Abstract

Red dragon fruit (Hylocereus polyrhizus), recognized globally for its substantial nutrient content and health benefits, has been extensively studied; studies have particularly focused on the fruit, while the composition of the stem remains less explored. This research focuses on optimizing fermentation parameters for red dragon fruit wine, specifically examining yeast-strain selection, juice-to-water dilution ratios, and yeast concentrations. Saccharomyces cerevisiae RV002 emerged as the optimal strain due to its robust performance and adaptability under adverse conditions. The study identified a 50% dilution ratio as ideal for maximizing clarity and the sensory attributes of the wine, whereas dilution ratios exceeding 90% significantly reduced ethanol content below acceptable commercial standards. An optimal yeast concentration of 1 g/L was found to balance microbial suppression and alcohol yield effectively; deviations from this concentration led to microbial contamination or impaired fermentation dynamics. Fermentation markedly altered the biochemical properties of Hylocereus polyrhizus, reducing sugar and vitamin C levels while increasing polyphenol content and antioxidant activity, thereby enhancing potential health benefits. These findings underscore the transformative effects of microbial activity on the substrate’s chemical landscape and highlight the potential of tailored fermentation strategies to enhance the utility and value of underutilized fruits in sustainable agricultural practices.

1. Introduction

Over the past decade, the global wine industry has seen a surge in innovative approaches to diversifying wine sources beyond traditional grapes [1]. Notably, dragon fruit (Hylocereus spp.), a vibrant and nutrient-rich fruit, has entered the scene as a novel ingredient for wine production [2]. Originating from the Americas and cultivated extensively in Southeast Asia, particularly in Vietnam, where annual agricultural outputs reach about 1.4 million tons, dragon fruit is valued not only for its rich content of vitamins, minerals, and antioxidants, but also for its potential uses in creating high-value products such as wine [3,4]. The launch of red dragon fruit wine over a decade ago was a pivotal moment in the beverage industry. This not only diversified the wine market but also attracted consumers with its vibrant color and distinctive taste [5]. The wine’s unique health benefits, derived from the dragon fruit’s rich nutritional profile, including antioxidants, vitamins, and minerals, added to its allure [6,7]. Moreover, its exotic appeal, rooted in the fruit’s tropical origin, offered a novel experience that resonated with consumers seeking alternatives to traditional grape wines, enhancing its market presence [8].

The production of dragon fruit wine represents a crucial strategy through which to enhance the agricultural value of this crop, especially given the fruit’s limited fresh storage life of up to 14 days at 10 °C and only 5 days at room temperature [9]. Fermentation into wine not only extends the usability of dragon fruit, but also adds economic value, turning a perishable product into a more stable and internationally marketable commodity [2,8,10]. However, the fermentation process is an ecologically complex activity, heavily reliant on the effective role of yeasts, particularly Saccharomyces cerevisiae, which catalyzes the conversion of fruit juice into an alcoholic beverage through biochemical transformation [2].

The process of fermenting red dragon fruit wine is influenced by various factors that are crucial to ensuring the production of high-quality wine. These factors include the specific yeast strain used, the fermentation protocol, and the fruit’s unique characteristics, such as pH levels, soluble solids content, and sugar concentration [11]. Notably, recent advancements have highlighted the importance of selecting optimal yeast strains and adjusting fermentation conditions to enhance the organoleptic qualities of fruit wines. Research has shown that the right combination of yeast variety, fermentation conditions, and post-harvest treatments significantly affects the chemical composition and overall sensory profile of the wine, making these aspects vital for producing premium-quality fruit wine [12].

Moreover, fermentation is not just a simple conversion of sugars into alcohol; it involves a complex set of biochemical reactions that are sensitive to the ecological conditions within the fermentation vessel [13]. These include the interactions between different yeast strains and how they manage nutrient competition, sugar metabolism, and stress from by-products like ethanol [14]. Understanding and controlling these interactions are key to preventing common issues such as excessive haze, which can be mitigated by managing polyphenol and protein interactions within the wine. Such knowledge is essential not only for enhancing the clarity and taste of the wine but also for extending its shelf life and improving its marketability. Therefore, a deep dive into the fermentation process, backed by rigorous scientific research, is indispensable for innovating and refining the production of red dragon fruit wine [15].

This research aims to systematically evaluate the factors that influence the fermentation of red dragon fruit wine and to assess their impact on both the chemical composition and the sensory qualities of the final product. After the fermentation protocol had been optimized to enhance wine production from red dragon fruit, the biochemical composition of Hylocereus polyrhizus before and after fermentation was meticulously analyzed. The study particularly focuses on three critical variables: the dilution ratio of dragon fruit juice to water, the yeast strain employed, and the yeast concentration. The current fermentation-dilution ratio is 50%, as higher dilution ratios reduce the amount of reducing sugars, affecting yeast growth and fermentation efficiency. The yeast strain used is Saccharomyces cerevisiae, specifically Angel RV002, which is known for its high citric-acid resistance, and Fermentis yeast, which is known for its tolerance to hypertonic environments and cold conditions [16]. While these strains exhibit robust fermentation capabilities, challenges include their cost and need for precise management to prevent by-product formation. Previous investigations into fermentation have explored various aspects, but the distinct properties of dragon fruit and its significance in Vietnamese agriculture warrant a specialized examination. This study underscores the importance of optimizing these fermentation parameters to improve wine quality, providing valuable insights for enhancing the commercial viability of dragon fruit wine [16,17,18,19,20]. The importance of this research lies in its potential to furnish a scientific foundation for refining the processes of dragon fruit wine production, thus elevating the fruit’s commercial value and supporting sustainable agricultural practices. By exploring and optimizing key fermentation parameters, this study contributes to the broader knowledge base regarding fruit wine production, providing novel insights into the use of non-traditional fruits in winemaking and addressing challenges related to post-harvest losses.

2. Materials and Methods

2.1. Materials

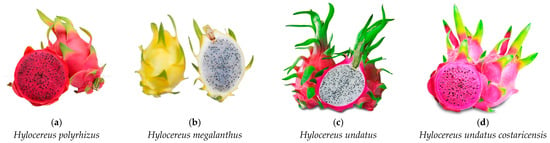

One hundred kilograms of red dragon fruit, encompassing four varieties, Red Pulp Dragon Fruit, Pink Purple Pulp Dragon Fruit, White Pulp Red Skin Dragon Fruit, and Yellow Skin White Pulp Dragon Fruit, were sourced from Binh Thuan, with equal masses of 25 kg of each variety. Each fruit of the Red Pulp variety, which was selected based on the national standard TCVN 7523:2014 CODEX STAN 237-2003 [21], weighed between 301 to 400 g (Figure 1). Three common types of yeast available in the Vietnamese market were used: Angel yeast from Angel Food Yeast Co., Ltd., (Yichang, China); Saigon yeast from Saigon Food Yeast Co., Ltd., (Ho Chi Minh City, Vietnam); and Fermentis yeast from Lesaffre Yeast Co., Ltd., (Lille, France).

Figure 1.

Varieties of Hylocereus used in fermentation studies.

2.2. Experimental Methods

2.2.1. Sample Preparation

The fruits were first processed by washing them with a saline solution consisting of 0.9% sodium chloride in water. They were then peeled and juiced using a slow juicer. The resulting juice was filtered through a cloth filter and diluted to initial concentrations of 50%, 60%, 70%, 80%, and 90%. The pH was adjusted to 4.5 using citric acid and sodium carbonate (Na2CO3). Citric acid was used in a 1% solution, with approximately 10 mL added per liter of juice to lower the pH. If necessary, a 0.5% sodium carbonate solution was used to increase the pH, with about 5 mL per liter of juice. The soluble solids content was set to 24°Bx by adding refined sucrose from Khanh Hoa Sugar Company (Khanh Hoa, Vietnam), which had a purity >99.5%, moisture content <0.05%, and reducing sugars <0.1%. Additionally, a pectinase enzyme from Novoferin 14 at a concentration of 0.1% and sodium metabisulfite (Na2S2O5) at 0.05 g/L were added. The mixture was left at room temperature for one day to stabilize before fermentation.

Yeast Strains and Fermentation Setup

Commercial yeast strains of Saccharomyces cerevisiae were used, specifically Angel yeast, Saigon yeast, and Fermentis yeast. The fermentation trials were set up in a fully randomized design with three replicates. Each fermentation batch was 10 L, with a yeast dosage of 10 g per batch. The fermentation process was maintained at a constant temperature of 25 °C. Samples of 250 mL were withdrawn daily for analysis, ensuring sufficient volume for experimental purposes, and were well mixed prior to sampling to maintain uniformity.

There were three yeast treatments: Angel yeast, Fermentis yeast, and Saigon yeast, each tested at different dilutions. Angel yeast was supplemented at 10 g with 100 mL water per 10 L batch, Fermentis yeast at 20 g with 200 mL water, and Saigon yeast at 200 g with 2000 mL water. The fermentation trials included five dilution ratios of dragon fruit juice to water: 50%, 60%, 70%, 80%, and 90%, each with three replicates, for a total of 45 treatments.

