Development of Durum Wheat Breads Low in Sodium Using a Natural Low-Sodium Sea Salt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Physico-Chemical and Rheological Analyses of Remilled Semolina

2.2.2. Bread Sample Production and Packaging

2.2.3. Bread Quality Evaluation

Determination of the Physico-Chemical Properties of the Breads

2.3. Texture Profile Analysis of Breads

2.4. HMF Extraction and HPLC Analysis

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Physico-Chemical and Rheological Characterization of the Durum Wheat Remilled Semolina

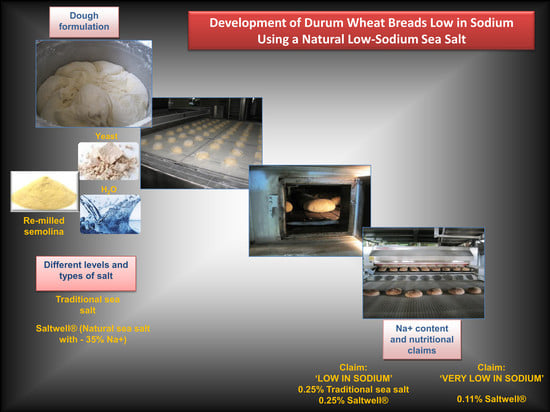

3.2. Sodium Content in Bread

3.3. The Quality Parameters of Breads and Their Evolution during Storage

3.4. Sensory Evaluation

3.5. Multivariate Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Whelton, P.K.; He, J.; Gail, T.L. Lifestyle Modifications for the Prevention and Treatment of Hypertension; Whelton, P.K., He, J., Gail, T.L., Eds.; Marcel Dekker, Inc. Publisher’s Location: New York, NY, USA, 2003; p. 403. [Google Scholar]

- Appel, L.J.; Frohlich, E.D.; Hall, J.E.; Pearson, T.A.; Sacco, R.L.; Seals, D.R.; Sacks, F.M.; Smith, S.C.; Vafiadis, D.K.; Van Horn, L.V. The importance of population-wide sodium reduction as a means to prevent cardiovascular disease and stroke: A call to action from the American Heart Association. Circulation 2011, 123, 1138–1143. [Google Scholar] [CrossRef]

- Strazzullo, P.; D’Elia, L.; Kandala, N.B.; Cappuccio, F.P. Salt intake, stroke and cardiovascular disease: Meta-analysis of prospective studies. Br. Med. J. 2009, 339, b4567. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beaglehole, R.; Bonita, R.; Horton, R.; Adams, C.; Alleyne, G.; Asaria, P.; Baugh, V.; Bekedam, H.; Billo, N.; Casswell, S.; et al. Priority actions for the non-communicable disease crisis. Lancet 2011, 377, 1438–1447. [Google Scholar] [CrossRef]

- Beauchamp, G.K.; Mennella, J.A. Early flavour learning and its impact on later feeding behaviour. J. Pediatr. Gastroenterol. Nutr. 2009, 48, S25–S30. [Google Scholar] [CrossRef] [PubMed]

- Stein, L.J.; Cowart, B.J.; Beauchamp, G.K. The development of salty taste acceptance is related to dietary experience in human infants: A prospective study. Am. J. Clin. Nutr. 2012, 94, 123–129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strazzullo, P.; Campanozzi, A.; Avallone, S. Does salt intake in the first two years of life affect the development of cardiovascular disorders in adult hood? Nutr. Metab. Cardiovasc. Dis. 2012, 22, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Strazzullo, P.; Cairella, G.; Campanozzi, A.; Carcea, M.; Galeone, D.; Galletti, F.; Giampaoli, S.; Iacoviello, L.; Scalfi, L. Population based strategy for dietary salt intake reduction: Italian initiatives in the European framework. Nutr. Metab. Cardiovasc. Dis. 2012, 22, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Donfrancesco, C.; Ippolito, R.; Lo Noce, C.; Palmieri, L.; Iacone, R.; Russo, O.; Vanuzzo, D.; Galletti, F.; Galeone, D.; Giampaoli, S.; et al. Excess dietary sodium and inadequate potassium intake in Italy: Results of the MINISAL study. Nutr. Metab. Cardiovasc. Dis. 2013, 23, 850–856. [Google Scholar] [CrossRef]

- Campanozzi, A.; Avallone, S.; Barbato, A.; Iacone, R.; Russo, O.; De Filippo, G.; D’Angelo, G.; Pensabene, L.; Malamisura, B.; Cecere, G.; et al. High Sodium and Low Potassium Intake among Italian Children: Relationship with Age, Body Mass and Blood Pressure. PLoS ONE 2015, 10, e0121183. [Google Scholar] [CrossRef]

- Eaton, S.B.; Konner, M. Paleolithic nutrition. A consideration of its nature and current implications. N. Engl. J. Med. 1985, 312, 283–289. [Google Scholar] [CrossRef]

- Leclercq, C.; Ferro-Luzzi, A. Total and domestic consumption of salt and their determinants in three regions of Italy. Eur. J. Clin. Nutr. 1991, 45, 151–159. [Google Scholar] [PubMed]

- European Food Safety Authority (EFSA). Opinion of the scientific panel on dietetic products, nutrition and allergies on a request from the commission related to the tolerable upper intake level of sodium. EFSA J. 2005, 209, 1–26. [Google Scholar]

- WASH World Action on Salt & Health. Available online: http://www.worldactiononsalt.com/ (accessed on 3 May 2020).

- CASH Consensus Action on Salt and Health. Available online: http://www.actiononsalt.org.uk/about (accessed on 3 May 2020).

- Food Standard Agency. Food. Using Traffic Lights to Make Healthier Choices; Ancient House Printing Group: Ipswich, UK; Available online: http://www.resourcesorg.co.uk/assets/pdfs/foodtrafficlight1107.pdf (accessed on 3 May 2020).

