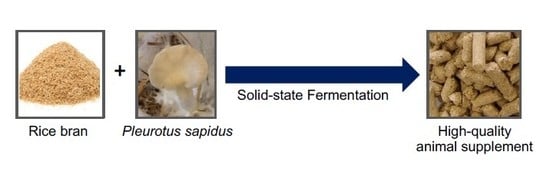

Upgrading the Nutritional Value of Rice Bran by Solid-State Fermentation with Pleurotus sapidus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rice Bran

2.2. Microorganism and Inoculum Preparation

2.3. Culture Conditions for Solid-State Fermentation

2.4. Proximate Composition Analysis

2.5. Extraction and Esterification of Fatty Acids

Determination of the Fatty Acid Composition by Gas Chromatography

2.6. Statistical Analysis

3. Results and Discussion

3.1. Effects of the SSF on the Nutritional Composition of Rice Bran

3.2. Effects of the SSF on the Fatty Acid Composition of Rice Bran

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singhania, R.R.; Sukumaran, R.K.; Patel, A.K.; Larroche, C.; Pandey, A. Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme Microb. Technol. 2010, 46, 541–549. [Google Scholar] [CrossRef]

- Sadh, P.K.; Kumar, S.; Chawla, P.; Duhan, J.S. Fermentation: A Boon for Production of Bioactive Compounds by Processing of Food Industries Wastes (By-Products). Molecules 2018, 23, 2560. [Google Scholar] [CrossRef] [PubMed]

- Omarini, A.; Dambolena, J.S.; Lucini, E.; Jaramillo Mejía, S.; Albertó, E.; Zygadlo, J.A. Biotransformation of 1,8-cineole by solid state fermentation of spent Eucalyptus wastes from the essential oil industry using Pleurotus ostreatus and Favolus tenuiculus. Folia Microbiol. 2016, 61, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Massarolo, K.C.; Denardi de Souza, T.; Christ Ribeiro, A.; Badiale Furlong, E.; Almeida de Souza Soares, L. Influence of cultivation Rhizopus oryzae on rice bran on lipid fraction: Fatty acids and phospholipids. Biocatal. Agric. Biotechnol. 2016, 8, 204–208. [Google Scholar] [CrossRef]

- Gul, K.; Yousuf, B.; Singh, A.K.; Singh, P.; Wani, A.A. Rice bran: Nutritional values and its emerging potential for development of functional food-A review. Bioact. Carbohyd. Dietary Fibre 2015, 6, 24–30. [Google Scholar] [CrossRef]

- Alauddin, M.; Islam, J.; Shirakawa, H.; Koseki, T.; Ardiansyah and Komai, M. Rice Bran as a Functional Food: An Overview of the Conversion of Rice Bran into a Superfood/Functional Food. In Superfood and Functional Food—An Overview of Their Processing and Utilization; Waisundara, V., Shiom, N., Eds.; IntechOpen: London, UK, 2017. [Google Scholar]

- Lemos, M.R.B.; Souza-Soares, L.A. Rice and its byproducts in southern Brazil. J. Exact Sci. Eng. 2000, 10, 21–36. [Google Scholar]

- Oliveira, M.d.S.; Feddern, V.; Kupsk, L.; Cipolatti, E.P.; Badiale-Furlong, E.; de Souza-Soares, L.A. Changes in lipid, fatty acids and phospholipids composition of whole rice bran after solid-state fungal fermentation. Bioresour. Technol. 2011, 102, 8335–8338. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.D.; Yang, S.S. Polyunsaturated fatty acids production with a solid-state column reactor. Bioresour. Technol. 2008, 99, 6181–6189. [Google Scholar] [CrossRef]

- Fonseca, G.G.; Avila Gandra, E.; Fossati Sclowitz, L.; Antunes Correa, A.P.; Vieira Costa, J.A. Protein enrichment and digestibility of soft rush (Juncus effusus) and rice residues using edible mushrooms Pleurotus ostreatus and Pleurotus sajor-caju. World J. Microbiol. Biotechnol. 2009, 25, 449–456. [Google Scholar] [CrossRef]

- Cohen, R.; Persky, L.; Hadar, Y. Biotechnological applications and potential of wood-degrading mushrooms of the genus Pleurotus. Appl. Microbiol. Biotechnol. 2002, 58, 582–594. [Google Scholar] [CrossRef]

- Omarini, A.B.; Schimanski, S.; Plagemannn, I.; Krings, U.; Berger, R.G. Crosses between monokaryons of Pleurotus sapidus or Pleurotus florida show an improved biotransformation of (+)-valencene to (+)-nootkatone. Bioresour. Technol. 2014, 171C, 113–119. [Google Scholar] [CrossRef]

- Omarini, A.B.; Henning, C.; Ringuelet, J.; Zygadlo, J.A.; Albertó, E. Volatile composition and nutritional quality of the edible mushroom Polyporus tenuiculus grown on different agroindustrial waste. Inter. J. Food Sci. Technol. 2010, 45, 1603–1609. [Google Scholar] [CrossRef]