Yeast-cell counting was conducted using a hemocytometer. The sample was diluted in a ratio of 5:4:1 and thoroughly mixed, and 10 µL was placed onto the hemocytometer grid. The chamber was filled by capillary action and examined under a microscope at 40× magnification using an Optika B-352A microscope (Ponteranica, Italy) to count the cells in five large square grids. This ratio refers to 50 µL water, 40 µL fermentation broth, and 10 µL methylene blue. Regarding the colony-forming units (CFU) per gram, Angel yeast had approximately 5 × 109 CFU/g, Fermentis yeast had 6 × 109 CFU/g, and Saigon yeast had 7 × 109 CFU/g. This quantification is crucial, as the amount of fermentation inoculum directly relates to the number of active yeast cells, impacting fermentation efficacy and outcomes.

2.2.2. Chemicals and Equipment

For the study, a range of high-purity chemicals was utilized to ensure the accuracy and repeatability of the results. These included Folin reagent (sodium 3,4-dioxo-3,4-dihydronaphthalene-1-sulfonate) at 1 N concentration (Darmstadt, Germany), methanol with 98% purity (Xilong, China), and sulfuric acid graded at ≥98.08% (Duc Giang Chemicals Group JSC, Ha Noi, Vietnam). Additional substances included 3,5-dinitrosalicylic acid (Shanghai Zhanyun Chemical, Shanghai, China) and sodium carbonate (TangShang, China). The experimental procedures were supported by sophisticated laboratory equipment, including a PhotoLab 6100 VIS spectrometer (WTW, Oberbayern, Germany) for precise absorbance measurements across a wide spectral range.

The chemicals were sourced primarily from established suppliers in China and Vietnam, guaranteeing their quality and consistency for use in biochemical analyses and fermentation processes. Additionally, the experimental procedures were supported by advanced weighing scales and electronic scales from Sartorius (Goettingen, Germany), a manufacturer known for their accuracy. The fermentation processes were monitored using a 14 L thermostatic tank from Memmert, which allowed precise temperature control.

2.2.3. Methods

Vitamin C Determination: The total ascorbic acid content was measured using a UV-VIS spectrophotometer (WTW—A xylem brand, Weilheim, Germany). Thirty grams of the sample were weighed into a 50 mL Falcon tube, centrifuged at 1970× g for 15 min; next, the supernatant was collected. Then, 0.23 mL of 3% bromine was pipetted into 4 mL of the sample solution, and this step was followed by the addition of 0.13 mL of 10% thiourea to reduce the excess bromine. Then, 1 mL of 2,4-dinitrophenylhydrazine was added. The solution was placed in a water bath at 30 °C for 3 h and cooled for 30 min, then 5 mL of 85% H2SO4 was added. The vitamin C was cooled at a refrigeration temperature of 10 °C. The absorbance of the colored solution was measured at 521 nm, with the vitamin C content calculated based on an ascorbic acid standard curve [22].

Polyphenol Content: The polyphenol concentration was quantified using the Folin–Ciocalteu method. After the extract was diluted to the appropriate concentration, 0.5 mL of the diluted extract was added to a test tube, following which 5 mL of Folin–Ciocalteu reagent was added. The mixture was homogenized using a vortex, and then 4 mL of 7.5% Na2CO3 was added. The reaction mixture was kept at room temperature for 30 min before the absorbance at 765 nm was measured on a spectrophotometer, with results reported as milligrams of gallic acid equivalent (mg GAE)/g dry matter [23].

DPPH Radical-Scavenging Activity: The antioxidant capacity was assessed by the DPPH assay, which measures the ability of antioxidants to stabilize the purple DPPH free radical, detected spectrophotometrically at 517 nm [24]. One milliliter of the extract was placed in a test tube, and this step was followed by the addition of 3 mL of methanol and 0.5 mL of 0.6 mM 2,2-Diphenyl-1-picrylhydrazyl (DPPH) in methanol. A blank was prepared by adding 0.5 mL of DPPH to 4 mL of methanol. The samples were incubated at room temperature for 28–30 min. The radical-scavenging activity was determined using the following formula:

DPPH (%) = ((Ac − A)/Ac) × 100

Total Acidity: The total acidity was determined using an automatic potentiometric titrator (Titroline 7000, SI Analytics, Oberbayern, Germany). Ten milliliters of the sample were pipetted into an Erlenmeyer flask, and this step was followed by the addition of 50 mL of distilled water and 3 drops of 0.1% phenolphthalein. The glass electrode was cleaned with distilled water before it was immersed into the sample solution. The flask was placed on a magnetic stirrer with a magnetic stir bar. The electrode was immersed in the solution, with the researcher ensuring it did not touch the sides or bottom of the flask and maintained a 1 cm distance from the stir bar to avoid breakage. The magnetic stirrer was turned on for continuous stirring during the titration. The sample was titrated with 0.1 N NaOH until the endpoint was reached, and the result was recorded in g/L [25]. The volume of 0.1 N NaOH used (mL) was recorded, and the acidity was calculated using the following formula:

(K × V2)/V((m2 − m1) × 0.92)/V × 1000 (g/L)

- V: Volume of the sample used for titration (mL)

- V2: Volume of 0.1 N NaOH consumed in titration (mL)

- K: The amount of acid (in grams) equivalent to 1 mL of 0.1 N NaOH. For milk and fermented foods, the result is expressed as lactic acid, K = 0.0090K = 0.0090K = 0.0090

Reducing Sugars: Reducing-sugar levels were analyzed by the DNS method. This involves a colorimetric assay where reducing sugars react with 3,5-dinitrosalicylic acid to form a colored complex measurable at 540 nm. The fresh dragon fruit juice was weighed into a 50 mL centrifuge tube, ensuring equal weights for all tubes. The samples were centrifuged at 3070× g for 15 min and diluted to the appropriate concentration, and 1 mL of the diluted sample was pipetted into a test tube. This step was followed by the addition of 2 mL of DNS reagent. The test tubes were placed in a boiling water bath for 5 min and cooled to 25–30 °C, and the absorbance was measured at 540 nm [26].

Alcohol Content: The alcohol concentration in the wine samples was determined through distillation followed by density measurement using an Anton Paar densitometer [27].

Yeast Cell Counting: Yeast viability and concentration were assessed using a hemocytometer under a microscope, allowing for precise cell counts within specified grid areas. The cell suspension was vortexed, and 10 μL of the suspension was pipetted onto the surface of the counting chamber, which was placed under the microscope. The microscope was adjusted with a 40× objective lens and appropriate light intensity, and the number of cells in 5 large squares was counted [28].

Soluble Solids Content: Soluble solids were measured using a handheld refractometer, which provides a direct reading of the Brix value in the samples [29].

pH Measurement: The pH values of the samples were determined using a benchtop pH meter calibrated with standard buffers, ensuring accurate acidity assessment [30].

Total Sugar Content: Total sugars were quantified by hydrolyzing the samples with dilute hydrochloric acid and then by measurement with the DNS method, providing a colorimetric estimate of sugar concentration. The sample was treated by pipetting 1 mL of the sample with 40 mL of 2% HCl into a 50 mL centrifuge tube, which was then heated at 110 °C for 60 min, cooled, adjusted to pH 7 with 10% NaOH, transferred to a 100 mL volumetric flask, made up to volume with distilled water, filtered, and diluted to the appropriate concentration. Exactly 1 mL of the sample was pipetted into a test tube. Next, 2 mL of DNS reagent was added and the mixture was boiled in a water bath for 5 min, then cooled to 25–30 °C, at which point the absorbance was measured at 540 nm [31].

Transmittance: The juice was shaken, and a 10 mL portion of juice was centrifuged at 1590× g for 10 min to remove pulp and coarse cloud particles. Percent transmittance was determined at 660 nm by spectrophotometer (Systronics, Gujarat, India). The percent transmittance was considered a measure of juice clarity. The formula was as follows:

%T = 100.10 − A

- A-is the optical absorbance at wavelength 660 nm [32].

Anthocyanin Content: Anthocyanin levels were determined by differential pH spectrophotometry, exploiting the color change undergone by anthocyanins between pH 1.0 and 4.5, quantified at 520 nm [33]. Ten milliliters of the sample were pipetted into a 50 mL volumetric flask with pH 1.0 buffer solution (0.025 M KCl). The appropriate dilution factor was determined at 520 nm. The diluted test sample was prepared using pH 1.0 (KCl) buffer, and another was prepared using pH 4.5 (CH3COONa) buffer. Both solutions were measured at 520 nm and 700 nm. Anthocyanin content was calculated using the formula:

- Absorbance of the sample at pH 1.0 measured at a wavelength of 520 nm;

- Absorbance of the sample at pH 1.0 measured at a wavelength of 700 nm;

- Absorbance of the sample at pH 4.5 measured at a wavelength of 520 nm;

- Absorbance of the sample at pH 4.5 measured at a wavelength of 700 nm.