- Wyness, L.A.; Butriss, J.L.; Stanner, S.A. Reducing the population’s sodium intake: The UK Food Standards Agency’s salt reduction programme. Public Health Nutr. 2012, 15, 254–261. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- WHO & FAO—World Health Organisation & Food and Agriculture Organisation. Diet, Nutrition and the Prevention of Chronic Diseases; WHO Technical Report: Geneva, Switzerland, 2003; Volume 916, p. 149. [Google Scholar]

- WHO World Health Organisation. Reducing Salt Intake in Populations. Report of a WHO Forum and Technical Meeting 5–7 October 2006, Paris, France. Geneva, Switzerland. 2007. Available online: http://www.who.int/dietphysicalactivity/Salt_Report_VC_april07.pdf (accessed on 3 May 2020).

- European Parliament & Council of the European Union. Regulation (EC) No. 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union (OJEU) 2006, L404, 9–25. [Google Scholar]

- Commission Regulation (EU) No. 1047/2012 of 8 November 2012 amending Regulation (EC) No 1924/2006 with regard to the list of nutrition claims (Text with EEA relevance). Off. J. Eur. Union (OJEU) 2012, L310, 36–37.

- European Parliament & Council of the European Union. Regulation (EU) No. 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers. Off. J. Eur. Union (OJEU) 2011, L304, 18–63. [Google Scholar]

- Lynch, E.J.; Dal Bello, F.; Sheehan, E.M.; Cashman, K.D.; Arendt, E.K. Fundamental studies on the reduction of salt on dough and bread characteristics. Food Res. Int. 2009, 42, 885–891. [Google Scholar] [CrossRef]

- Pasqualone, A.; Caponio, F.; Pagani, M.A.; Summo, C.; Paradiso, V.M. Effect of salt reduction on quality and acceptability of durum wheat bread. Food Chem. 2019, 289, 575–581. [Google Scholar] [CrossRef]

- Noort, J.H.F.; Bult, M.; Stieger, M. Saltiness enhancement by taste contrast in bread prepared with encapsulated salt. J. Cereal Sci. 2012, 55, 218–225. [Google Scholar] [CrossRef]

- Simsek, S.; Martinez, M.O. Quality of dough and bread prepared with sea salt or sodium chloride. J. Food Process Eng. 2016, 39, 44–52. [Google Scholar] [CrossRef]

- Miller, R.A.; Jeong, J. Sodium reduction in bread using low-sodium sea salt. Cereal Chem. 2014, 91, 41–44. [Google Scholar] [CrossRef]

- Spina, A.; Brighina, S.; Muccilli, S.; Mazzaglia, A.; Rapisarda, P.; Fallico, B.; Arena, E. Partial Replacement of NaCl in Bread from Durum Wheat (Triticum turgidum L. subsp. durum Desf.) with KCl and Yeast Extract: Evaluation of Quality Parameters During Long Storage. Food Bioprocess Technol. 2015, 8, 1089–1101. [Google Scholar] [CrossRef]

- Raffo, A.; Carcea, M.; Moneta, E.; Narducci, V.; Nicoli, S.; Peparaio, M.; Sinesio, F.; Turfani, V. Influence of different levels of sodium chloride and of a reduced-sodium salt substitute on volatiles formation and sensory quality of wheat bread. J. Cereal Sci. 2018, 79, 518–526. [Google Scholar] [CrossRef]

- Sinesio, F.; Raffo, A.; Peparaio, M.; Moneta, E.; Civitelli, E.S.; Narducci, V.; Turfani, V.; Ferrari Nicoli, S.; Carcea, M. Impact of sodium reduction strategies on volatile compounds; sensory properties and consumer perception in commercial wheat bread. Food Chem. 2019, 301, 125252. [Google Scholar] [CrossRef] [PubMed]

- Delcour, J.; Hoseney, R.C. Principles of Cereal Science and Technology; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Carcea, M.; Narducci, V.; Turfani, V.; Aguzzi, A. A survey of sodium chloride content in Italian artisanal and industrial bread. Foods 2018, 7, 181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fiore, M.C.; Mercati, F.; Spina, A.; Blangiforti, S.; Venora, G.; Dell’Acqua, M.; Lupini, A.; Preiti, G.; Monti, M.; Pè, M.E.; et al. High-throughput genotyping, morphological and quality traits to assess genetic diversity of wheat landraces from Sicily. Plants 2019, 8, 116. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pasqualone, A. Italian Durum Wheat Breads. In Bread Consumption and Health; Pedrosa Silva Clerici, M.T., Ed.; Nova Science Publisher Inc.: Hauppauge, NY, USA, 2012; pp. 57–79. [Google Scholar]

- Boyacioglu, M.H.; D’Appolonia, B.L. Characterization and utilization of durum wheat for breadmaking. I. Comparison of chemical, rheological, and baking properties between bread wheat flour and durum wheat flours. Cereal Chem. 1994, 71, 21–28. [Google Scholar]

- Boyacioglu, M.H.; D’Appolonia, B.L. Characterization and utilization of durum wheat for breadmaking. II. Study of flour blends and various additives. Cereal Chem. 1994, 71, 28–34. [Google Scholar]

- Liu, C.Y.; Shepherd, K.W.; Rathjen, A.J. Improvement of durum wheat pastamaking and breadmaking qualities. Cereal Chem. 1996, 73, 155–166. [Google Scholar]

- Pasqualone, A.; De Angelis, D.; Squeo, G.; Difonzo, G.; Caponio, F.; Summo, C. The Effect of the Addition of Apulian black Chickpea Flour on the Nutritional and Qualitative Properties of Durum Wheat-Based Bakery Products. Foods 2019, 8, 504. [Google Scholar] [CrossRef] [Green Version]

