Gel Rheological Properties and Storage Texture Kinetics of Starches Isolated from Anchote (Coccinia abyssinica (Lam.) Cogn.) Cultivars

Abstract

1. Introduction

2. Results and Discussion

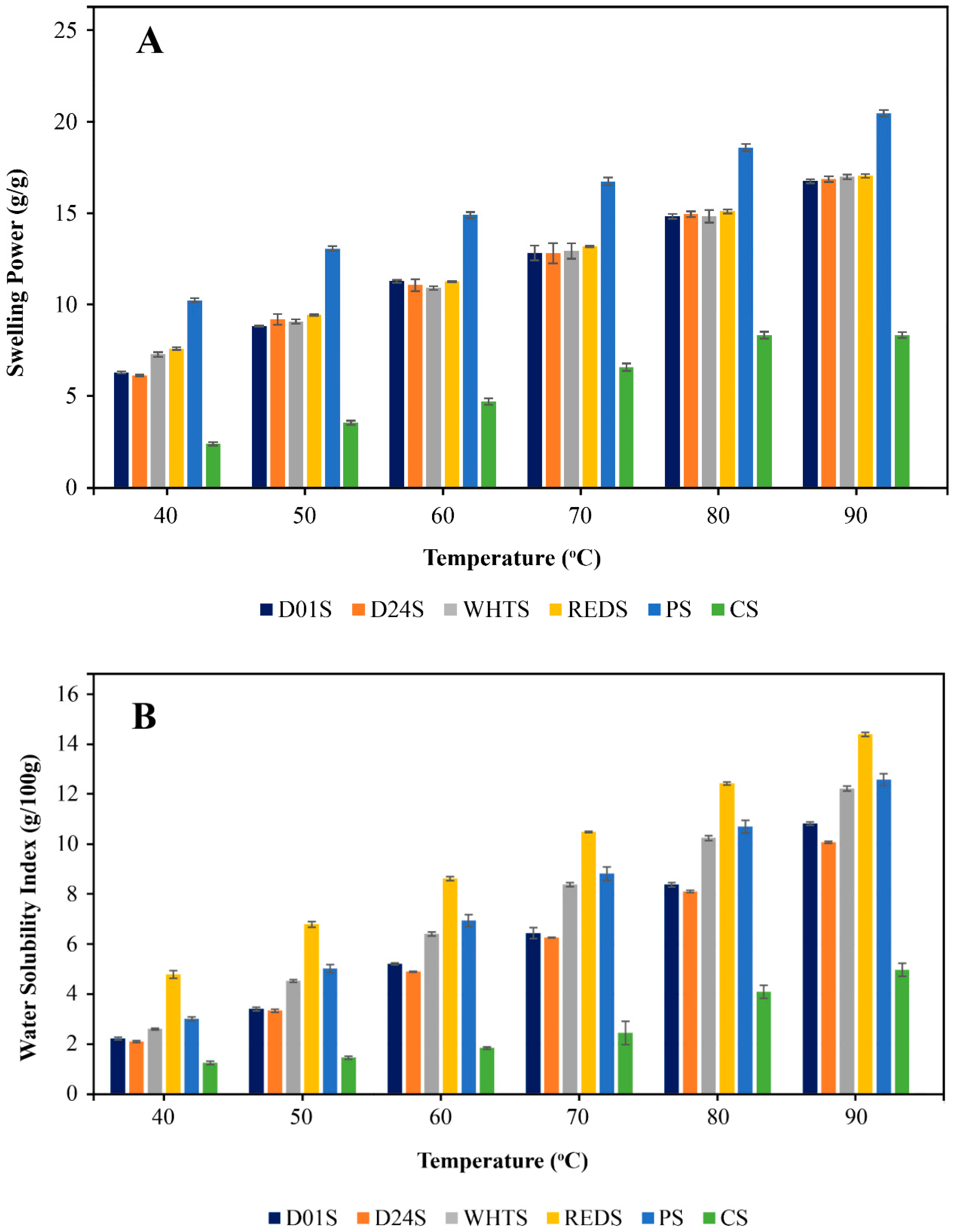

2.1. Strach Swelling Power (SP) and Water Solubility Index (WSI)

2.2. Color Measurements

2.3. Gel Rheological Properties

2.3.1. Strain Sweeps

2.3.2. Frequency Sweeps

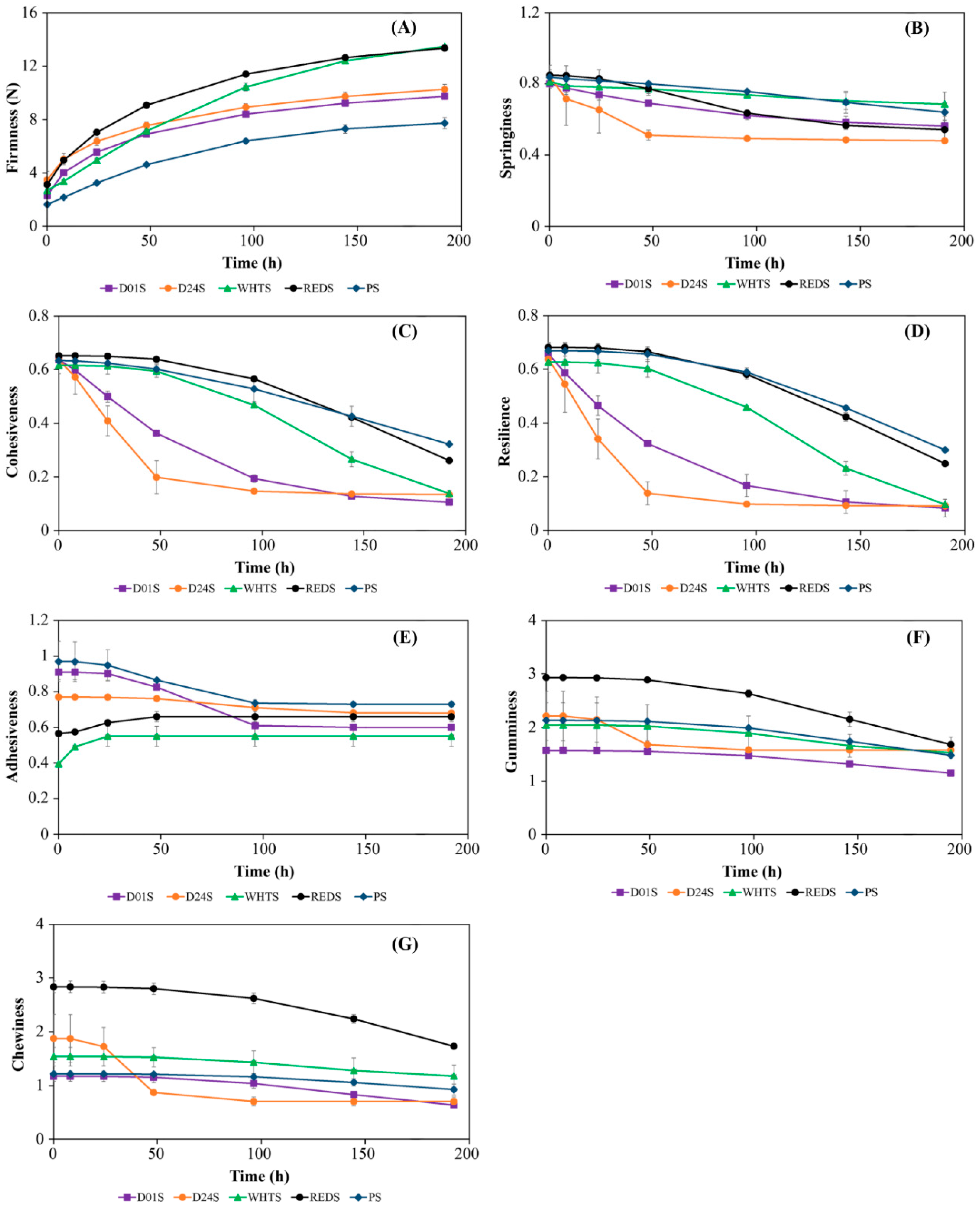

2.4. Gel Storage Texture Kinetics

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Isolation of Starch

4.3. Starch Swelling Power (SP) and Water Solubility Index (WSI)

4.4. Color Measurements

4.5. Gel Rheological Properties

4.6. Gel Storage Texture Kinetics

4.7. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dereje, B. Composition, morphology and physicochemical properties of starches derived from indigenous Ethiopian tuber crops: A review. Int. J. Biol. Macromol. 2021, 187, 911–921. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Hua, Y.; Li, G. Food Hydrocolloids Physicochemical properties of potato, sweet potato and quinoa starch blends. Food Hydrocoll. 2020, 100, 105278. [Google Scholar] [CrossRef]

- Wolde, Y.T.; Emire, S.A.; Abebe, W.; Ronda, F. Physicochemical, Morphological, Thermal, and Rheological Properties of Native Starches Isolated from Four Cultivars of Anchote (Coccinia abyssinica (Lam.) Cogn.) Tuber. Gels 2022, 8, 591. [Google Scholar] [CrossRef] [PubMed]

