Use of Turkey Meat Affected by White Striping Myopathy for the Development of Low-Fat Cooked Sausage Enriched with Chitosan

Abstract

:1. Introduction

2. Materials and Methods

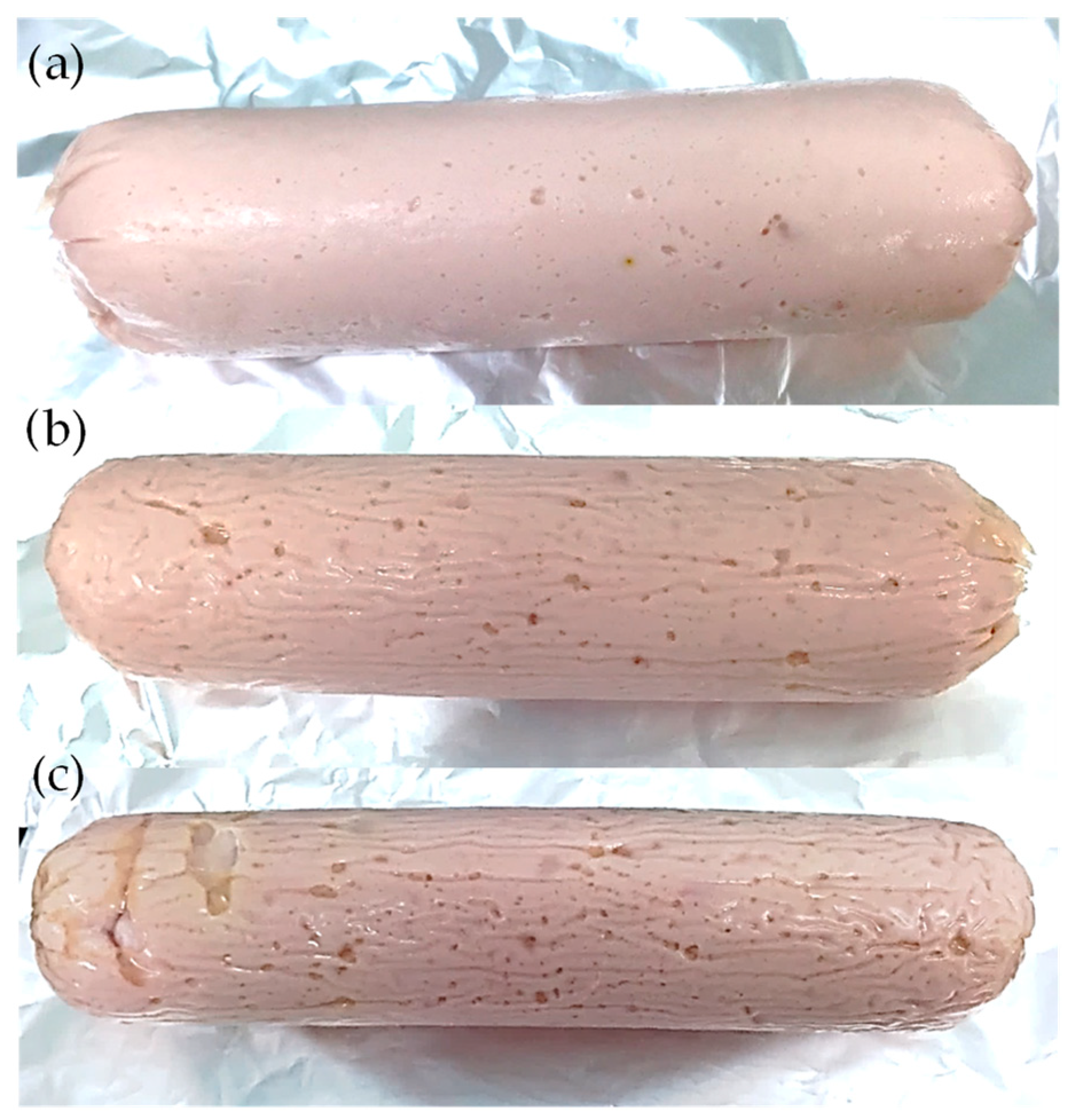

2.1. Cooked Sausages Processing

2.2. Proximate Composition Analysis

2.3. Color Parameters and pH Analysis

2.4. Analysis of Weight Loss by Pressure and Drip Losses

2.5. Texture Profile Analysis

2.6. Lipid Oxidation Determination

2.7. Volatile Compounds Analysis

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Initial Composition and Stability during Storage

