3 | 26–33 | n-C31, n-C29, n-C27 | |||

| Walnut oil | 3 | 7–30 | n-C29, n-C27, n-C31 | |||

| Peanut/Groundnut oil | 3 | 27–40 | n-C29, n-C31, n-C27 | |||

| Hazelnut oil (crude) | Turkey, France, Belgium, Italy, Spain | 10 | 0.6–13.9 | n-C25, n-C23, n-C27 | [29] | |

| Hazelnut oil (refined) | 7 | 0.6–5.17 | n-C29, n-C25, n-C27 | |||

| Avocado oil | Persea americana | Gioia Tauro (Italy) | 16.8–25.2 | n-C24, n-C25, n-C23 | [30] | |

| Grapessed oil | 4 | n-C31, n-C29, n-C27 | [3] | |||

| Hazelnut oil | 4 | n-C29, n-C31, n-C27 | ||||

| Peanut oil | 4 | n-C31, n-C29, n-C27 | ||||

| Corn oil | 4 | n-C31, n-C33, n-C29 | ||||

| Sunflower oil | 4 | n-C29, n-C31, n-C27 | ||||

| Tomato seed oil | Principe Borghese | Southern Italy | 347.3 ± 4.04 | n-C21, n-C25, n-C23 | [1] | |

| Rebelion | 216.0 ± 3.05 | |||||

| San Marzano | 106.7 ± 0.58 |

| Sample Amount—Internal Standard (I.S.) | Saponification and LLE for Unsaponifiable Extraction | Column Chromatography and/or Further Purification | Analysis (Injection Mode)—Column Type—Chromatographic Conditions | Ref. |

|---|---|---|---|---|

| 20 g oil sample + I.S. (n-C20) in 1 mL hexane | According to the Official European Community method—Annex XVII, for the determination of stigmastadienes in vegetable oils, 1995 *. | A glass column (1.5 cm i.d. × 50 cm) was filled with 15 g silica gel, slurried in hexane. After sample loading, the n-alkane fraction was eluted with hexane (50 mL) at 1 mL/min and concentrated to 1 mL. | GC-FID/ GC-MS Wide bore capillary column of borosilicate glass (30 m × 0.75 mm i.d.), coated with SPB-1, 1 µm film thickness. Oven temperature: 110 °C (6 min) to 300 °C at 5 °C/min. Injector: 300 °C; Detector: 320 °C; carrier gas: nitrogen at 14 mL/min. | [25] |

| 20 g oil sample + I.S. (n-C20) in 1 mL hexane | According to the Official European Community method—Annex XVII, for the determination of stigmastadienes in vegetable oils, 1995 *. | A glass column (2.0 cm i.d. × 50 cm) was filled with 15 g silica gel slurried in hexane. After sample loading, the n-alkane fraction was eluted with hexane (50 mL) and concentrated. | GC-FID (split/splitless injection; split ratio 1:20). Fused silica capillary column (30 m × 0.32 mm i.d.), coated with SPB 5; 1.0 µm film thickness. Oven temperature: 120 °C (4 min) to 280 °C (5 min) at 4 °C/min, then to 305 °C (10 min) at 4 °C/min; Injector and detector: 315 °C; carrier gas: helium (2 mL/min). | [27] |

| 20 g oil sample + I.S. (n-C11) | According to the Official European Community method—Annex XVII, for the determination of stigmastadienes in vegetable oils, 1995 *. | A glass column (1.5 cm i.d. × 50 cm) was filled with a 2 mm layer of anhydrous sodium sulphate and 15 g of silica gel and conditioned with hexane. After sample loading, the n-alkane fraction was eluted with n-hexane (120 mL) and concentrated to 1 mL. | GC-FID (on-column injection). Fused silica capillary column (25 m × 0.32 mm i.d.), coated with SE54, 0.25 µm film thickness. Oven temperature: 60 °C (1 min) to 290 °C (40 min) at 5 °C/min. Detector: 310 °C. | [30] |

| 20 g oil sample + I.S. (n-C20) in 1 mL hexane | According to the Official European Community method—Annex XVII, for the determination of stigmastadienes in vegetable oils, 1995 *. The solution was then passed through anhydrous sodium sulphate (50 g), washed with 20 mL of hexane and evaporated to dryness. | A glass column was filled with silica gel. After sample loading, the n-alkane fraction was eluted with hexane (30 mL). | GC-FID (split injection). Fused silica capillary column (30 m × 0.32 mm i.d.), coated with SE 54, 0.5 µm film thickness. Oven temperature: 100 °C (1 min) to 300 °C (10 min) at 4 °C/min. Injector: 280 °C; detector: 310 °C; carrier gas: helium (10 psi). | [1] |