- Abegunde, O.K.; Mu, T.H.; Chen, J.W.; Deng, F.M. Physicochemical characterization of sweet potato starches popularly used in Chinese starch industry. Food Hydrocoll. 2013, 33, 169–177. [Google Scholar] [CrossRef]

- Abera, G.; Woldeyes, B.; Dessalegn, H.; Miyake, G.M. International Journal of Biological Macromolecules Comparison of physicochemical properties of indigenous Ethiopian tuber crop (Coccinia abyssinica) starch with commercially available potato and wheat starches. Int. J. Biol. Macromol. 2019, 140, 43–48. [Google Scholar] [CrossRef]

- Ayalew, Y.; Retta, N.; Desse, G.; Mohammed, A.; Mellesse, A. Amino acid profile and protein quality in tuber and leaf of Coccnia abyssinica (Lam.) (Cogn.) accessions of Ethiopia. Food Sci. Nutr. 2017, 5, 722–729. [Google Scholar] [CrossRef]

- Tessema, A.; Admassu, H. Extraction and characterization of starch from anchote (Coccinia abyssinica): Physico—Chemical, functional, morphological and crystalline properties. J. Food Meas. Charact. 2021, 15, 3096–3110. [Google Scholar] [CrossRef]

- Bikila, A.M.; Tola, Y.; Esho, T.B.; Forsido, S.F. Effect of predrying treatment and drying temperature on proximate composition, mineral contents, and thermophysical properties of anchote (Coccinia abyssinica (Lam.) Cogn.) flour. Food Sci. Nutr. 2020, 8, 5532–5544. [Google Scholar] [CrossRef]

- Parmar, A.; Gebre, B.A.; Legesse, A.; Demelash, Y.; Fladung, K.; Hensel, O. Nutritional comparison of white and red Coccinia Abyssinica (Lam.) cong. accessions: An underutilised edible tuber of the Ethiopian highlands. Foods 2017, 6, 71. [Google Scholar] [CrossRef]

- Fekadu, H. Effect of Traditional Processing Methods on Nutritional Composition and Anti-nutritional Factors of Anchote (Coccinia Abyssinica (lam.) Cogn.) Tubers Grown in Western Ethiopia. J. Food Process. Technol. 2013, 4. [Google Scholar] [CrossRef]

- Liu, J.; Xu, B. A comparative study on texture, gelatinisation, retrogradation and potential food application of binary gels made from selected starches and edible gums. Food Chem. 2019, 296, 100–108. [Google Scholar] [CrossRef] [PubMed]

- Kumar, Y.; Singh, L.; Sharanagat, V.S.; Patel, A.; Kumar, K. Effect of microwave treatment (low power and varying time) on potato starch: Microstructure, thermo-functional, pasting and rheological properties. Int. J. Biol. Macromol. 2020, 155, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Cai, J.; Han, W.; Huai, H.; Chen, Y.; Wei, C. Comparison of starches isolated from three different Trapa species. Food Hydrocoll. 2014, 37, 174–181. [Google Scholar] [CrossRef]

- Tako, M.; Tamaki, Y.; Teruya, T.; Takeda, Y. The Principles of Starch Gelatinization and Retrogradation. Food Nutr. Sci. 2014, 5, 280–291. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, G.; Wu, Y.; Yang, Z.; Ouyang, J. In fl uence of amylose on the pasting and gel texture properties of chestnut starch during thermal processing. Food Chem. 2019, 294, 378–383. [Google Scholar] [CrossRef]

- Chisenga, S.M.; Workneh, T.S.; Bultosa, G.; Laing, M. Characterization of physicochemical properties of starches from improved cassava varieties grown in Zambia. AIMS Agric. Food 2019, 4, 939–966. [Google Scholar]

- Guo, K.; Liu, T.; Xu, A.; Zhang, L.; Bian, X.; Wei, C. Food Hydrocolloids Structural and functional properties of starches from root tubers of white, yellow, and purple sweet potatoes. Food Hydrocoll. 2019, 89, 829–836. [Google Scholar] [CrossRef]

- Ren, Y.; Wei, Q.; Lin, L.; Shi, L.; Cui, Z.; Li, Y.; Huang, C.; Wei, C. Physicochemical properties of a new starch from ramie (Boehmeria nivea) root. Int. J. Biol. Macromol. 2021, 174, 392–401. [Google Scholar] [CrossRef]

- Astuti, R.M.; Widaningrum, N.A.; Ade Setyowati, R.F. Food Hydrocolloids Effect of physical modi fi cation on granule morphology, pasting behavior, and functional properties of arrowroot (Marantha arundinacea L.) starch. Food Hydrocoll. 2018, 81, 23–30. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, N.; Ezekiel, R.; Guraya, H.S. Physicochemical, thermal and pasting properties of starches separated from different potato cultivars grown at different locations. Food Chem. 2007, 101, 643–651. [Google Scholar] [CrossRef]

