Abstract

Background: Schedule reliability in container liner services is essential for the efficiency of maritime and inland transport, terminal operations, and the overall supply chain. Disruptions to vessel schedules can trigger a series of disruptions at other points, generating additional operational costs for carriers, terminal operators, inland transport providers, and ultimately, for importers, exporters, and end consumers. Methods: The research paper combines literature reviews and shipping company data. A qualitative analysis contains specific causes of vessel delays and corrective actions used to realign schedules with the pro forma plan. The analysis was expanded to include transport of cargo in containers from origin to the final inland destination. Results: Disruption factors are identified and classified by their place of occurrence: (1) inland transport, (2) anchorage, (3) ports, and (4) navigation between ports. The research produced several new disruptive factors previously not identified and published. It has been confirmed that port congestion acts as the principal cause of delay in liner service. Conclusions: The findings indicate that while the number and complexity of disruptive factors are increasing due to global and regional dynamics, the range of recovery measures remains narrow. A deeper understanding of these causes enables more effective prevention, aiming to minimize supply chain disruptions and costs and increase the reliability of door-to-door container transport.

1. Introduction

Maintaining schedule reliability in liner shipping is of critical importance for the efficiency of maritime transport, terminal operations involving the loading and unloading of containers, transshipment between mainline and feeder vessels, inland transportation, and the overall performance of the supply chain.

Delays in vessel schedules can cause costs for shipping lines, terminal operators, and inland transport providers. It is particularly important for importers, where delayed cargo delivery may cause production stoppages due to the lack of raw materials [] or components, or result in stock shortages [] in retail chains (especially for seasonal goods or perishable products). Similarly, delays in the shipment of export containers can prolong total transit times from origin to destination, creating additional challenges. For this reason, schedule reliability is a crucial factor for shippers when selecting liner services, as it ensures that cargo reaches its destination within the planned timeframe.

Several authors have explored this topic, often focusing on measures aimed at improving schedule reliability [,,]. Regarding the analysis of specific causes of unreliability in liner services, many studies refer to the categorization proposed by Notteboom (2006) [].

According to Dulebenets et al. (2021) [], liner shipping companies operate across three decision-making levels: strategic (varying from 6 months to several years and including long-term planning of fleet size, network design, and alliances), tactical (medium-term planning, which is made every 3–6 months, such as service frequency and fleet deployment), and operational (short-term, day-to-day decisions). Our study focuses on identifying disruptions that occur at the operational level, thereby primarily serving as a foundation for developing effective recovery strategies. In turn, these insights can support decision-making at the tactical and strategic levels as well.

In addition to the literature review, we used internal documents from shipping companies, which were not always available to others, as confirmed by Mulder & Dekker (2019) []. In these documents, vessel operations teams monitor and analyze liner service performance on a daily basis for internal purposes. These records typically document the causes of service disruptions and specify the measures for realigning vessels with the original long-term pro forma schedule. In this respect, this paper provides a deeper understanding of potential and real disruptions.

The analysis of literature and documentation within the shipping companies allowed us to conclude that the actual number of factors disrupting schedule reliability appears to be significantly higher than what is typically reported elsewhere, while the available corrective measures applied to restore schedule adherence are not expanding proportionally.

Considering that the primary purpose of containerization is to enable multimodal transport of cargo in containers from the point of origin to the final inland destination, the analysis of potential delay causes was extended to inland transport. The study analyzes potential causes of delays affecting containerized cargo throughout the entire transport chain: from inland transport at origin to the port of loading; through sea transport from the port of loading to the port of discharge; and finally, inland transport from the port of discharge to the final destination.

The paper is organized as follows: Section 2 reviews the scientific literature about time factors in liner shipping, disruptions that negatively affect schedule reliability, and measures aimed at reducing schedule reliability. Evidence of the liner schedule reliability problems is analyzed in Section 3. Section 4 discusses the research methodology according to the type of manuscript. In Section 5, the results of the research are elaborated. A deeper analysis of the root causes of disruptions and unreliability of the liner service schedule was conducted. In Section 6, an analysis of the conflict between the measures aimed at reducing schedule reliability and their negative consequences on business was carried out and discussed, together with practical strategic scheduling measures implemented by shipping companies. Section 7 discusses the proposals and implications for practice. In the concluding Section 8, the main findings and their significance are summarized, with suggestions for future research directions on the topic.

2. Theoretical Background and Literature Review: Towards the Definition of the Liner Schedule Reliability Problem

The container liner system enables the multimodal transport of cargo from the inland origin (exporter’s warehouse) to the inland final destination (importer’s warehouse) through the use of standardized containers that are compatibly handled across various transport modes: trucks and trains in the inland transport segment, barges/vessels on inland waterways, and vessels in maritime transport. Within this transport system, port terminals, inland terminals, and depots play a crucial role, as they must be equipped with sufficient space and facilities to handle containers efficiently. This complex, containerized system brings together operations of multiple stakeholders, whose efficiency and productivity directly affect the overall reliability of liner container services and the quality of the door-to-door transport service [].

Over 80% of world trade volume is carried by sea []. Measured by value, about 70% of the value of international trade is carried by maritime transportation. About two-thirds are carried by containers, particularly because most high-value commercial goods are containerized []. This widespread use of container transport systems is a clear indicator of their global development and their vital role in facilitating trade between overseas regions across the world.

Liner container services connect overseas regions through an organized group of vessels operating according to a published sailing schedule, providing transportation at regular intervals between designated ports, and accepting various types of cargo from different shippers and in varying quantities. Liner shipping networks meet the growing demand in global supply chains in terms of frequency, direct accessibility, and transit times. Cargo bundling, as one of the key drivers of container service network dynamics, can take place at two levels: (1) within an individual liner service and (2) by combining or linking two or more liner services []. Thus, liner container carriers offer their customers different types of services: direct services (end-to-end), in which cargo is transported from the port of loading to the port of discharge on the same vessel, and various transshipment service options, in which cargo is transferred from the loading port to transshipment ports, where it is loaded onto other vessels for final delivery to the discharge port. These include hub-and-spoke networks that connect short-distance feeder vessels (and ports) with long-distance deep-sea mother vessels; intersection transshipment, where the hub serves as a transfer point between two deep-sea vessels operating on different liner services; and relay transshipment, where the hub connects shipping routes within the same region, serving different port calls.

Today, over 1950 liner shipping services provide regularly scheduled service between ports along a trade route or a group of trade routes, globally [].

Although there are no precise statistics on the volume of container transport via direct and transshipment services, it is estimated that approximately 35% of containers are transshipped at least once during the journey from the port of loading to the final port of discharge. This estimate further emphasizes the complexity of the containerized transport system, where delays occurring at one stage of the transport chain can trigger a cascading or domino effect across other segments of the door-to-door multimodal transport service.

The causes of vessel delays and the resulting unreliability of liner container services have been thoroughly addressed in the literature. Several authors have examined how carriers can mitigate or eliminate the sources of unreliability in liner services. In this respect, Notteboom (2006) [] identifies several causes that may lead to delays in liner service operations and outlines a set of tactical measures that carriers can use to restore schedule adherence (Table 1).

Table 1.

Disruptions that negatively affect schedule reliability and measures aimed at reducing schedule reliability.

The causes of delays are categorized into four groups: terminal operations, port access, maritime passages, and chance. Tactical measures that carriers may use to bring vessels back on schedule include reshuffling the order of ports; skipping a port entirely; cut-and-run tactics; deploying other vessels to take over in combination with a delivery to a hub; speed up future port turnaround times; or increase vessel speed between ports, especially on intercontinental legs. Christiansen et al. (2004) [] conducted a literature review on vessel routing and scheduling. Their study covered strategic fleet planning levels and the design of fleets and sea transport systems. They analyzed tactical and operational fleet planning at the level of industrial, tramp, and liner shipping, considering various problems related to vessel routing and scheduling aspects.

