New Frontiers for Raw Wooden Residues, Biochar Production as a Resource for Environmental Challenges

Abstract

1. Introduction

2. Standards of Biochar Production

3. Biochar: A Potential Ally for Improving Soil Health

4. The Uses of Biochar in Forestry

4.1. Biochar’s Effects on Tree Growth

4.2. Biochar: A Forest Fire Prevention Tool

4.3. Effects of Biochar on Forest Litter

5. The Uses of Biochar in Agriculture

6. Forest Waste As Feedstocks: Key Types and Characteristics of the Biochar Produced

6.1. Physico-Chemical Characterization of Biochar Produced by Different Forest Waste

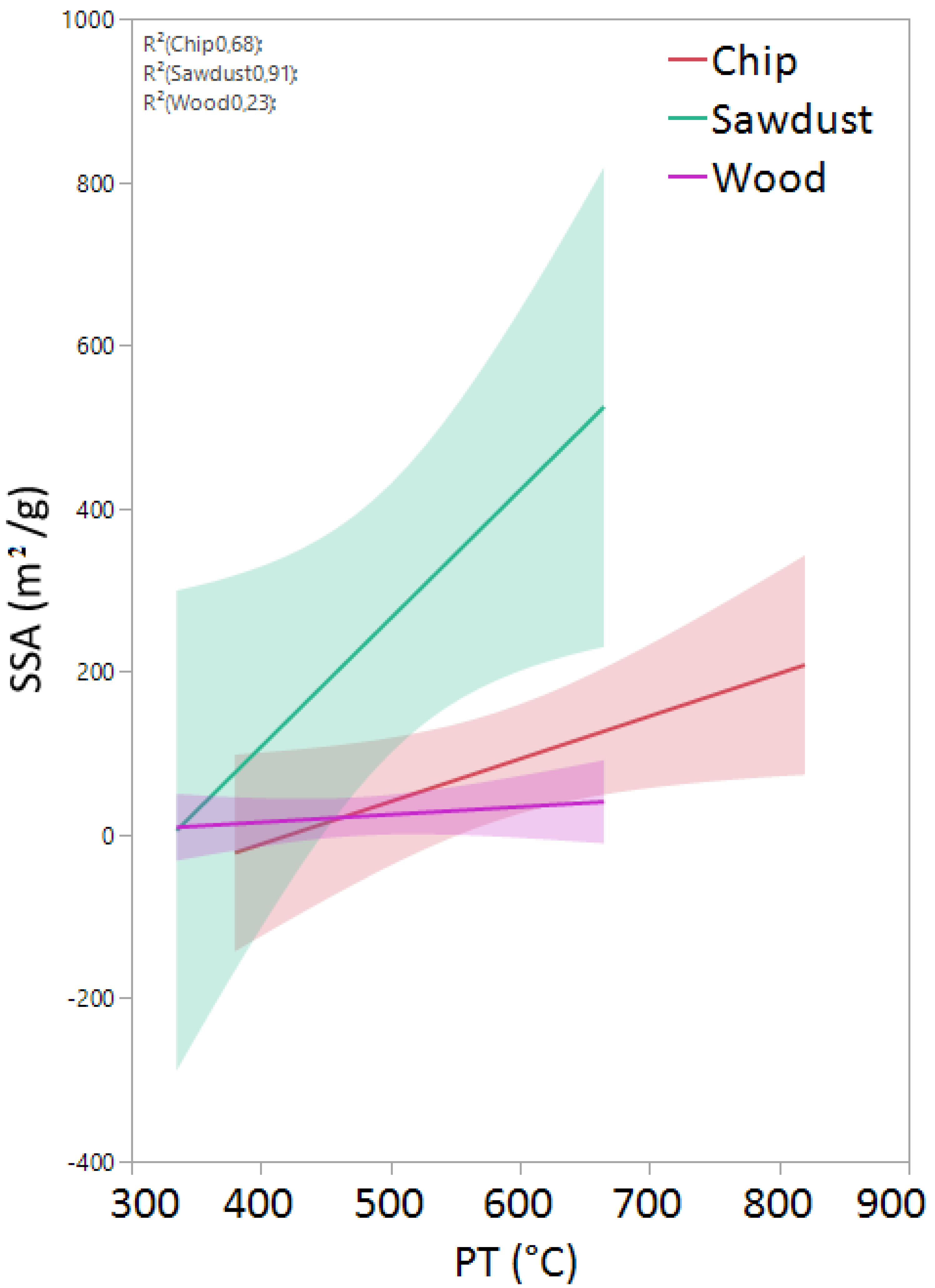

6.1.1. Specific Surface Area

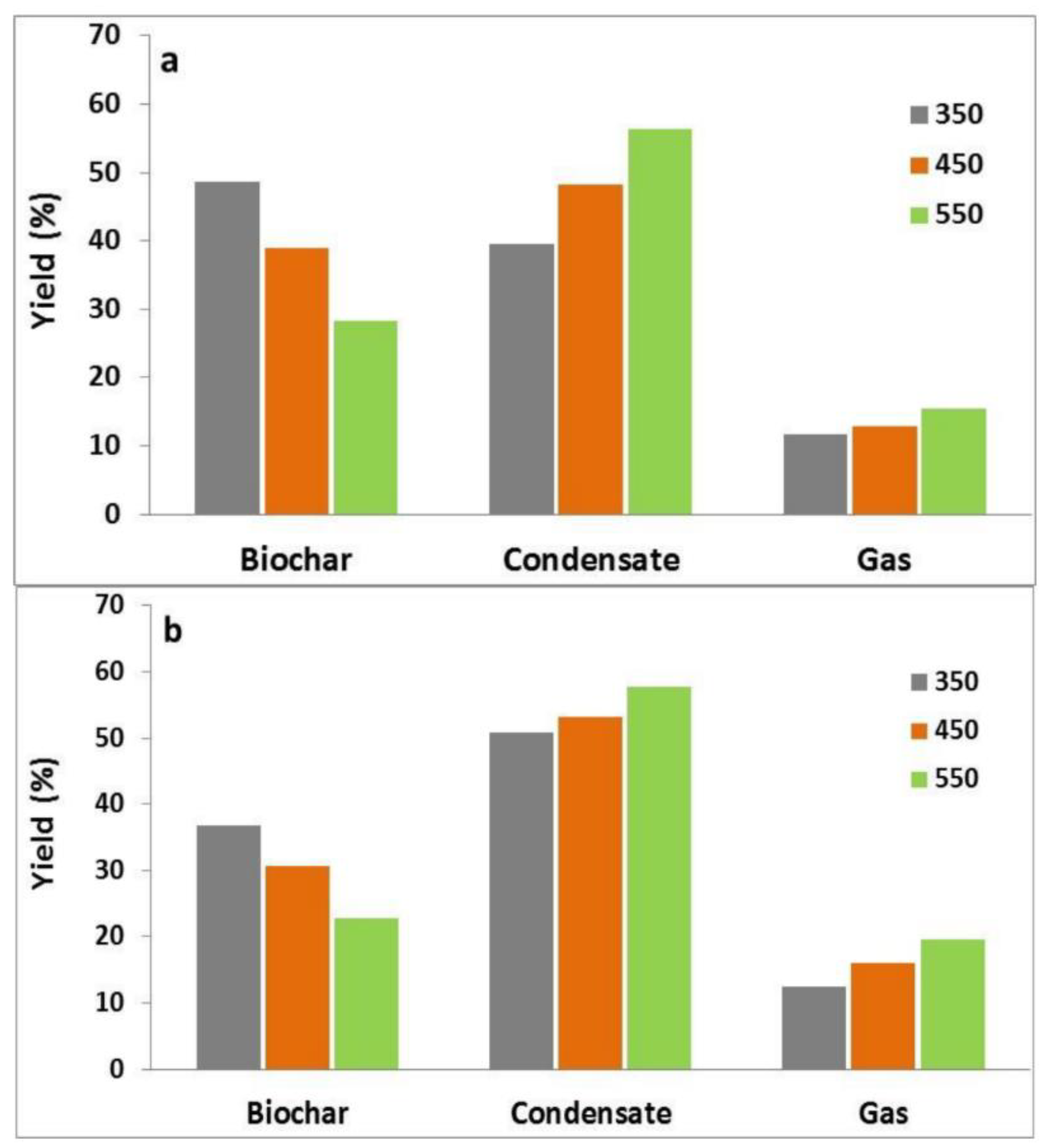

6.1.2. Biochar Yield, Volatile Matter and Ash

6.1.3. pH and Cation Exchange Capacity

6.2. Elemental Composition and Carbon Content

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Corona, P.; Di Stefano, V.; Mariano, A. Knowledge Gaps and Research Opportunities in the Light of the European Union Regulation on Deforestation-Free Products. Ann. Silvic. Res. 2023, 48, 87–89. [Google Scholar] [CrossRef]

- Islam Rony, Z.; Rasul, M.G.; Jahirul, M.I.; Mofijur, M. Harnessing Marine Biomass for Sustainable Fuel Production through Pyrolysis to Support United Nations’ Sustainable Development Goals. Fuel 2024, 358, 130099. [Google Scholar] [CrossRef]

- Yu, D.; Niu, J.; Zhong, L.; Chen, K.; Wang, G.; Yan, M.; Li, D.; Yao, Z. Biochar Raw Material Selection and Application in the Food Chain: A Review. Sci. Total Environ. 2022, 836, 155571. [Google Scholar] [CrossRef]

- Lehmann, J.; Gaunt, J.; Rondon, M. Bio-Char Sequestration in Terrestrial Ecosystems—A Review. Mitig. Adapt. Strateg. Glob. Chang. 2006, 11, 403–427. [Google Scholar] [CrossRef]

- Lehmann, J. Bio-Energy in the Black. Front. Ecol. Environ. 2007, 5, 381–387. [Google Scholar] [CrossRef]

- Zhang, B.; Yin, R.; Tan, Y.; Fan, B.; Li, H.; Peng, Y.; Yang, R.; Li, G. Evaluation of Maturity and Greenhouse Gas Emission in Co-Composting of Chicken Manure with Tobacco Powder and Vinasse/Mushroom Bran. Processes 2021, 9, 2105. [Google Scholar] [CrossRef]

- Goswami, M.; Pant, G.; Mansotra, D.K.; Sharma, S.; Joshi, P.C. Biochar: A Carbon Negative Technology for Combating Climate Change. In Advances in Carbon Capture and Utilization; Springer: Singapore, 2021; pp. 251–272. [Google Scholar]