- AOAC—Association of Official Analytical Chemists. Official Methods of Analysis, 17th ed.; AOAC (CDROM): Washington, DC, USA, 2000. [Google Scholar]

- Labuckas, D.O.; Lamarque, A.L.; Maestri, D. Partially defatted peanut flour: A functional ingredient to improve nutritional value of bakery products. Rev. Chil. Nutr. 2016, 43, 380–387. [Google Scholar] [CrossRef]

- Maestri, D.; Martínez, M.; Bodoira, R.; Rossi, Y.; Oviedo, A.; Pierantozzi, P.; Torres, M. Variability in almond oil chemical traits from traditional cultivars and native genetic resources from Argentina. Food Chem. 2015, 170, 55–56. [Google Scholar] [CrossRef]

- Blandino, A.; Al-Aseeri, M.E.; Pandiella, S.S.; Cantero, D.; Webb, C. Cereal-based fermented foods and beverages. Food Res. Int. 2003, 36, 527–543. [Google Scholar] [CrossRef]

- Oliveira, M.d.S.; Feddern, V.; Kupski, L.; Cipolatti, E.P.; Badiale-Furlong, E.; Souza-Soares, L.A. Physicochemical characterization of fermented rice bran biomass. CyTA J. Food. 2010, 8, 229–236. [Google Scholar] [CrossRef]

- De Groot, P.W.J.; Visser, J.; Van Griensven, L.J.L.D.; Schapp, P.J. Biochemical and molecular aspects of growth and fruiting of the edible mushroom Agaricus bisporus. Mycol. Res. 1998, 102, 1297–1308. [Google Scholar] [CrossRef]

- Xie, C.; Yan, L.; Gong, W.; Zhu, Z.; Tan, S.; Chen, D.; Hu, Z.; Peng, Y. Effects of Different Substrates on Lignocellulosic Enzyme Expression, Enzyme Activity, Substrate Utilization and Biological Efficiency of Pleurotus Eryngii. Cell Physiol. Biochem. 2016, 39, 1479–1494. [Google Scholar] [CrossRef] [PubMed]

- Kalač, P. A review of chemical composition and nutritional value of wild-growing and cultivated mushrooms. J. Sci. Food Agric. 2013, 93, 209–218. [Google Scholar] [CrossRef]

- Abu, O.A.; Tewe, O.O.; Losel, D.M.; Onifade, A.A. Changes in lipid, fatty acids and protein composition of sweet potato (Ipomoea batatas) after solid-state fungal fermentation. Bioresour. Technol. 2000, 72, 189–192. [Google Scholar] [CrossRef]

- Kupski, L.; Cipolatti, E.; da Rocha, M.; Oliveira, M.d.S.; de Almeida Souza-Soares, L.; Badiale-Furlong, E. Solid-State Fermentation for the Enrichment and Extraction of Proteins and Antioxidant Compounds in Rice Bran by Rhizopus oryzae. Braz. Arch. Biol. Technol. 2012, 55, 937–942. [Google Scholar] [CrossRef]

- Kim, H.Y.; Kim, J.H.; Yang, S.B.; Hong, S.G.; Lee, S.A.; Hwang, S.J. A polysaccharide extracted from rice bran fermented with Lentinus edodes enhances natural killer cell activity and exhibits anticancer effects. J. Med. Food. 2007, 10, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Faria, S.A.S.C.; Bassinello, P.Z.; Penteado, M.V.C. Nutritional composition of rice bran submitted to different stabilization procedures. Braz. J. Pharm. Sci. 2012, 48, 651–657. [Google Scholar] [CrossRef] [Green Version]

- Günç Ergönül, P.; Akata, I.; Kalyoncu, F.; Ergönül, B. Fatty acid compositions of six wild edible mushroom species. Sci. World J. 2013, 2013, 163964. [Google Scholar] [CrossRef]

- Silveira, C.M.; Oliveira, M.S.; Badiale-Furlong, E. Lipid content and fatty acid profile of defatted rice bran and wheat bran submitted to solid state fermentation by Aspergillus oryzae. Bol. CEPPA 2010, 28, 133–140. [Google Scholar]

- Asadi, S.Z.; Khosravi-Darani, k.; Nikoopour, H.; Bakhoda, H. Evaluation of the effect of process variables on the fatty acid profile of single cell oil produced by Mortierella using solid-state fermentation. Crit. Rev. Biotechnol. 2015, 35, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Dimou, D.M.; Georgala, A.; Komaitis, M.; Aggelis, G. Mycelial fatty acid composition of Pleurotus spp. and its application in the intrageneric differentiation. Mycol. Res. 2002, 106, 925–929. [Google Scholar] [CrossRef]

| Components * | Control Samples | Fermented Rice Bran Samples | |||

|---|---|---|---|---|---|

| P. sapidus | Rice bran | Day 4 | Day 6 | Day 10 | |

| moisture (%) | 95.1 ± 1.3 a | 20.7 ± 0.8 b | 28.7 ± 6.2 c | 35.2 ± 2.1 c,d | 37.9 ± 8.1 d |