- Giannone, V.; Giarnetti, M.; Spina, A.; Todaro, A.; Pecorino, B.; Summo, C.; Caponio, F.; Paradiso, V.M.; Pasqualone, A. Physico-chemical properties and sensory profile of durum wheat Dittaino PDO (Protected Designation of Origin) bread and quality of re-milled semolina used for its production. Food Chem. 2018, 241, 242–249. [Google Scholar] [CrossRef] [PubMed]

- Pasqualone, A.; Piergiovanni, A.R.; Caponio, F.; Paradiso, V.M.; Summo, C.; Simeone, R. Evaluation of the technological characteristics and bread-making quality of alternative wheat cereals in comparison with common and durum wheat. Food Sci. Technol. Int. 2011, 17, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Palumbo, M.; Spina, A.; Boggini, G. Bread-making quality of Italian durum wheat (Triticum durum Desf.) cultivars. Ital. J. Food Sci. 2002, 14, 123–134. [Google Scholar]

- AACC International. Approved Methods of Analysis, 10th ed.; American Association of Cereal Chemists: St Paul, MN, USA, 2000. [Google Scholar]

- UNI. UNI Method No. 10690. Durum Wheat and Semolina. Determination of Gluten Quality. Gluten Index Method; UNI: Milan, Italy, 1979. [Google Scholar]

- ISO. ISO 3093:2009. Wheat, Rye and Their Flours, Durum Wheat and Durum Wheat Semolina. Determination of the Falling Number according to Hagberg-Perten; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Lefebvre, D.; Gabriel, V.; Vayssier, Y.; Fontagne’-Faucher, C. Simultaneous HPLC determination of sugars, organic acids and ethanol in sourdough process. Lebensm.-Wiss. u.-Technol. 2002, 35, 407–414. [Google Scholar] [CrossRef]

- Lanza, C.M.; Mazzaglia, A.; Scacco, A.; Pecorino, B. Changes in sensory and instrumental features of industrial Sicilian bread during storage. Ital. J. Food Sci. 2011, 23, 6–12. [Google Scholar]

- UNI EN ISO 8586:2014. Sensory Analysis. General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors; UNI, Ente Nazionale Italiano di Unificazione: Milano, Italy, 2012. [Google Scholar]

- Raffo, A.; Pasqualone, A.; Sinesio, F.; Paoletti, F.; Quaglia, G.; Simeone, R. Influence of durum wheat cultivar on the sensory profile and staling rate of Altamura bread. Eur. Food Res. Technol. 2003, 218, 49–55. [Google Scholar] [CrossRef]

- Spina, A.; Brighina, S.; Muccilli, S.; Mazzaglia, A.; Fabroni, S.; Fallico, B.; Rapisarda, P.; Arena, E. Wholegrain durum wheat bread fortified with citrus fibers: Evaluation of quality parameters during long storage. Front. Nutr. 2019, 6, 13. [Google Scholar] [CrossRef] [Green Version]

- Ficco, D.B.M.; Muccilli, S.; Padalino, L.; Giannone, V.; Lecce, L.; Giovanniello, V.; Del Nobile, M.A.; De Vita, P.; Spina, A. Durum wheat breads ‘high in fibre’and with reduced in vitro glycaemic response obtained by partial semolina replacement with minor cereals and pulses. J. Food Sci. Technol. 2018, 55, 4458–4467. [Google Scholar] [CrossRef]

- UNI EN ISO 8589:2014. Sensory Analysis—General Guidance for the Design of Test Rooms; UNI, Ente Nazionale Italiano di Unificazione: Milano, Italy, 2012. [Google Scholar]

- Hammer, Ø.; Harper, D.A.T.; Ryan, P.D. PAST: Paleontological statistics software package for education and data analysis. Palaeontol. Electron. 2001, 4, 9. [Google Scholar]

- D.P.R. 187. Decreto del Presidente Della Repubblica 9 febbraio 2001, n. 187, “Regolamento per la Revisione Della Normativa Sulla Produzione e Commercializzazione di Sfarinati e Paste Alimentari, a Norma dell’articolo 50 Della Legge 22 Febbraio 1994, n. 146”; Gazzetta Ufficiale Della Repubblica Italiana: Roma, Italy, 2001; p. 13.

- Giannone, V.; Lauro, M.R.; Spina, A.; Pasqualone, A.; Auditore, L.; Puglisi, I.; Puglisi, G. A novel α-amylase-lipase formulation as anti-staling agent in durum wheat bread. LWT-Food Sci. Technol. 2016, 65, 381–389. [Google Scholar] [CrossRef]

- Siswoyo, T.A.; Tanaka, N.; Morita, N. Effect of lipase combined with alpha-amylase on retrogradation of bread. Food Sci. Technol. Res. 1999, 5, 356–361. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, S.J. Water and solids mobility in foods. In Advances in Food and Nutrition Research; Steve, L.T., Ed.; Elsevier Academic Press 525 B Street, Suite 1900: San Diego, CA, USA, 2004; Volume 48, pp. 1–89. [Google Scholar]

- Arena, E.; Fallico, B.; Maccarone, E. Thermal damage in blood orange juice: Kinetics of 5-hydroxymethyl-2-furancarboxaldehyde formation. Int. J. Food. Sci. Technol. 2001, 36, 145–151. [Google Scholar] [CrossRef]

- Fallico, B.; Zappalà, M.; Arena, E.; Verzera, A. Effect of conditioning on HMF content in unifloral honeys. Food Chem. 2004, 85, 305–313. [Google Scholar] [CrossRef]

- Capuano, E.; Fogliano, V. Acrylamide and 5-hydroxymethylfurfural (HMF): A review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT Food Sci. Technol. 2011, 44, 793–810. [Google Scholar] [CrossRef]

- Mesias, M.; Delgado-Andrade, C.; Morales, F.J. Process contaminants in battered and breaded foods prepared at public food service establishments. Food Control 2020, 114, 107217. [Google Scholar] [CrossRef]