- Sri Shalini, S.; Palanivelu, K.; Ramachandran, A.; Raghavan, V. Biochar from Biomass Waste as a Renewable Carbon Material for Climate Change Mitigation in Reducing Greenhouse Gas Emissions—A Review. Biomass Convers. Biorefinery 2021, 11, 2247–2267. [Google Scholar] [CrossRef]

- Zhu, H.; Saddler, J.; Bi, X. An Economic and Environmental Assessment of Biofuel Produced via Microwave-Assisted Catalytic Pyrolysis of Forest Residues. Energy Convers. Manag. 2022, 263, 115723. [Google Scholar] [CrossRef]

- Klasson, K.T. Biochar Characterization and a Method for Estimating Biochar Quality from Proximate Analysis Results. Biomass Bioenergy 2017, 96, 50–58. [Google Scholar] [CrossRef]

- Tan, X.; Liu, Y.; Zeng, G.; Wang, X.; Hu, X.; Gu, Y.; Yang, Z. Application of Biochar for the Removal of Pollutants from Aqueous Solutions. Chemosphere 2015, 125, 70–85. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; De Melo, I.C.N.A.; Melo, L.C.A.; Magriotis, Z.M.; Sánchez-Monedero, M.A. Properties of Biochar Derived from Wood and High-Nutrient Biomasses with the Aim of Agronomic and Environmental Benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K.; Avasthe, R.K.; Sinha, K. Compositional Heterogeneity of Different Biochar: Effect of Pyrolysis Temperature and Feedstocks. J. Environ. Manag. 2021, 278, 111501. [Google Scholar] [CrossRef]

- Wu, Y.; Brickler, C.; Li, S.; Chen, G. Synthesis of Microwave-Mediated Biochar-Hydrogel Composites for Enhanced Water Absorbency and Nitrogen Release. Polym. Test. 2021, 93, 106996. [Google Scholar] [CrossRef]

- Ghodke, P.K.; Sharma, A.K.; Pandey, J.K.; Chen, W.H.; Patel, A.; Ashokkumar, V. Pyrolysis of Sewage Sludge for Sustainable Biofuels and Value-Added Biochar Production. J. Environ. Manag. 2021, 298, 113450. [Google Scholar] [CrossRef]

- Robinson, A.J.; Giuliano, A.; Abdelaziz, O.Y.; Hulteberg, C.P.; Koutinas, A.; Triantafyllidis, K.S.; Barletta, D.; De Bari, I. Techno-Economic Optimization of a Process Superstructure for Lignin Valorization. Bioresour. Technol. 2022, 364, 128004. [Google Scholar] [CrossRef]

- Sharma, P.K.; Sharma, A.K.; Pulla, R.H.; Sahoo, P.K. Performance Analysis of a Medium-Scale Downdraft Gasifier Using Lantana Camera Biomass as Feeding Material. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–15. [Google Scholar] [CrossRef]