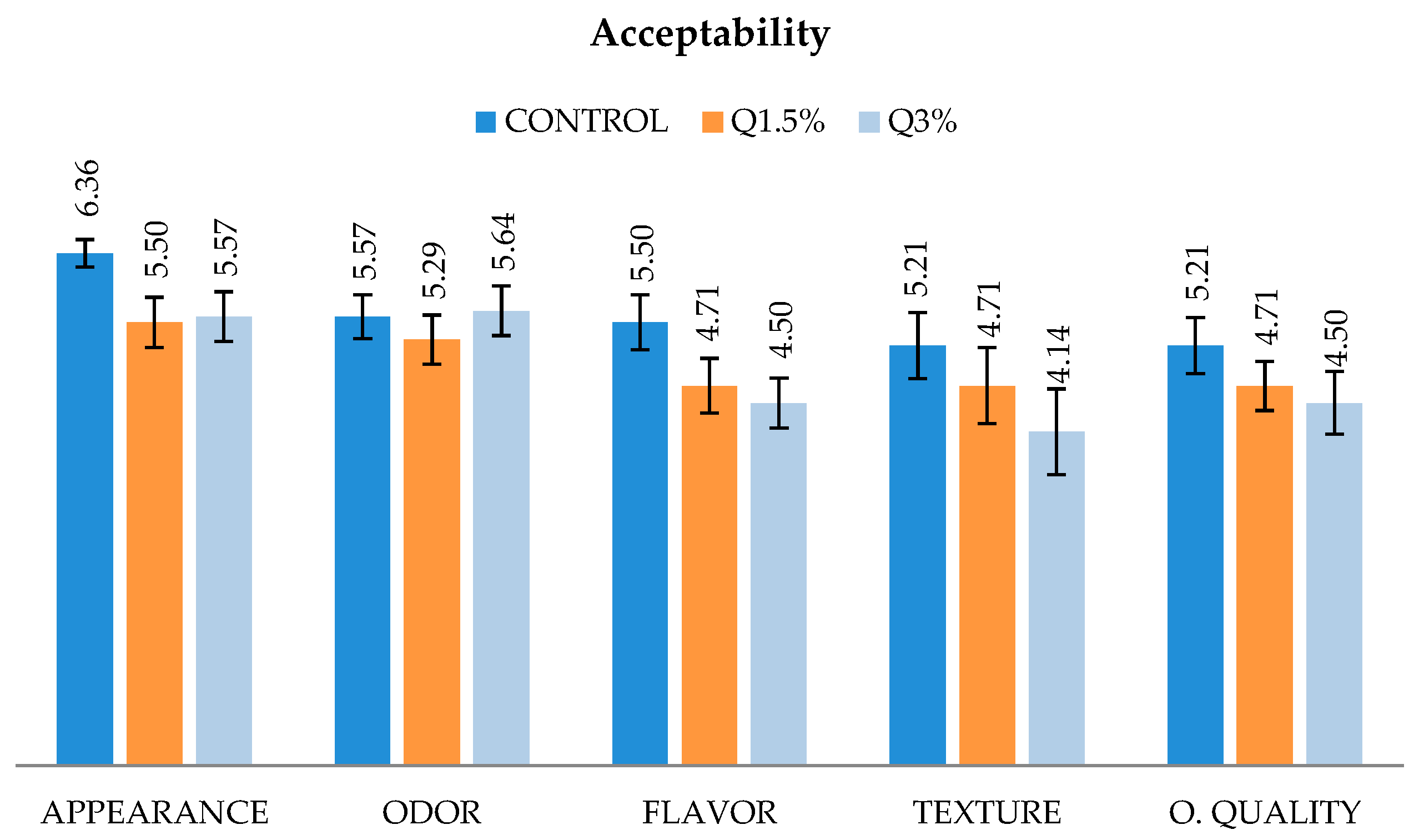

3.2. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ozaki, M.M.; Munekata, P.E.S.; Lopes, A.d.S.; Nascimento, M.d.S.d.; Pateiro, M.; Lorenzo, J.M.; Pollonio, M.A.R. Using chitosan and radish powder to improve stability of fermented cooked sausages. Meat Sci. 2020, 167, 108165. [Google Scholar] [CrossRef]