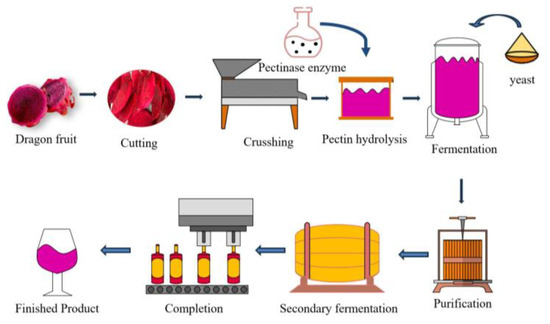

Figure 2 illustrates the comprehensive dragon fruit wine fermentation process. This includes the preparation of dragon fruit juice, the introduction of yeast, and the detailed monitoring of fermentation conditions such as temperature, pH, and sugar content over time.

Figure 2.

Dragon fruit Wine fermentation process.

2.2.4. Optimization of Fermentation Parameters

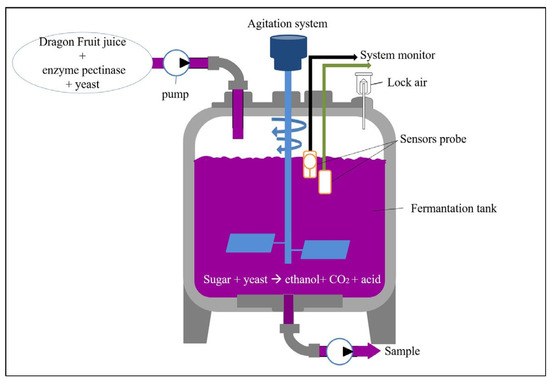

The experimental setup for the fermentation of dragon fruit juice involves a system that was carefully designed to ensure optimal conditions for yeast activity and efficient fermentation. The system comprises a fermentation tank equipped with an agitation system; sensors for monitoring pH, temperature, and oxygen levels; and a sample outlet for periodic analysis. The tank has a capacity of 30 L, with the liquid volume maintained below 75% to allow adequate headspace for foam and gas formation during fermentation (Figure 3).

Figure 3.

Experimental setup for the fermentation process.

Dragon fruit juice, pre-treated with pectinase enzyme and inoculated with yeast, was pumped into the fermentation tank through an inlet pump on the upper left side. All chemicals and enzymes were added to the juice at this stage to ensure thorough mixing and interaction. The mixture was then subjected to primary fermentation at room temperature (approximately 25 °C) for seven days.

Key components of the setup include the following:

- (1)

- Fermentation Tank: A temperature-controlled vessel where the fermentation takes place. The tank is equipped with an agitation system to ensure continuous mixing.

- (2)

- Agitation System: Ensures the homogeneity of the fermenting mixture, preventing sedimentation of yeast cells and facilitating efficient fermentation.

- (3)

- System Monitor: Includes sensors that continuously monitor critical parameters such as pH, temperature, and oxygen levels to ensure optimal fermentation conditions.

- (4)

- Pump: Used to introduce the mixture of dragon fruit juice, enzyme, and yeast into the fermentation tank.

- (5)

- Airlock: Maintains anaerobic conditions by preventing the ingress of external air; essential for anaerobic fermentation.

- (6)

- Sensors Probe: Measures the fermentation parameters, ensuring real-time monitoring and adjustments to maintain ideal conditions.

- (7)

- Sample Outlet: Located at the bottom of the tank, this outlet allows for the periodic collection of samples for analysis to track the progress and quality of the fermentation process.

The fermentation process is divided into two stages: primary fermentation and secondary fermentation. Primary fermentation occurs at room temperature for seven days, during which the majority of the sugars are converted into ethanol and carbon dioxide. After two days, the viscosity decreases and the foam dissipates, indicating active fermentation. The fermentation environment is strictly anaerobic to prevent oxidative degradation of bioactive compounds and the production of unwanted acids.

Following primary fermentation, the mixture undergoes secondary fermentation at cooler temperatures (15–18 °C) for ten days. This stage aims to stabilize the wine and enhance its aroma. Cooling is achieved using an air conditioning system, eliminating the need for water baths or additional heating/cooling systems.

Throughout both fermentation stages, the system monitor ensures that the conditions remain within optimal ranges. The sensors provide continuous feedback on the pH, temperature, and oxygen levels, allowing for immediate adjustments if necessary. This setup prevents oxygen from entering the tank, as oxygen can oxidize bioactive compounds in the juice and produce unwanted acids, thereby compromising the wine quality.

This comprehensive fermentation setup is designed to maximize the efficiency and quality of dragon fruit wine production. By optimizing the fermentation parameters and maintaining strict anaerobic conditions, the system ensures the production of a high-quality, flavorful wine with desirable sensory and chemical properties. This setup provides valuable insights into the fermentation process, offering potential improvements for both commercial wine production and research applications.

2.2.5. Analytical Methods

Each experiment was conducted in triplicate, and the results were presented as the mean ± standard error. Data analysis was performed using Microsoft Office Excel 2019 and JMP Pro 17 Statistical Discovery™ from SAS. Analysis of variance (ANOVA) was carried out with a 95% confidence level, utilizing the least significant difference (LSD) test for comparing means. The modeling and optimization processes were executed using JMP 17 Pro software with an alpha level of 5%.

3. Results

3.1. Comparative Nutritional and Phytochemical Profiles of Dragon Fruit Varieties

The data outlined in Table 1 provide a detailed comparative analysis of the biochemical properties of four Hylocereus species: H. polyrhizus, H. megalanthus, H. costaricensis, and H. undatus. These species were evaluated across a range of biochemical parameters including vitamin C content, polyphenol levels, sugar content (both total and reducing), antioxidant activity, dry-matter content, acidity, pH, and anthocyanin concentrations. This comprehensive profiling offers insights into the nutritional values of the samples and has potential for various industrial applications.

Table 1.

Comparative analysis of nutritional and chemical parameters of different varieties of dragon fruit.

Among the species studied, H. megalanthus exhibited the highest vitamin C content at 29.91 ± 2.00 mg AA/100 g; this level is significantly greater than those found in other species, suggesting potential health benefits. Conversely, H. polyrhizus led in polyphenol content with 580.35 ± 0.61 mg GAE/100 g, indicating its potential as a superior antioxidant source. H. polyrhizus also showed the highest reducing-sugar content at 80.94 ± 0.19 g/L, enhancing its sweetness and flavor profile and making it desirable for fresh consumption and dessert production.

The antioxidant activity, measured by the DPPH assay, was significantly higher in H. polyrhizus at 38.23 ± 2.06%, correlating with its substantial polyphenol and anthocyanin contents, the latter being the highest among the species at 345.66 ± 0.02 mg/L. This enhances the fruit’s antioxidant capacity and contributes to its vibrant coloration, increasing consumer appeal.

H. undatus had the highest acidity at 7.24 ± 0.01 g/L, influencing its sensory properties and suitability for fermentation. The pH values for the species ranged from 3.96 to 4.28, which are typical for fruits and beneficial for food preservation and processing. All species exhibited a consistent range of dry-matter content, approximately 12–13%, suggesting uniformity in their physical composition and influencing textural attributes and processing behavior.

Given the results, H. polyrhizus has been chosen for further experimental studies due to its superior polyphenol content, high levels of antioxidants and anthocyanins, and potential for commercial applications.

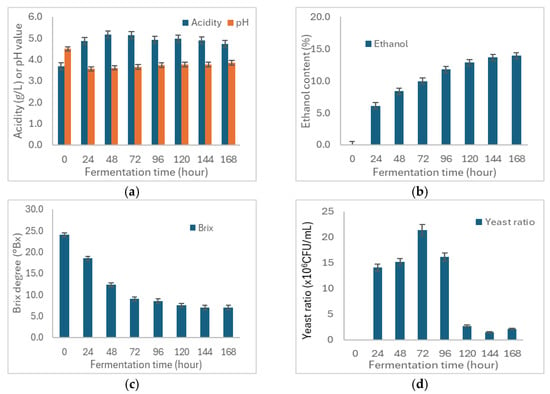

3.2. Influence of Fermentation Time

The analysis of the fermentation process of red dragon fruit (H. polyrhizus) wine over a period of 168 h revealed several significant changes in the key parameters of acidity, pH, Brix, ethanol concentration, and yeast ratio, which are essential for understanding the fermentation dynamics and wine quality (Figure 4).

Figure 4.

Main parameters impacting dragon fruit wine fermentation. (a) pH levels over the fermentation period; (b) ethanol content over the fermentation period; (c) Brix value, indicating sugar content; (d) yeast-cell concentration.

