Biotechnological Strategies for Ethanol Reduction in Wine

Abstract

1. Introduction

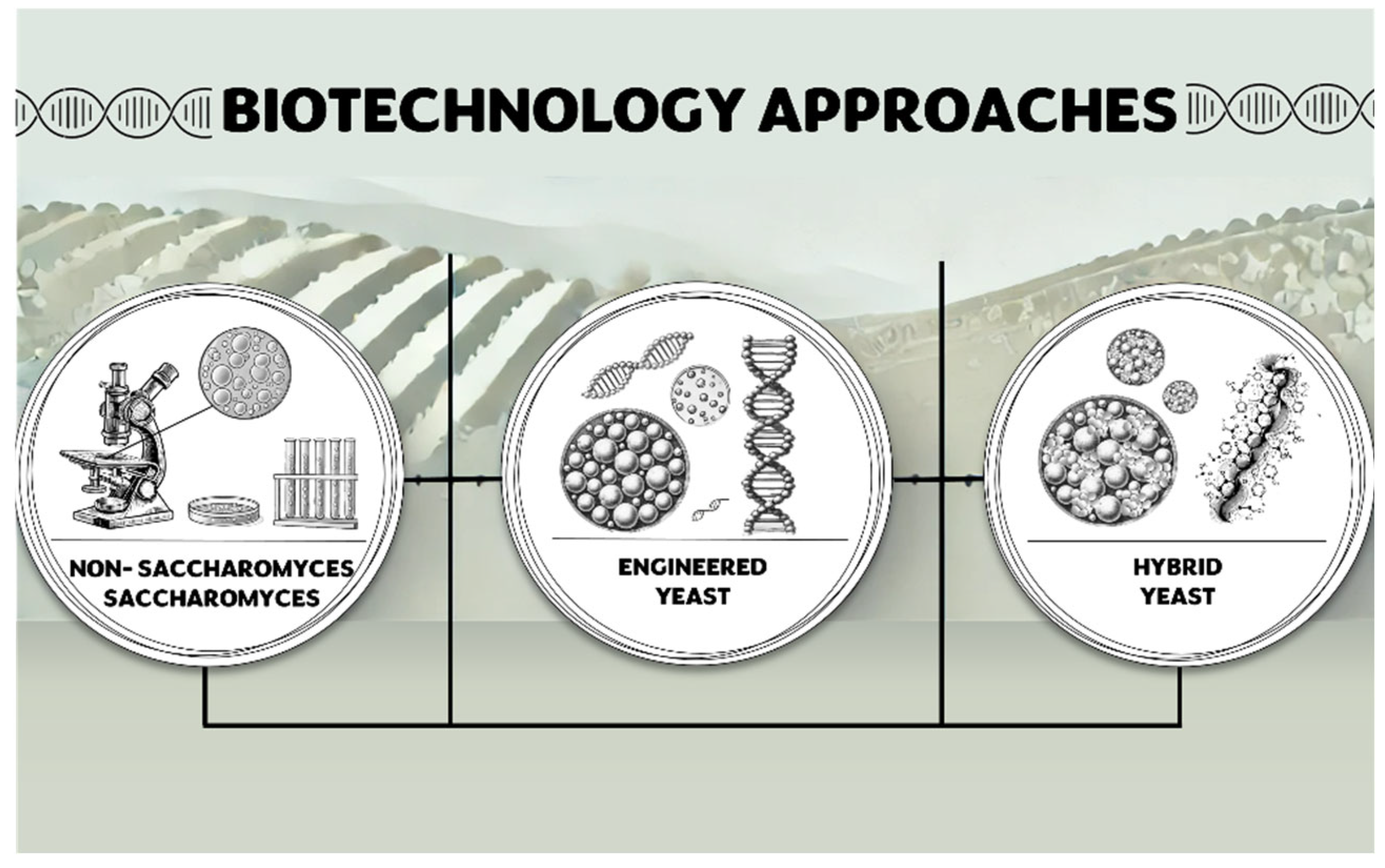

2. Saccharomyces Yeasts and Their Hybrids

3. Non-Saccharomyces Yeasts

4. Genetically Engineered Saccharomyces Yeasts

5. Saccharomyces and Non-Saccharomyces Co-Starter Cultures

6. Other Methods

6.1. Arrested or Limited Fermentation

6.2. Biomass Reduction

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rolle, L.; Englezos, V.; Torchio, F.; Cravero, F.; Río Segade, S.; Rantsiou, K.; Giacosa, S.; Gambuti, A.; Gerbi, V.; Cocolin, L. Alcohol Reduction in Red Wines by Technological and Microbiological Approaches: A Comparative Study. Aust. J. Grape Wine Res. 2018, 24, 62–74. [Google Scholar] [CrossRef]

- Cosme, F.; Nunes, F.M.; Filipe-Ribeiro, L. Winemaking: Advanced Technology and Flavor Research. Foods 2024, 13, 1937. [Google Scholar] [CrossRef] [PubMed]

- Di Renzo, M.; Letizia, F.; Di Martino, C.; Karaulli, J.; Kongoli, R.; Testa, B.; Avino, P.; Guerriero, E.; Albanese, G.; Monaco, M.; et al. Natural Fiano Wines Fermented in Stainless Steel Tanks, Oak Barrels, and Earthenware Amphora. Processes 2023, 11, 1273. [Google Scholar] [CrossRef]

- Pickering, G.J. Low- and Reduced-Alcohol Wine: A Review. J. Wine Res. 2000, 11, 129–144. [Google Scholar] [CrossRef]

- Sam, F.E.; Ma, T.-Z.; Salifu, R.; Wang, J.; Jiang, Y.-M.; Zhang, B.; Han, S.-Y. Techniques for Dealcoholization of Wines: Their Impact on Wine Phenolic Composition, Volatile Composition, and Sensory Characteristics. Foods 2021, 10, 2498. [Google Scholar] [CrossRef]

- Okaru, A.O.; Lachenmeier, D.W. Defining No and Low (NoLo) Alcohol Products. Nutrients 2022, 14, 3873. [Google Scholar] [CrossRef]

- Silva, P. Low-Alcohol and Nonalcoholic Wines: From Production to Cardiovascular Health, along with Their Economic Effects. Beverages 2024, 10, 49. [Google Scholar] [CrossRef]

- Corona, O.; Liguori, L.; Albanese, D.; Matteo, M.; Cinquanta, L.; Russo, P. Quality and Volatile Compounds in Red Wine at Different Degrees of Dealcoholization by Membrane Process. Eur. Food Res. Technol. 2019, 245, 2601–2611. [Google Scholar] [CrossRef]

- Varela, J.; Varela, C. Microbiological Strategies to Produce Beer and Wine with Reduced Ethanol Concentration. Curr. Opin. Biotechnol. 2019, 56, 88–96. [Google Scholar] [CrossRef]

- Longo, R.; Blackman, J.W.; Torley, P.J.; Rogiers, S.Y.; Schmidtke, L.M. Changes in Volatile Composition and Sensory Attributes of Wines during Alcohol Content Reduction. J. Sci. Food Agric. 2017, 97, 8–16. [Google Scholar] [CrossRef]

- Iorizzo, M.; Bagnoli, D.; Vergalito, F.; Testa, B.; Tremonte, P.; Succi, M.; Pannella, G.; Letizia, F.; Albanese, G.; Lombardi, S.J.; et al. Diversity of Fungal Communities on Cabernet and Aglianico Grapes from Vineyards Located in Southern Italy. Front. Microbiol. 2024, 15, 1399968. [Google Scholar] [CrossRef] [PubMed]

