Experimental and Numerical Investigation on Oil Displacement Mechanism of Weak Gel in Waterflood Reservoirs

Abstract

:1. Introduction

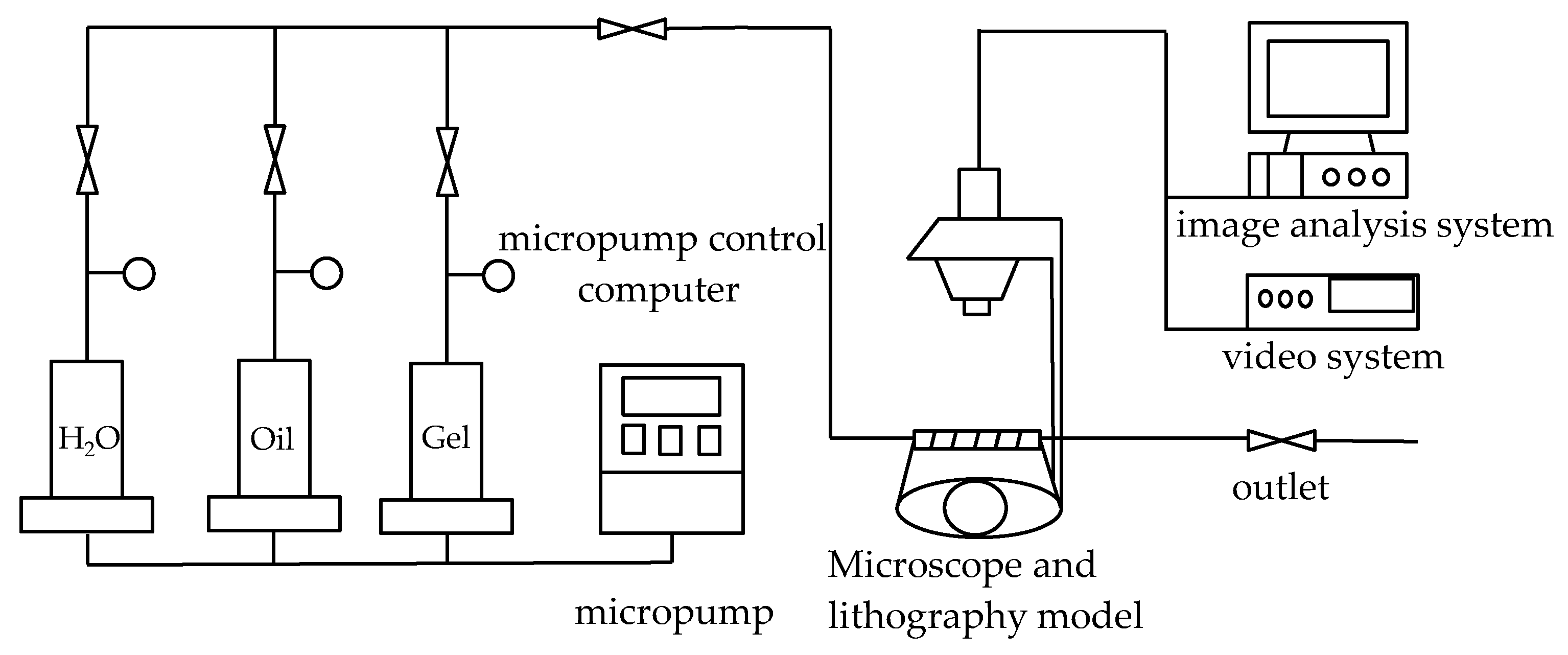

2. Experiment

2.1. Experimental Equipment and Materials

2.2. Experimental Procedure

- Preparing the weak gel system required by the experiment: 0.4 g polymer was added into 200 mL produced formation water and stirred for 1 h. Then 0.9 g crosslinking agent and 0.2 g stabilizer were added to the solution and stirred for 1 h.

- Filtering the crude oil to avoid blocking the model.

- Saturating oil after the model is vacuumed.

- Water flooding (constant speed 0.03 mL/h), observe the microscopic seepage process in the process of water flooding, and film the distribution and morphology of residual oil in the micro model until no oil is produced by water flooding.

- Injecting 0.3 PV weak gel system into the lithography model while recording the microscopic oil displacement process by micro-camera.

- Placing the lithographic model in a 45 °C incubator for 2 h, and wait for the weak gel system to gel.

- The photolithography model was displaced by subsequent water until no oil was produced in the model. The microscopic oil flooding process was recorded by micro-camera.

- Image analysis.

- Cleaning the visualized model and preparing for the next experiment.

