Miscanthus-Derived Biochar as a Platform for the Production of Fillers for the Improvement of Mechanical and Electromagnetic Properties of Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. BC Production

2.2.2. Fe-BC Production

2.2.3. Filler Characterization

2.2.4. Composite Preparation and Characterization

3. Results and Discussion

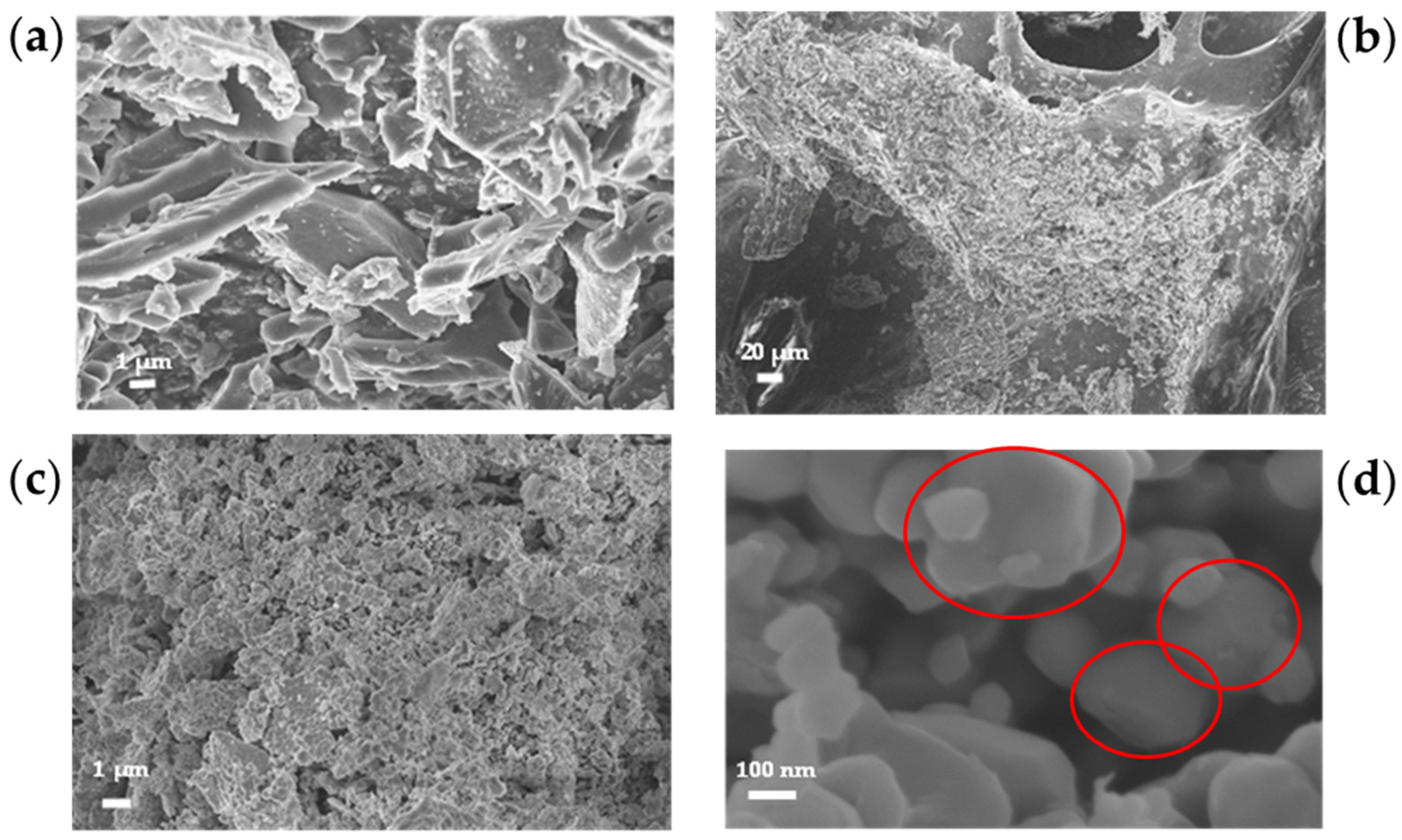

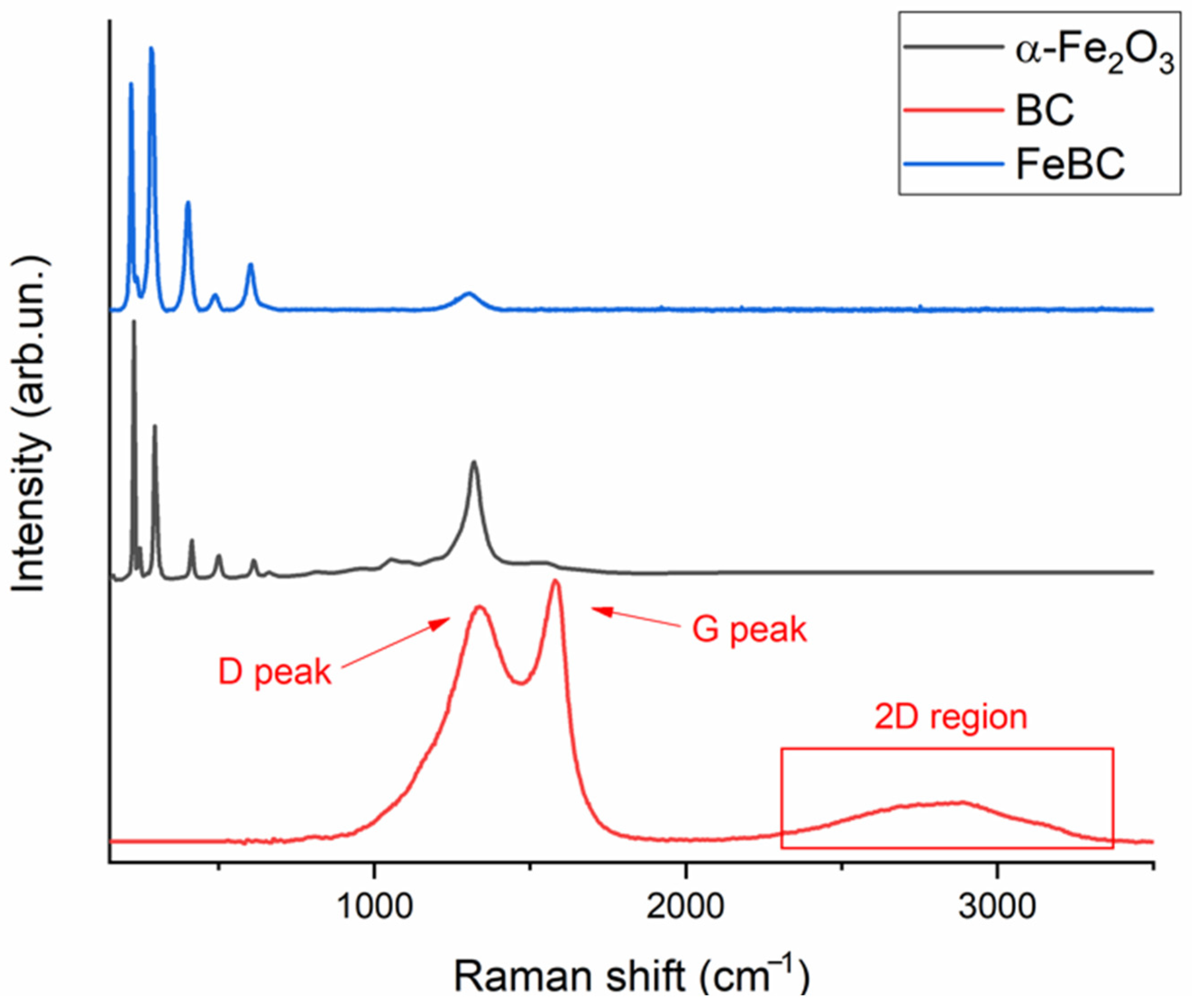

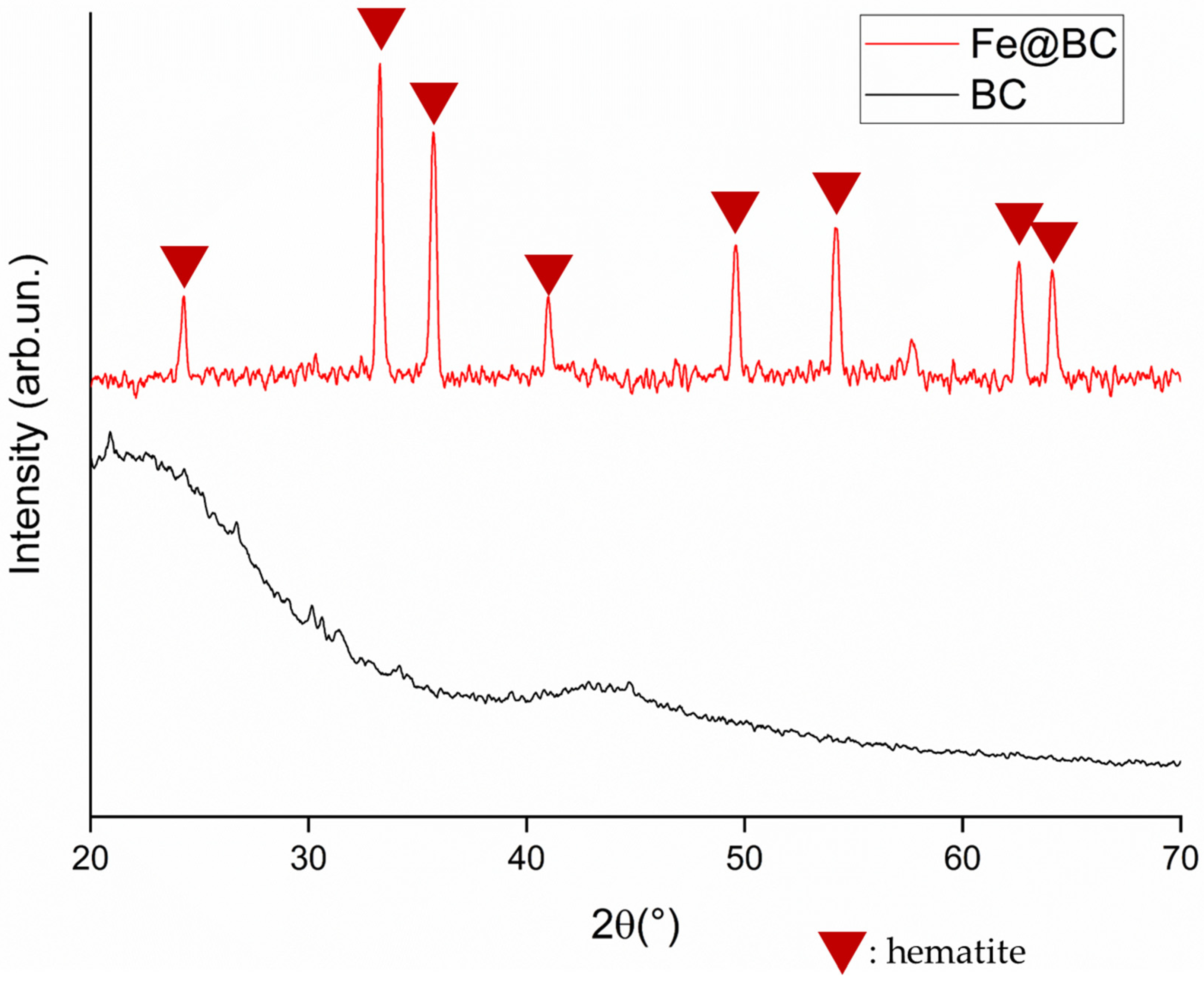

3.1. Filler Characterization

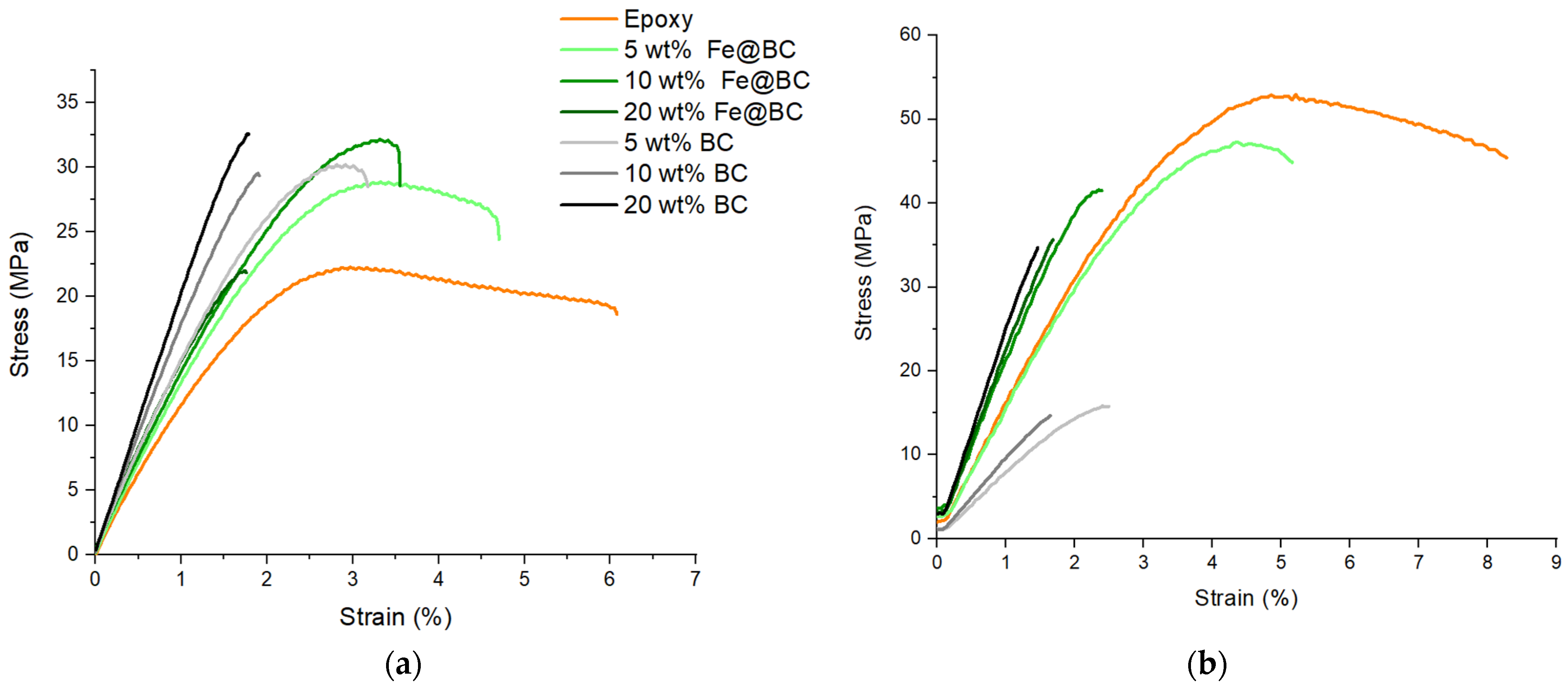

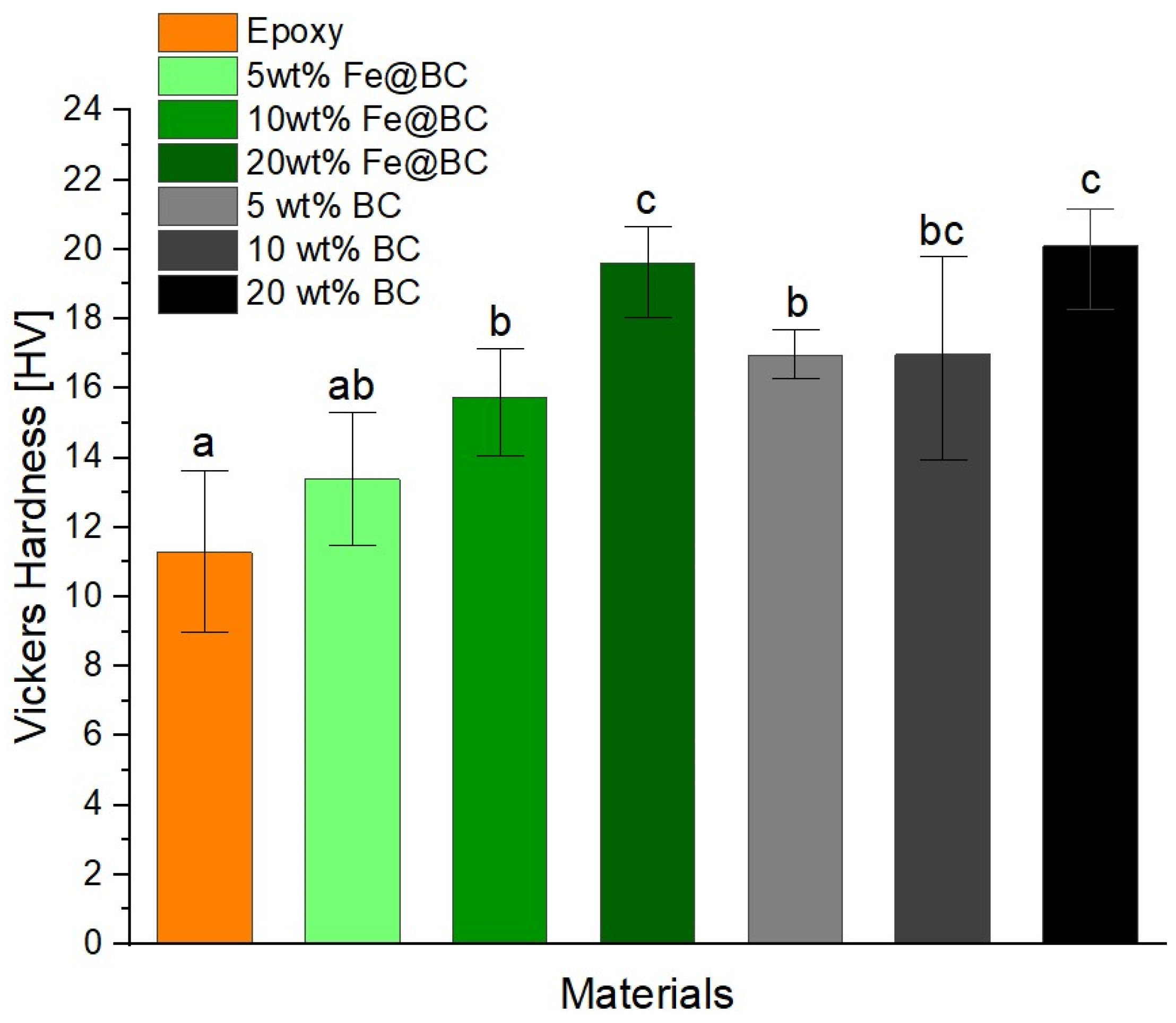

3.2. Mechanical Properties

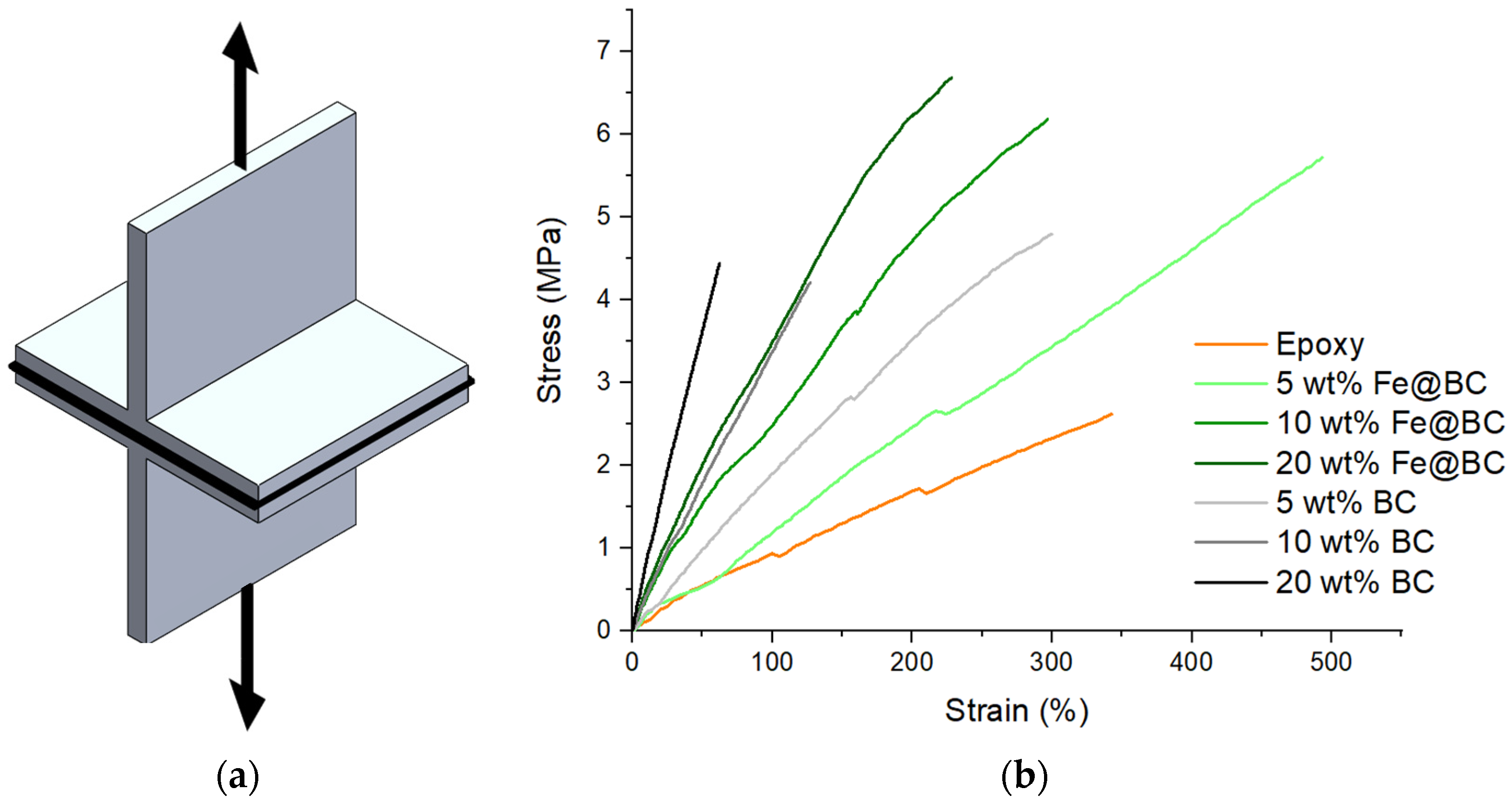

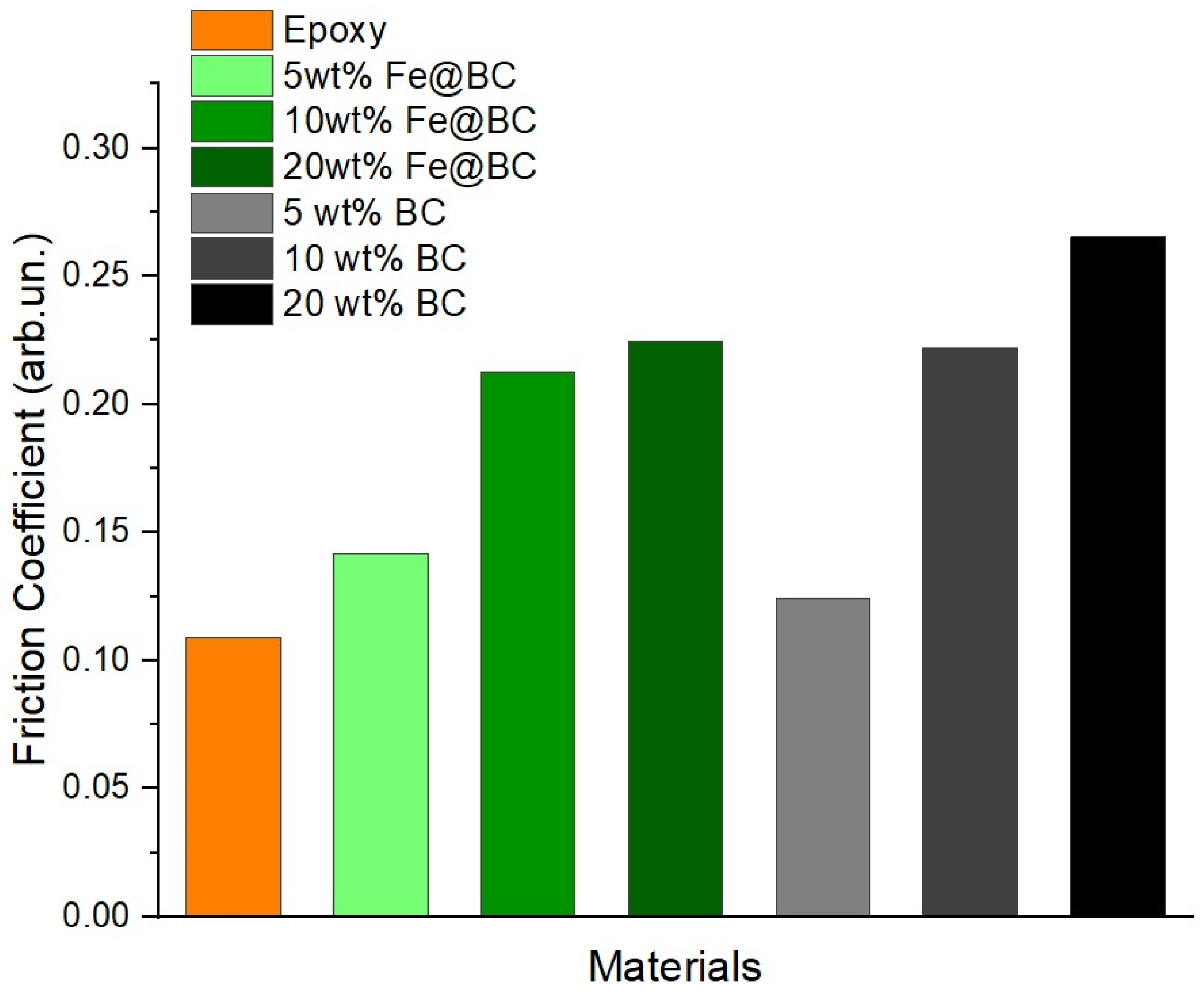

3.3. Surface Properties

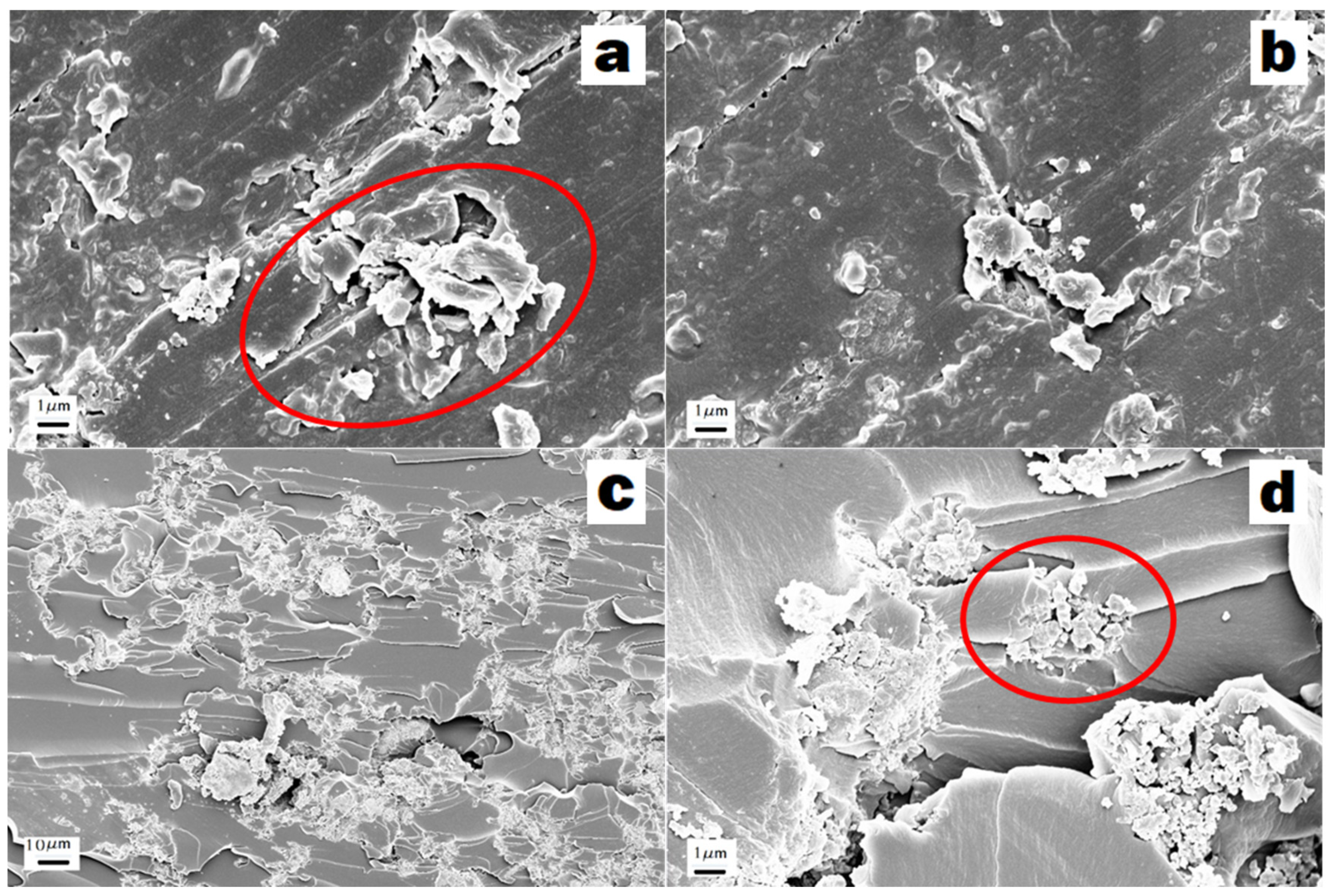