| 20 g oil sample + I.S. (n-C20) in 1 mL hexane | Saponification: 30 min slight boiling with 75 mL of 10% ethanolic KOH. LLE: the saponified solution was transferred to a 500 mL separatory funnel, added to 100 mL of distilled water and extracted twice with 100 mL hexane. The combined extracts were concentrated to 1 mL. | A glass column (1.5 cm i.d. × 50 cm) was filled with 15 g silica gel, slurried in hexane. After loading the unsaponifiable fraction (together with washes), the n-alkane fraction was eluted with hexane (60 mL) at a rate of about 1 mL/min. | GC-FID/ GC-MS. Wide bore capillary column of borosilicate glass (30 m × 0.75 mm i.d.), coated with SPB-1, 1 µm film thickness. Oven temperature: 110 °C (60 min) to 300 °C at 5 °C/min. Injector: 300 °C; detector: 320 °C; carrier gas: nitrogen (14 mL/min). | [26] |

| 20 g of oil sample + I.S. (n-C20) in 1 mL hexane | Saponification 30 min slight boiling with 75 mL of 10% ethanolic KOH. LLE: The saponified solution was transferred to a 500 mL decanting funnel, 100 mL distilled water was added, and the mixture was extracted twice with 100 mL portions of hexane. The hexane solution was dried over anhydrous sodium sulfate, evaporated to dryness and dissolved in 1 mL of hexane | A glass column (1.5 cm i.d. × 40 cm) was filled with 15 g of silica gel. After sample loading, the n-alkane fraction was eluted with hexane (100 mL) and concentrated to about 0.5 mL. | GC-MS (on column injection). Fused silica capillary column (30 m × 0.25 mm i.d.), coated with DB-5, 0.25 µm film thickness. Oven temperature: 60 °C (1 min) to 120 °C at 3 °C/min, and finally to 300 °C at 7 °C/min. Detector: 300 °C; carrier gas: helium (1.3 mL/min). | [2] |

| 5 g of oil sample + I.S. (n-C16) | Saponification: ethanolic KOH 12% (w/v) at 60 °C for 1.5 h. After cooling, 50 mL of water was added and the unsaponifiable matter was extracted with 4 × 50 mL of petroleum ether. The combined extracts were washed with 50 mL of ethanol: water (1:1), dried over anhydrous sodium sulfate and evaporated to dryness. | The dry residue was dissolved in chloroform and deposited on a silica gel TLC plate. After developing the plate with hexane/diethyl ether (6:4, v/v), it was sprayed with 2,7-dichlorofluorescein and the band corresponding to hydrocarbons was scraped, extracted 3 times with chloroform/diethyl ether (1:1, v/v), filtered and dried in a rotary. evaporator. | GC-FID (split injection; 60:1 split ratio). Fused silica capillary column (30 m × 0.25 mm i.d.), coated with DB-5MS, 0.25 µm film thickness. Oven temperature: 150 °C to 300 °C (10 min) at 4 °C/min. Injector and detector: 250 °C.; carrier gas: helium (mL/min). The transfer line: 250 °C. Electron impact mass spectra were measured at an acceleration energy of 70 eV. | [23] |

| 5 g of oil sample + I.S. (n-C15) | Saponification: 19 mL of a 10% ethanolic KOH under reflux for 20 min. After cooling, 25 mL distilled water was added and the unsaponifiable fraction was extracted with 2 × 25 mL of n-hexane. The combined extracts were washed with 3 × 12.5 mL of ethanol:water mixture (1:1), dried on anhydrous sodium sulfate and evaporated to dryness. | A glass column (1.5 cm i.d. × 40 cm) was filled with 15 g of silica gel. After sample loading, the n-alkane fraction was eluted with n-hexane (40 mL) and concentrated to 0.5 mL. | GC-MS (splitless injection)—Fused silica capillary column (30 m × 0.25 mm i.d.), coated with TR-5MS, 0.25 µm film thickness. Oven temperature: 60 °C (3 min) to 300 °C (10 min) at 5 °C/min. Injector and transfer line at 300 °C. Ion source temperature: 225 °C; Carrier gas: helium (1 mL/min). | [3] |

| Sample Amount—Internal Standard (I.S.) | Column Chromatography | Analysis (Injection Mode)—Column Type—Chromatographic Conditions | Ref. |