Initially, the acidity of the juice started at 3.690 g/L, and this value increased sharply within the first 48 h to 5.160 g/L due to the production of organic acids rapid microbial activity. After 48 h, the acidity stabilized, and it slightly decreased to 4.740 g/L by 168 h, indicating a gradual adjustment in the microbial environment. The pH levels started at 4.500 and initially decreased to 3.563 within 24 h, reflecting increased acidity (Figure 4a). This pH reduction is typical in early fermentation stages as acids are produced. Over time, the pH adjusted, ending at a slightly higher value of 3.857, which corresponded with the reduced acidity as fermentation stabilized. This pattern reflects the active yeast metabolic phase, which is crucial for flavor development and preservation due to the antimicrobial properties of acids.

The Brix value, indicating sugar content, started at 24% and consistently declined to 7% by 144 h, stabilizing over the 168 h. This decline reflects sugar consumption by yeast, which converts sugars into ethanol and by-products (Figure 4c). This consistent decrease highlights the yeast’s efficiency in sugar conversion, which minimized the content of residual sugars and achieved the desired dryness level in the final product. Ethanol content, starting at 0%, gradually increased as yeast metabolized sugars (Figure 4b). By 168 h, the ethanol content reached 13.917%, indicating efficient sugar-to-alcohol conversion, a desirable outcome in wine fermentation.

The yeast cell concentration, shown in Figure 4d, initially rose to a peak of 21,400,000 cells/mL by 72 h, demonstrating rapid yeast proliferation. This peak was followed by a decline to 2,150,000 cells/mL by 168 h, likely due to sugar depletion and ethanol inhibition. This pattern indicates a well-adjusted fermentation process wherein initial yeast growth was supported by abundant sugars and subsequently declined as the environment became less conducive to growth.

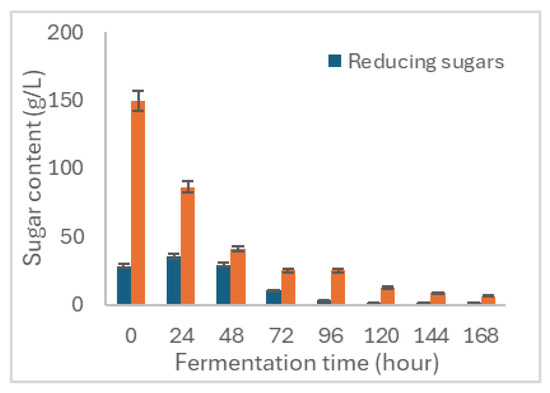

Total sugar content started at 149.161 g/L, dropped sharply to 86.419 g/L within the first 24 h, and continued to decrease to 6.491 g/L by the end of fermentation, indicating effective sugar utilization by yeast (Figure 5). Reducing sugars, which initially increased from 28.484 g/L to 35.277 g/L due to non-reducing sugar hydrolysis, consistently declined thereafter, reaching 1.769 g/L, reflecting efficient yeast metabolism.

Figure 5.

Sugar consumption during dragon fruit wine fermentation.

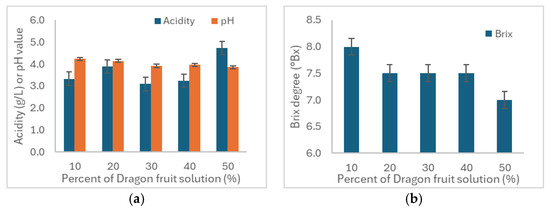

3.3. Effects of Dragon Fruit Solution Concentration on Fermentation Dynamics

The impact of varying dragon fruit-solution concentrations on key fermentation parameters was measured with concentrations ranging from 10% to 50% dragon fruit solution to water (Figure 6). The analysis revealed substantial impacts on several crucial fermentation metrics, including acidity, pH levels, ethanol production, sugar consumption, and degrees Brix, which collectively determine the fermentation profile and the final qualities of dragon fruit wine.

Figure 6.

Impact of dragon fruit solution concentration on fermentation parameters. (a) Acidity (g/L) and pH value; (b) degrees Brix (°Bx); (c) ethanol content (%); (d) sugar content (g/L), including reducing sugars and total sugars.

Results indicate a significant impact of fruit-solution concentration on acidity and pH (Figure 6a). As the concentration increased, acidity values exhibited fluctuations, peaking at 4.740 in the 50% concentration solution. Simultaneously, pH levels progressively declined from 4.240 at 10% concentration to 3.857 at 50%. This pattern suggests that higher fruit concentrations create a more acidic environment, which is generally beneficial for yeast activity, thus enhancing the fermentation process. Additionally, ethanol production demonstrated a positive correlation with the increase in the concentration of the dragon fruit-solution concentration, rising from 11.340% at 10% concentration to 13.917% at 50% (Figure 6c). This trend suggests that higher concentrations not only potentially enhance the flavor profile of the wine but also improve ethanol yield, likely due to the increased availability of fermentable sugars. Correspondingly, both reducing sugars and total sugars showed significant declines as the concentration increased—reducing sugars decreased from 11.839 g/L at 10% to 1.769 g/L at 50%, and total sugars decreased from 11.969 g/L to 6.491 g/L (Figure 6b,d).

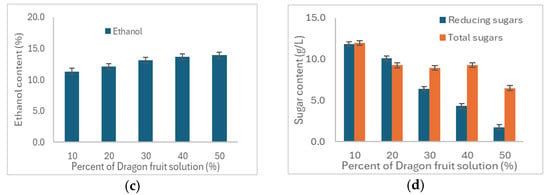

3.4. Optimization of Yeast Strain and Concentration

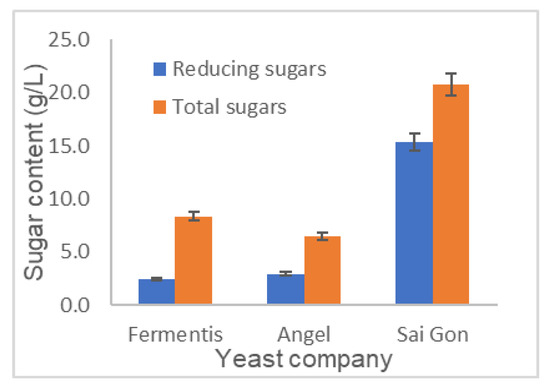

The study evaluated the effectiveness of different yeast strains (Fermentis, Angel, and Sai Gon) in fermenting dragon fruit wine under identical conditions (Figure 7a).

Figure 7.

Impact of yeast strains on fermentation parameters in dragon fruit wine production. (a) Acidity (g/L) and pH value; (b) degrees Brix (°Bx); (c) ethanol content (%); (d) yeast ratio (×10⁶ CFU/mL).

Acidity levels varied significantly among the yeasts, with Sai Gon exhibiting the highest acidity at 12.12, suggesting a stronger acid-production capability. The pH readings correlated with these acidity levels, where Sai Gon had the lowest pH at 3.530, indicating a more acidic environment compared to those associated with Fermentis (3.887) and Angel (4.000).

In the comparative study of yeast strains for dragon fruit wine fermentation, distinct differences in sugar utilization were evident. Both Fermentis and Angel maintained a moderate Brix level of 7, indicative of consistent sugar-conversion rates. In contrast, Sai Gon showed a higher Brix of 10, alongside significantly greater levels of reducing sugars at 15.340 g/L, compared to just 2.393 g/L and 2.945 g/L for Fermentis and Angel, respectively (Figure 7b).

Ethanol-production figures support this inference, with Fermentis and Angel achieving 13.23% and 13.46% ethanol content, outperforming Sai Gon’s 8.11% (Figure 7c). Despite Angel’s higher yeast concentration (4,220,000 cells/mL), it did not yield the highest ethanol output, hinting that the conversion efficiency of yeast strains may rely on specific metabolic traits beyond simple cell count (Figure 7d).

Figure 8 illustrates the sugar content—including both reducing and total sugars—across three different yeast strains (Fermentis, Angel, Sai Gon) used in dragon fruit wine fermentation. The data indicate that Sai Gon yeast was associated with significantly higher total sugars compared to Fermentis and Angel, reaching approximately 20 g/L; Fermentis and Angel both were associated with lower sugar levels. This analysis indicates that the Sai Gon yeast strain may be less efficient at converting sugars into ethanol, potentially producing sweeter wines with lower alcohol content. The high levels of reducing sugars in the Sai Gon strain further underscore its diminished fermentation efficiency compared to the Fermentis and Angel strains.

Figure 8.

Sugar-content variation across different yeast strains in dragon fruit wine fermentation.