3. Analysis of Experimental Results

3.1. Phenomenon Description

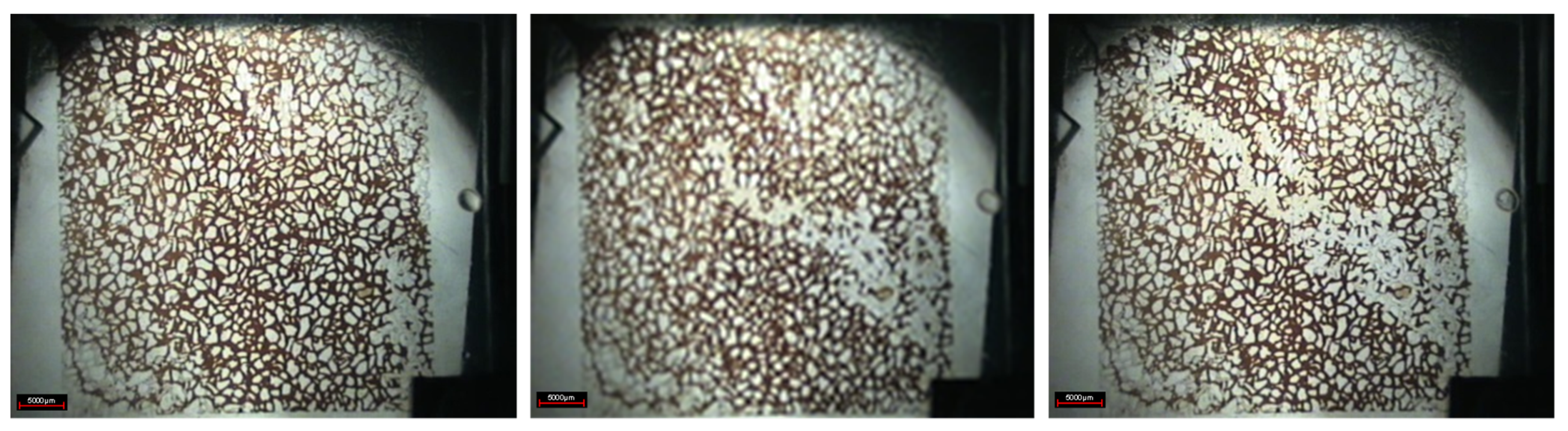

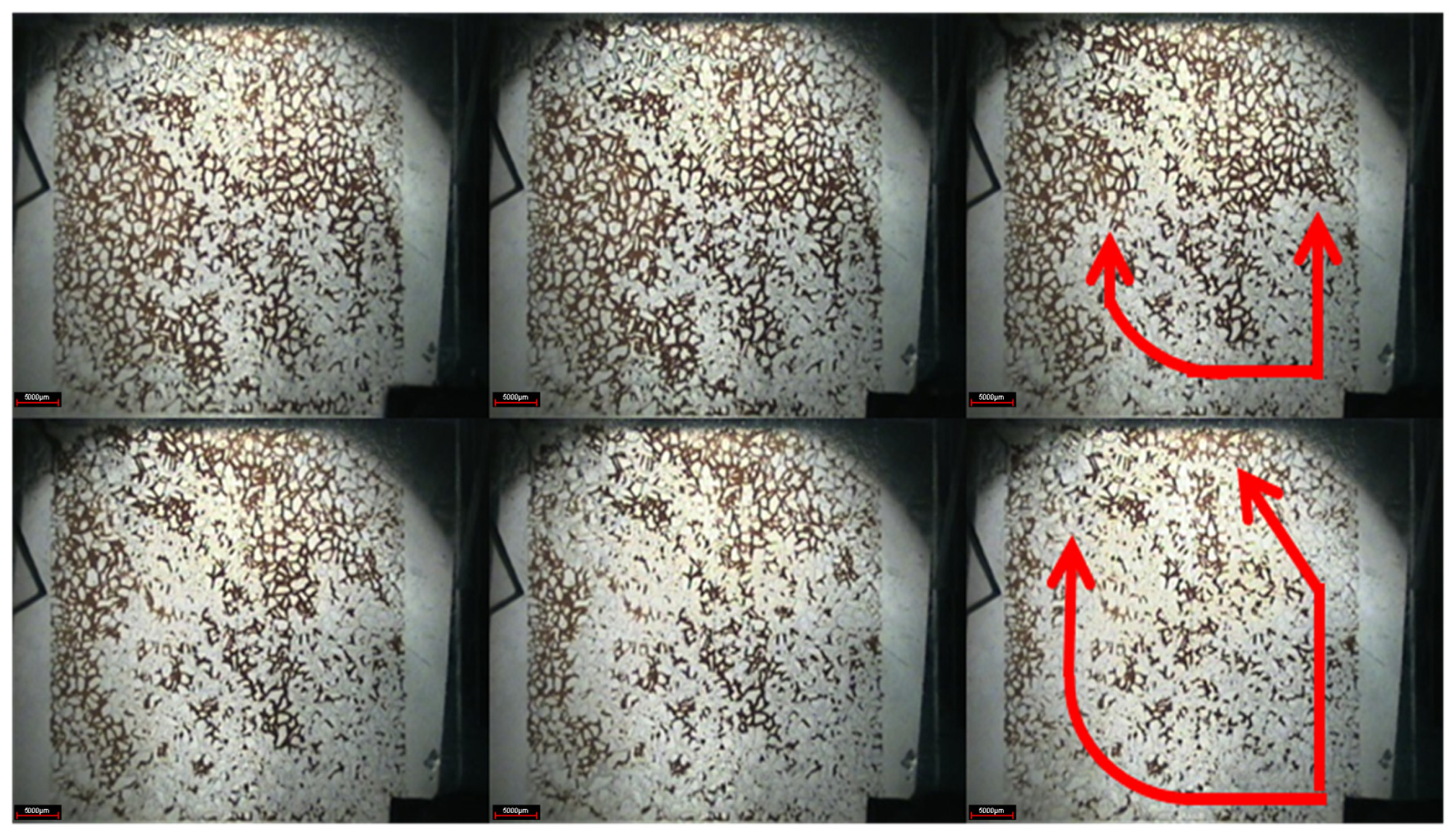

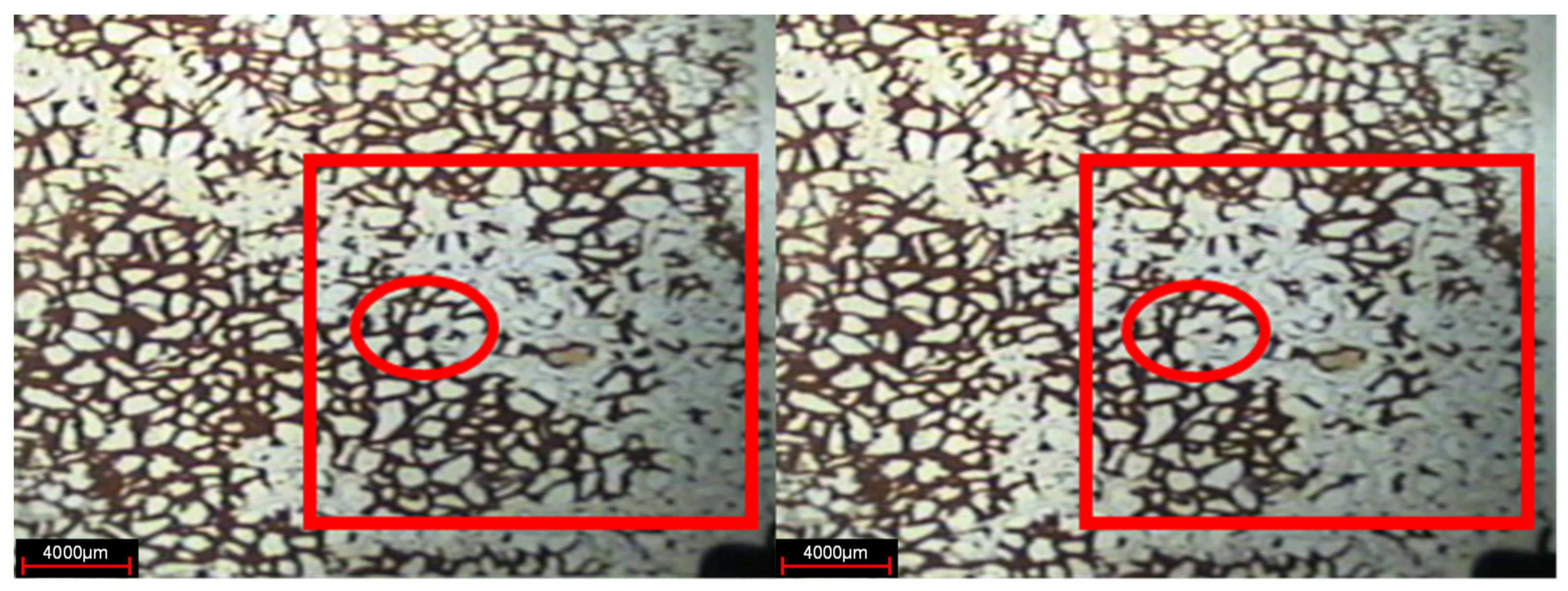

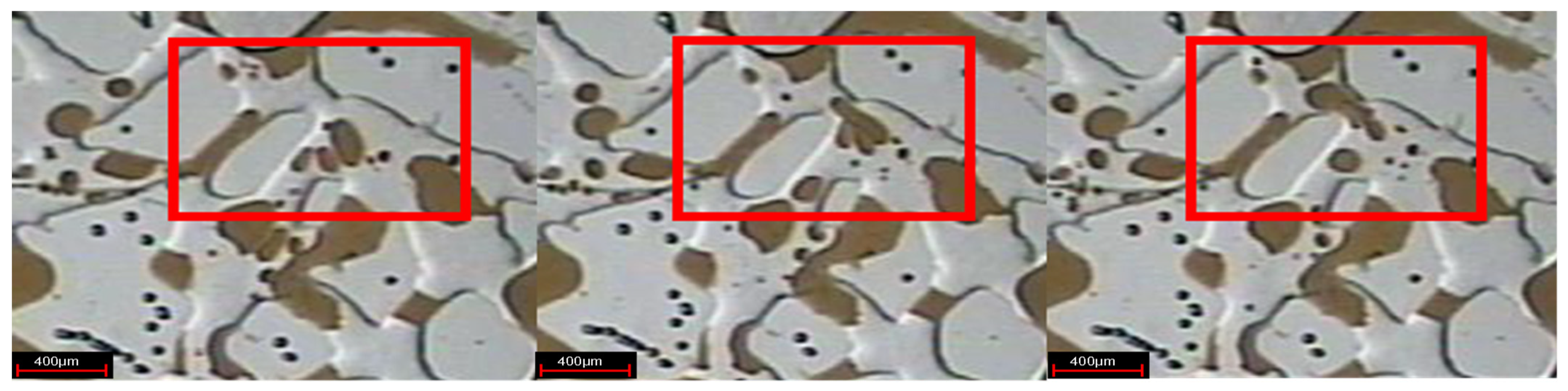

3.1.1. Oil Displacement Dynamics and Residual Oil Types in Water Flooding Stage

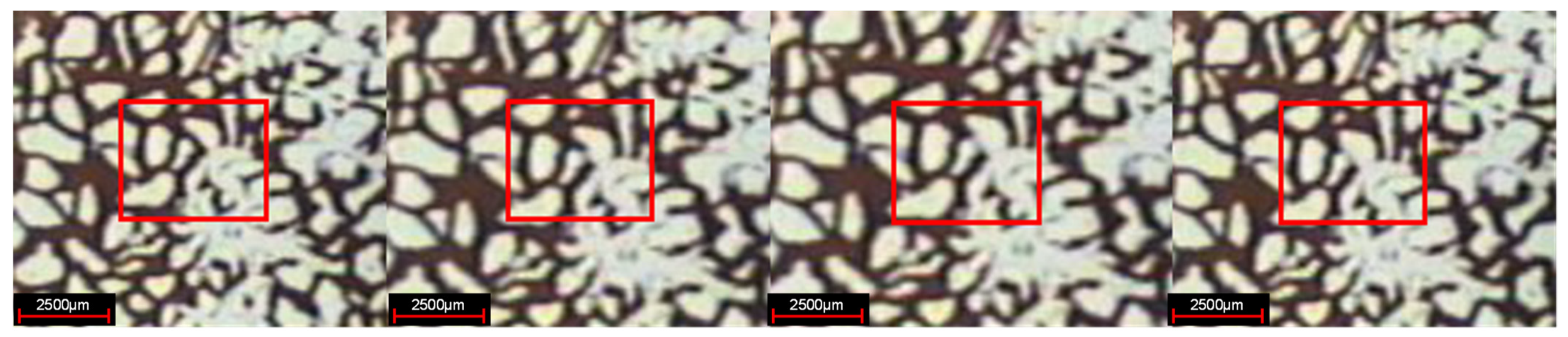

