Effect of Hydration on Gluten-Free Breads Made with Hydroxypropyl Methylcellulose in Comparison with Psyllium and Xanthan Gum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bread Ingredients

2.2. Gluten-Free Breadmaking

2.3. Defining the Optimum Hydration Level of Breads

2.4. Physical Characteristics of Breads

2.5. Statistical Analysis

3. Results

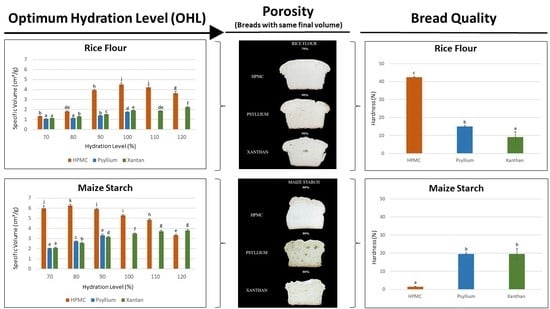

3.1. Optimum Hydration Level

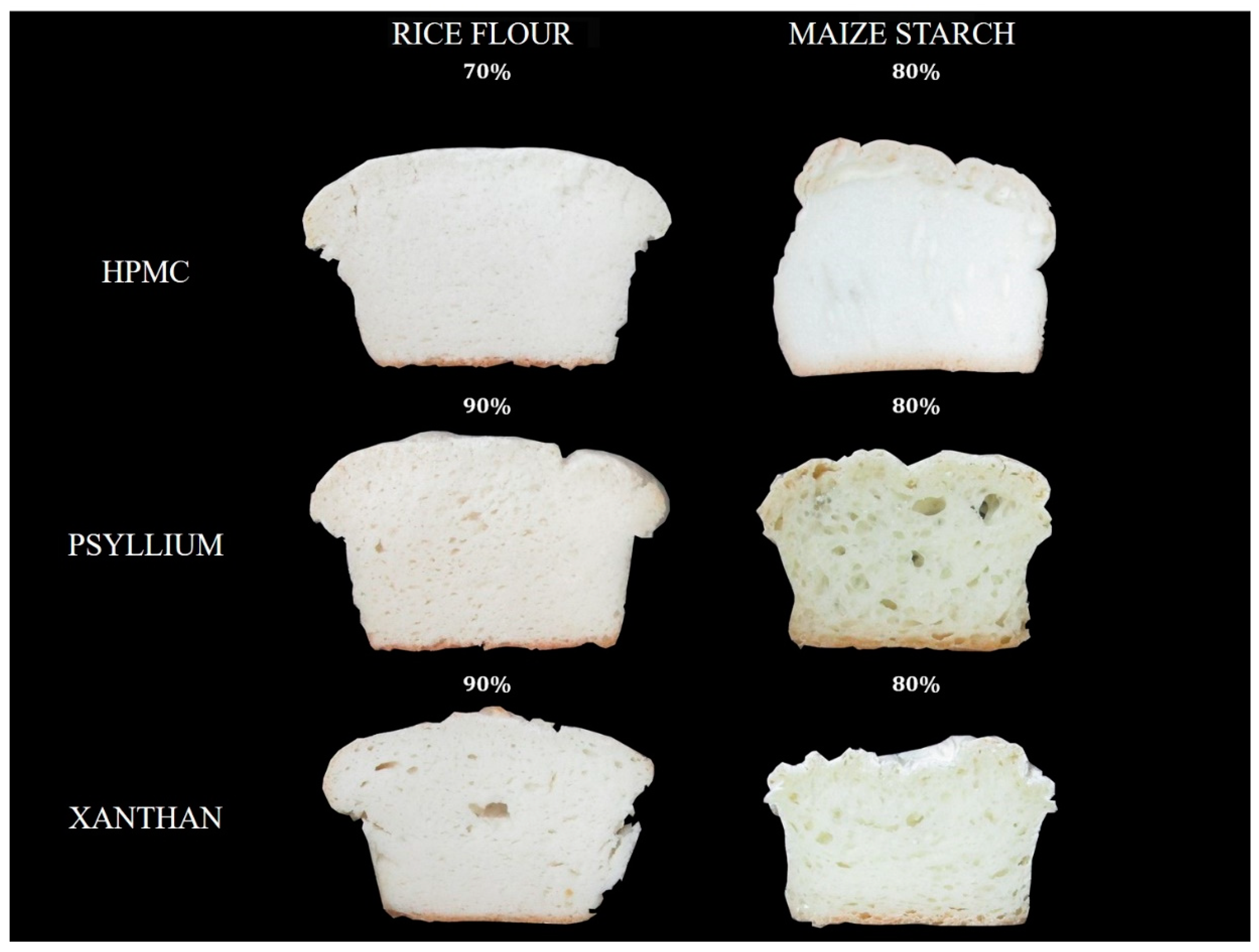

3.2. Gluten-Free Bread Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Delcour, J.A.; Joye, I.J.; Pareyt, B.; Wilderjans, E.; Brijs, K.; Lagrain, B. Wheat gluten functionality as a quality determinant in cereal-based food products. Annu. Rev. Food Sci. Technol. 2012, 3, 469–492. [Google Scholar] [CrossRef] [PubMed]

- Mir, S.A.; Shah, M.A.; Naik, H.R.; Zargar, I.A. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Sabanis, D.; Tzia, C. Effect of hydrocolloids on selected properties of gluten-free dough and bread. Food Sci. Technol. Int. 2011, 17, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Sciarini, L.S.; Ribotta, P.D.; León, A.E.; Pérez, G.T. Effect of hydrocolloids on gluten-free batter properties and bread quality. Int. J. Food Sci. Technol. 2010, 45, 2306–2312. [Google Scholar] [CrossRef]

- Anton, A.A.; Artfield, S.D. Hydrocolloids in gluten-free breads: A review. Int. J. Food Sci. Nutr. 2008, 59, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Masure, H.G.; Fierens, E.; Delcour, J.A. Current and forward looking experimental approaches in gluten-free bread making research. J. Cereal Sci. 2016, 67, 92–111. [Google Scholar] [CrossRef]

- Román, L.; Belorio, M.; Gomez, M. Gluten-free breads: The gap between research and commercial reality. Compr. Rev. Food Sci. Food Saf. 2018, 18, 690–702. [Google Scholar] [CrossRef] [Green Version]

