Radially and Axially Oriented Ammonium Alginate Aerogels Modified with Clay/Tannic Acid and Crosslinked with Glutaraldehyde

Abstract

:1. Introduction

2. Results and Discussion

2.1. Determination of Molecular Weight

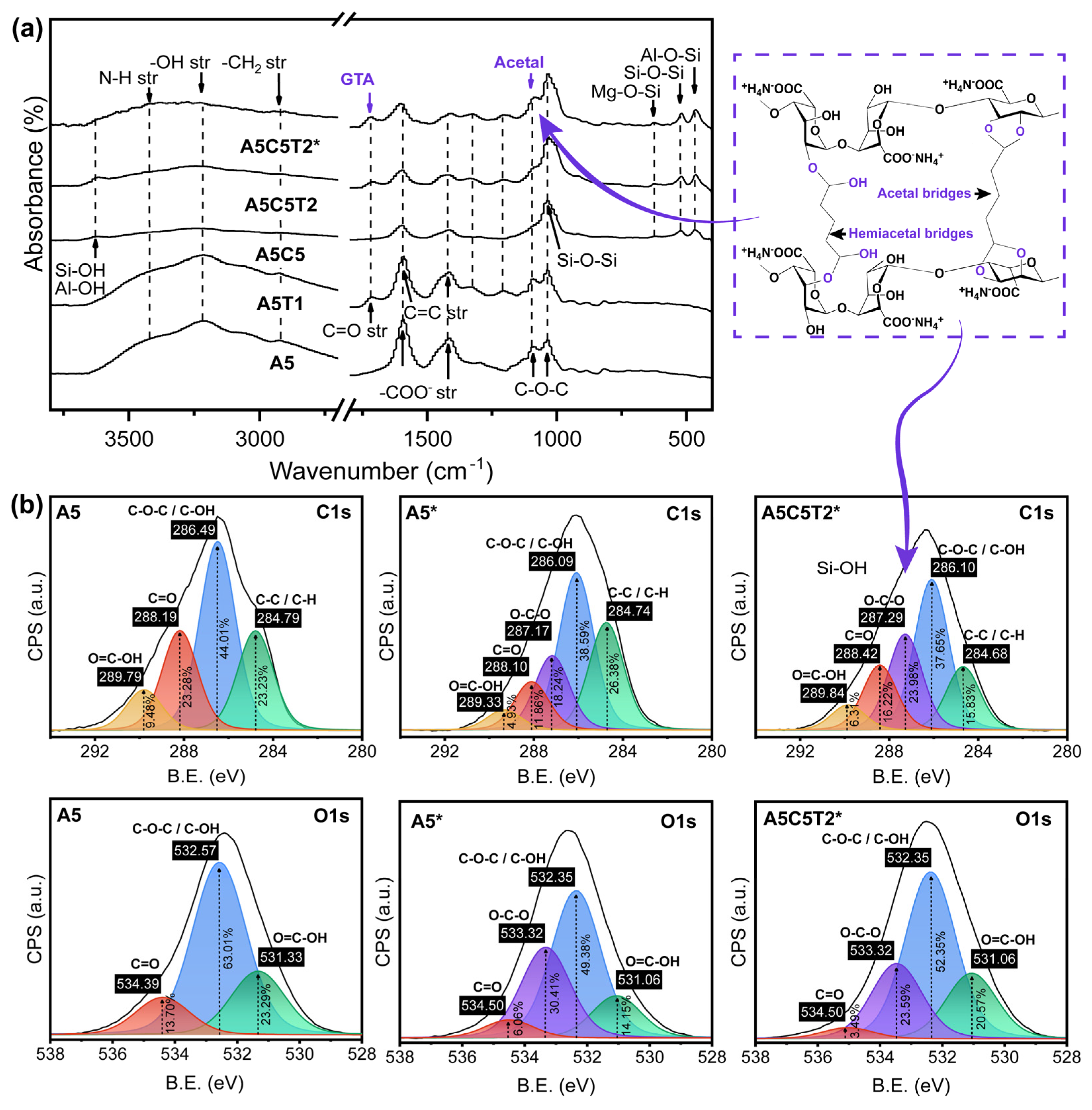

2.2. Chemical Structure

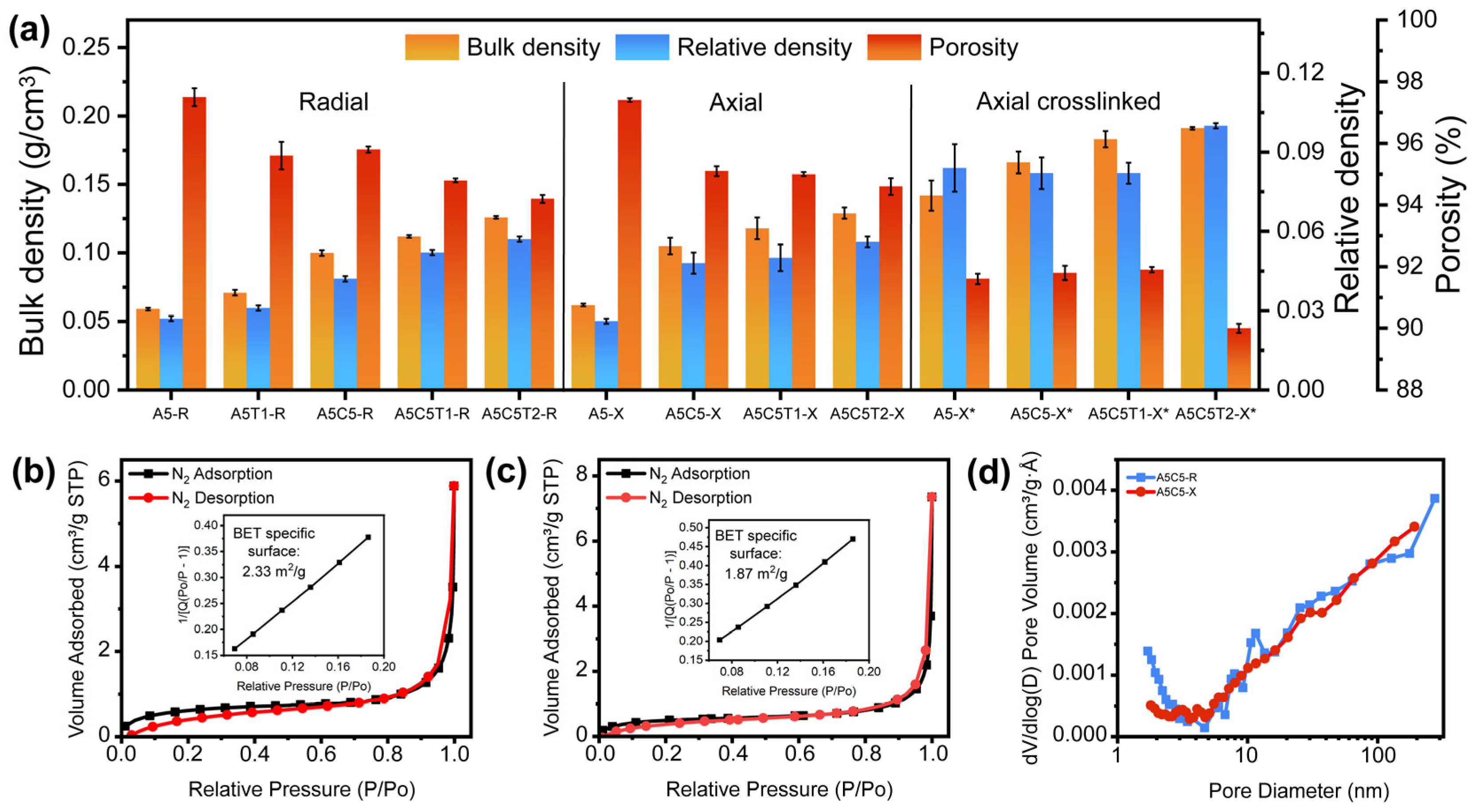

2.3. Density and Porosity

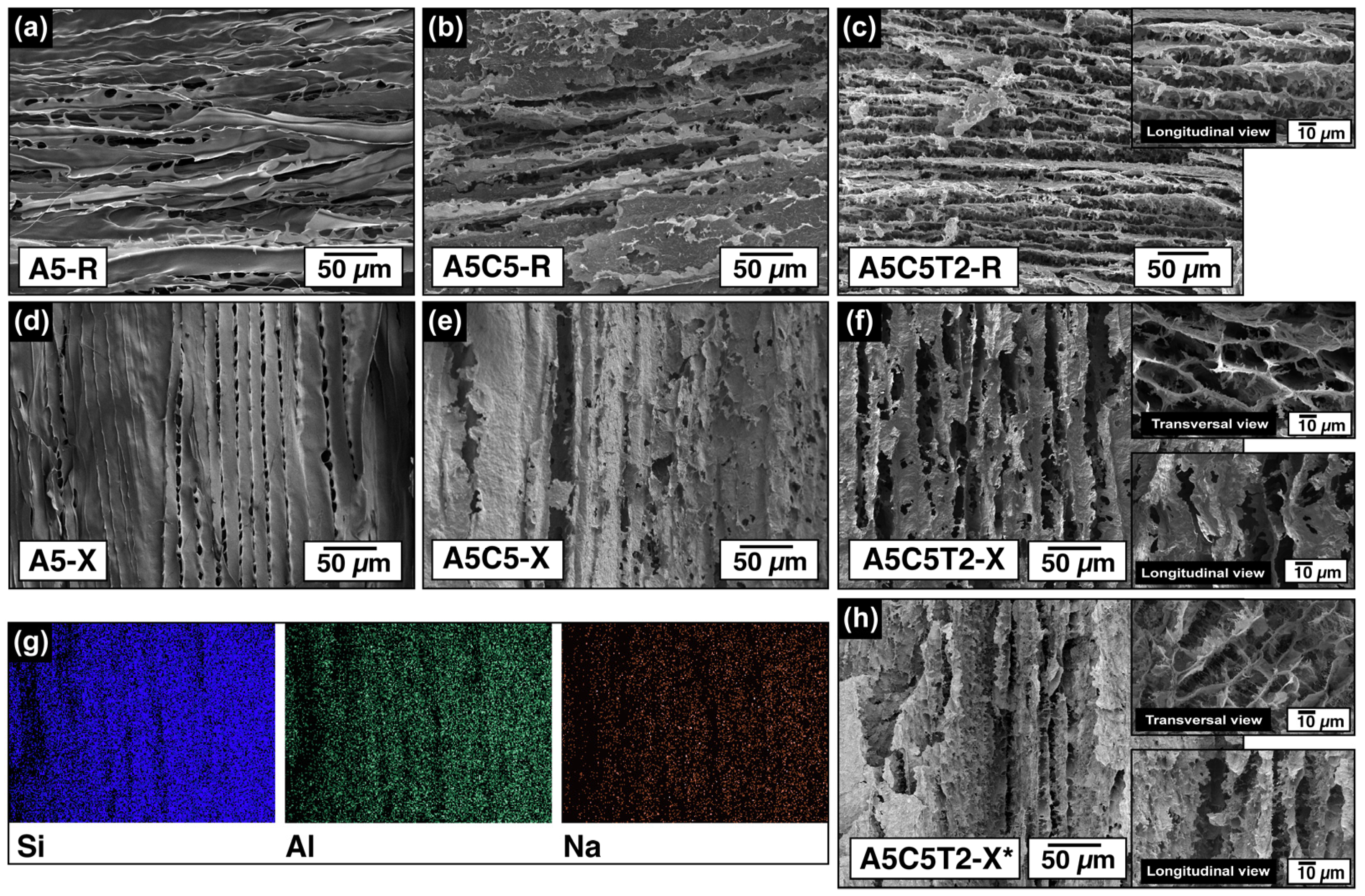

2.4. Aerogel Morphology

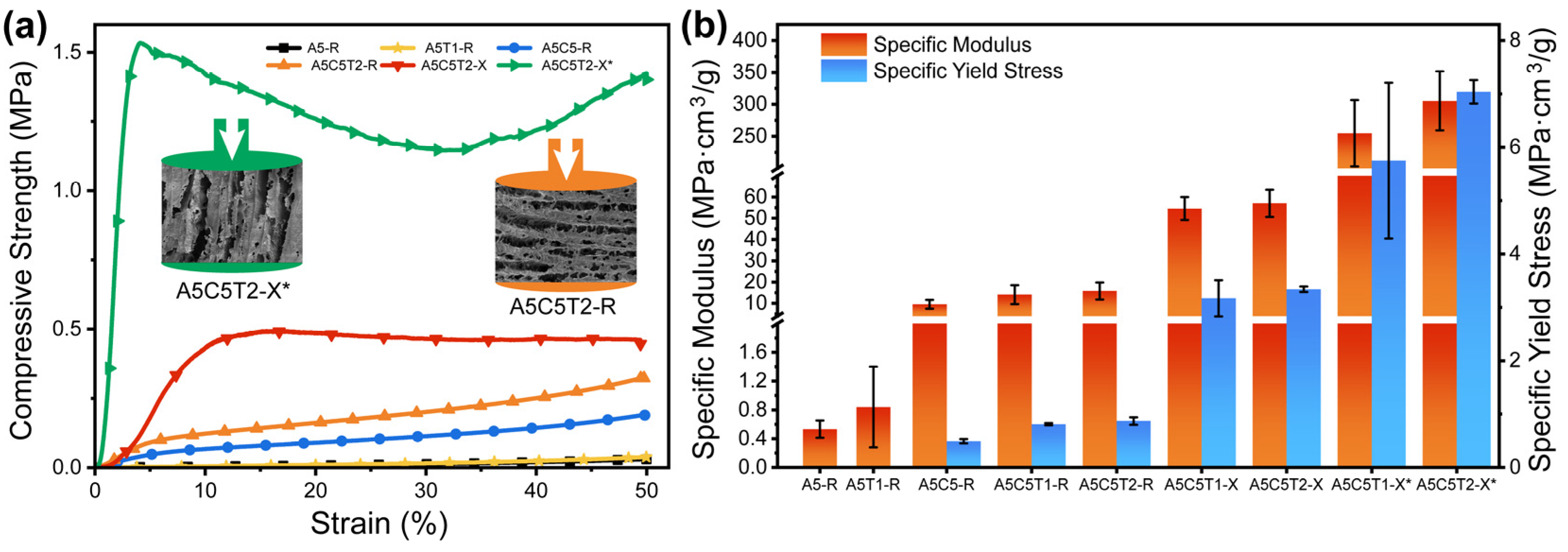

2.5. Compressive Behavior

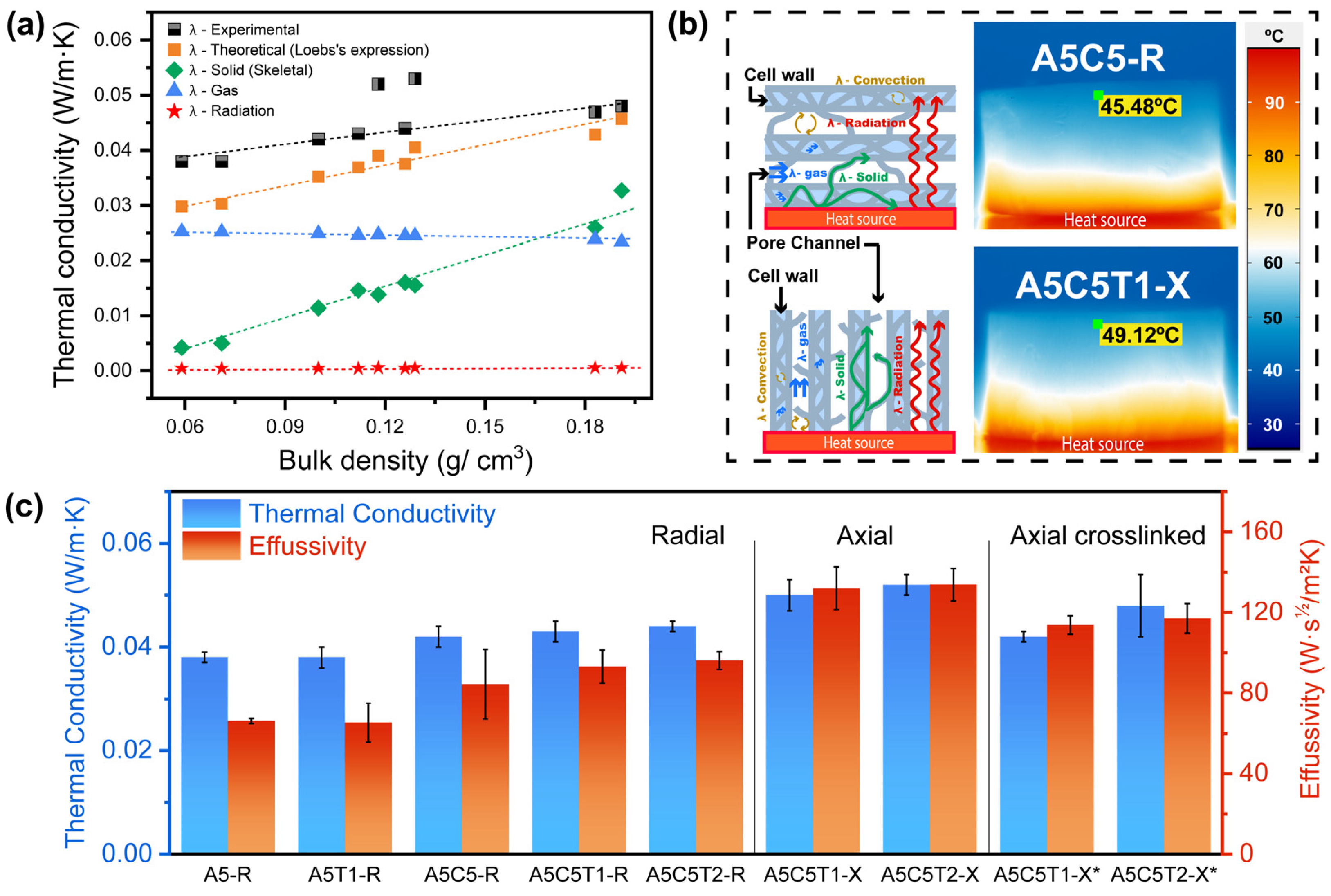

2.6. Thermal Transport Properties

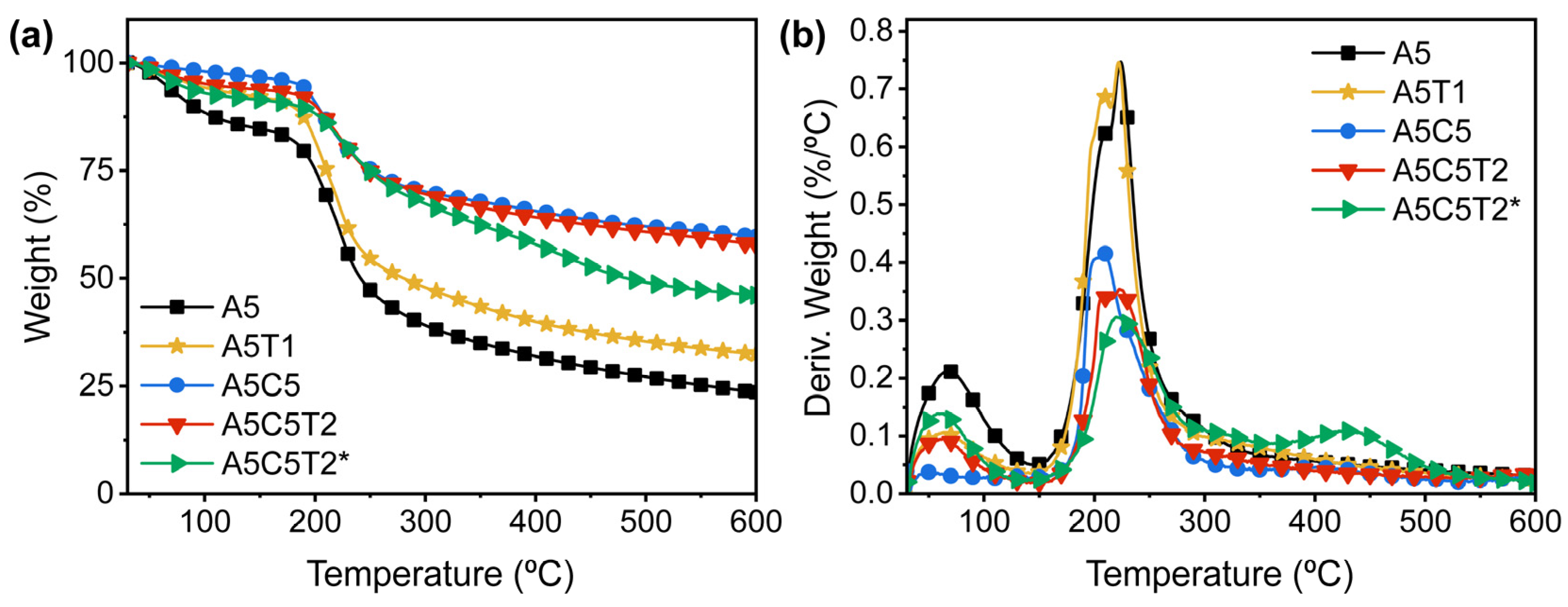

2.7. Thermal Stability

2.8. Fire Behavior and Char Mechanism

3. Conclusions

4. Materials and Methods

4.1. Materials

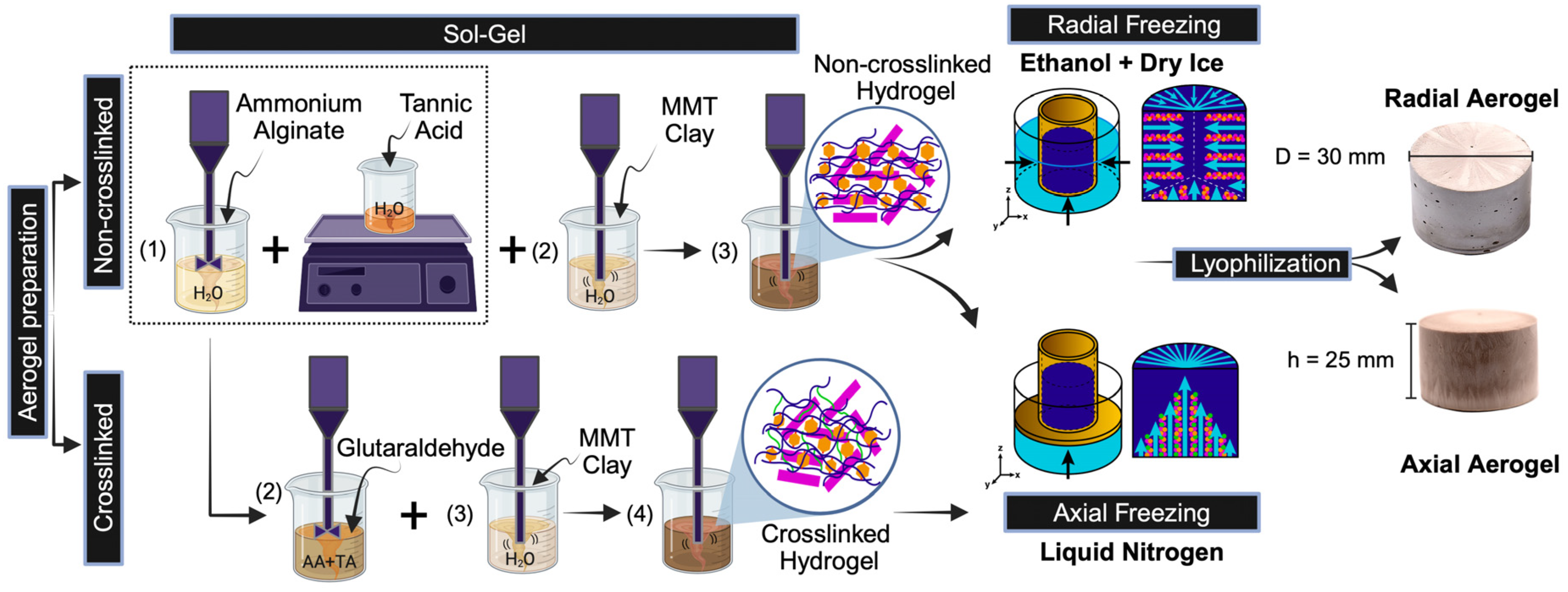

4.2. Aerogel Preparation

