An Insight into Pasting and Rheological Behavior of Potato Starch Pastes and Gels with Whole and Ground Chia Seeds

Abstract

:1. Introduction

2. Results and Discussion

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Methods

4.2.1. Chemical Analyses of Chia Seeds

4.2.2. Pasting Characteristics

4.2.3. Flow Measurements

4.2.4. Textural Properties

4.3. Statistics

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Swinkels, J.J.M. Composition and properties of commercial native starches. Starch-Stärke 1985, 37, 1–5. [Google Scholar] [CrossRef]

- Nakorn, K.N.; Tongdang, T.; Sirivongpaisal, P. Crystallinity and Rheological Properties of Pregelatinized Rice Starches Differing in Amylose Content. Starch-Stärke 2009, 61, 101–108. [Google Scholar] [CrossRef]

- Leszczyński, W.; Zięba, T.; Prośba-Białczyk, U.; Mydlarski, M. Wpływ Sposobu Uprawy Ograniczającego Rozwój Zarazy Ziemniaka Na Zawartość i Właściwości Skrobi. Żywność. Nauka Technol. Jakość 2000, 4, 84–90. [Google Scholar]

- Lewandowicz, J.; Baranowska, H.M.; Szwengiel, A.; Thanh-Blicharz, J.L. Molecular Structure vs. Functional Properties of Waxy and Normal Corn Starch. In Proceedings of the 12th International Conference on Polysaccharides-Glycoscience, Prague, Czech Republic, 21 October 2016; pp. 19–21. [Google Scholar]

- Tegge, G. Skrobia i Jej Pochodne, 1st ed.; Polskie Towarzystwo Technologii Żywności, Oddział Małopolski: Kraków, Poland, 2010. [Google Scholar]

- Małyszek, Z.; Lewandowicz, J.; Le Thanh-Blicharz, J.; Walkowiak, K.; Kowalczewski, P.Ł.; Baranowska, H.M. Water Behavior of Emulsions Stabilized by Modified Potato Starch. Polymers 2021, 13, 2200. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, Paste, and Gel Properties of Starch–Hydrocolloid Combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making Sense of the “Clean Label” Trends: A Review of Consumer Food Choice Behavior and Discussion of Industry Implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef] [PubMed]

- Bearth, A.; Cousin, M.-E.; Siegrist, M. The Consumer’s Perception of Artificial Food Additives: Influences on Acceptance, Risk and Benefit Perceptions. Food Qual. Prefer. 2014, 38, 14–23. [Google Scholar] [CrossRef]

- Rownan, A. Increasing Consumer Confidence and Driving Value through Clean Label Claims Globally. In Proceedings of the Euromonitor to Speak at Clean Label Conference, Itasca, IL, USA, 25 February 2017. [Google Scholar]

- Capitani, M.I.; Spotorno, V.; Nolasco, S.M.; Tomás, M.C. Physicochemical and Functional Characterization of By-Products from Chia (Salvia hispanica L.) Seeds of Argentina. LWT-Food Sci. Technol. 2012, 45, 94–102. [Google Scholar] [CrossRef]

- Cahill, J.P. Ethnobotany of Chia, Salvia hispanica L. (Lamiaceae). Econ. Bot. 2003, 57, 604–618. [Google Scholar] [CrossRef]

- Jiménez, F.E.G.; Beltrán-Orozco, M.C.; Martínez, M.G.V. The Antioxidant Capacity and Phenolic Content of Chía’s (Salvia Hispánica L.). Integral Seed and Oil. J. Biotechnol. 2010, 150, 315. [Google Scholar] [CrossRef]

- Ayerza, R.; Coates, W. Protein Content, Oil Content and Fatty Acid Profiles as Potential Criteria to Determine the Origin of Commercially Grown Chia (Salvia hispanica L.). Ind. Crops Prod. 2011, 34, 1366–1371. [Google Scholar] [CrossRef]

- Coates, W. Chapter 37—Whole and Ground Chia (Salvia hispanica L.) Seeds, Chia Oil—Effects on Plasma Lipids and Fatty Acids. In Nuts and Seeds in Health and Disease Prevention; Elsevier: London, UK, 2011; pp. 309–315. [Google Scholar] [CrossRef]

- Reyes-Caudillo, E.; Tecante, A.; Valdivia-López, M.A. Dietary Fibre Content and Antioxidant Activity of Phenolic Compounds Present in Mexican Chia (Salvia hispanica L.) Seeds. Food Chem. 2008, 107, 656–663. [Google Scholar] [CrossRef]

- European Parliament and of the Council. Commission Decision of 13 October 2009 Authorising the Placing on the Market of Chia Seed (Salvia hispanica) as Novel Food Ingredient under Regulation (EC) No 258/97 of the European Parliament and of the Council. Off. J. Eur. Union 2009, 14–15. [Google Scholar]