- Testa, B.; Coppola, F.; Iorizzo, M.; Di Renzo, M.; Coppola, R.; Succi, M. Preliminary Characterisation of Metschnikowia pulcherrima to Be Used as a Starter Culture in Red Winemaking. Beverages 2024, 10, 88. [Google Scholar] [CrossRef]

- Morata, A.; Escott, C.; Bañuelos, M.A.; Loira, I.; del Fresno, J.M.; González, C.; Suárez-Lepe, J.A. Contribution of Non-Saccharomyces yeasts to Wine Freshness. A Review. Biomolecules 2020, 10, 34. [Google Scholar] [CrossRef]

- Karaulli, J.; Xhaferaj, N.; Coppola, F.; Testa, B.; Letizia, F.; Kyçyk, O.; Kongoli, R.; Ruci, M.; Lamçe, F.; Sulaj, K.; et al. Bioprospecting of Metschnikowia pulcherrima Strains, Isolated from a Vineyard Ecosystem, as Novel Starter Cultures for Craft Beer Production. Fermentation 2024, 10, 513. [Google Scholar] [CrossRef]

- González-Arenzana, L.; Garijo, P.; Berlanas, C.; López-Alfaro, I.; López, R.; Santamaría, P.; Gutiérrez, A.R. Genetic and Phenotypic Intraspecific Variability of Non-Saccharomyces yeasts Populations from La Rioja Winegrowing Region (Spain). J. Appl. Microbiol. 2017, 122, 378–388. [Google Scholar] [CrossRef]

- Afonso, S.M.; Inês, A.; Vilela, A. Bio-Dealcoholization of Wines: Can Yeast Make Lighter Wines? Fermentation 2024, 10, 36. [Google Scholar] [CrossRef]

- Tilloy, V.; Cadière, A.; Ehsani, M.; Dequin, S. Reducing Alcohol Levels in Wines through Rational and Evolutionary Engineering of Saccharomyces cerevisiae. Int. J. Food Microbiol. 2015, 213, 49–58. [Google Scholar] [CrossRef]

- Tilloy, V.; Ortiz-Julien, A.; Dequin, S. Reduction of Ethanol Yield and Improvement of Glycerol Formation by Adaptive Evolution of the Wine Yeast Saccharomyces cerevisiae under Hyperosmotic Conditions. Appl. Environ. Microbiol. 2014, 80, 2623–2632. [Google Scholar] [CrossRef]

- Xu, N.; Gao, H.; Wang, Y.; Liu, C.; Hu, L.; He, A.; Jiang, W.; Xin, F. Recent Advances in Bio-Based Production of Organic Acids by Genetically Engineered Yeasts. Biochem. Eng. J. 2025, 215, 109587. [Google Scholar] [CrossRef]

- de Assis, L.J.; Zingali, R.B.; Masuda, C.A.; Rodrigues, S.P.; Montero-Lomelí, M. Pyruvate Decarboxylase Activity Is Regulated by the Ser/Thr Protein Phosphatase Sit4p in the Yeast Saccharomyces cerevisiae. FEMS Yeast Res. 2013, 13, 518–528. [Google Scholar] [CrossRef]

- Cebollero, E.; Gonzalez-Ramos, D.; Tabera, L.; Gonzalez, R. Transgenic Wine Yeast Technology Comes of Age: Is It Time for Transgenic Wine? Biotechnol. Lett. 2007, 29, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Del-Real, J.; Contreras-Ruiz, A.; Castiglioni, G.L.; Barrio, E.; Querol, A. The Use of Mixed Populations of Saccharomyces cerevisiae and S. Kudriavzevii to Reduce Ethanol Content in Wine: Limited Aeration, Inoculum Proportions, and Sequential Inoculation. Front. Microbiol. 2017, 8, 2087. [Google Scholar] [CrossRef]

- Zhao, L.-Z.; Chen, J.; Wei, X.-Y.; Lin, B.; Zheng, F.-J.; Verma, K.K.; Chen, G.-L. Response of Alcohol Fermentation Strains, Mixed Fermentation and Extremozymes Interactions on Wine Flavor. Front. Microbiol. 2025, 16, 1532539. [Google Scholar] [CrossRef]

- Parpinello, G.; Ricci, A.; Folegatti, B.; Patrignani, F.; Lanciotti, R.; Versari, A. Unraveling the Potential of Cryotolerant Saccharomyces eubayanus in Chardonnay White Wine Production. LWT 2020, 134, 110183. [Google Scholar] [CrossRef]

- Canonico, L.; Gattucci, S.; Moretti, L.; Agarbati, A.; Comitini, F.; Ciani, M. Ethanol Reduction in Montepulciano Wine: Starmerella Bombicola Sequential Fermentation at Pilot Scale Under Aeration Conditions. Foods 2025, 14, 618. [Google Scholar] [CrossRef] [PubMed]

- Coppola, F.; Picariello, L.; Forino, M.; Moio, L.; Gambuti, A. Comparison of Three Accelerated Oxidation Tests Applied to Red Wines with Different Chemical Composition. Molecules 2021, 26, 815. [Google Scholar] [CrossRef]

- Romano, P.; Braschi, G.; Siesto, G.; Patrignani, F.; Lanciotti, R. Role of Yeasts on the Sensory Component of Wines. Foods 2022, 11, 1921. [Google Scholar] [CrossRef] [PubMed]

- Mendoza, L.M.; Fernández de Ullivarri, M.; Raya, R. Saccharomyces cerevisiae: A Key Yeast for the Wine-Making Process. In A Closer Look at Grapes, Wines and Winemaking; Nova Science Publishers Inc.: New York, NY, USA, 2018; pp. 173–202. [Google Scholar]

- Chen, Y.; Jiang, J.; Song, Y.; Zang, X.; Wang, G.; Pei, Y.; Song, Y.; Qin, Y.; Liu, Y. Yeast Diversity during Spontaneous Fermentations and Oenological Characterisation of Indigenous Saccharomyces cerevisiae for Potential as Wine Starter Cultures. Microorganisms 2022, 10, 1455. [Google Scholar] [CrossRef]

- Testa, B.; Coppola, F.; Letizia, F.; Albanese, G.; Karaulli, J.; Ruci, M.; Pistillo, M.; Germinara, G.S.; Messia, M.C.; Succi, M.; et al. Versatility of Saccharomyces cerevisiae 41CM in the Brewery Sector: Use as a Starter for “Ale” and “Lager” Craft Beer Production. Processes 2022, 10, 2495. [Google Scholar] [CrossRef]

- Tronchoni, J.; Gonzalez, R.; Guindal, A.M.; Calleja, E.; Morales, P. Exploring the Suitability of Saccharomyces cerevisiae Strains for Winemaking under Aerobic Conditions. Food Microbiol. 2022, 101, 103893. [Google Scholar] [CrossRef]

- Kutyna, D.R.; Varela, C.; Henschke, P.A.; Chambers, P.J.; Stanley, G.A. Microbiological Approaches to Lowering Ethanol Concentration in Wine. Trends Food Sci. Technol. 2010, 21, 293–302. [Google Scholar] [CrossRef]

- Varela, C.; Dry, P.R.; Kutyna, D.R.; Francis, I.L.; Henschke, P.A.; Curtin, C.D.; Chambers, P.J. Strategies for Reducing Alcohol Concentration in Wine. Aust. J. Grape Wine Res. 2015, 21, 670–679. [Google Scholar] [CrossRef]

- Hwang, H.; Nam, S.-J. The Influence of Consumers’ Knowledge on Their Responses to Genetically Modified Foods. GM Crops Food 2021, 12, 146–157. [Google Scholar] [CrossRef]

- Ivit, N.N.; Longo, R.; Kemp, B. The Effect of Non-Saccharomyces and Saccharomyces Non-Cerevisiae Yeasts on Ethanol and Glycerol Levels in Wine. Fermentation 2020, 6, 77. [Google Scholar] [CrossRef]