- Sharma, A.K.; Ghodke, P.K.; Goyal, N.; Bobde, P.; Kwon, E.E.; Lin, K.Y.A.; Chen, W.H. A Critical Review on Biochar Production from Pine Wastes, Upgradation Techniques, Environmental Sustainability, and Challenges. Bioresour. Technol. 2023, 387, 129632. [Google Scholar] [CrossRef]

- IPCC. 2018 Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Devi, M.; Rawat, S. A Comprehensive Review of the Pyrolysis Process: From Carbon Nanomaterial Synthesis to Waste Treatment. Oxf. Open Mater. Sci. 2021, 1, itab014. [Google Scholar] [CrossRef]

- Deng, J.; Zhou, Y.; Zhao, Y.; Meng, L.; Qin, T.; Chen, X.; Li, K.; Yuan, S. Catalytic Pyrolysis of Pine Needle Biomass over Fe–Co–K Catalyst for H2-Rich Syngas Production: Influence of Catalyst Preparation. Energy 2022, 244, 122602. [Google Scholar] [CrossRef]

- IBI. Standardized Product Definition and Product Testing Guidelines for Biochar That Is Used in Soil (Aka IBI Biochar Standards); IBI: Canandaigua, NY, USA, 2015. [Google Scholar]

- European Biochar Foundation. EBC (2012) European Biochar Certificate—Guidelines for a Sustainable Production of Biochar. Version 9.5E; European Biochar Foundation: Arbaz, Switzerland, 2021. [Google Scholar]

- Agegnehu, G.; Srivastava, A.K.; Bird, M.I. The Role of Biochar and Biochar-Compost in Improving Soil Quality and Crop Performance: A Review. Appl. Soil Ecol. 2017, 119, 156–170. [Google Scholar] [CrossRef]

- Doran, J.W.; Zeiss, M.R. Soil Health and Sustainability: Managing the Biotic Component of Soil Health and Sustainability: Managing the Biotic Component of Soil Quality. Appl. Soil Ecol. 2000, 15, 3–11. [Google Scholar] [CrossRef]

- Borrelli, P.; Robinson, D.A.; Fleischer, L.R.; Lugato, E.; Ballabio, C.; Alewell, C.; Meusburger, K.; Modugno, S.; Schütt, B.; Ferro, V.; et al. An Assessment of the Global Impact of 21st Century Land Use Change on Soil Erosion. Nat. Commun. 2017, 8, 2013. [Google Scholar] [CrossRef] [PubMed]

- Verheijen, F.G.A.; Jones, R.J.A.; Rickson, R.J.; Smith, C.J. Tolerable versus Actual Soil Erosion Rates in Europe. Earth Sci. Rev. 2009, 94, 23–38. [Google Scholar] [CrossRef]

- Lal, R. Managing Soils and Ecosystems for Mitigating Anthropogenic Carbon Emissions and Advancing Global Food Security. Bioscience 2010, 60, 708–721. [Google Scholar] [CrossRef]

- Lal, R. Sequestering Carbon and Increasing Productivity by Conservation Agriculture. J. Soil Water Conserv. 2015, 70, 55A–62A. [Google Scholar] [CrossRef]

- Anderson, N.; Gu, H.; Bergman, R. Comparison of Novel Biochars and Steam Activated Carbon from Mixed Conifer Mill Residues. Energies 2021, 14, 8472. [Google Scholar] [CrossRef]

- EU—The European Union. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—The European Green Deal; The European Union: Luxembourg, 2019. [Google Scholar]

- Barrow, C.J. Biochar: Potential for Countering Land Degradation and for Improving Agriculture. Appl. Geogr. 2012, 34, 21–28. [Google Scholar] [CrossRef]

- Bruckman, V.J.; Terada, T.; Uzun, B.B.; Apaydin-Varol, E.; Liu, J. Biochar for Climate Change Mitigation: Tracing the in-Situ Priming Effect on a Forest Site. Energy Procedia 2015, 76, 381–387. [Google Scholar] [CrossRef]

- Blanco-Canqui, H. Biochar and Soil Physical Properties. Soil Sci. Soc. Am. J. 2017, 81, 687–711. [Google Scholar] [CrossRef]

- Oni, B.A.; Oziegbe, O.; Olawole, O.O. Significance of Biochar Application to the Environment and Economy. Ann. Agric. Sci. 2019, 64, 222–236. [Google Scholar] [CrossRef]

- O’Neill, B.; Grossman, J.; Tsai, M.T.; Gomes, J.E.; Lehmann, J.; Peterson, J.; Neves, E.; Thies, J.E. Bacterial Community Composition in Brazilian Anthrosols and Adjacent Soils Characterized Using Culturing and Molecular Identification. Microb. Ecol. 2009, 58, 23–35. [Google Scholar] [CrossRef]

- Pietikäinen, J.; Kiikkilä, O.; Fritze, H. Charcoal as a Habitat for Microbes and Its Effect on the Microbial Community of the Underlying Humus. Oikos 2000, 89, 231–242. [Google Scholar] [CrossRef]

- Yeboah, E.; Asamoah, G.; Ofori, P.; Amoah, B.; Agyeman, K.O.A. Method of Biochar Application Affects Growth, Yield and Nutrient Uptake of Cowpea. Open Agric. 2020, 5, 352–360. [Google Scholar] [CrossRef]

- Bationo, A.; Kihara, J.; Vanlauwe, B.; Waswa, B.; Kimetu, J. Soil Organic Carbon Dynamics, Functions and Management in West African Agro-Ecosystems. Agric. Syst. 2007, 94, 13–25. [Google Scholar] [CrossRef]

- Vanlauwe, B.; Bationo, A.; Chianu, J.; Giller, K.E.; Merckx, R.; Mokwunye, U.; Ohiokpehai, O.; Pypers, P.; Tabo, R.; Shepherd, K.D.; et al. Integrated Soil Fertility Management: Operational Definition and Consequences for Implementation and Dissemination. Outlook Agric. 2010, 39, 17–24. [Google Scholar] [CrossRef]

- Jeffery, S.; Abalos, D.; Prodana, M.; Bastos, A.C.; Van Groenigen, J.W.; Hungate, B.A.; Verheijen, F. Biochar Boosts Tropical but Not Temperate Crop Yields. Environ. Res. Lett. 2017, 12, 053001. [Google Scholar] [CrossRef]

- Agegnehu, G.; Bird, M.I.; Nelson, P.N.; Bass, A.M. The Ameliorating Effects of Biochar and Compost on Soil Quality and Plant Growth on a Ferralsol. Soil Res. 2015, 53, 1–12. [Google Scholar] [CrossRef]