3.4. Microscopical Analysis of the Fracture Surfaces

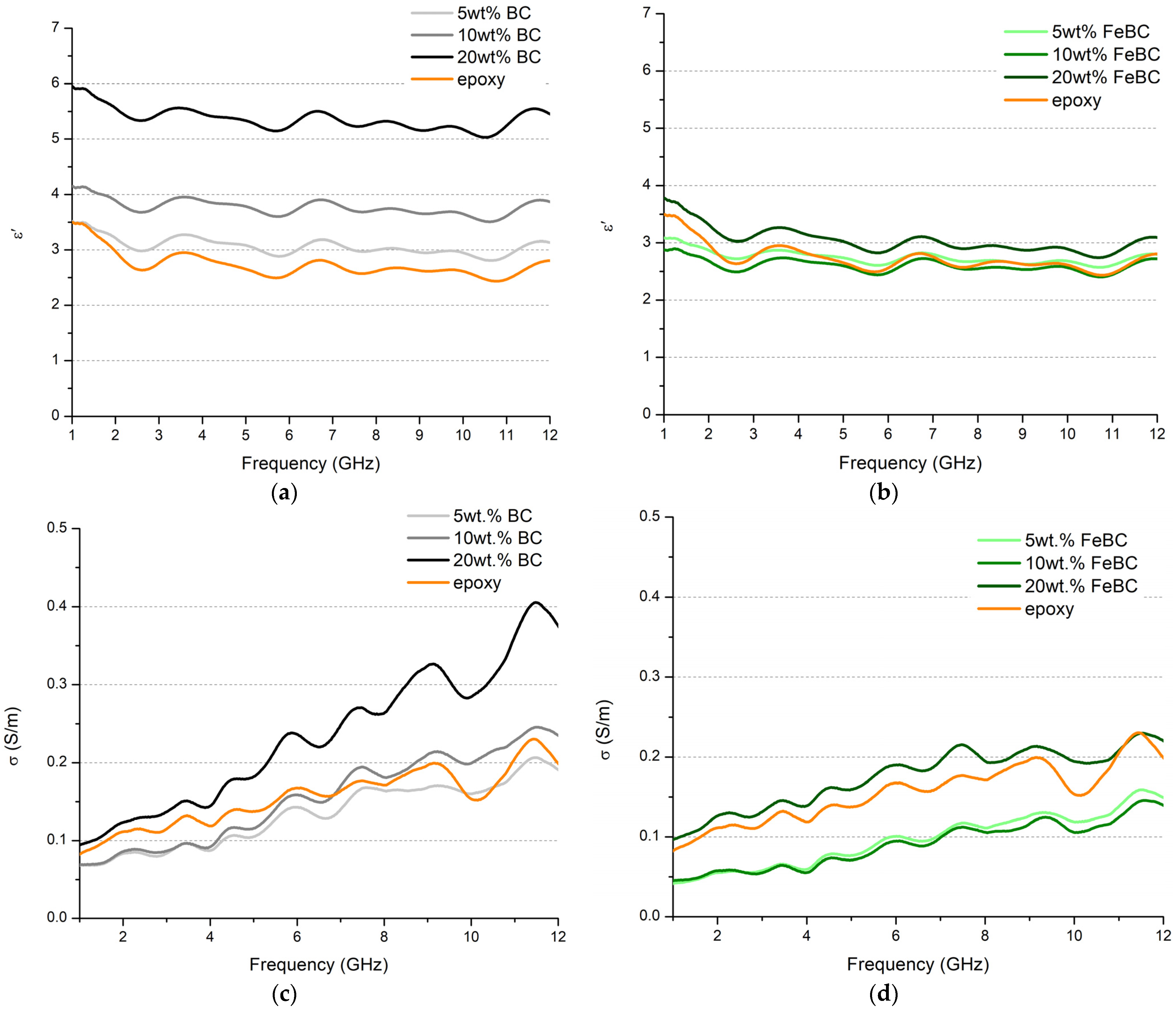

3.5. Electromagnetic Characterization

3.6. Mechanical Properties of Other Polymer–BC Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mangino, E.; Carruthers, J.; Pitarresi, G. The future use of structural composite materials in the automotive industry. Int. J. Veh. Des. 2007, 44, 211–232. [Google Scholar] [CrossRef]

- Soni, R.; Verma, R.; Garg, R.K.; Sharma, V. A critical review of recent advances in the aerospace materials. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Bakht, S.M.; Pardo, A.; Gómez-Florit, M.; Reis, R.L.; Domingues, R.M.; Gomes, M.E. Engineering next-generation bioinks with nanoparticles: Moving from reinforcement fillers to multifunctional nanoelements. J. Mater. Chem. B 2021, 9, 5025–5038. [Google Scholar] [CrossRef]