4.3. Characterization

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vrabič-Brodnjak, U. Hybrid Materials of Bio-Based Aerogels for Sustainable Packaging Solutions. Gels 2024, 10, 27. [Google Scholar] [CrossRef] [PubMed]

- Zou, F.; Budtova, T. Polysaccharide-Based Aerogels for Thermal Insulation and Superinsulation: An Overview. Carbohydr. Polym. 2021, 266, 118130. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Li, H.; Peng, C.; Ma, J.; Huang, S.; Wang, R.; Wu, B.; Xiong, Q.; Peng, D.; Huang, S.; et al. Application of Protein/Polysaccharide Aerogels in Drug Delivery System: A Review. Int. J. Biol. Macromol. 2023, 247, 125727. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Su, Y.; Wang, W.; Fang, Y.; Riffat, S.B.; Jiang, F. The Advances of Polysaccharide-Based Aerogels: Preparation and Potential Application. Carbohydr. Polym. 2019, 226, 115242. [Google Scholar] [CrossRef] [PubMed]

- Fertah, M.; Belfkira, A.; Taourirte, M.; Brouillette, F. Extraction and Characterization of Sodium Alginate from Moroccan Laminaria Digitata Brown Seaweed. Arab. J. Chem. 2017, 10, S3707–S3714. [Google Scholar] [CrossRef]

- Zhang, J.; Ji, Q.; Shen, X.; Xia, Y.; Tan, L.; Kong, Q. Pyrolysis Products and Thermal Degradation Mechanism of Intrinsically Flame-Retardant Calcium Alginate Fibre. Polym. Degrad. Stab. 2011, 96, 936–942. [Google Scholar] [CrossRef]

- Chen, H.-B.; Schiraldi, D.A. Flammability of Polymer/Clay Aerogel Composites: An Overview. Polym. Rev. 2019, 59, 1–24. [Google Scholar] [CrossRef]