- Lin, K.-Y.; Daniel, J.R.; Whistler, R.L. Structure of Chia Seed Polysaccharide Exudate. Carbohydr. Polym. 1994, 23, 13–18. [Google Scholar] [CrossRef]

- Goh, K.K.T.; Matia-Merino, L.; Chiang, J.H.; Quek, R.; Soh, S.J.B.; Lentle, R.G. The Physico-Chemical Properties of Chia Seed Polysaccharide and Its Microgel Dispersion Rheology. Carbohydr. Polym. 2016, 149, 297–307. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Ovando, A.; Rosado-Rubio, G.; Chel-Guerrero, L.; Betancur-Ancona, D. Physicochemical Properties of a Fibrous Fraction from Chia (Salvia hispanica L.). LWT-Food Sci. Technol. 2009, 42, 168–173. [Google Scholar] [CrossRef]

- Fernandes, S.S.; Salas-Mellado, M. de las M. Addition of Chia Seed Mucilage for Reduction of Fat Content in Bread and Cakes. Food Chem. 2017, 227, 237–244. [Google Scholar] [CrossRef]

- European Parliament and of the Council. Commission Implementing Decision of 22 January 2013 Authorising an Extension of Use of Chia (Salvia hispanica) Seed as a Novel Food Ingredient under Regulation (EC) No 258/97 of the European Parliament and of the Council. Off. J. Eur. Union 2013, 34–35. [Google Scholar]

- Akman, F.; Kazachenko, A.S.; Vasilyeva, N.Y.; Malyar, Y.N. Synthesis and Characterization of Starch Sulfates Obtained by the Sulfamic Acid-Urea Complex. J. Mol. Struct. 2020, 1208, 127899. [Google Scholar] [CrossRef]

- Sikora, M.; Dobosz, A.; Krystyjan, M.; Adamczyk, G.; Tomasik, P.; Berski, W.; Kutyła-Kupidura, E.M. Thixotropic Properties of the Normal Potato Starch—Locust Bean Gum Blends. Lwt 2017, 75, 590–598. [Google Scholar] [CrossRef]

- Baranowska, H.; Sikora, M.; Kowalski, S.; Tomasik, P. Interactions of Potato Starch with Selected Polysaccharide Hydrocolloids as Measured by Low-Field NMR. Food Hydrocoll. 2008, 22, 336–345. [Google Scholar] [CrossRef]

- Kowalski, S.; Sikora, M.; Tomasik, P.; Krystyjan, M. Starch Polysaccharide Hydrocolloid Gels. Polimery 2008, 53, 457–464. [Google Scholar] [CrossRef] [Green Version]

- Timilsena, Y.P.; Adhikari, R.; Kasapis, S.; Adhikari, B. Molecular and Functional Characteristics of Purified Gum from Australian Chia Seeds. Carbohydr. Polym. 2016, 136, 128–136. [Google Scholar] [CrossRef] [PubMed]

- Orona-Tamayo, D.; Valverde, M.E.; Paredes-López, O. Chia—The New Golden Seed for the 21st Century: Nutraceutical Properties and Technological Uses. In Sustainable Protein Sources; Elsevier: London, UK, 2017; pp. 265–281. [Google Scholar] [CrossRef]

- US Department of Agriculture, Agricultural Research Service. Nutrient Data Laboratory. In USDA National Nutrient Database for Standard Reference; Release 28 (Slightly revised); Version Current: May 2016; US Department of Agriculture: Washington, DC, USA, 2016. Available online: http://www.ars.usda.gov/nea/bhnrc/mafcl (accessed on 16 August 2022).

- Knez Hrnčič, M.; Ivanovski, M.; Cör, D.; Knez, Ž. Chia Seeds (Salvia hispanica L.): An Overview—Phytochemical Profile, Isolation Methods, and Application. Molecules 2020, 25, 11. [Google Scholar] [CrossRef] [PubMed]

- Deka, R.; Das, A. Advances in Chia Seed Research. Adv. Biotech. Micro. 2017, 5, 555661. [Google Scholar] [CrossRef]

- Kulczyński, B.; Kobus-Cisowska, J.; Taczanowski, M.; Kmiecik, D.; Gramza-Michałowska, A. The Chemical Composition and Nutritional Value of Chia Seeds—Current State of Knowledge. Nutrients 2019, 11, 1242. [Google Scholar] [CrossRef] [PubMed]

