Emerging Technologies for Aerial Decontamination of Food Storage Environments to Eliminate Microbial Cross-Contamination

Abstract

1. Introduction

2. Sources of Airborne Contamination in Processing Plants

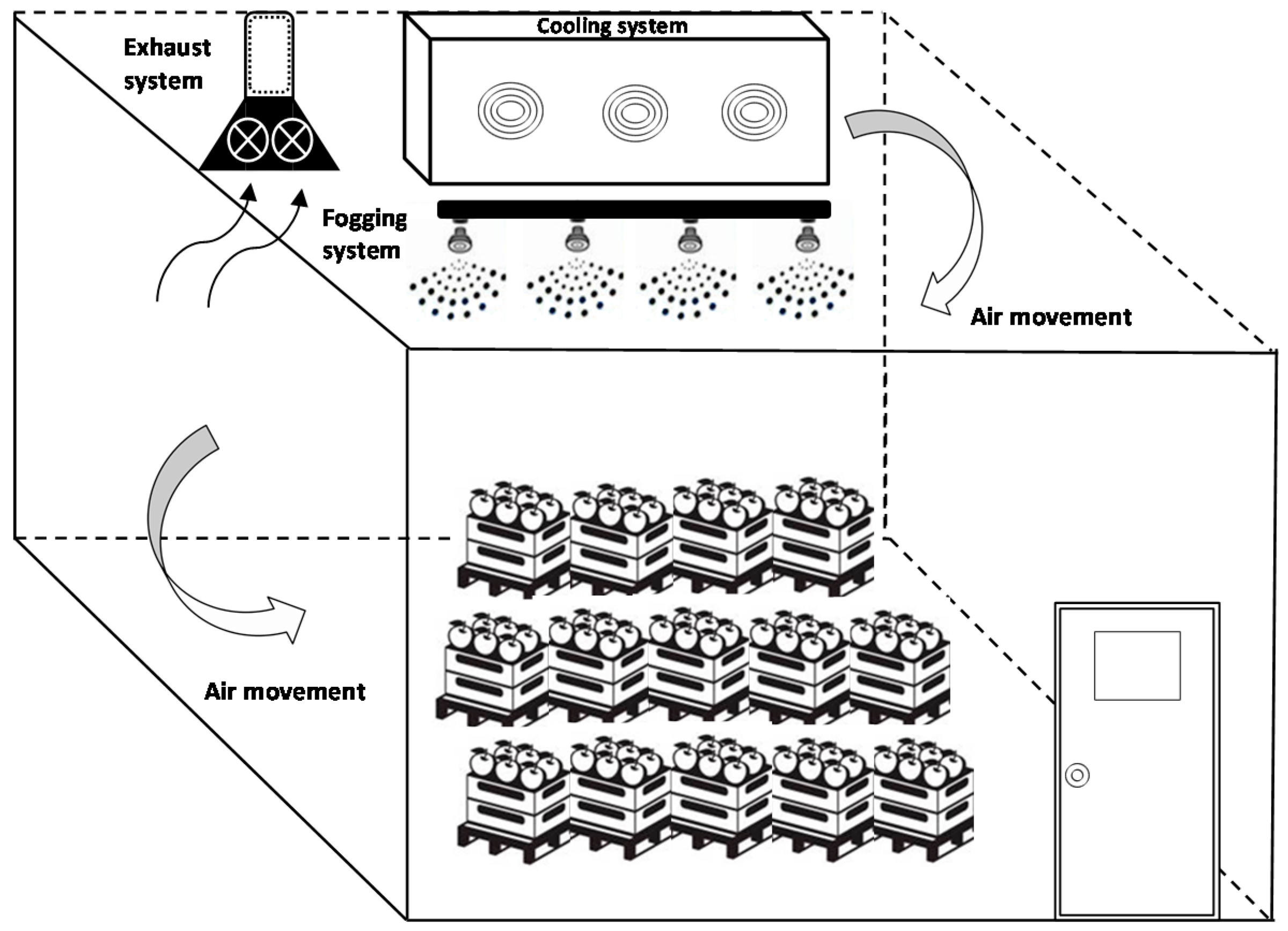

Cold Room Microbial Cross-Contamination

3. Current and Emerging Air Decontamination Methods

3.1. Ultraviolet Light (UV) Irradiation

Application of UV in Cold Storage Room

3.2. Oxygen-Based Technologies

3.2.1. Fogging

Application of Fogging in Cold Storage Room

3.2.2. Ozone

Application of Ozone in Cold Storage Room

3.3. Other Decontamination Techniques

4. Challenges and Future Considerations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parrett, F.; Crilly, K. Microbiological air monitoring. Int. Food Hyg. 2000, 10, 5–7. [Google Scholar]