- Li, Z.; Delvaux, B. Phytolith-Rich Biochar: A Potential Si Fertilizer in Desilicated Soils. GCB Bioenergy 2019, 11, 1264–1282. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.M.; Dallmeyer, I.; Garcia-Pérez, M. The Role of Biochar Porosity and Surface Functionality in Augmenting Hydrologic Properties of a Sandy Soil. Sci. Total Environ. 2017, 574, 139–147. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.M.; Dallmeyer, I.; Garcia-Perez, M. Influence of Feedstock Source and Pyrolysis Temperature on Biochar Bulk and Surface Properties. Biomass Bioenergy 2016, 84, 37–48. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.M.; Dallmeyer, I.; Garcia-Perez, M. Modification of Biochar Surface by Air Oxidation: Role of Pyrolysis Temperature. Biomass Bioenergy 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Gray, M.; Johnson, M.G.; Dragila, M.I.; Kleber, M. Water Uptake in Biochars: The Roles of Porosity and Hydrophobicity. Biomass Bioenergy 2014, 61, 196–205. [Google Scholar] [CrossRef]

- Kinney, T.J.; Masiello, C.A.; Dugan, B.; Hockaday, W.C.; Dean, M.R.; Zygourakis, K.; Barnes, R.T. Hydrologic Properties of Biochars Produced at Different Temperatures. Biomass Bioenergy 2012, 41, 34–43. [Google Scholar] [CrossRef]

- Hardie, M.; Clothier, B.; Bound, S.; Oliver, G.; Close, D. Does Biochar Influence Soil Physical Properties and Soil Water Availability? Plant Soil 2014, 376, 347–361. [Google Scholar] [CrossRef]

- Chan, K.Y.; Van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Agronomic Values of Greenwaste Biochar as a Soil Amendment. Aust. J. Soil Res. 2007, 45, 629–634. [Google Scholar] [CrossRef]

- Lehmann, J.; Da Silva, J.P.; Steiner, C.; Nehls, T.; Zech, W.; Glaser, B. Nutrient Availability and Leaching in an Archaeological Anthrosol and a Ferralsol of the Central Amazon Basin: Fertilizer, Manure and Charcoal Amendments. Plant Soil 2003, 249, 343–357. [Google Scholar] [CrossRef]

- Basso, A.S.; Miguez, F.E.; Laird, D.A.; Horton, R.; Westgate, M. Assessing Potential of Biochar for Increasing Water-Holding Capacity of Sandy Soils. GCB Bioenergy 2013, 5, 132–143. [Google Scholar] [CrossRef]

- Bera, T.; Collins, H.P.; Alva, A.K.; Purakayastha, T.J.; Patra, A.K. Biochar and Manure Effluent Effects on Soil Biochemical Properties under Corn Production. Appl. Soil Ecol. 2016, 107, 360–367. [Google Scholar] [CrossRef]

- Glaser, B.; Lehmann, J.; Zech, W. Ameliorating Physical and Chemical Properties of Highly Weathered Soils in the Tropics with Charcoal—A Review. Biol. Fertil. Soils 2002, 35, 219–230. [Google Scholar] [CrossRef]

- Laird, D.A.; Fleming, P.; Davis, D.D.; Horton, R.; Wang, B.; Karlen, D.L. Impact of Biochar Amendments on the Quality of a Typical Midwestern Agricultural Soil. Geoderma 2010, 158, 443–449. [Google Scholar] [CrossRef]

- Lone, A.H.; Najar, G.R.; Ganie, M.A.; Sofi, J.A.; Ali, T. Biochar for Sustainable Soil Health: A Review of Prospects and Concerns. Pedosphere 2015, 25, 639–653. [Google Scholar] [CrossRef]

- Lehmann, J.; Rillig, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar Effects on Soil Biota—A Review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Deb, D.; Kloft, M.; Lässig, J.; Walsh, S. Variable Effects of Biochar and P Solubilizing Microbes on Crop Productivity in Different Soil Conditions. Agroecol. Sustain. Food Syst. 2016, 40, 145–168. [Google Scholar] [CrossRef]

- Warnock, D.D.; Mummey, D.L.; McBride, B.; Major, J.; Lehmann, J.; Rillig, M.C. Influences of Non-Herbaceous Biochar on Arbuscular Mycorrhizal Fungal Abundances in Roots and Soils: Results from Growth-Chamber and Field Experiments. Appl. Soil Ecol. 2010, 46, 450–456. [Google Scholar] [CrossRef]

- Ameray, A.; Bergeron, Y.; Valeria, O.; Montoro Girona, M.; Cavard, X. Forest Carbon Management: A Review of Silvicultural Practices and Management Strategies Across Boreal, Temperate and Tropical Forests. Curr. For. Rep. 2021, 7, 245–266. [Google Scholar] [CrossRef]

- Al Masud, M.A.; Shin, W.S.; Sarker, A.; Septian, A.; Das, K.; Deepo, D.M.; Iqbal, M.A.; Islam, A.R.M.T.; Malafaia, G. A Critical Review of Sustainable Application of Biochar for Green Remediation: Research Uncertainty and Future Directions. Sci. Total Environ. 2023, 904, 166813. [Google Scholar] [CrossRef] [PubMed]

- Korb, J.E.; Johnson, N.C.; Covington, W.W. Slash Pile Burning Effects on Soil Biotic and Chemical Properties and Plant Establishment: Recommendations for Amelioration. Restor. Ecol. 2004, 12, 52–62. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, R.; Jin, B.; Shen, D.; Chen, R.; Xiao, G. Catalytic Fast Pyrolysis of Straw Biomass in an Internally Interconnected Fluidized Bed to Produce Aromatics and Olefins: Effect of Different Catalysts. Bioresour. Technol. 2013, 137, 82–87. [Google Scholar] [CrossRef]

- Han, H.S.; Jacobson, A.; Bilek, E.M.; Sessions, J. Waste to Wisdom: Utilizing Forest Residues for the Production of Bioenergy and Biobased Products. Appl. Eng. Agric. 2018, 34, 5–10. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in Climate Change Mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable Biochar to Mitigate Global Climate Change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Page-Dumroese, D.S.; Busse, M.D.; Archuleta, J.G.; McAvoy, D.; Roussel, E. Methods to Reduce Forest Residue Volume after Timber Harvesting and Produce Black Carbon. Scientifica 2017, 2017, 2745764. [Google Scholar] [CrossRef] [PubMed]

- Pierson, D.; Anderson, N.; Brewen, J.; Clark, N.; Hardy, M.C.; McCollum, D.; McCormick, F.H.; Morisette, J.; Nicosia, T.; Page-Dumroese, D.; et al. Beyond the Basics: A Perspective on Barriers and Opportunities for Scaling up Biochar Production from Forest Slash. Biochar 2024, 6, 1. [Google Scholar] [CrossRef]