- Antonini, E.; Torri, L.; Piochi, M.; Cabrino, G.; Meli, M.A.; De Bellis, R. Nutritional, Antioxidant and Sensory Properties of Functional Beef Burgers Formulated with Chia Seeds and Goji Puree, before and after in vitro Digestion. Meat Sci. 2020, 161, 108021. [Google Scholar] [CrossRef] [PubMed]

- Palka, A.; Wilczyńska, A.; Flis, M. Wpływ Dodatku Nasion Oleistych Na Zawartość Podstawowych Składników Odżywczych w Koktajlach Mleczno-Owocowych Oraz Na Ich Kwasowość. Probl. Hig. Epidemiol. 2017, 98, 334–339. [Google Scholar]

- Kobus-Cisowska, J.; Kmiecik, D.; Flaczyk, E.; Jędrusek-Golińska, A.; Szymandera-Buszka, K.; Hęś, M. Ocena wpływu nasion chia na jakość sensoryczną batonów zbożowych. Bromatol. Chem. Toksykol. 2016, 49, 526–530. [Google Scholar]

- Grancieri, M.; Martino, H.S.D.; Gonzalez de Mejia, E. Chia Seed (Salvia hispanica L.) as a Source of Proteins and Bioactive Peptides with Health Benefits: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 480–499. [Google Scholar] [CrossRef] [PubMed]

- Coates, W.; Ayerza, R. Production Potential of Chia in Northwestern Argentina. Ind. Crops Prod. 1996, 5, 229–233. [Google Scholar] [CrossRef]

- Ullah, R.; Nadeem, M.; Khalique, A.; Imran, M.; Mehmood, S.; Javid, A.; Hussain, J. Nutritional and Therapeutic Perspectives of Chia (Salvia hispanica L.): A Review. J. Food Sci. Technol. 2016, 53, 1750–1758. [Google Scholar] [CrossRef] [PubMed]

- Urbizo-Reyes, U.; San Martin-González, M.F.; Garcia-Bravo, J.; López Malo Vigil, A.; Liceaga, A.M. Physicochemical Characteristics of Chia Seed (Salvia hispanica) Protein Hydrolysates Produced Using Ultrasonication Followed by Microwave-Assisted Hydrolysis. Food Hydrocoll. 2019, 97, 105187. [Google Scholar] [CrossRef]

- Noshe, A.S.; Al-Bayyar, A.H. Effect of Extraction Method of Chia Seeds Oil on Its Content of Fatty Acids and Antioxidants. Int. Res. J. Eng. Technol. 2017, 4, 545–551. [Google Scholar]

- Ashura, K.-K.; Lillian, D.K.; Oscar, K.; Leonard, M.P.R. Nutritional, Health Benefits and Usage of Chia Seeds (Salvia hispanica): A Review. Afr. J. Food Sci. 2021, 15, 48–59. [Google Scholar] [CrossRef]

- Mañas, E.; Bravo, L.; Saura-Calixto, F. Sources of Error in Dietary Fibre Analysis. Food Chem. 1994, 50, 331–342. [Google Scholar] [CrossRef]

- da Silva Marineli, R.; Lenquiste, S.A.; Moraes, É.A.; Maróstica, M.R., Jr. Antioxidant Potential of Dietary Chia Seed and Oil (Salvia hispanica L.) in Diet-Induced Obese Rats. Int. Food Res. J. 2015, 76, 666–674. [Google Scholar] [CrossRef]

- Marcinek, K.; Krejpcio, Z. Chia Seeds (Salvia hispanica): Health Promoting Properties and Therapeutic Applications—A Review. Rocz. Panstw. Zakl. Hig. 2017, 68, 123–129. [Google Scholar]

- Suri, S.; Passi, S.J.; Goyat, J. Chia Seed (Salvia hispanica L.)—A New Age Functional Food. In Proceedings of the 4th International Conference on Recent Innovations in Science Engineering and Management, New Delhi, India, 20 March 2016; Volume 4, pp. 286–299. [Google Scholar]

- Sikora, M.; Tomasik, P.; Krystyjan, M. Characterization of Potato Starch Fractions and Their Interaction with Hydrocolloids. Starch-Stärke 2010, 62, 341–349. [Google Scholar] [CrossRef]

- Sikora, M.; Adamczyk, G.; Krystyjan, M.; Dobosz, A.; Tomasik, P.; Berski, W.; Lukasiewicz, M.; Izak, P. Thixotropic Properties of Normal Potato Starch Depending on the Degree of the Granules Pasting. Carbohydr. Polym. 2015, 121, 254–264. [Google Scholar] [CrossRef]

- Segura-Campos, M.R.; Ciau-Solís, N.; Rosado-Rubio, G.; Chel-Guerrero, L.; Betancur-Ancona, D. Chemical and Functional Properties of Chia Seed (Salvia hispanica L.) Gum. Int. J. Food Sci. 2014, 2014, 241053. [Google Scholar] [CrossRef] [PubMed]