| Protein (%) | 26.5 ± 0.1 a | 7.4 ± 0.6 b | 10.8 ± 1.3 c | 9.7 ± 0.8 c | 12.8 ± 0.6 d |

| Ash (%) | 6.5 ± 0.05 a | 7.6 ± 0.5 b | 11.2 ± 1.4 c | 10.3 ± 1.1 c | 11.5 ± 0.05 c |

| Total carbohydrates | 60.5 ± 0.6 a | 36.6 ± 0.6 b | 50.2 ± 2.1 c | 43.2 ± 1.8 d | 45.0 ± 0.8 d |

| Lipids (%) | 6.6 ± 0.7 a | 48.5 ± 3.9 b | 27.8 ± 6.5 c | 36.9 ± 0.2 d | 30.8 ± 11.8 c,d |

| Energetic value | 407.4 | 612.1 | 494.2 | 543.3 | 508.4 |

| % RDD ** | 20.4 | 30.6 | 24.7 | 27.2 | 25.4 |

| Fatty Acid Profile (%) | |||||

|---|---|---|---|---|---|

| Fatty Acid | Nº Carbons | P. sapidus | Rice Bran | FRB day 4 | FRB day 6 |

| Undecanoic acid | C11:0 | 2.28 ± 0.00 a | nd b | nd b | nd b |

| Lauric acid | C12:0 | 5.16 ± 0.28 a | 0.02 ± 0.02 b | 0.05 ± 0.02 b | 0.06 ± 0.03 b |

| Myristic acid | C14:0 | 1.28 ± 1.11 a | nd b | nd b | nd b |

| Pentadecanoic acid | C15:0 | 2.02 ± 1.67 a | nd b | nd b | nd b |

| Palmitic acid | C16:0 | 16.03 ± 0.85 a | 21.27 ± 0.14 b | 22.09 ± 1.96 b,c | 21.08 ± 0.62 b |

| Palmitoleic acid | C16:1 | 0.83 ± 0.26 a | 0.22 ± 0.02 b | 0.19 ± 0.01 b | 0.17 ± 0.03 b |

| Margaric acid | C17:0 | 0.72 ± 0.00 a | nd b | nd | nd |

| Stearic acid | C18:0 | 8.50 ± 0.38 a | 1.76 ± 0.53 b | 2.04 ± 0.21 b | 1.99 ± 0.10 b |

| Oleic acid | C18:1 | 19.62 ± 4.29 a | 39.93 ± 0.35 b | 40.26 ± 1.04 b | 40.36 ± 0.28 b |

| Linoleic acid | C18:2 | 39.07 ± 4.52 a | 33.94 ± 0.18 b | 32.79 ± 0.87 c | 34.07 ± 0.82 b |

| Linolenic acid | C18:3 | 0.42 ± 0.00 a | 1.50 ± 0.01 b | 1.35 ± 0.03 c | 1.50 ± 0.24 b,c |

| Arachidic acid | C20:0 | nd a | 0.85 ± 0.01 b | 0.83 ± 0.09 b | nd a |

| Eicosenoic acid | C20.1 | 0.67 ± 0.00 a | 0.66 ± 0.18 a,b | 0.69 ± 0.19 a,b | 0.80 ± 0.06 b |

| Behenic acid | C22:0 | 1.05 ± 0.47 a | 0.37 ± 0.00 b | 0.05 ± 0.01 c | nd d |

| Lignoceric acid | C24:0 | 2.81 ± 0.95 a | nd b | nd b | nd b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omarini, A.B.; Labuckas, D.; Zunino, M.P.; Pizzolitto, R.; Fernández-Lahore, M.; Barrionuevo, D.; Zygadlo, J.A. Upgrading the Nutritional Value of Rice Bran by Solid-State Fermentation with Pleurotus sapidus. Fermentation 2019, 5, 44. https://doi.org/10.3390/fermentation5020044

Omarini AB, Labuckas D, Zunino MP, Pizzolitto R, Fernández-Lahore M, Barrionuevo D, Zygadlo JA. Upgrading the Nutritional Value of Rice Bran by Solid-State Fermentation with Pleurotus sapidus. Fermentation. 2019; 5(2):44. https://doi.org/10.3390/fermentation5020044

Chicago/Turabian StyleOmarini, Alejandra B., Diana Labuckas, María P. Zunino, Romina Pizzolitto, Marcelo Fernández-Lahore, Damián Barrionuevo, and Julio A. Zygadlo. 2019. "Upgrading the Nutritional Value of Rice Bran by Solid-State Fermentation with Pleurotus sapidus" Fermentation 5, no. 2: 44. https://doi.org/10.3390/fermentation5020044

APA StyleOmarini, A. B., Labuckas, D., Zunino, M. P., Pizzolitto, R., Fernández-Lahore, M., Barrionuevo, D., & Zygadlo, J. A. (2019). Upgrading the Nutritional Value of Rice Bran by Solid-State Fermentation with Pleurotus sapidus. Fermentation, 5(2), 44. https://doi.org/10.3390/fermentation5020044