A Guide for the Food Industry to Meet the Future Skills Requirements Emerging with Industry 4.0

Abstract

1. Introduction

2. Materials and Methods

- The first step is evaluating the current state of the digital transformation of the food industry [20], and analysing the key trends about the upcoming technological developments [21]. After identifying the main technological developments and the related required skills and competencies, a future scenario can be developed. Economic development related to digital transformations should be also considered [11,20]. The manufacturing processes and workforce that are affected by the digital transformation will be determined.

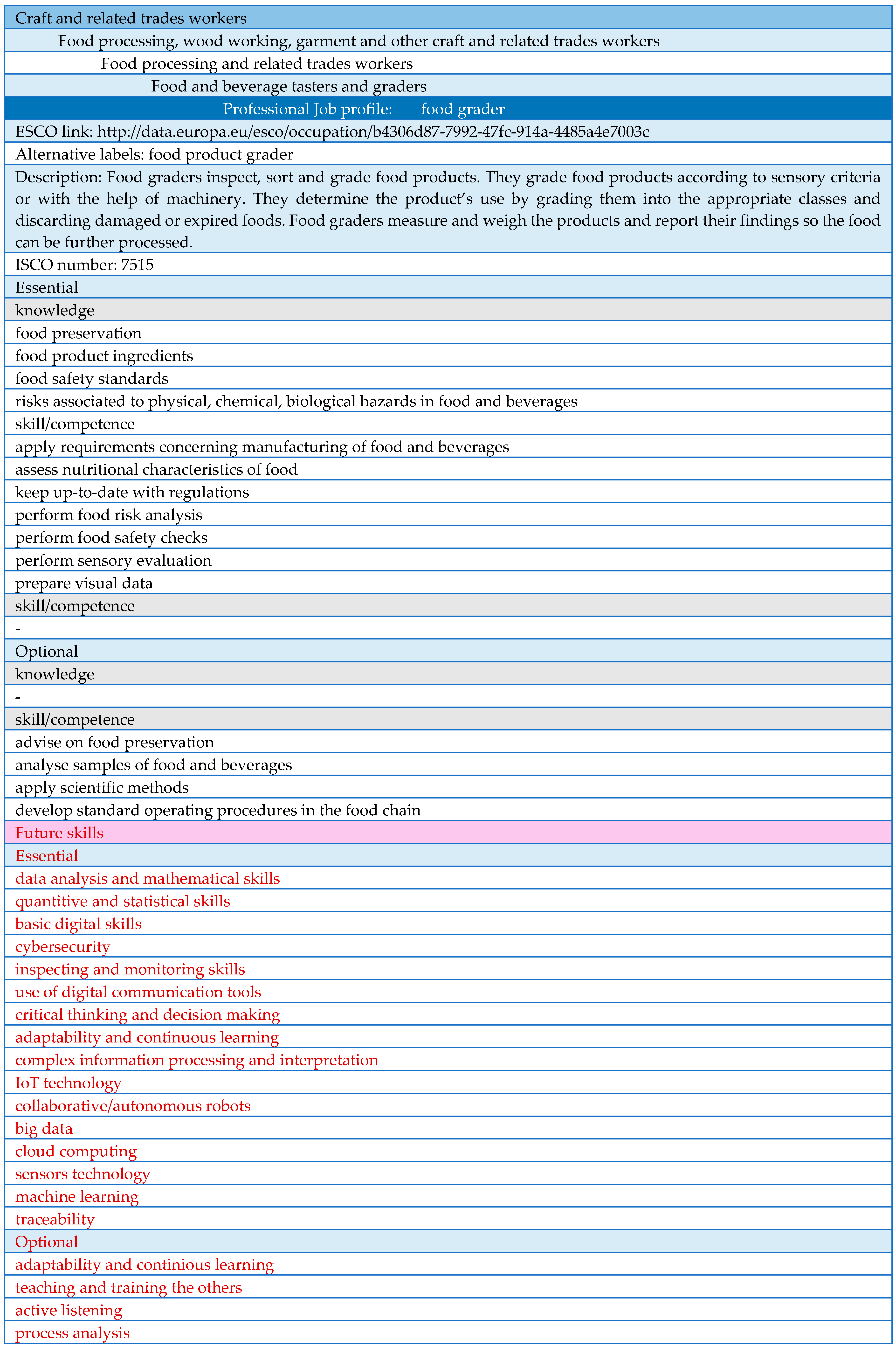

- This step involves identifying the skills and professional job profiles that will be needed in the future and determining the skills gaps that are created by the current and the foreseen technological developments [20,21]. The most crucial part of this step is to identify the skills demands of the industry in proactive ways, taking skills gaps and shortages into account [20]. An automated database of the sector-related job profiles defining the needed skills and competencies will be generated. It will enable an internationally common ground and mutual recognition for the needed skills and jobs in the food industry.

- As the next step, the training and curricula requirements will be determined considering the skills gaps, and then, the training programs will be created for the selected skills and job profiles [21]. New methods should be discovered to implement education content in a rapid and effective way, not only in the companies but also in the formal education and training institutions. Training programs should be upgraded and updated continuously to reach a higher quality [20]. Talent management and recruitment processes should be also included in the training process [20].

- The final step is called monitoring. All the adjustments coming with the strategy will be monitored continuously to adopt upcoming new developments [9].

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| IoT | Internet of Things |

| ESCO | European Skills, Competences, Qualifications and Occupations |

