Environmental and Health Risk Assessment of Fugitive Dust from Magnesium Slag Yards

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Analysis

2.2. Characterization of Dust Emission Risk from Stockpiles

2.2.1. Emission Characterization of Pollutants

2.2.2. Migration and Dispersion Characterization of Pollutants

2.2.3. Risk Characterization

2.3. Uncertainty and Sensitivity Characterization

3. Results and Discussion

3.1. Characteristics of Dust Pollution from Stockpiled Magnesium Slag

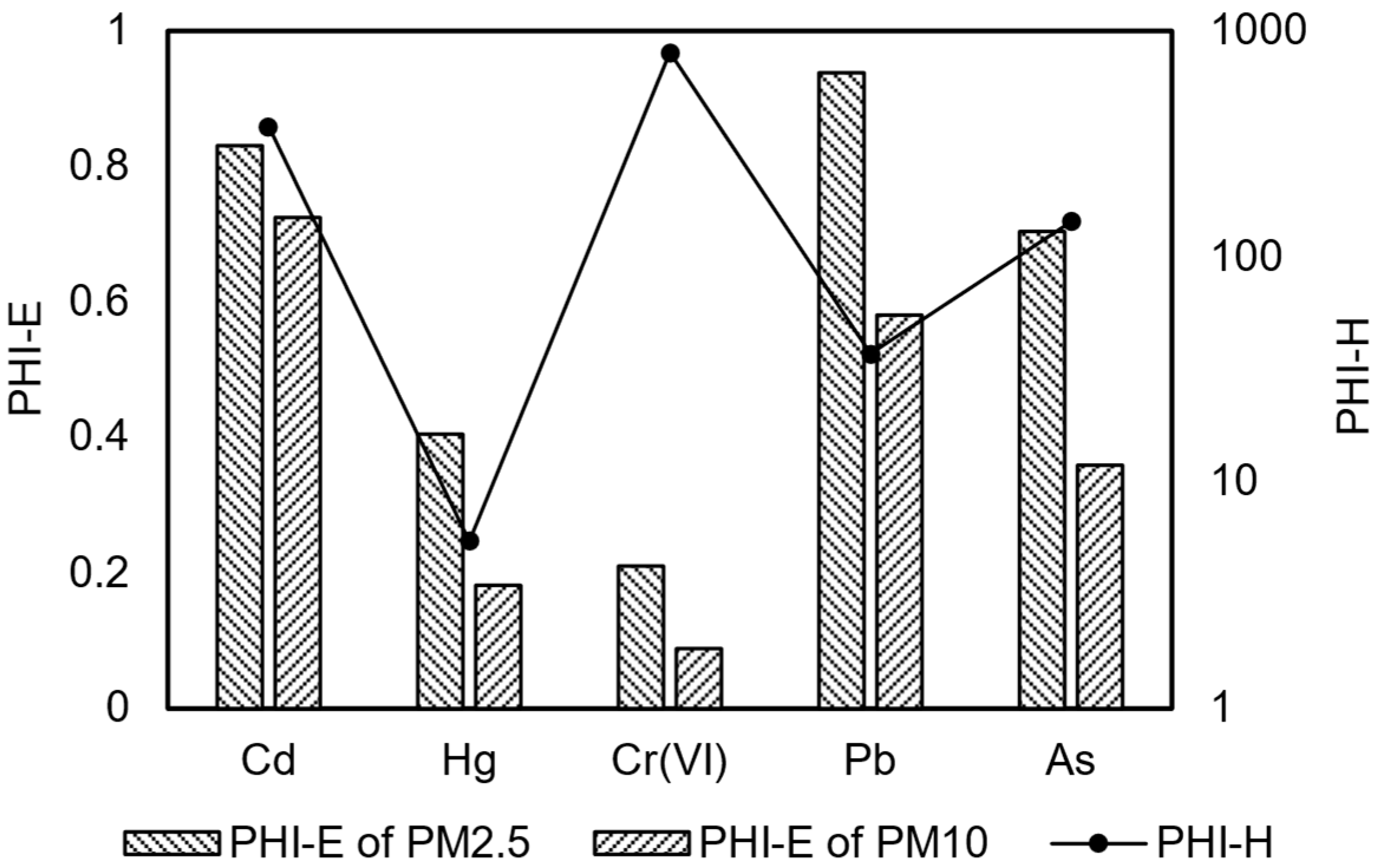