Vernimmen et al. (2007) [] examined schedule unreliability in liner shipping, with a particular focus on shippers and consignees. Their use case deals with a manufacturer located in South Africa who sources spare parts from South America and is based on real-life data. The goal was to analyze the consequences of unreliable services for inventory management and logistics costs.

Mulder (2009) [] investigated the feasibility of Markov decision theory to perform a model that can determine which action should be performed in case of a known position and known delay of a vessel. Only two recovery actions were considered: increasing the sailing speed of the vessel and increasing the port handling capacity.

Wang and Meng (2012) [] analyzed a practical liner route schedule design problem considering two main sources of uncertainty in liner schedule planning: uncertainty at sea (stemming from adverse weather conditions such as storms, low visibility, and strong currents) and uncertainty at port, including factors such as insufficient berth planning systems, variability in quay crane efficiency, and inconsistent container volumes.

Xiaye Tang (2015) [] evaluated vessel schedule recovery by investigating a disruption scenario. To find out how to keep schedule reliability in real operation, this paper tries to use mathematical methods to solve the problem. Furthermore, several typical disruption scenarios were considered, such as port congestion, tidal restrictions, and canal impacts, as well as recovery options, including speed adjustments, port omission, and resequencing calls.

Mulder & Dekker (2019) [] considered the problem of delays management, focusing on recovery strategies. They determined an optimal recovery policy and buffer time allocation to the vessel route using publicly available data due to the unavailability of internal company data. The goal was to minimize the total costs associated with delays and define recovery actions, such as changing the vessel speed, skipping a port on the route, and extreme recovery action (cut-and-go).

Mulder et al. (2019) [] developed an approach for buffer allocation in liner shipping that uses a stochastic dynamic program (SDP) for modelling timetable execution, i.e., occurrence and propagation of delays and optimal dynamic recovery actions. In their experiments, the algorithm computes the optimal buffer time allocation in about 70 s. However, a comprehensive examination of the underlying causes of delays is beyond the scope of this paper and is therefore not addressed in detail.

Dulebenets et al. (2021) [] conducted a comprehensive literature review on liner vessel scheduling. The collected studies are classified into different categories, including general vessel scheduling, uncertainty in liner shipping operations, collaborative agreements, vessel schedule recovery, and green liner shipping. Although disruptions are mentioned in their work, the primary focus remains on recovery actions.

Elmi et al. (2022) [] provided a thorough review of the current liner shipping research, primarily focusing on two major themes: uncertainties in liner shipping operations, and vessel schedule recovery in response to disruptive events. They concluded that a proper selection of vessel schedule recovery strategies is expected to minimize deviations from the original schedule and reduce delays in the delivery of cargoes to the destination ports. Their theoretical framework includes an analysis of disruptions as well; however, it lacks empirical validation. Okur and Tuna (2022) [] investigated liner shipping schedule reliability. They attempted to evaluate the transit time reliability performance of shipping lines and to examine the factors that may affect transit time reliability. According to the results, approximately 50% of the vessels do not arrive on time, concluding that shipping companies must increase their time management skills. However, the real causes of disruptions are only partially explored in this study. Yue and Mangan (2023) [] conducted a systematic literature review of the reliability concept in transportation, focusing on container shipping networks.

One of the studies most closely related to our research is the analysis of delay causes at the Port of Rotterdam by Nikghadam et al. (2023) []. The authors investigated various delay-related issues (using port call data and expert interviews) that could be mitigated through improved information sharing.

Zhou et al. (2024) [] addressed the issue of schedule recovery for liner ships operating under Emission Control Areas (ECAs) regulations in the face of disruptive events. From the scenario analysis, delays caused by unforeseen disruptive events may not necessarily be fully recovered to the original level, as there is a limit to the degree of recovery. Furthermore, the model proposed in their paper is a post-strategy approach, and the causes of delays were mentioned only in general terms without in-depth elaboration.

In their paper, Zhen et al. (2025) [] present a reinforcement-learning-based approach to optimize the scheduling of vessels in a one-way channel, aiming to quickly identify a scheduling solution that enhances port operational efficiency. This method models the vessel scheduling problem in a one-way channel by incorporating navigational constraints, safety requirements, and vessel-specific characteristics. However, the model assumes, for example, that pilots and tugboats are always available and ready. In practice, as our work shows, problems such as pilot shortages or delays in tugboat allocation may occur.

In their work, Bavandi et al. (2025) [] emphasise complexity of decision-making processes in transportation planning. Transportation in an uncertain environment requires flexibility and the ability to adapt quickly. The authors investigated a multi-commodity network flow problem with fractional objective function with multi-choice, fuzzy random, and fuzzy variables related to time-reliability and uncertainty.

Our study moves beyond existing work by providing a grounded, real-world perspective on schedule unreliability in liner shipping. Reviews have shown that there is no unified or absolute definition of reliability in container shipping networks. Rather than building a conceptual framework, we contribute empirical insight into disruptions and how reliability challenges are managed in day-to-day operations. Drawing on several years of daily operational reports from a global liner shipping company, we identify and systematize a much broader range of disruption factors than previously documented, covering sea and port operations, anchorage, and inland transport. This comprehensive view allows us to uncover newly observed disruptions and better understand their underlying causes. Crucially, we also examine the conflicts between schedule recovery measures and their unintended negative impacts on operations, offering insight into issues shipping companies face when realigning schedules. By integrating empirical evidence with a full-chain, door-to-door perspective, our research strengthens the link between theory and practice and provides actionable guidance for improving schedule reliability in container liner services.

3. The Evidence

Schedule reliability in liner shipping can be defined as the likelihood that a vessel arrives at a port of call no more than one calendar day earlier or later than the pro forma schedule. In this context, an arrival is considered “on time” if it occurs within one day before or after the scheduled date [].

Sea-Intelligence is a leading provider of Research & Analysis, Data Services, and Advisory Services within the global supply chain industry, with a strong focus on container shipping. The industry’s by far most comprehensive study of ocean liner schedule reliability, measuring schedule reliability and vessel delays across all deep-sea liner services, based on more than 12,000 vessel arrivals, and measures and benchmarks the schedule reliability performance of 60+ container carriers in 34 different trade lanes, across more than 300 liner services/loops. Schedule reliability is a measure of the actual on-time performance of individual vessel arrivals in global ports.

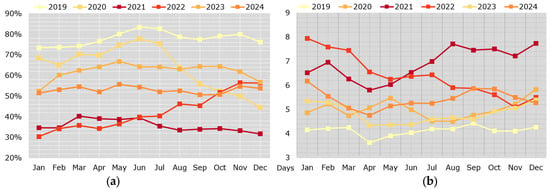

Derived from the Global Liner Performance (GLP) report, with schedule reliability figures up to and including December 2024 [], Figure 1a illustrates the trend in liner service schedule reliability, expressed as a percentage over the period from 2019 to 2024. The highest reliability was recorded in 2019, after which it began to decline sharply in mid-2020 as a result of the COVID-19 pandemic. The lowest reliability was observed in 2021, falling below 40%. For most of 2023, reliability remained above 60%, but in 2024 it dropped again to a level of 50–55%. This decline was driven by geopolitical factors, particularly the conflict in the Red Sea, which led to the suspension of liner service transits through the Red Sea and Suez Canal, ultimately affecting global schedule adherence.

Figure 1.

Global schedule reliability (a) and global average delays for late vessels arrivals (b) in the period 2019–2024. Adapted from [].

Figure 1b shows the average global delay of liner services, expressed in days. During the periods of the lowest schedule reliability, namely, 2021 and 2022, delays ranged from 5 to 8 days. In 2024, the average global delay remains between 5 and 6 days.