| CEPIS | Council of European Professional Informatics Societies |

| CEN | European Committee for Standardization |

| ESSA | Blueprint “New Skills Agenda Steel”: Industry-driven sustainable European Steel Skills Agenda and Strategy |

| DRIVES | Development and Research on Innovative Vocational Educational Skills |

| APPRENTICESHIPQ | Mainstreaming Procedures for Quality Apprenticeships in Educational Organisations and Enterprises |

| SMeART | Knowledge Alliance for Upskilling Europe’s SMES to Meet the Challenges of Smart Engineering |

| SMEs | Small and Medium Enterprises |

| ISCO | International Standard Classification of Occupations |

| ILO | International Labor Organization |

| ICT | Information and communications technology |

| VBA | Visual Basic for Applications |

| HACCP | Hazard analysis and critical control points |

| GMP | Good manufacturing practice |

References

- Nestle, M. Food Politics: How the Food Industry Influences Nutrition and Health; University California Press: Berkeley, CA, USA, 2013; Volume 3. [Google Scholar]

- Luque, A.; Estela Peralta, M.; de las Heras, D.; Cordoba, A. State of the Industry 4.0 in the Andalusian food sector. Procedia Manuf. 2017, 13, 1199–1205. [Google Scholar] [CrossRef]

- Karacay, G. Talent Development for Industry 4.0. In Industry 4.0: Managing the Digital Transformation, 2nd ed.; Springer Series in Advanced Manufacturing; Ustundag, A., Cevikcan, E., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 123–135. [Google Scholar]

- Branca, T.A.; Fornai, B.; Colla, V.; Murri, M.M.; Streppa, E.; Schroder, A.J. The Challenge of Digitalization in the Steel Sector. Metals 2020, 10, 288. [Google Scholar] [CrossRef]

- Stahl Institute VDEh. Annual Report of Steel Institute Vdeh 2016—Summary of Main Topics of Technical-Scientific Joint Cooperation and Work; Stahl-Zentrum Düsseldorf: Düsseldorf, Germay, 2016. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee, the Committee of the Regions and the European investment bank investing in a smart, innovative and sustainable industry a renewed EU industrial policy strategy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2017:0479:FIN (accessed on 9 January 2020).