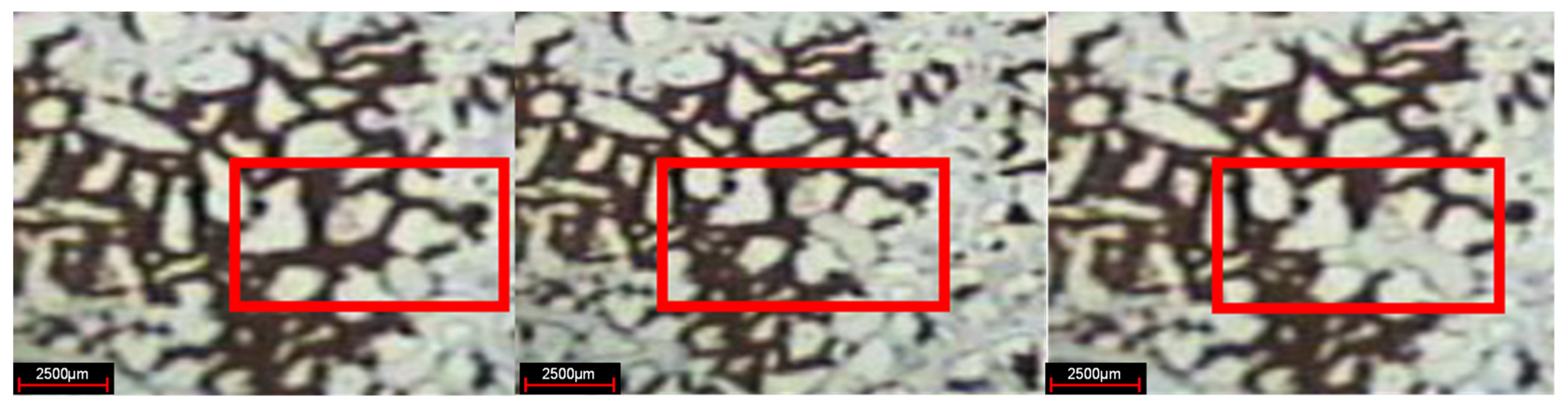

3.1.2. Oil Displacement Dynamics and Residual Oil Characteristics in Weak Gel Injection Stage

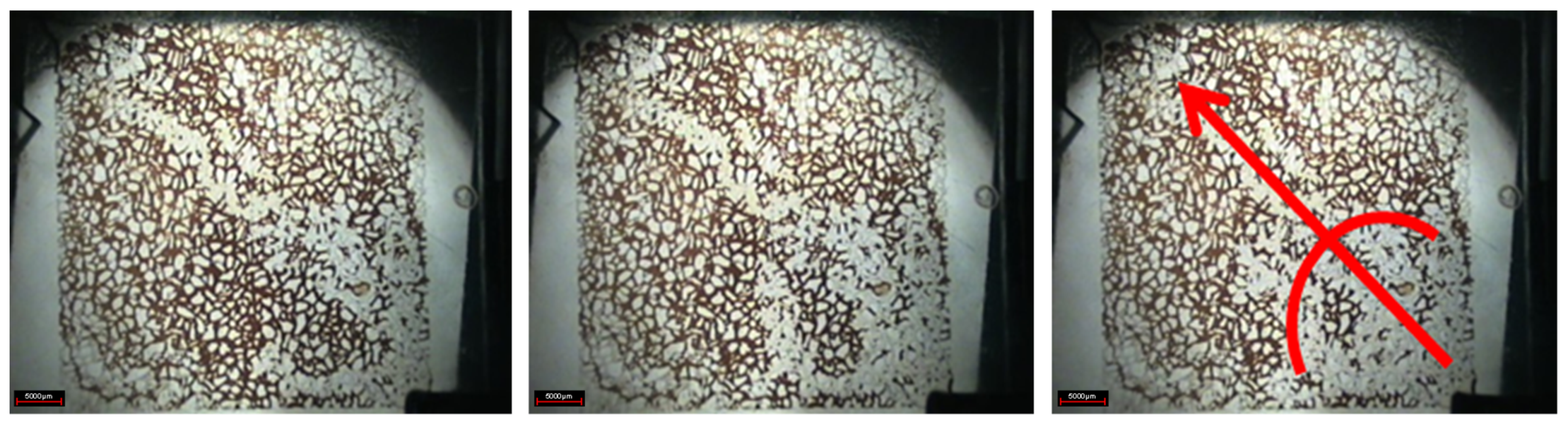

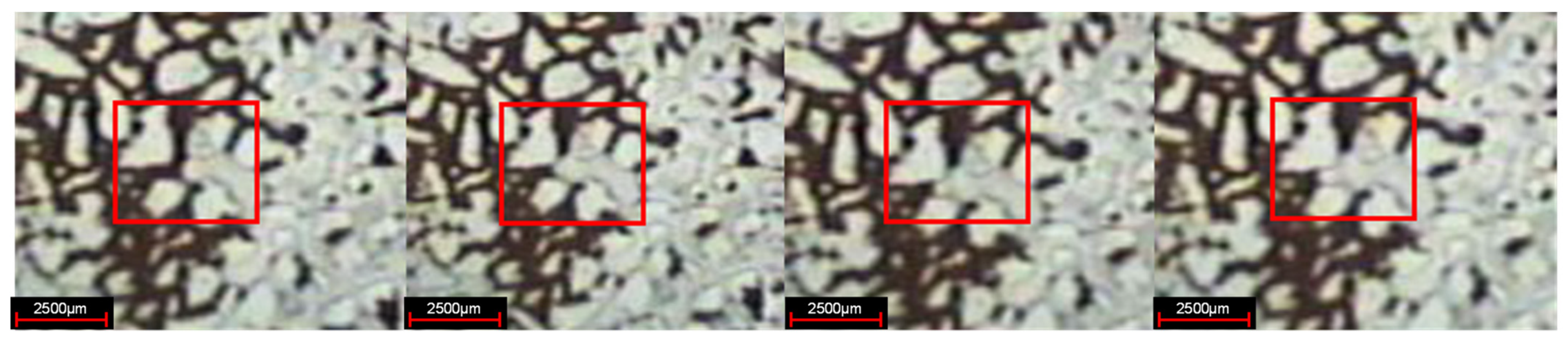

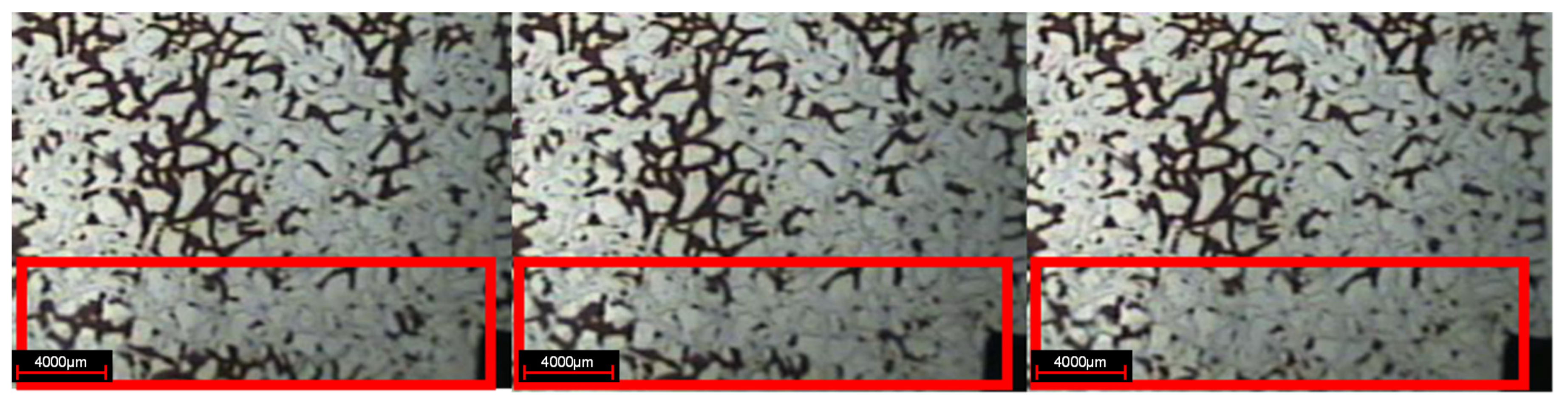

3.1.3. Oil Displacement Dynamics and Residual Oil Characteristics in Subsequent Water Flooding Stage