- Rahaman, M.; Theravalappil, R.; Bhandari, S.; Nayak, L.; Bhagabati, P. Electrical conductivity of polymer-graphene composites. In Polymer Nanocomposites Containing Graphene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 107–139. [Google Scholar]

- Rahman, M.R.; Rashid, M.M.; Islam, M.M.; Akanda, M.M. Electrical and chemical properties of graphene over composite materials: A technical review. Mater. Sci. Res. India 2019, 16, 142–163. [Google Scholar] [CrossRef]

- Moisala, A.; Li, Q.; Kinloch, I.; Windle, A. Thermal and electrical conductivity of single-and multi-walled carbon nanotube-epoxy composites. Compos. Sci. Technol. 2006, 66, 1285–1288. [Google Scholar] [CrossRef]

- Gardea, F.; Lagoudas, D.C. Characterization of electrical and thermal properties of carbon nanotube/epoxy composites. Compos. Part B Eng. 2014, 56, 611–620. [Google Scholar] [CrossRef]

- Nurazzi, N.; Sabaruddin, F.; Harussani, M.; Kamarudin, S.; Rayung, M.; Asyraf, M.; Aisyah, H.; Norrrahim, M.; Ilyas, R.; Abdullah, N. Mechanical performance and applications of cnts reinforced polymer composites—A review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef] [PubMed]

- Arash, B.; Wang, Q.; Varadan, V. Mechanical properties of carbon nanotube/polymer composites. Sci. Rep. 2014, 4, 6479. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Palermo, V.; Kinloch, I.A.; Ligi, S.; Pugno, N.M. Nanoscale mechanics of graphene and graphene oxide in composites: A scientific and technological perspective. Adv. Mater. 2016, 28, 6232–6238. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Peng, H.; Liu, Z. Synthesis challenges for graphene industry. Nat. Mater. 2019, 18, 520–524. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Huang, J.Q.; Zhao, M.Q.; Qian, W.Z.; Wei, F. Carbon nanotube mass production: Principles and processes. ChemSusChem 2011, 4, 864–889. [Google Scholar] [CrossRef]

- Gábor, T.; Aranyi, D.; Papp, K.; Kármán, F.; Kálmán, E. Dispersibility of Carbon Nanotubes. In Materials Science Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2007; pp. 161–168. [Google Scholar]

- Perumal, S.; Atchudan, R.; Cheong, I.W. Recent studies on dispersion of graphene–polymer composites. Polymers 2021, 13, 2375. [Google Scholar] [CrossRef]