- Domínguez, R.; Munekata, P.E.; Pateiro, M.; López-Fernández, O.; Lorenzo, J.M. Immobilization of oils using hydrogels as strategy to replace animal fats and improve the healthiness of meat products. Curr. Opin. Food Sci. 2021, 37, 135–144. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; de Carvalho, F.A.L.; Pateiro, M.; Barba, F.J.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Use of tiger nut (Cyperus esculentus L.) oil emulsion as animal fat replacement in beef burgers. Foods 2020, 9, 44. [Google Scholar] [CrossRef] [Green Version]

- Vargas-Ramella, M.; Munekata, P.E.S.; Pateiro, M.; Franco, D.; Campagnol, P.C.B.; Tomasevic, I.; Domínguez, R.; Lorenzo, J.M. Physicochemical Composition and Nutritional Properties of Deer Burger Enhanced with Healthier Oils. Foods 2020, 9, 571. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Munekata, P.E.S.; Gagaoua, M.; Franco, D.; Campagnol, P.C.B.; Pateiro, M.; Barretto, A.C.d.S.; Domínguez, R.; Lorenzo, J.M. Inclusion of Healthy Oils for Improving the Nutritional Characteristics of Dry-Fermented Deer Sausage. Foods 2020, 9, 1487. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Pateiro, M.; Barba, F.J.; Franco, D.; Campagnol, P.C.B.; Munekata, P.E.S.; Tomasevic, I.; Domínguez, R.; Lorenzo, J.M. Microencapsulation of healthier oils to enhance the physicochemical and nutritional properties of deer pâté. LWT 2020, 125, 109223. [Google Scholar] [CrossRef]

- Gálvez, F.; Domínguez, R.; Pateiro, M.; Carballo, J.; Tomasevic, I.; Lorenzo, J.M. Effect of gender on breast and thigh turkey meat quality. Br. Poult. Sci. 2018, 59, 408–415. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vasilatos, G.C.; Savvaidis, I.N. Chitosan or rosemary oil treatments, singly or combined to increase turkey meat shelf-life. Int. J. Food Microbiol. 2013, 166, 54–58. [Google Scholar] [CrossRef] [PubMed]

- Kuttappan, V.A.; Brewer, V.B.; Apple, J.K.; Waldroup, P.W.; Owens, C.M. Influence of growth rate on the occurrence of white striping in broiler breast fillets. Poult. Sci. 2012, 91, 2677–2685. [Google Scholar] [CrossRef]

- Kuttappan, V.A.; Shivaprasad, H.L.; Shaw, D.P.; Valentine, B.A.; Hargis, B.M.; Clark, F.D.; McKee, S.R.; Owens, C.M. Pathological changes associated with white striping in broiler breast muscles. Poult. Sci. 2013, 92, 331–338. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Pateiro, M.; Domínguez, R.; Barba, F.J.; Putnik, P.; Kovačević, D.B.; Shpigelman, A.; Granato, D.; Franco, D. Berries extracts as natural antioxidants in meat products: A review. Food Res. Int. 2018, 106, 1095–1104. [Google Scholar] [CrossRef] [PubMed]

- Munekata, P.E.S.; Domínguez, R.; Franco, D.; Bermúdez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of natural antioxidants in Spanish salchichón elaborated with encapsulated n-3 long chain fatty acids in konjac glucomannan matrix. Meat Sci. 2017, 124, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Vargas, F.C.; Strozzi, I.; Pateiro, M.; Furtado, M.M.; Sant’Ana, A.S.; Rocchetti, G.; Barba, F.J.; Dominguez, R.; Lucini, L.; et al. Influence of pitanga leaf extracts on lipid and protein oxidation of pork burger during shelf-life. Food Res. Int. 2018, 114, 47–54. [Google Scholar] [CrossRef]

- Pateiro, M.; Vargas, F.C.; Chincha, A.A.I.A.; Sant’Ana, A.S.; Strozzi, I.; Rocchetti, G.; Barba, F.J.; Domínguez, R.; Lucini, L.; do Amaral Sobral, P.J.; et al. Guarana seed extracts as a useful strategy to extend the shelf life of pork patties: UHPLC-ESI/QTOF phenolic profile and impact on microbial inactivation, lipid and protein oxidation and antioxidant capacity. Food Res. Int. 2018, 114, 55–63. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Rocchetti, G.; Pateiro, M.; Lucini, L.; Domínguez, R.; Lorenzo, J.M. Addition of plant extracts to meat and meat products to extend shelf-life and health-promoting attributes: An overview. Curr. Opin. Food Sci. 2020, 31, 81–87. [Google Scholar] [CrossRef]