- González, S.S.; Gallo, L.; Climent, M.D.; Barrio, E.; Querol, A. Enological Characterization of Natural Hybrids from Saccharomyces cerevisiae and S. kudriavzevii. Int. J. Food Microbiol. 2007, 116, 11–18. [Google Scholar] [CrossRef]

- Magalhães, F.; Krogerus, K.; Castillo, S.; Ortiz-Julien, A.; Dequin, S.; Gibson, B. Exploring the Potential of Saccharomyces eubayanus as a Parent for New Interspecies Hybrid Strains in Winemaking. FEMS Yeast Res. 2017, 17, fox049. [Google Scholar] [CrossRef]

- Álvarez, R.; Garces, F.; Louis, E.J.; Dequin, S.; Camarasa, C. Beyond S. Cerevisiae for Winemaking: Fermentation-Related Trait Diversity in the Genus Saccharomyces. Food Microbiol. 2023, 113, 104270. [Google Scholar] [CrossRef]

- Coloretti, F.; Zambonelli, C.; Tini, V. Characterization of Flocculent Saccharomyces Interspecific Hybrids for the Production of Sparkling Wines. Food Microbiol. 2006, 23, 672–676. [Google Scholar] [CrossRef]

- Contreras, A.; Curtin, C.; Varela, C. Yeast Population Dynamics Reveal a Potential “collaboration” between Metschnikowia pulcherrima and Saccharomyces uvarum for the Production of Reduced Alcohol Wines during Shiraz Fermentation. Appl. Microbiol. Biotechnol. 2015, 99, 1885–1895. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Doucette, C.; McSweeney, M.; English, M.; Song, J.; Vinqvist-Tymchuk, M.; Kernaghan, G. Non-traditional Yeasts from Cool-climate Vineyards for Novel Low-alcohol Wines. Plants People Planet 2024. [Google Scholar] [CrossRef]

- Varela, C.; Sengler, F.; Solomon, M.; Curtin, C. Volatile Flavour Profile of Reduced Alcohol Wines Fermented with the Non-Conventional Yeast Species Metschnikowia pulcherrima and Saccharomyces uvarum. Food Chem. 2016, 209, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Varela, C.; Barker, A.; Tran, T.; Borneman, A.; Curtin, C. Sensory Profile and Volatile Aroma Composition of Reduced Alcohol Merlot Wines Fermented with Metschnikowia pulcherrima and Saccharomyces uvarum. Int. J. Food Microbiol. 2017, 252, 1–9. [Google Scholar] [CrossRef]

- Orlić, S.; Sulejman, R.; Jero, A.; Herjavec, S.; Iacumin, L. Influence of Indigenous Saccharomyces paradoxus Strains on Chardonnay Wine Fermentation Aroma. Int. J. Food Sci. Technol. 2007, 42, 95–101. [Google Scholar] [CrossRef]

- Costantini, A.; Cravero, M.C.; Panero, L.; Bonello, F.; Vaudano, E.; Pulcini, L.; Garcia-Moruno, E. Wine Fermentation Performance of Indigenous Saccharomyces cerevisiae and Saccharomyces paradoxus Strains Isolated in a Piedmont Vineyard. Beverages 2021, 7, 30. [Google Scholar] [CrossRef]

- Bellon, J.R.; Schmid, F.; Capone, D.L.; Dunn, B.L.; Chambers, P.J. Introducing a New Breed of Wine Yeast: Interspecific Hybridisation between a Commercial Saccharomyces cerevisiae Wine Yeast and Saccharomyces Mikatae. PLoS ONE 2013, 8, e62053. [Google Scholar] [CrossRef]

- Gonzalez, R.; Guindal, A.M.; Tronchoni, J.; Morales, P. Biotechnological Approaches to Lowering the Ethanol Yield during Wine Fermentation. Biomolecules 2021, 11, 1569. [Google Scholar] [CrossRef]

- Coral-Medina, A.; Morrissey, J.P.; Camarasa, C. The Growth and Metabolome of Saccharomyces uvarum in Wine Fermentations Are Strongly Influenced by the Route of Nitrogen Assimilation. J. Ind. Microbiol. Biotechnol. 2023, 49, kuac025. [Google Scholar] [CrossRef]

- Stribny, J.; Querol, A.; Pérez-Torrado, R. Differences in Enzymatic Properties of the Saccharomyces Kudriavzevii and Saccharomyces uvarum Alcohol Acetyltransferases and Their Impact on Aroma-Active Compounds Production. Front. Microbiol. 2016, 7, 897. [Google Scholar] [CrossRef]

- Muratore, G.; Asmundo, C.; Lanza, C.; Caggia, C.; Licciardello, F.; Restuccia, C. Influence of Saccharomyces uvarum on Volatile Acidity, Aromatic and Sensory Profile of Malvasia Delle Lipari Wine. Food Technol. Biotechnol. 2007, 45, 101–106. [Google Scholar]

- Oliveira, B.M.; Barrio, E.; Querol, A.; Pérez-Torrado, R. Enhanced Enzymatic Activity of Glycerol-3-Phosphate Dehydrogenase from the Cryophilic Saccharomyces kudriavzevii. PLoS ONE 2014, 9, e87290. [Google Scholar] [CrossRef]

- Contreras-Ruiz, A.; Alonso-del-Real, J.; Barrio, E.; Querol, A. Saccharomyces cerevisiae Wine Strains Show a Wide Range of Competitive Abilities and Differential Nutrient Uptake Behavior in Co-Culture with S.kudriavzevii. Food Microbiol. 2023, 114, 104276. [Google Scholar] [CrossRef] [PubMed]

- Stribny, J.; Gamero, A.; Pérez-Torrado, R.; Querol, A. Saccharomyces Kudriavzevii and Saccharomyces uvarum Differ from Saccharomyces cerevisiae during the Production of Aroma-Active Higher Alcohols and Acetate Esters Using Their Amino Acidic Precursors. Int. J. Food Microbiol. 2015, 205, 41–46. [Google Scholar] [CrossRef] [PubMed]

- Libkind, D.; Hittinger, C.T.; Valério, E.; Gonçalves, C.; Dover, J.; Johnston, M.; Gonçalves, P.; Sampaio, J.P. Microbe Domestication and the Identification of the Wild Genetic Stock of Lager-Brewing Yeast. Proc. Natl. Acad. Sci. USA 2011, 108, 14539–14544. [Google Scholar] [CrossRef]

- Iorizzo, M.; Letizia, F.; Albanese, G.; Coppola, F.; Gambuti, A.; Testa, B.; Aversano, R.; Forino, M.; Coppola, R. Potential for Lager Beer Production from Saccharomyces cerevisiae Strains Isolated from the Vineyard Environment. Processes 2021, 9, 1628. [Google Scholar] [CrossRef]

- Iorizzo, M.; Coppola, F.; Letizia, F.; Testa, B.; Sorrentino, E. Role of Yeasts in the Brewing Process: Tradition and Innovation. Processes 2021, 9, 839. [Google Scholar] [CrossRef]

- Su, Y.; Origone, A.C.; Rodríguez, M.E.; Querol, A.; Guillamón, J.M.; Lopes, C.A. Fermentative Behaviour and Competition Capacity of Cryotolerant Saccharomyces Species in Different Nitrogen Conditions. Int. J. Food Microbiol. 2019, 291, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Sommer, S.; Tondini, F. Sustainable Replacement Strategies for Bentonite in Wine Using Alternative Protein Fining Agents. Sustainability 2021, 13, 1860. [Google Scholar] [CrossRef]