- Constantinidou, H.A.; Hirano, S.S.; Baker, L.S.; Upper, C.D. Atmospheric dispersal of ice nucleation-active bacteria-the role of rain. Phytopathology 1990, 80, 934–937. [Google Scholar] [CrossRef]

- Lindemann, J.; Upper, C.D. Aerial dispersal of epiphytic bacteria over bean-plants. Appl Env. Microbiol 1985, 50, 1229–1232. [Google Scholar] [CrossRef]

- Cevallos-Cevallos, J.M.; Gu, G.Y.; Danyluk, M.D.; Dufault, N.S.; van Bruggen, A.H.C. Salmonella can reach tomato fruits on plants exposed to aerosols formed by rain. Int. J. Food Microbiol. 2012, 158, 140–146. [Google Scholar] [CrossRef]

- Kwon, Y.M.; Woodward, C.L.; Pillai, S.D.; Pena, J.; Corrier, D.E.; Byrd, J.A.; Ricke, S.C. Litter and aerosol sampling of chicken houses for rapid detection of Salmonella Typhimurium contamination using gene amplification. J. Ind. Microbiol. Biotechnol. 2000, 24, 379–382. [Google Scholar] [CrossRef]

- Pearce, R.A.; Sheridan, J.J.; Bolton, D.J. Distribution of airborne microorganisms in commercial pork slaughter processes. Int. J. Food Microbiol. 2006, 107, 186–191. [Google Scholar] [CrossRef] [PubMed]

- Harbaugh, E.; Trampel, D.; Wesley, I.; Hoff, S.; Griffith, R.; Hurd, H.S. Rapid aerosol transmission of Salmonella among turkeys in a simulated holding-shed environment. Poult. Sci. 2006, 85, 1693–1699. [Google Scholar] [CrossRef] [PubMed]

- Proux, K.; Cariolet, R.; Fravalo, P.; Houdayer, C.; Keranflech, A.; Madec, F. Contamination of pigs by nose-to-nose contact or airborne transmission of Salmonella Typhimurium. Vet. Res. 2001, 32, 591–600. [Google Scholar] [CrossRef] [PubMed]

- Griffiths, W.D.; Decosemo, G.A.L. The assessment of bioaerosols-A critical Review. J. Aerosol Sci. 1994, 25, 1425–1458. [Google Scholar] [CrossRef]

- Roth, Y.; Chapnik, J.S.; Cole, P. Feasibility of aerosol vaccination in humans. Ann. Otol. Rhinol. Laryngol. 2003, 112, 264–270. [Google Scholar] [CrossRef] [PubMed]

- Sattar, S.A.; Ijaz, M.K. Spread of viral-infections by aerosols. Crit. Rev. Environ. Contr. 1987, 17, 89–131. [Google Scholar] [CrossRef]

- Ijaz, M.K.; Zargar, B.; Wright, K.E.; Rubino, J.R.; Sattar, S.A. Generic aspects of the airborne spread of human pathogens indoors and emerging air decontamination technologies. Am. J. Infect. Control. 2016, 44, S109–S120. [Google Scholar] [CrossRef] [PubMed]

- McDermid, A.S.; Lever, M.S. Survival of Salmonella Enteritidis PT4 and Salmonella Typhimurium Swindon in aerosols. Lett. Appl. Microbiol. 1996, 23, 107–109. [Google Scholar] [CrossRef]

- Whyte, P.; Collins, J.D.; McGill, K.; Monahan, C.; O’Mahony, H. Distribution and prevalence of airborne microorganisms in three commercial poultry processing plants. J. Food Prot. 2001, 64, 388–391. [Google Scholar] [CrossRef] [PubMed]

- Spurlock, A.T.; Zottola, E.A. The survival of Listeria monocytogenes in aerosols. J. Food Prot. 1991, 54, 910–912. [Google Scholar] [CrossRef] [PubMed]

- Dutkiewicz, J.; Krysinska-Traczyk, E.; Skorska, C.; Sitkowska, J.; Prazmo, Z.; Golec, M. Exposure to airborne microorganisms and endotoxin in herb processing plants. Ann. Agric. Environ. Med. 2001, 8, 201–211. [Google Scholar]

- Sawyer, B.; Elenbogen, G.; Rao, K.C.; Obrien, P.; Zenz, D.R.; Luehing, C. Bacterial aerosol emission rates from municipal waste-water aeration tanks. Appl. Environ. Microbiol. 1993, 59, 3183–3186. [Google Scholar] [CrossRef]