These low levels of service reliability are far from the performance goals publicly set by major container carriers. For example, MAERSK has stated its ambition to achieve at least 90% schedule reliability of liner shipping services through the GEMINI & HAPAG-LLOYD cooperation: “Our ambition is to deliver a flexible and interconnected ocean network with historically unmatched and industry-leading reliability. We have set the ambitious target of aiming to deliver schedule reliability of above 90% (SeaIntel) once the network is fully phased in.” [,].

The delay of a single vessel in a liner service can cause an intra-round-trip effect, meaning a schedule disruption of one vessel disturbs the pre-planned, regular frequency of port calls by other vessels in the same liner service. As a result, instead of weekly port calls on a fixed day, the vessels in a given liner service may call at the port at irregular, unplanned intervals, e.g., every 5 days, then 9 days, then 7 days.

The problem of delays in liner shipping arises from the complexity of organizing liner container services, particularly those based on transshipment operations (hub & spoke, intersection, and relay), and the fact that a delay at one port tends to cascade through the entire door-to-door transport chain. A vessel’s delay at one port, whether due to navigational conditions during sailing or the vessel’s inability to berth on time because of port congestion, affects all subsequent ports of call in the liner service schedule (regardless of their full operability), as well as the planned inland transport of cargo from its origin, or to its final destination.

Given the complexity of organizing different types of liner container services and the involvement of multiple transport modes used to move containerized cargo in a multimodal door-to-door system, as well as the large number of stakeholders participating in cargo transport and in the handling of vessels at ports and containers at seaport and inland terminals (Table 2), disruptions can easily arise.

Table 2.

Study-related major stakeholders in multimodal transport.

In addition, unforeseen weather conditions at sea, rivers, and land further increase the risk of service unreliability, making it essential to break down the door-to-door container transport process, identify the key stakeholders, and determine the root causes of disruptions affecting overall service performance.

4. Research Methodology

It has already been emphasized that a larger number of authors have analyzed measures to reduce schedule unreliability, while in analyses of the causes of liner service unreliability, many of them have referred to Notteboom (2006) []. It is most likely that these authors did not have access to the internal documents of shipping companies, in which vessel operations personnel analyze the performance of liner services for internal use, list various reasons for service disruptions, and specify the measures by which vessels in the service will be brought back in line with the original long-term schedule.

This study employs a descriptive qualitative and empirical approach aimed at synthesizing insights from previous research, industry documentation, and professional practice.

The research process comprised five main stages: (1) review and analysis of previous research, (2) examination of industry documentation, (3) integration of professional insights, (4) a focused operative analysis of port disruptions, and (5) analysis of conflicts.

The first stage involved a comprehensive review of recent academic and industry literature, with a particular focus on studies addressing the causes of liner service unreliability and measures aimed at improving schedule performance. To complement the maritime analysis and provide a basic contextual understanding of the broader door-to-door transport chain, a limited review of inland transport disruptions (road, rail, and river) was conducted. Given that inland transport was not the core focus of this research, only a small set of indicative sources was included. These were selected for their ability to illustrate common types of inland disruptions. Consequently, inland transport disruptions are discussed in general terms to offer a baseline perspective and support a more holistic view of the door-to-door disruption landscape, despite the paper’s primary focus on maritime and port-related issues/disruptions. The review provided the conceptual foundation for the analysis and helped define the main disruption categories, later examined in industry documentation.

The second stage centered on the analysis of industry data, primarily through the examination of internal operational reports from a major container carrier covering the period 2012 to 2025. These daily reports, prepared for each liner service, monitor every vessel’s schedule performance, list causes of delays, and specify corrective measures to align actual operations with the original long-term schedule. Access to these reports and to operational meetings was facilitated by the first author’s professional experience as a line manager in a shipping company and as a manager in a maritime agency representing one of the world’s three largest liner container carriers. This background provided unique insights into schedule management practices, while ensuring a grounded interpretation of the operational data.

As a supplementary means, online resources were used, particularly customer advisories in which shipping companies inform their clients on changes in liner service operations. An example is provided from the carrier MAERSK, which informed customers that due to significant terminal congestion in Mediterranean and Asian ports, they were experiencing substantial delays in vessel schedules. These congestions resulted in extended waiting times at various ports, affecting their ability to maintain regular schedules, and leading to the introduction of voyage “slidings” []. Additionally, relevant research findings from the Background Section were incorporated into the analysis.

The third stage extended the research to inland transport modes (road, railway, and inland waterway), recognizing their role in connecting the origin of container cargo to the port of loading and the port of discharge to the final destination. Internal reports from the shipping company’s departments responsible for inland transport were analyzed along with data from Travel Disruptions in Europe []. This online source consolidates reports on disruptions or planned works on railway tracks and stations across Europe. To account for trends in road freight transport, the study Shortage of Qualified Personnel in Road Freight Transport [] was used, while insights into disruptions affecting inland vessel cargo handling in seaports and on rivers were drawn from the study Disruption in the Container Supply Chain [].

The fourth stage involved conducting a focused operative analysis to provide a concrete and up-to-date view of port congestion and operational disruptions. This assessment was based on operational reports from 8 April 2025, covering ports in the Far East, the Mediterranean, Northern Europe, and the Black Sea. It captured the same-day operational status of a large number of ports, identifying congestion, weather-related berthing restrictions, labour strikes, and infrastructure-related disruptions, to mention some. This operative snapshot served as a triangulation tool, verifying the patterns observed in long-term operational data and aligning with external industry observations.

Finally, after the identification and investigation of the main disruptive factors’ categories, we analysed the conflicts between corrective measures aimed at restoring vessel schedules and their unintended negative impacts on operations. This step examined how actions such as port skipping/omission, port skipping with container diversion, sailing speed adjustments, cut and run strategies, double calls, and other strategic scheduling measures, while intended to improve overall service reliability, can create new inefficiencies, increase operational costs, or introduce further disruptions elsewhere in the transport chain.

In addition, original proposals were developed in areas where gaps in the literature or operational documentation were identified. These proposals are based on the combined insights from the reviewed materials and the authors’ professional experience, making them relevant for both academic research and practical application in the industry. To strengthen the credibility of the findings, information from different sources was compared and cross-checked, ensuring that the conclusions are supported by consistent evidence. Although the methodology is primarily qualitative and descriptive, it offers a clear and comprehensive view of the key factors affecting liner service reliability and related inland transport operations.

5. Results

The aim of this paper was to investigate existing and identify new, various influential factors that reduce the liner container services’ reliability, together with other factors related to the inland transport segment when the carrier provides a multimodal door-to-door transport service.

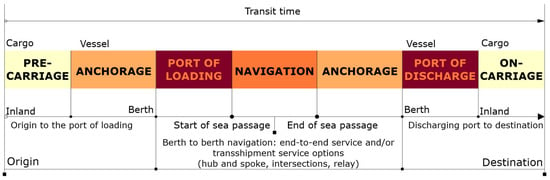

In Figure 2, the categorization of various disruptions that negatively affect schedule reliability is systematized by service phases. The disruptive factors are divided into four groups, depending on the location and cause of the disruption:

- Inland transport: Pre-carriage (origin to the port of loading) and on-carriage (discharging port to the final destination) of cargo with different modes of transport (road/truck, rail, river/Barge transport);

- Anchorage (vessel) at the port of loading, at the port of discharge, and at the transshipment port;

- Port of loading, port of discharge, and transshipment port;

- Navigation from the port of loading to the port of discharge (including possible transshipment port).

Figure 2.

Disruption categories (phases) that negatively affect schedule reliability. Made by authors.

The detailed results are presented in Table 3 as disruptions identified in the literature, covering a wide range of factors that also occur in practice. The table includes several original (own identified) disruptions, not covered in previous research. These original contributions are marked in bold. Overall, the table combines literature and practice-based insights, offering a more comprehensive overview of all factors affecting schedule reliability through the transportation process.

Table 3.