- Punia, S.; Dhull, S.B. Chia Seed (Salvia hispanica L.) Mucilage (a Heteropolysaccharide): Functional, Thermal, Rheological Behaviour and Its Utilization. Int. J. Biol. Macromol. 2019, 140, 1084–1090. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, L.A.; Cobos, A.; Diaz, O.; Aguilera, J.M. Chia Seeds: Microstructure, Mucilage Extraction and Hydration. J. Food Eng. 2012, 108, 216–224. [Google Scholar] [CrossRef]

- Berski, W.; Krystyjan, M.; Buksa, K.; Zięć, G.; Gambuś, H. Chemical, Physical and Rheological Properties of Oat Flour Affected by the Isolation of Beta-Glucan Preparation. J. Cereal Sci. 2014, 60, 533–539. [Google Scholar] [CrossRef]

- McPherson, A.; Jane, J. Comparison of Waxy Potato with Other Root and Tuber Starches. Carbohydr. Polym. 1999, 40, 57–70. [Google Scholar] [CrossRef]

- Wasteffeng, L.Z.; White, P.J. Structure and Physicochemical Properties of Starches from Oats with Different Lipid Contents. Cereal Chem. 1994, 71, 443–450. [Google Scholar]

- Berski, W. Wybrane Właściwości Fizykochemiczne Skrobi Wyizolowanych z Polskich Odmian i Rodów Owsa Nagoziarnistego. Żywność Nauka Technol. Jakość 2010, 3, 76–87. [Google Scholar]

- Yildiz, Ö.; Yurt, B.; Baştürk, A.; Toker, Ö.S.; Yilmaz, M.T.; Karaman, S.; Dağlıoğlu, O. Pasting Properties, Texture Profile and Stress–Relaxation Behavior of Wheat Starch/Dietary Fiber Systems. Food Res. Int. 2013, 53, 278–290. [Google Scholar] [CrossRef]

- Adamczyk, G.; Krystyjan, M.; Jaworska, G. The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch. Polymers 2020, 12, 321. [Google Scholar] [CrossRef]

- Thirathumthavorn, D.; Charoenrein, S. Thermal and Pasting Properties of Native and Acid-Treated Starches Derivatized by 1-Octenyl Succinic Anhydride. Carbohydr. Polym. 2006, 66, 258–265. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering, 2nd ed.; Freeman Press: East Lansing, MI, USA, 1996. [Google Scholar]

- Adamczyk, G.; Sikora, M.; Krystyjan, M. Methods of Measuring Thixotropic Food Products. Żywność Nauka Technol. Jakość 2012, 3, 19–34. [Google Scholar] [CrossRef]

- Campanella, O.H.; Dorward, N.M.; Singh, H. A Study of the Rheological Properties of Concentrated Food Emulsions. J. Food Eng. 1995, 25, 427–440. [Google Scholar] [CrossRef]

- Schramm, G. A Practical Approach to Rheology and Rheometry, 2nd ed.; Thermo Electron (Karlsruhe) GmbH: Karlsruhe, Germany, 2004. [Google Scholar]

- Muller, F.L.; Pain, J.P.; Villon, P. On the Behaviour of Non-Newtonian Liquids in Collinear Ohmic Heaters. In Proceedings of the International Heat Transfer Conference 10, Brighton, UK, 14–18 August 1994; Begellhouse: Brighton, UK, 1994; pp. 285–290. [Google Scholar] [CrossRef]

- Samavati, V.; Skandari, F. Recovery, Chemical and Rheological Characterization of Gum from Assyrian Pulm. Int. J. Biol. Macromol. 2014, 67, 172–179. [Google Scholar] [CrossRef]

- Tavares, L.S.; Junqueira, L.A.; de Oliveira Guimarães, Í.C.; de Resende, J.V. Cold Extraction Method of Chia Seed Mucilage (Salvia hispanica L.): Effect on Yield and Rheological Behavior. J. Food Sci. Technol. 2018, 55, 457–466. [Google Scholar] [CrossRef] [PubMed]

- Karim, A.A.; Norziah, M.H.; Seow, C.C. Methods for the Study of Starch Retrogradation. Food Chem. 2000, 71, 9–36. [Google Scholar] [CrossRef]

- Karam, L.B.; Grossmann, M.V.E.; Silva, R.S.S.F.; Ferrero, C.; Zaritzky, N.E. Gel Textural Characteristics of Corn, Cassava and Yam Starch Blends: A Mixture Surface Response Methodology Approach. Starch-Stärke 2005, 57, 62–70. [Google Scholar] [CrossRef]

