Effect of Drum-Drying Conditions on the Content of Bioactive Compounds of Broccoli Pulp

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Drum Dryer

2.3. Experimental Design and Statistical Analyses

2.4. Analytical Determinations

2.4.1. Chemicals

2.4.2. Moisture Content

2.4.3. Sulforaphane Content

2.4.4. Glucoraphanin Content

2.4.5. Total Phenolic Compounds

2.4.6. Ascorbic Acid Content

2.4.7. Free Radical Scavenging Ability

2.4.8. Ferric Reducing Ability

3. Results and Discussion

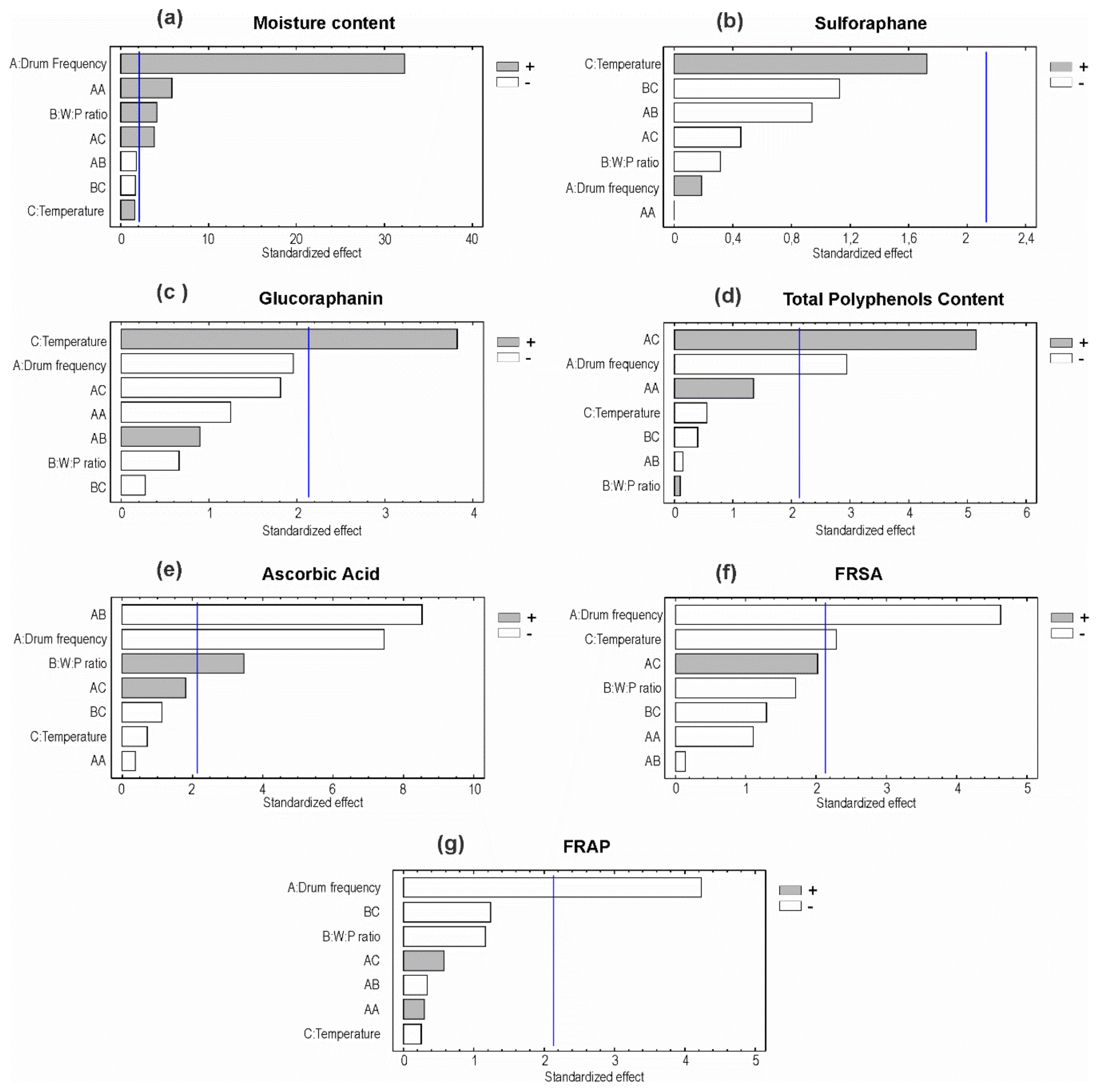

3.1. Final Moisture Content

3.2. Sulforaphane and Glucoraphanin Content

3.3. Total Phenolic Compounds

3.4. Ascorbic Acid

3.5. Antioxidant Activity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martínez, S.; Armesto, J.; Gómez-Limia, L.; Carballo, J. Impact of processing and storage on the nutritional and sensory properties and bioactive components of Brassica spp. A review. Food Chem. 2020, 313, 126065. [Google Scholar] [CrossRef] [PubMed]

