Concentrated Buffalo Whey as Substrate for Probiotic Cultures and as Source of Bioactive Ingredients: A Local Circular Economy Approach towards Reuse of Wastewaters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Downstream Process

2.3. Spray Drying

2.4. Analytical Methods

2.5. Total Protein Quantification

2.6. Bottle and Bioreactor Experiments

2.7. Cell Cultures and Treatments

2.8. In Vitro Scratch Test and Time-Lapse Video Microscopy (TLVM)

2.9. Statistical Analysis

3. Results and Discussion

3.1. Clean Water Generation, Spray Drying of Concentrated Ultrafiltered Whey and Characterization of the Obtained Fractions

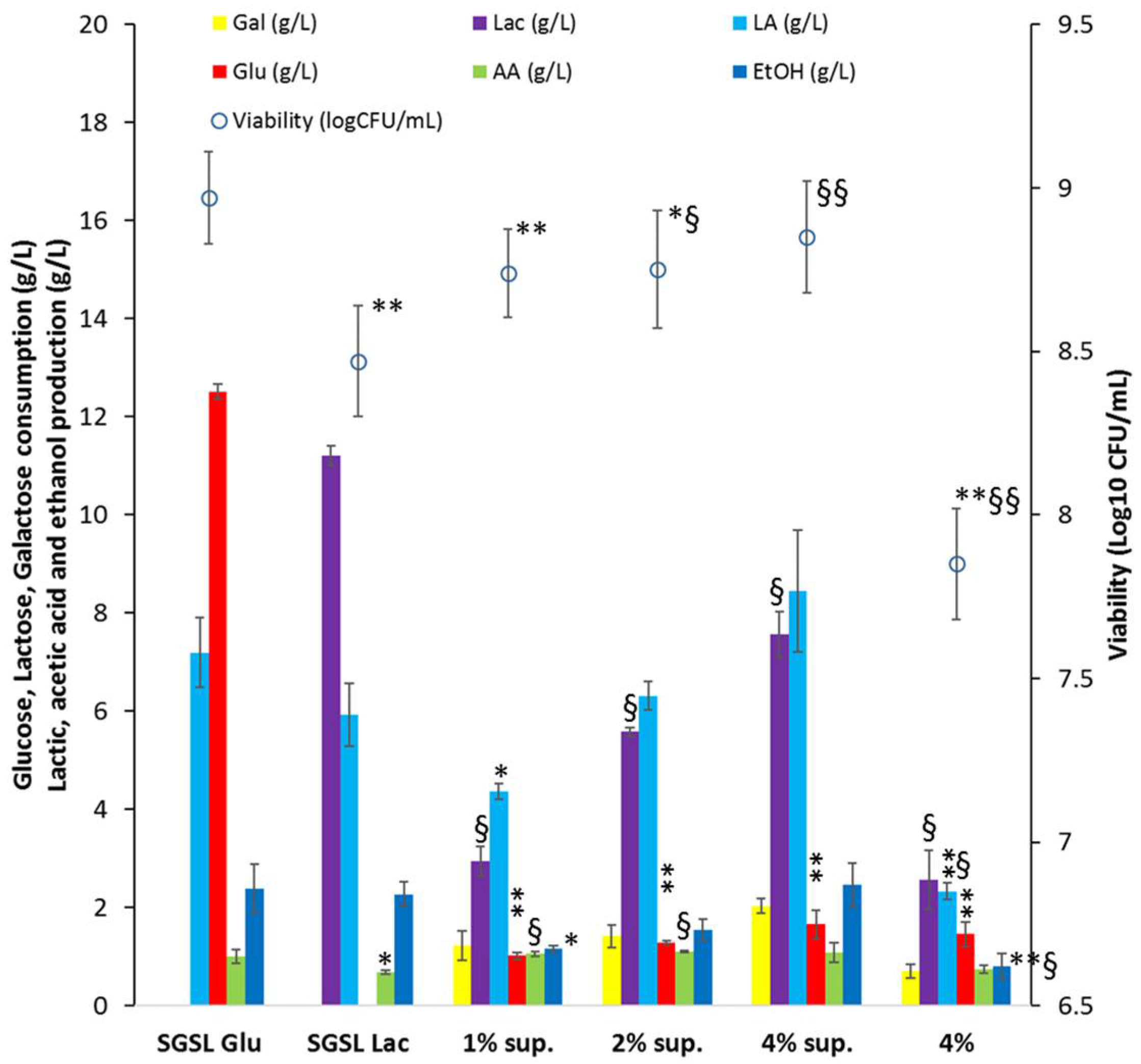

3.2. Evaluation of Ultrafiltered Spray-Dried Whey as Substrate for the Growth of L. fermentum

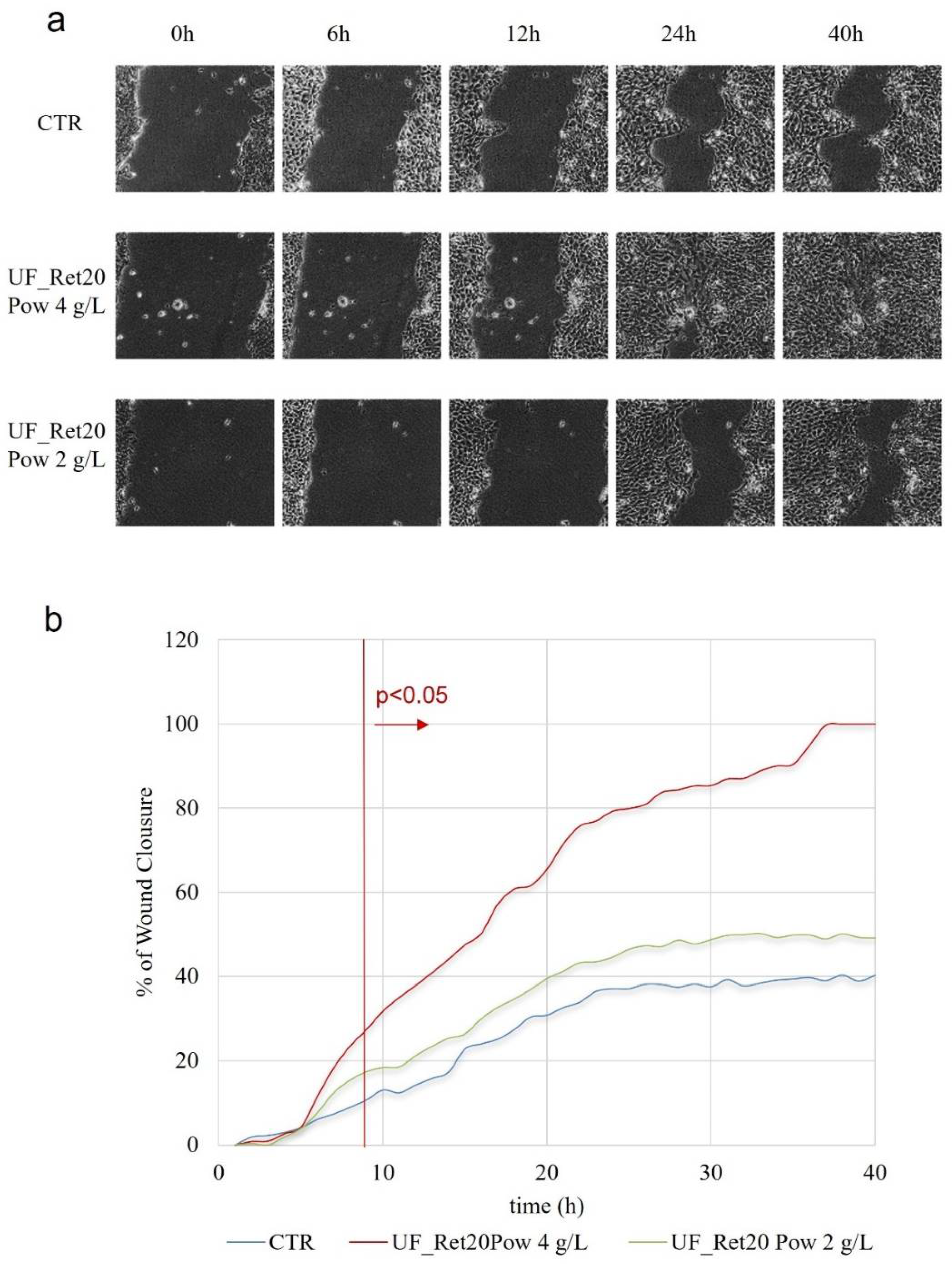

3.3. Whey Valorization as Wound Repair Agent

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baldasso, C.; Barros, T.C.; Tessaro, I.C. Concentration and purification of whey proteins by ultrafiltration. Desalination 2011, 278, 381–386. [Google Scholar] [CrossRef]