- Kauling, A.P.; Seefeldt, A.T.; Pisoni, D.P.; Pradeep, R.C.; Bentini, R.; Oliveira, R.V.; Novoselov, K.S.; Castro Neto, A.H. The worldwide graphene flake production. Adv. Mater. 2018, 30, 1803784. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, Q.; Zhao, M.; Wei, F. A review of the large-scale production of carbon nanotubes: The practice of nanoscale process engineering. Chin. Sci. Bull. 2012, 57, 157–166. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Rosso, C.; Rovere, M.; Jagdale, P.; Tagliaferro, A. Influence of commercial biochar fillers on brittleness/ductility of epoxy resin composites. Appl. Sci. 2019, 9, 3109. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-cost carbon fillers to improve mechanical properties and conductivity of epoxy composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.D.; Phang, I.Y.; Liu, T. Growth of carbon nanotubes on clay: Unique nanostructured filler for high-performance polymer nanocomposites. Adv. Mater. 2006, 18, 73–77. [Google Scholar] [CrossRef]

- Zhao, W.; Li, T.; Li, Y.; O’Brien, D.J.; Terrones, M.; Wei, B.; Suhr, J.; Lu, X.L. Mechanical properties of nanocomposites reinforced by carbon nanotube sponges. J. Mater. 2018, 4, 157–164. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent advances in biochar polymer composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Torsello, D.; Ghigo, G.; Malucelli, G. Thermal, dynamic-mechanical and electrical properties of UV-LED curable coatings containing porcupine-like carbon structures. Mater. Today Commun. 2021, 28, 102630. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosso, C.; Giorcelli, M.; Rovere, M.; Jagdale, P.; Tagliaferro, A.; Chae, M.; Bressler, D.C. Effect of incorporation of microstructured carbonized cellulose on surface and mechanical properties of epoxy composites. J. Appl. Polym. Sci. 2020, 137, 48896. [Google Scholar] [CrossRef]

- Bifulco, A.; Bartoli, M.; Climaco, I.; Franchino, M.C.; Battegazzore, D.; Mensah, R.A.; Das, O.; Vahabi, H.; Malucelli, G.; Aronne, A. Coffee waste-derived biochar as a flame retardant for epoxy nanocomposites. Sustain. Mater. Technol. 2024, 41, e01079. [Google Scholar] [CrossRef]

- Bartoli, M.; Duraccio, D.; Faga, M.G.; Piatti, E.; Torsello, D.; Ghigo, G.; Malucelli, G. Mechanical, electrical, thermal and tribological behavior of epoxy resin composites reinforced with waste hemp-derived carbon fibers. J. Mater. Sci. 2022, 57, 14861–14876. [Google Scholar] [CrossRef]

- Bartoli, M.; Torsello, D.; Piatti, E.; Giorcelli, M.; Sparavigna, A.C.; Rovere, M.; Ghigo, G.; Tagliaferro, A. Pressure-responsive conductive poly (vinyl alcohol) composites containing waste cotton fibers biochar. Micromachines 2022, 13, 125. [Google Scholar] [CrossRef]

- Torsello, D.; Ghigo, G.; Giorcelli, M.; Bartoli, M.; Rovere, M.; Tagliaferro, A. Tuning the microwave electromagnetic properties of biochar-based composites by annealing. Carbon Trends 2021, 4, 100062. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel Sci. 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Yee-Foong, L.N.; Lawal, A.A.; Farid, M.A.A.; Yusuf, M.Z.M.; Hassan, M.A.; Ariffin, H. Emerging application of biochar as a renewable and superior filler in polymer composites. RSC Adv. 2022, 12, 13938–13949. [Google Scholar] [CrossRef]

- Giorcelli, M.; Bartoli, M.; Sanginario, A.; Padovano, E.; Rosso, C.; Rovere, M.; Tagliaferro, A. High-temperature annealed biochar as a conductive filler for the production of piezoresistive materials for energy conversion application. ACS Appl. Electron. Mater. 2021, 3, 838–844. [Google Scholar] [CrossRef]

- Bélanger, N.; Prasher, S.; Dumont, M.-J. Tailoring biochar production for use as a reinforcing bio-based filler in rubber composites: A review. Polym. Technol. Mater. 2023, 62, 54–75. [Google Scholar] [CrossRef]

- Zecchi, S.; Ruscillo, F.; Cristoforo, G.; Bartoli, M.; Loebsack, G.; Kang, K.; Piatti, E.; Torsello, D.; Ghigo, G.; Gerbaldo, R. Effect of Red Mud Addition on Electrical and Magnetic Properties of Hemp-Derived-Biochar-Containing Epoxy Composites. Micromachines 2023, 14, 429. [Google Scholar] [CrossRef]

- Park, S.; Bernet, N.; De La Roche, S.; Hahn, H.T. Processing of iron oxide-epoxy vinyl ester nanocomposites. J. Compos. Mater. 2003, 37, 465–476. [Google Scholar] [CrossRef]

- Gnanavel, M.; Maridurai, T. Effect of surface modification and particle size on dielectric properties of iron (III) oxide-epoxy composite film. Dig. J. Nanomater. Biostruct. 2018, 13, 39–48. [Google Scholar]

- Javidparvar, A.; Ramezanzadeh, B.; Ghasemi, E. The effect of surface morphology and treatment of Fe3O4 nanoparticles on the corrosion resistance of epoxy coating. J. Taiwan Inst. Chem. Eng. 2016, 61, 356–366. [Google Scholar] [CrossRef]

- Tamborrino, V.; Costamagna, G.; Bartoli, M.; Rovere, M.; Jagdale, P.; Lavagna, L.; Ginepro, M.; Tagliaferro, A. Catalytic oxidative desulphurization of pyrolytic oils to fuels over different waste derived carbon-based catalysts. Fuel 2021, 296, 120693. [Google Scholar] [CrossRef]

- Tagliaferro, A.; Rovere, M.; Padovano, E.; Bartoli, M.; Giorcelli, M. Introducing the novel mixed gaussian-lorentzian lineshape in the analysis of the raman signal of biochar. Nanomaterials 2020, 10, 1748. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Ba, D.; Sabouroux, P. Epsimu, a toolkit for permittivity and permeability measurement in microwave domain at real time of all materials: Applications to solid and semisolid materials. Microw. Opt. Technol. Lett. 2010, 52, 2643–2648. [Google Scholar] [CrossRef]

- Nicolson, A.M.; Ross, G.F. Measurement of the intrinsic properties of materials by time-domain techniques. IEEE Trans. Instrum. Meas. 1970, 19, 377–382. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.; Vanzura, E.J.; Kissick, W.A. Improved technique for determining complex permittivity with the transmission/reflection method. IEEE Trans. Microw. Theory Tech. 1990, 38, 1096–1103. [Google Scholar] [CrossRef]

- Matykiewicz, D. Biochar as an Effective Filler of Carbon Fiber Reinforced Bio-Epoxy Composites. Processes 2020, 8, 724. [Google Scholar] [CrossRef]

- Sparavigna, A.C. Raman Spectroscopy of the Iron Oxides in the Form of Minerals, Particles and Nanoparticles. ChemRxiv 2023. [Google Scholar] [CrossRef]

- De Faria, D.L.; Venâncio Silva, S.; de Oliveira, M.T. Raman microspectroscopy of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 1997, 28, 873–878. [Google Scholar] [CrossRef]

- Tang, B.; Guoxin, H.; Gao, H. Raman spectroscopic characterization of graphene. Appl. Spectrosc. Rev. 2010, 45, 369–407. [Google Scholar] [CrossRef]

- Minugu, O.P.; Gujjala, R.; Shakuntala, O.; Manoj, P.; Chowdary, M.S. Effect of biomass derived biochar materials on mechanical properties of biochar epoxy composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 5626–5638. [Google Scholar] [CrossRef]

- Ahmetli, G.; Kocaman, S.; Ozaytekin, I.; Bozkurt, P. Epoxy composites based on inexpensive char filler obtained from plastic waste and natural resources. Polym. Compos. 2013, 34, 500–509. [Google Scholar] [CrossRef]