- Belorio, M.; Marcondes, G.; Goméz, M. Influence of psyllium versus xanthan gum in starch properties. Food Hydrocoll. 2020, 105, 105843. [Google Scholar] [CrossRef]

- Zhang, J.; Wen, C.; Zhang, H.; Duan, Y. Review of isolation, structural properties, chain conformation, and bioactivities of psyllium polysaccharides. Int. J. Biol. Macromol. 2019, 139, 409–420. [Google Scholar] [CrossRef]

- Saha, D.; Bhattacharya, S. Hydrocolloids as thickening and gelling agents in food: A critical review. J. Food Sci. Technol. 2010, 47, 587–597. [Google Scholar] [CrossRef] [Green Version]

- Singh, B. Psyllium as therapeutic and drug delivery agent. Int. J. Pharm 2007, 334, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Haque, A.; Richardson, R.K.; Morris, E.R.; Dea, I.C.M. Xanthan-like “weak gel” rheology from dispersions of ispaghula seed husk. Carbohydr. Polym. 1993, 22, 223–232. [Google Scholar] [CrossRef]

- Cappa, C.; Lucisano, M.; Mariotti, M. Influence of psyllium, sugar beet fibre and water on gluten-free dough properties and bread quality. Carbohydr. Polym. 2013, 98, 1657–1666. [Google Scholar] [CrossRef]

- Haque, A.; Morris, E.R. Combined use of ispaghula and HPMC to replace or augment gluten in breadmaking. Food Res. Int. 1994, 21, 379–393. [Google Scholar] [CrossRef]

- Mancebo, C.M.; San Miguel, M.Á.; Martínez, M.M.; Gómez, M. Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J. Cereal Sci. 2015, 61, 8–15. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Martínez, M.M.; Merino, C.; de la Hera, E.; Gómez, M. Effect of oil and shortening in rice bread quality: Relationship between dough rheology and quality characteristics. J. Texture Stu 2017, 48, 597–606. [Google Scholar] [CrossRef]