- Reyes, A.; Mahn, A.; Guzmán, C.; Antoniz, D. Analysis of the drying of broccoli florets in a fluidized pulsed bed. Dry. Technol. 2012, 30, 1368–1376. [Google Scholar] [CrossRef]

- Mahn, A.; Zamorano, M.; Reyes, A. Effect of freeze-drying conditions on antioxidant compounds of broccoli. J. Food Proc. Technol. 2014, 5, 1000360. [Google Scholar] [CrossRef]

- Mahn, A.; Martin, C.; Reyes, A.; Saavedra, A. Evolution of sulforaphane content in sulforaphane-rich broccoli during tray drying. J. Food Eng. 2016, 186, 27–33. [Google Scholar] [CrossRef]

- Karaaslan, S. Investigation of drying parameters of broccoli during fan-assisted microwave, air and a combined microwave/air drying. J. Anim. Plant Sci. 2016, 26, 123–130. [Google Scholar]

- Salim, N.S.; Garièpy, Y.; Raghavan, V. Design of Continuous Flow Osmotic Dehydration and its Performance on Mass Transfer Exchange during Osmotic Dehydration of Broccoli Stalk Slices. Food Bioproc. Technol. 2016, 9, 1455–1470. [Google Scholar] [CrossRef]

- Ferreira, S.S.; Passosa, C.P.; Cardosoa, S.M.; Wessel, D.F.; Coimbra, M.A. Microwave assisted dehydration of broccoli by-products and simultaneous extraction of bioactive compounds. Food Chem. 2018, 246, 386–393. [Google Scholar] [CrossRef]

- Quintero, J.; Román, D.; Salazar, J.L.; Mahn, A. Economic assessment of a small-scale plant for production of sulforaphane-rich broccoli flour in Chile. Biofuels Bioprod. Bioref. 2020, 14, 544–552. [Google Scholar] [CrossRef]

- Moore, J.G. Drum Driers. In Handbook of Industrial Drying, 2nd ed.; Mujumdar, A.S., Ed.; Marcel Dekker Inc.: New York, NY, USA, 1995. [Google Scholar]

- Villous, N.A.; Gavrielidou, M.A.; Karapantsios, T.D.; Kostoglou, M. Performance of a double drum dryer for producing pregelatinized maize starches. J. Food Eng. 2002, 51, 171–183. [Google Scholar] [CrossRef]

- Kakade, R.H.; Das, H.; Ali, S. Performance evaluation of a double drum dryer for potato flake production. J. Food Sci. Technol. 2011, 48, 432–439. [Google Scholar] [CrossRef]

- Arocho, Y.D.; Bellmer, D.; Maness, N.; McGlynn, W.; Rayas-Duarte, P. Watermelon pomace composition and the effect of drying and storage on lycopene content and color. J. Food Qual. 2012, 35, 331–340. [Google Scholar] [CrossRef]

- Henríquez, M.; Almonacid, S.; Lutz, M.; Simpson, R.; Valdenegro, M. Comparison of three drying processes to obtain an apple peel food ingredient. CYTA J. Food 2013, 11, 127–135. [Google Scholar] [CrossRef]

- Galaz, P.; Valdenegro, M.; Ramírez, C.; Nuñez, H.; Amonacid, S.; Simpson, R. Effect of drum drying temperature on drying kinetic and polyphenol contents in pomegranate peel. J. Food Eng. 2017, 208, 19–27. [Google Scholar] [CrossRef]

- Majzoobi, M.; Kaveh, Z.; Farahnaky, A. Effect of acetic acid on physical properties of pregelatinized wheat and corn starch gels. Food Chem. 2016, 196, 720–725. [Google Scholar] [CrossRef] [PubMed]

- Milczarek, R.R.; Ferry, J.J.; Alleyne, F.S.; Olsen, C.W.; Olson, D.A.; Winston, R. Solar thermal drum drying performance of prune and tomato pomaces. Food Bioprod. Proc. 2017, 106, 53–64. [Google Scholar] [CrossRef]