- Chen, H.-B.; Wang, Y.-Z.; Sánchez-Soto, M.; Schiraldi, D.A. Low Flammability, Foam-like Materials Based on Ammonium Alginate and Sodium Montmorillonite Clay. Polymer 2012, 53, 5825–5831. [Google Scholar] [CrossRef]

- Xu, B.-T.; Jin, D.; Yu, Y.; Zhang, Q.; Weng, W.; Ren, K.; Tai, Y.-L. Nanoclay-Reinforced Alginate Aerogels: Preparation and Properties. RSC Adv. 2024, 14, 954–962. [Google Scholar] [CrossRef] [PubMed]

- Guan, F.; Feng, S.; Sun, J.; Yang, Q.; Zhang, Y.; Li, Z.; Tao, J.; Ji, X.; Wang, Y.; Bao, D.; et al. Low–Temperature Superelastic, Anisotropic, Silane-Crosslinked Sodium Alginate Aerogel for Thermal Insulation. Int. J. Biol. Macromol. 2024, 262, 129800. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Y.; Zhao, X.; Li, N.; Guo, X.; Zhao, L.; Yin, Y. Anisotropic Composite Aerogel with Thermal Insulation and Flame Retardancy from Cellulose Nanofibers, Calcium Alginate and Boric Acid. Int. J. Biol. Macromol. 2024, 267, 131450. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Zhou, Z.; Liu, X.; Xu, M.; Zhao, F.; Zhao, F.; Li, S.; Liu, Z.; Li, L.; et al. Flame-Retardant Effect of Tannic Acid-Based Intumescent Fire-Retardant Applied on Flammable Natural Rubber. RSC Adv. 2022, 12, 29928–29938. [Google Scholar] [CrossRef]

- Masuelli, M.A.; Illanes, C.O. Review of the Characterization of Sodium Alginate by Intrinsic Viscosity Measurements. Comparative Analysis between Conventional and Single Point Methods. Int. J. BioMaterials Sci. Eng. 2014, 1, 1–11. [Google Scholar]

- Gómez-Ordóñez, E.; Rupérez, P. FTIR-ATR Spectroscopy as a Tool for Polysaccharide Identification in Edible Brown and Red Seaweeds. Food Hydrocoll. 2011, 25, 1514–1520. [Google Scholar] [CrossRef]