- Abraham, K.; Gürtler, R.; Berg, K.; Heinemeyer, G.; Lampen, A.; Appel, K.E. Toxicology and risk assessment of 5-Hydroxymethylfurfural in food. Mol. Nutr. Food. Res. 2011, 55, 667–678. [Google Scholar] [CrossRef]

- Choudhary, A.; Kumar, V.; Kumar, S.; Majid, I.; Aggarwal, P.; Suri, S. 5-Hydroxymethylfurfural (HMF) formation, occurrence and potential health concerns: Recent developments. Toxin Rev. 2020, 1–17. [Google Scholar] [CrossRef]

- Rufián-Henares, J.A.; de la Cueva, S.P. Assessment of hydroxymethylfurfural intake in the Spanish diet. Food Addit. Contam. A. 2008, 25, 1306–1312. [Google Scholar] [CrossRef]

- Moreau, L.; Bindzus, W.; Hill, S. Influence of salts on starch degradation: Part II—salt classification and caramelisation. Starch-Starke 2011, 63, 676–682. [Google Scholar] [CrossRef]

| Bread Types Code | Salt Added (% w/w Remilled Semolina) |

|---|---|

| Control A | 1.70% Traditional sea salt |

| Control B | 1.70% Saltwell® |

| 1A | 0.35% Traditional sea salt |

| 1B | 0.35% Saltwell® |

| 2A | 0.15% Traditional sea salt |

| 2B | 0.15% Saltwell® |

| Attributes | Definition | Scale Anchors | ||

|---|---|---|---|---|

| Crumb appearance | Crumb color | Color intensity of crumb | Whitish | Light yellow |

| Alveolar structure | Porosity of crumb | Fine and uniform | Coarse and poorly homogeneous | |

| Visual-tactile | Elasticity | Ability of the crumb to recover from compression exerted by fingers | Slow and partial recovery | Fast and complete recovery |

| Humidity | Humidity perceived at the surface of bread crumb | Dry | Humid | |

| Aroma/Flavor | Bread | The typical aroma/flavor of bread just taken out of the oven | Weak | Strong |

| Yeasty | The aroma/flavor of a fermented yeast-like | None | Strong | |

| Wheat | The typical aroma/flavor of wheat | None | Strong | |

| Off-odour/Off-flavour | Aroma/Flavor unpleasant, not characteristic of bread perceived through taste and smell when swallowing | None | Strong | |

| Taste | Sweet | A basic taste factor produced by sugars | None | Strong |

| Salty | A basic taste factor produced by sodium chloride | None | Strong | |

| Sour | A basic taste factor produced by acids | None | Strong | |

| Bitter | A basic taste factor produced by caffeine | None | Strong | |

| Mouthfeel | Astringent | Sensory perception in the oral cavity that may include drying sensation and roughing of the oral tissue | None | Strong |

| Texture | Softness | Force required to compress the product with the molars | Hard | Soft |

| Overall evaluation | An overall assessment expressed by considering all of the attributes | Low | High | |

| Type | Salt in Experimental Bread (%) | Na+ Content (g/100g) | Regulations (EU) No. 1924/2006 and No. 1047/2012—Nutritional Claims |

|---|---|---|---|

| Control A | 1.22% Traditional sea salt | 0.430 ± 0.014A | - |

| Control B | 1.22% Saltwell® | 0.240 ± 0.014B | - |

| 1A | 0.25% Traditional sea salt | 0.087 ± 0.001C | 0.12 g of Na+—low in sodium |

| 1B | 0.25% Saltwell® | 0.064 ± 0.001C | 0.12 g of Na+—low in sodium |

| 2A | 0.11% Traditional sea salt | 0.048 ± 0.001C | - |

| 2B | 0.11% Saltwell® | 0.035 ± 0.000C | 0.04 g of Na+—very low in sodium |

| Factors of Variability | Degrees of Freedom | Specific Volume | Specific Weight | h/d Ratio | Porosity | Internal Structure | Top Crust Thickness | Basis Crust Thickness | Hardness | Springiness | Resilience | Gumminess | Chewiness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type (A) | 5 | 0.002 | 0.014 | 0.000 | 0.000 | 0.000 | 0.000 | 0.444 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Storage time (B) | 4 | 0.000 | 0.000 | 0.000 | 0.156 | 0.007 | 0.000 | 0.571 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| A × B | 20 | 0.011 | 0.008 | 0.000 | 0.021 | 0.824 | 0.064 | 0.568 | 0.000 | 0.529 | 0.088 | 0.000 | 0.000 |

| Days of Storage | Type | Specific Volume (mL/g) | Specific Weight (g/mL) | h/d Ratio | Porosity (1-8) a | Internal Structure (1-2) b | Top Crust Thickness (mm) | Basis Crust Thickness (mm) |

|---|---|---|---|---|---|---|---|---|

| 0 | Control A | 3.03 ± 0.09 gh | 0.33 ± 0.01 ab | 4.46 ± 0.25 a | 6.00 ± 0.00 abc | 2.00 ± 0.00 | 3.50 ± 0.00 | 4.50 ± 0.00 |

| Control B | 3.14 ± 0.20 cdefgh | 0.32 ± 0.02 abcd | 3.75 ± 0.11 bcd | 6.00 ± 0.00 abc | 1.00 ± 0.00 | 3.00 ± 0.00 | 4.17 ± 0.29 | |

| 1A | 3.06 ± 0.04 fgh | 0.33 ± 0.00 abc | 3.60 ± 0.16 bcdefg | 6.00 ± 0.00 abc | 1.00 ± 0.00 | 3.17 ± 0.29 | 4.00 ± 0.00 | |

| 1 B | 3.09 ± 0.04 defgh | 0.32 ± 0.00 abcd | 3.58 ± 0.06 bcdefg | 6.00 ± 0.00 abc | 1.00 ± 0.00 | 3.83 ± 0.29 | 4.50 ± 0.50 | |