- Buckland, F.E.; Tyrell, D.A.J. Experiments on the spread of colds. 1. Laboratory studies in dispersal of nasal secretions. J. Hyg. 1964, 62, 365–379. [Google Scholar] [CrossRef]

- Burfoot, D.; Whyte, R.T.; Tinker, D.B.; Hall, K.; Allen, V.M. A novel method for assessing the role of air in the microbiological contamination of poultry carcasses. Int. J. Food Microbiol. 2007, 115, 48–52. [Google Scholar] [CrossRef]

- Burfoot, D.; Whyte, R.; Tinker, D.; Howell, M.; Hall, K.; Holah, J.; Smith, D.; White, R.; Baker, D.; McIntosh, J. Importance of airborne contamination during dressing of beef and lamb carcasses. J. Food Protec. 2006, 69, 2828–2836. [Google Scholar] [CrossRef]

- Sirami, J. La contamination microbiologique de l’air dans le hall d’abbatage: Factures de variation et influence sur la carcasse. Viande Prod. Carne. 1989, 10, 109–116. [Google Scholar]

- Rahkio, T.M.; Korkeala, H.J. Airborne bacteria and carcass contamination in slaughterhouses. J. Food Protec. 1997, 60, 38–42. [Google Scholar] [CrossRef]

- Kang, Y.J.; Frank, J.F. Biological aerosols: A review of airborne contamination and its measurement in dairy processing plants. J. Food Protec. 1989, 52, 512–524. [Google Scholar] [CrossRef]

- Ye, S.Y.; Song, X.L.; Liang, J.L.; Zheng, S.H.; Lin, Y. Disinfection of airborne spores of Penicillium expansum in cold storage using continuous direct current corona discharge. Biosyst. Eng. 2012, 113, 112–119. [Google Scholar] [CrossRef]

- Okraszska-Lasica, W.; Bolton, D.J.; Sheridan, J.J.; McDowell, D.A. Comparison of aerial counts at different sites in beef and sheep abattoirs and the relationship between aerial and beef carcass contamination. Food Microbiol. 2012, 32, 325–331. [Google Scholar] [CrossRef] [PubMed]

- Ellerbroek, L. Airborne microflora in poultry slaughtering establishments. Food Microbiol 1997, 14, 527–531. [Google Scholar] [CrossRef]

- Fries, R.; Graw, C. Water and air in two poultry processing plant’s chilling facilities-a bacteriological survey. Br. Poult. Sci. 1999, 40, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Barkai-Golan, R. Reinfestation of citrus fruits by pathogenic fungi in the packing house. Isr. J. Agric. Res. 1966, 16, 133–138. [Google Scholar]

- Marriott, N.G.; Gravani, R.B. Principles of Food Sanitation; Springer: Boston, MA, USA, 2006. [Google Scholar]

- Kowalski, W.J.; Bahnfleth, W.P.; Striebig, B.A.; Whittam, T.S. Demonstration of a hermetic airborne ozone disinfection system: Studies on E. coli. AIHA J. 2003, 64, 222–227. [Google Scholar] [CrossRef]

- Saks, Y.; Ward, G.; Erdman, S.; Goldstein, Y.; Lichter, A.; Rodov, V. Pulsed UV light for decontamination of cold storage facilities. Acta Hortic. 2006, 712, 893–898. [Google Scholar] [CrossRef]

- Cundith, C.J.; Kerth, C.R.; Jones, W.R.; McCaskey, T.; Kuhlers, D.L. Air-cleaning system effectiveness for control of airborne microbes in a meat-processing plant. J. Food Sci. 2002, 67, 1170–1174. [Google Scholar] [CrossRef]

- Sholberg, P.L. Bin and storage room sanitation. In Proceedings of the Washington Tree Fruit Postharvest Conference, Yakima, WA, USA, 8 December 2004; pp. 1–8. [Google Scholar]

- Vardar, C.; Ilhan, K.; Karabulut, O.A. The application of various disinfectants by fogging for decreasing postharvest diseases of strawberry. Postharvest Biol. Technol. 2012, 66, 30–34. [Google Scholar] [CrossRef]

- Karabulut, O.A.; Ilhan, K.; Arslan, U.; Vardar, C. Evaluation of the use of chlorine dioxide by fogging for decreasing postharvest decay of Figure. Postharvest Biol. Technol. 2009, 52, 313–315. [Google Scholar] [CrossRef]

- Gibson, C.A.; Elliot, J.A.; Beckett, D.C. Ozone for controlling mold on cheddar cheese. Can. Dairy Ice Cream J. 1960, 14, 24–28. [Google Scholar]