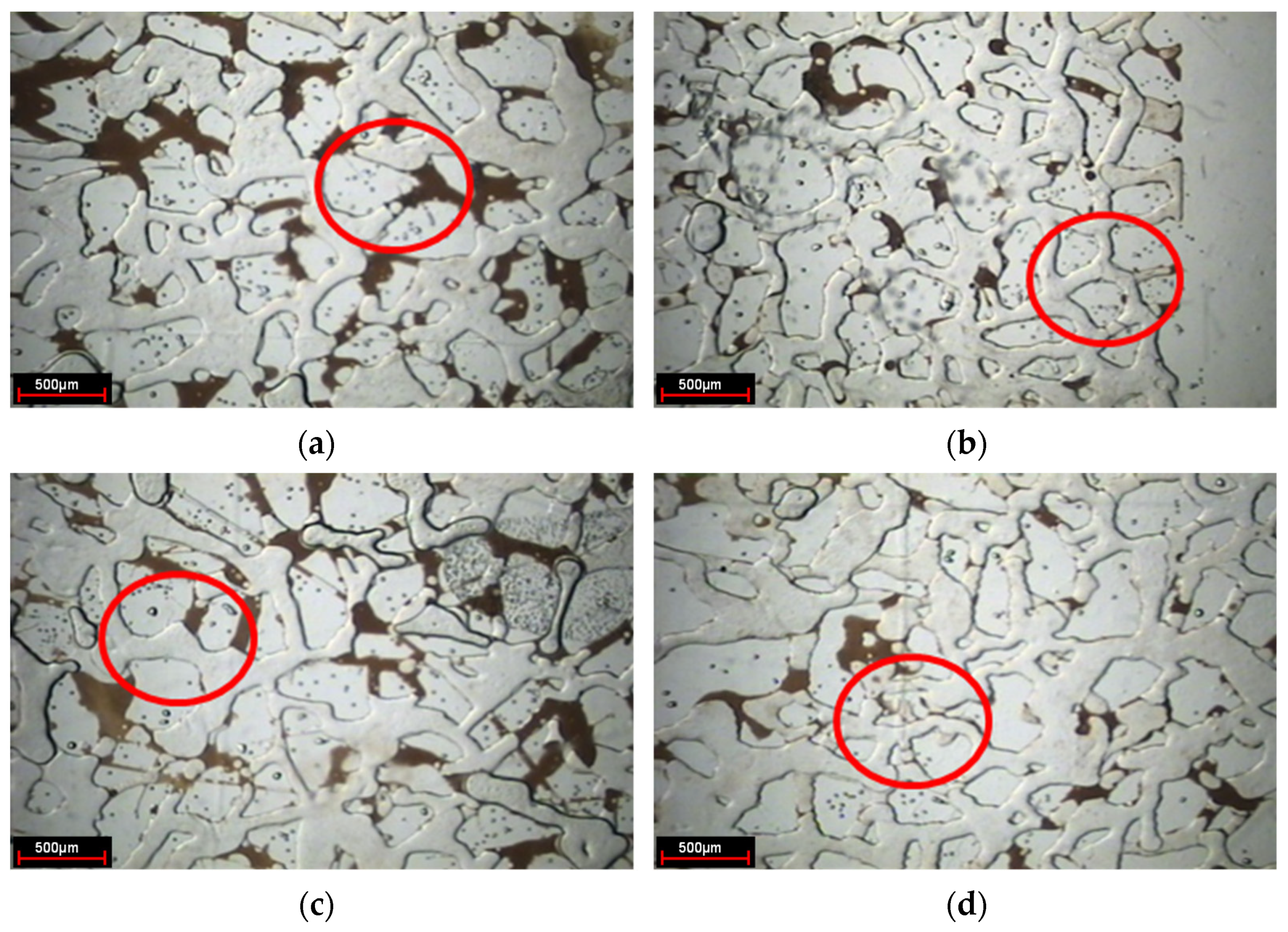

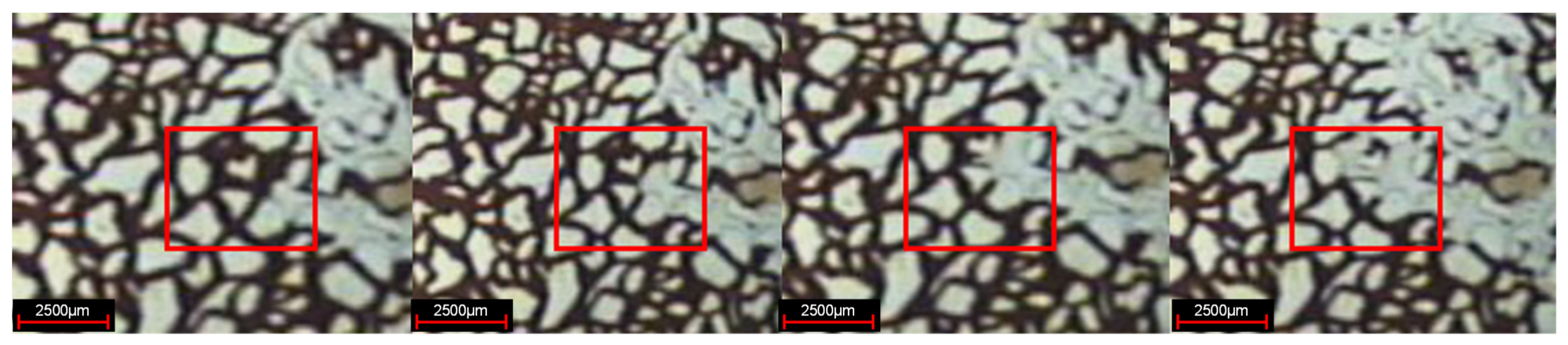

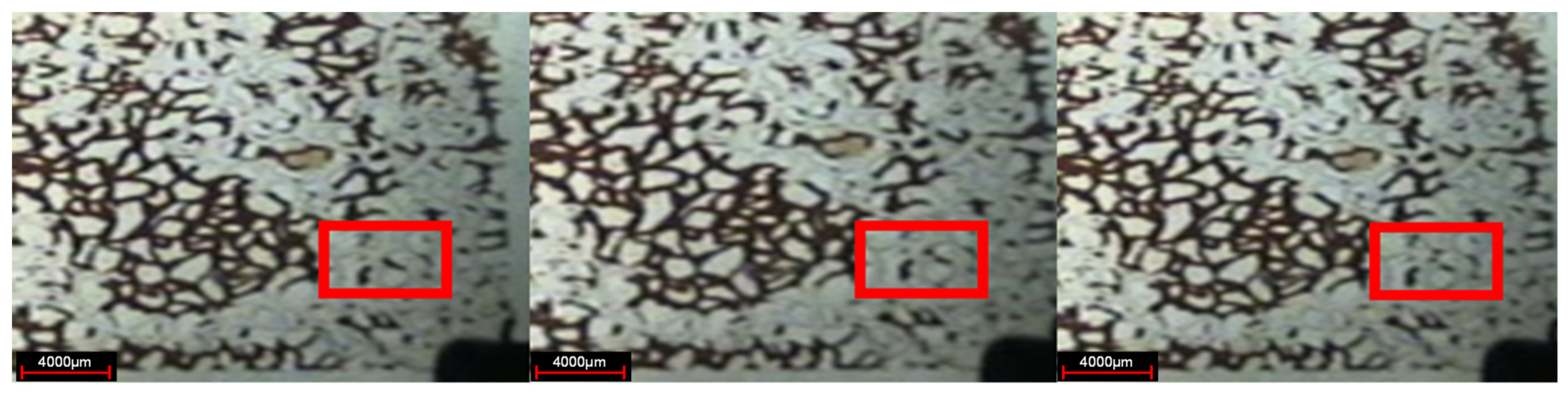

3.1.4. Description of Local Oil Displacement

3.2. The Porous Flow Mechanism

- Preferential plugging of large channels

- 2.

- The integral and staged transport of weak gel

- 3.

- The residual oil flow along pore walls in weak gel displacement

3.3. The Profile-Control Mechanism

- The weak gel selectively enters the large pore channels

- 2.

- The gelation blocks the large pore channels and diverts the subsequent water flow direction

- 3.

- The viscoelastic gelation moves integrally to absorb oil by negative pressure

- 4.