| 2 A | 3.09 ± 0.04 efgh | 0.32 ± 0.00 abcd | 3.23 ± 0.11 defgh | 6.00 ± 0.00 abc | 1.33 ± 0.58 | 3.83 ± 0.29 | 4.67 ± 0.29 | |

| 2 B | 2.96 ± 0.07 h | 0.34 ± 0.01 a | 3.11 ± 0.04 gh | 7.00 ± 0.00 a | 1.00 ± 0.00 | 4.00 ± 0.00 | 4.83 ± 0.29 | |

| 15 | Control A | 3.20 ± 0.09 cdefgh | 0.31 ± 0.01 abcdef | 3.77 ± 0.09 bc | 5.67 ± 0.00 bc | 2.00 ± 0.00 | 3.50 ± 0.50 | 4.33 ± 0.29 |

| Control B | 3.13 ± 0.18 cdefgh | 0.32 ± 0.02 abcd | 3.70 ± 0.12 bcde | 6.00 ± 0.00 abc | 1.33 ± 0.58 | 3.17 ± 0.29 | 5.00 ± 0.00 | |

| 1A | 3.33 ± 0.03 abcdefgh | 0.30 ± 0.00 abcdefg | 3.42 ± 0.16 bcdefgh | 6.00 ± 0.00 abc | 1.00 ± 0.00 | 3.83 ± 0.29 | 4.83 ± 0.29 | |

| 1 B | 3.23 ± 0.23 bcdefgh | 0.31 ± 0.02 abcdefg | 3.65 ± 0.20 bcdef | 6.00 ± 0.00 abc | 1.00 ± 0.00 | 4.33 ± 0.29 | 4.67 ± 0.29 | |

| 2 A | 3.35 ± 0.11 abcdefgh | 0.30 ± 0.01 abcdefg | 3.29 ± 0.27 bcdefgh | 6.50 ± 0.00 ab | 1.00 ± 0.00 | 4.33 ± 0.29 | 5.50 ± 0.50 | |

| 2 B | 3.43 ± 0.05 abcdefgh | 0.29 ± 0.00 bcdefg | 3.23 ± 0.04 defgh | 7.00 ± 0.00 a | 1.00 ± 0.00 | 4.67 ± 0.29 | 5.17 ± 0.29 | |

| 30 | Control A | 3.33 ± 0.31 abcdefgh | 0.30 ± 0.03 abcdefg | 3.77 ± 0.22 bc | 5.67 ± 0.00 bc | 2.00 ± 0.00 | 3.67 ± 0.00 | 4.50 ± 0.00 |

| Control B | 3.59 ± 0.04 abc | 0.28 ± 0.00 defg | 3.83 ± 0.03 b | 5.67 ± 0.00 bc | 1.67 ± 0.58 | 3.67 ± 0.29 | 4.50 ± 0.00 | |

| 1A | 3.52 ± 0.03 abcdef | 0.28 ± 0.00 cdefg | 3.39 ± 0.06 bcdefgh | 6.00 ± 0.00 abc | 1.67 ± 0.58 | 3.67 ± 0.29 | 5.00 ± 0.00 | |

| 1 B | 3.30 ± 0.09 abcdefgh | 0.30 ± 0.01 abcdefg | 3.27 ± 0.07 cdefgh | 6.00 ± 0.00 abc | 1.67 ± 0.58 | 4.33 ± 0.29 | 4.67 ± 0.29 | |

| 2 A | 3.45 ± 0.01 abcdefg | 0.29 ± 0.00 bcdefg | 3.32 ± 0.13 bcdefgh | 7.00 ± 0.00 a | 1.33 ± 0.58 | 4.17 ± 0.29 | 5.50 ± 0.50 | |

| 2 B | 3.23 ± 0.06 bcdefgh | 0.31 ± 0.01 abcdefg | 3.34 ± 0.09 bcdefgh | 7.00 ± 0.00 a | 1.00 ± 0.00 | 3.83 ± 0.29 | 4.83 ± 0.29 | |

| 60 | Control A | 3.17 ± 0.17 cdefgh | 0.32 ± 0.02 abcde | 3.62 ± 0.08 bcdefg | 5.33 ± 0.00 c | 2.00 ± 0.00 | 3.33 ± 0.58 | 4.83 ± 0.76 |

| Control B | 3.51 ± 0.19 abcdef | 0.29 ± 0.02 bcdefg | 3.71 ± 0.09 bcde | 5.67 ± 0.00 bc | 1.33 ± 0.58 | 3.33 ± 0.58 | 5.17 ± 0.29 | |

| 1A | 3.40 ± 0.10 abcdefgh | 0.29 ± 0.01 abcdefg | 3.52 ± 0.14 bcdefgh | 5.67 ± 0.00 bc | 2.00 ± 0.00 | 3.50 ± 0.50 | 5.17 ± 0.29 | |

| 1 B | 3.42 ± 0.05 abcdefgh | 0.29 ± 0.00 abcdefg | 3.55 ± 0.09 bcdefgh | 5.33 ± 0.00 c | 1.00 ± 0.00 | 3.33 ± 0.29 | 5.17 ± 0.29 | |

| 2 A | 3.54 ± 0.09 abcde | 0.28 ± 0.01 cdefg | 3.16 ± 0.16 fgh | 7.00 ± 0.00 a | 1.67 ± 0.58 | 3.50 ± 0.50 | 5.00 ± 0.00 | |

| 2 B | 3.42 ± 0.08 abcdefgh | 0.29 ± 0.01 abcdefg | 3.18 ± 0.04 efgh | 7.00 ± 0.00 a | 1.33 ± 0.58 | 3.50 ± 0.00 | 4.50 ± 0.50 | |

| 90 | Control A | 3.57 ± 0.19 abcd | 0.27 ± 0.03 g | 3.49 ± 0.16 bcdefgh | 5.33 ± 0.00 c | 2.00 ± 0.00 | 3.00 ± 0.50 | 4.50 ± 0.00 |