- McCarthy, D.F.; Gallagher, E.; Gormley, T.R.; Schober, T.J.; Arendt, E.K. Application of response surface methodology in the development of gluten-free bread. Cereal. Chem. 2005, 82, 609–615. [Google Scholar] [CrossRef]

- Martínez, M.M.; Oliete, B.; Román, L.; Gómez, M. Influence of the addition of extruded flours on rice bread quality. J. Food Qual. 2014, 37, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Nunes, M.H.B.; Ryan, L.A.M.; Arendt, E.K. Effect of low lactose dairy powder addition on the properties of gluten-free batters and bread quality. Eur. Food Res. Technol. 2009, 229, 31–41. [Google Scholar] [CrossRef]

- Ziobro, R.; Juszczak, L.; Witczak, M.; Korus, J. Non-gluten proteins as structure forming agents in gluten free bread. J. Food Sci. Technol. 2016, 53, 571–580. [Google Scholar] [CrossRef] [Green Version]

- Ziobro, R.; Witczak, T.; Juszczak, L.; Korus, J. Supplementation of gluten-free bread with non-gluten proteins. Effect on dough rheological properties and bread characteristic. Food Hydrocoll. 2013, 32, 213–220. [Google Scholar] [CrossRef]

- Ren, Y.; Linter, B.R.; Linforth, R.; Foster, T.J. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020. [Google Scholar] [CrossRef] [PubMed]

- Sahagún, M.; Gómez, M. Assessing influence of protein source on characteristics of gluten-free breads optimising their hydration level. Food Bioproc. Technol. 2018, 11, 1686–1694. [Google Scholar] [CrossRef]

- Crockett, R.; Ie, P.; Vodovotz, Y. How do xanthan and hydroxypropyl methylcellulose individually affect the physicochemical properties in a model gluten-free dough. J. Food Sci. 2011, 76, 274–282. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Monteiro, F.; Teixeira, J.A.; Gonzales-Barron, U. Physicochemical and textural quality attributes of gluten-free bread formulated with guar gum. Eur. Food Res. Technol. 2019, 245, 443–458. [Google Scholar] [CrossRef] [Green Version]

- Martínez, M.M.; Gómez, M. Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J. Food Eng. 2017, 197, 78–86. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Axel, C.; Arendt, E.K. Water absorption as a prediction tool for the application of hydrocolloids in potato starch-based bread. Food Hydrocoll. 2018, 81, 129–138. [Google Scholar] [CrossRef]

- Matia-Merino, L.; Prieto, M.; Román, L.; Gómez, M. The impact of basil seed gum on native and pregelatinized corn flour and starch gel properties. Food Hydrocoll. 2019, 89, 122–130. [Google Scholar] [CrossRef]

- Gallagher, E.; Gormley, T.R.; Arendt, E.K. Crust and crumb characteristics of gluten free breads. J. Food Eng. 2003, 56, 153–161. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Schober, T.J.; Bean, S.R.; Boyle, D.L. Gluten-free sorghum bread improved by sourdough fermentation: Biochemical, rheological, and microstructural background. J. Agric. Food Chem. 2007, 55, 5137–5146. [Google Scholar] [CrossRef]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Laure, M. Influence of different hydrocolloids on dough thermo-mechanical properties and in vitro starch digestibility of gluten-free steamed bread based on potato flour. Food Chem. 2018, 239, 1064–1074. [Google Scholar] [CrossRef] [Green Version]

- Grover, J.A. Methylcellulose (MC) and hydroxypropyl methylcellulose (HPMC). In Food Hydrocolloids; CRC Press: Boca Raton, FL, USA, 1982. [Google Scholar]

- Mancebo, C.M.; Merino, C.; Martinez, M.M.; Gomez, M. Mixture design of rice flour, maize starch and wheat starch for optimization of gluten free bread quality. J. Food Sci. Technol. 2015, 52, 6323–6333. [Google Scholar] [CrossRef] [Green Version]

- Purlis, E.; Salvadori, V.O. Modelling the browning of bread during baking. Food Res. Int. 2009, 42, 865–870. [Google Scholar] [CrossRef]