Disruptions that negatively affect schedule reliability. Categories and factors accompanied by references are derived from existing studies, while unreferenced factors marked in bold represent the authors’ original contribution.

The results referring to the particular disruption and its implications for the vessel schedule are elaborated further.

5.1. Inland Transport: Pre-Carriage and On-Carriage

The identified causes affecting disruptions, delays, and unreliability in the inland part of transport, as well as in river navigation by container barges, include shortage of truckers and other inland transport providers; labour strikes by inland transport providers, pandemic protocols affecting labour availability; bad weather conditions on roads and railways that can halt regular inland transport, road and railway closures (due to various types of damage, incidents, construction, maintenance, etc.); congestion at inland terminals or depots (such as lack of storage capacity or terminal equipment); low water levels in rivers, which can limit barge transport; accumulated ice on rivers, which can significantly disrupt or stop barge operations; and limited lock chamber sizes which can restrict the size of river vessels.

The shipping line, acting as a multimodal transport operator offering customers a complete door-to-door transport service, has no control over these identified disruption causes in the inland transport segment. It is therefore essential to have a thorough understanding of the potential causes of disruption in this part of the transport chain and to proactively and preventively work to mitigate their impact.

5.2. Anchorage at the Port of Loading, Discharge, and Transshipment

The identified causes that lead to disruptions at anchorage, i.e., in the maritime area in front of the port where the berthing and operations of the liner container vessel are scheduled, are primarily related to external service providers to the vessel. These include:

- Tugboat operators (disruptions may occur due to a lack of available tugs, or if tugboats are assigned to other high-priority vessels, or due to technical incidents involving the tugboats);

- Pilots (disruptions may result from a shortage of pilots in the port, pilot strikes, or if pilots are assigned to other high-priority vessels; in some ports, night-time pilotage is suspended for safety reasons);

- Mooring crews (there may be an insufficient number of mooring staffs, or they may be busy handling another priority vessel at the same time);

- Bunker operators (unplanned delays in bunker delivery or debunkering operations can happen due to limited capacity, or poor coordination between the operations and bunker departments, etc.).

It is clear that the carrier has no control over the disruptive factors caused by third-party service providers before the vessel is berthed and cargo operations begin. It should also be emphasized that disruptions and delays can occur during the vessel’s planned departure from the port, even after all cargo operations have been completed.

It is essential to have a thorough understanding of the potential causes of disruption that may arise in the port’s maritime area, both before the vessel berths and after it completes cargo operations and is ready to depart. A preventive approach, efficient information exchange, and strong business relationships with port service providers are key to minimizing the impact of such disruptions.

5.3. Disruptions Related to Ports

5.3.1. General Disruptions in Port(s) of Loading, Discharge, and Transshipment

The highest number of delay causes occur at the port(s) of loading and discharge, as well as transshipment. The most common cause impacting the reliability of liner services is port congestion, a situation in which there are not enough available berths. Congestion can be measured as the time deviation between the time instant in which the vessel first anchors in the port area [] (or from the beginning of drifting manoeuvre when the vessel arrives at the anchorage) and the time instant in which the vessel faces the right conditions to enter the assigned berth.

There is also yard congestion, which refers to a lack of available space for stacking containers within the terminal. In such cases, the terminal operator may impose restrictions on carriers, such as restricting the number of containers that can be handled per vessel call, not accepting empty containers at the terminal or for vessel loading, or restricting the number of reefer containers that can be accepted, particularly when the terminal has a high volume of reefer cargo and a limited number of reefer plugs.

A limiting factor for carriers in certain ports is the draft restriction, which prevents the carrier from utilizing the vessel’s full commercial or cargo capacity in that port. Port operations may also be delayed due to dredging activities along the shoreline or construction works on the terminal’s quay wall. National holidays reduce the number of operational days available in some ports. For example, especially low schedule reliability combined with the import boom in the US before Christmas resulted in many ships waiting at the ports to berth and continued to reduce program reliability [].

Operational disruptions in ports can also result from various labor-related issues. These may include strikes, general labor shortages, the inability to operate during the third (night) shift due to insufficient workforce, work stoppages during parts of the day in extreme heat conditions during summer months, and reduced labor availability during epidemics due to mandatory quarantine regulations or other public health measures.

Unfavorable weather conditions (high waves, strong winds, and dense fog) can prevent port operations. Natural disasters (earthquakes, tsunamis) can cause unwanted consequences in ports and container terminals, in a way that both phenomena can cause port closures, leading to disruptions in cargo handling and delays in vessel operations [].

In cases of oil spills from the vessel or cargo leakage from containers, port operations may be interrupted until the cause is removed and the investigation is completed. Fire and explosions of cargo in containers are possible causes of work disruptions at container terminals, which also affect the regularity of terminal operations. Any disruption at the terminal also results in work with vessels in the port, stoppage of commercial operations, reduced productivity, and, in the worst case, the inability of vessels to berth alongside the terminal. Delays in maintaining the vessel’s planned schedule within the liner service can also result from low terminal productivity, such as an insufficient number of quay cranes and terminal equipment for container handling, as well as various technical problems, including crane breakdowns, crane and equipment maintenance, power outages, or fender replacement. Possible disruptions to terminal operations in the port may occur due to Terminal Operating System (TOS) failures or cyberattacks.

The productivity of port operations and the speed of container clearance from the port are also influenced by government authorities such as Customs, Veterinary, and Phytosanitary services.

The reliability of the liner container service can be affected by disruptions occurring in the port area due to limiting factors related to the terminal itself: the port terminal operator, service providers operating at the terminal, as well as external weather conditions. In this context, it is recommended to have in-depth knowledge of potential in-the-port disruptive factors to maintain strong business relationships with port service providers, ensure timely exchange of information, and take preventive measures to minimize disruptions that could impact the reliability of the long-term planned liner schedule.

5.3.2. Port Congestion

One of the main conclusions, which requires special attention, refers to port congestion as the most frequent cause of delays and disruptions in the liner service schedule.

The problem of port congestion and the resulting challenges for both carriers and users of liner services can reach an extreme, where the carrier temporarily refuses to accept bookings for cargo that would be transshipped through ports already known to be congested. For example, HAPAG-LLOYD informed Canadian exporters that it would temporarily stop accepting bookings, stating: “The reality is that we took the stance that we will not accept bookings if we know your cargo will be stranded at a transshipment port.” []. Such a drastic decision may significantly disrupt trade on certain cargo routes.

Due to the costs arising from port congestion, carriers have imposed a Congestion Surcharge (CGS)—an additional charge on top of the base freight rate intended to cover their extra operational expenses. An example of the introduction of this measure is the notice circulated by the MSC stating that due to congestion in Northern Europe, which creates difficult operating conditions and increases costs, the company will apply the CGS for all cargo from Northern Europe to the Far East []. A recent, new example related to congestion in the ports of Rotterdam and Antwerp is the “Inland Peak Surcharge” introduced by Maersk. This surcharge applies to all forms of inland transport carried out by Maersk and within the multi-carrier inland services. The new fee applies to shipments to and from deep-water terminals in both ports and, according to the shipowner, will be in force as long as necessary to ensure the availability of adequate shipping capacity in the face of declining efficiency of land operations [].

Due to issues caused by the port congestion and due to restrictions and closures on the railways, railway operators are also imposing a congestion surcharge. An example of such a surcharge is the notice issued by Metrans to its rail transport customers [].

It is clear that low schedule reliability has a significant impact on stakeholders across the entire logistics ecosystem. The negative effects are particularly felt by logistics providers, manufacturers and suppliers, retailers, and end customers.

In modern containerized transport, sea transport is just one stage in the overall production process, and any delay compared to the planned sailing schedule and total transit time from origin to final destination has a major negative impact on stock levels.