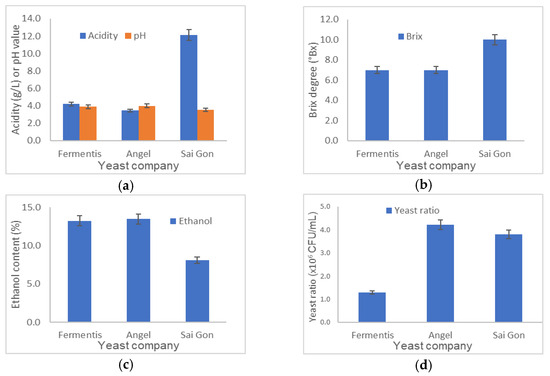

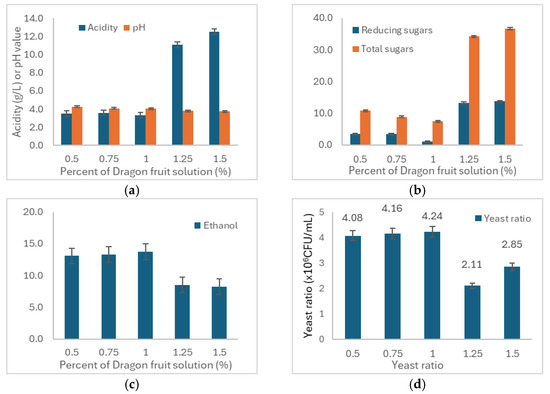

3.5. Factors Influencing Sensory Evaluation

The data derived from Figure 9 elucidate the profound impact of dragon fruit-solution concentration on fermentation dynamics and the resultant sensory qualities of the wine. As the dragon fruit-solution concentration increased, marked changes were observed in acidity and pH levels. Specifically, acidity escalated sharply from 3.3 at 1% to 12.54 at 1.5% concentration, significantly influencing the tartness of the wine. Concurrently, pH levels dropped, creating a more acidic environment, which enhances the perceived sharpness and intensity of the wine flavors (Figure 9a).

Figure 9.

Impact of dragon fruit-solution concentration on key fermentation metrics. (a) Acidity (g/L) and pH value; (b) sugar content (g/L), including reducing sugars and total sugars; (c) ethanol content (%); (d) yeast ratio (×10⁶ CFU/mL).

The sugar profile, indicated by Brix, reducing sugars, and total sugars, exhibited notable variations with changing dragon fruit-solution concentrations. While lower concentrations (0.5% to 1%) were associated with relatively stable sugar levels, conducive to optimal ethanol production, concentrations of 1.25% and 1.5% yielded a significant increase in sugars (Figure 9b). This elevation in sugar content could potentially result in sweeter, fuller-bodied wines, appealing to certain consumer preferences. However, it is crucial to note that while these higher sugar concentrations may enhance sweetness and body, they also risk inhibiting ethanol production. This is evident from the fact that ethanol content peaked within the lower concentration range (13.08% to 13.74% at 0.5% to 1%) and declined as sugar levels increased, indicating a possible threshold beyond which sugar levels adversely affect ethanol yield (Figure 9c).

Managing these sugar levels is vital to preventing excessive acidity that might compromise the desirable fruity characteristics of the wine. The variation in sugar content across different concentrations highlights this crucial balance in winemaking. While the increase in sugars at higher concentrations (1.25% and 1.5%) can enhance the sensory appeal of the wine by producing a sweeter and more robust flavor profile, it simultaneously poses challenges for ethanol production, likely due to osmotic pressure or yeast nutrient imbalance. These conditions can impair yeast metabolic activities and reduce ethanol yields (Figure 9d).

3.6. Impact of Fermentation on the Biochemical and Nutritional Properties of H. polyrhizus

Table 2 delineates significant alterations in the biochemical composition of H. polyrhizus following fermentation, offering insights into the metabolic impacts of this process. Fermentation, a biotechnological application involving microbial activity, profoundly affects the nutritional and phytochemical profile of substrates, as is evident from the changes observed in various parameters measured

Table 2.

Biochemical composition of fruit juice made from H. polyrhizus before and after fermentation.

There was a noticeable decrease in vitamin C content from 29.74 mg AA/100 g to 11.36 mg AA/100 g post-fermentation. This reduction could be attributed to the sensitivity of vitamin C to oxidative processes and enzymatic activity during fermentation, which often leads to its degradation. Such a decrease might impact the antioxidant capacity of the fruit, although other components may compensate for this loss.

Contrastingly, the polyphenol content increased from 39.18 mg GAE/100 g to 55.04 mg GAE/100 g. This increase suggests that fermentation facilitates the release or synthesis of polyphenols, possibly through the breakdown of cell walls by enzymes produced by fermentative microbes or the conversion of bound phenolic compounds into free forms. This enhancement enhances the fruit’s health-promoting properties, given the role of polyphenols in preventing oxidative stress.

A significant transformation was observed in the sugar profiles. Total sugars decreased sharply from 84.93 g/L to 13.48 g/L, and reducing sugars decreased from 73.84 g/L to 9.88 g/L. This substantial reduction is typically a result of sugar utilization by yeast for alcohol production during fermentation. The reduction in sugar content is beneficial for reducing caloric intake and can be particularly advantageous for consumers monitoring sugar consumption.

The DPPH antioxidant activity increased from 38.23% to 45.69%. This increase aligns with the rise in polyphenol content, as these compounds are known for their antioxidant properties. This finding suggests that fermentation not only preserves but also enhances the antioxidant potential of H. polyrhizus, potentially increasing its efficacy in combating oxidative stress in the body.

There was a slight decrease in dry-matter content from 13.00 Brix to 11.17 Brix, which might be linked to the breakdown of structural carbohydrates and other dry-matter constituents. The acidity of the sample increased from 2.31 g/L to 5.59 g/L, indicative of organic-acid production during fermentation, which is typical, as microbes metabolize sugars and produce acids as byproducts.

The pH value slightly increased from 3.96 to 4.35, which could have been the result of organic-acid production and other fermentative transformations. The anthocyanin content decreased from 345.66 mg/L to 250.34 mg/L, possibly due to the structural breakdown of these compounds under fermentation conditions or to their conversion into other molecules.

4. Discussion

Red dragon fruits (Hylocereus spp.) are celebrated for their high levels of health-promoting betalains, although these compounds exhibit notably low bioavailability in plasma (less than 1.0%) [34]. To address this issue, fermentation techniques utilizing autochthonous strains have been developed to enhance the yield of betalains in fermented red dragon fruit drinks through concentration processes [35]. Additionally, the production of fruit wines, including red dragon fruit wine, is a burgeoning field of biotechnological advancement with substantial commercial implications. As the demand for alternative fruit wines increases, understanding the nuances of their production is becoming essential [36,37,38].

Historically, wine is globally cherished for its distinctive flavors and aromas and is traditionally crafted from grapes [39]. However, there is growing consumer interest in wines made from non-grape fruits such as mango, jackfruit, and, notably, red dragon fruit, which offer unique aromas, lower alcohol content, and additional health benefits due to their high levels of phenolics and flavonoids [40]. This shift is particularly notable in Vietnam, the world’s second-largest producer of red dragon fruits, where rapid post-harvest processing can mitigate sucrose degradation, thereby enhancing product stability and shelf life while also improving the bioavailability of health-promoting compounds through fermentation [2,41,42,43]. Recent studies have highlighted the potential of red dragon fruit wine in terms of its antioxidant properties. For instance, Jiang et al. found that using different yeast strains can significantly impact the wine’s physicochemical and oenological properties. They reported that certain yeast strains enhanced the antioxidant activity by up to 20% and improved color stability by 15% compared to control strains [44]. Similarly, Xiong et al. observed that red dragon fruit wine has a high phenolic content, measuring approximately 180 mg GAE/L, which contributes to its significant antioxidant properties, which are associated with a 25% increase in DPPH radical-scavenging activity compared to traditional fruit wines [45]. These findings underscore the importance of selecting appropriate yeast strains and fermentation conditions to optimize the wine’s health benefits and sensory attributes. Effective yeast selection and fermentation techniques can maximize the retention of bioactive compounds in the wine, enhancing both its nutritional value and its consumer appeal. Thus, the strategic optimization of fermentation variables is crucial for producing high-quality red dragon fruit wine with superior health benefits and sensory qualities, highlighting the potential for these wines in the growing market for health-promoting beverages.

Yeast plays a crucial role in wine fermentation, converting sugars into ethanol, carbon dioxide, and secondary metabolites such as esters, which significantly contribute to the wine’s flavor profile [46]. The type of yeast significantly affects the quality of the wine, with various strains of Saccharomyces cerevisiae being widely utilized due to their fermentation efficiency [47]. These include strains reported in several studies highlighting their different impacts on fermentation dynamics and wine characteristics [48,49,50,51]. During fermentation, these yeasts metabolize glucose and fructose into ethanol and CO2 [52]. However, red dragon fruit naturally lacks the requisite sugar levels to achieve the standard ethanol concentrations found in traditional wines, necessitating adjustments to the sugar content in the must [53,54].

The soluble solids content (SSC) serves as a rapid and accurate metric for assessing fruit ripeness and sugar adequacy for fermentation, measures that are crucial for selecting high-quality raw materials [55]. The inherently acidic environment of dragon fruit juice (pH approximately 3.0–4.0) and the presence of enzymes such as invertase aid in the hydrolysis of sucrose into fermentable sugars, facilitating yeast metabolism [56]. Our study meticulously monitored the transformation of reducing sugars during fermentation, revealing a substantial correlation between sugar consumption and ethanol production. This correlation underscores the efficacy of our fermentation strategy, which was carefully designed to maximize alcohol yield while minimizing the production of unwanted by-products.