- Bogner, E.; Voelklein, T.; Schroedel, O.; Franke, J. Study based analysis on the current digitalization degree in the manufacturing industry in Germany. Procedia CIRP 2016, 57, 14–19. [Google Scholar] [CrossRef]

- Beltrametti, L.; Guarnacci, N.; Intini, N.; La Forgia, C. La Fabbrica Connessa. La Manifattura Italiana (Attra) Verso Industria 4.0; goWare & Edizioni Guerini e Associati: Firenze, Italy, 2017. [Google Scholar]

- Lagnevik, M. The Dynamics of Innovation Clusters: A Study of the Food Industry; Edward Elgar Publishing: Cheltenham, UK, 2003. [Google Scholar]

- Zhao, X.; Fan, H.; Zhu, H.; Fu, Z.; Fu, H. The Design of the Internet of Things Solution for Food Supply Chain. In Proceedings of the 2015 International Conference on Education, Management, Information and Medicine, Shenyang, China, 24–26 April 2015. [Google Scholar]

- Olajide Ojo, O.; Shah, S.; Coutroubis, A.; Torres Jiménez, M.; Munoz Ocana, Y. Potential Impact of Industry 4.0 in Sustainable Food Supply Chain Environment. In Proceedings of the IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD), Marrakech, Morocco, 21–23 November 2018. [Google Scholar]

- Executive Agency forSmall and Medium-sized Enterprises (European Commission). Blueprint for Sectoral Cooperation on Skills: Towards an EU Strategy Addressing the Skills Needs of the Steel Sector: European Vision on Steel-Related Skills of Today and Tomorrow; Publication Office of the European Union: Luxembourg, 2019. [Google Scholar]

- How AI Is Changing the Way Companies Are Organized. Available online: https://www.fastcompany.com/3068492/how-ai-is-changing-the-way-companies-are-organized (accessed on 18 July 2019).

- Bughin, J.; Hazan, E.; Lund, S.; Dahlström, P.; Wiesinger, A.; Subramaniam, A. Skill Shift, Automation and the Future of the Workforce; Mckinsey & Company: Washington, DC, USA, 2018. [Google Scholar]

- Deming, D.J. The growing importance of social skills in the labor market. Q. J. Econ. 2017, 132, 1593–1640. [Google Scholar] [CrossRef]

- Grundke, R.; Squicciarini, M.; Jamet, S.; Kalamova, M. Having the right mix: The role of skill bundles for comparative advantage and industry performance in GVCs. In OECD Science, Technology and Industry Working Papers; OECD Publishing: Paris, France, 2017. [Google Scholar]

- Akyazi, T.; Oyarbide, A.; Goti, A.; Gaviria, J.; Bayon, F. Roadmap for the future professional skills for the Oil and Gas Industry facing Industrial Revolution 4.0. Hydrocarbon Process. 2020. [Google Scholar]

- Horrillo Tello, J.; Triado Aymerich, J. Carencias formativas de los grados de ingeniería para la Industria 4.0 en España. Una propuesta de actualizaciones. Dyna 2018, 93, 365–369. [Google Scholar] [CrossRef]

- Freddi, D. Digitalization and employment in manufacturing. AI Soc. 2018, 33, 393–397. [Google Scholar] [CrossRef]

- Project Title: Blueprint “New Skills Agenda Steel”: Industry-driven sustainable European Steel Skills Agenda and Strategy (ESSA), Program: Erasmus+ Knowledge Alliances, Project lifetime: 1 January 2019–31 December 2022, Project Co-ordinator: Dortmund University (Germany), Project Reference Number: 600886-EPP-1-2018-1-DE-EPPKA2-SSA-B. Available online: https://www.estep.eu/essa/essa-project/ (accessed on 19 January 2020).

- Project Title: DRIVES: Development and Research on Innovative Vocational Educational Skills, Program: Erasmus+ Knowledge Alliances, Project lifetime: 1 January 2018–31 December 2021, Project Co-ordinator: Technical University of Ostrava (Czech Republic). Available online: https://www.project-drives.eu/en/home (accessed on 21 February 2020).