- Tarzynska, N.; Bednarowicz, A.; Pabjanczyk-Wlazlo, E.; Draczyński, Z. The Interphase Gas-Solid Synthesis of Ammonium Alginate—The Comparison of Two Synthesis Methods and the Effect of Low Molecular Weight Electrolyte Presence. Materials 2022, 15, 4321. [Google Scholar] [CrossRef]

- Sartori, C.; Finch, D.S.; Ralph, B.; Gilding, K. Determination of the Cation Content of Alginate Thin Films by FTi.r. Spectroscopy. Polymer 1997, 38, 43–51. [Google Scholar] [CrossRef]

- Kim, S.; Kwak, S.; Lee, S.; Cho, W.K.; Lee, J.K.; Kang, S.M. One-Step Functionalization of Zwitterionic Poly[(3-(Methacryloylamino)Propyl)Dimethyl(3-Sulfopropyl)Ammonium Hydroxide] Surfaces by Metal–Polyphenol Coating. Chem. Commun. 2015, 51, 5340–5342. [Google Scholar] [CrossRef]

- Wahyono, T.; Astuti, D.A.; Gede Wiryawan, I.K.; Sugoro, I.; Jayanegara, A. Fourier Transform Mid-Infrared (FTIR) Spectroscopy to Identify Tannin Compounds in The Panicle of Sorghum Mutant Lines. IOP Conf. Ser. Mater. Sci. Eng. 2019, 546, 042045. [Google Scholar] [CrossRef]

- Madejová, J. FTIR Techniques in Clay Mineral Studies. Vib. Spectrosc. 2003, 31, 1–10. [Google Scholar] [CrossRef]

- Ma, Y.; Zhu, J.; He, H.; Yuan, P.; Shen, W.; Liu, D. Infrared Investigation of Organo-Montmorillonites Prepared from Different Surfactants. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2010, 76, 122–129. [Google Scholar] [CrossRef]

- Sakizci, M.; Erdoğan Alver, B.; Alver, Ö.; Yörükoğullari, E. Spectroscopic and Thermal Studies of Bentonites from Ünye, Turkey. J. Mol. Struct. 2010, 969, 187–191. [Google Scholar] [CrossRef]

- Saarai, A.; Kasparkova, V.; Sedlacek, T.; Saha, P. On the Development and Characterisation of Crosslinked Sodium Alginate/Gelatine Hydrogels. J. Mech. Behav. Biomed. Mater. 2013, 18, 152–166. [Google Scholar] [CrossRef]

- Mansur, H.S.; Sadahira, C.M.; Souza, A.N.; Mansur, A.A.P. FTIR Spectroscopy Characterization of Poly (Vinyl Alcohol) Hydrogel with Different Hydrolysis Degree and Chemically Crosslinked with Glutaraldehyde. Mater. Sci. Eng. C 2008, 28, 539–548. [Google Scholar] [CrossRef]

- Rajapaksha, W.; Nicholas, I.H.W.; Thoradeniya, T.; Karunaratne, D.N.; Karunaratne, V. Novel Alginate Nanoparticles for the Simultaneous Delivery of Iron and Folate: A Potential Nano-Drug Delivery System for Anaemic Patients. RSC Pharm. 2024, 1, 259–271. [Google Scholar] [CrossRef]

- Jejurikar, A.; Seow, X.T.; Lawrie, G.; Martin, D.; Jayakrishnan, A.; Grøndahl, L. Degradable Alginate Hydrogels Crosslinked by the Macromolecular Crosslinker Alginate Dialdehyde. J. Mater. Chem. 2012, 22, 9751–9758. [Google Scholar] [CrossRef]

- Park, M.J.; Nisola, G.M.; Seo, D.H.; Wang, C.; Phuntsho, S.; Choo, Y.; Chung, W.-J.; Shon, H.K. Chemically Cross-Linked Graphene Oxide as a Selective Layer on Electrospun Polyvinyl Alcohol Nanofiber Membrane for Nanofiltration Application. Nanomaterials 2021, 11, 2867. [Google Scholar] [CrossRef]

- Dilks, A. Characterisation of Polymers by Esca. In Developments in Polymer Characterisation; Dawkins, J.V., Ed.; Springer: Dordrecht, The Netherlands, 1980; pp. 145–182. ISBN 978-94-010-9237-1. [Google Scholar]

- Wang, Y.; Gawryla, M.D.; Schiraldi, D.A. Effects of Freezing Conditions on the Morphology and Mechanical Properties of Clay and Polymer/Clay Aerogels. J. Appl. Polym. Sci. 2013, 129, 1637–1641. [Google Scholar] [CrossRef]

- Horvat, G.; Pantić, M.; Knez, Ž.; Novak, Z. A Brief Evaluation of Pore Structure Determination for Bioaerogels. Gels 2022, 8, 438. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of Gases, with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Alavarse, A.C.; Frachini, E.C.G.; da Silva, R.L.C.G.; Lima, V.H.; Shavandi, A.; Petri, D.F.S. Crosslinkers for Polysaccharides and Proteins: Synthesis Conditions, Mechanisms, and Crosslinking Efficiency, a Review. Int. J. Biol. Macromol. 2022, 202, 558–596. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Lainez, M.; Rodriguez-Perez, M.A.; DE Saja, J.A. Thermal Conductivity of Open-Cell Polyolefin Foams. J. Polym. Sci. Part B: Polym. Phys. 2008, 46, 212–221. [Google Scholar] [CrossRef]

- Cunningham, A.; Hilyard, N.C. Physical Behaviour of Polymeric Foams—an Overview. In Low Density Cellular Plastics: Physical Basis of Behaviour; Hilyard, N.C., Cunningham, A., Eds.; Springer: Dordrecht, The Netherlands, 1994; pp. 1–21. ISBN 978-94-011-1256-7. [Google Scholar]