By conducting detailed measurements of soluble solids content (SSC) and tracking sugar transformation, the study highlighted the successful adaptation of the fermentation process, optimizing alcohol production to ensure that sugars were efficiently converted into ethanol [57]. This approach is crucial, as it prevents the formation of undesirable compounds that could degrade the wine’s quality and flavor. Precision in managing sugar levels and their conversion to ethanol is vital in winemaking, as it directly affects the final alcohol content and overall sensory attributes of the wine. Achieving an optimal balance in this conversion process sets a valuable benchmark for future fermentation endeavors, particularly with non-traditional fruits like dragon fruit [58]. This method serves as a model for similar applications in the wine industry, emphasizing the efficient use of natural sugar resources to produce high-quality wines with the desired alcoholic strength and minimal residual sugars.

To further validate the influence of soluble solids content (SSC) on fermentation outcomes, we investigated the effects of diluting the dragon fruit juice. Reducing the juice concentration lowered the sugar content and degrees Brix from the original range of 10–12 to below 10, necessitating the addition of sucrose. This added sucrose underwent hydrolysis due to the acids and enzymes present in the juice, indicating that the observed reduction in sugar levels primarily resulted from yeast activity. Additionally, the residual sugar content helps categorize the resulting wine into dry, off-dry, or sweet categories and informs storage strategies. For example, storing wine without pasteurization in cool conditions could lead to ongoing fermentation, potentially increasing alcohol content and generating gases, as is seen in sparkling wines such as Champagne [59,60,61]. This underscores the necessity of appropriate storage methods and highlights how monitoring reducing sugars during fermentation aligns with SSC management to ensure quality control and the achievement of the desired wine characteristics. This study also observed a significant increase in volatile components, particularly ethanol and esters, following fermentation. Fatty acids and aldehydes were predominantly decomposed, with ethanol emerging as the most abundant volatile compound in the fermented wine samples [62,63,64]. The fermentation process, starting with an initial Brix of 24, produced an alcohol level of approximately 12%, aligning with standard wine alcohol content. The study emphasized the importance of using the manufacturer-recommended yeast concentrations for optimizing fermentation efficiency and cost-effectiveness. While Fermentis yeast resulted in satisfactory alcohol production, its higher cost compared to Angel yeast made it less cost-effective. The use of Saigon yeast led to increased acid content and decreased pH, resulting in a more acidic and potentially hazy wine and indicating that it was not economically viable or beneficial for wine clarity.

Finally, our findings illuminate the multifaceted nature of wine fermentation, especially when using unconventional fruits like red dragon fruit. This study accentuates the necessity of meticulous substrate selection, the use of specific yeast strains, and precise fermentation management to enhance the transformation of raw materials into superior-quality wines. The implemented techniques not only extend the product’s shelf life but also amplify the bioavailability of health-promoting compounds, potentially setting a new precedent in fruit-wine production for both commercial and health-oriented markets. This holistic approach not only seeks to refine the sensory and quality attributes of the wine, but also demonstrates the potential associated with integrating innovative biotechnological strategies to boost economic efficiency and sustainability in fruit-wine manufacturing. As consumer interest in diverse, health-supportive wines intensifies, this research provides a crucial foundation for further exploration and refinement of fermentation techniques tailored to meet both flavor and nutritional demands. Looking forward, the prospects of fruit wine production are promising, poised to introduce a new genre of specialty wines that align with modern consumer preferences.

The study noted a significant decrease in vitamin C content from 29.74 mg AA/100 g to 11.36 mg AA/100 g after fermentation, likely due to its susceptibility to oxidative and enzymatic breakdown; this decrease could influence the antioxidant capacity of the wine, though other components might compensate for this loss. Yeasts are crucial in the production of polyphenols during the fermentation process. They contribute significantly to the transformation of raw materials into final products with enhanced bioactive properties [65]. Specifically, certain yeast strains have been shown to either synthesize polyphenols directly or facilitate their release from the plant matrix through enzymatic activity. This enzymatic disintegration of cell walls or conversion of bound phenolics into free forms significantly enhances the health benefits of the fermented product [66]. In our study, we observed a significant increase in polyphenol levels from 39.18 mg GAE/100 g to 55.04 mg GAE/100 g post-fermentation. This rise suggests that fermentation not only preserves these compounds but may also boost their availability and efficacy. The increased polyphenol content is likely due to the yeast’s metabolic activities, which can enhance the release or synthesis of these beneficial compounds. By leveraging the metabolic capabilities of yeast, our fermentation process optimizes the polyphenol content, thus enhancing the antioxidant properties of the final product. This finding underscores the importance of selecting appropriate yeast strains to maximize the health benefits and sensory attributes of red dragon fruit wine.

Despite the promising findings of this study, several limitations should be noted. One significant limitation is the inherently low bioavailability of betalains in plasma, which remains less than 1.0%. This low bioavailability can affect the overall health benefits of the wine. Future research should explore methods to enhance betalain bioavailability, potentially through advanced fermentation techniques or novel delivery systems. Additionally, while our study optimized fermentation conditions for red dragon fruit wine, the scope was limited to specific parameters. Future studies should investigate a broader range of variables, including different yeast strains, fermentation temperatures, and durations, to further refine the process. Another area for future research is the long-term stability of the bioactive compounds in the wine and their effects on health over extended storage periods. By addressing these limitations, future research can provide a more comprehensive understanding of the fermentation process and its impact on the nutritional and sensory qualities of red dragon fruit wine.

5. Conclusions

This study on dragon fruit wine fermentation has demonstrated the pivotal roles of yeast strain selection and fermentation parameters in influencing wine quality. Saccharomyces cerevisiae RV002 was identified as the most effective yeast strain due to its robust fermentation capabilities and tolerance to high alcohol and acidic conditions. Optimal wine quality was achieved with a 50% dilution ratio, which led to enhanced clarity and sensory attributes, whereas dilution ratios exceeding 90% significantly reduced ethanol content below the standards stipulated by QCVN 6-3:2010/BYT. An optimal yeast concentration of 1 g/L was established; concentrations above this threshold adversely impacted the wine’s appearance and flavor, and lower concentrations failed to adequately suppress microbial contamination, resulting in off-flavors and diminished alcohol yields. These findings underscore the importance of maintaining meticulous control over fermentation variables to optimize wine quality and highlight the potential of using agricultural by-products to mitigate post-harvest losses and diversify product offerings in agriculture. This research provides a foundational framework for scaling up dragon fruit wine production and encourages further exploration into value-added processing of other fruits.

The study has limitations, including the fact that it was conducted under controlled lab conditions that may not reflect commercial-scale complexities. Future research should scale up fermentation, evaluate industrial feasibility, and explore the use of temperature variations, nutrient supplementation, and extended aging periods to enhance wine quality. Broader sensory evaluations could offer valuable insights into consumer preferences.

Author Contributions

Conceptualization, P.V.T., T.B.N., L.Q.H., L.H.U. and N.N.K.N.; methodology, N.T.K.T., P.H.T.K., D.T.M., T.B.N., L.H.U. and N.N.K.N.; formal analysis, N.T.K.T., P.H.T.K., D.T.M. and T.B.N.; investigation, T.N.M.; resources, P.V.T. and L.Q.H.; data curation, T.N.M., D.T.M. and N.Q.T.; writing—original draft preparation, T.N.M. and N.Q.T.; writing—review and editing, T.N.M. and N.Q.T.; visualization, P.V.T.; supervision, N.Q.T. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Nguyen Quang Trung and Truong Ngoc Minh.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The research support was provided by the Faculty of Food Science and Technology at Ho Chi Minh City University of Industry and Trade, along with Caty Foods Joint Stock Company, which supplied the necessary facilities for this study.

Conflicts of Interest

Author L.Q.H. is employee at Caty Foods Joint Stock Company; Author T.N.M. is employee at Vicomi Tam an Investment and Commercial Company Limited; Author N.Q.T. is employee at Hera USA Corporation; Other authors declare no conflict of interest.