- Huang, M.; Kennedy, J.F.; Li, B.; Xu, X.; Xie, B.J. Characters of Rice Starch Gel Modified by Gellan, Carrageenan, and Glucomannan: A Texture Profile Analysis Study. Carbohydr. Polym. 2007, 69, 411–418. [Google Scholar] [CrossRef]

- Sandhu, K.; Singh, N. Some Properties of Corn Starches II: Physicochemical, Gelatinization, Retrogradation, Pasting and Gel Textural Properties. Food Chem. 2007, 101, 1499–1507. [Google Scholar] [CrossRef]

- Krystyjan, M.; Adamczyk, G.; Sikora, M.; Tomasik, P. Long-Term Storage Stability of Selected Potato Starch—Non-Starchy Hydrocolloid Binary Gels. Food Hydrocoll. 2013, 31, 270–276. [Google Scholar] [CrossRef]

- Vandeputte, G.E.; Vermeylen, R.; Geeroms, J.; Delcour, J.A. Rice Starches. III. Structural Aspects Provide Insight in Amylopectin Retrogradation Properties and Gel Texture. J. Cereal Sci. 2003, 38, 61–68. [Google Scholar] [CrossRef]

- Tako, M.; Tamaki, Y.; Teruya, T.; Takeda, Y. The Principles of Starch Gelatinization and Retrogradation. Food Nutr. Sci. 2014, 5, 280–291. [Google Scholar] [CrossRef]

- Gambuś, H.; Gumul, D. Charakterystyka Żeli Sporządzonych Ze Skrobi Wyodrębnionej z Niedojrzałych Zbóż. Acta Sci. Pol. Technol. Aliment. 2004, 3, 33–43. [Google Scholar]

- Pietrzyk, S.; Fortuna, T. Wpływ Rodzaju Skrobi i Warunków Jej Utleniania Na Retrogradację. Żywność Nauka Technol. Jakość 2005, 2, 23–32. [Google Scholar]

- Dobosz, A.; Sikora, M.; Krystyjan, M.; Tomasik, P.; Lach, R.; Borczak, B.; Berski, W.; Lukasiewicz, M. Short- and Long-Term Retrogradation of Potato Starches with Varying Amylose Content: Retrogradation of Potato Starches with Varying Amylose Content. J. Sci. Food Agric. 2019, 99, 2393–2403. [Google Scholar] [CrossRef]

- Fredriksson, H.; Silverio, J.; Andersson, R.; Eliasson, A.-C.; Åman, P. The Influence of Amylose and Amylopectin Characteristics on Gelatinization and Retrogradation Properties of Different Starches. Carbohydr. Polym. 1998, 35, 119–134. [Google Scholar] [CrossRef]

- Hoover, R. Composition, Molecular Structure, and Physicochemical Properties of Tuber and Root Starches: A Review. Carbohydr. Polym. 2001, 45, 253–267. [Google Scholar] [CrossRef]

- Zhang, W.; Jackson, D.S. Retrogradation Behavior of Wheat Starch Gels with Differing Molecular Profiles. J. Food Sci. 1992, 57, 1428–1432. [Google Scholar] [CrossRef]

| Sample | T0 [°C] | ηmax [B.U.] | ηmin [B.U.] | η95 °C [B.U.] | η95 °C after 5 min [B.U.] | BD [B.U.] | η50 °C [B.U.] |

|---|---|---|---|---|---|---|---|

| 5%PS | 64.0 ± 0.1 a | 1802.0 ± 11.3 a | 733.0 ± 7.1 b | 983.0 ± 18.4 a | 806.5 ± 10.6 bc | 1069.0 ± 18.4 a | 927.5 ± 7.8 b |

| 5%PS + 1%CHw | 61.1 ± 0.1 c | 1047.0 ± 36.8 b | 816.5 ± 33.2 a | 1000.5 ± 36.1 a | 887.5 ± 40.3 a | 230.5 ± 3.5 b | 1037.0 ± 36.8 a |

| 5%PS + 1%CHg | 62.1 ± 0.1 b | 748.0 ± 25.5 c | 768.0 ± 25.5 b | 805.5 ± 7.8 b | 825.0 ± 2.8 ab | 70.0 ± 17.0 c | 1039.0 ± 4.2 a |

| Sample | T0 [°C] | ηmax [B.U.] | ηmin [B.U.] | η95 °C [B.U.] | η95 °C after 5 min [B.U.] | BD [B.U.] | η50 °C [B.U.] |