- Shiler, G.G.; Eliseeva, N.N.; Chebotarev, L.N. Use of ozone and ultra-violet radiation for the inactivation of mould spores. In Proceedings of the 20th International Dairy Congress, Paris, France, 26–30 June 1978; p. E616. [Google Scholar]

- Serra, R.; Abrunhosa, L.; Kozakiewicz, Z.; Venancio, A.; Lima, N. Use of ozone to reduce molds in a cheese ripening room. J. Food Prot. 2003, 66, 2355–2358. [Google Scholar] [CrossRef] [PubMed]

- Pinto, A.T.; Schmidt, V.; Raimundo, S.A.; Raihmer, F. Moulds control by ozonization in ripening cheese room. Acta Sci. Vet. 2007, 35, 333–337. [Google Scholar] [CrossRef]

- Lanita, C.S.; Silva, S.B. Use of ozone in industrial cold rooms to control yeasts and moulds during parmesan cheese ripening. Braz. J. Food Technol. 2008, 11, 182–189. [Google Scholar]

- Malinowska, A.; Holah, J. Whole Room Disinfection; Campden BRI R&D: Chipping Campden, UK, 2010. [Google Scholar]

- Bintsis, T.; Litopoulou-Tzanetaki, E.; Robinson, R.K. Existing and potential applications of ultraviolet light in the food industry-a critical review. J. Sci. Food Agric. 2000, 80, 637–645. [Google Scholar] [CrossRef]

- Memarzadeh, F.; Olmsted, R.N.; Bartley, J.M. Applications of ultraviolet germicidal irradiation disinfection in health care facilities: Effective adjunct, but not stand-alone technology. Am. J. Infect. Control. 2010, 38, S13–S24. [Google Scholar] [CrossRef]

- Rutala, W.A.; Weber, D.J. Sterilization, high-level disinfection, and environmental cleaning. Infect. Dis. Clin. North. Am. 2011, 25, 45. [Google Scholar] [CrossRef]

- Burfoot, D. Clean air and a clean environment. Milk Ind. Inter. 1999, 6, 19–21. [Google Scholar]

- Holah, J.T.; Rogers, S.J.; Holder, J.; Hall, K.E.; Taylor, J.; Brown, K.L. The Evaluation of Air Disinfection Systems; CCFRA R&D Report No. 13; Camden and Chorleywood Food Research Association: Gloucestershire, UK, 1995; pp. 1–22. [Google Scholar]

- Shah, B.P.; Shah, U.S.; Siripurapu, S.C.B. Ultraviolet irradiation and laminar air flow systems for clean air in dairy plants. Indian Dairym. 1994, 46, 757–759. [Google Scholar]

- Bodmer, R. Hygiene durch UVC-Entkeimung [Hygiene with UV-C sterilization]. Fleischerei 1999, 50, 42. [Google Scholar]

- Morgan, R. UV ‘green’ light disinfection. Dairy Ind. Int. 1989, 54, 33–35. [Google Scholar]

- Hoehn, R.C.; Shorney-Darby, H.; Neemann, J. Chlorine dioxide. In White’s Handbook of Chlorination and Alternative Disinfectants, Black and Veatch Corporation; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 700–766. [Google Scholar]

- Tuladhar, E.; Terpstra, P.; Koopmans, M.; Duizer, E. Virucidal efficacy of hydrogen peroxide vapour disinfection. J. Hosp. Infect. 2012, 80, 110–115. [Google Scholar] [CrossRef]

- Morino, H.; Fukuda, T.; Miura, T.; Shibata, T. Effect of low-concentration chlorine dioxide gas against bacteria and viruses on a glass surface in wet environments. Lett. Appl. Microbiol. 2011, 53, 628–634. [Google Scholar] [CrossRef]

- Yeap, J.W.; Kaur, S.; Lou, F.F.; DiCaprio, E.; Morgan, M.; Linton, R.; Li, J.R. Inactivation kinetics and mechanism of a human norovirus surrogate on stainless steel coupons via chlorine dioxide gas. Appl. Environ. Microbiol 2016, 82, 116–123. [Google Scholar] [CrossRef]

- Hedrick, T.I. Engineering and science of aeromicrobiological contamination control in dairy plants. Chem. Ind. 1975, 20, 868–872. [Google Scholar]

- Burfoot, D.; Hall, K.; Brown, K.; Xu, Y. Fogging for the disinfection of food processing factories and equipment. Trends Food Sci. Technol. 1999, 10, 205–210. [Google Scholar] [CrossRef]

- McDonnell, G.; Russell, A.D. Antiseptics and disinfectants: Activity, action, and resistance. Clin. Microbiol. Rev. 1999, 12, 147. [Google Scholar] [CrossRef]