- Pérez, D.; Denat, M.; Pérez-Través, L.; Heras, J.M.; Guillamón, J.M.; Ferreira, V.; Querol, A. Generation of Intra- and Interspecific Saccharomyces Hybrids with Improved Oenological and Aromatic Properties. Microb. Biotechnol. 2022, 15, 2266–2280. [Google Scholar] [CrossRef]

- Pérez-Torrado, R.; Barrio, E.; Querol, A. Alternative Yeasts for Winemaking: Saccharomyces Non-cerevisiae and Its Hybrids. Crit. Rev. Food Sci. Nutr. 2018, 58, 1780–1790. [Google Scholar] [CrossRef]

- Querol, A.; Pérez-Torrado, R.; Alonso-Del-Real, J.; Minebois, R.; Stribny, J.; Oliveira, B.M.; Barrio, E. New Trends in the Uses of Yeasts in Oenology. Adv. Food Nutr. Res. 2018, 85, 177–210. [Google Scholar] [CrossRef]

- Steensels, J.; Snoek, T.; Meersman, E.; Picca Nicolino, M.; Voordeckers, K.; Verstrepen, K.J. Improving Industrial Yeast Strains: Exploiting Natural and Artificial Diversity. FEMS Microbiol. Rev. 2014, 38, 947–995. [Google Scholar] [CrossRef] [PubMed]

- Ciani, M.; Capece, A.; Comitini, F.; Canonico, L.; Siesto, G.; Romano, P. Yeast Interactions in Inoculated Wine Fermentation. Front. Microbiol. 2016, 7, 555. [Google Scholar] [CrossRef]

- Renault, P.; Miot-Sertier, C.; Marullo, P.; Hernández-Orte, P.; Lagarrigue, L.; Lonvaud-Funel, A.; Bely, M. Genetic Characterization and Phenotypic Variability in Torulaspora delbrueckii Species: Potential Applications in the Wine Industry. Int. J. Food Microbiol. 2009, 134, 201–210. [Google Scholar] [CrossRef]

- Loira, I.; Vejarano, R.; Bañuelos, M.A.; Morata, A.; Tesfaye, W.; Uthurry, C.; Villa, A.; Cintora, I.; Suárez-Lepe, J.A. Influence of Sequential Fermentation with Torulaspora delbrueckii and Saccharomyces cerevisiae on Wine Quality. LWT-Food Sci. Technol. 2014, 59, 915–922. [Google Scholar] [CrossRef]

- van Breda, V.; Jolly, N.; van Wyk, J. Characterisation of Commercial and Natural Torulaspora delbrueckii Wine Yeast Strains. Int. J. Food Microbiol. 2013, 163, 80–88. [Google Scholar] [CrossRef]

- Ogawa, M.; Vararu, F.; Moreno-García, J.; Mauricio, J.; Moreno, J.; García-Martínez, T. Analyzing the Minor Volatilome of Torulaspora delbrueckii in an Alcoholic Fermentation. Eur. Food Res. Technol. 2022, 248, 613–624. [Google Scholar] [CrossRef]

- Belda, I.; Navascués, E.; Marquina, D.; Santos, A.; Calderon, F.; Benito, S. Dynamic Analysis of Physiological Properties of Torulaspora delbrueckii in Wine Fermentations and Its Incidence on Wine Quality. Appl. Microbiol. Biotechnol. 2015, 99, 1911–1922. [Google Scholar] [CrossRef]

- Cañas, P.M.I.; García, A.T.P.; Romero, E.G. Enhancement of Flavour Properties in Wines Using Sequential Inoculations of Non-Saccharomyces (Hansenula and Torulaspora) and Saccharomyces yeast. VITIS-J. Grapevine Res. 2011, 50, 177. [Google Scholar]

- Morales, P.; Rojas, V.; Quirós, M.; Gonzalez, R. The Impact of Oxygen on the Final Alcohol Content of Wine Fermented by a Mixed Starter Culture. Appl. Microbiol. Biotechnol. 2015, 99, 3993–4003. [Google Scholar] [CrossRef]

- Röcker, J.; Strub, S.; Ebert, K.; Grossmann, M. Usage of Different Aerobic Non-Saccharomyces yeasts and Experimental Conditions as a Tool for Reducing the Potential Ethanol Content in Wines. Eur. Food Res. Technol. 2016, 242, 2051–2070. [Google Scholar] [CrossRef]

- Tronchoni, J.; Curiel, J.A.; Sáenz-Navajas, M.P.; Morales, P.; de-la-Fuente-Blanco, A.; Fernández-Zurbano, P.; Ferreira, V.; Gonzalez, R. Aroma Profiling of an Aerated Fermentation of Natural Grape Must with Selected Yeast Strains at Pilot Scale. Food Microbiol. 2018, 70, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Contreras, A.; Hidalgo, C.; Henschke, P.A.; Chambers, P.J.; Curtin, C.; Varela, C. Evaluation of Non-Saccharomyces yeasts for the Reduction of Alcohol Content in Wine. Appl. Environ. Microbiol. 2014, 80, 1670–1678. [Google Scholar] [CrossRef]

- Canonico, L.; Comitini, F.; Oro, L.; Ciani, M. Sequential Fermentation with Selected Immobilized Non-Saccharomyces yeast for Reduction of Ethanol Content in Wine. Front. Microbiol. 2016, 7, 278. [Google Scholar] [CrossRef]

- Agarbati, A.; Canonico, L.; Ciani, M.; Comitini, F. Metschnikowia pulcherrima in Cold Clarification: Biocontrol Activity and Aroma Enhancement in Verdicchio Wine. Fermentation 2023, 9, 302. [Google Scholar] [CrossRef]

- Muñoz-Redondo, J.M.; Puertas, B.; Cantos-Villar, E.; Jiménez-Hierro, M.J.; Carbú, M.; Garrido, C.; Ruiz-Moreno, M.J.; Moreno-Rojas, J.M. Impact of Sequential Inoculation with the Non-Saccharomyces T. Delbrueckii and M. Pulcherrima Combined with Saccharomyces cerevisiae Strains on Chemicals and Sensory Profile of Rosé Wines. J. Agric. Food Chem. 2021, 69, 1598–1609. [Google Scholar] [CrossRef]

- Balikci, E.K.; Tanguler, H.; Jolly, N.P.; Erten, H. Influence of Lachancea thermotolerans on Cv. Emir Wine Fermentation. Yeast 2016, 33, 313–321. [Google Scholar] [CrossRef]

- Fresno, J.; Morata, A.; Loira, I.; Bañuelos, M.; Escott, C.; Benito, S.; Gonzalez, C.; Suárez-Lepe, J. Use of Non-Saccharomyces in Single-Culture, Mixed and Sequential Fermentation to Improve Red Wine Quality. Eur. Food Res. Technol. 2017, 243, 2175–2185. [Google Scholar] [CrossRef]

- Gobbi, M.; Comitini, F.; Domizio, P.; Romani, C.; Lencioni, L.; Mannazzu, I.; Ciani, M. Lachancea thermotolerans and Saccharomyces cerevisiae in Simultaneous and Sequential Co-Fermentation: A Strategy to Enhance Acidity and Improve the Overall Quality of Wine. Food Microbiol. 2013, 33, 271–281. [Google Scholar] [CrossRef]

- Vicente, J.; Wang, L.; Brezina, S.; Fritsch, S.; Navascués, E.; Santos, A.; Calderón, F.; Tesfaye, W.; Marquina, D.; Rauhut, D.; et al. Enhancing Wine Fermentation through Concurrent Utilization of Lachancea thermotolerans and Lactic Acid Bacteria (Oenococcus oeni and Lactiplantibacillus plantarum) or Schizosaccharomyces pombe. Food Chem. X 2024, 24, 102054. [Google Scholar] [CrossRef]