|---|---|---|---|---|---|---|---|

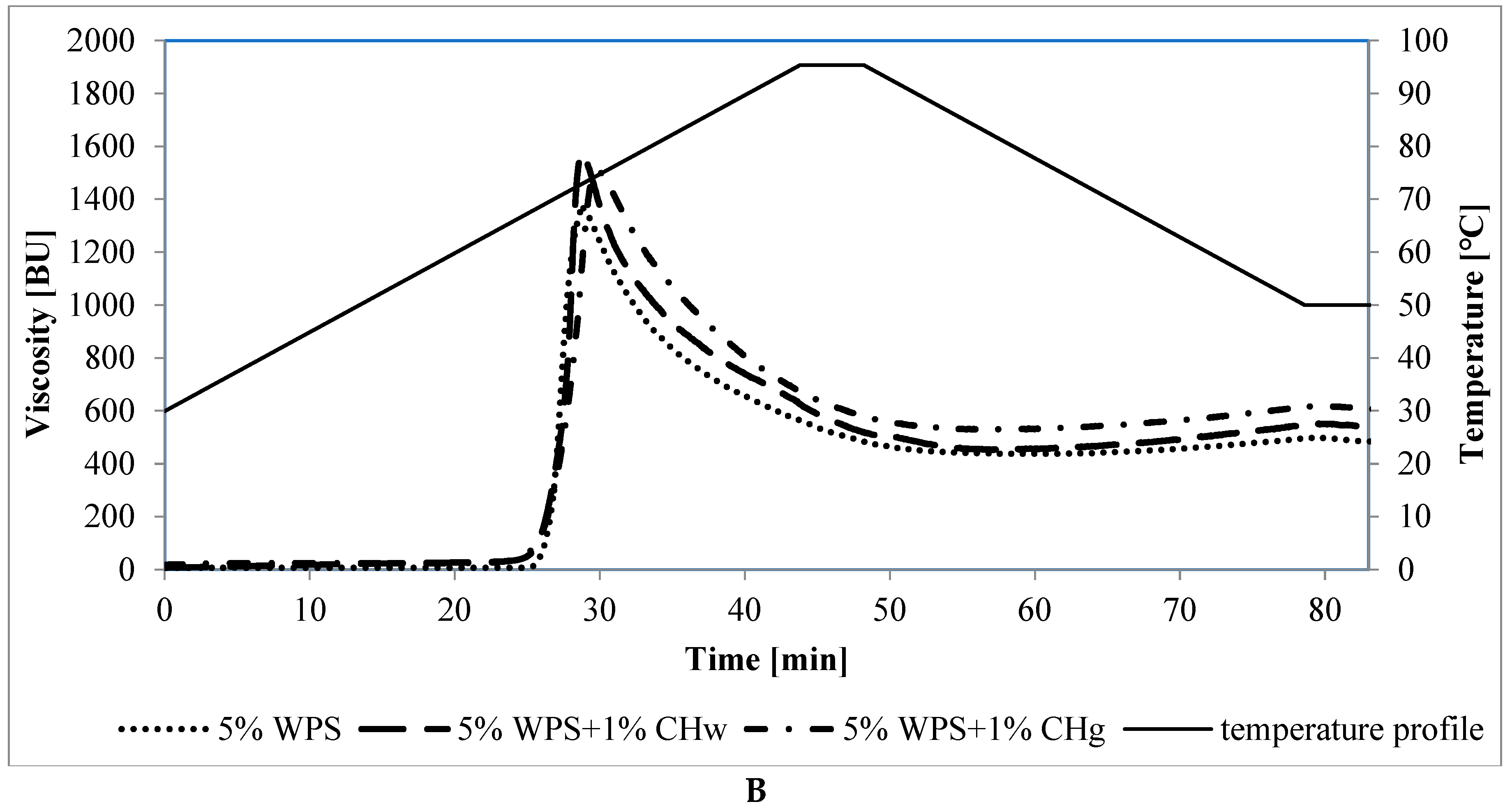

| 5%WPS | 67.6 ± 0.1 a | 1386.5 ± 0.7 c | 436.0 ± 1.4 b | 575.5 ± 3.5 c | 483.0 ± 5.7 c | 950.5 ± 2.1 b | 483.0 ± 0.0 c |

| 5%WPS + 1%CHw | 62.2 ± 0.6 c | 1576.0 ± 26.9 b | 452.0 ± 8.5 b | 645.0 ± 2.8 b | 517.5 ± 5.0 b | 1124 ± 18.4 a | 539.5 ± 6.4 b |

| 5%WPS + 1%CHg | 64.1 ± 0.5 b | 1509.0 ± 5.7 a | 528.0 ± 2.1 a | 687.5 ± 3.5 a | 578.5 ± 2.1 a | 980.5 ± 7.8 b | 607.5 ± 3.5 a |