- Brul, S.; Coote, P. Preservative agents in foods-Mode of action and microbial resistance mechanisms. Int. J. Food Microbiol. 1999, 50, 1–17. [Google Scholar] [CrossRef]

- Smilanick, J.L.; Mansour, M.; Sorenson, D. Performance of fogged disinfectants to inactivate conidia of Penicillium digitatum within citrus degreening rooms. Postharvest Biol. Technol. 2014, 91, 134–140. [Google Scholar] [CrossRef]

- Johnston, M.D.; Lawson, S.; Otter, J.A. Evaluation of hydrogen peroxide vapour as a method for the decontamination of surfaces contaminated with Clostridium botulinum spores. J. Microbiol. Methods 2005, 60, 403–411. [Google Scholar] [CrossRef] [PubMed]

- Tzanavaras, P.D.; Themelis, D.G.; Kika, F.S. Review of analytical methods for the determination of chlorine dioxide. Cent. Eur. J. Chem. 2007, 5, 1–12. [Google Scholar] [CrossRef]

- Vandekinderen, I.; Devlieghere, F.; Van Camp, J.; Kerkaert, B.; Cucu, T.; Ragaert, P.; De Bruyne, J.; De Meulenaer, B. Effects of food composition on the inactivation of foodborne microorganisms by chlorine dioxide. Int. J. Food Microbiol. 2009, 131, 138–144. [Google Scholar] [CrossRef]

- Huang, J.L.; Wang, L.; Ren, N.Q.; Ma, F.; Juli. Disinfection effect of chlorine dioxide on bacteria in water. Water Res. 1997, 31, 607–613. [Google Scholar] [CrossRef]

- Pillai, K.C.; Kwon, T.O.; Park, B.B.; Moon, I.S. Studies on process parameters for chlorine dioxide production using IrO2 anode in an un-divided electrochemical cell. J. Hazard. Mat. 2009, 164, 812–819. [Google Scholar] [CrossRef]

- Gómez-López, V.M.; Rajkovic, A.; Ragaert, P.; Smigic, N.; Devlieghere, F. Chlorine dioxide for minimally processed produce preservation: A review. Trends Food Sci. Technol. 2009, 20, 17–26. [Google Scholar] [CrossRef]

- Jeng, D.K.; Woodworth, A.G. Chlorine dioxide gas sterilization under square-wave conditions. Appl. Environ. Microbiol. 1990, 56, 514–519. [Google Scholar] [CrossRef]

- Wilson, S.C.; Wu, C.; Andriychuk, L.A.; Martin, J.M.; Brasel, T.L.; Jumper, C.A.; Straus, D.C. Effect of chlorine dioxide gas on fungi and Mycotoxins associated with sick building syndrome. Appl. Environ. Microbiol. 2005, 71, 5399–5403. [Google Scholar] [CrossRef][Green Version]

- Daus, A.; Horev, B.; Dvir, O.; Ish-Shalom, S.; Lichter, A. The efficacy of ultrasonic fumigation for disinfestation of storage facilities against postharvest pathogens. Postharvest Biol. Technol. 2011, 62, 310–313. [Google Scholar] [CrossRef]

- Tapp, C.; Rice, R.G. Generation and control of ozone. In Ozone in Food Processing; O’Donnell, C., Tiwari, B.K., Cullen, P.J., Rice, R.G., Eds.; Wiley-Blackwell: Oxford, UK, 2012; pp. 33–54. [Google Scholar]

- Weavers, L.K.; Wickramanayake, G.B. Disinfection and sterilization using ozone. In Disinfection, Sterilization, and Preservation; Block, S.S., Ed.; Lippincott, Williams and Wilkins: New York, NY, USA, 2001; pp. 205–214. [Google Scholar]

- Tiwari, B.K.; Rice, R.G. Regulatory and legislative issues. In Ozone in Food Processing; O’Donnell, C., Tiwari, B.K., Cullen, P.J., Rice, R.G., Eds.; Wiley-Blackwell: Oxford, UK, 2012; pp. 7–17. [Google Scholar]

- Cullen, P.J.; Tiwari, B.K.; O’Donnell, C.P.; Muthukumarappan, K. Modelling approaches to ozone processing of liquid foods. Trends Food Sci. Technol. 2009, 20, 125–136. [Google Scholar] [CrossRef]

- Khadre, M.A.; Yousef, A.E.; Kim, J.G. Microbiological aspects of ozone applications in food: A review. J. Food Sci. 2001, 66, 1242–1252. [Google Scholar] [CrossRef]