- Germer, S.P.M.; Tonin, I.P.; de Aguirre, J.M.; Alvim, I.D.; Ferrari, C.C. Influence of process variables on the drum drying of mango pulp. Dry. Technol. 2018, 36, 1488–1500. [Google Scholar] [CrossRef]

- Yamato, M.A.C.; Martins da Silva, V.; de Cássia, E.; Souza, G.; Ferrari, C.C.; Germer, S.P.M. Stability of mango flakes obtained by drum drying with different additives. Dry. Technol. 2020, 38, 361–375. [Google Scholar] [CrossRef]

- Pérez, C.; Barrientos, H.; Roman, J.; Mahn, A. Optimization of a blanching step to maximize sulforaphane synthesis in broccoli florets. Food Chem. 2014, 145, 264–271. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the AOAC; Association of Official Analytical Chemists: Arlington, VA, USA, 1990. [Google Scholar]

- Liang, H.; Yuan, Q.P.; Dong, H.R.; Liu, Y.M. Determination of sulforaphane in broccoli and cabbage by high-performance liquid chromatography. J. Food Comp. Anal. 2006, 19, 473–476. [Google Scholar] [CrossRef]

- Francisco, M.; Moreno, D.A.; Cartea, M.E.; Ferreres, F.; García-Viguera, C.; Velasco, P. Simultaneous identification of glucosinolates and phenolic compounds in a representative collection of vegetable Brassica rapa. J. Chromatogr. A 2009, 1216, 6611–6619. [Google Scholar] [CrossRef]

- Faller, A.L.K.; Fialho, E. The antioxidant capacity and polyphenol content of organic and conventional retail vegetables after domestic cooking. Food Res. Int. 2009, 42, 210–215. [Google Scholar] [CrossRef]

- Ullah, S.; Hussain, A.; Ali, J.; Ullah, K.; Ullah, A. A Simple and Rapid HPLC Method for Analysis of Vitamin-C in Local Packed Juices of Pakistan. Middle-East J. Sci. Res. 2012, 12, 1085–1091. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, M.E. Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. Int. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Zhou, L.; Cao, Z.; Bi, J.; Yi, J.; Chen, Q.; Wu, X.; Zhou, M. Degradation kinetics of total phenolic compounds, capsaicinoids and antioxidant activity in red pepper during hot air and infrared drying process. Int. J. Food Sci. Technol. 2016, 51, 842–853. [Google Scholar] [CrossRef]

- Acharya, P. A Process for Preparing a Dehydrated Food Composition. U.S. Patent No. WO2017/140439 Al, 24 August 2017. [Google Scholar]

- Tonin, I.P.; Ferrari, C.C.; Gomes da Silva, M.; de Oliveira, K.L.; Berto, M.I.; da Silva, V.M.; Germer, S.P.M. Performance of Different Process Additives on the Properties of Mango Powder Obtained by Drum Drying. Dry. Technol. 2018, 36, 355–365. [Google Scholar] [CrossRef]

- Mahn, A.; Román, J.; Reyes, A. Efecto de la liofilización de brócoli pre-procesado sobre la cinética de secado y el de sulforafano. Inf. Tecnol. 2016, 27, 95–106. [Google Scholar] [CrossRef]

- U.S. Food and Drugs Administration. CFR—Code of Federal Regulations Title 21, 21CFR137.200; U.S. Food and Drugs Administration: Silver Spring, MD, USA, 2019.

- Van Eylen, D.; Oey, I.; Hendrixx, M.; Van Loey, A. Kinetics of the stability of broccoli (Brassica oleracea cv. italica) myrosinase and isothiocyanates in broccoli juice during pressure/temperature treatments. J. Agric. Food Chem. 2007, 55, 2163–2170. [Google Scholar] [CrossRef]

- Ferreira, S.S.; Monteiro, F.; Passos, C.P.; Silva, A.M.S.; Wessel, D.F.; Coimbra, M.A.; Cardoso, S.M. Blanching impact on pigments, glucosinolates, and phenolics of dehydrated broccoli by-products. Food Res. Int. 2020, 132, 109055. [Google Scholar] [CrossRef]

- Mahn, A.; Pérez, C.; Reyes, A. Effect of drying conditions in a pulsed fluidized bed dryer on the sulforaphane content of broccoli. Int. J. Food Biosyst. Eng. 2017, 5, 39–44. [Google Scholar]

- Fischer, A.U.; Dettmann, J.S.; Carle, R.; Kammerer, D.R. Impact of processing and storage on the phenolic profiles and contents of pomegranate (Punica granatum L.) juices. Eur. Food Res. Technol. 2011, 233, 797–816. [Google Scholar] [CrossRef]