- Heiskanen, J.; Tammeorg, P.; Dumroese, R.K. Growth of Norway Spruce Seedlings after Transplanting into Silty Soil Amended with Biochar: A Bioassay in a Growth Chamber-Short Communication. J. For. Sci. 2013, 59, 125–129. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, Q.; Liu, G.; Cowie, A.L.; Bei, Q.; Liu, B.; Wang, X.; Ma, J.; Zhu, J.; Xie, Z. Effects of Different Biochars on Pinus Elliottii Growth, N Use Efficiency, Soil N2O and CH4 Emissions and C Storage in a Subtropical Area of China. Pedosphere 2017, 27, 248–261. [Google Scholar] [CrossRef]

- Sarauer, J.L.; Coleman, M.D. Douglas-Fir Seedling Quality in Biochar-Amended Peat Substrates. Reforesta 2019, 7, 1–14. [Google Scholar] [CrossRef]

- Sarauer, J.L.; Page-Dumroese, D.S.; Coleman, M.D. Soil Greenhouse Gas, Carbon Content, and Tree Growth Response to Biochar Amendment in Western United States Forests. GCB Bioenergy 2019, 11, 660–671. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A Mixed Biomass-Based Energy Supply Chain for Enhancing Economic and Environmental Sustainability Benefits: A Multi-Criteria Decision Making Framework. Appl. Energy 2017, 206, 1088–1101. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-Economic Analysis of Producing Solid Biofuels and Biochar from Forest Residues Using Portable Systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Parkhurst, K.M.; Saffron, C.M.; Miller, R.O. An Energy Analysis Comparing Biomass Torrefaction in Depots to Wind with Natural Gas Combustion for Electricity Generation. Appl. Energy 2016, 179, 171–181. [Google Scholar] [CrossRef]

- Berrill, J.P.; Han, H.S. Carbon, Harvest Yields, and Residues from Restoration in a Mixed Forest on California’s Coast Range. For. Sci. 2017, 63, 128–135. [Google Scholar] [CrossRef]

- Choi, J.Y.; Kim, Y.U.; Nam, J.; Kim, S.; Kim, S. Enhancing the Thermal Stability and Fire Retardancy of Bio-Based Building Materials through Pre-Biochar System. Constr. Build. Mater. 2023, 409, 134099. [Google Scholar] [CrossRef]

- Azman Mohammad Taib, M.N.; Hamidon, T.S.; Garba, Z.N.; Trache, D.; Uyama, H.; Hussin, M.H. Recent Progress in Cellulose-Based Composites towards Flame Retardancy Applications. Polymer 2022, 244, 124677. [Google Scholar] [CrossRef]

- Kovačević, Z.; Flinčec Grgac, S.; Bischof, S. Progress in Biodegradable Flame-Retardant Nano-Biocomposites. Polymers 2021, 13, 741. [Google Scholar] [CrossRef]

- Forest Europe 2020 FOREST EUROPE, 2020: State of Europe’s Forests; Ministerial Conference on the Protection of Forests in Europe; FOREST EUROPE Liaison Unit Bratislava: Madrid, Spain, 2020.

- Minamino, Y.; Fujitake, N.; Suzuki, T.; Yoshitake, S.; Koizumi, H.; Tomotsune, M. Effect of Biochar Addition on Leaf-Litter Decomposition at Soil Surface during Three Years in a Warm-Temperate Secondary Deciduous Forest, Japan. Sci. Rep. 2019, 9, 16961. [Google Scholar] [CrossRef]

- Saarnio, S.; Kettunen, R.; Saarnio, S.; Kettunen, R. Biochar Addition Affected Nutrient Leaching and Litter Decomposition Rates in Boreal Sandy Soils. Agric. Food Sci. 2020, 29, 287–296. [Google Scholar] [CrossRef]

- Weyers, S.L.; Spokas, K.A. Crop Residue Decomposition in Minnesota Biochar-Amended Plots. Solid Earth 2014, 5, 499–507. [Google Scholar] [CrossRef]

- Vannini, A.; Carbognani, M.; Chiari, G.; Forte, T.G.W.; Rodolfi, M.; Ganino, T.; Petraglia, A. Biochar Effects on Early Decomposition of Standard Litter in a European Beech Forest (Northern Italy). Sci. Total Environ. 2023, 903, 166224. [Google Scholar] [CrossRef]

- Schmidt, H.-P.; Kammann, C.; Hagemann, N.; Leifeld, J.; Bucheli, T.D.; Sánchez Monedero, M.A.; Cayuela, M.L. Biochar in Agriculture—A Systematic Review of 26 Global Meta-Analyses. GCB Bioenergy 2021, 13, 1708–1730. [Google Scholar] [CrossRef]

- Verheijen, F.; Jeffery, S.; Bastos, A.C. Biochar Application to Soils: A Critical Scientific Review of Effects on Soil Properties, Processes and Functions; European Commission: Luxembourg, 2010; ISBN 9789279142932. [Google Scholar]

- Rajkovich, S.; Enders, A.; Hanley, K.; Hyland, C.; Zimmerman, A.R.; Lehmann, J. Corn Growth and Nitrogen Nutrition after Additions of Biochars with Varying Properties to a Temperate Soil. Biol. Fertil. Soils 2012, 48, 271–284. [Google Scholar] [CrossRef]

- Asai, H.; Samson, B.K.; Stephan, H.M.; Songyikhangsuthor, K.; Homma, K.; Kiyono, Y.; Inoue, Y.; Shiraiwa, T.; Horie, T. Biochar Amendment Techniques for Upland Rice Production in Northern Laos: 1. Soil Physical Properties, Leaf SPAD and Grain Yield. Field Crops Res. 2009, 111, 81–84. [Google Scholar] [CrossRef]

- Steiner, C.; Teixeira, W.G.; Lehmann, J.; Nehls, T.; De MacÊdo, J.L.V.; Blum, W.E.H.; Zech, W. Long Term Effects of Manure, Charcoal and Mineral Fertilization on Crop Production and Fertility on a Highly Weathered Central Amazonian Upland Soil. Plant Soil 2007, 291, 275–290. [Google Scholar] [CrossRef]

- Solaiman, Z.M.; Murphy, D.V.; Abbott, L.K. Biochars Influence Seed Germination and Early Growth of Seedlings. Plant Soil 2012, 353, 273–287. [Google Scholar] [CrossRef]