References

- Golino, D.A. Trade in grapevine plant materials: Local, national and worldwide perspectives. Am. J. Enol. Vitic. 2000, 51, 216–221. [Google Scholar]

- Jiang, X.; Lu, Y.; Liu, S.Q. Effects of pectinase treatment on the physicochemical and oenological properties of red dragon fruit wine fermented with Torulaspora delbrueckii. LWT 2020, 132, 109929. [Google Scholar] [CrossRef]

- Thang, N.; Thai, P.M.; Dat, V.H.; Van Ngoc, V.T. Agricultural exports from Vietnam to China. Agric. In Trade between China and the Greater Mekong Subregion Countries: A Value Chain Analysis; Menon, J., Roth, V., Eds.; ISEAS Publishing: Singapore, 2022; pp. 256–267. [Google Scholar]

- Chakraborty, K.; Saha, J.; Raychaudhuri, U.; Chakraborty, R. Tropical fruit wines: A mini review. Nat. Prod. 2014, 10, 219–228. [Google Scholar]

- Yu, Z.H.; Gao, L.; Liu, Y.; Tian, Y.; Zhao, L.; Sun, X.; Wang, L.; Liu, M.; Yu, L. Winemaking characteristics of red-fleshed dragon fruit from three locations in Guizhou Province, China. Food Sci. Nutr. 2021, 9, 2508–2516. [Google Scholar] [CrossRef]

- Tenore, G.C.; Novellino, E.; Basile, A. Nutraceutical potential and antioxidant benefits of red pitaya (Hylocereus polyrhizus) extracts. J. Funct. Foods 2012, 4, 129–136. [Google Scholar] [CrossRef]

- German, J.B.; Walzem, R.L. The health benefits of wine. Annu. Rev. Nutr. 2000, 20, 561–593. [Google Scholar] [CrossRef] [PubMed]

- Sudiarta, I.W.; Saputra, I.W.R.; Singapurwa, N.M.A.S.; Candra, I.P.; Semariyani, A.A.M. Ethanol and methanol levels of red dragon fruit wine (Hylocereus costaricensis) with the treatment of sugar and fermentation time. J. Phys. Conf. Ser. 2021, 1869, 012032. [Google Scholar] [CrossRef]

- Foong, J.H.; Hon, W.M.; Ho, C.W. Bioactive compounds determination in fermented liquid dragon fruit (Hylocereus polyrhizus). Borneo Sci. 2012, 31, 37–56. [Google Scholar]

- Wang, X.; Liu, X.; Long, J.; Shen, K.; Qiu, S.; Wang, Y.; Huang, Y. Isolation, screening, and application of aroma-producing yeast for red dragon fruit wine. Food Biosci. 2024, 59, 103878. [Google Scholar] [CrossRef]

- Huan, P.T.; Hien, N.M.; Anh, N.H.T. Optimization of alcoholic fermentation of dragon fruit juice using response surface methodology. Food Res. 2020, 4, 1529–1536. [Google Scholar] [CrossRef]

- Guigou, M.; Lareo, C.; Pérez, L.V.; Lluberas, M.E.; Vázquez, D.; Ferrari, M.D. Bioethanol production from sweet sorghum: Evaluation of post-harvest treatments on sugar extraction and fermentation. Biomass Bioenergy 2011, 35, 3058–3062. [Google Scholar] [CrossRef]

- Hocking, M.B.; Hocking, M.B. Fermentation processes. Mod. Chem. Technol. Emiss. Control 1985, 338–377. [Google Scholar]

- Silcox, H.E.; Lee, S.B. Fermentation. Ind. Eng. Chem. 1948, 40, 1602–1608. [Google Scholar] [CrossRef]

- Thommes, K.; Strezov, V. Fermentation of biomass. Biomass Process. Technol. 2014, 257, 52. [Google Scholar]

- Minh, N.P.; Nhan, N.P.T.; Tha, D.T.; Thuy, L.K.; Khai, L.Q.; Tu, L.N. Different Aspects Affecting to Production of Dragon Fruit (Hylocereus undatus) Nectar. J. Pharm. Sci. Res. 2019, 11, 1040–1043. [Google Scholar]

- Ha, H.P.; Trang, V.T.; Nghia, N.C.; Son, V.H. Development of Freeze-dried red dragon fruit yoghurt containing probiotics. Red 2021, 31, 14–18. [Google Scholar]

- Luu, T.T.H.; Le, T.L.; Huynh, N.; Quintela-Alonso, P. Dragon fruit: A review of health benefits and nutrients and its sustainable development under climate changes in Vietnam. Czech J. Food Sci. 2021, 39, 71–94. [Google Scholar] [CrossRef]

- Le, P.T. Research processing process of fermented juice from red dragon fruit (Hylocereus polyrhizus): Research processing process of fermented juice from red dragon fruit (Hylocereus polyrhizus). JSTGU 2021, 1, 20–30. [Google Scholar]

- Mai, H.T.Q.; Pham, V.T.; Do, V.L.; Phuc, T.B.; Truc, T.T.; Ngan, T.T.K. Production process of a carbonated drink from red flesh dragon fruit (Hylocereus polyrhizus). Mater. Sci. Forum 2022, 1048, 514–523. [Google Scholar] [CrossRef]

- Vietnam National Technical Regulation TCVN 7523:2014; Specifications and Test Methods for Dragon Fruit. Vietnam National Technical Regulation: Hanoi, Vietnam, 2014.

- Mussa, S.B.; Sharaa, I.E. Analysis of vitamin C (ascorbic acid) contents packed fruit juice by UV-spectrophotometry and redox titration methods. IOSR J. Appl. Phys. 2014, 6, 46–52. [Google Scholar] [CrossRef]

- Sánchez-Rangel, J.C.; Benavides, J.; Heredia, J.B.; Cisneros-Zevallos, L.; Jacobo-Velázquez, D.A. The Folin–Ciocalteu assay revisited: Improvement of its specificity for total phenolic content determination. Anal. Methods 2013, 5, 5990–5999. [Google Scholar] [CrossRef]

- Minh, T.N.; Xuan, T.D.; Van, T.M.; Andriana, Y.; Viet, T.D.; Khanh, T.D.; Tran, H.D. Phytochemical analysis and potential biological activities of essential oil from rice leaf. Molecules 2019, 24, 546. [Google Scholar] [CrossRef] [PubMed]

- Rathod, B.B.; Murthy, S.; Bandyopadhyay, S. Is this solution pink enough? A smartphone tutor to resolve the eternal question in phenolphthalein-based titration. J. Chem. Educ. 2019, 96, 486–494. [Google Scholar] [CrossRef]

- Teixeira, R.S.S.; da Silva, A.S.A.; Ferreira-Leitão, V.S.; da Silva Bon, E.P. Amino acids interference on the quantification of reducing sugars by the 3,5-dinitrosalicylic acid assay mislead carbohydrase activity measurements. Carbohydr. Res. 2012, 363, 33–37. [Google Scholar] [CrossRef] [PubMed]

- Majstorovic, D.M.; Zivkovic, E.M.; Kijevčanin, M.L. Density, viscosity, and refractive index data for a ternary system of wine congeners (ethyl butyrate + diethyl succinate + isobutanol) in the temperature range from 288.15 to 323.15 K and at atmospheric pressure. J. Chem. Eng. Data 2017, 62, 275–291. [Google Scholar] [CrossRef]

- Martyniak, B.; Bolton, J.; Kuksin, D.; Shahin, S.M.; Chan, L.L.Y. A novel concentration and viability detection method for Brettanomyces using the Cellometer image cytometry. J. Ind. Microbiol. Biotechnol. 2017, 44, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Urraca, R.; Sanz-Garcia, A.; Tardaguila, J.; Diago, M.P. Estimation of total soluble solids in grape berries using a hand-held NIR spectrometer under field conditions. J. Sci. Food Agric. 2016, 96, 3007–3016. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.B.; Chen, L.C.; Mou, L. Quality control of potentiometric pH measurements with a combination of NBS and Tris buffers at salinities from 20 to 40 and pH from 7.2 to 8.6. J. Oceanogr. 2022, 78, 467–473. [Google Scholar] [CrossRef]

- Başkan, K.S.; Tütem, E.; Akyüz, E.; Özen, S.; Apak, R. Spectrophotometric total reducing sugars assay based on cupric reduction. Talanta 2016, 147, 162–168. [Google Scholar] [CrossRef]

- Pettinati, J.D.; Swift, C.E.; Cohen, E.H. Moisture and fat analysis of meat and meat products: A review and comparison of methods. J. Assoc. Off. Anal. Chem. 1973, 56, 544–561. [Google Scholar] [CrossRef]

- Hurtado, N.H.; Morales, A.L.; González-Miret, M.L.; Escudero-Gilete, M.L.; Heredia, F.J. Colour, pH stability and antioxidant activity of anthocyanin rutinosides isolated from tamarillo fruit (Solanum betaceum Cav.). Food Chem. 2009, 117, 88–93. [Google Scholar] [CrossRef]

- Choo, K.Y.; Kho, C.; Ong, Y.Y.; Thoo, Y.Y.; Lim, L.H.; Tan, C.P.; Ho, C.W. Fermentation of red dragon fruit (Hylocereus polyrhizus) for betalains concentration. Int. Food Res. J. 2018, 25, 2539–2546. [Google Scholar]

- Lourith, N.; Kanlayavattanakul, M. Antioxidant and stability of dragon fruit peel colour. Agro. Food Ind. Hi Tech 2013, 24, 56–58. [Google Scholar]