- Project Title: Mainstreaming Procedures for Quality Apprenticeships in Educational Organisations and Enterprises (ApprenticeshipQ), Program: Erasmus+ Knowledge Alliances, Project lifetime: 1 January 2018–31 December 2020, Project Co-ordinator: Baden-Wuerttemberg Cooperative State University (Duale Hochschule Baden-Württemberg—DHBW), Project Reference Number: 2017-1-DE02-KA202-004164. Available online: https://apprenticeshipq.eu/ (accessed on 20 February 2020).

- Project Title: “SMeART—Knowledge Alliance for Upskilling Europe’s SMES to Meet the Challenges of Smart Engineering’, Program: Erasmus+ Knowledge Alliances, Project Lifetime: 1 January 2017–31 December 2019, Project Co-ordinator: Fachhochschule des Mittelstands (FHM), Project Reference Number: 575932-EPP-1-2016-1-DE-EPPKA2-KA. Available online: http://www.smeart.eu/ (accessed on 20 February 2020).

- ESCO European Skills/Competences Qualifications and Occupations. Available online: https://ec.europa.eu/esco/portal/home (accessed on 17 January 2020).

- Council of European Professional Informatics Societies. Available online: https://www.cepis.org/index.jsp?p=636&n=637/ (accessed on 17 January 2020).

- European Committee for Standardization. Available online: https://www.cen.eu/about/Pages/default.aspx (accessed on 17 January 2020).

- The European ICT Role Profiles. Available online: https://www.cen.eu/work/areas/ict/eeducation/pages/ws-ict-skills.aspx (accessed on 17 January 2020).

| ESCO Occupation | Food Production Manager | Food Production Operator | Food Safety Specialist | Food & Beverage Packaging Technologist | Food Production Engineer | Food Analyst | Food Technician |

|---|---|---|---|---|---|---|---|

| web link to ESCO | http://data.europa.eu/esco/occupation/a7d6a377-3d3b-41cf-9301-f4a0a7ad3d96 | http://data.europa.eu/esco/occupation/e3dc66de-99c7-4607-a82b-7244036d316d | http://data.europa.eu/esco/occupation/00ab5610-e715-428f-99f6-b1e5e469dbcd | http://data.europa.eu/esco/occupation/8a925aca-f636-437c-8962-5deae170e246 | http://data.europa.eu/esco/occupation/2f26a52b-cf45-4282-9138-478252161f00 | http://data.europa.eu/esco/occupation/33fe4c90-c4fd-4860-bdc5-24fcab16f45a | http://data.europa.eu/esco/occupation/afee6a28-f654-4ac7-a665-f758616bc689 |

| Alternative labels | no alternative labels | food production operative//food production worker//food manufacturing worker//food worker | food production quality controller//trainee food safety specialist//food safety controller//senior food safety specialist//food scientist//food safety monitor//… | food and beverage packaging expert//food and beverage packaging specialist//food and drinks packaging technologist//food and drinks packaging expert | food engineer | food researcher//food research specialist//food analysis expert//food analysis specialist | food tech expert//food technology expert//food technology specialist//food tech specialist |

| Description | Food production managers oversee and monitor production and have overall responsibility for staffing and related issues. Hence, they have a detailed knowledge of the manufacturing products and their production processes. On the one hand, they control process parameters and their influence on the product and on the other hand, they ensure that staffing and recruitment levels are adequate. | Food production operators supply and perform one or more tasks in different stages of the food production process. They perform manufacturing operations and processes to foods and beverages, perform packaging, operate machines manually or automatically, follow predetermined procedures, and take food safety regulations on board. | Food safety specialists organise processes and implement procedures to avoid problems with food safety. They comply with regulations. | Food and beverage packaging technologists assess appropriate packaging for various food products. They manage matters in relation to packaging while ensuring customer specifications and company targets. They develop packaging projects as required. | Food production engineers oversee the electrical and mechanical needs of the equipment and machinery required in the process of manufacturing food or beverages. They strive to maximise plant productivity by engaging in preventive actions in reference to health and safety, good manufacturing practices (GMP), hygiene compliance, and performance of routine maintenance of machines and equipment. | Food analysts perform standardised tests to determine the chemical, physical, or microbiological features of products for human consumption. | Food technicians assist food technologists in the development of processes for manufacturing foodstuffs and related products based on chemical, physical, and biological principles. They perform research and experiments on ingredients, additives and packaging. Food technicians also check product quality to ensure compliance with legislation and regulations. |