- Vaccari, F.P.; Baronti, S.; Lugato, E.; Genesio, L.; Castaldi, S.; Fornasier, F.; Miglietta, F. Biochar as a Strategy to Sequester Carbon and Increase Yield in Durum Wheat. Eur. J. Agron. 2011, 34, 231–238. [Google Scholar] [CrossRef]

- Dunlop, S.J.; Camps Arbestain, M.; Bishop, P.A.; Wargent, J.J. Closing the Loop: Use of Biochar Produced from Tomato Crop Green Waste as a Substrate for Soilless, Hydroponic Tomato Production. HortScience 2015, 50, 1572–1581. [Google Scholar] [CrossRef]

- Major, J.; Rondon, M.; Molina, D.; Riha, S.J.; Lehmann, J. Maize Yield and Nutrition during 4 Years after Biochar Application to a Colombian Savanna Oxisol. Plant Soil 2010, 333, 117–128. [Google Scholar] [CrossRef]

- Yamato, M.; Okimori, Y.; Wibowo, I.F.; Anshori, S.; Ogawa, M. Effects of the Application of Charred Bark of Acacia Mangium on the Yield of Maize, Cowpea and Peanut, and Soil Chemical Properties in South Sumatra, Indonesia. Soil Sci. Plant Nutr. 2006, 52, 489–495. [Google Scholar] [CrossRef]

- Hammond, J.; Shackley, S.; Prendergast-Miller, M.; Cook, J.; Buckingham, S.; Pappa, V.A. Biochar Field Testing in the UK: Outcomes and Implications for Use. Carbon Manag. 2013, 4, 159–170. [Google Scholar] [CrossRef]

- Schulz, H.; Dunst, G.; Glaser, B. Positive Effects of Composted Biochar on Plant Growth and Soil Fertility. Agron. Sustain. Dev. 2013, 33, 817–827. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Calero, J.M.; Barrón, V.; Torrent, J.; del Campillo, M.C.; Gallardo, A.; Villar, R. Effects of Biochars Produced from Different Feedstocks on Soil Properties and Sunflower Growth. J. Plant Nutr. Soil Sci. 2014, 177, 16–25. [Google Scholar] [CrossRef]

- Novak, J.; Sigua, G.; Watts, D.; Cantrell, K.; Shumaker, P.; Szogi, A.; Johnson, M.G.; Spokas, K. Biochars Impact on Water Infiltration and Water Quality through a Compacted Subsoil Layer. Chemosphere 2016, 142, 160–167. [Google Scholar] [CrossRef]

- Singh Yadav, S.P.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar Application: A Sustainable Approach to Improve Soil Health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, R.K.; Zhang, H. The Forms of Alkalis in the Biochar Produced from Crop Residues at Different Temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef]

- Di Stefano, V.; Di Domenico, G.; Menta, M.; Pontuale, E.; Bianchini, L.; Colantoni, A. Comparison between Different Mechanization Systems: Economic Sustainability of Harvesting Poplar Plantations in Italy. Forests 2024, 15, 397. [Google Scholar] [CrossRef]

- Mohan, D.; Rajput, S.; Singh, V.K.; Steele, P.H.; Pittman, C.U. Modeling and Evaluation of Chromium Remediation from Water Using Low Cost Bio-Char, a Green Adsorbent. J. Hazard. Mater. 2011, 188, 319–333. [Google Scholar] [CrossRef]

- Gheorghe-Bulmau, C.; Volceanov, A.; Stanciulescu, I.; Ionescu, G.; Marculescu, C.; Radoiu, M. Production and Properties Assessment of Biochars from Rapeseed and Poplar Waste Biomass for Environmental Applications in Romania. Environ. Geochem. Health 2022, 44, 1683–1696. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G.; Chen, L.; Chen, Y.; Lehmann, J.; McBride, M.B.; Hay, A.G. Adsorption of Copper and Zinc by Biochars Produced from Pyrolysis of Hardwood and Corn Straw in Aqueous Solution. Bioresour. Technol. 2011, 102, 8877–8884. [Google Scholar] [CrossRef]

- Zama, E.F.; Zhu, Y.G.; Reid, B.J.; Sun, G.X. The Role of Biochar Properties in Influencing the Sorption and Desorption of Pb(II), Cd(II) and As(III) in Aqueous Solution. J. Clean. Prod. 2017, 148, 127–136. [Google Scholar] [CrossRef]

- Khan, A.; Rashid, A.; Younas, R. Adsorption of Reactive Black-5 by Pine Needles Biochar Produced Via Catalytic and Non-Catalytic Pyrolysis. Arab. J. Sci. Eng. 2015, 40, 1269–1278. [Google Scholar] [CrossRef]

- Vamvuka, D.; Esser, K.; Marinakis, D. Characterization of Pyrolysis Products of Forest Residues and Refuse-Derived Fuel and Evaluation of Their Suitability as Bioenergy Sources. Appl. Sci. 2023, 13, 1482. [Google Scholar] [CrossRef]

- Pariyar, P.; Kumari, K.; Jain, M.K.; Jadhao, P.S. Evaluation of Change in Biochar Properties Derived from Different Feedstock and Pyrolysis Temperature for Environmental and Agricultural Application. Sci. Total Environ. 2020, 713, 136433. [Google Scholar] [CrossRef]

- Venegas, A.; Rigol, A.; Vidal, M. Viability of Organic Wastes and Biochars as Amendments for the Remediation of Heavy Metal-Contaminated Soils. Chemosphere 2015, 119, 190–198. [Google Scholar] [CrossRef]

- Asadullah, M.; Rahman, M.A.; Ali, M.M.; Rahman, M.S.; Motin, M.A.; Sultan, M.B.; Alam, M.R. Production of Bio-Oil from Fixed Bed Pyrolysis of Bagasse. Fuel 2007, 86, 2514–2520. [Google Scholar] [CrossRef]

- Chen, B.; Zhou, D.; Zhu, L. Transitional Adsorption and Partition of Nonpolar and Polar Aromatic Contaminants by Biochars of Pine Needles with Different Pyrolytic Temperatures. Environ. Sci. Technol. 2008, 42, 5137–5143. [Google Scholar] [CrossRef]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sanchez-Monedero, M.A.; Sonoki, T. Physical and Chemical Characterization of Biochars Derived from Different Agricultural Residues. Biogeosciences 2014, 11, 6613–6621. [Google Scholar] [CrossRef]

- Mukherjee, A.; Zimmerman, A.R.; Harris, W. Surface Chemistry Variations among a Series of Laboratory-Produced Biochars. Geoderma 2011, 163, 247–255. [Google Scholar] [CrossRef]