| Control B | 3.54 ± 0.12 abcde | 0.28 ± 0.01 cdefg | 3.74 ± 0.30 bcd | 5.67 ± 0.00 bc | 1.33 ± 0.58 | 2.67 ± 0.58 | 4.00 ± 0.00 | |

| 1A | 3.71 ± 0.15 a | 0.27 ± 0.01 fg | 3.33 ± 0.07 bcdefgh | 5.67 ± 0.00 bc | 2.00 ± 0.00 | 3.33 ± 0.58 | 4.33 ± 0.58 | |

| 1 B | 3.54 ± 0.15 abcde | 0.28 ± 0.01 cdefg | 3.40 ± 0.07 bcdefgh | 5.33 ± 0.00 c | 1.33 ± 0.58 | 3.17 ± 0.29 | 4.00 ± 0.00 | |

| 2 A | 3.68 ± 0.17 ab | 0.27 ± 0.01 efg | 3.25 ± 0.09 cdefgh | 7.00 ± 0.00 a | 1.33 ± 0.58 | 3.17 ± 0.29 | 4.00 ± 0.00 | |

| 2 B | 3.28 ± 0.11 abcdefgh | 0.30 ± 0.01 abcdefg | 3.03 ± 0.25 h | 7.00 ± 0.00 a | 1.00 ± 0.00 | 3.17 ± 0.29 | 3.83 ± 0.29 |

| Days of Storage | Type | Hardness (N) | Springiness mm) | Resilience | Gumminess | Chewiness (N × mm) |

|---|---|---|---|---|---|---|

| 0 | Control A | 10.57 ± 0.43 o | 5.10 ± 0.60 | 0.91 ± 0.02 | 9.58 ± 0.31 q | 50.36 ± 2.94 o |

| Control B | 16.97 ± 0.68 mn | 4.76 ± 0.46 | 0.91 ± 0.01 | 10.26 ± 0.58 pq | 52.44 ± 4.99 o | |

| 1A | 28.11 ± 0.63 jkl | 5.32 ± 0.10 | 0.85 ± 0.01 | 20.14 ± 0.32 mno | 108.70 ± 0.90 m | |

| 1 B | 34.10 ± 2.40 hi | 5.12 ± 0.04 | 0.81 ± 0.01 | 27.58 ± 2.03 ijk | 145.49 ± 1.70 l | |

| 2 A | 23.70 ± 3.06 l | 6.12 ± 0.22 | 0.80 ± 0.05 | 25.72 ± 1.60 ijkl | 163.56 ± 2.74 k | |

| 2 B | 37.70 ± 0.46 h | 5.92 ± 0.58 | 0.79 ± 0.04 | 35.42 ± 0.93 h | 202.35 ± 4.35 h | |

| 15 | Control A | 25.85 ± 0.14 kl | 5.07 ± 0.68 | 0.87 ± 0.03 | 14.87 ± 0.60 opq | 79.40 ± 1.59 n |

| Control B | 28.84 ± 0.28 ijkl | 5.58 ± 0.39 | 0.89 ± 0.01 | 15.53 ± 0.41 nopq | 76.20 ± 2.44 n | |

| 1A | 47.76 ± 2.36 g | 6.26 ± 1.14 | 0.82 ± 0.03 | 27.92 ± 1.19 ij | 168.22 ± 3.37 ijk | |

| 1 B | 34.19 ± 0.78 hi | 5.85 ± 0.56 | 0.81 ± 0.01 | 29.90 ± 0.97 i | 177.55 ± 1.94 i | |

| 2 A | 62.25 ± 0.57 cd | 5.81 ± 0.40 | 0.76 ± 0.03 | 29.65 ± 2.21 i | 176.42 ± 2.52 ij | |

| 2 B | 53.51 ± 3.96 ef | 6.47 ± 0.22 | 0.77 ± 0.02 | 37.91 ± 2.97 fgh | 243.61 ± 3.80 g | |

| 30 | Control A | 17.45 ± 1.39 m | 5.05 ± 0.86 | 0.89 ± 0.02 | 22.39 ± 0.81 klm | 114.59 ± 1.88 m |

| Control B | 26.34 ± 1.14 kl | 5.29 ± 0.40 | 0.88 ± 0.02 | 23.00 ± 1.47 jklm | 117.35 ± 0.24 m | |

| 1A | 46.85 ± 0.46 g | 5.91 ± 0.15 | 0.81 ± 0.01 | 36.73 ± 2.35 gh | 206.66 ± 1.86 h | |

| 1 B | 32.11 ± 1.30 hij | 5.78 ± 0.34 | 0.80 ± 0.03 | 38.22 ± 1.36 fgh | 210.03 ± 3.49 h | |

| 2 A | 62.16 ± 1.93 cd | 6.26 ± 0.32 | 0.70 ± 0.02 | 38.02 ± 2.69 fgh | 237.42 ± 2.09 g | |

| 2 B | 36.85 ± 0.63 h | 6.61 ± 0.24 | 0.71 ± 0.02 | 40.27 ± 0.76 efgh | 256.17 ± 1.89 f | |

| 60 | Control A | 11.32 ± 1.65 no | 6.85 ± 0.15 | 0.87 ± 0.07 | 20.90 ± 3.12 lmn | 157.87 ± 2.66 k |

| Control B | 35.16 ± 1.04 h | 6.90 ± 0.18 | 0.84 ± 0.03 | 24.70 ± 0.71 ijklm | 165.73 ± 1.66 jk | |

| 1A | 66.44 ± 1.10 cd | 7.14 ± 0.44 | 0.77 ± 0.01 | 43.36 ± 1.40 cdef | 285.83 ± 4.77 e | |

| 1 B | 60.56 ± 0.34 de | 7.49 ± 0.06 | 0.70 ± 0.01 | 42.46 ± 1.91 def | 283.67 ± 2.31 e | |