- Vicente, J.; Kelanne, N.; Rodrigo-Burgos, L.; Navascués, E.; Calderón, F.; Santos, A.; Marquina, D.; Yang, B.; Benito, S. Influence of Different Lachancea thermotolerans Strains in the Wine Profile in the Era of Climate Challenge. FEMS Yeast Res. 2023, 23, foac062. [Google Scholar] [CrossRef]

- Hranilovic, A.; Albertin, W.; Capone, D.L.; Gallo, A.; Grbin, P.R.; Danner, L.; Bastian, S.E.P.; Masneuf-Pomarede, I.; Coulon, J.; Bely, M.; et al. Impact of Lachancea thermotolerans on Chemical Composition and Sensory Profiles of Merlot Wines. Food Chem. 2021, 349, 129015. [Google Scholar] [CrossRef] [PubMed]

- Blanco, P.; Rabuñal, E.; Neira, N.; Castrillo, D. Dynamic of Lachancea thermotolerans Population in Monoculture and Mixed Fermentations: Impact on Wine Characteristics. Beverages 2020, 6, 36. [Google Scholar] [CrossRef]

- Rossouw, D.; Bauer, F.F. Exploring the Phenotypic Space of Non-Saccharomyces Wine Yeast Biodiversity. Food Microbiol. 2016, 55, 32–46. [Google Scholar] [CrossRef] [PubMed]

- Mestre, M.V.; Maturano, Y.P.; Gallardo, C.; Combina, M.; Mercado, L.; Toro, M.E.; Carrau, F.; Vazquez, F.; Dellacassa, E. Impact on Sensory and Aromatic Profile of Low Ethanol Malbec Wines Fermented by Sequential Culture of Hanseniaspora uvarum and Saccharomyces cerevisiae Native Yeasts. Fermentation 2019, 5, 65. [Google Scholar] [CrossRef]

- Tristezza, M.; Tufariello, M.; Capozzi, V.; Spano, G.; Mita, G.; Grieco, F. The Oenological Potential of Hanseniaspora uvarum in Simultaneous and Sequential Co-Fermentation with Saccharomyces cerevisiae for Industrial Wine Production. Front. Microbiol. 2016, 7, 670. [Google Scholar] [CrossRef]

- Hu, K.; Jin, G.-J.; Xu, Y.-H.; Tao, Y.-S. Wine Aroma Response to Different Participation of Selected Hanseniaspora uvarum in Mixed Fermentation with Saccharomyces cerevisiae. Food Res. Int. 2018, 108, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Jin, G.-J.; Mei, W.-C.; Li, T.; Tao, Y.-S. Increase of Medium-Chain Fatty Acid Ethyl Ester Content in Mixed H. Uvarum/S. Cerevisiae Fermentation Leads to Wine Fruity Aroma Enhancement. Food Chem. 2018, 239, 495–501. [Google Scholar] [CrossRef]

- Maturano, Y.P.; Mestre, M.V.; Kuchen, B.; Toro, M.E.; Mercado, L.A.; Vazquez, F.; Combina, M. Optimization of Fermentation-Relevant Factors: A Strategy to Reduce Ethanol in Red Wine by Sequential Culture of Native Yeasts. Int. J. Food Microbiol. 2019, 289, 40–48. [Google Scholar] [CrossRef]

- Testa, B.; Coppola, F.; Lombardi, S.J.; Iorizzo, M.; Letizia, F.; Di Renzo, M.; Succi, M.; Tremonte, P. Influence of Hanseniasporauvarum AS27 on Chemical and Sensorial Characteristics of Aglianico Wine. Processes 2021, 9, 326. [Google Scholar] [CrossRef]

- Hu, L.; Wang, J.; Ji, X.; Liu, R.; Chen, F.; Zhang, X. Selection of Non-Saccharomyces yeasts for Orange Wine Fermentation Based on Their Enological Traits and Volatile Compounds Formation. J. Food Sci. Technol. 2018, 55, 4001–4012. [Google Scholar] [CrossRef]

- Filippousi, M.-E.; Chalvantzi, I.; Mallouchos, A.; Marmaras, I.; Banilas, G.; Nisiotou, A. The Use of Hanseniaspora Opuntiae to Improve ‘Sideritis’ Wine Quality, a Late-Ripening Greek Grape Variety. Foods 2024, 13, 1061. [Google Scholar] [CrossRef]

- Vaquero, C.; Escott, C.; Heras, J.M.; Carrau, F.; Morata, A. Co-Inoculations of Lachancea thermotolerans with Different Hanseniaspora spp.: Acidification, Aroma, Biocompatibility, and Effects of Nutrients in Wine. Food Res. Int. 2022, 161, 111891. [Google Scholar] [CrossRef] [PubMed]

- Testa, B.; Lombardi, S.J.; Iorizzo, M.; Letizia, F.; Martino, C.; Renzo, M.; Strollo, D.; Tremonte, P.; Pannella, G.; Ianiro, M.; et al. Use of Strain Hanseniaspora guilliermondii BF1 for Winemaking Process of White Grapes Vitis Vinifera Cv Fiano. Eur. Food Res. Technol. 2020, 246, 549–561. [Google Scholar] [CrossRef]

- Moreira, N.; Pina, C.; Mendes, F.; Couto, J.A.; Hogg, T.; Vasconcelos, I. Volatile Compounds Contribution of Hanseniaspora guilliermondii and Hanseniaspora uvarum during Red Wine Vinifications. Food Control 2011, 22, 662–667. [Google Scholar] [CrossRef]

- Lage, P.; Barbosa, C.; Mateus, B.; Vasconcelos, I.; Mendes-Faia, A.; Mendes-Ferreira, A.H. Guilliermondii Impacts Growth Kinetics and Metabolic Activity of S. Cerevisiae: The Role of Initial Nitrogen Concentration. Int. J. Food Microbiol. 2014, 172, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Benito, S.; Hofmann, T.; Laier, M.; Lochbühler, B.; Schüttler, A.; Ebert, K.; Fritsch, S.; Röcker, J.; Rauhut, D. Effect on Quality and Composition of Riesling Wines Fermented by Sequential Inoculation with Non-Saccharomyces and Saccharomyces cerevisiae. Eur. Food Res. Technol. 2015, 241, 707–717. [Google Scholar] [CrossRef]

- Dutraive, O.; Benito, S.; Fritsch, S.; Beisert, B.; Patz, C.-D.; Rauhut, D. Effect of Sequential Inoculation with Non-Saccharomyces and Saccharomyces yeasts on Riesling Wine Chemical Composition. Fermentation 2019, 5, 79. [Google Scholar] [CrossRef]

- Vicente, J.; Calderón, F.; Santos, A.; Marquina, D.; Benito, S. High Potential of Pichia Kluyveri and Other Pichia Species in Wine Technology. Int. J. Mol. Sci. 2021, 22, 1196. [Google Scholar] [CrossRef]

- Barata, A.; Nobre, A.; Correia, P.; Malfeito-Ferreira, M.; Loureiro, V. Growth and 4-Ethylphenol Production by the Yeast Pichia Guilliermondii in Grape Juices. Am. J. Enol. Vitic. 2006, 57, 133–138. [Google Scholar] [CrossRef]

- García, M.; Esteve-Zarzoso, B.; Cabellos, J.M.; Arroyo, T. Sequential Non-Saccharomyces and Saccharomyces cerevisiae Fermentations to Reduce the Alcohol Content in Wine. Fermentation 2020, 6, 60. [Google Scholar] [CrossRef]

- del Mónaco, S.M.; Barda, N.B.; Rubio, N.C.; Caballero, A.C. Selection and Characterization of a Patagonian Pichia kudriavzevii for Wine Deacidification. J. Appl. Microbiol. 2014, 117, 451–464. [Google Scholar] [CrossRef]