- Wang, L.; Xie, B.; Shi, J.; Xue, S.; Deng, Q.; Wei, Y.; Tian, B. Physicochemical properties and structure of starches from Chinese rice cultivars. Food Hydrocoll. 2010, 24, 208–216. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Villanueva, M. Rheological Properties of Gluten-Free Bread Doughs: Relationship with Bread Quality. In Advances in Food Rheology and Its Applications; Woodhead Publishing: Sawston, UK, 2017; pp. 297–334. ISBN 9780081004326. [Google Scholar]

- Villanueva, M.; Ronda, F.; Moschakis, T.; Lazaridou, A.; Biliaderis, C.G. Impact of acidification and protein fortification on thermal properties of rice, potato and tapioca starches and rheological behaviour of their gels. Food Hydrocoll. 2018, 79, 20–29. [Google Scholar] [CrossRef]

- Tangsrianugul, N.; Wongsagonsup, R.; Suphantharika, M. Physicochemical and rheological properties of flour and starch from Thai pigmented rice cultivars. Int. J. Biol. Macromol. 2019, 137, 666–675. [Google Scholar] [CrossRef]

- Jacobson, M.R.; Obanni, M.; Bemiller, J.N. Retrogradation of starches from different botanical sources. Cereal Chem. 1997, 74, 511–518. [Google Scholar] [CrossRef]

- Yu, S.; Liu, J.; Yang, Y.; Ren, J.; Zheng, X.; Kopparapu, N.K. Effects of amylose content on the physicochemical properties of Chinese chestnut starch. Starch-Stärke 2016, 68, 112–118. [Google Scholar] [CrossRef]

- Deriu, A.G.; Vela, A.J.; Ronda, F. Techno-Functional and Gelling Properties of Acha (Fonio) (Digitaria exilis stapf) Flour: A Study of Its Potential as a New Gluten-Free Starch Source in Industrial Applications. Foods 2022, 11, 183. [Google Scholar] [CrossRef] [PubMed]

- Abebe, W.; Ronda, F. Rheological and textural properties of tef [Eragrostis tef (Zucc.) Trotter] grain fl our gels. J. Cereal Sci. 2014, 60, 122–130. [Google Scholar] [CrossRef]

- Huang, M.; Kennedy, J.F.; Li, B.; Xu, X.; Xie, B.J. Characters of rice starch gel modi W ed by gellan, carrageenan, and glucomannan: A texture pro W le analysis study. Carbohydr. Polym. 2007, 69, 411–418. [Google Scholar] [CrossRef]

- Truong, V.D.; Hamann, D.D.; Walter, W.M. Relationship Between Instrumental and Sensory Parameters of Cooked Sweet potato Texture. J. Texture Stud. 1997, 28, 163–185. [Google Scholar] [CrossRef]

- Marta, H.; Cahyana, Y.; Djali, M.; Arcot, J.; Tensiska, T. A comparative study on the physicochemical and pasting properties of starch and flour from different banana (Musa spp.) cultivars grown in Indonesia. Int. J. Food Prop. 2019, 22, 1562–1575. [Google Scholar] [CrossRef]

- Vela, A.J.; Villanueva, M.; Náthia-Neves, G.; Ronda, F. Impact of Solubilized Substances on the Techno-Functional, Pasting and Rheological Properties of Ultrasound-Modified Rice, Tef, Corn and Quinoa Flours. Foods 2023, 12, 484. [Google Scholar] [CrossRef] [PubMed]

- Kale, R.V.; Shere, D.M.; Ks, G. Effect of isolation methods on physicochemical and functional properties of sweet potato (Ipomoea batatas L.) starch. J. Pharmacogn. Phytochem. 2017, 6, 223–227. [Google Scholar]

- Ronda, F.; Villanueva, M.; Collar, C. Influence of acidification on dough viscoelasticity of gluten-free rice starch-based dough matrices enriched with exogenous protein. LWT Food Sci. Technol. 2014, 59, 12–20. [Google Scholar] [CrossRef]

| Samples | L* | a* | b* | Whiteness (W) |

|---|---|---|---|---|

| D01S | 97.72 ± 0.31 cd | 0.018 ± 0.007 a | 0.827 ± 0.047 ab | 97.57 ± 0.30 cd |