- Cuartas-Uribe, B.; Alcaina-Miranda, M.I.; Soriano-Costa, E.; Bes-Piá, A. Comparison of the behavior of two nanofiltration membranes for sweet whey demineralization. J. Dairy Sci. 2007, 90, 1094–1101. [Google Scholar] [CrossRef]

- Baisali, S.; Chakrabarti, P.P.; Vijaykumar, A.; Kale, V. Wastewater treatment in dairy industries—Possibility of reuse. Desalination 2006, 195, 141–152. [Google Scholar]

- Dullius, A.; Goettert, M.I.; Volken de Souza, C.F. Whey protein hydrolysates as a source of bioactive peptides for functional foods—Biotechnological facilitation of industrial scale-up. J. Func. Foods 2018, 42, 58–74. [Google Scholar] [CrossRef]

- Pires, A.F.; Marnotes, N.G.; Rubio, O.D.; Garcia, A.C.; Pereira, C.D. Dairy By-Products: A Review on the Valorization of Whey and Second Cheese Whey. Foods 2021, 10, 1067. [Google Scholar] [CrossRef] [PubMed]

- Bounous, G. Whey protein concentrate (WPC) and glutathione modulation in cancer treatment. Anticancer Res. 2000, 20, 4785–4792. [Google Scholar]

- Teixeira, F.J.; Santos, H.O.; Howell, S.L.; Pimentel, G.D. Whey protein in cancer therapy: A narrative review. Pharmacol. Res. 2019, 144, 245–256. [Google Scholar] [CrossRef]

- Agin, D.; Gallagher, D.; Wang, J.; Heymsfield, S.B.; Pierson, R.N.; Jr Kotler, D.P. Effects of whey protein and resistance exercise on body cell mass, muscle strength, and quality of life in women with HIV. AIDS 2001, 15, 2431–2440. [Google Scholar] [CrossRef]

- Marshall, K. Therapeutic applications of whey protein. Altern. Med. Rev. 2004, 9, 136–156. [Google Scholar]

- Zotta, T.; Solieri, L.; Iacumin, L.; Picozzi, C.; Gullo, M. Valorization of cheese whey using microbial fermentations. Appl. Microbiol. Biotechnol. 2020, 104, 2749–2764. [Google Scholar] [CrossRef]

- Aguirre-Ezkauriatza, E.J.; Aguilar-Yáñez, J.M.; Ramírez-Medrano, A.; Alvarez, M.M. Production of probiotic biomass (Lactobacillus casei) in goat milk whey: Comparison of batch, continuous and fed-batch cultures. Bioresour. Technol. 2010, 101, 2837–2844. [Google Scholar] [CrossRef]

- Kumar, M.; Jain, A.K.; Ghosh, M.; Ganguli, A. Industrial whey utilization as a medium supplement for biphasic growth and bacteriocin production by probiotic Lactobacillus casei LA-1. Probiotics Antimicrob. Proteins 2012, 4, 198–207. [Google Scholar] [CrossRef]

- Malvido, M.C.; González, E.A.; Bazán Tantaleán, D.L.; Bendaña Jácome, R.J.; Guerra, N.P. Batch and fed-batch production of probiotic biomass and nisin in nutrient-supplemented whey media. Braz. J. Microbiol. 2019, 50, 915–925. [Google Scholar] [CrossRef]

- Meng, W.; Zhang, Y.; Cao, M.; Zhang, W.; Lü, C.; Yang, C.; Gao, C.; Xu, P.; Ma, C. Efficient 2,3-butanediol production from whey powder using metabolically engineered Klebsiella oxytoca. Microb. Cell Factories 2020, 19, 162–171. [Google Scholar] [CrossRef]