- Zuccarello, B.; Bartoli, M.; Bongiorno, F.; Militello, C.; Tagliaferro, A.; Pantano, A. New Concept in Bioderived Composites: Biochar as Toughening Agent for Improving Performances and Durability of Agave-Based Epoxy Biocomposites. Polymers 2021, 13, 198. [Google Scholar] [CrossRef]

- Bartoli, M.; Troiano, M.; Giudicianni, P.; Amato, D.; Giorcelli, M.; Solimene, R.; Tagliaferro, A. Effect of heating rate and feedstock nature on electrical conductivity of biochar and biochar-based composites. Appl. Energy Combust. Sci. 2022, 12, 100089. [Google Scholar] [CrossRef]

- Lin, F.; Feng, X.-T.; Yang, C.; Li, S.; Zhang, J.; Su, X.; Tong, T. Microwave response characteristics and influencing factors of ores based on dielectric properties of synthetic samples. J. Rock Mech. Geotech. Eng. 2022, 14, 315–328. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Jagdale, P.; Rovere, M.; Tagliaferro, A. A Review of Non-Soil Biochar Applications. Materials 2020, 13, 261. [Google Scholar] [CrossRef] [PubMed]

- Giorcelli, M.; Bartoli, M. Development of coffee biochar filler for the production of electrical conductive reinforced plastic. Polymers 2019, 11, 1916. [Google Scholar] [CrossRef] [PubMed]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of biochar addition on mechanical properties, thermal stability, and water resistance of hemp-polylactic acid (PLA) composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef] [PubMed]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2016, 50, 1161–1168. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.-T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

| Sample ID | Resin (g) | Hardener (g) | Filler (g) |

|---|---|---|---|

| Blank epoxy | 0.67 | 0.33 | - |

| 5 wt.% Fe@BC | 0.66 | 0.34 | 0.05 |

| 10 wt.% Fe@BC | 0.60 | 0.30 | 0.10 |

| 20 wt.% Fe@BC | 0.53 | 0.27 | 0.20 |

| 5 wt.% BC | 0.66 | 0.34 | 0.05 |

| 10 wt.% BC | 0.60 | 0.30 | 0.10 |

| 20 wt.% BC | 0.53 | 0.27 | 0.20 |

| Sample | Elemental Composition (wt.%) | ||

|---|---|---|---|

| C | O | Fe | |

| BC | 88.8 | 11.2 | 0.0 |

| Fe@BC | 3.5 | 31.2 | 65.3 |

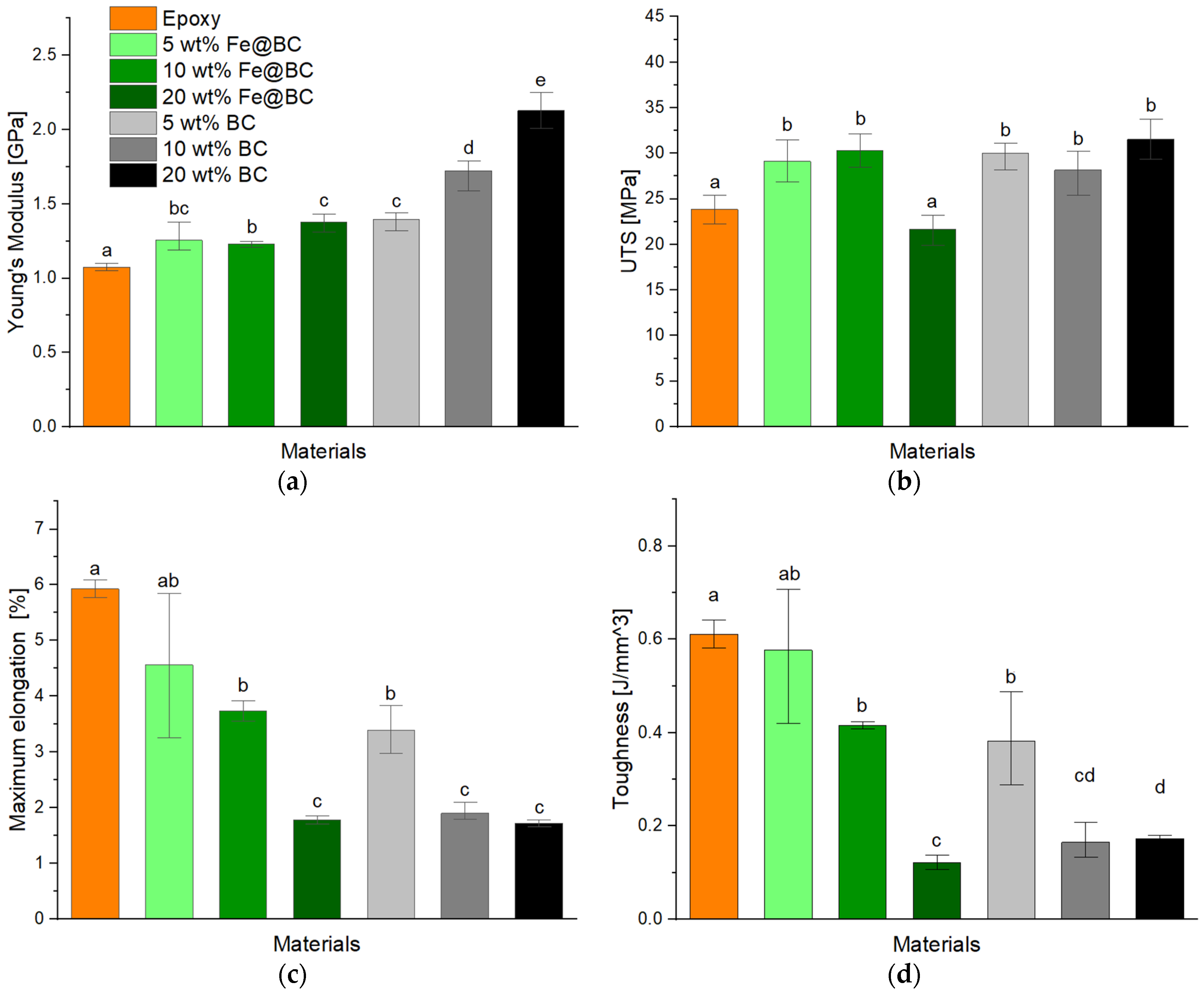

| Tensile Test | Elastic Modulus | UTS | Elongation at Break | Toughness | ||||

|---|---|---|---|---|---|---|---|---|

| Gpa | Variation (%) | Mpa | Variation (%) | % | Variation (%) | MJ/m3 | Variation (%) | |

| Epoxy | 1.1 ± 0.0 | 0 | 23.8 ± 1.6 | 0 | 5.9 ± 0.2 | 0 | 0.61 ± 0.03 | 0 |

| 5 wt.% Fe@BC | 1.2 ± 0.0 | +9 | 29.1 ± 2.3 | +22 | 4.6 ± 1.3 | −22 | 0.58 ± 0.14 | −5 |

| 10 wt.% Fe@BC | 1.1 ± 0.2 | +0 | 30.3 ± 1.8 | +27 | 3.7 ± 0.2 | −37 | 0.42 ± 0.01 | −31 |

| 20 wt.% Fe@BC | 1.4 ± 0.1 | +27 | 21.7 ± 1.7 | −9 | 1.8 ± 0.1 | −69 | 0.12 ± 0.02 | −80 |

| ρ | 0.898 | −0.803 | −0.944 | −0.944 | ||||

| 5 wt.% BC | 1.4 ± 0.1 | +27 | 30.0 ± 1.5 | +26 | 3.4 ± 0.4 | −42 | 0.39 ± 0.10 | −36 |