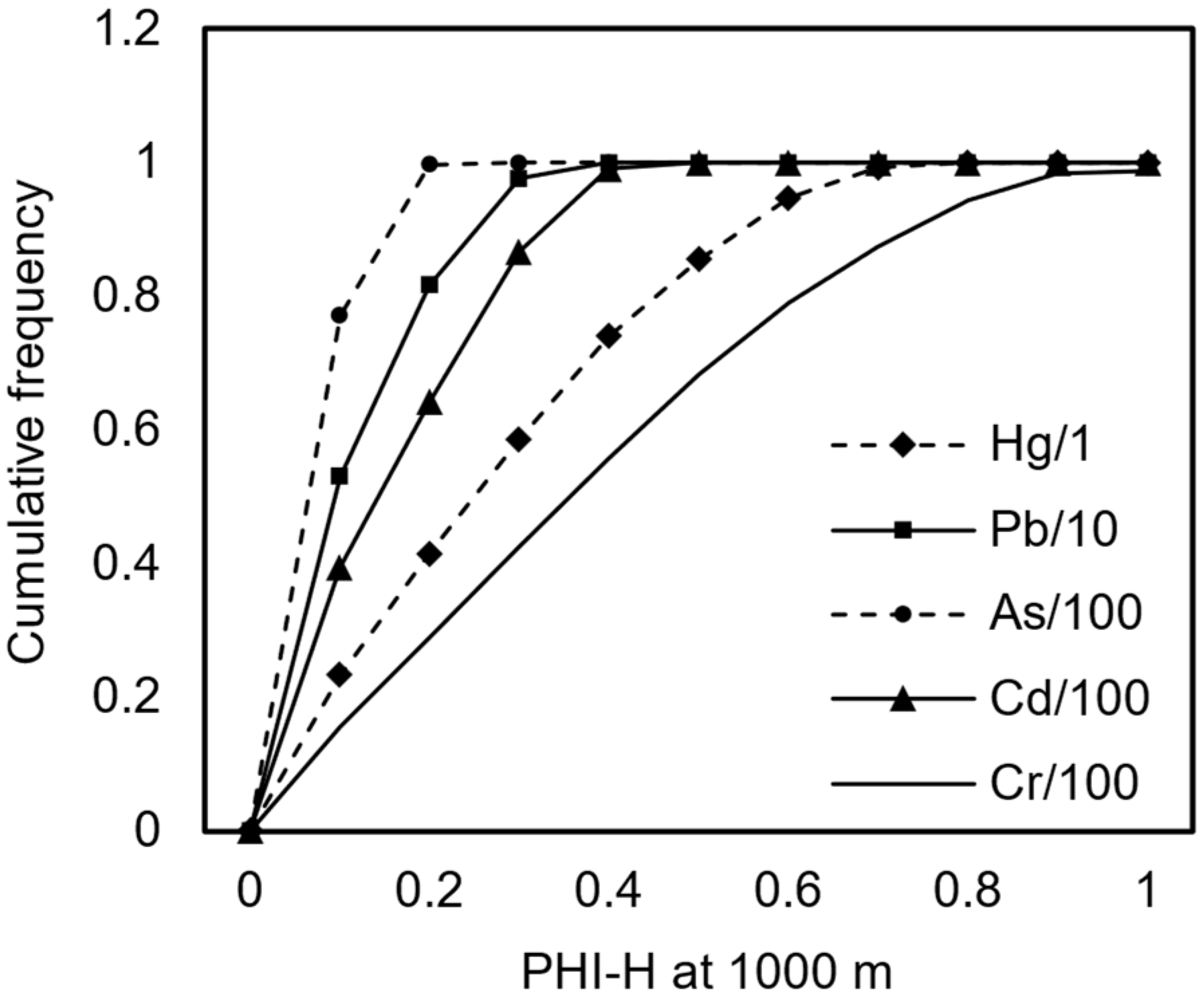

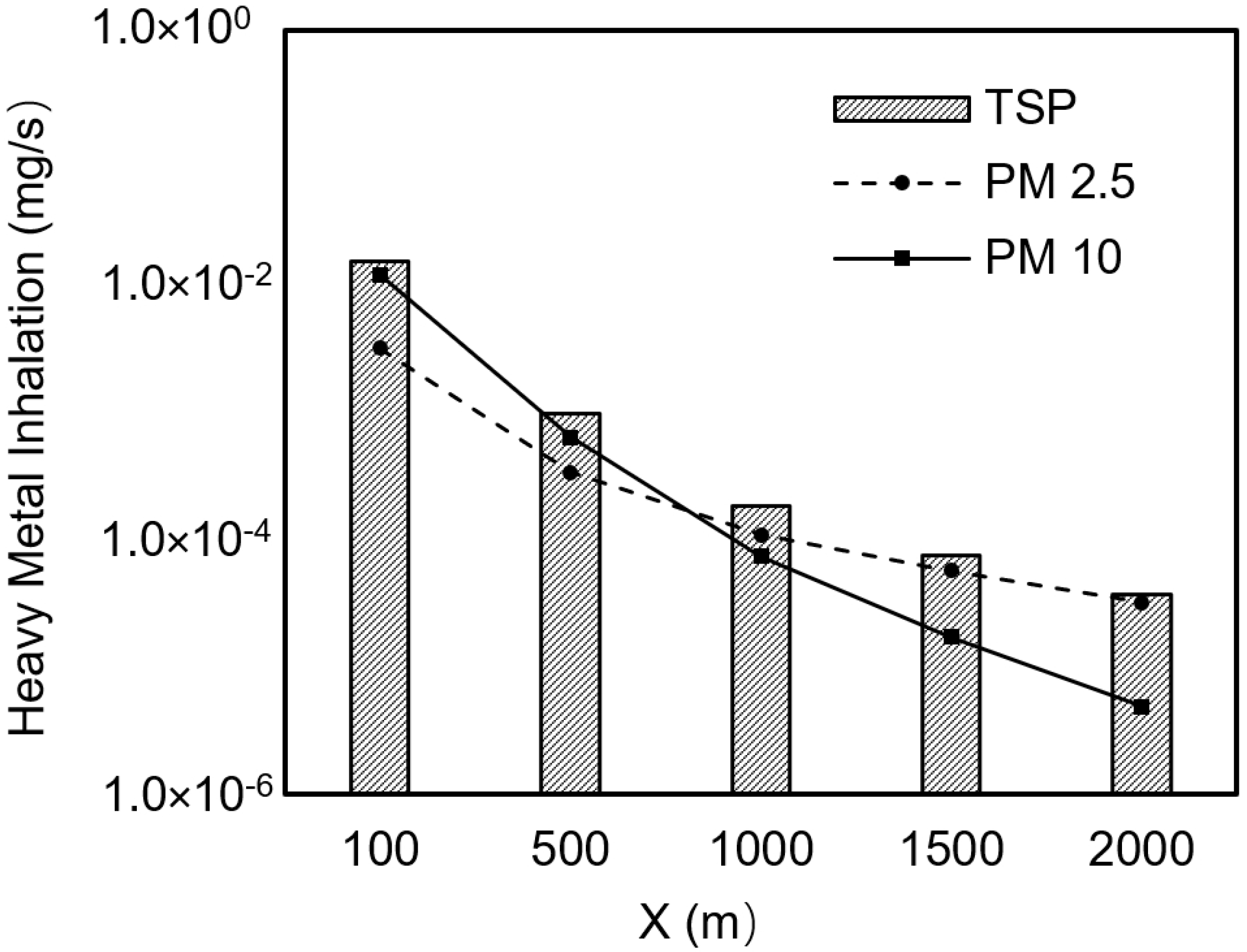

3.2. Environmental Risk and Evolution of Dust from Stockpiled Magnesium Slag

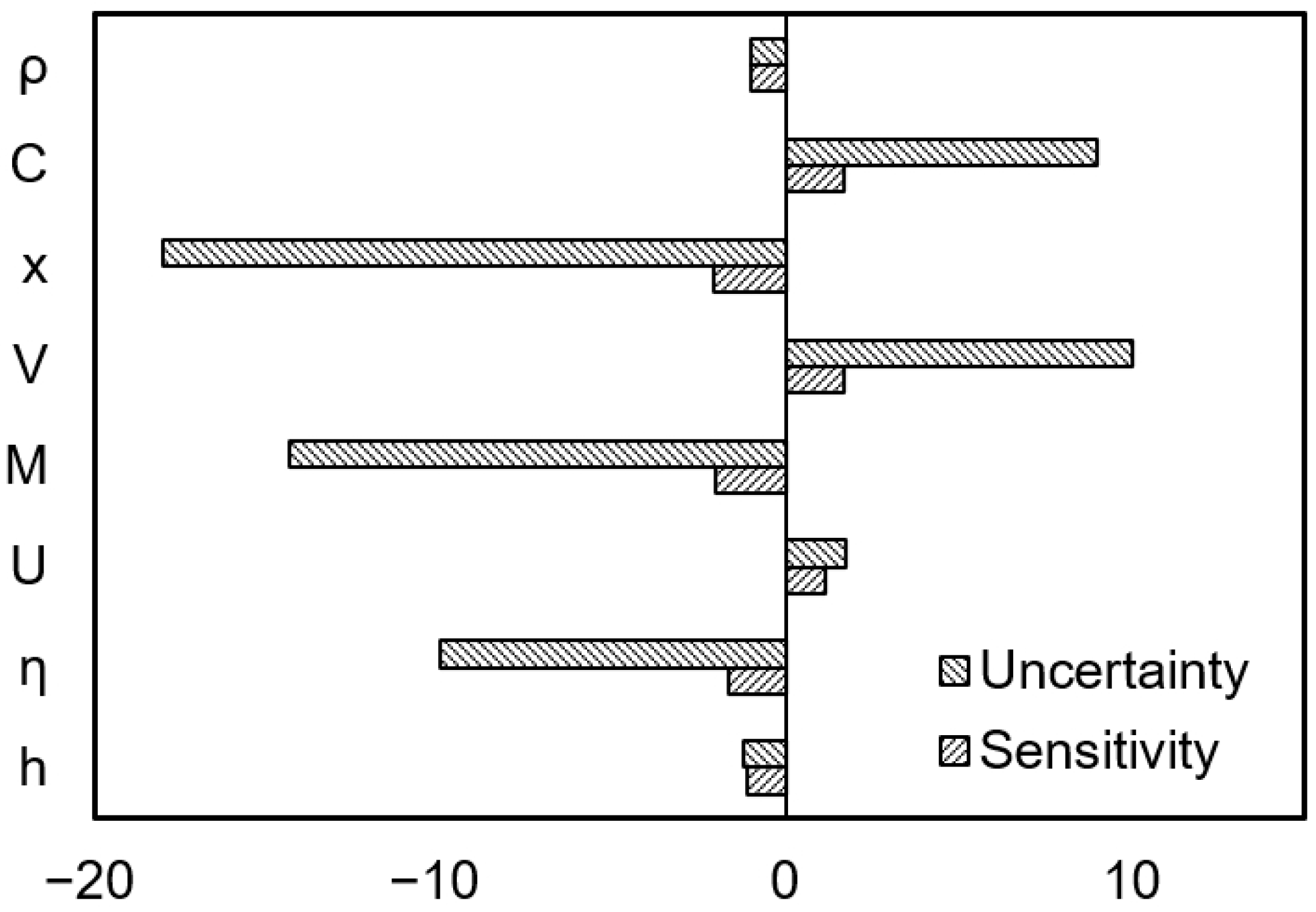

3.3. Uncertainty and Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, Z.; Liu, L.; He, W.; Han, K.; Lan, H.; Gao, Y.; Sun, W.; Han, Z.; Xia, L.; Yang, P. Strength Characteristics and Carbonation Depth Evolution of Modified Magnesium Slag Based Solid Waste Storage Backfill Materials. J. Environ. Chem. Eng. 2024, 12, 111975. [Google Scholar] [CrossRef]

