Novel Technologies for Preserving Ricotta Cheese: Effects of Ultraviolet and Near-Ultraviolet–Visible Light

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Inoculation

2.3. UV-C and NUV–Vis Treatment

2.4. Shelf Life Study

2.5. Experimental Plan and Statistical Analysis

3. Results and Discussions

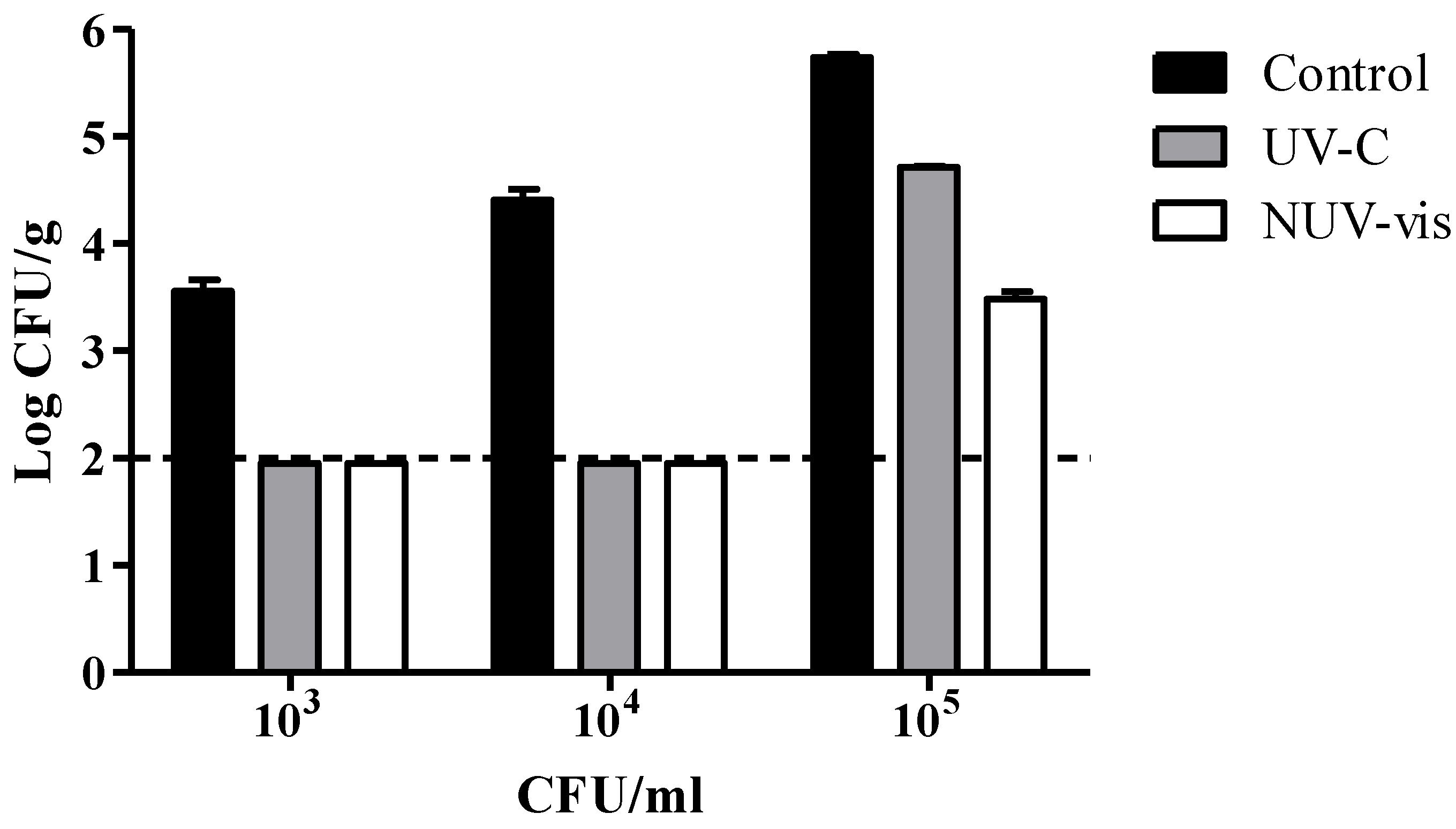

3.1. Effects of UV-C and NUV–Vis Light Depending on the Contamination Level