| ISCO Number | 1321 | 8160 | 2263 | 2141 | 2141 | 3111 | 3119 |

| Food Production Manager | Food Production Operator | Food Safety Specialist | Food & Beverage Packaging Technologist | Food Production Engineer | Food Analyst | Food Technician |

|---|---|---|---|---|---|---|

| essential | essential | essential | essential | essential | essential | essential |

| knowledge | knowledge | knowledge | knowledge | knowledge | knowledge | knowledge |

| financial capability | food safety principles | food legislation | packaging engineering | electrical engineering | food safety principles | food and beverage industry |

| food and beverage industry | food preservation | packaging functions | electronics | food safety standards | food preservation | |

| food legislation | food storage | packaging processes | food storage | food science | food product ingredients | |

| quality assurance methodologies | product package requirements | quality assurance methodologies | food toxicity | functional properties of foods | ||

| types of packaging materials | laboratory-based sciences | processes of foods and beverages manufacturing | ||||

| skill/competence | skill/competence | skill/competence | skill/competence | skill/competence | skill/competence | skill/competence |

| analyse production processes for improvement | administer ingredients in food production | control food safety regulations | analyse packaging requirements | apply GMP | analyse characteristics of food products at reception | apply GMP |

| analyse trends in the food and beverage industries | apply GMP | develop food safety programmes | apply GMP | apply HACCP | analyse samples of food and beverages | apply HACCP |

| apply control process statistical methods | apply HACCP | evaluate retail food inspection findings | apply HACCP | apply requirements concerning manufacturing of food and beverages | apply GMP | apply requirements concerning manufacturing of food and beverages |

| apply HACCP | be at ease in unsafe environments | keep task records | care for food aesthetic | configure plants for food industry | apply requirements concerning manufacturing of food and beverages | clean food and beverage machinery |

| apply requirements concerning manufacturing of food and beverages | carry out checks of production plant equipment | maintain personal hygiene standards | identify innovative concepts in packaging | develop food production processes | assess nutritional characteristics of food | ensure public safety and security |

| communicate production plan | clean food and beverage machinery | monitor packaging operations | keep up with innovations in food manufacturing | disaggregate the production plan | assess quality characteristics of food products | identify the factors causing changes in food during storage |

| control of expenses | disassemble equipment | plan inspections for prevention of sanitation violations | manage packaging development cycle from concept to launch | disassemble equipment | attend to detail regarding food and beverages | manage all process engineering activities |

| ensure cost efficiency in food manufacturing | ensure refrigeration of food in the supply chain | prepare reports on sanitation | manage packaging material | keep up with innovations in food manufacturing | blend food ingredients | manage delivery of raw materials |

| identify hazards in the workplace | ensure sanitation | take action on food safety violations | monitor filling machines | keep up-to-date with regulations | calibrate laboratory equipment | manage packaging material |

| implement short term objectives | follow production schedule | train employees | monitor packaging operations | manage all process engineering activities | collect samples for analysis | monitor freezing processes |

| Food Production Manager | Food Production Operator | Food Safety Specialist | Food & Beverage Packaging Technologist | Food Production Engineer | Food Analyst | Food Technician |

|---|---|---|---|---|---|---|

| optional | optional | optional | optional | optional | optional | optional |

| knowledge | knowledge | knowledge | knowledge | knowledge | knowledge | knowledge |