| D24S | 96.78 ± 0.23 b | 0.016 ± 0.002 a | 1.007 ± 0.051 b | 96.63 ± 0.23 b |

| WHTS | 97.11 ± 0.14 bc | 0.030 ± 0.010 a | 0.917 ± 0.055 b | 96.97 ± 0.13 bc |

| REDS | 95.40 ± 0.49 a | 0.207 ± 0.015 b | 1.433 ± 0.215 c | 95.17 ± 0.47 a |

| PS | 98.09 ± 0.30 d | 0.027 ± 0.006 a | 0.630 ± 0.061 a | 97.99 ± 0.28 d |

| CS | 98.53 ± 0.19 d | 0.033 ± 0.006 a | 0.793 ± 0.015 ab | 98.33 ± 0.17 d |

| Sample | Concentration | G1′ (Pa) | a | G1″ (Pa) | b | (tan δ)1 | c | Cross Point (Pa) | τmax (Pa) |

|---|---|---|---|---|---|---|---|---|---|

| D01S | 2 | 25 ± 4 fg | 0.13 ± 0.02 bcd | 5.70 ± 0.92 cd | 0.42 ± 0.01 i | 0.23 ± 0.01 cdef | 0.30 ± 0.02 h | 21 ± 3 abc | 0.1 ± 0.1 a |

| 4 | 71 ± 1 i | 0.13 ± 0.01 bcd | 15.41 ± 0.25 j | 0.29 ± 0.01 a | 0.22 ± 0.01 cde | 0.15 ± 0.01 abcdef | 108 ± 1 f | 24 ± 1 a | |

| 6 | 62 ± 7 h | 0.16 ± 0.02 bcd | 15.34 ± 1.49 ij | 0.32 ± 0.01 bcde | 0.25 ± 0.01 def | 0.16 ± 0.01 abcdefg | 225 ± 8 h | 128 ± 14 c | |

| 8 | 75 ± 2 ij | 0.16 ± 0.01 bcd | 20.03 ± 0.39 kl | 0.34 ± 0.01 def | 0.27 ± 0.01 f | 0.18 ± 0.01 cdefg | 467 ± 2 j | 305 ± 10 de | |

| 10 | 108 ± 11 mn | 0.13 ± 0.01 bcd | 26.44 ± 2.79 m | 0.34 ± 0.01 ef | 0.24 ± 0.01 def | 0.21 ± 0.01 fg | 772 ± 51 l | 608 ± 50 g | |

| D24S | 2 | 23 ± 1 efg | 0.10 ± 0.02 b | 3.73 ± 0.18 b | 0.52 ± 0.01 k | 0.16 ± 0.01 a | 0.43 ± 0.03 i | 5 ± 1 a | 1 ± 1 a |

| 4 | 115 ± 2 no | 0.11 ± 0.01 b | 18.78 ± 0.33 k | 0.31 ± 0.01 b | 0.16 ± 0.01 a | 0.20 ± 0.01 efg | 92 ± 1 ef | 31 ± 1 a | |

| 6 | 96 ± 17 l | 0.14 ± 0.01 bcd | 21.81 ± 3.73 l | 0.31 ± 0.01 b | 0.23 ± 0.01 cdef | 0.16 ± 0.01 abcdefg | 305 ± 11 i | 149 ± 24 c | |

| 8 | 103 ± 1 lm | 0.15 ± 0.01 bcd | 25.57 ± 0.19 m | 0.32 ± 0.01 bcde | 0.25 ± 0.01 def | 0.17 ± 0.01 bcdefg | 545 ± 1 k | 375 ± 10 f | |

| 10 | 130 ± 3 p | 0.14 ± 0.01 bcd | 31.13 ± 0.20 o | 0.33 ± 0.01 cdef | 0.24 ± 0.01 def | 0.20 ± 0.01 efg | 854 ± 11 n | 784 ± 6 i | |

| WHTS | 2 | 25 ± 1 fg | 0.14 ± 0.02 bcd | 4.91 ± 0.23 bc | 0.44 ± 0.01 ij | 0.19 ± 0.01 abc | 0.30 ± 0.03 h | 9 ± 1 ab | 2 ± 1 a |

| 4 | 77 ± 4 ij | 0.12 ± 0.01 bc | 13.58 ± 0.81 ghi | 0.33 ± 0.01 cdef | 0.17 ± 0.01 ab | 0.21 ± 0.01 fg | 70 ± 3 de | 29 ± 1 a | |

| 6 | 80 ± 3 jk | 0.13 ± 0.01 bcd | 16.66 ± 0.75 j | 0.32 ± 0.01 bcd | 0.21 ± 0.01 bcd | 0.19 ± 0.01 defg | 207 ± 6 gh | 79 ± 3 b | |