- Lafarga, T.; Viñas, I.; Bobo, G.; Simó, J.; Aguiló-Aguayo, I. Effect of steaming and sous vide processing on the total phenolic content, vitamin C and antioxidant potential of the genus Brassica. Innov. Food Sci. Emerg. Technol. 2018, 47, 412–420. [Google Scholar] [CrossRef]

- Jin, X.; Oliviero, T.; van der Sman, R.G.M.; Verkerk, R.; Dekker, M.; van Boxtel, A.J.B. Impact of different drying trajectories on degradation of nutritional compounds in broccoli (Brassica oleracea var. italica). LWT Food Sci. Technol. 2014, 59, 189–195. [Google Scholar] [CrossRef]

| Run | DF (Hz) | W:P Ratio | T (°C) |

|---|---|---|---|

| 1 | 4.2 (−1) | 0.25 (−1) | 125 (−1) |

| 2 | 5 (0) | 0.25 (−1) | 125 (−1) |

| 3 | 6.3 (+1) | 0.25 (−1) | 125 (−1) |

| 4 | 4.2 (−1) | 0.50 (+1) | 125 (−1) |

| 5 | 5 (0) | 0.50 (+1) | 125 (−1) |

| 6 | 6.3 (+1) | 0.50 (+1) | 125 (−1) |

| 7 | 4.2 (−1) | 0.25 (−1) | 128 (+1) |

| 8 | 5 (0) | 0.25 (−1) | 128 (+1) |

| 9 | 6.3 (+1) | 0.25 (−1) | 128 (+1) |

| 10 | 4.2 (−1) | 0.50 (+1) | 128 (+1) |

| 11 | 5 (0) | 0.50 (+1) | 128 (+1) |

| 12 | 6.3 (+1) | 0.50 (+1) | 128 (+1) |

| Initial Content in the Pulps | W:P Ratio | |

|---|---|---|

| 0.25 (kg/kg) | 0.50 (kg/kg) | |

| Moisture content (g water/g wb) | 93.3 ± 1.1 | 93.8 ± 1.1 |

| Moisture content (g water/g dw) | 14.0 ± 0.2 | 15.1 ± 0.2 |

| Sulforaphane (mg/100 g dw) | 151.2 ± 8.6 | 162.4 ± 8.3 |

| Glucoraphanin (mg/100 g dw) | 18.6 ± 1.3 | 20.8 ± 4.7 |

| Total polyphenols (GAE/100 g dw) | 397.6 ± 0.6 | 390.3 ± 17.7 |

| Ascorbic acid (mg/100 g dw) | 61.7 ± 7.1 | 65.9 ± 6.0 |

| FRSA (TE/100 g dw) | 300.1 ± 9.7 | 338.2 ± 19.6 |

| FRAP (TE/100 g dw) | 193.4 ± 3.4 | 173.7 ± 1.8 |

| Run | FMC (%) | X (g Water/g dw) | SFN (mg/100 g dw) | GFN (mg/100 g dw) | TPC (mg GAE/100 g dw) | AA (mg/100 g dw) | FRSA (TE/100 g dw) | FRAP (TE/100 g dw) |

|---|---|---|---|---|---|---|---|---|

| 1 | 6.9 ± 0.5 | 0.07 ± 0.01 | 96.0 ± 0.5 * | 14.6 ± 1.8 * | 587.0 ± 8.5 ** | 19.0 ± 0.9 * | 336.0 ± 2.1 ** | 197.0 ± 2.8 |

| 2 | 13.0 ± 2.2 | 0.15 ± 0.04 | 171.9 ± 2.4 | 24.9 ± 2.1 ** | 415.5 ± 29.0 | 24.3 ± 1.0 * | 318.1 ± 8.2 | 155.0 ± 1.4 * |

| 3 | 21.9 ± 0.3 | 0.28 ± 0.01 | 115.9 ± 4.2 * | 14.1 ± 0.6 * | 444.5 ± 3.5 ** | 14.7 ± 0.6 * | 295.0 ± 5.3 | 150.0 ± 0.0 * |

| 4 | 10.4 ± 0.1 | 0.12 ± 0.01 | 153.2 ± 7.1 | 15.3 ± 0.3 * | 571.5 ± 6.4 ** | 43.6 ± 0.2 * | 337.2 ± 1.4 | 181.5 ± 0.7 ** |

| 5 | 13.9 ± 1.8 | 0.16 ± 0.03 | 128.7 ± 15.2 * | 21.2 ± 2.6 | 536.0 ± 1.4 ** | 26.1 ± 1.5 * | 325.1 ± 22.8 | 175.0 ± 2.8 |