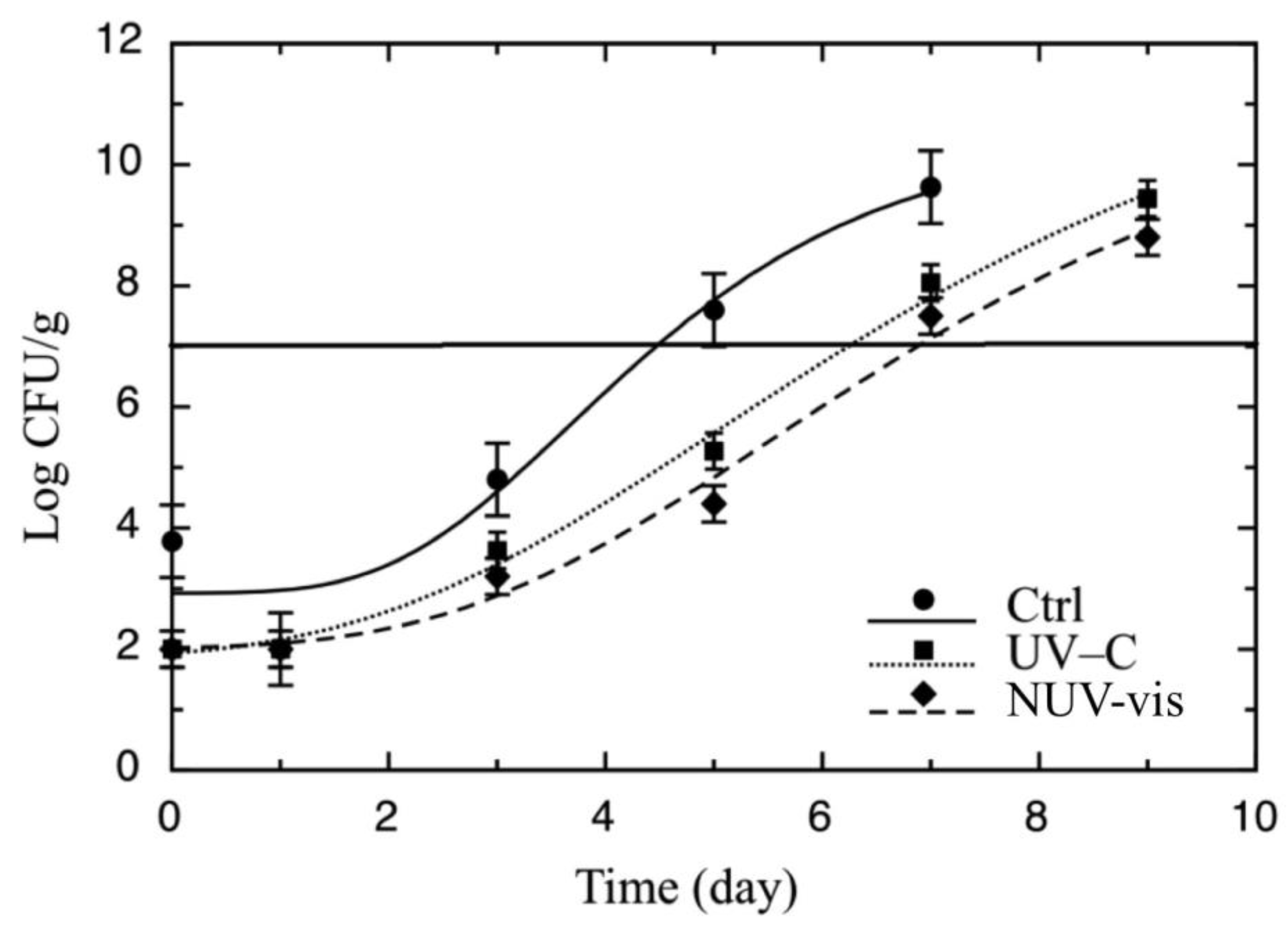

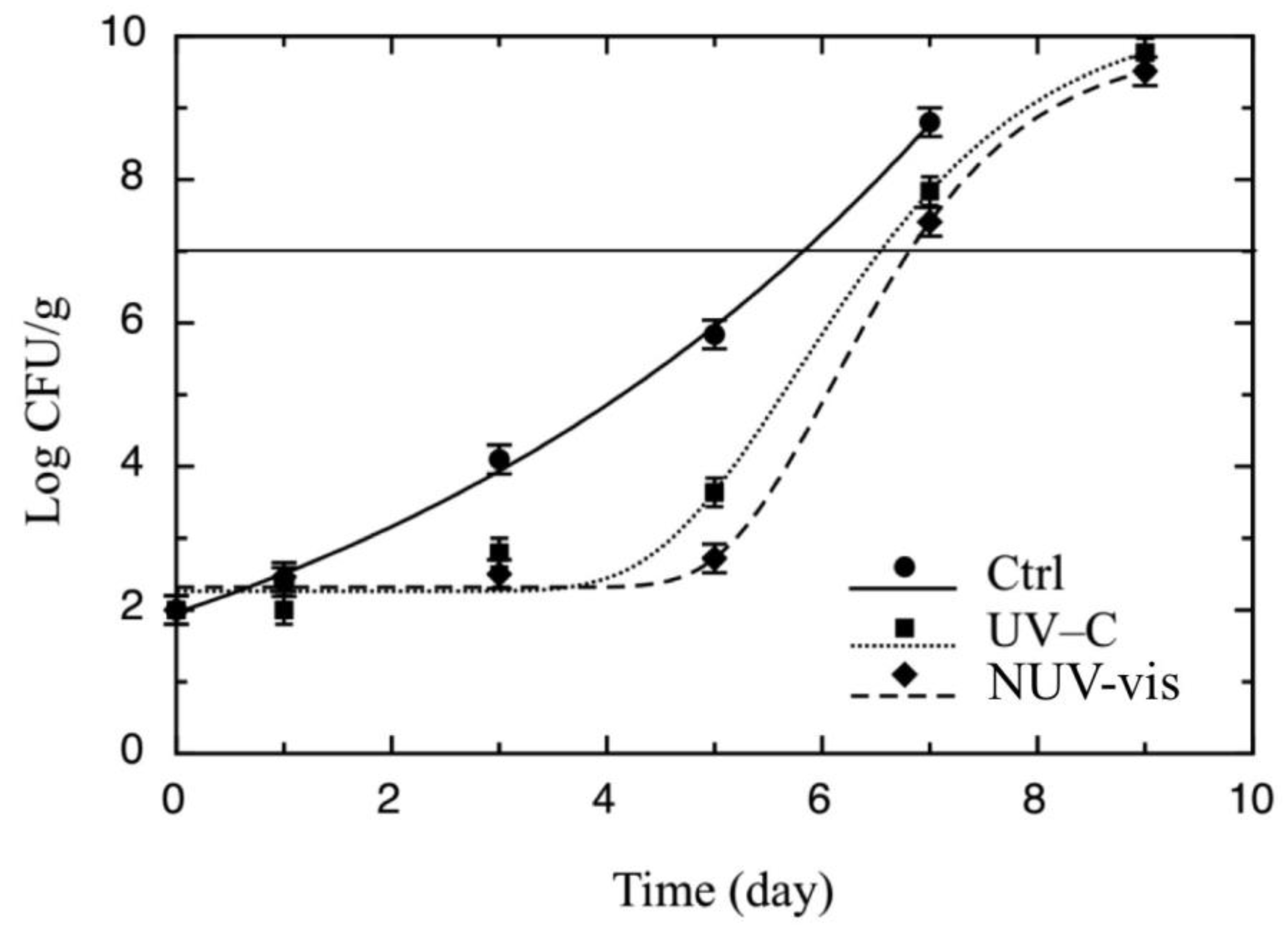

3.2. Shelf Life Study of Ricotta Cheese Treated with UV-C and NUV–Vis Light

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pintado, M.E.; Macedo, A.C.; Malcata, F.X.; Macedo, A.C.; Malcata, F.X. Review: Technology, chemistry and microbiology of whey cheeses. Food Sci. Technol. Int. 2001, 7, 105–116. [Google Scholar] [CrossRef]

- Modler, H.W.; Emmons, D.B. The use of continuous ricotta processing to reduce ingredient cost in ‘further processed’ cheese products. Int. Dairy J. 2002, 11, 517–523. [Google Scholar] [CrossRef]

- Ricciardi, E.F.; Lacivita, V.; Conte, A.; Chiaravalle, E.; Zambrini, A.V.; Del Nobile, M.A. X-ray irradiation as a valid technique to prolong food shelf life: The case of ricotta cheese. Int. Dairy J. 2019, 99, 104547. [Google Scholar] [CrossRef]