| 2 A | 51.12 ± 1.76 fg | 7.20 ± 0.15 | 0.70 ± 0.01 | 41.50 ± 0.85 defg | 314.36 ± 3.39 d | |

| 2 B | 74.27 ± 1.81 b | 6.86 ± 0.23 | 0.76 ± 0.03 | 49.66 ± 1.01 b | 372.13 ± 2.97 b | |

| 90 | Control A | 29.43 ± 1.00 ijkl | 6.36 ± 0.79 | 0.82 ± 0.02 | 23.13 ± 0.31 jklm | 159.13 ± 5.34 k |

| Control B | 54.60 ± 0.99 ef | 6.90 ± 0.11 | 0.83 ± 0.04 | 29.17 ± 1.11 i | 200.12 ± 4.55 h | |

| 1A | 45.72 ± 2.10 g | 7.17 ± 0.32 | 0.74 ± 0.04 | 45.23 ± 0.60 bcde | 332.35 ± 3.61 c | |

| 1 B | 58.08 ± 1.59 de | 7.00 ± 0.19 | 0.79 ± 0.05 | 48.01 ± 1.73 bc | 342.25 ± 4.40 c | |

| 2 A | 51.04 ± 1.27 fg | 7.57 ± 0.32 | 0.70 ± 0.01 | 46.21 ± 1.20 bcd | 362.72 ± 4.90 b | |

| 2 B | 80.69 ± 0.02 a | 7.41 ± 0.11 | 0.71 ± 0.01 | 57.97 ± 0.04 a | 425.86 ± 1.38 a |

| Factors of Variability | Degrees of Freedom | aw | Moisture | pH | HMF | Crumb | Crust | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ||||||

| Type (A) | 5 | 0.000 | 0.000 | 0.000 | 0.000 | 0.005 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Storage time (B) | 4 | 0.000 | 0.032 | 0.000 | 0.000 | 0.020 | 0.000 | 0.000 | 0.009 | 0.000 | 0.116 |

| A × B | 20 | 0.000 | 0.000 | 0.000 | 0.000 | 0.011 | 0.033 | 0.069 | 0.002 | 0.007 | 0.133 |

| Days of Storage | Type | aw | Moisture (%) | pH | HMF (mg/kg Dry Matter) |

|---|---|---|---|---|---|

| 0 | Control A | 0.92 ± 0.00 abc | 35.5 ± 0.07 n | 5.65 ± 0.01 i | 28.9 ± 1.73 fghi |

| Control B | 0.92 ± 0.00 a | 37.1 ± 0.02 g | 5.81 ± 0.00 efg | 32.6 ± 2.18 de | |

| 1A | 0.92 ± 0.00 ab | 36.1 ± 0.05 l | 5.88 ± 0.01 cde | 34.3 ± 1.40 cd | |

| 1B | 0.92 ± 0.00 ab | 38.4 ± 0.04 b | 5.94 ± 0.01 abc | 38.2 ± 1.19 b | |

| 2A | 0.93 ± 0.00 a | 35.8 ± 0.07 m | 5.36 ± 0.00 l | 39.2 ± 2.81 b | |

| 2B | 0.92 ± 0.00 a | 36.7 ± 0.07 h | 5.93 ± 0.02 abc | 23.0 ± 1.07 mnopqr | |

| 15 | Control A | 0.91 ± 0.00 bcdef | 36.6 ± 0.02 hi | 5.80 ± 0.00 g | 37.6 ± 0.58 bc |

| Control B | 0.92 ± 0.00 abcde | 35.7 ± 0.08 mn | 5.88 ± 0.01 cdef | 29.2 ± 0.51 efgh | |

| 1A | 0.92 ± 0.00 abcd | 39.5 ± 0.04 a | 5.92 ± 0.01 abc | 30.3 ± 0.98 efg | |

| 1B | 0.92 ± 0.00 abcd | 37.9 ± 0.06 cd | 5.93 ± 0.02 abc | 30.8 ± 1.61 def | |

| 2A | 0.92 ± 0.00 abcd | 37.12 ± 0.04 g | 5.92 ± 0.01 abc | 29.2 ± 0.64 efgh | |

| 2B | 0.92 ± 0.01 abcd | 36.7 ± 0.08 h | 5.96 ± 0.01 ab | 27.9 ± 1.37 fghij | |

| 30 | Control A | 0.91 ± 0.00 defgh | 35.9 ± 0.04 lm | 5.73 ± 0.01 h | 24.9 ± 0.27 jklmnop |

| Control B | 0.91 ± 0.01 cdefg | 35.8 ± 0.02 m | 5.78 ± 0.00 gh | 21.0 ± 0.14 qr | |

| 1A | 0.92 ± 0.00 abcd | 37.7 ± 0.05 de | 5.99 ± 0.04 a | 21.5 ± 0.03 pqr | |

| 1B | 0.92 ± 0.00 abcde | 36.4 ± 0.07 i | 5.88 ± 0.02 cdef | 24.1 ± 1.14 lmnopqr | |

| 2A | 0.92 ± 0.00 abcd | 37.3 ± 0.04 fg | 5.84 ± 0.02 defg | 37.8 ± 0.09 bc | |

| 2B | 0.92 ± 0.00 abcd | 35.9 ± 0.03 lm | 5.93 ± 0.02 abc | 16.3 ± 0.03 s | |

| 60 | Control A | 0.90 ± 0.00 j | 37.3 ± 0.07 fg | 5.82 ± 0.03 efg | 45.8 ± 0.07 a |

| Control B | 0.90 ± 0.00 ghij | 35.0 ± 0.02 p | 5.81 ± 0.01 fg | 22.4 ± 0.20 nopqr | |

| 1A | 0.91 ± 0.00 efghij | 37.5 ± 0.16 ef | 5.83 ± 0.01 efg | 27.7 ± 0.05 fghijk | |

| 1B | 0.91 ± 0.00 efghij | 38.1 ± 0.06 c | 5.78 ± 0.01 gh | 26.0 ± 0.15 hijklm | |