- Oil droplets converge to form oil stream

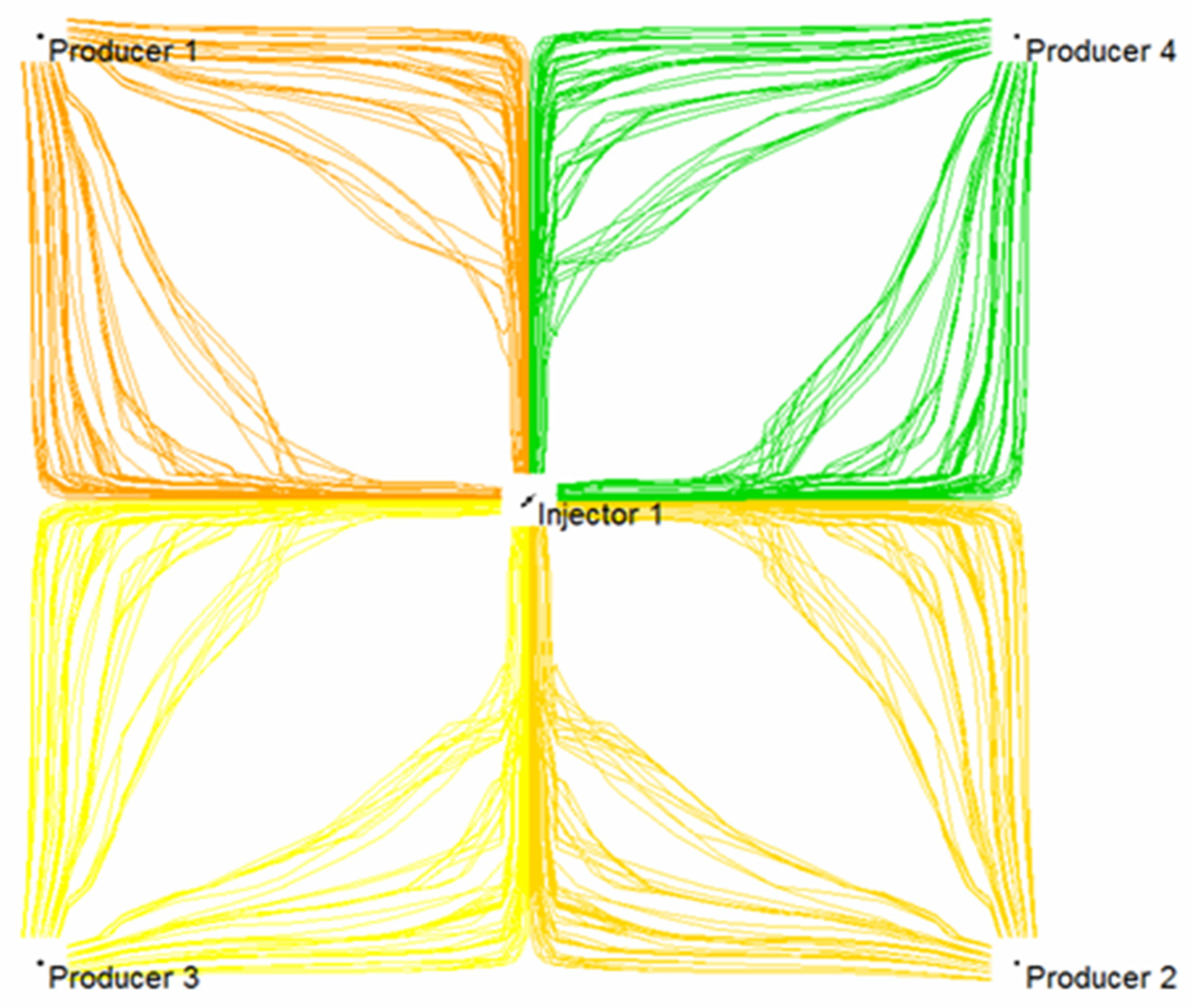

4. Numerical Simulation

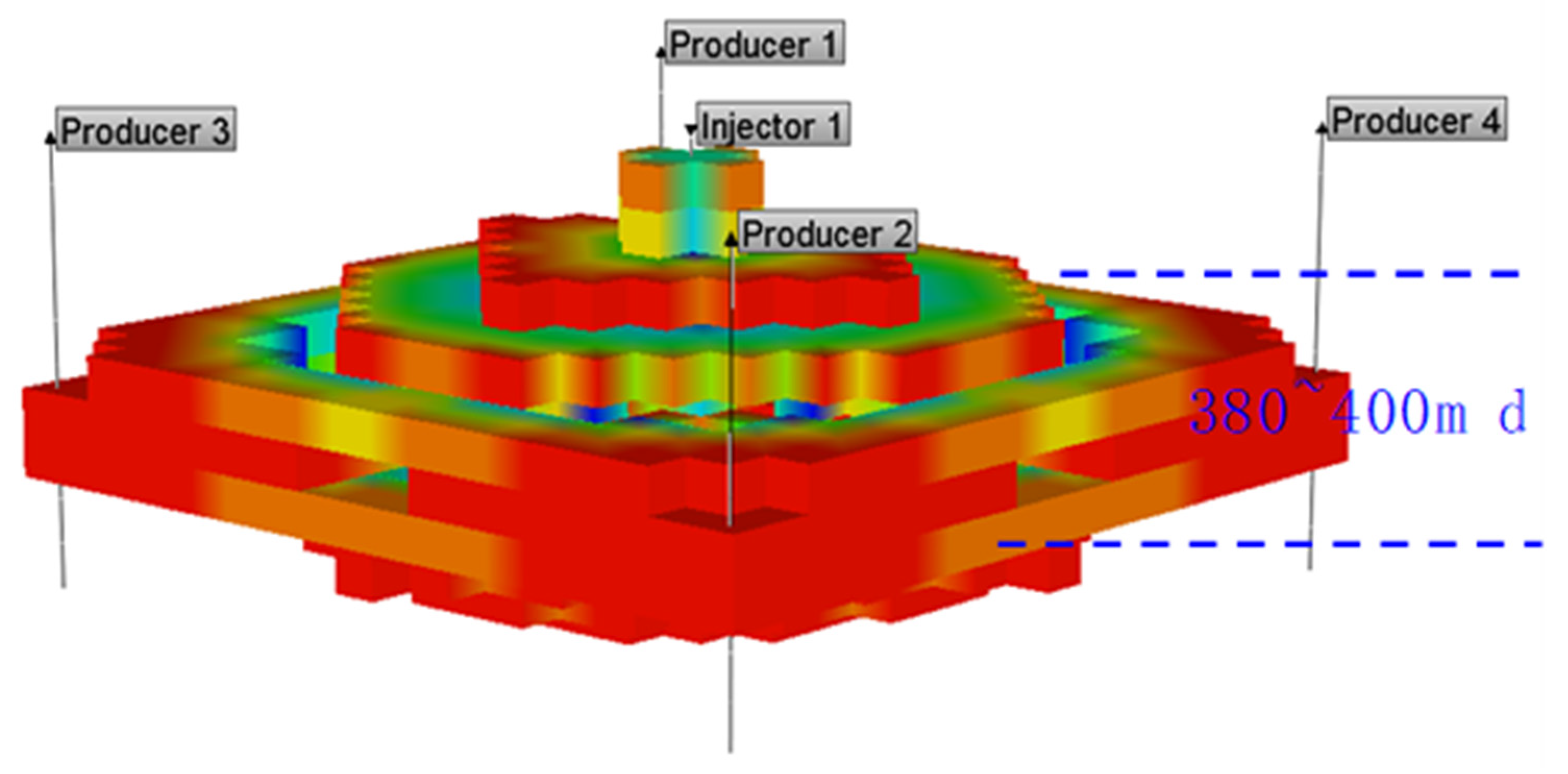

4.1. Simulation Model Parameters

4.2. Equations Influencing Weak Gel Displacement Dynamics

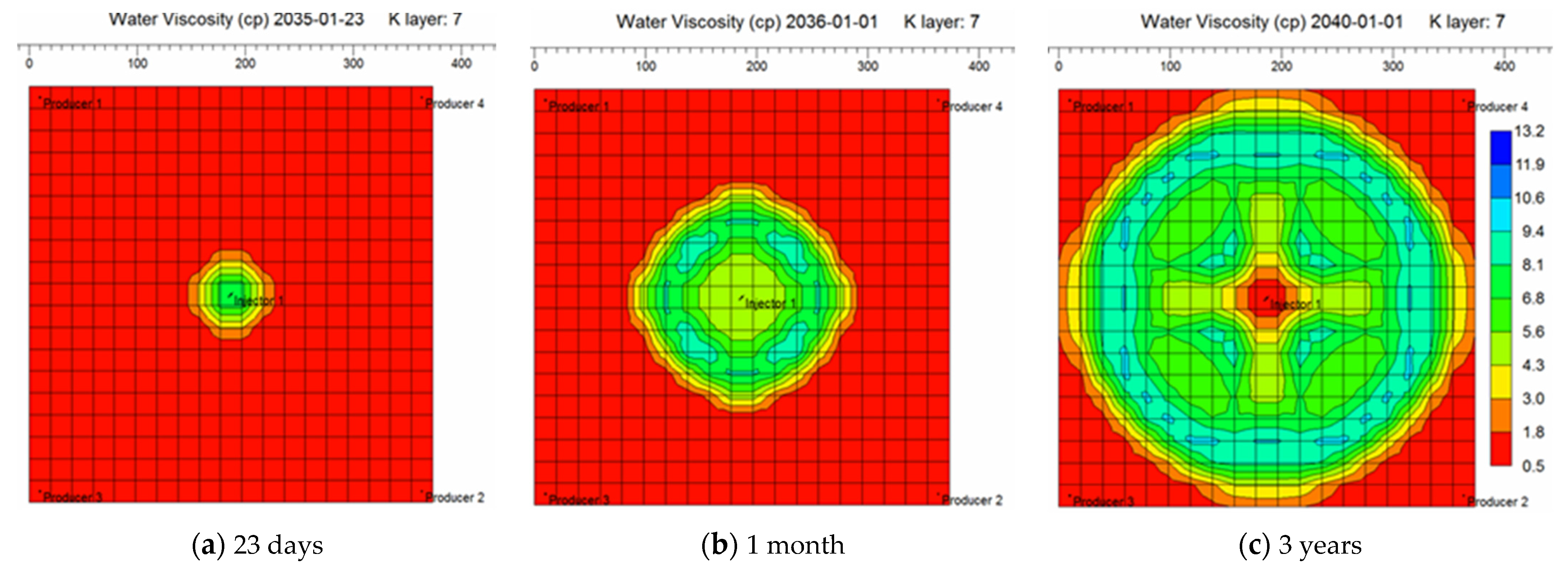

4.3. Dynamics of Weak Gel Injection

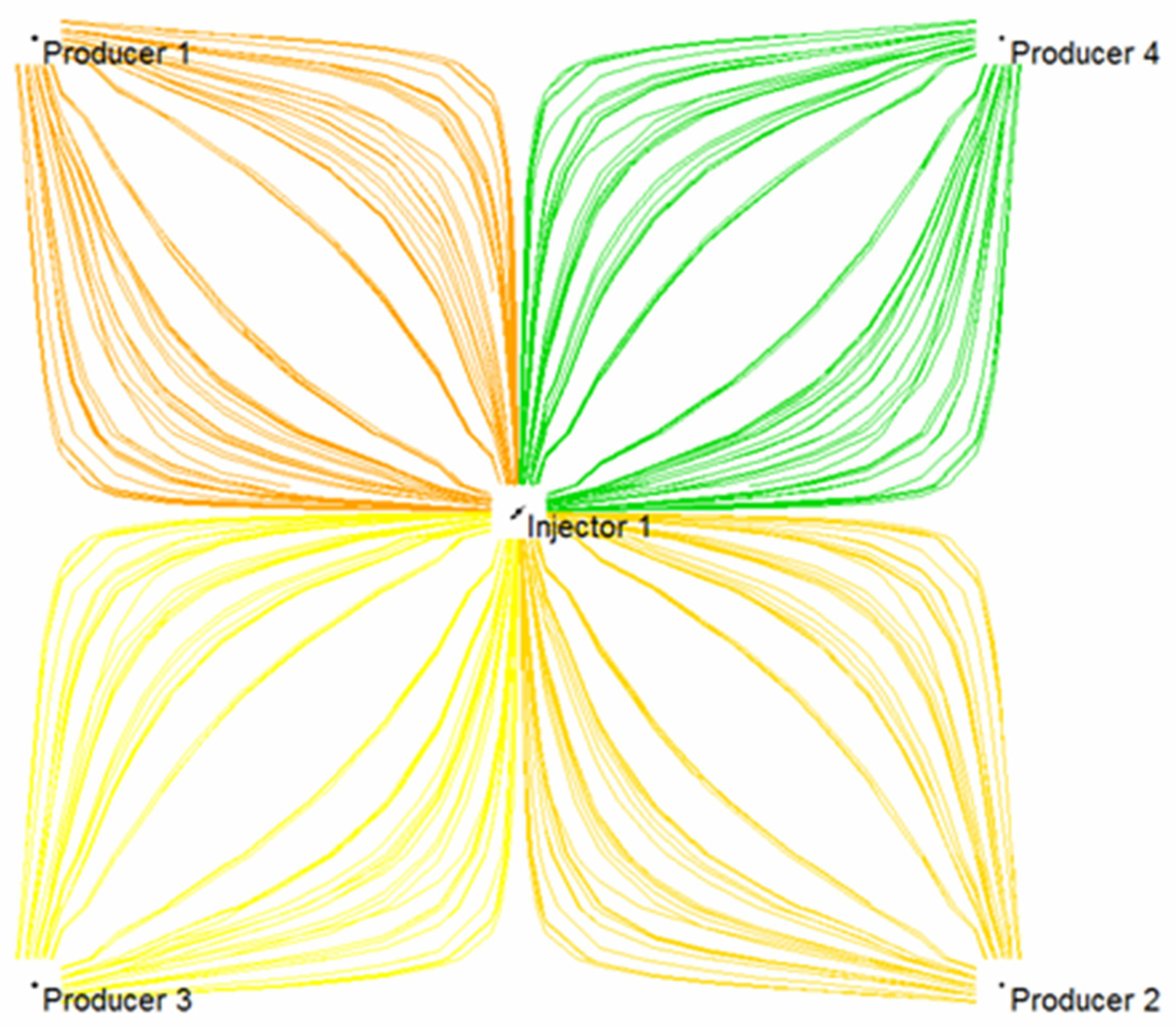

4.4. Diversion of Subsequent Water Flooding

5. Conclusions

- By analyzing the distribution patterns of residual oil in pores and throat through visualized microscopic oil displacement experiments at different stages, the residual oil of initial water flooding mainly exists in the form of cluster, column, dead end, and membranous, and it mainly exists in the form of cluster and dead end in subsequent water flooding stage following weak gel injection.

- The porous flow mechanism of weak gel includes the preferential plugging of large channels, the integral and staged transport of weak gel, and the residual oil flow along pore walls in weak gel displacement.

- The profile-control mechanism of weak gel is as follows: weak gel selectively enters the large channels, weak gel blocks large channels and forces subsequent water flow to change direction, weak gel uses viscoelastic bulk motion to form negative pressure oil absorption, and the oil droplets converge to form an oil stream, respectively.