- Carnevale, M.; Santangelo, E.; Colantoni, A.; Paris, E.; Palma, A.; Vincenti, B.; Paolini, V.; Petracchini, F.; Salerno, M.; Di Stefano, V.; et al. Thermogravimetric Analysis of Olive Tree Pruning as Pyrolysis Feedstock. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Virtual, 6–9 July 2020; pp. 581–584. [Google Scholar]

- Palma, A.; Gallucci, F.; Papandrea, S.; Carnevale, M.; Paris, E.; Vincenti, B.; Salerno, M.; Di Stefano, V.; Proto, A.R. Experimental Study of the Combustion of and Emissions from Olive and Citrus Pellets in a Small Boiler. Fire 2023, 6, 288. [Google Scholar] [CrossRef]

- Bagreev, A.; Bandosz, T.J.; Locke, D.C. Pore Structure and Surface Chemistry of Adsorbents Obtained by Pyrolysis of Sewage Sludge-Derived Fertilizer. Carbon 2001, 39, 1971–1979. [Google Scholar] [CrossRef]

- Leng, L.; Xiong, Q.; Yang, L.; Li, H.; Zhou, Y.; Zhang, W.; Jiang, S.; Li, H.; Huang, H. An Overview on Engineering the Surface Area and Porosity of Biochar. Sci. Total Environ. 2021, 76, 1442043. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Enders, A.; Hanley, K.; Whitman, T.; Joseph, S.; Lehmann, J. Characterization of Biochars to Evaluate Recalcitrance and Agronomic Performance. Bioresour. Technol. 2012, 114, 644–653. [Google Scholar] [CrossRef]

| Criterion | IBI Standard | EBC Standard | |

|---|---|---|---|

| Feedstock | Biomass, not including municipal solid waste, hazardous materials, or hazardous wastes | All biomasses included in the EBC-Positive list may be used individually or in combination as feedstock to produce EBC biochar. | |

| Carbon content (%) | 10% minimum in 3 classes: Class 1: ≥60 %Class 2: ≥30% and <60 %Class 3: ≥10% and <30% | 35–95% of dry matter | |

| Molar H:C organic ratio | <0.7 | <0.7 | |

| Surface area (m2 g−1) | No minimum | No method provides absolute values for the specific surface area | |

| Heavy metals | Range of maximum allowed thresholds | Thresholds of heavy metals related to EBC-Agro (Class III) | |

| Pb | 121–300 mg kg−1 | 150 g t−1 | |

| Cd | 1.4–39 mg kg−1 | 1.5 g t−1 | |

| Cu | 143–6000 mg kg−1 | 100 g t−1 | |

| Ni | 47–420 mg kg−1 | 50 g t−1 | |

| Hg | 1–17 mg kg−1 | 1 g t−1 | |

| Zn | 416–7400 mg kg−1 | 400 g t−1 | |

| Cr | 93–1200 mg kg−1 | 90 g t−1 | |

| As | 13–100 mg kg−1 | 13 g t−1 | |

| Polycyclic Aromatic Hydrocarbons (PAHs) | 6–300 mg kg−1 | 6.0 ± 2.2 g t−1 | |

| Polychlorinated Biphenyls (PCBs) | 0.2–1 mg kg−1 | 0.2 mg kg−1 | |

| Dioxins and furans | 17 ng kg−1 | 20 ng kg−1 | |

| MT | BF | Specie | PT (°C) | PY (%) | pH | SSA (m2/g) | VM (%) | A (%) | CEC (cmol/kg) | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Hardwood | Bark | Oak | 450 | 1.88 | 22.8 | 11.09 | [103] | |||

| Hardwood | Sawdust | Eucalyptus | 350 | 42.5 | 5.9 | 36.9 | 0.9 | [12] | ||

| Hardwood | Sawdust | Eucalyptus | 450 | 36 | 8 | 28.5 | 0.7 | [12] | ||

| Hardwood | Sawdust | Eucalyptus | 750 | 28.2 | 9.7 | 6.5 | 1.1 | [12] | ||

| Hardwood | Chip | White Poplar | 300 | 53 | 9.1 | 16.76 | 32.94 | [104] | ||

| Hardwood | Chip | White Poplar | 400 | 29 | 6.1 | 3.75 | 27.9 | 39.45 | [104] | |

| Hardwood | Chip | White Poplar | 500 | 31 | 9.5 | 8 | 24.84 | 43.04 | [104] | |

| Hardwood | Chip | White Poplar | 600 | 26 | 7.5 | 120.31 | 21.74 | 50.93 | [104] | |

| Hardwood | Chip | White Poplar | 700 | 22 | 10.9 | 228.5 | 13.67 | 52.17 | [104] | |

| Hardwood | Chip | White Poplar | 800 | 20 | 9.9 | 137.9 | 15.68 | 26.8 | [104] | |

| Hardwood | Wood | Hardwood | 450 | 5.6 | 0,4 | 38.6 | [105] | |||

| Hardwood | Wood | Oak | 400 | 2.73 | 15.6 | 2.92 | [103] | |||

| Hardwood | Wood | Mulberry | 350 | 37.5 | 10.2 | 16.6 | 7.5 | 23.3 | [106] | |

| Hardwood | Wood | Mulberry | 450 | 32.7 | 11.1 | 31.5 | 7.7 | 22.1 | [106] | |

| Hardwood | Wood | Mulberry | 550 | 26.2 | 10.6 | 58 | 9.8 | 19 | [106] | |

| Hardwood | Wood | Mulberry | 650 | 22.8 | 10.6 | 24.5 | 9.8 | 21.8 | [106] | |

| Softwood | Bark | Pine | 350 | 59.6 | 7.8 | 38.5 | 8.3 | [12] | ||

| Softwood | Bark | Pine | 450 | 49.3 | 8.3 | 29.3 | 7.9 | [12] | ||

| Softwood | Bark | Pine | 750 | 38.9 | 9.9 | 6 | 14.5 | [12] | ||

| Softwood | Chip | Pine | 500 | 6.2 | 22.4 | 2.6 | [99] | |||

| Softwood | Needles | Pine | 450 | 40.96 | 9.64 | 5.76 | [107] | |||

| Softwood | Pinecones | Pine | 350 | 49 | 76.9 | 12.1 | 24.8 | [108] | ||

| Softwood | Pinecones | Pine | 450 | 39 | 15.1 | 22.7 | [108] | |||

| Softwood | Pinecones | Pine | 550 | 28 | 20.5 | 21.8 | [108] | |||

| Softwood | Sawdust | Pine | 350 | 5.75 ± 0.02 | 3.39 ± 0.79 | 56.13 | [109] | |||

| Softwood | Sawdust | Pine | 450 | 6.31 ± 0.04 | 179.77 ± 2.35 | 52.43 | [109] | |||

| Softwood | Sawdust | Pine | 550 | 6.66 ± 0.08 | 431.91 ± 5.46 | 47.43 | [109] | |||