- Domínguez, R.; Gullón, P.; Pateiro, M.; Munekata, P.E.S.; Zhang, W.; Lorenzo, J.M. Tomato as potential source of natural additives for meat industry. A review. Antioxidants 2020, 9, 73. [Google Scholar] [CrossRef] [Green Version]

- Bis-Souza, C.V.; Pateiro, M.; Domínguez, R.; Lorenzo, J.M.; Penna, A.L.B.; da Silva Barretto, A.C. Volatile profile of fermented sausages with commercial probiotic strains and fructooligosaccharides. J. Food Sci. Technol. 2019, 56, 5465–5473. [Google Scholar] [CrossRef]

- Bis-Souza, C.V.; Pateiro, M.; Domínguez, R.; Penna, A.L.B.; Lorenzo, J.M.; Silva Barretto, A.C. Impact of fructooligosaccharides and probiotic strains on the quality parameters of low-fat Spanish Salchichón. Meat Sci. 2020, 159, 107936. [Google Scholar] [CrossRef]

- Hu, Z.; Gänzle, M.G. Challenges and opportunities related to the use of chitosan as a food preservative. J. Appl. Microbiol. 2019, 126, 1318–1331. [Google Scholar] [CrossRef] [Green Version]

- Hamed, I.; Özogul, F.; Regenstein, J.M. Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): A review. Trends Food Sci. Technol. 2016, 48, 40–50. [Google Scholar] [CrossRef]

- Soultos, N.; Tzikas, Z.; Abrahim, A.; Georgantelis, D.; Ambrosiadis, I. Chitosan effects on quality properties of Greek style fresh pork sausages. Meat Sci. 2008, 80, 1150–1156. [Google Scholar] [CrossRef] [PubMed]

- Kanatt, S.R.; Chander, R.; Sharma, A. Chitosan and mint mixture: A new preservative for meat and meat products. Food Chem. 2008, 107, 845–852. [Google Scholar] [CrossRef]

- Tayel, A.A.; Ibrahim, S.I.A.; Al-Saman, M.A.; Moussa, S.H. Production of fungal chitosan from date wastes and its application as a biopreservative for minced meat. Int. J. Biol. Macromol. 2014, 69, 471–475. [Google Scholar] [CrossRef]

- Lee, S.H. Effect of chitosan on emulsifying capacity of egg yolk. J. Korean Soc. Food Nutr. 1996, 25, 118–122. [Google Scholar]

- Sayas-Barberá, E.; Quesada, J.; Sánchez-Zapata, E.; Viuda-Martos, M.; Fernández-López, F.; Pérez-Alvarez, J.A.; Sendra, E. Effect of the molecular weight and concentration of chitosan in pork model burgers. Meat Sci. 2011, 88, 740–749. [Google Scholar] [CrossRef]

- Xia, W.; Liu, P.; Zhang, J.; Chen, J. Biological activities of chitosan and chitooligosaccharides. Food Hydrocoll. 2011, 25, 170–179. [Google Scholar] [CrossRef]

- Cardoso, G.P.; Dutra, M.P.; Fontes, P.R.; Ramos, A.d.L.S.; Gomide, L.A.d.M.; Ramos, E.M. Selection of a chitosan gelatin-based edible coating for color preservation of beef in retail display. Meat Sci. 2016, 114, 85–94. [Google Scholar] [CrossRef]

- Arslan, B.; Soyer, A. Effects of chitosan as a surface fungus inhibitor on microbiological, physicochemical, oxidative and sensory characteristics of dry fermented sausages. Meat Sci. 2018, 145, 107–113. [Google Scholar] [CrossRef]

- Qin, Y.Y.; Yang, J.Y.; Lu, H.B.; Wang, S.S.; Yang, J.Y.; Yang, X.C.; Chai, M.; Li, L.; Cao, J.X. Effect of chitosan film incorporated with tea polyphenol on quality and shelf life of pork meat patties. Int. J. Biol. Macromol. 2013, 61, 312–316. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Noipha, S. Active film from chitosan incorporating green tea extract for shelf life extension of pork sausages. Food Hydrocoll. 2012, 27, 102–108. [Google Scholar] [CrossRef]