- Bernardo, V.; Martin-de Leon, J.; Pinto, J.; Schade, U.; Rodriguez-Perez, M.A. On the Interaction of Infrared Radiation and Nanocellular Polymers: First Experimental Determination of the Extinction Coefficient. Colloids Surf. A Physicochem. Eng. Asp. 2020, 600, 124937. [Google Scholar] [CrossRef]

- LOEB, A.L. Thermal Conductivity: VIII, A Theory of Thermal Conductivity of Porous Materials. J. Am. Ceram. Soc. 1954, 37, 96–99. [Google Scholar] [CrossRef]

- Lee, G.-J.; Yoon, S.; Cho, W.-J. Effect of Bentonite Type on Thermal Conductivity in a HLW Repository. J. Nucl. Fuel Cycle Waste Technol. (JNFCWT) 2021, 19, 331–338. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Thermal, Electrical and Acoustic Properties of Foams. In Cellular Solids: Structure and Properties; Gibson, L.J., Ashby, M.F., Eds.; Cambridge Solid State Science Series; Cambridge University Press: Cambridge, UK, 1997; pp. 283–308. ISBN 978-0-521-49911-8. [Google Scholar]

- Sakai, K.; Kobayashi, Y.; Saito, T.; Isogai, A. Partitioned Airs at Microscale and Nanoscale: Thermal Diffusivity in Ultrahigh Porosity Solids of Nanocellulose. Sci. Rep. 2016, 6, 20434. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, J.-S.; Zhu, P.; Zhao, J.-C.; Zhang, C.-J.; Guo, Y.; Cui, L. Thermal Degradation Properties of Biobased Iron Alginate Film. J. Anal. Appl. Pyrolysis 2016, 119, 87–96. [Google Scholar] [CrossRef]

- Nam, S.; Easson, M.W.; Condon, B.D.; Hillyer, M.B.; Sun, L.; Xia, Z.; Nagarajan, R. A Reinforced Thermal Barrier Coat of a Na–Tannic Acid Complex from the View of Thermal Kinetics. RSC Adv. 2019, 9, 10914–10926. [Google Scholar] [CrossRef]

- Carvalho, H.W.P.; Santilli, C.V.; Briois, V.; Pulcinelli, S.H. Polymer–Clay Nanocomposites Thermal Stability: Experimental Evidence of the Radical Trapping Effect. RSC Adv. 2013, 3, 22830–22833. [Google Scholar] [CrossRef]

- Huggett, C. Estimation of Rate of Heat Release by Means of Oxygen Consumption Measurements. Fire Mater. 1980, 4, 61–65. [Google Scholar] [CrossRef]

- Reaction-to-Fire Tests – Heat release, smoke production and mass loss rate –, Parts 1–4. ISO 5660; ISO International Organization for Standardization: Geneva, Switzerland, 2015.

- Xu, Y.-J.; Qu, L.-Y.; Liu, Y.; Zhu, P. An Overview of Alginates as Flame-Retardant Materials: Pyrolysis Behaviors, Flame Retardancy, and Applications. Carbohydr. Polym. 2021, 260, 117827. [Google Scholar] [CrossRef]

- Shang, K.; Liao, W.; Wang, J.; Wang, Y.-T.; Wang, Y.-Z.; Schiraldi, D.A. Nonflammable Alginate Nanocomposite Aerogels Prepared by a Simple Freeze-Drying and Post-Cross-Linking Method. ACS Appl. Mater. Interfaces 2016, 8, 643–650. [Google Scholar] [CrossRef]

- De la Cruz, L.G.; Abt, T.; León, N.; Wang, L.; Sánchez-Soto, M. Ice-Template Crosslinked PVA Aerogels Modified with Tannic Acid and Sodium Alginate. Gels 2022, 8, 419. [Google Scholar] [CrossRef]

- Xu, H.; Li, X.; Tong, Z.; Zhang, B.; Ji, H. Thermal Radiation Shielding and Mechanical Strengthening of Mullite Fiber/SiC Nanowire Aerogels Using In Situ Synthesized SiC Nanowires. Materials 2022, 15, 3522. [Google Scholar] [CrossRef]

- Peralta, I.; Fachinotti, V.D.; Álvarez Hostos, J.C. A Brief Review on Thermal Metamaterials for Cloaking and Heat Flux Manipulation. Adv. Eng. Mater. 2020, 22, 1901034. [Google Scholar] [CrossRef]

- Cao, M.; Liu, B.-W.; Zhang, L.; Peng, Z.-C.; Zhang, Y.-Y.; Wang, H.; Zhao, H.-B.; Wang, Y.-Z. Fully Biomass-Based Aerogels with Ultrahigh Mechanical Modulus, Enhanced Flame Retardancy, and Great Thermal Insulation Applications. Compos. Part B Eng. 2021, 225, 109309. [Google Scholar] [CrossRef]

- Sun, J.; Wu, Z.; An, B.; Ma, C.; Xu, L.; Zhang, Z.; Luo, S.; Li, W.; Liu, S. Thermal-Insulating, Flame-Retardant and Mechanically Resistant Aerogel Based on Bio-Inspired Tubular Cellulose. Compos. Part B Eng. 2021, 220, 108997. [Google Scholar] [CrossRef]

- Varamesh, A.; Zhu, Y.; Hu, G.; Wang, H.; Rezania, H.; Li, Y.; Lu, Q.; Ren, X.; Jiang, F.; Bryant, S.L.; et al. Fully Biobased Thermal Insulating Aerogels with Superior Fire-Retardant and Mechanical Properties. Chem. Eng. J. 2024, 495, 153587. [Google Scholar] [CrossRef]