| Softwood | Sawdust | Pine | 650 | 6.84 ± 0.03 | 443.79 ± 0.98 | 39.22 | [109] | |||

| Bark | 400 | 8.9 | 23 | [110] | ||||||

| Forest residue | 350 | 38 | 84.5 | 1.4 | 24.2 | [108] | ||||

| Forest residue | 450 | 30 | 1.6 | 19.5 | [108] | |||||

| Forest residue | 550 | 23 | 2.3 | 15.2 | [108] |

| MT | BF | Specie | PT (°C) | C (%) | H (%) | N (%) | S (%) | O (%) | H/C | O/C | References |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hardwood | Bark | Oak | 450 | 71.25 | 2.63 | 0.46 | 0.02 | 12.99 | [103] | ||

| Hardwood | Sawdust | Eucalyptus | 350 | 70.4 | 3.81 | 0.02 | 24 | 0.65 | 0.26 | [12] | |

| Hardwood | Sawdust | Eucalyptus | 450 | 78.6 | 3.42 | 0.01 | 16.6 | 0.52 | 0.16 | [12] | |

| Hardwood | Sawdust | Eucalyptus | 750 | 90.9 | 1.52 | 0.04 | 5.6 | 0.20 | 0.05 | [12] | |

| Hardwood | Chip | White Poplar | 300 | 51.75 | 3.91 | 2.58 | 41.76 | 1.21 | 1.21 | 0.48 | [104] |

| Hardwood | Chip | White Poplar | 400 | 50.31 | 3.09 | 2.67 | 43.93 | 0.93 | 0.39 | [104] | |

| Hardwood | Chip | White Poplar | 500 | 56.89 | 2.86 | 2.82 | 37.43 | 0.82 | 0.39 | [104] | |

| Hardwood | Chip | White Poplar | 600 | 55.21 | 1.96 | 2.26 | 40.57 | 0.29 | 0.34 | [104] | |

| Hardwood | Chip | White Poplar | 700 | 50.44 | 1.51 | 2.07 | 45.97 | 0.25 | 0.45 | [104] | |

| Hardwood | Chip | White Poplar | 800 | 43.83 | 2.9 | 2.17 | 51.1 | 0.26 | 0.42 | [104] | |

| Hardwood | Wood | Hardwood | 450 | 53.4 | 2.3 | 0.07 | 5.7 | 0.52 | 0.08 | [105] | |

| Hardwood | Wood | Oak | 450 | 82.83 | 2.7 | 0.31 | 0.02 | 8.05 | [103] | ||

| Hardwood | Wood | Mulberry | 350 | 67.9 | 4.53 | 2.16 | 0.20 | 25.2 | 0,80 | 0,28 | [106] |

| Hardwood | Wood | Mulberry | 450 | 70.8 | 3.32 | 1.92 | 0.15 | 23.8 | 0.56 | 0.25 | [106] |

| Hardwood | Wood | Mulberry | 550 | 77 | 2.41 | 1.68 | 0.15 | 18.8 | 0.38 | 0.18 | [106] |

| Hardwood | Wood | Mulberry | 650 | 80.1 | 1.63 | 1.58 | 0.13 | 16.6 | 0.24 | 0.15 | [106] |

| Softwood | Bark | Pine | 350 | 67.6 | 3.73 | 0.01 | 28.7 | 0.66 | 0.32 | [12] | |

| Softwood | Bark | Pine | 450 | 75.2 | 2.74 | 0.02 | 24.7 | 0.44 | 0.25 | [12] | |

| Softwood | Bark | Pine | 750 | 86.3 | 1.16 | 0.04 | 19.1 | 0.16 | 0.17 | [12] | |

| Softwood | Chip | Pine | 500 | 88.9 | 3.14 | 0.45 | 0.002 | 4.97 | 0.43 | 0.04 | [99] |

| Softwood | Needles | Pine | 450 | 39.58 | 19.93 | 22.02 | [107] | ||||

| Softwood | Pinecones | Pine | 350 | 62.7 | 4.9 | 1 | 19.2 | [108] | |||

| Softwood | Pinecones | Pine | 450 | 62.9 | 3.2 | 1 | 17.8 | [108] | |||

| Softwood | Pinecones | Pine | 550 | 63.4 | 1.9 | 1 | 13.2 | [108] | |||

| Softwood | Sawdust | Pine | 350 | 52.28 | 5.17 | 0.15 | 0.00 | 30.5 | 1.19 | 0.44 | [109] |

| Softwood | Sawdust | Pine | 450 | 58.2 | 4.23 | 0.16 | 0.00 | 25.11 | 0.87 | 0.32 | [109] |

| Softwood | Sawdust | Pine | 550 | 59.19 | 3.97 | 0.51 | 0.00 | 20.73 | 0.80 | 0.26 | [109] |

| Softwood | Sawdust | Pine | 650 | 62.87 | 3.44 | 0.18 | 0.00 | 12 | 0.66 | 0.14 | [109] |

| Bark | 400 | 80 | 0.5 | [110] | |||||||

| Forest residue | 350 | 68.4 | 4 | 26.2 | [108] | ||||||

| Forest residue | 450 | 62.7 | 2.9 | 32.8 | [108] | ||||||

| Forest residue | 550 | 56.5 | 2.1 | 39.1 | [108] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Domenico, G.; Bianchini, L.; Di Stefano, V.; Venanzi, R.; Lo Monaco, A.; Colantoni, A.; Picchio, R. New Frontiers for Raw Wooden Residues, Biochar Production as a Resource for Environmental Challenges. C 2024, 10, 54. https://doi.org/10.3390/c10020054

Di Domenico G, Bianchini L, Di Stefano V, Venanzi R, Lo Monaco A, Colantoni A, Picchio R. New Frontiers for Raw Wooden Residues, Biochar Production as a Resource for Environmental Challenges. C. 2024; 10(2):54. https://doi.org/10.3390/c10020054

Chicago/Turabian StyleDi Domenico, Giorgia, Leonardo Bianchini, Valerio Di Stefano, Rachele Venanzi, Angela Lo Monaco, Andrea Colantoni, and Rodolfo Picchio. 2024. "New Frontiers for Raw Wooden Residues, Biochar Production as a Resource for Environmental Challenges" C 10, no. 2: 54. https://doi.org/10.3390/c10020054

APA StyleDi Domenico, G., Bianchini, L., Di Stefano, V., Venanzi, R., Lo Monaco, A., Colantoni, A., & Picchio, R. (2024). New Frontiers for Raw Wooden Residues, Biochar Production as a Resource for Environmental Challenges. C, 10(2), 54. https://doi.org/10.3390/c10020054