- Krkić, N.; Šojić, B.; Lazić, V.; Petrović, L.; Mandić, A.; Sedej, I.; Tomović, V. Lipid oxidative changes in chitosan-oregano coated traditional dry fermented sausage Petrovská klobása. Meat Sci. 2013, 93, 767–770. [Google Scholar] [CrossRef] [PubMed]

- Jo, C.; Lee, J.W.; Lee, K.H.; Byun, M.W. Quality properties of pork sausage prepared with water-soluble chitosan oligomer. Meat Sci. 2001, 59, 369–375. [Google Scholar] [CrossRef]

- Suman, S.P.; Mancini, R.A.; Joseph, P.; Ramanathan, R.; Konda, M.K.R.; Dady, G.; Yin, S. Packaging-specific influence of chitosan on color stability and lipid oxidation in refrigerated ground beef. Meat Sci. 2010, 86, 994–998. [Google Scholar] [CrossRef] [PubMed]

- ISO 937. International Standards Meat and Meat Products—Determination of Nitrogen Content; International Organization for Standarization: Geneva, Switzerland, 1978. [Google Scholar]

- ISO 1442. International Standards Meat and Meat Products—Determination of Moisture Content; International Organization for Standarization: Geneva, Switzerland, 1997. [Google Scholar]

- ISO 936. International Standards Meat and Meat Products—Determination of Ash Content; International Organization for Standarization: Geneva, Switzerland, 1998. [Google Scholar]

- AOCS. AOCS Official Procedure Am5-04. Rapid Determination of Oil/Fat Utilizing High Temperature Solvent Extraction; American Oil Chemists Society: Urbana, IL, USA, 2005. [Google Scholar]

- Vyncke, W. Evaluation of the direct thiobarbituric acid extraction method for determining oxidative rancidity in mackerel. Fette Seifen Anstrichm. 1975, 77, 239–240. [Google Scholar] [CrossRef]

- Domínguez, R.; Purriños, L.; Pérez-Santaescolástica, C.; Pateiro, M.; Barba, F.J.; Tomasevic, I.; Campagnol, P.C.B.; Lorenzo, J.M. Characterization of Volatile Compounds of Dry-Cured Meat Products Using HS-SPME-GC/MS Technique. Food Anal. Methods 2019, 12, 1263–1284. [Google Scholar] [CrossRef]

- UNE-EN ISO 8589:2010/Amd 1:2017. Sensory Analysis—Methodology—Ranking; International Organization for Standarization: Geneva, Switzerland, 2017. [Google Scholar]

- Alirezalu, K.; Hesari, J.; Nemati, Z.; Munekata, P.E.S.; Barba, F.J.; Lorenzo, J.M. Combined effect of natural antioxidants and antimicrobial compounds during refrigerated storage of nitrite-free frankfurter-type sausage. Food Res. Int. 2019, 120, 839–850. [Google Scholar] [CrossRef]

- Brazil Resolução RDC n° 27, de 13 de janeiro de 1998. Regulamento Técnico referente à Informação Nutricional Complementar (declarações relacionadas ao conteúdo de nutrientes). Diário Oficial da União; Poder Executivo, de 13 de janeiro de 1998; Ministério da Saúde, Agência Nacional de Vigilância Sanitária: Brasilia, Brazil, 1998. [Google Scholar]

- EC Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, 404, 9–25.

- Han, M.; Clausen, M.P.; Christensen, M.; Vossen, E.; Van Hecke, T.; Bertram, H.C. Enhancing the health potential of processed meat: The effect of chitosan or carboxymethyl cellulose enrichment on inherent microstructure, water mobility and oxidation in a meat-based food matrix. Food Funct. 2018, 9, 4017–4027. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef]

- Petracci, M.; Mudalal, S.; Bonfiglio, A.; Cavani, C. Occurrence of white striping under commercial conditions and its impact on breast meat quality in broiler chickens. Poult. Sci. 2013, 92, 1670–1675. [Google Scholar] [CrossRef] [PubMed]

- Mudalal, S.; Babini, E.; Cavani, C.; Petracci, M. Quantity and functionality of protein fractions in chicken breast fillets affected by white striping. Poult. Sci. 2014, 93, 2108–2116. [Google Scholar] [CrossRef] [PubMed]