|---|---|---|---|

| 100 mg oil sample in 5 mL hexane + I.S. mixture | A glass column (46 cm3) filled with silica gel heated al 550 °C for 18 h, pre-washed with 100 mL of hexane. After the sample was loaded, the n-alkane fraction was eluted with hexane (100 mL) and concentrated to 150 µL, followed by HPLC separation from aromatics on a 25 × 0.46 cm Lichrosorb Si-60, 5 µm. | GC-FID (on-column injection). Fused silica capillary column (25 cm × 0.25 mm i.d.), coated with 0.33 µm film of Ultra 1. Oven temperature: 60 °C (3 min) to 280 °C at 4 °C/min and held at this temperature until the end of the run. Injector and detector: 300 °C; carrier gas: nitrogen. | [24] |

| 500 mg of oil sample + I.S. mixture in 5 mL of isohexane | A glass column (2.0 cm i.d. × 11cm) filled with silica gel heated at 550 °C for 18 h and deactivated with 1% water, was washed with iso-hexane (100 mL). After loading the sample, the n-alkane fraction was eluted with isohexane (130 mL) and concentrated to 0.3 mL. Followed HPLC separation from aromatics on a 25 × 0.46 cm Lichrosorb Si-60, 5 µm. | GC-FID (on-column injection). Fused silica capillary column (25 cm × 0.25 mm i.d.), coated with Ultra 1, 0.33 µm film thickness. Oven temperature: 60 °C (3 min) to 280 °C at 4 °C/min and held at this temperature until the end of the run. Injector and detector: 300 °C; carrier gas: nitrogen. | [5] |

| 60 mg of oil sample + I.S. (n-C13, C14:1) in pentane | Online LC-GC-FID. | LC column: silica (Spherisorb), 100 × 4.6 mm i.d; wire interface; GC column: fused silica capillary column (12 m × 0.25 mm i.d.), coated with immobilized PS-255, 0.3 µm of film thickness. Transfer occurred at 49 °C; 8 min after the transfer the temperature was programmed at 15 °C/ min to 320 °C. The carrier gas (helium) inlet pressure was 70 kPa. | [11] |

| 75 mg of oil sample + I.S. (n-C15) in 0.5 mL of hexane | A glass Pasteur pipette (145 mm × 9 mm, packed with activated silica gel, was loaded with the sample and eluted with 5 mL of hexane. Each oil sample was extracted twice, and the eluents were combined and concentrated to 0.5 mL. | GC-FID (splitless mode) GC. Fused silica capillary column (30 m × 0.32 mm), coated with DB-5, 0.25 µm film thickness. Oven temperature: 50 °C (1 min) to 150 °C at 20 °C/min, then to 230 °C (10 min) at 8 °C/min. Injector: 300 °C; detector 280 °C; carrier gas: helium (1.2 mL/min). As an additional tool for [12], stable carbon and hydrogen isotope analyses of n-alkanes were performed using an isotope ratio mass spectrometer interfaced with GC. | [12,28] |

| 1 g of oil sample + I.S. (n-C15) | A glass column (1.5 cm i.d. × 50 cm) was filled with 40 mL hexane. About 18.5 g of silver-silica gel was poured slowly, avoiding bubbles. Later, a 1 cm layer of anhydrous sodium sulfate followed by a 1 cm layer of washed sand was added. Finally, the remaining solvent above the sand was discarded. After the sample was loaded, saturated hydrocarbons were eluted with 55 mL of hexane, concentrated and re-dissolved in 1 mL of heptane. | GC-FID (PTV). Fused silica capillary column (10 m × 0.32 mm) coated with CP-9070, 0.10 µm film thickness. Oven temperature: 60 °C (1 min) to 288 °C at 12 °C/min, then to 340 °C (4 min) at 6 °C/min. Detector temperature: 350 °C. Injection temperature program: 70 °C (1 min) to 300 °C (1 min) at 200 °C/min, and then back to 70 °C. Carrier gas: hydrogen at 15 mL/min. | [34] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srbinovska, A.; Conchione, C.; Menegoz Ursol, L.; Lucci, P.; Moret, S. Occurrence of n-Alkanes in Vegetable Oils and Their Analytical Determination. Foods 2020, 9, 1546. https://doi.org/10.3390/foods9111546

Srbinovska A, Conchione C, Menegoz Ursol L, Lucci P, Moret S. Occurrence of n-Alkanes in Vegetable Oils and Their Analytical Determination. Foods. 2020; 9(11):1546. https://doi.org/10.3390/foods9111546

Chicago/Turabian StyleSrbinovska, Ana, Chiara Conchione, Luca Menegoz Ursol, Paolo Lucci, and Sabrina Moret. 2020. "Occurrence of n-Alkanes in Vegetable Oils and Their Analytical Determination" Foods 9, no. 11: 1546. https://doi.org/10.3390/foods9111546