- Ruan, S.; Liu, L.; Zhu, M.; Shao, C.; Xie, L. Development and Field Application of a Modified Magnesium Slag-Based Mine Filling Cementitious Material. J. Cleaner Prod. 2023, 419, 138269. [Google Scholar] [CrossRef]

- Ruan, S.; Liu, L.; Zhu, M.; Shao, C.; Xie, L.; Hou, D. Application of Desulfurization Gypsum as Activator for Modified Magnesium Slag-Fly Ash Cemented Paste Backfill Material. Sci. Total Environ. 2023, 869, 161631. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Zhao, Y.; Zhang, N.; Wang, Y.; Zhang, J.; Zhang, Y.; Liu, X. Structural Characteristics and Cementitious Behavior of Magnesium Slag in Comparison with Granulated Blast Furnace Slag. Materials 2024, 17, 360. [Google Scholar] [CrossRef] [PubMed]

- Ruan, S.; Liu, L.; Shao, C.; Xie, L.; Zhu, M.; Wang, R. Study on the Source of Activity and Differences between Modified and Unmodified Magnesium Slag as a Filling Cementitious Materials. Constr. Build. Mater. 2023, 392, 132019. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, H.; Xiao, J.; Wang, S. Research Analysis on the Airflow-Particle Migration and Dust Disaster Impact Scope by the Moving Mining Truck in the Open-Pit Mine. Process Saf. Environ. Prot. 2024, 184, 1442–1458. [Google Scholar] [CrossRef]

- Wang, J.; Fang, F.; Lin, Y.; Wu, H.; Kuang, Y.; Wang, Y.; Wu, M. Distribution Characteristics and Health Risk Assessment of Mercuryin Dust in Primary and Secondary Schools in Tongling City. Environ. Chem. 2020, 39, 2349–2357. [Google Scholar]

- Shekarian, Y.; Rahimi, E.; Rezaee, M.; Su, W.-C.; Roghanchi, P. Respirable Coal Mine Dust: A Review of Respiratory Deposition, Regulations, and Characterization. Minerals 2021, 11, 696–721. [Google Scholar] [CrossRef]

- Flowerday, C.E.; Stanley, R.S.; Lawson, J.R.; Snow, G.L.; Brewster, K.; Goates, S.R.; Paxton, W.F.; Hansen, J.C. A Ten-Year Historical Analysis of Urban PM10 and Exceedance Filters along the Northern Wasatch Front, UT, USA. Sci. Total Environ. 2025, 959, 178202. [Google Scholar] [CrossRef] [PubMed]

- Wei, F.; Xiao, H.; Zhang, J.; He, Z.; Cao, X.; Guan, B. Feasibility Study of Magnesium Slag, Fly Ash, and Metakaolin to Replace Part of Cement as Cementitious Materials. Buildings 2024, 14, 3874. [Google Scholar] [CrossRef]

- GB 5085.6-2007; Identification Standards for Hazardous Wastes-Identification for Toxic Substance Content. China Environmental Science Press: Beijing, China, 2007.

- Wang, R.; Li, Q.; Chang, C.; Guo, Z.; Li, J.; Zou, X.; Zhang, C.; Yuan, Y.; Liu, Y.; Zhou, N. Review of Dust Emission in Soil Wind Erosion. J. Desert Res. 2023, 43, 85–103. [Google Scholar]

- Li, T.; Dong, W.; Dai, Q.; Feng, Y.; Bi, X.; Zhang, Y.; Wu, J. Application and Validation of the Fugitive Dust Source Emission Inventory Compilation Method in Xiong’an New Area, China. Sci. Total Environ. 2021, 798, 149114–149124. [Google Scholar] [CrossRef] [PubMed]

- Lashgari, A.; Kecojevic, V. Comparative Analysis of Dust Emission of Digging and Loading Equipment in Surface Coal Mining. Int. J. Min. Reclam. Environ. 2016, 30, 181–196. [Google Scholar] [CrossRef]

- Xue, S.; Ding, W.; Li, L.; Ma, J.; Chai, F.; Liu, J. Emission, Dispersion, and Potential Risk of Volatile Organic and Odorous Compounds in the Exhaust Gas from Two Sludge Thermal Drying Processes. Waste Manag. 2022, 138, 116–124. [Google Scholar] [CrossRef] [PubMed]

- HJ 25.3-2019; Technical Guidelines for Risk Assessment of Soil Contamination of Land for Construction. China Environmental Science Press: Beijing, China, 2019.