With the aim of conducting a concrete analysis of port congestion and operational disruptions in ports, we carried out a separate study in which the operational status of a large number of ports was analyzed. The research showed that, on the same day, port congestion was present in a large number of ports, confirming it as a key cause of unreliability in liner container services. Ports where congestion was recorded on that day, causing waiting for a berth, included Busan, Shanghai, Ningbo, Shekou, Alexandria, Rijeka, Koper, Trieste, Rotterdam, Casablanca, Tanger Med, Valencia, Genova, Malta, Piraeus, Naples, La Spezia, Bari, Costanza, Thessaloniki, Mersin, Oran, Alger, Skikda, Bejaia, Djen Djen, Annaba, Benghazi, Tripoli, and Sousse.

Ports where unfavorable weather conditions prevented vessel berthing included Tripoli, Poti, and Casablanca. Vessels experienced delays due to port strikes in Le Havre, Antwerp, and Marseille. In Beirut, vessels could not berth at night due to night pilotage suspensions, while in the port of Algeciras, fender replacement had a significant impact on vessel schedules. The results correspond with the independent analysis conducted by Kuehne & Nagel [] (17 April 2025), one of the world’s largest freight forwarders.

This research confirms that port congestion is the most frequent cause of delays and disruptions in the sailing schedules of liner services, with a cascading or domino effect that carries over to subsequent ports and stages of the door-to-door multimodal transport chain.

5.4. Navigation from Port of Loading to the Port of Discharge, Including Possible Transshipment Port(s)

Disruptions that occur during navigation from the port of loading to the port of discharge (including potential transshipment ports) refer to situations that may arise while the vessel is at sea, as well as during transit through straits, canals, and approach channels. The presence of one-way channels in port settings can result in congestion due to the need to comply with time or space clearance to allow evolution and safe navigation (i.e., two to six vessel lengths depending on the condition and the respective speed); in addition, there can be temporary or permanent restrictions of operations issued by the harbor master.

These are primarily external factors that affect the vessel and its navigation from the anchorage of the departure port to the anchorage of the destination port.

After the vessel’s scheduled departure from the port, as well as during its approach to the destination port, delays and waiting times may occur due to fairway congestion. A common factor affecting the vessel’s ability to maintain its scheduled liner service is the tidal effect in the port or in the access channels. While underway, the vessel may be affected by unfavorable weather conditions, such as typhoons, monsoons, dense fog, and adverse currents. In certain cases, the formation of ice can slow the vessel’s port entry.

Certain shallow sea passages can restrict the transit of vessels with a deep draft. Incidents (shipwrecks, collapsed bridges) can negatively impact the ability to maintain the scheduled liner service.

Similarly, disruptions to the schedule may be caused by dredging activities in canals, delays in canal transit due to grounded vessels or low water levels (e.g., Panama Canal) or waiting for naval escort and convoy formation in high-risk or conflict zones (e.g., Red Sea). Furthermore, because of the canal’s limited width, vessels are organized into convoys on both sides. Late-arriving container ships may miss their scheduled convoy, resulting in up to 12 h of additional waiting. Shipping lines reserve convoy slots in advance to ensure timely arrival at the canal entrance []. Navigation delays can also be influenced by piracy and terrorist acts.

We categorize another set of possible disruptions to container line services as restructuring of shipping alliances, i.e., the formation of a new alliance with new partners and the dissolution of others. The initial phase of a new alliance often involves schedule and operations adjustments, potentially leading to delays and service disruptions as carriers adapt to new partnerships and network configurations. In practice, these changes involve relocating vessels, shifting routes, changing ports of call, and terminals.

The delays over which the carrier has direct control, because they occur on the vessel itself, are few. These are unplanned maintenance or mechanical failure of the vessel’s engine or onboard systems; fire incidents on container vessels can cause liner service unreliability because of vessel delays and supply chain disruptions. As for the latter, it is important to stress life-threatening situations on board liner vessels, environmental impacts, and the damage to the container cargo. Another reason may be a sudden illness, injury, or death of a crew member or other persons on board, which requires the ship to be diverted for landing such persons.

Deviations of the vessels could also be due to actions to save lives at sea, to land persons saved at sea, or for the purpose of landing stowaways.

6. Analysis of the Conflict Between Measures Aimed at Restoring Vessel Schedule and Their Negative Impact on Operations

In the event of disruptions to liner container services caused by various factors, any corrective measure aimed at minimizing the negative impact and realigning vessel operations with the long-term published schedule and business plan inevitably entails direct financial and operational consequences, making such measures inherently conflicting.

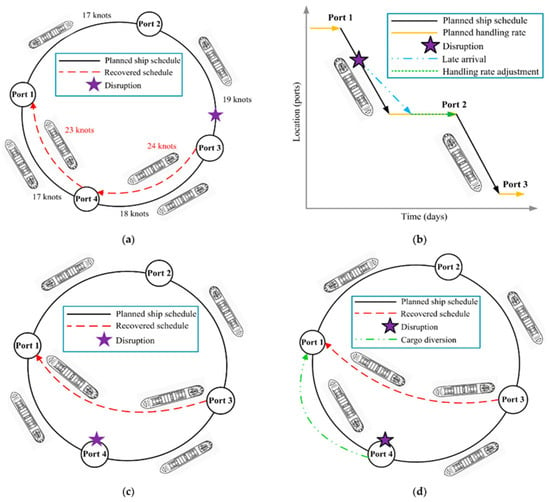

Elmi et al. (2022) [] analyzed the following options: sailing speed adjustment, handling rate adjustment, port skipping, and port skipping and container diversion (Figure 3).

Figure 3.

Vessel schedule recovery options considered: (a) sailing speed adjustment; (b) handling rate adjustment; (c) port skipping; and (d) port skipping and container diversion [].

Figure 3 provides a graphical representation of vessel schedule recovery options. In the following text, the authors describe each of the listed measures in more detail.

6.1. Sailing Speed Adjustment

Several authors have examined this measure [,,,,,,,,,]. As an example, when vessel sailing speed adjustment is applied to compensate for previously lost time and ensure arrival at the next port on the originally scheduled date, this inevitably results in increased fuel consumption and, consequently, higher voyage-related operational costs. Moreover, the acceleration of sailing speed contributes to increased greenhouse gas emissions, thereby posing a negative sustainable impact []. This type of measure, where the vessel increases speed to recover schedule delays, fundamentally conflicts with the strategy of slow steaming (Section 6.8).

However, if speed adjustments are made too early in the voyage, for example, between ports that come before the congested destination, the vessel may arrive at previous ports earlier than planned. Therefore, such speed adjustments should be carefully planned and applied only when necessary to avoid creating new delays or inefficiencies.

6.2. Handling Rate

This measure was also elaborated thoroughly [,,,,,]. The carrier may also opt for the handling rates adjustment option, by negotiating with the terminal operator to increase operational productivity (e.g., deploying more cranes) compared to the originally planned productivity for that vessel call, planned when no schedule disruption was expected. This measure can only be implemented if the terminal operator has available resources and the stowage plan allows such an adjustment. The terminal operator will likely request additional payment from the carrier to cover increased port handling costs.

6.3. Port Skipping/Omission

According to [,,,,,], a decision to skip or omit a port, results in full import containers remaining on board, being discharged at an alternative nearby port instead of the originally scheduled. These containers must then be transshipped onto another vessel that will deliver them to their intended destination port. As a result, the carrier incurs additional costs related to transshipment, port storage charges [], and additional transport expenses, while importers face extended import transit times and disruptions in their supply chains.

Negative consequences will also affect inland transport providers, particularly rail operators, who will be unable to carry out inland transport operations planned according to the originally scheduled vessel arrival. When the containers arrive with the next vessel, a double volume will be discharged, both the containers that were not unloaded from the previous vessel that skipped the port, and those already on board, originally scheduled for discharge. This will create disruption at the terminal in the form of unplanned occupation of terminal yard space and insufficient capacity of inland transport providers, who are now expected to handle the cargo volumes originally loaded onto two vessels but discharged from one.