- Shi, W.-K.; Wang, J.; Chen, F.-S.; Zhang, X.-Y. Effect of Issatchenkia terricola and Pichia kudriavzevii on Wine Flavor and Quality through Simultaneous and Sequential Co-Fermentation with Saccharomyces cerevisiae. LWT 2019, 116, 108477. [Google Scholar] [CrossRef]

- Mazzucco, M.B.; Jovanovich, M.; Rodríguez, M.E.; Oteiza, J.M.; Lopes, C.A. Pichia kudriavzevii and Saccharomyces cerevisiae Strategies for Ciders. Fermentation 2025, 11, 79. [Google Scholar] [CrossRef]

- Englezos, V.; Giacosa, S.; Rantsiou, K.; Rolle, L.; Cocolin, L. Starmerella bacillaris in Winemaking: Opportunities and Risks. Curr. Opin. Food Sci. 2017, 17, 30–35. [Google Scholar] [CrossRef]

- Englezos, V.; Rantsiou, K.; Cravero, F.; Torchio, F.; Ortiz-Julien, A.; Gerbi, V.; Rolle, L.; Cocolin, L. Starmerella bacillaris and Saccharomyces cerevisiae Mixed Fermentations to Reduce Ethanol Content in Wine. Appl. Microbiol. Biotechnol. 2016, 100, 5515–5526. [Google Scholar] [CrossRef]

- Englezos, V.; Di Gianvito, P.; Serafino, G.; Giacosa, S.; Cocolin, L.; Rantsiou, K. Strain Specific Starmerella bacillaris and Saccharomyces cerevisiae Interactions in Mixed Fermentations. J. Appl. Microbiol. 2024, 135, lxae085. [Google Scholar] [CrossRef] [PubMed]

- Moreira, L.D.P.D.; Nadai, C.; da Silva Duarte, V.; Brearley-Smith, E.J.; Marangon, M.; Vincenzi, S.; Giacomini, A.; Corich, V. Starmerella bacillaris Strains Used in Sequential Alcoholic Fermentation with Saccharomyces cerevisiae Improves Protein Stability in White Wines. Fermentation 2022, 8, 252. [Google Scholar] [CrossRef]

- Moreira, L.D.P.D.; Porcellato, D.; Marangon, M.; Nadai, C.; da Silva Duarte, V.; Devold, T.G.; Giacomini, A.; Corich, V. Interactions between Starmerella bacillaris and Saccharomyces cerevisiae during Sequential Fermentations Influence the Release of Yeast Mannoproteins and Impact the Protein Stability of an Unstable Wine. Food Chem. 2024, 440, 138311. [Google Scholar] [CrossRef]

- Suzzi, G.; Arfelli, G.; Schirone, M.; Corsetti, A.; Perpetuini, G.; Tofalo, R. Effect of Grape Indigenous Saccharomyces cerevisiae Strains on Montepulciano d’Abruzzo Red Wine Quality. Food Res. Int. 2012, 46, 22–29. [Google Scholar] [CrossRef]

- Whitener, M.E.B.; Stanstrup, J.; Carlin, S.; Divol, B.; Du Toit, M.; Vrhovsek, U. Effect of Non-Saccharomyces yeasts on the Volatile Chemical Profile of Shiraz Wine. Aust. J. Grape Wine Res. 2017, 23, 179–192. [Google Scholar] [CrossRef]

- Nadai, C.; da Silva Duarte, V.; Sica, J.; Vincenzi, S.; Carlot, M.; Giacomini, A.; Corich, V. Starmerella bacillaris Released in Vineyards at Different Concentrations Influences Wine Glycerol Content Depending on the Vinification Protocols. Foods 2023, 12, 3. [Google Scholar] [CrossRef] [PubMed]

- Lyu, X.; Zhou, Y.; Li, F.; Zhou, M.; Wei, C.; Lin, L.; Li, X.; Zhang, C. Improving Muscat Hamburg Wine Quality with Innovative Fermentation Strategies Using Schizosaccharomyces pombe Derived from Fermented Grains of Sauce-Flavor Baijiu. Foods 2024, 13, 1648. [Google Scholar] [CrossRef]

- Li, A.; Xiong, L.; Huang, Z.; Huang, R.; Tu, T.; Yu, S.; Wu, Q.; Bai, J.; Huang, Y. Enhancing the Quality and Flavor of Pomelo Wine through Sequential Fermentation with Schizosaccharomyces pombe and Saccharomyces cerevisiae: A Non-Targeted Metabolomic Analysis. Food Biosci. 2025, 63, 105585. [Google Scholar] [CrossRef]

- Albergaria, H.; Arneborg, N. Dominance of Saccharomyces cerevisiae in Alcoholic Fermentation Processes: Role of Physiological Fitness and Microbial Interactions. Appl. Microbiol. Biotechnol. 2016, 100, 2035–2046. [Google Scholar] [CrossRef] [PubMed]

- Ciani, M.; Comitini, F.; Mannazzu, I.; Domizio, P. Controlled Mixed Culture Fermentation: A New Perspective on the Use of Non-Saccharomyces yeasts in Winemaking. FEMS Yeast Res. 2010, 10, 123–133. [Google Scholar] [CrossRef]

- Lombardi, S.J.; Pannella, G.; Iorizzo, M.; Moreno-Arribas, M.; Tremonte, P.; Succi, M.; Sorrentino, E.; Macciola, V.; Renzo, M.; Coppola, R. Sequential Inoculum of Hanseniaspora guilliermondii and Saccharomyces cerevisiae for Winemaking Campanino on an Industrial Scale. World J. Microbiol. Biotechnol. 2018, 34, 161. [Google Scholar] [CrossRef]

- Padilla, B.; Gil, J.V.; Manzanares, P. Past and Future of Non-Saccharomyces yeasts: From Spoilage Microorganisms to Biotechnological Tools for Improving Wine Aroma Complexity. Front. Microbiol. 2016, 7, 411. [Google Scholar] [CrossRef]

- Alonso, A.; Belda, I.; Santos, A.; Navascués, E.; Marquina, D. Advances in the Control of the Spoilage Caused by Zygosaccharomyces Species on Sweet Wines and Concentrated Grape Musts. Food Control 2015, 51, 129–134. [Google Scholar] [CrossRef]

- Maicas, S.; Mateo, J.J. The Life of Saccharomyces and Non-Saccharomyces yeasts in Drinking Wine. Microorganisms 2023, 11, 1178. [Google Scholar] [CrossRef]

- Rantsiou, K.; Englezos, V.; Torchio, F.; Risse, P.-A.; Francesco, C.; Gerbi, V.; Rolle, L.; Cocolin, L. Modeling of the Fermentation Behavior of Starmerella bacillaris. Am. J. Enol. Vitic. 2017, 68, 378–385. [Google Scholar] [CrossRef]

- Belda, I.; Navascués, E.; Marquina, D.; Santos, A.; Calderón, F.; Benito, S. Outlining the Influence of Non-Conventional Yeasts in Wine Ageing over Lees. Yeast 2016, 33, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Mestre Furlani, M.V.; Maturano, Y.P.; Combina, M.; Mercado, L.A.; Toro, M.E.; Vazquez, F. Selection of Non-Saccharomyces yeasts to Be Used in Grape Musts with High Alcoholic Potential: A Strategy to Obtain Wines with Reduced Ethanol Content. FEMS Yeast Res. 2017, 17, fox010. [Google Scholar] [CrossRef]