| 2A | 0.91 ± 0.00 defghi | 36.1 ± 0.02 l | 5.83 ± 0.00 efg | 25.0 ± 0.03 jklmno | |

| 2B | 0.91 ± 0.00 defgh | 38.1 ± 0.08 c | 5.91 ± 0.01 bcd | 26.8 ± 0.08 ghijkl | |

| 90 | Control A | 0.88 ± 0.01 k | 34.8 ± 0.06 p | 5.73 ± 0.04 h | 25.5 ± 0.13 ijklmn |

| Control B | 0.90 ± 0.00 ij | 34.2 ± 0.02 q | 5.81 ± 0.01 fg | 24.2 ± 0.30 klmnopq | |

| 1A | 0.90 ± 0.00 hij | 35.3 ± 0.07 o | 5.78 ± 0.00 gh | 20.6 ± 0.13 r | |

| 1B | 0.90 ± 0.00 fghij | 34.2 ± 0.01 q | 5.82 ± 0.08 efg | 22.6 ± 0.03 mnopqr | |

| 2A | 0.90 ± 0.00 fghij | 32.4 ± 0.04 r | 5.80 ± 0.01 gh | 21.5 ± 0.27 opqr | |

| 2B | 0.90 ± 0.00 fghij | 32.4 ± 0.01 r | 5.82 ± 0.00 efg | 21.8 ± 0.00 opqr |

| Days of Storage | Attributes | F Values | Type | |||||

|---|---|---|---|---|---|---|---|---|

| Control A | Control B | 1A | 1B | 2A | 2B | |||

| 0 | Salty | 12.08 *** | 4.2b | 4.3b | 1.6a | 1.6a | 1.6a | 1.5a |

| 15 | Sweet | 5.23 *** | 2.9a | 3.0a | 4.3ab | 5.2bc | 5.8c | 5.0bc |

| Salty | 7.49 *** | 4.4b | 4.1b | 1.9a | 1.9a | 1.4a | 1.7a | |

| Bread flavor | 2.98 * | 6.1b | 6.2b | 4.9ab | 4.1a | 4.6ab | 3.6a | |

| Overall evaluation | 5.01 *** | 6.5b | 6.3b | 4.1a | 3.9a | 4.2a | 3.4a | |

| 30 | Sweet | 5.30 *** | 3.1ab | 2.8a | 4.3abc | 4.6bc | 6.4d | 5.3cd |

| Salty | 7.40 *** | 3.9b | 4.2b | 2.4a | 2.2a | 1.6a | 1.7a | |

| Bread flavor | 2.45 ** | 5.4b | 5.5b | 4.6ab | 3.8ab | 3.3a | 3.5a | |

| Overall evaluation | 3.48 ** | 5.8b | 5.7b | 4.6ab | 3.8a | 3.3a | 3.6a | |

| 60 | Sweet | 3.25 * | 2.9a | 3.4a | 4.1ab | 4.4ab | 5.6b | 5.0b |

| Salty | 9.45 *** | 5.2b | 4.8b | 2.8b | 3.2b | 1.9ab | 1.3a | |

| Overall | 3.17 * | 5.4bc | 5.6c | 4.0ab | 4.3abc | 3.7a | 3.2a | |

| 90 | Sweet | 6.45 *** | 5.4bc | 5.6c | 3.8ab | 4.1abc | 3.5a | 3.3a |

| Salty | 12.45 *** | 5.0b | 4.5b | 2.3a | 2.4a | 1.8a | 2.4a | |

| Overall evaluation | 2.87 * | 5.4bc | 5.6c | 3.8ab | 4.1abc | 3.5a | 3.3a | |

| Attribute | Days of Storage | Control A | Control B | 1A | 1B | 2A | 2B |

|---|---|---|---|---|---|---|---|

| Elasticity | 0 15 30 60 90 | 6.1 ab 7.5 b 6.5 ab 5.0 a 5.5 a | |||||

| Humidity | 0 15 30 60 90 | 7.2 b 6.7 b 4.3 a 4.4 a 4.8 a | 6.5 b 6.1 b 5.6 b 3.8 a 5.2 ab | 7.2 b 5.7 ab 5.1 a 4.0 a 4.4 a | |||

| Softness | 0 15 30 60 90 | 6.5 bc 6.8 c 5.2 abc 4.4 a 4.9 ab | 6.3 b 6.8 b 5.4 ab 4.2 a 5.4 ab |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arena, E.; Muccilli, S.; Mazzaglia, A.; Giannone, V.; Brighina, S.; Rapisarda, P.; Fallico, B.; Allegra, M.; Spina, A. Development of Durum Wheat Breads Low in Sodium Using a Natural Low-Sodium Sea Salt. Foods 2020, 9, 752. https://doi.org/10.3390/foods9060752

Arena E, Muccilli S, Mazzaglia A, Giannone V, Brighina S, Rapisarda P, Fallico B, Allegra M, Spina A. Development of Durum Wheat Breads Low in Sodium Using a Natural Low-Sodium Sea Salt. Foods. 2020; 9(6):752. https://doi.org/10.3390/foods9060752

Chicago/Turabian StyleArena, Elena, Serena Muccilli, Agata Mazzaglia, Virgilio Giannone, Selina Brighina, Paolo Rapisarda, Biagio Fallico, Maria Allegra, and Alfio Spina. 2020. "Development of Durum Wheat Breads Low in Sodium Using a Natural Low-Sodium Sea Salt" Foods 9, no. 6: 752. https://doi.org/10.3390/foods9060752

APA StyleArena, E., Muccilli, S., Mazzaglia, A., Giannone, V., Brighina, S., Rapisarda, P., Fallico, B., Allegra, M., & Spina, A. (2020). Development of Durum Wheat Breads Low in Sodium Using a Natural Low-Sodium Sea Salt. Foods, 9(6), 752. https://doi.org/10.3390/foods9060752