- Han, Z.-M.; Sun, W.-B.; Yang, K.-P.; Yang, H.-B.; Liu, Z.-X.; Li, D.-H.; Yin, C.-H.; Liu, H.-C.; Zhao, Y.-X.; Ling, Z.-C.; et al. An All-Natural Wood-Inspired Aerogel. Angew. Chem. Int. Ed. 2023, 62, e202211099. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Sun, M.; Wang, G.; Liu, Q.; Li, M.; Shulga, Y.M.; Li, Z. Aramid Pulp Reinforced Clay Aerogel Composites: Mechanical, Thermal and Combustion Behavior. Gels 2022, 8, 654. [Google Scholar] [CrossRef]

- De la Cruz, L.G.; Abt, T.; León, N.; Sánchez-Soto, M. Properties of Freeze-Dried Gelatin/Clay Aerogel Composites Crosslinked with Tannic Acid. ACS Appl. Polym. Mater. 2023, 5, 7774–7785. [Google Scholar] [CrossRef]

| Sample | C 1S (%) | N 1S (%) | O 1S (%) | O/C |

|---|---|---|---|---|

| A5 | 60.945 | 2.292 | 36.763 | 0.603 |

| A5* | 68.145 | 2.651 | 29.204 | 0.428 |

| A5C5T2* | 63.448 | 1.714 | 34.838 | 0.549 |

| Sample | E (MPa) | Esp (MPa·cm3/g) | σy (MPa) | σysp (MPa·cm3/g) | Eabs at 50% Strain (kJ/m3) |

|---|---|---|---|---|---|

| A5-R | 0.03 ± 0.01 | 0.52 ± 0.12 | - | - | 0.58 ± 0.11 |

| A5T1-R | 0.06 ± 0.04 | 0.84 ± 0.56 | - | - | 0.72 ± 0.08 |

| A5C5-R | 0.96 ± 0.21 | 9.53 ± 2.09 | 0.05 ± 0.01 | 0.49 ± 0.04 | 5.09 ± 0.15 |

| A5C5T1-R | 1.58 ± 0.50 | 14.08 ± 4.45 | 0.09 ± 0.01 | 0.81 ± 0.02 | 8.11 ± 0.80 |

| A5C5T2-R | 1.99 ± 0.50 | 15.79 ± 4.03 | 0.11 ± 0.01 | 0.87 ± 0.07 | 9.12 ± 0.63 |

| A5C5T1-X | 6.66 ± 1.28 | 54.60 ± 5.42 | 0.38 ± 0.02 | 3.17 ± 0.34 | 21.81 ± 0.99 |

| A5C5T2-X | 7.57 ± 1.69 | 57.10 ± 6.40 | 0.44 ± 0.05 | 3.34 ± 0.05 | 23.79 ± 1.88 |

| A5C5T1-X* | 47.06 ± 11.53 | 254.76 ± 51.89 | 1.06 ± 0.31 | 5.75 ± 1.46 | 57.49 ± 1.41 |

| A5C5T2-X* | 58.28 ± 8.41 | 305.29 ± 46.05 | 1.34 ± 0.03 | 7.04 ± 0.22 | 64.02 ± 2.33 |

| Sample | Tonset (°C) | Tdmax (°C) | dW/dTmax (%/°C) | WR (%) |

|---|---|---|---|---|

| A5 | 189 | 224 | 0.74 | 23.6 |

| A5T1 | 183 | 222 | 0.75 | 32.4 |

| A5C5 | 195 | 209 | 0.42 | 59.6 |

| A5C5T1 | 200 | 209 | 0.36 | 57.6 |

| A5C5T2 | 200 | 222 | 0.35 | 57.8 |

| A5C5T1* | 201 | 218 | 0.28 | 50.3 |

| A5C5T2* | 203 | 220 | 0.31 | 46.1 |

| Sample | TTI (s) | PHRR (kW/m2) | TTPHRR (s) | THR ♦ (MJ/m2) | THReff ∇ (MJ/m2·g) | FPI (kW/m2·s) | FIGRA (s·m2/kW) | MARHE (kW/m2) | WR (%) |

|---|---|---|---|---|---|---|---|---|---|

| A5 | 11 | 84.4 | 33 | 4.0 | 1.07 | 0.13 | 2.56 | 36.17 | 1.48 |

| A5T1 | 21 | 76.4 | 42 | 8.6 | 1.81 | 0.27 | 1.82 | 42.26 | 1.51 |

| A5C5 | No Flame | 42.3 | 45 | 5.7 | 0.92 | - | 0.94 | 29.96 | 42.69 |

| A5C5T1 | No Flame | 27.7 | 69 | 3.8 | 0.41 | - | 0.40 | 16.99 | 43.26 |

| A5C5T2 | No Flame | 21.1 | 87 | 3.0 | 0.34 | - | 0.24 | 13.79 | 39.64 |

| A5C5T1* | 6 | 67.4 | 39 | 7.7 | 0.85 | 0.09 | 1.73 | 47.97 | 34.35 |

| A5C5T2* | 8 | 59.7 | 42 | 9.3 | 0.89 | 0.13 | 1.42 | 50.58 | 23.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De la Cruz, L.G.; Abt, T.; León, N.; Sánchez-Soto, M. Radially and Axially Oriented Ammonium Alginate Aerogels Modified with Clay/Tannic Acid and Crosslinked with Glutaraldehyde. Gels 2024, 10, 526. https://doi.org/10.3390/gels10080526

De la Cruz LG, Abt T, León N, Sánchez-Soto M. Radially and Axially Oriented Ammonium Alginate Aerogels Modified with Clay/Tannic Acid and Crosslinked with Glutaraldehyde. Gels. 2024; 10(8):526. https://doi.org/10.3390/gels10080526

Chicago/Turabian StyleDe la Cruz, Lucía G., Tobias Abt, Noel León, and Miguel Sánchez-Soto. 2024. "Radially and Axially Oriented Ammonium Alginate Aerogels Modified with Clay/Tannic Acid and Crosslinked with Glutaraldehyde" Gels 10, no. 8: 526. https://doi.org/10.3390/gels10080526