- Martin, N.H.; Murphy, S.C.; Ralyea, R.D.; Wiedmann, M.; Boor, K.J. When cheese gets the blues: Pseudomonas fluorescens as the causative agent of cheese spoilage. J. Dairy Sci. 2011, 94, 3176–3183. [Google Scholar] [CrossRef] [PubMed]

- Meyer, J.M.; Geoffroy, V.A.; Baida, N.; Gardan, L.; Izard, D.; Lemanceau, P. Siderophore typing, a powerful tool for the identification of fluorescent and non fluorescent pseudomonads. Appl. Environ. Microbiol. 2002, 68, 2745–2753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andreani, N.A.; Carraro, L.; Martino, M.E.; Fondi, M.; Fasolato, L.; Miotto, G.; Magro, M.; Vianello, F.; Cardazzo, B. A genomic and transcriptomic approach to investigate the blue pigment phenotype in Pseudomonas fluorescens. Int. J. Food Microbiol. 2015, 213, 88–98. [Google Scholar] [CrossRef] [Green Version]

- Heyndrickx, M.; Scheldeman, P. Bacilli associated with spoilage in dairy and other food products. In Applications and Systematics of Bacillus and Relatives; Berkely, R., Heyndrickx, M., Logan, N.A., De Vos, P., Eds.; Blackwell Science: Oxford, UK, 2002; pp. 64–82. [Google Scholar]

- Soni, A.; Oey, I.; Silcock, P.; Bremer, P. Bacillus spores in the food industry: A review on resistance and response to novel inactivation technologies. Compr. Rev. Food Sci. Food Saf. 2016, 15, 1139–1148. [Google Scholar] [CrossRef] [Green Version]

- Spanu, C.; Piras, F.; Mocci, A.M.; Nieddu, G.; De Santis, E.P.L.; Scarano, C. Use of Carnobacterium spp. protective culture in MAP packed Ricotta fresca cheese to control Pseudomonas spp. Food Microbiol. 2018, 74, 50–56. [Google Scholar] [CrossRef]

- Pala, C.; Scarano, C.; Venusti, M.; Sardo, D.; Casti, D.; Cossu, F.; Lamon, S.; Spanu, V.; Ibba, M.; Marras, M.; et al. Shelf-life evaluation of sheep’s ricotta fresca cheese in modified atmosphere packaging. J. Food Saf. 2016, 5, 134–139. [Google Scholar]

- Li, X.; Farid, M. A review on recent development in non-conventional food sterilization technologies. J. Food Eng. 2016, 182, 33–45. [Google Scholar] [CrossRef]

- Pereira, R.N.; Vicente, A.A. Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res. Int. 2010, 43, 1936–1943. [Google Scholar] [CrossRef] [Green Version]

- Hinds, L.M.; O’Donnell, C.P.; Akhter, M.; Tiwari, B.K. Principles and mechanisms of ultraviolet light emitting diode technology for food industry applications. Inn. Food Sci. Emerg. Technol. 2019, 56, 102153. [Google Scholar] [CrossRef]

- Koutchma, T. Advances in ultraviolet light technology for non-thermal processing of liquid foods. Food Biopro. Technol. 2009, 2, 138–155. [Google Scholar] [CrossRef]

- Gayán, E.; Condón, S.; Álvarez, I. A review: Biological aspects in food preservation by ultraviolet light. Food Biopro. Technol. 2014, 7, 1–20. [Google Scholar] [CrossRef]

- Haunghton, P.N.; Lyng, J.G.; Cronin, D.A.; Morgan, D.J.; Fanning, S.; Whyte, P. Efficacy of UV Light Treatment for the Microbiological Decontamination of Chicken, Associated Packaging, and Contact Surfaces. J. Food Protect. 2011, 74, 565–572. [Google Scholar] [CrossRef]

- Luksienė, Z.; Zukauskas, A. Review article: Prospects of photosensitization in control of pathogenic and harmful microorganisms. J. Appl. Microbial. 2009, 107, 1415–1424. [Google Scholar] [CrossRef]