- Restaino, L.; Frampton, E.W.; Hemphill, J.B.; Palnikar, P. Efficacy of ozonated water against various food-related microorganisms. Appl Environ. Microbiol. 1995, 61, 3471–3475. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.G.; Yousef, A.E. Inactivation kinetics of foodborne spoilage and pathogenic bacteria by ozone. J. Food Sci. 2000, 65, 521–528. [Google Scholar] [CrossRef]

- Taylor, J.; Chana, D. The Evaluation of Ozone for Airborne and Surface Disinfection; Campden and Chorleywood Food Research Association: Chipping Campden, UK, 2000. [Google Scholar]

- Gabriel’yants’, M.A.; Teplova, L.N.; Karpova, T.I.; Kozlova, R.A.; Makarova, G.F. Storage of hard rennet cheeses in cold stores with ozonation of air. Kholodil’naya Tekhnika 1980, 5, 35–37. [Google Scholar]

- Cullen, P.J.; Norton, T. Ozone sanitisation in the food industry. In Ozone in Food Processing; O’Donnell, C., Tiwari, B.K., Cullen, P.J., Rice, R.G., Eds.; Wiley-Blackwell: Oxford, MS, USA, 2012; pp. 163–176. [Google Scholar]

- Fujishima, A.; Rao, T.N.; Tryk, D.A. Titanium dioxide photocatalysis. J. Photochem. Photobiol. C Photochem. Rev. 2000, 1, 1–21. [Google Scholar] [CrossRef]

- Horie, Y.; Taya, M.; Tone, S. Evaluation of photocatalytic sterilization rates of Escherichia coli cells in titanium dioxide slurry irradiated with various light sources. J. Chem. Eng. Jpn. 1998, 31, 577–584. [Google Scholar] [CrossRef]

- Matsunaga, T.; Tomoda, R.; Nakajima, T.; Wake, H. Photoelectrochemical sterilization of microbial cells by semiconductor. FEMS Microbiol. Lett. 1985, 29, 211–214. [Google Scholar] [CrossRef]

- Goswami, D.Y.; Trivedi, D.M.; Block, S.S. Photocatalytic disinfection of indoor air. J. Sol. Energy Eng. 1997, 119, 92–96. [Google Scholar] [CrossRef]

- Greist, H.T.; Hingorani, S.K.; Kelly, K.; Goswami, D.Y. Using scanning electron microscopy to visualize photocatalytic mineralization of airborne microorganisms. In Proceedings of the 9th International Conference on Indoor Air Quality and Climate Indoor Air 2002, Monterey, CA, USA, 30 June–5 July 2002; p. 712. [Google Scholar]

- Lin, C.Y.; Li, C.S. Inactivation of microorganisms on the photocatalytic surfaces in air. Aerosol Sci. Technol. 2003, 37, 939–946. [Google Scholar] [CrossRef]

- Wolfrum, E.J.; Huang, J.; Blake, D.M.; Maness, P.C.; Huang, Z.; Fiest, J.; Jacoby, W.A. Photocatalytic oxidation of bacteria, bacterial and fungal spores, and model biofilm components to carbon dioxide on titanium dioxide-coated surfaces. Environ. Sci. Technol. 2002, 36, 3412–3419. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.P.; Lee, G.W.M.; Lin, Z.Y.; Huang, C.P. Removal of bioaerosols by the combination of a photocatalytic filter and negative air ions. J. Aerosol Sci. 2008, 39, 377–392. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.Y.; Fan, M.L.; Song, X.L.; Luo, S.C. Enhanced photocatalytic disinfection of Penicillium expansum in cold storage using a TiO2/ACF film. Int. J. Food Microbiol. 2010, 136, 332–339. [Google Scholar] [CrossRef]

- Skowron, K.; Grudlewska, K.; Kwiecinska-Pirog, J.; Gryn, G.; Srutek, M.; Gospodarek-Komkowska, E. Efficacy of radiant catalytic ionization to reduce bacterial populations in air and on different surfaces. Sci. Total Environ. 2018, 610, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Grinshpun, S.A.; Adhikari, A.; Honda, T.; Kim, K.Y.; Toivola, M.; Rao, K.S.R.; Reponen, T. Control of aerosol contaminants in indoor air: Combining the particle concentration reduction with microbial inactivation. Environ. Sci. Technol. 2007, 41, 606–612. [Google Scholar] [CrossRef] [PubMed]

- Ferro, S.; Coppellotti, O.; Roncucci, G.; Ben Amor, T.; Jori, G. Photosensitized inactivation of Acanthamoeba palestinensis in the cystic stage. J. Appl. Microbiol. 2006, 101, 206–212. [Google Scholar] [CrossRef]