For exporters, the issue of port skipping means that their export containers will not be loaded onto the originally scheduled vessel. This results in longer transit times, causing supply chain disruptions. In addition, carriers incur extra costs due to the need to re-nominate containers to the next vessel, as well as port storage charges and other related expenses.

A carrier’s decision to implement port skipping or omission is often driven by congestion at a specific port, which in turn reduces the port coverage originally planned in the pro forma schedule of the liner service.

Port skipping/omission can be a one-time measure, applied to a single vessel on a single voyage as part of recovery measures. However, if a port remains congested over a longer period or frequently, the carrier may decide to remove it from the pro forma schedule for multiple vessels and voyages, even permanently. The port in question is then no longer served directly, but instead via a feeder service through a transshipment hub, as recognized in [].

There are examples where carriers expect congestion issues in ports and announce planned changes to services in advance, aiming to minimize the impact on schedule reliability. Such measures include port omission and change in rotation. For instance, CMA CGM informed customers that it is forced to reduce port coverage in order to limit the impact on schedule reliability. As part of this decision, the ports of Barcelona and Algeciras are omitted until further notice. In a detailed notice to customers (Customer Advisory), it is stated that imports to Barcelona will be offered via transshipment through Valencia, while exports will be handled via transshipment through the port of Fos-sur-Mer [].

MAERSK informs its customers that in order to minimize potential delays caused by weather-related congestion expected in Sydney, a specific vessel will perform a change in rotation between Sydney and Melbourne, with Melbourne now being called prior to Sydney to mitigate the impact on the onward schedule [].

6.4. Port Skipping with Container Diversion

There is also the option for a carrier to implement vessel schedule recovery by deciding on port skipping combined with container diversion []. This means that the carrier will skip one port in the service, but the containers intended for discharge at that port will be transported to the next port of call, from where they will then be delivered by land to the port that was skipped. Similarly, export containers that were scheduled to be loaded at the skipped port will be transported by land to another port in the vessel’s rotation, where they will be loaded onto the same vessel. As a result, all containers are still loaded and discharged as planned, not at the originally intended port but at an “alternative” port being part of the service schedule. In this case, importers and exporters experience less disruption compared to port skipping without container diversion. However, carriers incur additional costs related to inland transport and port handling at the alternative ports. At the same time, they do not bear the vessel’s port-related expenses of the skipped port.

In analyzing additional measures available to carriers for mitigating the negative effects of delays and schedule disruptions, and for bringing the vessel back in line with the originally planned sailing schedule, the authors identified three further options: cut and run, deployment of another vessel, and double call.

6.5. Cut and Run

This measure was elaborated by [,,,]. When the decision for a cut & run is made, a firm departure time is set, after which the vessel must leave the port and stop cargo loading and unloading operations, regardless of the fact that some import containers scheduled for discharge may remain onboard, and some export containers intended for loading may be left behind at the terminal.

Such a decision is typically made to ensure the vessel arrives on time for a scheduled canal convoy, a fixed berthing slot in the next port, or to take advantage of favorable departure tide conditions. The primary goal is to bring the vessel back in line with the long-term published sailing schedule. However, this measure negatively affects importers, as their cargo may not be discharged at the intended port of discharge, but instead at an alternative port, resulting in significant delivery delays.

Exporters are also affected, since their containers may not be loaded onto the scheduled vessel, which extends the overall transit time. The decision also generates port storage charges and reduces container turnaround efficiency. As a result, the containers that were not discharged or loaded as planned remain unused for longer periods, which reduces their availability for new cargo.

In such situations, it is often the case that empty containers scheduled for loading are excluded from the vessel plan. This measure disrupts the carrier’s internal logistics planning, and the port that was meant to receive those empty containers may consequently face equipment shortages for its upcoming export bookings.

6.6. Deployment of Another Vessel

When a certain vessel in liner service is significantly delayed or is unable to complete its rotation due to more disruptions, a substitute vessel can be deployed to take over []. Such a decision requires that the carrier have an available vessel that can be put into service at the loading ports. With such a decision, which is very expensive for the carrier, delays will be reduced and a certain level of liner service will be maintained. In this way, the carrier provides the possibility of loading cargo for the shippers at the intervals provided for in its pro forma sailing schedule.

6.7. Double Call

In practice, carriers apply another option within schedule recovery management. In cases where a specific port and its yard are congested, and the carrier is limited either by the amount of time the vessel can remain in the port or by the volume of cargo that can be handled during the call, a decision may be made to implement a double call at that port.

This means that during the vessel’s first call, only import containers will be discharged. The vessel will then depart to perform commercial operations at other ports in the region and return, within the same vessel voyage, for a second call, during which only export containers will be loaded. This results in doubled port-related costs for the carrier (use of tugs, pilots, mooring services, waste disposal), and deviation cost of additional navigation.

6.8. Strategic Scheduling

In practice, carriers develop strategic scheduling through their internal operational policies. The most well-known approaches include incorporating buffer time during the initial design of the liner service, applying smart steaming strategies during the vessel’s voyage, and strategically planning cargo loading and stowage with the option of spreading cargo across multiple ports (so-called optional stowage).

The oldest form of anticipating various negative factors that cause vessel delays and reduce liner service reliability is the use of buffer time [,,,,,,,]. This represents a proactive approach in the design of a liner service and its sailing schedule, whereby buffer time is incorporated into the schedule to absorb potential delays caused by various disruptions [,]. However, determining the appropriate buffer time depends on the carrier’s internal assessment and policy, usually based on historical data analysis. The ongoing unreliability of vessel schedules indicates that such calculations are often unreliable []. The sensitivity of buffer time calculations lies in carefully balancing between the buffer itself and the associated operational costs. If a longer buffer time is applied, it may improve service reliability, but it simultaneously increases the vessel’s round-trip time, thus raising the operating costs of vessels within the liner service.

In practice, carriers develop smart steaming strategies [,] aimed at dynamically optimizing vessel speeds based on real-time sea conditions, waiting times for canal transits, and the current situation in specific ports, as elaborated in Section 6.1. It is inefficient to sail at full planned speed if it is already known that the destination port is congested, and the vessel will have to wait at anchorage for a berth alongside the operational quay. Smart steaming allows for fuel savings and helps reduce pollutant emissions.

This strategy aligns with the IMO project Just in Time [], aiming to increase port efficiency and port call optimization. The successful implementation of JIT arrivals can have a significant environmental impact through reduced GHG emissions from optimizing the vessel’s speed to arrive on time. The concept is based on the ship maintaining an optimal operating speed to arrive at the pilot boarding place when the availability is assured of: 1. berth, 2. fairway, and 3. nautical services (pilots, tugs, mooringmen). Arrivals also contribute to reduced time at anchorage and, therefore, reduced congestion in the port area. It is estimated that ships spend up to 9% of their time waiting at anchorage, which could be reduced through the implementation of JIT Arrivals.

Carriers also have the option of strategic cargo planning and optional stowage on board. This specifically means that if a carrier plans to call at multiple ports within the same region, where the hinterland areas of these ports overlap, the cargo can be stowed in a way that allows for flexible changes in the originally scheduled port rotation []. The aim is to minimize anchorage time at congested ports by discharging the cargo at the other nearby port, without incurring additional costs related to shifting or restowing containers.

7. Discussion

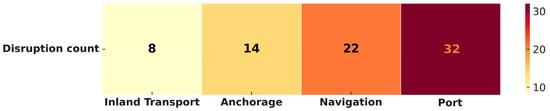

Identified and confirmed disruptions are categorized into four groups, which represent four phases of the door-to-door transportation process: 8 disruptive factors were identified in inland transportation, 14 disruptive factors were identified at anchorage, 22 disruptive factors were identified in navigation, and 32 disruptive factors were identified in the port, respectively (Figure 4).

Figure 4.