| 8 | 78 ± 1 ij | 0.16 ± 0.01 bcd | 19.54 ± 0.35 k | 0.34 ± 0.02 f | 0.25 ± 0.01 ef | 0.18 ± 0.01 cdefg | 458 ± 13 j | 271 ± 9 d | |

| 10 | 120 ± 9 o | 0.14 ± 0.01 bcd | 28.66 ± 1.92 n | 0.34 ± 0.01 def | 0.24 ± 0.01 def | 0.20 ± 0.01 efg | 819 ± 83 m | 676 ± 84 h | |

| REDS | 2 | 23 ± 1 efg | 0.13 ± 0.01 bcd | 4.39 ± 0.22 bc | 0.45 ± 0.01 j | 0.19 ± 0.01 abc | 0.32 ± 0.02 h | 7 ± 1 a | 2 ± 1 a |

| 4 | 73 ± 1 ij | 0.11 ± 0.01 b | 12.50 ± 0.13 g | 0.33 ± 0.01 cdef | 0.17 ± 0.01 ab | 0.22 ± 0.01 g | 58 ± 1 d | 28 ± 1 a | |

| 6 | 77 ± 3 ij | 0.13 ± 0.01 bcd | 14.89 ± 0.69 hij | 0.33 ± 0.01 cdef | 0.19 ± 0.01 abc | 0.20 ± 0.01 efg | 184 ± 3 g | 81 ± 4 b | |

| 8 | 87 ± 5 k | 0.14 ± 0.01 bcd | 20.57 ± 0.90 kl | 0.34 ± 0.01 ef | 0.24 ± 0.01 def | 0.20 ± 0.01 efg | 436 ± 10 j | 321 ± 22 e | |

| 10 | 129 ± 9 p | 0.13 ± 0.01 bcd | 29.14 ± 1.41 n | 0.34 ± 0.01 f | 0.23 ± 0.01 cdef | 0.21 ± 0.01 fg | 822 ± 52 mn | 617 ± 109 g | |

| PS | 2 | 9 ± 1 abc | 0.20 ± 0.02 de | 3.36 ± 0.15 b | 0.32 ± 0.02 bcd | 0.38 ± 0.01 h | 0.12 ± 0.03 abc | 7 ± 1 a | 1 ± 1 a |

| 4 | 11 ± 2 bc | 0.27 ± 0.04 ef | 5.15 ± 0.42 bc | 0.37 ± 0.03 gh | 0.46 ± 0.04 ij | 0.11 ± 0.04 a | 48 ± 5 cd | 2 ± 1 a | |

| 6 | 17 ± 1 cdef | 0.24 ± 0.01 ef | 7.95 ± 0.36 e | 0.37 ± 0.01 gh | 0.46 ± 0.02 ij | 0.13 ± 0.01 abcd | ND | ND | |

| 8 | 30 ± 1 g | 0.25 ± 0.01 ef | 13.33 ± 0.40 gh | 0.36 ± 0.01 g | 0.45 ± 0.01 i | 0.11 ± 0.01 ab | ND | ND | |

| 10 | 80 ± 9 jk | 0.19 ± 0.01 cde | 25.79 ± 2.50 m | 0.32 ± 0.01 bc | 0.32 ± 0.01 g | 0.12 ± 0.01 abcd | ND | ND | |

| CS | 2 | 1 ± 1 a | −0.39 ± 0.24 a | 0.73 ± 0.01 a | 0.59 ± 0.05 l | 0.59 ± 0.12 l | 0.92 ± 0.19 j | 0.07 ± 0.01 a | 0.01 ± 0.01 a |

| 4 | 6 ± 1 ab | 0.24 ± 0.04 ef | 3.34 ± 0.12 b | 0.38 ± 0.01 h | 0.52 ± 0.01 k | 0.14 ± 0.06 abcde | 42 ± 3 bcd | 0.37 ± 0.01 a | |

| 6 | 13 ± 1 bcd | 0.26 ± 0.02 ef | 5.91 ± 0.15 cd | 0.39 ± 0.01 h | 0.45 ± 0.01 i | 0.13 ± 0.01 abcd | ND | ND | |

| 8 | 15 ± 1 bcde | 0.28 ± 0.01 f | 7.35 ± 0.19 de | 0.44 ± 0.01 ij | 0.50 ± 0.01 k | 0.15 ± 0.01 abcdef | ND | ND | |

| 10 | 21 ± 1 def | 0.29 ± 0.01 f | 10.22 ± 0.75 f | 0.44 ± 0.01 ij | 0.50 ± 0.01 jk | 0.16 ± 0.01 abcdefg | ND | ND | |