- Ghate, V.S.; Ng, K.S.; Zhou, W.; Yang, H.; Khoo, G.H.; Yoon, W.-B.; Yuk, H.-G. Antibacterial effect of light emitting diodes of visible wavelengths on selected food borne pathogens at different illumination temperatures. Int. J. Food Microbiol. 2013, 166, 399–406. [Google Scholar] [CrossRef]

- Haughton, P.N.; Grau, E.G.; Lyng, J.; Cronin, D.; Fanning, S.; Whyte, P. Susceptibility of Campylobacter to high intensity near ultraviolet/visible 395 ± 5 nm light and its effectiveness for the decontamination of raw chicken and contact surfaces. Int. J. Food Microbiol. 2012, 159, 267–273. [Google Scholar] [CrossRef]

- D’ Souza, C.; Yuk, H.G.; Khoo, G.H.; Zhou, W. Application of light-emitting diodes in food production, postharvest preservation, and microbiological food safety. Compr. Rev. Food Sci. Food Saf. 2015, 14, 719–740. [Google Scholar] [CrossRef]

- Akgün, M.P.; Ünlütürk, S. Effects of ultraviolet light emitting diodes (LEDs) on microbial and enzyme inactivation of apple juice. Int. J. Food Microbiol. 2017, 260, 65–74. [Google Scholar] [CrossRef]

- Lacivita, V.; Conte, A.; Manzocco, L.; Plazzotta, S.; Zambrini, V.A.; Del Nobile, M.A.; Nicoli, M.C. Surface UV-C light treatments to prolong the shelf-life of Fiordilatte cheese. Inn. Food Sci. Emerg. Technol. 2016, 36, 150–155. [Google Scholar] [CrossRef]

- Gammariello, D.; Conte, A.; Lucera, A.; Mastromatteo, M.; Del Nobile, M.A. Anti-yeast activity of natural compounds: In vitro and in vivo tests. Food Pack. Shelf Life 2014, 1, 30–37. [Google Scholar] [CrossRef]

- Fleet, G.H. A Review: Yeasts in dairy products. J. Appl. Bacteriol. 1990, 68, 199–211. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Wolle, D.; Sommer, D. Mozzarella. In The Sensory Evaluation of Dairy Products, 2nd ed.; Clark, S., Costello, M., Drake, M., Bodyfelt, F., Eds.; Springer Science + Business Media: Dordrecht, The Netherlands, 2009; pp. 468–469. [Google Scholar]

- Hyun, J.E.; Lee, S.-J. Antibacterial effect and mechanisms of action of 460–470 nm light-emitting diode against Listeria monocytogenes and Pseudomonas fluorescens on the surface of packaged sliced cheese. Food Microbiol. 2020, 86, 103314. [Google Scholar] [CrossRef]

- Bottino, F.; Rodrigues, B.L.; Ribeiro, J.D.; Lázaro, C.A.; Conte-Junior, C.A. 9th International Conference on Predictive Modelling in Food. Effect of UV-C radiation on shelf life of vacuum package Colossoma macropomum x Piaractus mesopotamicus fillets. Procedia Food Sci. 2016, 7, 13–16. [Google Scholar] [CrossRef] [Green Version]

- Pedrós-Garrido, S.; Condón-Abanto, S.; Clemente, I.; Beltrán, J.A.; Lyng, J.G.; Bolton, D.; Brunton, N.; Whyte, P. Efficacy of ultraviolet light (UV-C) and pulsed light (PL) for the microbiological decontamination of raw salmon (Salmo salar) and food contact surface materials. Inn. Food Sci. Emerg. Technol. 2018, 50, 124–131. [Google Scholar] [CrossRef] [Green Version]

- Koutchma, T. UV disinfection of air, water and surfaces. In Food Plant Safety, UV Applications for Food and Nonfood Surfaces, 1st ed.; Koutchma, T., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Guerrero-Beltran, J.A.; Barbosa-Canovas, G.V. Advantages and limitations on processing foods by UV light. Food Sci. Technol. Int. 2004, 10, 137–147. [Google Scholar] [CrossRef]

- Allende, A.; McEvoy, J.L.; Luo, Y.G.; Artes, F.; Wang, C.Y. Effectiveness of two side UV-C treatments in inhibiting natural microflora and extending the shelf-life of minimally processed ‘Red Oak Leaf’ lettuce. Food Microbiol. 2006, 23, 241–249. [Google Scholar] [CrossRef] [Green Version]