| Sample | K (Pa∙sn) | n (-) | R2 | |||

|---|---|---|---|---|---|---|

| 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | |

| 5%PS | 1.27 ± 0.05 b | 12.52 ± 0.00 a | 0.93 ± 0.01 a | 0.52 ± 0.00 a | 1.00 ± 0.00 | 1.00 ± 0.00 |

| 5%PS + 1%CHw | 1.31 ± 0.31 b | 4.05 ± 0.04 c | 0.76 ± 0.02 b | 0.54 ± 0.02 a | 1.00 ± 0.00 | 1.00 ± 0.00 |

| 5%PS + 1%CHg | 7.27 ± 0.97 a | 4.58 ± 0.19 b | 0.45 ± 0.02 c | 0.52 ± 0.01 a | 1.00 ± 0.00 | 1.00 ± 0.00 |

| Sample | K (Pa∙sn) | n (-) | R2 | |||

|---|---|---|---|---|---|---|

| 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | 0–300 s−1 | 300–0 s−1 | |

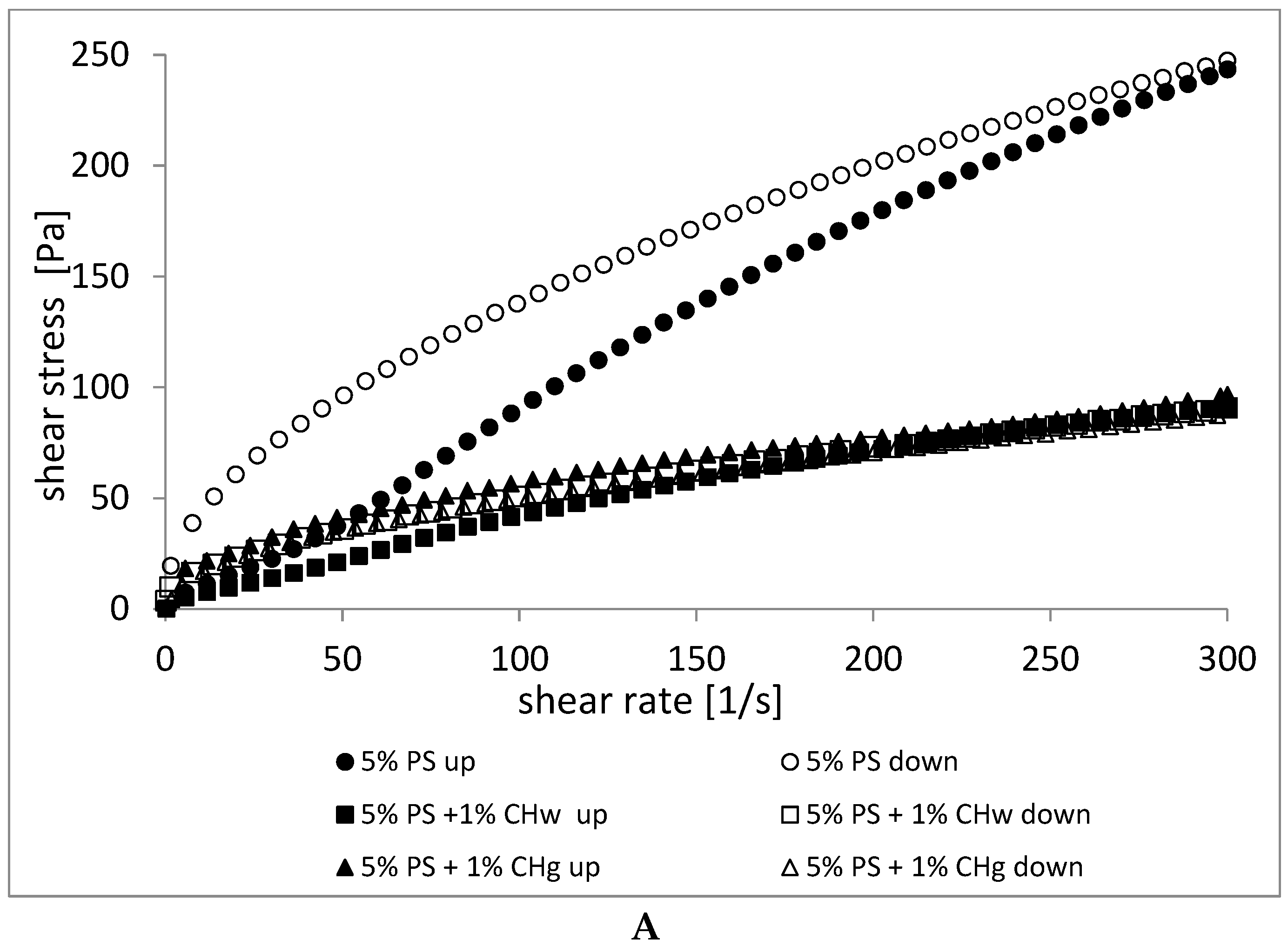

| 5%WPS | 2.35 ± 0.28 a | 9.80 ± 0.20 a | 0.72 ± 0.02 b | 0.50 ± 0.05 a | 0.99 ± 0.00 | 1.00 ± 0.00 |