- Pais, J.; Serafim, L.S.; Freitas, F.; Reis, M.A. Conversion of cheese whey into poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Haloferax mediterranei. New Biotechnol. 2016, 33, 224–230. [Google Scholar] [CrossRef]

- Prasad, S.; Srikanth, K.; Limaye, A.M.; Sivaprakasam, S. Homofermentative production of D-lactic acid by Lactobacillus sp. employing casein whey permeate as a raw feed-stock. Biotechnol. Lett. 2014, 36, 1303–1307. [Google Scholar] [CrossRef]

- Atra, R.; Vatai, G.; Békássy-Molnár, E.; Bálint, A. Investigation of ultra- and nanofiltration for utilization of whey protein and lactose. J. Food Eng. 2005, 67, 325–332. [Google Scholar] [CrossRef]

- Yorgun, M.S.; Balcioğlu, I.A.; Saygin, O. Performance comparison of ultrafiltration, nanofiltration and reverse osmosis on whey treatment. Desalination 2008, 229, 204–216. [Google Scholar] [CrossRef]

- Naghmouchi, K.; Belguesmia, Y.; Bendali, F.; Spano, G.; Seal, B.S.; Drider, D. Lactobacillus fermentum: A bacterial species with potential for food preservation and biomedical applications. Crit. Rev. Food Sci. Nutr. 2020, 60, 3387–3399. [Google Scholar] [CrossRef] [PubMed]

- Baldini, M.; Fabietti, F.; Giammarioli, S.; Onori, R.; Orefice, L.; Stacchini, A. Determinazione delle Ceneri nel Formaggio, nel Formaggio Fuso e Nella Ricotta. G. U. Supplemento al n. 229 del 02/10/1986. Istituto Superiore di Sanità. Available online: https://www.iss.it/ (accessed on 10 October 2021).

- Jin, J.; Lao, J.; Zhou, R.; He, W.; Qin, Y.; Zhong, C.; Xie, J.; Liu, H.; Wan, D.; Zhang, S.; et al. Simultaneous identification and dynamic analysis of saccharides during steam processing of rhizomes of Polygonatum cyrtonema by HPLC-QTOF-MS/MS. Molecules 2018, 11, 2855. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Wayah, S.B.; Philip, K. Characterization, yield optimization, scale up and biopreservative potential of fermencin SA715, a novel bacteriocin from Lactobacillus fermentum GA715 of goat milk origin. Microb. Cell Factories 2018, 17, 125–142. [Google Scholar] [CrossRef] [Green Version]

- Hanoune, S.; Djeghri-Hocine, S.; Kassas, S.; Derradji, S.; Boudour, S.; Boukhemis, S. Optimization of Lactobacillus fermentum DSM 20049 growth on whey and lupin based medium using response surface methodology. J. Adv. J. Food Sci. Technol. 2015, 9, 679–685. [Google Scholar] [CrossRef]

- Gao, X.; Qiao, S.Y.; Lu, W.Q. Determination of an economical medium for growth of Lactobacillus fermentum using response surface methodology. Lett. Appl. Microbiol. 2009, 49, 556–561. [Google Scholar] [CrossRef]

- Kariluoto, S.; Aittamaa, M.; Korhola, M.; Salovaara, H.; Vahteristo, L.; Piironen, V. Effects of yeasts and bacteria on the levels of folates in rye sourdoughs. Int. J. Food Microbiol. 2006, 106, 137–143. [Google Scholar] [CrossRef] [PubMed]

- Ebaid, H.; Salem, A.; Sayed, A.; Metwalli, A. Whey protein enhances normal inflammatory responses during cutaneous wound healing in diabetic rats. Lipids Health Dis. 2011, 10, 235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kalinina, P.; Vorstandlechner, V.; Buchberger, M.; Eckhart, L.; Lengauer, B.; Golabi, B.; Mildner, M. The whey acidic protein WFDC12 is specifically expressed in terminally differentiated keratinocytes and regulates epidermal serine protease activity. J. Investig. Dermatol. 2021, 141, 1198–1206. [Google Scholar] [CrossRef]