- Manzocco, L.; Plazzotta, S.; Maifreni, M.; Calligaris, S.; Anese, M.; Nicoli, M.C. Impact of UV-C light on storage quality of fresh-cut pineapple in two different packages. LWT 2015, 65, 1138–1143. [Google Scholar] [CrossRef]

- Salvatore, E.; Pes, M.; Falchi, G.; Pagnozzi, D.; Furesi, S.; Fiori, M.; Roggio, T.; Addis, M.F.; Pirisi, A. Effect of whey concentration on protein recovery in fresh ovine ricotta cheese. J. Dairy Sci. 2014, 97, 4686–4694. [Google Scholar] [CrossRef]

- Reinemann, D.J.; Gouws, P.; Cilliers, T.; Houck, K.; Bishop, J.R. New methods for UV treatment of milk for improved food safety and product quality. Am. Soc. Agric. Biol. Eng. 2006. Presentation N. 066088. [Google Scholar] [CrossRef]

- Srimagal, A.; Ramesh, T.; Sahu, J.K. Effect of light emitting diode treatment on inactivation of Escherichia coli in milk. LWT-Food Sci. Technol. 2016, 71, 378–385. [Google Scholar] [CrossRef]

- Conte, A.; Gammariello, D.; Di Giulio, S.; Attanasio, M.; Del Nobile, M.A. Active coating and modified-atmosphere packaging to extend the shelf-life of Fiordilatte cheese. J. Dairy Sci. 2009, 92, 887–894. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Wang, S.; Xu, J.; Liu, S.; Li, G. Effects of combined aqueous chlorine dioxide and UV-C on shelf-life quality of blueberries. Post. Biol. Technol. 2016, 117, 125–131. [Google Scholar] [CrossRef]

- Loi, M.; Liuzzia, V.C.; Fanelli, F.; De Leonardis, S.; Creanza, T.M.; Ancona, N.; Paciolla, C.; Mulè, G. Effect of different light-emitting diode (LED) irradiation on the shelf life and phytonutrient content of broccoli (Brassica oleracea L. var. italic). Food Chem. 2019, 283, 206–214. [Google Scholar] [CrossRef]

- Donsingha, S.; Assatarakul, K. Kinetics model of microbial degradation by UV radiation and shelf life of coconut water. Food Control. 2018, 92, 162–168. [Google Scholar] [CrossRef]

| Samples | MALYeasts (day) | MALPseudomonas spp. (day) | SALOverall Quality (day) | Shelf Life (day) |

|---|---|---|---|---|

| Ctrl | 5.82 ± 0.19 b (χ2 = 0.06) | 4.46 ± 0.86 b (χ2 = 1.75) | 4.50 ± 0.40 b (χ2 = 0.20) | 4.46 ± 0.86 b |

| UV-C | 6.53 ± 0.25 a (χ2 = 0.42) | 6.23 ± 0.25 a (χ2 = 0.24) | 8.02 ± 1.08 a (χ2 = 0.78) | 6.23 ± 0.25 a |

| NUV–vis | 6.81 ± 0.17 a (χ2 = 0.15) | 6.87 ± 0.45 a (χ2 = 0.45) | 6.78 ± 0.42 a (χ2 = 0.30) | 6.78 ± 0.42 a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricciardi, E.F.; Pedros-Garrido, S.; Papoutsis, K.; Lyng, J.G.; Conte, A.; Del Nobile, M.A. Novel Technologies for Preserving Ricotta Cheese: Effects of Ultraviolet and Near-Ultraviolet–Visible Light. Foods 2020, 9, 580. https://doi.org/10.3390/foods9050580

Ricciardi EF, Pedros-Garrido S, Papoutsis K, Lyng JG, Conte A, Del Nobile MA. Novel Technologies for Preserving Ricotta Cheese: Effects of Ultraviolet and Near-Ultraviolet–Visible Light. Foods. 2020; 9(5):580. https://doi.org/10.3390/foods9050580

Chicago/Turabian StyleRicciardi, Emilio Francesco, Selene Pedros-Garrido, Kostas Papoutsis, James G. Lyng, Amalia Conte, and Matteo A. Del Nobile. 2020. "Novel Technologies for Preserving Ricotta Cheese: Effects of Ultraviolet and Near-Ultraviolet–Visible Light" Foods 9, no. 5: 580. https://doi.org/10.3390/foods9050580