- Escott, C.; Del Fresno, J.M.; Loira, I.; Morata, A.; Suárez-Lepe, J.A. Zygosaccharomyces Rouxii: Control Strategies and Applications in Food and Winemaking. Fermentation 2018, 4, 69. [Google Scholar] [CrossRef]

- Zhu, X.; Navarro, Y.; Mas, A.; Torija, M.-J.; Beltran, G. A Rapid Method for Selecting Non-Saccharomyces Strains with a Low Ethanol Yield. Microorganisms 2020, 8, 658. [Google Scholar] [CrossRef] [PubMed]

- Jolly, N.P.; Varela, C.; Pretorius, I.S. Not Your Ordinary Yeast: Non-Saccharomyces yeasts in Wine Production Uncovered. FEMS Yeast Res. 2014, 14, 215–237. [Google Scholar] [CrossRef]

- Molina-Espeja, P. Next Generation Winemakers: Genetic Engineering in Saccharomyces cerevisiae for Trendy Challenges. Bioengineering 2020, 7, 128. [Google Scholar] [CrossRef]

- Kessi-Pérez, E.I.; Gómez, M.; Farías, W.; García, V.; Ganga, M.A.; Querol, A.; Martínez, C. Genetically Improved Yeast Strains with Lower Ethanol Yield for the Wine Industry Generated Through a Two-Round Breeding Program. J. Fungi 2025, 11, 137. [Google Scholar] [CrossRef]

- Goold, H.D.; Kroukamp, H.; Williams, T.C.; Paulsen, I.T.; Varela, C.; Pretorius, I.S. Yeast’s Balancing Act between Ethanol and Glycerol Production in Low-Alcohol Wines. Microb. Biotechnol. 2017, 10, 264–278. [Google Scholar] [CrossRef]

- Cuello, R.A.; Flores Montero, K.J.; Mercado, L.A.; Combina, M.; Ciklic, I.F. Construction of Low-Ethanol-Wine Yeasts through Partial Deletion of the Saccharomyces cerevisiae PDC2 Gene. AMB Express 2017, 7, 67. [Google Scholar] [CrossRef]

- Heux, S.; Cachon, R.; Dequin, S. Cofactor Engineering in Saccharomyces cerevisiae: Expression of a H2O-Forming NADH Oxidase and Impact on Redox Metabolism. Metab. Eng. 2006, 8, 303–314. [Google Scholar] [CrossRef]

- Du, Q.; Liu, Y.; Song, Y.; Qin, Y. Creation of a Low-Alcohol-Production Yeast by a Mutated SPT15 Transcription Regulator Triggers Transcriptional and Metabolic Changes During Wine Fermentation. Front. Microbiol. 2020, 11, 597828. [Google Scholar] [CrossRef] [PubMed]

- Malherbe, D.F.; du Toit, M.; Cordero Otero, R.R.; van Rensburg, P.; Pretorius, I.S. Expression of the Aspergillus Niger Glucose Oxidase Gene in Saccharomyces cerevisiae and Its Potential Applications in Wine Production. Appl. Microbiol. Biotechnol. 2003, 61, 502–511. [Google Scholar] [CrossRef] [PubMed]

- Rossouw, D.; Heyns, E.H.; Setati, M.E.; Bosch, S.; Bauer, F.F. Adjustment of Trehalose Metabolism in Wine Saccharomyces cerevisiae Strains to Modify Ethanol Yields. Appl. Environ. Microbiol. 2013, 79, 5197–5207. [Google Scholar] [CrossRef]

- Xu, A.; Xiao, Y.; He, Z.; Liu, J.; Wang, Y.; Gao, B.; Chang, J.; Zhu, D. Use of Non-Saccharomyces yeast Co-Fermentation with Saccharomyces cerevisiae to Improve the Polyphenol and Volatile Aroma Compound Contents in Nanfeng Tangerine Wines. J. Fungi 2022, 8, 128. [Google Scholar] [CrossRef]

- Peskova, I.; Tanashchuk, T.; Ostroukhova, E.; Slastya, E.; Levchenko, S.; Lutkova, N. Prospects of Using Lachancea thermotolerans Yeast in Winemaking. E3S Web Conf. 2021, 247, 01012. [Google Scholar] [CrossRef]

- Lemos Junior, W.J.F.; da Silva Duarte, V.; Treu, L.; Campanaro, S.; Nadai, C.; Giacomini, A.; Corich, V. Whole Genome Comparison of Two Starmerella bacillaris Strains with Other Wine Yeasts Uncovers Genes Involved in Modulating Important Winemaking Traits. FEMS Yeast Res. 2018, 18, foy069. [Google Scholar] [CrossRef]

- Mestre, V.; Maturano, P.; Mercado, L.; Toro, M.; Vazquez, F.; Combina, M. Evaluation of Different Co-Inoculation Time of Non-Saccharomyces/Saccharomyces yeasts in Order to Obtain Reduced Ethanol Wines. BIO Web Conf. 2016, 7, 02025. [Google Scholar] [CrossRef]

- Quirós, M.; Rojas, V.; Gonzalez, R.; Morales, P. Selection of Non-Saccharomyces yeast Strains for Reducing Alcohol Levels in Wine by Sugar Respiration. Int. J. Food Microbiol. 2014, 181, 85–91. [Google Scholar] [CrossRef]

- Sadoudi, M.; Tourdot-Maréchal, R.; Rousseaux, S.; Steyer, D.; Gallardo-Chacón, J.-J.; Ballester, J.; Vichi, S.; Guérin-Schneider, R.; Caixach, J.; Alexandre, H. Yeast-Yeast Interactions Revealed by Aromatic Profile Analysis of Sauvignon Blanc Wine Fermented by Single or Co-Culture of Non-Saccharomyces and Saccharomyces yeasts. Food Microbiol. 2012, 32, 243–253. [Google Scholar] [CrossRef]

- Contreras, A.; Hidalgo, C.; Schmidt, S.; Henschke, P.A.; Curtin, C.; Varela, C. The Application of Non-Saccharomyces yeast in Fermentations with Limited Aeration as a Strategy for the Production of Wine with Reduced Alcohol Content. Int. J. Food Microbiol. 2015, 205, 7–15. [Google Scholar] [CrossRef]

- Jolly, N.; Mehlomakulu, N.N.; Nortje, S.; Beukes, L.; Hoff, J.; Booyse, M.; Erten, H. Non-Saccharomyces yeast for Lowering Wine Alcohol Levels: Partial Aeration versus Standard Conditions. FEMS Yeast Res. 2022, 22, foac002. [Google Scholar] [CrossRef] [PubMed]

- Strejc, J.; Kyselová, L.; Karabin, M.; Silva, J.; Brányik, T. Production of Alcohol-free Beer with Elevated Amounts of Flavouring Compounds Using Lager Yeast Mutants. J. Inst. Brew. 2013, 119, 149–155. [Google Scholar] [CrossRef]

- Ferreira, M. Yeasts and Wine Off-Flavours: A Technological Perspective. Ann. Microbiol. 2011, 61, 95–102. [Google Scholar] [CrossRef]

- Capece, A.; Romano, P. Yeasts and Their Metabolic Impact on Wine Flavour; Springer: New York, NY, USA, 2019; pp. 43–80. ISBN 978-1-4939-9780-0. [Google Scholar]