- Vidal, J.C.; Bonel, L.; Ezquerra, A.; Hernández, S.; Bertolín, J.R.; Cubel, C.; Castillo, J.R. Electrochemical affinity biosensors for detection of mycotoxins: A review. Biosens. Bioelectron. 2013, 49, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Villamor, R.R.; Evans, M.A.; Ross, C.F. Effects of ethanol, tannin, and fructose concentrations on sensory properties of model red wines. Am. J. Enol. Vitic. 2013, 64, 342–348. [Google Scholar] [CrossRef]

- Alarcón-Flores, M.I.; Romero-González, R.; Vidal, J.L.M.; Frenich, A.G. Multiclass determination of phytochemicals in vegetables and fruits by ultra high performance liquid chromatography coupled to tandem mass spectrometry. Food Chem. 2013, 141, 1120–1129. [Google Scholar] [CrossRef]

- Millon, M. Wine: A Global History; Reaktion Books; The University of Chicago Press: Chicago, IL, USA, 2013. [Google Scholar]

- Hu, L.; Liu, R.; Wang, X.; Zhang, X. The sensory quality improvement of citrus wine through co-fermentations with selected non-Saccharomyces yeast strains and Saccharomyces cerevisiae. Microorganisms 2020, 8, 323. [Google Scholar] [CrossRef]

- Wakchaure, G.C.; Kumar, S.; Meena, K.K.; Rane, J.; Pathak, H. Dragon fruit cultivation in India: Scope, constraints and policy issues. Tech. Bull. 2021, 27, 47. [Google Scholar]

- Tran, D.H.; Yen, C.R.; Chen, Y.K.H.; Le, T.K.O. Dragon Fruit Production and Consumption in Vietnam; Agricultural Experimental Institute, Fengshan Tropical Horticulture Experimental Branch, National Pingtung University of Science and Technology, Department of Agricultural Production: Kaohsiung, Taiwan, 2015; pp. 15–22. [Google Scholar]

- Longhi, S.J.; Martín, M.C.; Fontana, A.; de Ambrosini, V.I.M. Different approaches to supplement polysaccharide-degrading enzymes in vinification: Effects on color extraction, phenolic composition, antioxidant activity and sensory profiles of Malbec wines. Food Res. Int. 2022, 157, 111447. [Google Scholar] [CrossRef]

- Berovič, M.; Mavri, J.; Wondra, M.; Košmerl, T.; Bavčar, D. Influence of temperature and carbon dioxide on fermentation of cabernet sauvignon must. Food Technol. Biotechnol. 2003, 41, 353–359. [Google Scholar]

- Jiang, X.; Lu, Y.; Liu, S.Q. Effects of Different Yeasts on Physicochemical and Oenological Properties of Red Dragon Fruit Wine Fermented with Saccharomyces cerevisiae, Torulaspora delbrueckii and Lachancea thermotolerans. Microorganisms 2020, 8, 315. [Google Scholar] [CrossRef]

- Niyomvong, N.; Sritawan, R.; Keabpimai, J.; Trakunjae, C.; Boondaeng, A. Comparison of the Chemical Properties of Vinegar Obtained via One-Step Fermentation and Sequential Fermentation from Dragon Fruit and Pineapple. Beverages 2022, 8, 74. [Google Scholar] [CrossRef]

- Torija, M.J.; Rozes, N.; Poblet, M.; Guillamón, J.M.; Mas, A. Effects of fermentation temperature on the strain population of Saccharomyces cerevisiae. Int. J. Food Microbiol. 2003, 80, 47–53. [Google Scholar] [CrossRef]

- Belda, I.; Navascués, E.; Marquina, D.; Santos, A.; Calderon, F.; Benito, S. Dynamic analysis of physiological properties of Torulaspora delbrueckii in wine fermentations and its incidence on wine quality. Appl. Microbiol. Biotechnol. 2015, 99, 1911–1922. [Google Scholar] [CrossRef] [PubMed]

- Perrone, B.; Giacosa, S.; Rolle, L.; Cocolin, L.; Rantsiou, K. Investigation of the dominance behavior of Saccharomyces cerevisiae strains during wine fermentation. Int. J. Food Microbiol. 2013, 165, 156–162. [Google Scholar] [CrossRef]

- Querol, A.; Barrio, E.; Ramón, D. Population dynamics of natural Saccharomyces strains during wine fermentation. Int. J. Food Microbiol. 1994, 21, 315–323. [Google Scholar] [CrossRef]

- Mouret, J.R.; Cadière, A.; Aguera, E.; Rollero, S.; Ortiz-Julien, A.; Sablayrolles, J.M.; Dequin, S. Dynamics and quantitative analysis of the synthesis of fermentative aromas by an evolved wine strain of Saccharomyces cerevisiae. Yeast 2015, 32, 257–269. [Google Scholar] [PubMed]

- Gueddari-Aourir, A.; García-Alaminos, A.; García-Yuste, S.; Alonso-Moreno, C.; Canales-Vázquez, J.; Zafrilla, J.E. The carbon footprint balance of a real-case wine fermentation CO2 capture and utilization strategy. Renew. Sustain. Energy Rev. 2022, 157, 112058. [Google Scholar] [CrossRef]

- Ali, A.; Sharma, N.; Vishwakarma, P.K.; Chavda, D. Exploring Dragon Fruit in India: From Taxonomy to Nutritional Benefits and Sustainable Cultivation Practices. Appl. Fruit Sci. 2024, 1, 1–15. [Google Scholar]

- Jalgaonkar, K.; Mahawar, M.K.; Bibwe, B.; Kannaujia, P. Postharvest profile, processing and waste utilization of dragon fruit (Hylocereus spp.): A review. Food Rev. Int. 2022, 38, 733–759. [Google Scholar] [CrossRef]

- Muzaifa, M.; Rohaya, S.; Nilda, C.; Harahap, K.R. Kombucha fermentation from cascara with addition of red dragon fruit (Hylocereus polyrhizus): Analysis of alcohol content and total soluble solid. In Proceedings of the International Conference on Tropical Agrifood, Feed and Fuel (ICTAFF 2021), Balikpapan, Indonesia 7 September 2021; Atlantis Press: Amsterdam, The Netherlands, 2022; pp. 125–129. [Google Scholar]

- Wong, Y.M.; Siow, L.F. Effects of heat, pH, antioxidant, agitation and light on betacyanin stability using red-fleshed dragon fruit (Hylocereus polyrhizus) juice and concentrate as models. J. Food Sci. Technol. 2015, 52, 3086–3092. [Google Scholar] [CrossRef] [PubMed]

- Panjaitan, R.G.P. Anti-diabetic activity of the red dragon fruit peel (Hylocereus polyrhizus) in ethanol extract against diabetic rats. Pharmacogn. J. 2021, 13, 1079–1085. [Google Scholar] [CrossRef]

- Cauilan, P.L. Hepatoprotective potential of Hylocereus polyrhizus (dragon fruit) on carbon tetrachloride induced hepatic damages in albino wistar rats. Int. J. Sci. Basic Appl. Res. 2019, 46, 49–61. [Google Scholar]

- Hutkins, R.W. Wine fermentation. In Wine Fermentation; Blackwell Publishing: Ames, IA, USA, 2006; pp. 349–396. [Google Scholar]

- Amerine, M.A.; Singleton, V.L. Wine: An Introduction; University of California Press: Berkeley, CA, USA, 1976. [Google Scholar]

- Lea, A.G.; Drilleau, J.F. Cidermaking. In Fermented Beverage Production; Springer: Boston, MA, USA, 2003; pp. 59–87. [Google Scholar]

- Ma, Y.; Li, T.; Xu, X.; Ji, Y.; Jiang, X.; Shi, X.; Wang, B. Investigation of volatile compounds, microbial succession, and their relation during spontaneous fermentation of Petit Manseng. Front. Microbiol. 2021, 12, 717387. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Liu, Y.; Ma, Q.; Wang, J.; Luo, J.; Suo, R.; Sun, J. Effects of low temperature on the dynamics of volatile compounds and their correlation with the microbial succession during the fermentation of Longyan wine. LWT 2022, 154, 112661. [Google Scholar] [CrossRef]

- Zhao, C.; Su, W.; Mu, Y.; Jiang, L.; Mu, Y. Correlations between microbiota with physicochemical properties and volatile flavor components in black glutinous rice wine fermentation. Food Res. Int. 2020, 138, 109800. [Google Scholar] [CrossRef]

- Ndlovu, T. Mannoprotein Production and Wine Haze Reduction by Wine Yeast Strains. Doctoral Dissertation, Stellenbosch University, Stellenbosch, South Africa, 2012. [Google Scholar]

- Tadioto, V.; Giehl, A.; Cadamuro, R.D.; Guterres, I.Z.; dos Santos, A.A.; Bressan, S.K.; Werlang, L.; Stambuk, B.U.; Fongaro, G.; Silva, I.T.; et al. Bioactive Compounds from and against Yeasts in the One Health Context: A Comprehensive Review. Fermentation 2023, 9, 363. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).