General disruption count affecting liner schedule reliability by phases. Made by authors.

These disruptions appear to be increasing due to challenges such as COVID-19; armed attacks on vessels in the Red Sea; climate change; and other, mostly geopolitical, factors. This is further supported by the Global Schedule Reliability analysis, which concluded that reliability in 2024 ranged between 50–55%, despite carriers publicly aiming for a reliability target of at least 90%.

The research revealed that the measures used by operational departments of shipping companies to optimize schedule maintenance and return vessels to their originally planned long-term sailing schedules do not increase proportionally with the growing number of disruptions caused; rather, they remain quite limited. Each measure aimed at mitigating the negative effects of disruptions and bringing vessels back on track with the long-term published schedule and business plan also carries direct financial and operational consequences and is inherently conflicting.

A deeper understanding and analysis of the various potential causes of liner schedule unreliability is necessary, especially given that these causes continue to grow due to new global and local challenges. Preventive measures should be applied before disruptions occur in order to avoid additional costs and situations where vessels, for example, are forced to wait for a berth upon arrival at port. The ultimate goal is to minimize operational costs and negative impacts on the reliability of liner services. Particular emphasis is placed on maintaining an optimal operating speed, as the successful implementation of JIT arrivals can significantly reduce GHG emissions by optimizing vessel speed to ensure timely arrival.

Given the nature of containerization and its capacity for multimodal transport of cargo in standardized containers from origin to final destination using multiple modes of transport, the authors expanded their research to include potential disruptive factors within inland transportation, that is, the movement of goods via truck, rail, and barge. This dimension is particularly important from the perspective of the end-user, who evaluates both the reliability of liner services offered by individual carriers and the total transit time from origin to final destination.

It is evident that a liner shipping company, which provides maritime transport services for containerized cargo and offers a multimodal door-to-door transport service, has no direct control over disruptions occurring at sea during the vessel’s voyage, in ports where vessels are berthed for cargo operations, or on land, where containerized cargo is moved using various transport modes. These disruptions can significantly affect the reliability of the liner service and the adherence to the scheduled sailing plan. The only exceptions are disruptions that occur onboard the vessel itself, such as engine failure or other unforeseen technical breakdowns, and possible deviations due to the disembarkation of a crew member.

All of the mentioned factors have a cumulative impact, as they can occur multiple times during a single vessel voyage within a liner service, at anchorage in the ports of loading, transshipment, and discharge; during the navigation between ports; and during inland from the place of origin to the loading port and during the transport from the discharging port to the final destination place. Delays in the planned sailing schedule of a liner service tend to cascade from the initial point of disruption, affecting subsequent ports of call and the overall door-to-door cargo transportation process.

8. Conclusions

By systematically analyzing internal documents from shipping companies, the academic literature, and publicly available online sources, we identified dozens of disruption factors that affect liner service reliability. These factors are increasing due to new global and local challenges (e.g., COVID-19, armed attacks on vessels in the Red Sea, the war in Ukraine, US-China trade tensions, other geopolitical issues, and climate change).

This research identified and systematized the causes of liner service reliability disruptions based on their origin: at anchorages in the ports of loading, transshipment, and discharge; within the ports themselves; and during sea navigation between these ports. The scope of the research was extended to include inland transport and the disruptive factors that may arise in that part of the transport chain, given that containerized cargo is moved on a multimodal door-to-door basis, from origin to the final destination. As an additional contribution, new disruptive factors were identified, together with the confirmation of the port congestion as the biggest cause of delay in liner service.

Of the 76 identified and confirmed disruptive factors, the author’s contribution is in the identification of 31 factors that were not found in the existing literature. The research also confirmed that port congestion is the primary cause of delays in container liner services.

It has been found that the measures available to operational departments within shipping companies for optimizing schedule maintenance and returning vessels to the originally planned long-term sailing schedule do not increase in proportion to the growing number of disruptions caused; rather, they remain limited.

The practical implications of this research, reflected in a comprehensive understanding of the various causes of disruption and schedule unreliability, can primarily benefit practitioners, those working in the operational departments of shipping lines, who, by recognizing potential disruption factors in liner services, can act preventively to mitigate their negative impact on service reliability. Such preventive action aims to reduce the effects of potential causes of disruption before any actual schedule deviation occurs.

A proactive approach, which entails a deep understanding of potential causes of disruption in the liner services, from anticipatory monitoring of weather and other navigational conditions, to various factors contributing to congestion in ports and terminals, as well as other disruptions caused by service providers in ports and during inland transport and cargo delivery, can enable carriers to develop strategic scheduling, proactively adjust their liner service schedules, perform optional stowage of cargo which could be discharged in two nearby ports without additional restows, and coordinate with the logistics teams of exporters and shipping companies/carriers to explore possible rerouting of shipments. This aims to minimize vessel waiting times and reduce schedule unreliability. In doing so, importers and exporters, and the liner services end-users, would suffer less disruption to their supply chains.

The limitation of this paper is that it does not provide quantified results for different identified disruptive factors (e.g., frequency of occurrence and share of delay duration). The acknowledged research limitations also indicate potential avenues for future investigation into liner schedule reliability problems.

Due to the continuous and emerging dynamic changes occurring in ports, maritime navigation, and inland transport, the authors recommend further research into the causes of schedule unreliability in container liner services and inland transport within the framework of door-to-door multimodal transportation, along with efforts to quantify these disruptions.

It is also recommended to conduct research on specific world regions in order to identify potential region-specific causes of disruptions in liner services and inland transport. The aim is to develop targeted measures to bring vessels back in line with the pro forma sailing schedule and the planned door-to-door transit times.

Author Contributions

Conceptualization, J.K.; methodology, J.K. and D.B.; validation, M.J.M. and A.P.H.; formal analysis, M.J.M. and A.P.H.; investigation, J.K. and M.J.M.; resources, J.K.; writing—original draft preparation, J.K.; writing—review and editing, M.J.M. and D.B., A.P.H.; visualization, D.B. and M.J.M.; supervision, D.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the first author due to their confidentiality and nature of data.

Acknowledgments

We acknowledge the liner company’s willingness to grant permission for the usage of the operational data, on request and under confidentiality.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vernimmen, B.; Dullaert, W.; Engelen, S. Schedule Unreliability in Liner Shipping: Origins and Consequences for the Hinterland Supply Chain. Marit. Econ. Logist. 2007, 9, 193–213. [Google Scholar] [CrossRef]

- Yazar Okur, İ.G.; Tuna, O. Schedule Reliability in Liner Shipping. Pomorstvo 2022, 36, 389–400. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Liner Ship Route Schedule Design with Sea Contingency Time and Port Time Uncertainty. Transp. Res. Part B Methodol. 2012, 46, 615–633. [Google Scholar] [CrossRef]

- Tang, X. Research on Liner Shipping Schedule Recovery. Available online: https://commons.wmu.se/cgi/viewcontent.cgi?article=2578&context=all_dissertations (accessed on 14 July 2025).

- Mulder, J.; Dekker, R. Designing Robust Liner Shipping Schedules: Optimizing Recovery Actions and Buffer Times. Eur. J. Oper. Res. 2019, 272, 132–146. [Google Scholar] [CrossRef]

- Notteboom, T.E. The Time Factor in Liner Shipping Services. Marit. Econ. Logist. 2006, 8, 19–39. [Google Scholar] [CrossRef]

- Dulebenets, M.A.; Pasha, J.; Abioye, O.F.; Kavoosi, M. Vessel Scheduling in Liner Shipping: A Critical Literature Review and Future Research Needs. Flex. Serv. Manuf. J. 2021, 33, 43–106. [Google Scholar] [CrossRef]

- United Nations Conference on Trade and Development Review of Martime Transport. Available online: https://unctad.org/publication/review-maritime-transport-2024 (accessed on 22 July 2025).