- Nogueira, A.; Quéré, J.M.L.; Gestin, P.; Michel, A.; Wosiacki, G.; Drilleau, J.F. Slow Fermentation in French Cider Processing Due to Partial Biomass Reduction. J. Inst. Brew. 2008, 114, 102–110. [Google Scholar] [CrossRef]

| Saccharomyces spp. | Ethanol Reduction | Grape Variety | Comments | References |

|---|---|---|---|---|

| Saccharomyces kudriavzevii | 1.9–3% | Tempranillo, Macabeo, Synthetic grape must | ↑ higher alcohols (2-phenylethanol, isobutanol) | [22,36] |

| Saccharomyces eubayanus | 0.4% | Sauvignon blanc, Macabeu; Synthetic grape must | ↑ higher alcohols (2-phenylethanol), ↑ glycerol | [37,38] |

| Saccharomyces uvarum | 0.5–1.7% | Trebbiano, Chardonnay, Pinot, Shiraz, Merlot | ↑ higher alcohols (2-phenylethanol); ↑ esters (2-phenylethyl acetate, ethyl 2-methyl butanoate); ↑ glycerol; ↑ volatile acid (2-Methyl butanoic acid) | [39,40,41,42,43] |

| Saccharomyces paradoxus | 0.3–0.56% | Chardonnay, Grignolino | ↑ higher alcohols (1-propanol, hexanol, 2-phenylethanol, cis-3-hexenol) | [44,45] |

| Saccharomyces mikatae | 0.5% | Chardonnay; Synthetic grape must | ↑ higher alcohols (2-phenyl ethyl alcohol, 4-hydroxybenzene ethanol); ↑ glycerol | [38,46] |

| Non-Saccharomyces spp. | Ethanol Reduction | Grape Variety | Comments | References |

|---|---|---|---|---|

| Torulaspora delbrueckii | 0.3–1.3% | Tempranillo; Chenin blanc–Chardonnay blend; Airen, Synthetic grape must | ↑ higher alcohols (isoamyl alcohol, 2-phenylethanol, isobutanol); ↑ ester (phenylethyl acetate, ethyl lactate, 2-phenylethyl acetate, isoamyl acetate, ethyl heptanoate); ↑ glycerol; ↑ organic acid (succinic acid); ↑ aldheydes (nonanal, decanal) | [64,65,66,67,68,69] |

| Metschnikowia pulcherrima | 0.8–7.5% | Chardonnay, Shiraz, Verdicchio, Viura–Malvasìa blend, Riesling, Merlot, Synthetic grape must, Aglianico, Verdicchio, Garnacha tinta–Cabernet Sauvignon blend | ↑ higher alcohols (methyl propanol, 2-methyl butanol, 3-methyl butanol, isobutanol, 3-methylbutanol); ↑ esters (2-methylbutyl acetate, ethyl 2-methyl propanoate, ethyl acetate, ethyl propionate, ethyl octanoate, ethyl hexanoate); ↑ glycerol; ↑ terpene (geraniol) | [12,43,70,71,72,73,74,75,76] |

| Lachancea thermotolerans | 0.5–2.6% | Emir, Tempranillo, Sangiovese–Cabernet Sauvignon blend; Merlot, Treixadura, Mencía | ↑ higher alcohols (butanol, isobutanol, 2-methyl butanol, propanol, hexanol); ↑ glycerol; increased of esters (ethyl lactate, ethyl acetate, ethyl 3-hydroxybutyrate, ethyl octanoate, ethyl hexanoate); ↑ terpene (linalool) | [77,78,79,80,81,82,83] |

| Hanseniaspora uvarum | 0.4–6.7% | Malbec, Pinotage, Negroamaro, Ecolly, Cabernet Sauvignon, Aglianico | ↑ glycerol; ↑ higher alcohols (2-methyl-1-propanol, 1-pentanol, 1-eexanol, 3-ethoxy-1-propanol, benzyl alcohol, 2-pentanol); ↑ esters (ethyl hexanoate, ethyl octanoate, ethyl decanoate, ethyl lactate, isoamyl acetate; ethyl acetate); ↑ terpenes (linalool, nerol, nonanol) | [84,85,86,87,88,89,90] |

| Hanseniaspora opuntiae | 0.6–1.25% | Negroamaro, Pinotage, Sauvignon Blanc, Sideritis, Airén | ↑ higher alcohols (1-pentanol, 1-hexanol, 2-methyl-1-propanol, 2-nonanol); ↑ esters (phenethyl acetate, isoamyl acetate, ethyl hexanoate, ethyl caprylate, ethyl acetate, methyl acetate); ↑ organic acid (lactic acid) | [84,91,92,93] |

| Hanseniaspora guilliermondii | 3.3–3.3% | Fiano, Campanino | ↑ higher alcohols (1-propanol, 2-phenylethanol, 2–3-butanediol, 2-methyl-butanol); ↑ esters (2-phenylethyl acetate); ↑ organic acid (3-methylthio propionic acid); ↑ terpenes (nerol, α-terpineol) | [90,94,95,96] |

| Pichia kluyveri | 0.16–5% | Riesling | ↑ esters (ethyl hexanoate, ethyl octanoate); ↓ isovaleric acid; ↑ esters (ethyl butanoate, ethyl octanoate); ↑ terpenes (linalool oxide, hotrienol) | [71,97,98,99] |

| Meyerozyma guilliermondii | 0.8–2% | Riesling, Synthetic grape must, White Malvar | ↓ isovaleric acid; ↑ phenol (4-ethyl-phenol) ↑ higher alcohols (1-butanol, isoamyl alcohol, β-phenylethyl alcohol, isobutanol); ↑ esters (isoamyl acetate); ↑ ketone (acetoin) | [71,99,100,101] |

| Pichia kudriavzevii | 0.16–2.5% | Cabernet Sauvignon, Pinot noir, Cider | ↑ higher alcohols (n-pentanol, 1-phenylethanol, isoamyl alcohol, 1 octanol); ↑ glycerol; ↑ esters (ethyl propanoate, ethyl octanoate, ethyl acetate, benzyl acetate); ↑ terpenes (limonene, linalool) | [102,103,104] |

| Starmerella bacillaris | 0.5–4% | Barbera, Riesling, Montepulciano, Nebbiolo, Pinot grigio; Sauvignon blanc, Manzoni bianco, Raboso Piave | ↑ glycerol; ↑ higher alcohols (isoamyl alcohols, 1-octanol, phenylethyl alcohol, 2-phenylethanol); ↑ esters (ethyl hexanoate, ethyl acetate, ethyl octanoate); ↑ terpenes (linalool, geraniol) | [1,71,105,106,107,108,109,110,111,112] |

| Starmerella bombicola | 0.8–2.24% | Verdicchio, Synthetic grape must, Montepulciano | ↑ esters (ethyl acetate, isoamyl acetate); ↑ glycerol; ↑ terpenes (linalool); ↑ higher alcohols (β-phenyl ethanol, isobutanol) | [25,33,70,109,110,111] |

| Schizosaccharomyces pombe | 0.2–1% | Airen, Tempranillo, Zhenlong pomelo | ↑ higher alcohols (1-propanol, isobutanol, isoamyl alcohol, phenylethanol); ↓ organic acid (malic acid) | [80,97,113,114] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Testa, B.; Coppola, F.; Succi, M.; Iorizzo, M. Biotechnological Strategies for Ethanol Reduction in Wine. Fermentation 2025, 11, 159. https://doi.org/10.3390/fermentation11030159

Testa B, Coppola F, Succi M, Iorizzo M. Biotechnological Strategies for Ethanol Reduction in Wine. Fermentation. 2025; 11(3):159. https://doi.org/10.3390/fermentation11030159

Chicago/Turabian StyleTesta, Bruno, Francesca Coppola, Mariantonietta Succi, and Massimo Iorizzo. 2025. "Biotechnological Strategies for Ethanol Reduction in Wine" Fermentation 11, no. 3: 159. https://doi.org/10.3390/fermentation11030159

APA StyleTesta, B., Coppola, F., Succi, M., & Iorizzo, M. (2025). Biotechnological Strategies for Ethanol Reduction in Wine. Fermentation, 11(3), 159. https://doi.org/10.3390/fermentation11030159