- Mudalal, S.; Lorenzi, M.; Soglia, F.; Cavani, C.; Petracci, M. Implications of white striping and wooden breast abnormalities on quality traits of raw and marinated chicken meat. Animal 2015, 9, 728–734. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pateiro, M.; Domínguez, R.; Bermúdez, R.; Munekata, P.E.S.; Zhang, W.; Gagaoua, M.; Lorenzo, J.M. Antioxidant active packaging systems to extend the shelf life of sliced cooked ham. Curr. Res. Food Sci. 2019, 1, 24–30. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Carballo, J. Changes in physico-chemical properties and volatile compounds throughout the manufacturing process of dry-cured foal loin. Meat Sci. 2015, 99, 44–51. [Google Scholar] [CrossRef]

- Barriuso, B.; Astiasarán, I.; Ansorena, D. A review of analytical methods measuring lipid oxidation status in foods: A challenging task. Eur. Food Res. Technol. 2013, 236, 1–15. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Agregán, R.; Lorenzo, J.M. Effect of the partial replacement of pork backfat by microencapsulated fish oil or mixed fish and olive oil on the quality of frankfurter type sausage. J. Food Sci. Technol. 2017, 54, 26–37. [Google Scholar] [CrossRef] [Green Version]

- Domínguez, R.; Gómez, M.; Fonseca, S.; Lorenzo, J.M. Influence of thermal treatment on formation of volatile compounds, cooking loss and lipid oxidation in foal meat. LWT Food Sci. Technol. 2014, 58, 439–445. [Google Scholar] [CrossRef]

- Domínguez, R.; Gómez, M.; Fonseca, S.; Lorenzo, J. Effect of different cooking methods on lipid oxidation and formation of volatile compounds in foal meat. Meat Sci. 2014, 97, 223–230. [Google Scholar] [CrossRef]

- Rivas-Cañedo, A.; Nuñez, M.; Fernández-García, E. Volatile compounds in Spanish dry-fermented sausage “salchichón” subjected to high pressure processing. Effect of the packaging material. Meat Sci. 2009, 83, 620–626. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Munekata, P.E.S.; Campagnol, P.C.B.; Lorenzo, J.M. Influence of partial pork backfat replacement by fish oil on nutritional and technological properties of liver pâté. Eur. J. Lipid Sci. Technol. 2017, 119, 1600178. [Google Scholar] [CrossRef]

- Roller, S.; Sagoo, S.; Board, R.; O’Mahony, T.; Caplice, E.; Fitzgerald, G.; Fogden, M.; Owen, M.; Fletcher, H. Novel combinations of chitosan, carnocin and sulphite for the preservation of chilled pork sausages. Meat Sci. 2002, 62, 165–177. [Google Scholar] [CrossRef]