| food safety standards | centrifugal force | cold chain | food safety principles | food and beverage industry | fermentation processes of food | cleaning of reusable packaging |

| legislation about animal origin products | cleaning of reusable packaging | food homogenisation | food safety standards | food homogenisation | food homogenisation | combination of flavours |

| condiment manufacturing processes | food policy | food science | food preservation | food legislation | combination of textures | |

| fermentation processes of food | general principles of food law | ingredient threats | food safety standards | food products composition | fermentation processes of beverages | |

| food canning production line | risks associated to physical, chemical, biological hazards in food and beverages | risks associated to physical, chemical, biological hazards in food and beverages | fermentation processes of food | |||

| skill/competence | skill/competence | skill/competence | skill/competence | skill/competence | skill/competence | skill/competence |

| adapt production levels | adjust drying process to goods | analyse samples of food and beverages | assess HACCP implementation in plants | analyse work-related written reports | analyse packaging requirements | adjust production schedule |

| advocate for consumer matters in production plants | administer materials to tea bag machines | assess food samples | detect microorganisms | assess HACCP implementation in plants | analyse trends in the food and beverage industries | administer ingredients in food production |

| apply foreign language for international trade | apply different dehydration processes of fruits and vegetables | audit HACCP | develop new food products | be at ease in unsafe environments | analyse work-related written reports | analyse packaging requirements |

| assess environmental plans against financial costs | apply extruding techniques | develop food policy | develop standard operating procedures in the food chain | ensure compliance with environmental legislation in food production | apply scientific methods | analyse production processes for improvement |

| ensure continuous preparedness for audits | apply preservation treatments | ensure correct goods labelling | ensure correct goods labelling | ensure full functioning of food plant machinery | assess environmental parameters at the workplace for food products | analyse work-related written reports |

| hire new personnel | check bottles for packaging | monitor sugar uniformity | keep up-to-date with regulations | food plant design | assess food samples | apply control process statistical methods |

| lead process optimisation | check quality of products on the production line | use instruments for food measurement | label foodstuffs | lead process optimisation | assess shelf life of food products | apply food technology principles |

| manage medium-term objectives | conduct cleaning in place | participate in the development of new food products | write work-related reports | check quality of products on the production line | be at ease in unsafe environments | |

| manage staff | dispose food waste | interpret extraction data | detect microorganisms | calibrate laboratory equipment |

| Food Production Manager | Food Production Operator | Food Safety Specialist | Food & Beverage Packaging Technologist | Food Production Engineer | Food Analyst | Food Technician |

|---|---|---|---|---|---|---|

| future skills | future skills | future skills | future skills | future skills | future skills | future skills |

| essential | essential | essential | essential | essential | essential | essential |

| advanced communication and negotiation skills | advanced data analysis and mathematical skills | data analysis and mathematical skills | basic digital skills | basic digital skills | data analysis and mathematical skills | advanced data analysis and mathematical skills |

| leadership and managing others | use of complex digital communication tools | quantitive and statistical skills | advanced data analysis and mathematical skills | advanced data analysis and mathematical skills | quantitive and statistical skills | use of complex digital communication tools |

| adaptability and continuous learning | Interpersonal skills and empathy | basic digital skills | cybersecurity | advanced IT skills & Programming | basic digital skills | Interpersonal skills and empathy |

| critical thinking & decision making | adaptability and continuous learning | cybersecurity | use of complex digital communication tools | use of complex digital communication tools | cybersecurity | adaptability and continuous learning |

| personal experience | teaching and training others | inspecting and monitoring skills | advanced IT skills & programming | cybersecurity | inspecting and monitoring skills | teaching and training others |

| active listening | active listening | use of digital communication tools | entrepreneurship and initiative taking | advanced communication skills | use of digital communication tools | active listening |

| work autonomously | basic numeracy and communication | critical thinking and decision making | adaptability and continuous learning | leadership and managing others | critical thinking and decision making | basic numeracy and communication |