- Gonzales, A.S.P.; Naranjo, G.B.; Leiva, G.E.; Malec, L.S. Maillard reaction kinetics in milk powder: Effect of water activity at mild temperatures. Int. Dairy J. 2010, 20, 40–45. [Google Scholar] [CrossRef]

| Samples | CH (%) | Specific Volume (cm3/g) | Weight Loss (g/100g) |

|---|---|---|---|

| RF HPMC | 70 | 1.33 ± 0.01 a | 9.33 ± 0.88 a |

| RF Psyllium | 90 | 1.44 ± 0.02 ab | 9.89 ± 0.18 a |

| RF Xanthan | 90 | 1.48 ± 0.03 b | 9.76 ± 0.18 a |

| MS HPMC | 80 | 7.58 ± 0.04 d | 28.20 ± 0.12 c |

| MS Psyllium | 80 | 2.37 ± 0.08 c | 16.60 ± 0.86 b |

| MS Xanthan | 80 | 2.25 ± 0.08 c | 17.50 ± 1.50 b |

| Samples | Hardness (N) | Springiness | Cohesiveness | Resilience |

|---|---|---|---|---|

| RF HPMC | 42.44 ± 0.21 d | 0.796 ± 0.004 a | 0.656 ± 0.023 ab | 0.383 ± 0.009 a |

| RF Psyllium | 14.98 ± 0.60 c | 0.891 ± 0.025 b | 0.748 ± 0.037 c | 0.479 ± 0.041 bc |

| RF Xanthan | 9.04 ± 3.00 b | 0.922 ± 0.043 bc | 0.807 ± 0.024 c | 0.501 ± 0.013 bc |

| MS HPMC | 1.44 ± 0.12 a | 1.011 ± 0.023 d | 0.754 ± 0.030 c | 0.493 ± 0.034 bc |

| MS Psyllium | 19.51 ± 3.40 c | 0.974 ± 0.004 cd | 0.733 ± 0.037 bc | 0.550 ± 0.052 c |

| MS Xanthan | 19.58 ± 1.55 c | 0.964 ± 0.002 cd | 0.606 ± 0.037 a | 0.420 ± 0.047 ab |

| Samples | L* | a* | b* |

|---|---|---|---|

| RF HPMC | 81.68 ± 3.05 c | 1.64 ± 0.25 bc | 17.15 ± 0.68 bc |

| RF Psyllium | 79.92 ± 4.67 bc | 1.23 ± 0.39 b | 15.36 ± 0.18 b |

| RF Xanthan | 75.05 ± 0.83 ab | 4.48 ± 0.08 d | 20.25 ± 1.22 c |

| MS HPMC | 82.09 ± 0.04 c | 2.64 ± 0.14 c | 19.32 ± 0.22 c |

| MS Psyllium | 86.20 ± 2.13 c | -0.05 ± 1.07 a | 14.56 ± 2.64 b |

| MS Xanthan | 71.26 ± 1.92 a | 0.06 ± 0.09 a | 9.72 ± 1.93 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belorio, M.; Gómez, M. Effect of Hydration on Gluten-Free Breads Made with Hydroxypropyl Methylcellulose in Comparison with Psyllium and Xanthan Gum. Foods 2020, 9, 1548. https://doi.org/10.3390/foods9111548

Belorio M, Gómez M. Effect of Hydration on Gluten-Free Breads Made with Hydroxypropyl Methylcellulose in Comparison with Psyllium and Xanthan Gum. Foods. 2020; 9(11):1548. https://doi.org/10.3390/foods9111548

Chicago/Turabian StyleBelorio, Mayara, and Manuel Gómez. 2020. "Effect of Hydration on Gluten-Free Breads Made with Hydroxypropyl Methylcellulose in Comparison with Psyllium and Xanthan Gum" Foods 9, no. 11: 1548. https://doi.org/10.3390/foods9111548

APA StyleBelorio, M., & Gómez, M. (2020). Effect of Hydration on Gluten-Free Breads Made with Hydroxypropyl Methylcellulose in Comparison with Psyllium and Xanthan Gum. Foods, 9(11), 1548. https://doi.org/10.3390/foods9111548