- Notteboom, T.; Pallis, A.; Rodrigue, J.-P. Chapter 1.1—Ports, Maritime Shipping and International Trade—Value of Containerized Trade, 2020. In Port Economics, Management and Policy; Routledge: New York, NY, USA, 2022; ISBN 9780429318184. [Google Scholar]

- Ducruet, C.; Notteboom, T. Developing Liner Service Networks in Container Shipping. In Maritime Logistics: A Complete Guide to Effective Shipping and Port Management; Song, D.W., Panayides, P., Eds.; Kogan Page: London, UK, 2012. [Google Scholar]

- World Shipping Council. Liner Services. Available online: https://www.worldshipping.org/explore-liner-services?rq=Liner%20Services (accessed on 22 July 2025).

- Christiansen, M.; Fagerholt, K.; Ronen, D. Ship Routing and Scheduling: Status and Perspectives. Transp. Sci. 2004, 38, 1–18. [Google Scholar] [CrossRef]

- Mulder, J. Determining the Optimal Recovery Policy in Liner Shipping Networks Using a Markov Decision Model. Available online: https://thesis.eur.nl/pub/5511 (accessed on 21 June 2025).

- Mulder, J.; van Jaarsveld, W.; Dekker, R. Simultaneous Optimization of Speed and Buffer Times with an Application to Liner Shipping. Transp. Sci. 2019, 53, 365–382. [Google Scholar] [CrossRef]

- Elmi, Z.; Singh, P.; Meriga, V.K.; Goniewicz, K.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. Uncertainties in Liner Shipping and Ship Schedule Recovery: A State-of-the-Art Review. J. Mar. Sci. Eng. 2022, 10, 563. [Google Scholar] [CrossRef]

- Yue, Z.; Mangan, J. A Framework for Understanding Reliability in Container Shipping Networks. Marit. Econ. Logist. 2024, 26, 523–544. [Google Scholar] [CrossRef]

- Nikghadam, S.; Molkenboer, K.F.; Tavasszy, L.; Rezaei, J. Information Sharing to Mitigate Delays in Port: The Case of the Port of Rotterdam. Marit. Econ. Logist. 2023, 25, 576–601. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, Y.; Yan, X.; Wang, M. Strategy and Impact of Liner Shipping Schedule Recovery under ECA Regulation and Disruptive Events. J. Mar. Sci. Eng. 2024, 12, 1405. [Google Scholar] [CrossRef]

- Zhen, R.; Sun, M.; Fang, Q. Optimization of Inbound and Outbound Vessel Scheduling in One-Way Channel Based on Reinforcement Learning. J. Mar. Sci. Eng. 2025, 13, 237. [Google Scholar] [CrossRef]

- Bavandi, S.; Nasseri, S.H.; Postorino, M.N.; Paganelli, F.; Mantecchini, L. Navigating a Transportation System Challenge with Hybrid Fuzzy Stochastic Multi-Choice Travel Time and Reliability: An Application to Maritime Transportation. Transp. B Transp. Dyn. 2025, 13, 2452204. [Google Scholar] [CrossRef]

- Sea-Intelligence Global Liner Performance August 2018 Report. Available online: https://www.sea-intelligence.com/images/products/glp_84.pdf (accessed on 22 July 2025).

- Sea Intelligence Global Liner Performance Report—Issue 161. Available online: https://www.sea-intelligence.com/press-room/307-2024-schedule-reliability-largely-within-50-55 (accessed on 22 July 2025).

- Maersk. How Will Reliability Be Improved? Available online: https://www.maersk.com/support/faqs/how-will-reliability-be-improved (accessed on 22 July 2025).

- Maersk. When Do You Expect to Reach the 90% Schedule Reliability in the New Gemini Cooperation? Available online: https://www.maersk.com/support/faqs/schedule-reliability-gemini-cooperation (accessed on 22 July 2025).

- Vineyard, J. Ocean Carriers to Introduce “Slidings”—Will They Help Reliability? Available online: https://www.universalcargo.com/ocean-carriers-to-introduce-slidings-will-they-help-reliability/ (accessed on 22 July 2025).

- Eurail. Travel Disruptions in Europe. Available online: https://www.eurail.com/en/help/travel-disruptions (accessed on 22 July 2025).

- Directorate-General for Mobility and Transport. Policy Department Structural and Cohesion Policies Shortage of Qualified Personnel in Road Freight Transport. Available online: https://www.europarl.europa.eu/RegData/etudes/etudes/join/2009/419101/IPOL-TRAN_ET(2009)419101_EN.pdf (accessed on 22 July 2025).

- Central Commission for the Navigation of the Rhine. Disruption in the Container Supply Chain. Available online: https://ccr-zkr.org/files/documents/omanalysesthematiques/Report_Congestion_Final_en.pdf (accessed on 22 July 2025).

- Xie, Q.; Wu, Y.; Zhang, R. The Impact of COVID-19 on Freight Transport in the Post-Epidemic Period: The Modal Shift from Road to Waterway. Transp. Res. Procedia 2025, 82, 124–138. [Google Scholar] [CrossRef]

- Drozhzhyn, O. International Liner Shipping: Current Challenges and Threats. Sci. J. Silesian Univ. Technol. Ser. Transp. 2024, 125, 51–68. [Google Scholar] [CrossRef]

- Allianz. Commercial Safety and Shipping Review 2025—An Annual Review of Trends and Developments in Shipping Losses and Safety. Available online: https://commercial.allianz.com/content/dam/onemarketing/commercial/commercial/reports/commercial-safety-shipping-review-2025.pdf (accessed on 30 July 2025).

- Verschuur, J.; Koks, E.E.; Hall, J.W. Port Disruptions Due to Natural Disasters: Insights into Port and Logistics Resilience. Transp. Res. Part D Transp. Environ. 2020, 85, 102393. [Google Scholar] [CrossRef]

- Hapag-Lloyd Won’t Take Bookings If Port Congestion Leaves Cargo Stranded. Available online: https://indiaseatradenews.com/hapag-lloyd-wont-take-bookings-if-port-congestion-leaves-cargo-stranded/ (accessed on 22 July 2025).

- MSC CGS. Price Announcement—Port Congestion Surcharge—Trade from Northern Europe (Inc. NWC & SCANBALTIC) to Far East. Available online: https://www.msc.com/en/newsroom/customer-advisories/2025/may/price-announcement-port-congestion-surcharge-trade-from-northern-europe-to-far-east (accessed on 30 July 2025).

- Kulikowska-Wielgus, A. Congestions in European Ports: Maersk Gives up on Rotterdam. Available online: https://trans.info/en/maersk-rotterdam-2-411938 (accessed on 22 July 2025).

- Metrans. Introduction of Congestion Surcharge. Available online: https://metrans.eu/introduction-of-congestion-surcharge/ (accessed on 22 July 2025).

- Kuehne & Nagel. Port Operational Updates from around the World. Available online: https://mykn.kuehne-nagel.com/news/article/port-operational-updates-from-around-the-worl-17-Apr-2025 (accessed on 30 July 2025).

- CMA CGM. Customer Advisory—MEDEX Service: Change in Port Coverage. Available online: https://www.cma-cgm.com/assets/public/documents/ADVISORY%20-%20MEDEX-%20CHANGE%20IN%20PORT%20COVERAGE%2014-04-25.pdf (accessed on 22 July 2025).

- Maersk. PANZ—Maersk Yellowstone 523S/528N Sydney and Melbourne Port Swap. Available online: https://www.maersk.com/news/articles/2025/07/04/panz-maersk-yellowstone-523s-528n-sydney-and-melbourne-port-swap (accessed on 22 July 2025).

- International Maritime Organization. Just In Time Arrival Guide Issued to Support Smarter, More Efficient Shipping. Available online: https://www.imo.org/en/mediacentre/pages/whatsnew-1502.aspx (accessed on 22 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).