| Proximate Composition (g/100g) | Treatments | SE | Sig. | ||

|---|---|---|---|---|---|

| CONTROL | Q1.5% | Q3% | |||

| Protein | 21.25 a | 20.69 b | 20.27 b | 0.13 | *** |

| Lipids | 0.31 a | 0.14 b | 0.08 b | 0.03 | *** |

| Moisture | 76.20 a | 75.58 ab | 74.98 b | 0.16 | ** |

| Ashes | 2.14 c | 2.88 b | 3.39 a | 0.14 | *** |

| Parameters | Treatments | SE | Sig. | ||

|---|---|---|---|---|---|

| CONTROL | Q1.5% | Q3% | |||

| Drip loss (%) | 0.80 | 1.57 | 1.01 | 0.14 | ns |

| Weight loss (%) | 15.99 a | 4.01 b | 3.77 b | 1.54 | *** |

| Hardness (N) | 22.74 c | 27.93 b | 32.44 a | 1.21 | *** |

| Cohesiveness | 0.56 b | 0.67 a | 0.67 a | 0.01 | *** |

| Springiness (mm) | 0.86 | 0.86 | 0.86 | 0.00 | ns |

| Gumminess (N) | 12.74 c | 18.82 b | 21.76 a | 1.11 | *** |

| Chewiness (N.mm) | 10.88 c | 15.97 b | 18.72 a | 0.91 | *** |

| Parameter | Treatments | Storage Days | SE | Sig. | |

|---|---|---|---|---|---|

| 0 | 56 | ||||

| TBARS | CONTROL | - | - | - | - |

| Q1.5% | - | - | - | - | |

| Q3% | - | - | - | - | |

| SE | - | - | - | - | |

| Sig. | - | - | - | - | |

| pH | CONTROL | 5.99 bB | 6.11 bA | 0.03 | * |

| Q1.5% | 6.73 aB | 6.95 aA | 0.04 | *** | |

| Q3% | 6.77 aB | 6.99 aA | 0.04 | *** | |

| SE | 0.10 | 0.11 | - | - | |

| Sig. | *** | *** | - | - | |

| Lightness (L*) | CONTROL | 80.53 a | 80.84 a | 0.09 | ns |

| Q1.5% | 74.82 b | 74.75 b | 0.07 | ns | |

| Q3% | 74.41 b | 74.14 c | 0.11 | ns | |

| SE | 0.75 | 0.81 | - | - | |

| Sig. | *** | *** | - | - | |

| Redness (a*) | CONTROL | 4.13 aA | 3.94 aB | 0.05 | * |

| Q1.5% | 3.72 aA | 3.10 bB | 0.12 | *** | |

| Q3% | 3.23 bA | 2.48 cB | 0.16 | ** | |

| SE | 0.12 | 0.17 | - | - | |

| Sig. | *** | *** | - | - | |

| Yellowness (b*) | CONTROL | 10.19 | 10.16 c | 0.04 | ns |

| Q1.5% | 10.53 B | 11.60 bA | 0.22 | ** | |

| Q3% | 10.76 B | 12.30 aA | 0.29 | *** | |

| SE | 0.13 | 0.25 | - | - | |

| Sig. | ns | *** | - | - | |

| Volatile Compound | Days | Treatments | SE | Sig. | ||

|---|---|---|---|---|---|---|

| CONTROL | Q1.5% | Q3% | ||||

| Octane | 0 | 12.63 bB | 23.02 bA | 20.12 bAB | 1.43 | *** |

| 56 | 43.52 a | 53.77 a | 55.63 a | 4.61 | ns | |

| Sig. | *** | *** | *** | |||

| Nonanal | 0 | 17.36 A | 9.85 aB | 9.55 aB | 0.93 | *** |

| 56 | 17.34 A | 1.27 bB | 3.75 bB | 0.85 | *** | |

| Sig. | ns | *** | *** | |||

| Hexanal | 0 | 25.42 aA | 12.28 aAB | 9.10 aB | 1.24 | *** |

| 56 | 4.33 bA | 3.60 bA | 2.11 bB | 0.37 | ** | |

| Sig. | *** | *** | *** | |||

| 1-Butanol | 0 | 5.14 b | 4.15 b | 4.80 b | 0.52 | ns |

| 56 | 9.96 aB | 27.95 aA | 9.27 aB | 2.11 | *** | |

| Sig. | ** | *** | ** | |||

| 1-Hexanol | 0 | 1.56 bB | 2.03 bB | 2.83 bA | 0.25 | ** |

| 56 | 19.06 aA | 10.70 aB | 15.63 aA | 1.54 | ** | |

| Sig. | *** | *** | *** | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, L.T.; Lorenzo, J.M.; de Carvalho, F.A.L.; Bellucci, E.R.B.; Trindade, M.A.; Domínguez, R. Use of Turkey Meat Affected by White Striping Myopathy for the Development of Low-Fat Cooked Sausage Enriched with Chitosan. Foods 2020, 9, 1866. https://doi.org/10.3390/foods9121866

Carvalho LT, Lorenzo JM, de Carvalho FAL, Bellucci ERB, Trindade MA, Domínguez R. Use of Turkey Meat Affected by White Striping Myopathy for the Development of Low-Fat Cooked Sausage Enriched with Chitosan. Foods. 2020; 9(12):1866. https://doi.org/10.3390/foods9121866

Chicago/Turabian StyleCarvalho, Larissa Tátero, José M. Lorenzo, Francisco Allan L. de Carvalho, Elisa Rafaela Bonadio Bellucci, Marco Antonio Trindade, and Rubén Domínguez. 2020. "Use of Turkey Meat Affected by White Striping Myopathy for the Development of Low-Fat Cooked Sausage Enriched with Chitosan" Foods 9, no. 12: 1866. https://doi.org/10.3390/foods9121866

APA StyleCarvalho, L. T., Lorenzo, J. M., de Carvalho, F. A. L., Bellucci, E. R. B., Trindade, M. A., & Domínguez, R. (2020). Use of Turkey Meat Affected by White Striping Myopathy for the Development of Low-Fat Cooked Sausage Enriched with Chitosan. Foods, 9(12), 1866. https://doi.org/10.3390/foods9121866