| Analysis of variance and significance (p-values) | |||||||||

| Type (A) | *** | *** | *** | *** | *** | *** | *** | *** | |

| Concentration (B) | *** | *** | *** | *** | *** | *** | *** | *** | |

| A × B | *** | *** | *** | *** | *** | *** | *** | *** | |

| Sample | P0 (N) | P∞ (N) | k (h−n) | n | t1/2 (h) |

|---|---|---|---|---|---|

| Firmness | |||||

| D01S | 2.302 ± 0.259 ab | 9.76 ± 0.149 b | 0.054 ± 0.014 c | 0.690 ± 0.045 a | 41.89 ± 5.58 a |

| D24S | 3.472 ± 0.644 c | 10.267 ± 0.372 b | 0.053 ± 0.010 c | 0.654 ± 0.007 a | 53.18 ± 12.78 ab |

| WHTS | 2.679 ± 0.373 bc | 13.484 ± 0.113 c | 0.005 ± 0.003 a | 1.169 ± 0.108 b | 67.38 ± 6.31 b |

| REDS | 3.119 ± 0.180 bc | 13.350 ± 0.063 c | 0.033 ± 0.012 bc | 0.809 ± 0.109 a | 45.19 ± 2.14 a |

| PS | 1.628 ± 0.182 a | 7.730 ± 0.416 a | 0.009 ± 0.005 ab | 1.115 ± 0.104 b | 52.88 ± 7.93 ab |

| Springiness | |||||

| D01S | 0.801 ± 0.024 a | 0.563 ± 0.034 ab | 3.0 × 10−4 ± 1.3 × 10−4 a | 1.271 ± 0.003 b | 72.49 ± 3.01 b |

| D24S | 0.842 ± 0.027 a | 0.480 ± 0.003 a | 0.017 ± 0.003 b | 1.187 ± 0.029 b | 22.80 ± 1.04 a |

| WHTS | 0.813 ± 0.004 a | 0.687 ± 0.068 b | 0.005 ± 0.002 a | 1.614 ± 0.177 c | 21.74 ± 1.17 a |

| REDS | 0.850 ± 0.056 a | 0.543 ± 0.051 ab | 1.14 × 10−4 ± 0.16 × 10−4 a | 1.919 ± 0.037 c | 93.81 ± 1.31 c |

| PS | 0.838 ± 0.042 a | 0.641 ± 0.114 ab | 1.40 × 10−2 ± 0.02 × 10−2 b | 0.842 ± 0.003 a | 100.97 ± 0.15 d |

| Cohesiveness | |||||

| D01S | 0.637 ± 0.001 a | 0.104 ± 0.001 a | 0.006 ± 0.004 a | 1.276 ± 0.205 a | 47.38 ± 0.57 b |

| D24S | 0.637 ± 0.015 a | 0.133 ± 0.007 b | 0.017 ± 0.024 a | 1.951 ± 1.375 a | 24.71 ± 4.28 a |

| WHTS | 0.616 ± 0.031 a | 0.136 ± 0.012 b | 0.004 ± 2.0 × 10−5 a | 1.320 ± 0.035 a | 50.99 ± 5.52 b |

| REDS | 0.652 ± 0.013 a | 0.260 ± 0.002 c | 0.009 ± 0.001 a | 1.063 ± 0.016 a | 61.92 ± 4.49 b |

| PS | 0.634 ± 0.011 a | 0.321 ± 0.004 d | 3.30 × 10−4 ± 0.14 × 10−4 a | 1.668 ± 0.011 a | 97.81 ± 5.40 c |

| Resilience | |||||

| D01S | 0.658 ± 0.007 a | 0.081 ± 0.033 a | 0.017 ± 0.002 a | 1.082 ± 0.298 a | 40.52 ± 2.61 b |

| D24S | 0.638 ± 0.001 a | 0.089 ± 0.001 a | 2.00 × 10−3 ± 0.10 × 10−3 a | 2.017 ± 0.087 b | 18.83 ± 1.59 a |

| WHTS | 0.628 ± 0.039 a | 0.094 ± 0.020 a | 1.97 × 10−4 ± 0.14 × 10−4 a | 1.887 ± 0.017 b | 75.79 ± 0.02 c |

| REDS | 0.683 ± 0.015 a | 0.247 ± 0.010 b | 6.10 × 10−5 ± 0.83 × 10−5 a | 2.032 ± 0.021 b | 98.89 ± 1.85 d |

| PS | 0.670 ± 0.031 a | 0.298 ± 0.007 c | 2.25 × 10−5 ± 0.25 × 10−5 a | 2.291 ± 0.290 b | 111.57 ± 5.80 e |