| 10 wt.% BC | 1.7 ± 0.1 | +54 | 28.2 ± 2.4 | +18 | 1.9 ± 0.2 | −68 | 0.17 ± 0.04 | −72 |

| 20 wt.% BC | 2.1 ± 0.1 | +90 | 31.5 ± 2.2 | +32 | 1.7 ± 0.1 | −71 | 0.17 ± 0.01 | −72 |

| ρ | 0.950 | −0.254 | −0.930 | −0.821 | ||||

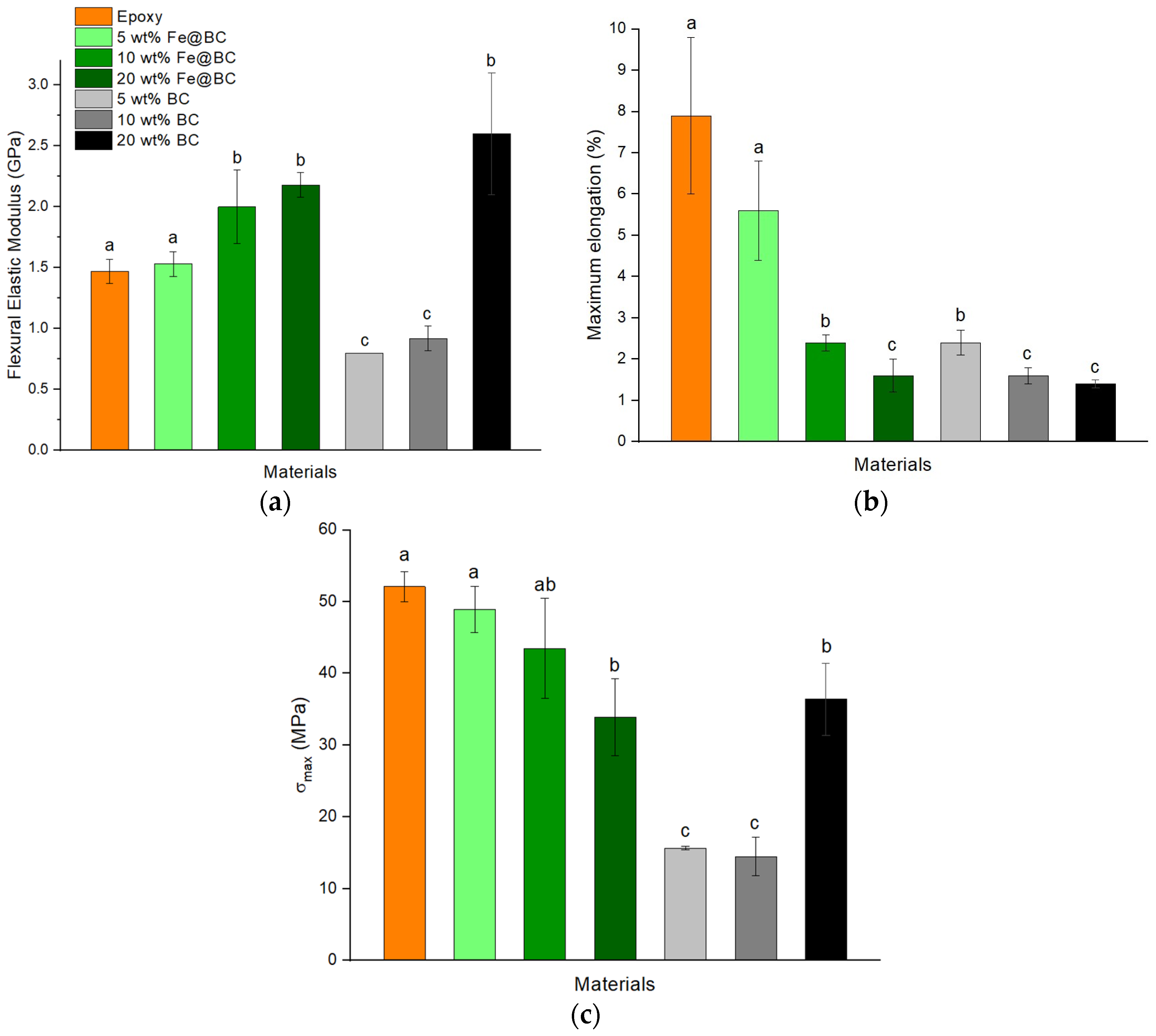

| Flexural Test | Flexural Modulus | Maximum Stress | Deformation at Break | |||

|---|---|---|---|---|---|---|

| Gpa | Variation (%) | Mpa | Variation (%) | % | Variation (%) | |

| Epoxy | 1.5 ± 0.1 | 0 | 52.1 ± 2.1 | 0 | 7.9 ± 1.9 | 0 |

| 5 wt.% Fe@BC | 1.5 ± 0.1 | +0 | 48.9 ± 3.2 | −6 | 5.6 ± 1.2 | −29 |

| 10 wt.% Fe@BC | 2.0 ± 0.3 | +33 | 43.5 ± 7.0 | −17 | 2.4 ± 0.2 | −70 |

| 20 wt.% Fe@BC | 2.2 ± 0.1 | +47 | 33.9 ± 5.4 | −35 | 1.6 ± 0.4 | −80 |

| ρ | 0.860 | −0.930 | −0.931 | |||

| 5 wt.% BC | 0.8 ± 0.0 | −47 | 15.7 ± 0.2 | −70 | 2.4 ± 0.3 | −70 |

| 10 wt.% BC | 0.9 ± 0.1 | −53 | 14.5 ± 2.7 | −72 | 1.6 ± 0.2 | −80 |

| 20 wt.% BC | 2.6 ± 0.5 | +73 | 36.4 ± 5.0 | −30 | 1.4 ± 0.1 | −82 |

| ρ | 0.896 | 0.731 | −0.870 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scavuzzo, S.; Zecchi, S.; Cristoforo, G.; Rosso, C.; Torsello, D.; Ghigo, G.; Lavagna, L.; Giorcelli, M.; Tagliaferro, A.; Etzi, M.; et al. Miscanthus-Derived Biochar as a Platform for the Production of Fillers for the Improvement of Mechanical and Electromagnetic Properties of Epoxy Composites. C 2024, 10, 81. https://doi.org/10.3390/c10030081

Scavuzzo S, Zecchi S, Cristoforo G, Rosso C, Torsello D, Ghigo G, Lavagna L, Giorcelli M, Tagliaferro A, Etzi M, et al. Miscanthus-Derived Biochar as a Platform for the Production of Fillers for the Improvement of Mechanical and Electromagnetic Properties of Epoxy Composites. C. 2024; 10(3):81. https://doi.org/10.3390/c10030081

Chicago/Turabian StyleScavuzzo, Salvatore, Silvia Zecchi, Giovanni Cristoforo, Carlo Rosso, Daniele Torsello, Gianluca Ghigo, Luca Lavagna, Mauro Giorcelli, Alberto Tagliaferro, Marco Etzi, and et al. 2024. "Miscanthus-Derived Biochar as a Platform for the Production of Fillers for the Improvement of Mechanical and Electromagnetic Properties of Epoxy Composites" C 10, no. 3: 81. https://doi.org/10.3390/c10030081

APA StyleScavuzzo, S., Zecchi, S., Cristoforo, G., Rosso, C., Torsello, D., Ghigo, G., Lavagna, L., Giorcelli, M., Tagliaferro, A., Etzi, M., & Bartoli, M. (2024). Miscanthus-Derived Biochar as a Platform for the Production of Fillers for the Improvement of Mechanical and Electromagnetic Properties of Epoxy Composites. C, 10(3), 81. https://doi.org/10.3390/c10030081