- Friedberg, J.S.; Skema, C.; Baum, E.D.; Burdick, J.; Vinogradov, S.A.; Wilson, D.F.; Horan, A.D.; Nachamkin, I. In vitro effects of photodynamic therapy on Aspergillus Fumigatus. J Antimicrob. Chemother. 2001, 48, 105–107. [Google Scholar] [CrossRef]

- Lambrechts, S.A.G.; Aalders, M.C.G.; Van Marle, J. Mechanistic study of the photodynamic inactivation of Candida albicans by a cationic porphyrin. Antimicrob. Agents Chemother. 2005, 49, 2026–2034. [Google Scholar] [CrossRef]

- Zeina, B.; Greenman, J.; Purcell, W.M.; Das, B. Killing of cutaneous microbial species by photodynamic therapy. Br. J. Derm. 2001, 144, 274–278. [Google Scholar] [CrossRef]

- Maclean, M.; MacGregor, S.J.; Anderson, J.G.; Woolsey, G. Inactivation of bacterial pathogens following exposure to light from a 405-nanometer light-emitting diode array. Appl. Environ. Microbiol. 2009, 75, 1932–1937. [Google Scholar] [CrossRef] [PubMed]

- Landa-Solis, C.; Gonzalez-Espinosa, D.; Guzman-Soriano, B.; Snyder, M.; Reyes-Teran, G.; Torres, K.; Gutierrez, A.A. Microcyn (TM): A novel super-oxidized water with neutral pH and disinfectant activity. J. Hosp. Infect. 2005, 61, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Vorobjeva, N.V.; Vorobjeva, L.I.; Khodjaev, E.Y. The bactericidal effects of electrolyzed oxidizing water on bacterial strains involved in hospital infections. Artif. Organs 2004, 28, 590–592. [Google Scholar] [CrossRef] [PubMed]

- Rahman, S.M.E.; Khan, I.; Oh, D.H. Electrolyzed water as a novel sanitizer in the food industry: Current trends and future perspectives. Compr. Rev. Food Sci. Food Saf. 2016, 15, 471–490. [Google Scholar] [CrossRef]

- Abadias, M.; Usall, J.; Oliveira, M.; Alegre, I.; Viñas, I. Efficacy of neutral electrolyzed water (NEW) for reducing microbial contamination on minimally-processed vegetables. Int. J. Food Microbiol. 2008, 123, 151–158. [Google Scholar] [CrossRef]

- Pangloli, P.; Hung, Y.C.; Beuchat, L.R.; King, C.H.; Zha, Z.H. Reduction of Escherichia coli O157:H7 on produce by use of electrolyzed water under simulated food service operation conditions. J. Food Prot. 2009, 72, 1854–1861. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dev, S.; Demirci, A.; Graves, R.; Puri, V. Electrolyzed Oxidizing Water for Cleaning-in-Place of Milking Systems on Dairy Farms; Paper # NABEC/CSBE 12-063; Canadian Society for Bioengineering: Winnipeg, MB, Canada, 2012; Available online: http://www.csbe-scgab.ca/docs/meetings/2012/CSBE12063.pdf (accessed on 2 April 2020).

- Hati, S.; Mandal, S.; Minz, P.S.; Vij, S.; Khetra, Y.; Singh, B.P.; Yadav, D. Electrolyzed oxidized water (EOW): Non-thermal approach for decontamination of foodborne microorganisms in food industry. Food Nutr. Sci. 2012, 3, 760–768. [Google Scholar] [CrossRef]

- Hung, Y.C.; Tilly, P.; Kim, C. Efficacy of electrolyzed oxidizing (EO) water and chlorinated water for inactivation of Escherichia coli O157:H7 on strawberries and broccoli. J. Food Qual. 2010, 33, 559–577. [Google Scholar] [CrossRef]

- Pintaric, R.; Matela, J.; Pintaric, S. Suitability of electrolyzed oxidizing water for the disinfection of hard surfaces and equipment in radiology. J. Environ. Health Sci. Eng. 2015, 13, 6. [Google Scholar] [CrossRef][Green Version]

- Clark, J.; Barrett, S.P.; Rogers, M.; Stapleton, R. Efficacy of super-oxidized water fogging in environmental decontamination. J. Hosp. Infect. 2006, 64, 386–390. [Google Scholar] [CrossRef]

- Chuang, C.Y.; Yang, S.H.; Chang, M.Y.; Huang, H.C.; Luo, C.H.; Hung, P.C.; Fang, W. Inactivation efficiency to Bacillus subtilis and Escherichia coli bacterial aerosols of spraying neutral electrolyzed water. J. Air Waste Manag. Assoc. 2013, 63, 1447–1456. [Google Scholar] [CrossRef] [PubMed]