| Adhesiveness | |||||

| D01S | 0.910 ± 0.042 cd | 0.600 ± 0.010 ab | 2.00 × 10−3 ± 0.03 × 10−3 c | 1.401 ± 0.018 b | 68.41 ± 4.38 d |

| D24S | 0.770 ± 0.014 c | 0.680 ± 0.014 c | 1.80 × 10−2 ± 0.04 × 10−2 e | 1.204 ± 0.013 a | 20.59 ± 0.31 b |

| WHTS | 0.395 ± 0.007 a | 0.550 ± 0.057 a | 3.40 × 10−3 ± 0.12 × 10−3 d | 2.615 ± 0.003 d | 7.64 ± 0.10 a |

| REDS | 0.565 ± 0.007 b | 0.660 ± 0.028 bc | 1.30 × 10−4 ± 0.10 × 10−4 a | 2.774 ± 0.007 e | 22.01 ± 0.45 b |

| PS | 0.970 ± 0.113 d | 0.730 ± 0.014 c | 1.00 × 10−3 ± 0.12 × 10−3 b | 1.735 ± 0.009 c | 41.23 ± 3.46 c |

| Gumminess | |||||

| D01S | 1.566 ± 0.023 a | 1.143 ± 0.026 a | 9.19 × 10−6 ± 5.44 × 10−6 a | 2.392 ± 0.135 c | 113.85 ± 0.30 c |

| D24S | 2.216 ± 0.462 a | 1.576 ± 0.006 b | 0.026 ± 0.002 b | 1.042 ± 0.022 a | 23.20 ± 0.39 a |

| WHTS | 2.044 ± 0.419 a | 1.525 ± 0.095 b | 3.15 × 10−6 ± 0.39 × 10−6 a | 2.682 ± 0.015 cd | 98.26 ± 2.02 b |

| REDS | 2.935 ± 0.017 b | 1.678 ± 0.142 b | 1.27 × 10−4 ± 0.33 × 10−4 a | 1.838 ± 0.050 b | 108.76 ± 1.81 c |

| PS | 2.134 ± 0.006 a | 1.477 ± 0.031 b | 2.32 × 10−7 ± 1.22 × 10−7 a | 2.992 ± 0.097 d | 149.61 ± 3.40 d |

| Chewiness | |||||

| D01S | 1.172 ± 0.096 a | 0.634 ± 0.038 a | 1.92 × 10−5 ± 0.03 × 10−5 a | 2.254 ± 0.037 b | 105.50 ± 7.35 b |

| D24S | 1.872 ± 0.448 b | 0.701 ± 0.081 a | 0.018 ± 0.002 b | 1.090 ± 0.031 a | 28.12 ± 0.45 a |

| WHTS | 1.536 ± 0.171 ab | 1.175 ± 0.205 b | 9.15 × 10−6 ± 0.96 × 10−6 a | 2.509 ± 0.275 b | 103.21 ± 3.35 b |

| REDS | 2.834 ± 0.107 c | 1.726 ± 0.055 c | 3.02 × 10−5 ± 0.93 × 10−5 a | 2.125 ± 0.055 b | 113.93 ± 2.81 bc |

| PS | 1.216 ± 0.006 a | 0.923 ± 0.103 ab | 2.16 × 10−5 ± 0.06 × 10−5 a | 2.153 ± 0.010 b | 123.89 ± 0.99 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolde, Y.T.; Emire, S.A.; Zeleke, W.A.; Ronda, F. Gel Rheological Properties and Storage Texture Kinetics of Starches Isolated from Anchote (Coccinia abyssinica (Lam.) Cogn.) Cultivars. Gels 2023, 9, 631. https://doi.org/10.3390/gels9080631

Wolde YT, Emire SA, Zeleke WA, Ronda F. Gel Rheological Properties and Storage Texture Kinetics of Starches Isolated from Anchote (Coccinia abyssinica (Lam.) Cogn.) Cultivars. Gels. 2023; 9(8):631. https://doi.org/10.3390/gels9080631

Chicago/Turabian StyleWolde, Yohannes Tolesa, Shimelis Admassu Emire, Workineh Abebe Zeleke, and Felicidad Ronda. 2023. "Gel Rheological Properties and Storage Texture Kinetics of Starches Isolated from Anchote (Coccinia abyssinica (Lam.) Cogn.) Cultivars" Gels 9, no. 8: 631. https://doi.org/10.3390/gels9080631

APA StyleWolde, Y. T., Emire, S. A., Zeleke, W. A., & Ronda, F. (2023). Gel Rheological Properties and Storage Texture Kinetics of Starches Isolated from Anchote (Coccinia abyssinica (Lam.) Cogn.) Cultivars. Gels, 9(8), 631. https://doi.org/10.3390/gels9080631