| 6 | 24.9 ± 1.5 | 0.33 ± 0.04 | 151.5 ± 34.7 | 15.1 ± 1.0 * | 365.5 ± 36.1 | 10.8 ± 0.1 * | 279.0 ± 17.1 * | 147.0 ± 12.7 * |

| 7 | 5.9 ± 0.6 | 0.06 ± 0.01 | 156.0 ± 5.5 | 32.0 ± 3.6 ** | 477.5 ± 37.5 ** | 14.3 ± 1.4 * | 317.0 ± 23.1 | 194.5 ± 2.1 |

| 8 | 13.7 ± 1.1 | 0.16 ± 0.02 | 158 ± 17.3 | 24.1 ± 1.4 ** | 461.5 ± 20.5 ** | 22.9 ± 0.0 * | 322.0 ± 10.7 | 152.5 ± 2.1 * |

| 9 | 26.3 ± 0.3 | 0.36 ± 0.01 | 168 ± 10.2 | 19.8 ± 3.5 | 499.5 ± 34.6 ** | 22.9 ± 0.7 * | 291.5 ± 17.9 | 175.5.5 ± 17.7 |

| 10 | 8.7 ± 0.5 | 0.10 ± 0.01 | 160.0 ± 7.6 | 27.6 ± 3.4 ** | 451.5 ± 7.1 ** | 42.1 ± 4.4 * | 301.1 ± 14.8 | 168.5 ± 13.4 |

| 11 | 14.4 ± 0.2 | 0.17 ± 0.00 | 132.5 ± 5.0 * | 20.2 ± 1.1 | 447.0 ± 7.1 ** | 18.4 ± 0.5 * | 285.1 ± 9.3 * | 178.5 ± 0.7 ** |

| 12 | 25.9 ± 0.2 | 0.35 ± 0.01 | 140.3 ± 20.0 | 23.1 ± 5.3 | 524.5 ± 0.7 ** | 10.9 ± 0.6 * | 289.0 ± 16.1 * | 125.5 ± 3.5 * |

| Drying Method | SFN Content (mg/100 g dw) | TPC Content (mg GAE/100 g dw) | ||||||

|---|---|---|---|---|---|---|---|---|

| Final Moisture Content (% wb) | Initial SFN | Final SFN | SFN Retention (%) | Final Moisture Content (% wb) | Initial TPC | Final TPC | TPC Retention (%) | |

| Drum dryer † | 13.0 | 151.2 ± 8.6 | 171.9 ± 2.4 | 113.7 | 6.9 ± 0.5 | 397.6 ± 0.6 | 587.0 ± 8.5 | 147.6 |

| Fluidized bed dryer | 16.8 | 143.6 ± 5.4 | 26.6 ± 1.8 | 18.5 [33] | 5.0 ± 0.0 | 329.6 ± 6.9 | 309.1 ± 14.5 | 93.8 [33] |

| Freeze dryer | 14.5 | 41.8 ± 6.7 | 54.2 ± 16.3 | 129.7 [29] | 6.5 ± 0.0 | 957.2 ± 5.7 | 674.6 ± 17.0 | 70.5 [29] |

| Tunnel dryer | 8.1 | 104.0 ± 1.5 | 19.9 ± 2.4 | 19.1 [4] | 6.2 ± 0.1 | 520.5 ± 21.2 | 117.5 ± 2.7 | 22.6 [4] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Córdova, C.; Vivanco, J.P.; Quintero, J.; Mahn, A. Effect of Drum-Drying Conditions on the Content of Bioactive Compounds of Broccoli Pulp. Foods 2020, 9, 1224. https://doi.org/10.3390/foods9091224

Córdova C, Vivanco JP, Quintero J, Mahn A. Effect of Drum-Drying Conditions on the Content of Bioactive Compounds of Broccoli Pulp. Foods. 2020; 9(9):1224. https://doi.org/10.3390/foods9091224

Chicago/Turabian StyleCórdova, Constanza, Juan P. Vivanco, Julián Quintero, and Andrea Mahn. 2020. "Effect of Drum-Drying Conditions on the Content of Bioactive Compounds of Broccoli Pulp" Foods 9, no. 9: 1224. https://doi.org/10.3390/foods9091224

APA StyleCórdova, C., Vivanco, J. P., Quintero, J., & Mahn, A. (2020). Effect of Drum-Drying Conditions on the Content of Bioactive Compounds of Broccoli Pulp. Foods, 9(9), 1224. https://doi.org/10.3390/foods9091224