- Numerical simulation coupling equations characterizing weak gel viscosity induced dynamics indicate that weak gel can effectively reduce the water-oil mobility ratio, preferentially block the high permeability layer and the large pore channels, divert the subsequent water to flood the low permeability layer, and improve the water injection swept efficiency. A weak gel system is able to flow forward under high-pressure difference, which can further improve oil displacement efficiency besides flow diversion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Xiong, C.; Luo, J. Studies on indepth fluid diverting in oil reservoirs at high water cut stages. Oilfield Chem. 2006, 23, 248–251. [Google Scholar]

- Yu, J. Study on reservoir property change in the late stage of waterflooding development in Daqing Oilfield. Oil Gas Field Surf. Eng. 2007, 26, 15–16. [Google Scholar]

- Zhao, X.; Yang, M.; Zhang, L.; Liu, L. Research progress of deep profile control technology in oilfield. Chem. Sci. Technol. 2015, 5, 75–79. [Google Scholar]

- Lu, X.; Ca, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 169–178. [Google Scholar] [CrossRef]

- El-Karsani, K.S.M.; Al-Muntasheri, G.A.; Hussein, I.A. Polymer Systems for Water Shutoff and Profile Modification: A Review over the Last Decade. SPE J. 2014, 19, 135–149. [Google Scholar] [CrossRef]

- Quezada, G.R.; Toro, N.; Saavedra, J.H.; Robles, P.; Salazar, I.; Navarra, A.; Jeldres, R.I. Molecular Dynamics Study of the Conformation, Ion Adsorption, Diffusion and Water Structure of Soluble Polymers in Saline Solutions. Polymers 2021, 13, 3550. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H. Dynamic Weak-Gel Profile-Control in Conventional Heavy-Oil Reservoir. Spec. Oil Gas Reserv. 2018, 25, 125–128. [Google Scholar]

- Jia, H. Research on deep profile control and water shutoff technology in Daqing Oilfield based on geology. China Pet. Chem. Stand. Qual. 2019, 39, 250–252. [Google Scholar]

- Cui, C.; Zhou, Z.; He, Z. Enhance oil recovery in low permeability reservoirs: Optimization and evaluation of ultra-high molecular weight HPAM/phenolic weak gel system. J. Pet. Sci. Eng. 2020, 195, 107908. [Google Scholar] [CrossRef]

- Akbar, I.; Hongtao, Z. The opportunities and challenges of preformed particle gel in enhanced oil recovery. Recent Innov. Chem. Eng. (Former. Recent Pat. Chem. Eng.) 2020, 13, 290–302. [Google Scholar] [CrossRef]

- Al-Lbadi, A.; Civan, F. Experimental Investigation and Correlation of Treatment in Weak and High-Permeability Formations by Use of Gel Particles. SPE Prod. Oper. 2013, 28, 387–401. [Google Scholar]

- Li, Z.; Zhao, G.; Xiang, C. Synthesis and Properties of a Gel Agent with a High Salt Resistance for Use in Weak-Gel-Type Water-Based Drilling Fluid. Arab. J. Sci. Eng. 2022, 1–11. [Google Scholar] [CrossRef]

- Williamson, N.H.; Dower, A.M.; Codd, S.L.; Broadbent, A.L.; Gross, D.; Seymour, J.D. Glass Dynamics and Domain Size in a Solvent-Polymer Weak Gel Measured by Multidimensional Magnetic Resonance Relaxometry and Diffusometry. Phys. Rev. Lett. 2019, 122, 068001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diaz, D.; Somaruga, C.; Norman, C.; Romero, J.L. Colloidal Dispersion Gels Improve Oil Recovery in a Heterogeneous Argentina Waterflood. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Qi, Y.B.; Zheng, C.G.; Lv, C.Y.; Lun, Z.M.; Ma, T. Compatibility between weak gel and microorganisms in weak gel-assisted microbial enhanced oil recovery. J. Biosci. Bioeng. 2018, 126, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, S.; Zou, Y.; Zhang, X.; Ma, X.; Wu, S.; Zhang, Z.; Sun, Z.; Liu, C. Experimental study on the feasibility of supercritical CO2-gel fracturing for stimulating shale oil reservoirs. Eng. Fract. Mech. 2020, 238, 107276. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, J. Study on performance evaluation of weak gel control flooding system. China Dly. Chem. Ind. 2019, 49, 87–91. [Google Scholar]

- Pi, Y. Performance evaluation and influence factors of weak gel. Hangzhou Chem. Ind. 2021, 51, 10–12. [Google Scholar]

- Ji, G.; Li, H.; Wu, X.; Xu, C.; Li, X. Performance of weak gel plugging high permeability zone and conditions for starting low permeability layer. Sci. Technol. Eng. 2017, 17, 204–209. [Google Scholar]

- Li, Y.; Su, Y.; Ma, K.; Wang, L. Numerical simulation of indoor displacement experiments in weak gel. Daqing Pet. Geol. Dev. 2014, 33, 117–120. [Google Scholar]

- Zhang, Y. Study on influence factors of gelling performance of weak gel flooding system. Oil Gas Reserv. Eval. Dev. 2013, 3, 50–53. [Google Scholar]

- Zhao, G.; Dai, C.; You, Q. Characteristics and displacement mechanisms of the dispersed particle gel soft heterogeneous compound flooding system. Pet. Explor. Dev. 2018, 45, 481–490. [Google Scholar] [CrossRef]

- Di, Q.; Zhang, J.; Hua, S.; Chen, H.; Gu, C. Visualization experiments on polymer-weak gel profile control and displacement by NMR technique. Pet. Explor. Dev. 2017, 44, 294–298. [Google Scholar] [CrossRef]

- Hua, S.; Di, Q.; Wang, W.; Yang, P.; Zhang, J.; Ye, F. Study on weak gel’s mobility in porous media using nuclear reasonable technique. Spec. Top. Rev. Porous Media 2018, 9, 13–20. [Google Scholar] [CrossRef]

| Reservoir Parameters | Parameter Value |

|---|---|

| Reservoir top depth (m) | 1400 |

| Permeability (mD) | 50, 55, 60, 80, 380, 400, 390, 180, 100, 50 |

| Porosity (%) | 0.23 |

| Original formation pressure (MPa) | 16 |

| Reservoir Parameters | Parameter Value |

|---|---|

| Underground oil viscosity (mPa·s) | 8 |

| Surface crude oil density (kg/m3) | 860 |

| Water viscosity (mPa·s) | 0.5 |

| Oil volume coefficient (m3/m3) | 1.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, H.; Zheng, X.; Wu, Y.; Zhang, J.; Zhao, X.; Li, C. Experimental and Numerical Investigation on Oil Displacement Mechanism of Weak Gel in Waterflood Reservoirs. Gels 2022, 8, 309. https://doi.org/10.3390/gels8050309

Cheng H, Zheng X, Wu Y, Zhang J, Zhao X, Li C. Experimental and Numerical Investigation on Oil Displacement Mechanism of Weak Gel in Waterflood Reservoirs. Gels. 2022; 8(5):309. https://doi.org/10.3390/gels8050309

Chicago/Turabian StyleCheng, Hongjie, Xianbao Zheng, Yongbin Wu, Jipeng Zhang, Xin Zhao, and Chenglong Li. 2022. "Experimental and Numerical Investigation on Oil Displacement Mechanism of Weak Gel in Waterflood Reservoirs" Gels 8, no. 5: 309. https://doi.org/10.3390/gels8050309

APA StyleCheng, H., Zheng, X., Wu, Y., Zhang, J., Zhao, X., & Li, C. (2022). Experimental and Numerical Investigation on Oil Displacement Mechanism of Weak Gel in Waterflood Reservoirs. Gels, 8(5), 309. https://doi.org/10.3390/gels8050309