- Harmon O’Driscoll, J.; McGinley, J.; Healy, M.G.; Siggins, A.; Mellander, P.-E.; Morrison, L.; Gunnigle, E.; Ryan, P.C. Stochastic Modelling of Pesticide Transport to Drinking Water Sources via Runoff and Resulting Human Health Risk Assessment. Sci. Total Environ. 2024, 918, 170589. [Google Scholar] [CrossRef] [PubMed]

- GB/T 3840-1991; Technical Methods for Making Local Emission Standards of Air Pollutants. China Environmental Science Press: Beijing, China, 1991.

- Wang, J.; Du, C.; Wang, Y.; Chen, Z. Microstructure and Adhesion Force of Dust on Soil Pavement in Open-Pit Mine. Int. J. Coal Sci. Technol. 2023, 10, 88–98. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, L.; Li, B.; He, S.; Li, Y.; He, Y.; Liang, X.; Zhan, F. Remediation of Cadmium and Lead in Mine Soil by Ameliorants and Its Impact on Maize (Zea mays L.) Cultivation. Agronomy 2024, 14, 372. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.; Li, Q.; Zhang, K.; Liu, Z.; Ren, Z. Multidimensional Spatial Monitoring of Open Pit Mine Dust Dispersion by Unmanned Aerial Vehicle. Sci. Rep. 2023, 13, 6815–6829. [Google Scholar] [CrossRef] [PubMed]

- Almeida, V.O.; Silvestro, L.; Gleize, P.J.P.; Kirchheim, A.P.; Schneider, I.A.H. Application of Leached Iron Ore Tailings to Produce Sustainable Cements. Constr. Build. Mater. 2023, 377, 131095. [Google Scholar] [CrossRef]

| CR of PM2.5 | HQ of PM2.5 | CR of PM10 | HQ of PM10 | |

|---|---|---|---|---|

| Cd | 8.74 × 10−8 | 2.95 × 10−2 | 2.31 × 10−7 | 7.81 × 10−2 |

| Hg | - | 2.70 × 10−4 | - | 3.68 × 10−4 |

| As | 1.49 × 10−7 | 1.40 × 10−2 | 3.45 × 10−7 | 3.25 × 10−2 |

| Cr(VI) | 3.35 × 10−8 | 1.70 × 10−4 | 5.41 × 10−8 | 2.74 × 10−4 |

| Total | 2.70 × 10−7 | 4.40 × 10−2 | 6.31 × 10−7 | 1.11 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, J.; Zhao, Y.; Zhang, Y.; Zhu, Y.; Liu, C.; Wang, F.; Xu, X.; Yu, Q. Environmental and Health Risk Assessment of Fugitive Dust from Magnesium Slag Yards. Toxics 2025, 13, 307. https://doi.org/10.3390/toxics13040307

Hua J, Zhao Y, Zhang Y, Zhu Y, Liu C, Wang F, Xu X, Yu Q. Environmental and Health Risk Assessment of Fugitive Dust from Magnesium Slag Yards. Toxics. 2025; 13(4):307. https://doi.org/10.3390/toxics13040307

Chicago/Turabian StyleHua, Jing, Yuanchao Zhao, Yuanzheng Zhang, Yining Zhu, Chang Liu, Fenghe Wang, Xiaowei Xu, and Qi Yu. 2025. "Environmental and Health Risk Assessment of Fugitive Dust from Magnesium Slag Yards" Toxics 13, no. 4: 307. https://doi.org/10.3390/toxics13040307

APA StyleHua, J., Zhao, Y., Zhang, Y., Zhu, Y., Liu, C., Wang, F., Xu, X., & Yu, Q. (2025). Environmental and Health Risk Assessment of Fugitive Dust from Magnesium Slag Yards. Toxics, 13(4), 307. https://doi.org/10.3390/toxics13040307