- D’Agostino, A.; Pirozzi, A.V.A.; Finamore, R.; Grieco, F.; Minale, M.; Schiraldi, C. Molecular mechanisms at the basis of pharmaceutical grade Triticum vulgare extract efficacy in prompting keratinocytes healing. Molecules 2020, 25, 431. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| (a) | Nanofiltration Parameters | Initial Vol. (L) | Final Vol. (L) | Concentration Factor | Initial Flux (LMH) | Final Flux (LMH) | Initial TMP (bar) | Final TMP (bar) |

|---|---|---|---|---|---|---|---|---|

| 150–200 Da cut-off | 10 | 1.25 | 8 | 33 | 28 | 10 | 12 | |

| (b) | Sample | Protein (g/L) | Lactose (g/L) | Lactic Acid (g/L) | Vol (L) | |||

| Buffalo whey | 1.10 | 29.8 | 5.0 | 10,000 | ||||

| UF ret | 5.19 | 42.9 | 6.7 | 800 | ||||

| UF per | 0.05 | 31.7 | 5.5 | 9200 (10 *) | ||||

| NF ret | 0.09 | 120.3 | 10.9 | 1.25 | ||||

| NF per | n.d. | 0.03 | 2.3 | 8 | ||||

| Sample | Protein w/v (%) | Lac w/v (%) | Gal w/v (%) | Glu w/v (%) | LA w/v (%) | Ins. Solids w/v (%) | Water w/w (%) | Ash w/w (%) |

|---|---|---|---|---|---|---|---|---|

| Dried powder | 6 | 44 | 8 | 6 | 5 | 7 | 4 | 11 |

| Viability (Log10 CFU/mL) | Lac (g/L) | Glu (g/L) | Gal (g/L) | Sugars Cons. (g/L) | LA (g/L) | AA (g/L) | EtOH (g/L) | YLA/s (g/g) | |

|---|---|---|---|---|---|---|---|---|---|

| UF_Ret20Pow | 8.1 ± 0.2 | 3.3 ± 0.8 ** | 2.5 ± 0.8 * | 1.5 ± 0.2 | 7.2 ± 1.4 ** | 3.0 ± 0.6 ** | 1.3 ± 0.4 | 1.4 ± 0.5 | 0.42 ± 0.01 |

| UF_Ret20Pow sup | 8.0 ± 0.2 | 9.4 ± 0.3 | 5.1 ± 0.3 | 2.0 ± 0.2 | 16.4 ± 0.3 | 10.0 ± 0.3 | 1.5 ± 0.4 | 1.9 ± 0.2 | 0.61 ± 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfano, A.; D’ambrosio, S.; D’Agostino, A.; Finamore, R.; Schiraldi, C.; Cimini, D. Concentrated Buffalo Whey as Substrate for Probiotic Cultures and as Source of Bioactive Ingredients: A Local Circular Economy Approach towards Reuse of Wastewaters. Fermentation 2021, 7, 281. https://doi.org/10.3390/fermentation7040281

Alfano A, D’ambrosio S, D’Agostino A, Finamore R, Schiraldi C, Cimini D. Concentrated Buffalo Whey as Substrate for Probiotic Cultures and as Source of Bioactive Ingredients: A Local Circular Economy Approach towards Reuse of Wastewaters. Fermentation. 2021; 7(4):281. https://doi.org/10.3390/fermentation7040281

Chicago/Turabian StyleAlfano, Alberto, Sergio D’ambrosio, Antonella D’Agostino, Rosario Finamore, Chiara Schiraldi, and Donatella Cimini. 2021. "Concentrated Buffalo Whey as Substrate for Probiotic Cultures and as Source of Bioactive Ingredients: A Local Circular Economy Approach towards Reuse of Wastewaters" Fermentation 7, no. 4: 281. https://doi.org/10.3390/fermentation7040281

APA StyleAlfano, A., D’ambrosio, S., D’Agostino, A., Finamore, R., Schiraldi, C., & Cimini, D. (2021). Concentrated Buffalo Whey as Substrate for Probiotic Cultures and as Source of Bioactive Ingredients: A Local Circular Economy Approach towards Reuse of Wastewaters. Fermentation, 7(4), 281. https://doi.org/10.3390/fermentation7040281