| quantitative and statistical skills | basic data input and processing | adaptability and continious learning | critical thinking & decision making | entrepreneurship and initiative taking | adaptability and continious learning | basic data input and processing |

| complex information processing and interpretation | advanced literacy | complex information processing and interpretation | basic numeracy and communication | adaptability and continuous learning | complex information processing and interpretation | advanced literacy |

| prcess analysis | complex information processing and interpretation | process analysis | basic data input and processing | teaching and training others | process analysis | complex information processing and interpretation |

| creativity | process analysis | initiative taking | advanced literacy | critical thinking & decision making | initiative taking | process analysis |

| complex problem solving | creativity | advanced IT skills & Programming | auantitative and statistical skills | active listening | advanced IT skills & Programming | creativity |

| basic digital skills | complex problem solving | traceability | complex information processing and interpretation | complex information processing and interpretation | traceability | complex problem solving |

| advanced data analysis and mathematical skills | IoT | adaptability and continuous learning | process analysis | process analysis | adaptability and continuous learning | IoT |

| cybersecurity | Manufacturing Execution System (MES) | IoT technology | creativity | creativity | collaborative/autonomous robots | Manufacturing Execution System (MES) |

| use of complex digital communication tools | traceability | cloud computing | complex problem solving | complex problem solving | IoT technology | traceability |

| advanced IT skills & programming | cybersecurity | big data | traceability | traceability | big data | cybersecurity |

| interpersonal skills and empathy | cloud computing | sensors technology | collaborative/autonomous robots | collaborative/autonomous robots | cloud computing | cloud computing |

| entrepreneurship and initiative taking | big data | machine learning | IoT technology | IoT technology | sensors technology | big data |

| Manufacturing Execution System (MES) | collaborative/autonomous robots | collaborative/autonomous robots | big data | big data | machine learning | collaborative/autonomous robots |

| IoT technology | cloud computing | cloud computing | ||||

| cloud computing | sensors technology | sensors technology | ||||

| big data | augmented reality | |||||

| machine learning | machine learning | |||||

| deep learning | ||||||

| optional | optional | optional | optional | optional | optional | optional |

| adaptability and continuous learning | personal experience | personal experience | personal experience | interpersonal skills and empathy | personal experience | personal experience |

| training and teaching others | initiative taking | active listening | teaching and training others | personal experience | active listening | initiative taking |

| sensors technology | augmented reality | work autonomously | work autonomously | work autonomously | teaching and training the others | augmented reality |

| collaborative/autonomous robots | machine learning | augmented reality | active listening | quantitative and statistical skills | augmented reality | machine learning |

| traceability | interpersonal skills and empathy | basic data input and processing | ||||

| machine learning | ||||||

| augmented reality |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akyazi, T.; Goti, A.; Oyarbide, A.; Alberdi, E.; Bayon, F. A Guide for the Food Industry to Meet the Future Skills Requirements Emerging with Industry 4.0. Foods 2020, 9, 492. https://doi.org/10.3390/foods9040492

Akyazi T, Goti A, Oyarbide A, Alberdi E, Bayon F. A Guide for the Food Industry to Meet the Future Skills Requirements Emerging with Industry 4.0. Foods. 2020; 9(4):492. https://doi.org/10.3390/foods9040492

Chicago/Turabian StyleAkyazi, Tugce, Aitor Goti, Aitor Oyarbide, Elisabete Alberdi, and Felix Bayon. 2020. "A Guide for the Food Industry to Meet the Future Skills Requirements Emerging with Industry 4.0" Foods 9, no. 4: 492. https://doi.org/10.3390/foods9040492

APA StyleAkyazi, T., Goti, A., Oyarbide, A., Alberdi, E., & Bayon, F. (2020). A Guide for the Food Industry to Meet the Future Skills Requirements Emerging with Industry 4.0. Foods, 9(4), 492. https://doi.org/10.3390/foods9040492