| 5%WPS + 1%CHw | 0.71 ± 0.04 b | 5.47 ± 0.40 b | 0.83 ± 0.03 a | 0.45 ± 0.01 a | 0.98 ± 0.01 | 1.00 ± 0.00 |

| 5%WPS + 1%CHg | 0.76 ± 0.03 b | 6.70 ± 0.31 b | 0.85 ± 0.01 a | 0.45 ± 0.01 a | 0.99 ± 0.01 | 1.00 ± 0.00 |

| Sample | Hardness [N] | |||||||

|---|---|---|---|---|---|---|---|---|

| Fresh Gel (0 Day) | After 1 Day of Storage | After 2 Days of Storage | After 3 Days of Storage | After 7 Days of Storage | After 10 Days of Storage | After 20 Days of Storage | Day 20/0 | |

| 5%PS | 0.60 ± 0.02 c | 3.85 ± 0.44 a | 3.86 ± 0.15 a | 3.83 ± 0.43 a | 3.63 ± 0.25 a | 4.31 ± 0.05 a | 4.72 ± 0.2 a | 7.87 a |

| 5%PS + 1%CHw | 0.96 ± 0.04 a | 1.93 ± 0.06 b | 1.89 ± 0.03 b | 1.76 ± 0.48 b | 1.44 ± 0.03 b | 1.77 ± 0.06 b | 2.10 ± 0.03 b | 2.19 c |

| 5%PS + 1%CHg | 0.77 ± 0.01 b | 1.22 ± 0.02 c | 1.18 ± 0.06 c | 1.16 ± 0.05 b | 1.10 ± 0.04 c | 1.16 ± 0.02 c | 2.06 ± 0.30 b | 2.67 b |

| Sample | Hardness [N] | |||||||

|---|---|---|---|---|---|---|---|---|

| Fresh Gel (0 Day) | After 1 Day of Storage | After 2 Days of Storage | After 3 Days of Storage | After 7 Days of Storage | After 10 Days of Storage | After 20 Days of Storage | Day 20/0 | |

| 5%WPS | 0.18 ± 0.01 b | 0.35 ± 0.01 b | 0.53 ± 0.08 b | 0.64 ± 0.07 b | 0.94 ± 0.02 c | 1.34 ± 0.40 b | 1.58 ± 0.33 b | 8.78 c |

| 5%WPS + 1%CHw | 0.17 ± 0.01 b | 0.36 ± 0.02 b | 0.60 ± 0.01 ab | 0.80 ± 0.02 a | 1.06 ± 0.05 b | 1.27 ± 0.06 b | 2.51 ± 0.04 a | 14.76 a |

| 5%WPS + 1%CHg | 0.23 ± 0.01 a | 0.46 ± 0.02 a | 0.67 ± 0.01 a | 0.80 ± 0.02 a | 1.30 ± 0.05 a | 1.85 ± 0.13 a | 2.68 ± 0.07 a | 11.65 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamczyk, G.; Krystyjan, M.; Kuźniar, P.; Kowalczewski, P.Ł.; Bobel, I. An Insight into Pasting and Rheological Behavior of Potato Starch Pastes and Gels with Whole and Ground Chia Seeds. Gels 2022, 8, 598. https://doi.org/10.3390/gels8090598

Adamczyk G, Krystyjan M, Kuźniar P, Kowalczewski PŁ, Bobel I. An Insight into Pasting and Rheological Behavior of Potato Starch Pastes and Gels with Whole and Ground Chia Seeds. Gels. 2022; 8(9):598. https://doi.org/10.3390/gels8090598

Chicago/Turabian StyleAdamczyk, Greta, Magdalena Krystyjan, Piotr Kuźniar, Przemysław Łukasz Kowalczewski, and Inna Bobel. 2022. "An Insight into Pasting and Rheological Behavior of Potato Starch Pastes and Gels with Whole and Ground Chia Seeds" Gels 8, no. 9: 598. https://doi.org/10.3390/gels8090598

APA StyleAdamczyk, G., Krystyjan, M., Kuźniar, P., Kowalczewski, P. Ł., & Bobel, I. (2022). An Insight into Pasting and Rheological Behavior of Potato Starch Pastes and Gels with Whole and Ground Chia Seeds. Gels, 8(9), 598. https://doi.org/10.3390/gels8090598