- Chuang, C.Y.; Fang, W.; Yang, S.H.; Chang, M.Y.; Hung, P.C.; Chang, C.P. A study of membrane-less electrolyzed water fogging-spread for airborne bacteria and fungus decontamination in hen house. In Proceedings of the 2011 International Conference on Agricultural and Biosystems Engineering, Amsterdam, The Netherlands, 13–15 July 2011; Volume 1–2. [Google Scholar]

| Application | Treatment Conditions | Target Microorganisms and Initial Load | Results | References |

|---|---|---|---|---|

| Fruit and vegetables cold storage rooms | Pulsed ultraviolet light (Xtend® DeContam™ Alfa-01)—66 and 1000 s treatment Hydrogen peroxide by ultrasound fogging—1 h treatment | Total aerobic bacteria Moulds Initial values not reported | PUV significantly reduced the microbial load in the air of the storage room 66 s yielded similar results as 1000 s of treatment Stabilized H2O2 reduced microbial counts in the air on the day of treatment but an increase in air counts was observed after 24 h | [31] |

| Meat chill cooler | Germicidal air cleaning console unit (combination of filtration, electrostatic polarization and UV light) Several treatment times were used in combination with console unit | Total aerobic and facultative anaerobic bacteria Mould spores Initial values not reported | Reduction in 1 to 1.5 logs in airborne bacteria and moulds | [32] |

| Strawberry cold storage room | Chlorine dioxide Sodium hypochlorite Hydrogen peroxide Citric acid Ethanol By ultrasonic fogging—30 min of the fogging period and fog remained during 60 min treatment | Total aerobic bacteria—127.3 cfu Moulds—56.3 cfu | Reduced mould contamination to low levels compared to the untreated control | [33] |

| Pome fruit cold storage room | StorOx® (mixture of hydrogen peroxide and peroxyacetic acid) by cold fogging | Moulds—200 cfu | The microorganism populations in the air were significantly reduced by all fogging applications | [34] |

| Fig cold storage room | Chlorine dioxide By ultrasonic fogging—30 min of the fogging period and fog remained during 60 min treatment | Total aerobic bacteria—425.0 cfu Moulds—762.4 cfu | The microorganism population was significantly reduced by fogging at 500 and 1000 µL/L Fogging at 1000 µL/L reduced fungal populations by more than 3.0 log units as compared to the control | [35] |

| Cheese storage room a | Gaseous ozone | Moulds | 88% reduction in mould spore counts | [36] |

| Cheese ripening room a | Gaseous ozone | Moulds | Up to 99% decrease in viable counts of airborne moulds | [37] |

| Cheese ripening room | Gaseous ozone 8 g/h 6:00 p.m. to 6:00 a.m. for 5 weeks 4 g/h 6:00 p.m. to 6:00 a.m. for 2 weeks 8 g/h 40 min of each hour for 12 weeks | Moulds—524, 497 and 176 MPN/m3 depending of the sample area | A 10-fold reduction in the viable airborne mould loud (to <50 MPN/m3) compared with the control | [38] |

| Cheese ripening room | Gaseous ozone 0.48 mg de O3/m3 for 70% of the total time | Moulds—3.60 log cfu | After 40 days, a significant decrease in fungal viable counts, about 1.5 log | [39] |

| Cheese ripening room | Gaseous ozone 6 O3 generators of 30 mg/h for 60 days | Yeasts and moulds—10 cfu/plate | After 60 days of maturation, a decrease in viable yeasts and moulds counts were observed (3.7 cfu/plate) | [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, M.; Tiwari, B.K.; Duffy, G. Emerging Technologies for Aerial Decontamination of Food Storage Environments to Eliminate Microbial Cross-Contamination. Foods 2020, 9, 1779. https://doi.org/10.3390/foods9121779

Oliveira M, Tiwari BK, Duffy G. Emerging Technologies for Aerial Decontamination of Food Storage Environments to Eliminate Microbial Cross-Contamination. Foods. 2020; 9(12):1779. https://doi.org/10.3390/foods9121779

Chicago/Turabian StyleOliveira, Márcia, Brijesh K. Tiwari, and Geraldine Duffy. 2020. "Emerging Technologies for Aerial Decontamination of Food Storage Environments to Eliminate Microbial Cross-Contamination" Foods 9, no. 12: 1779. https://doi.org/10.3390/foods9121779

APA StyleOliveira, M., Tiwari, B. K., & Duffy, G. (2020). Emerging Technologies for Aerial Decontamination of Food Storage Environments to Eliminate Microbial Cross-Contamination. Foods, 9(12), 1779. https://doi.org/10.3390/foods9121779