Spray-Dried Nipa Palm Vinegar Powder: Production and Evaluation of Physicochemical, Nutritional, Sensory, and Storage Aspects

Abstract

:1. Introduction

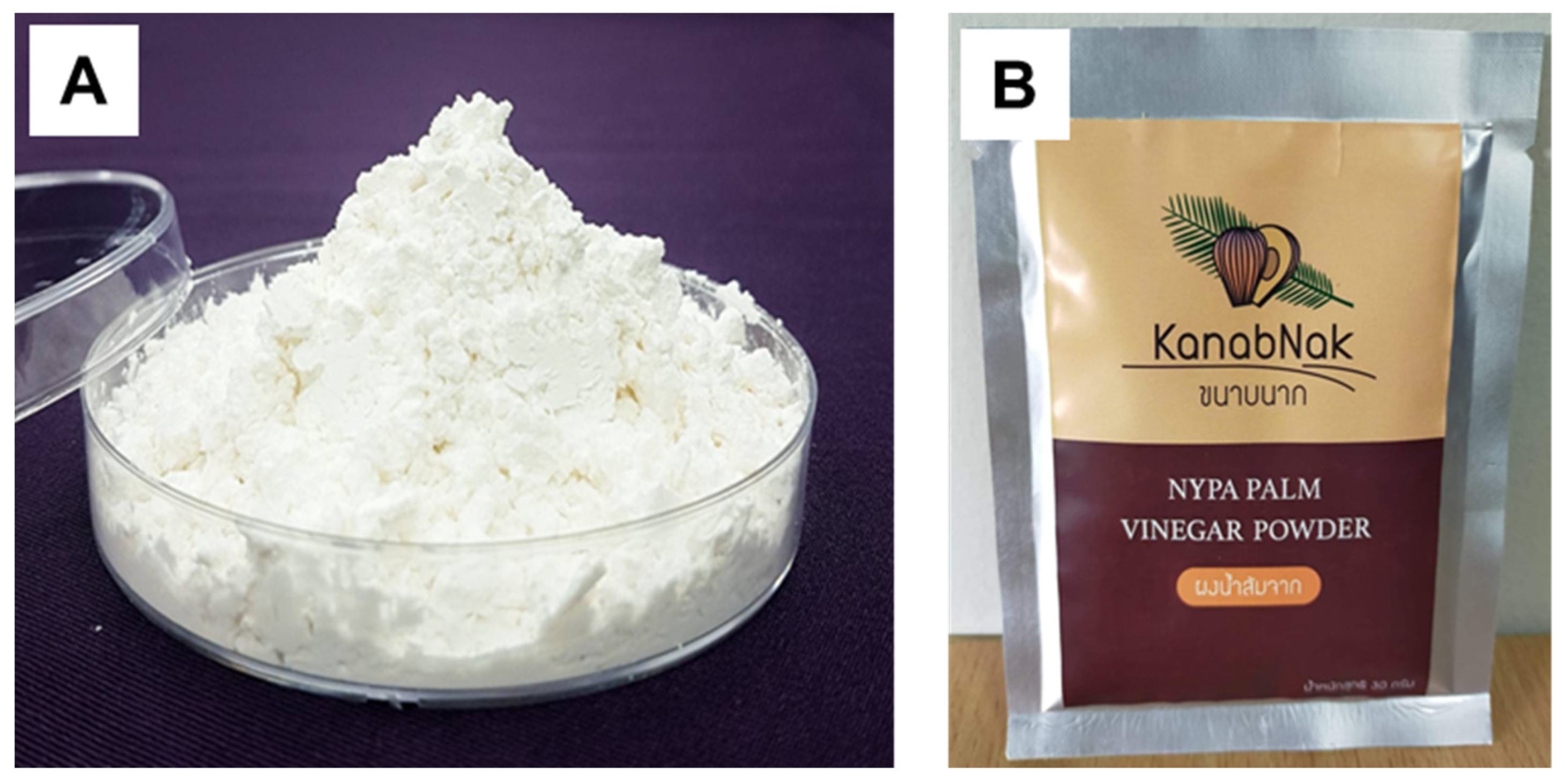

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Nipa Palm Vinegar

2.3. Spray Drying of Nipa Palm Vinegar

2.3.1. Experimental Design

2.3.2. Selection of the Optimal Point

2.4. Physicochemical Characterization

2.4.1. Product Yield

2.4.2. Bulk Density

2.4.3. Total Soluble Solids, Moisture Content, and Water Activity

2.4.4. The pH and Acetic Acid Determination

2.4.5. Color Analysis

2.5. Nutritional Characteristics

2.6. Sensory Evaluations of NPV and NPV Powder

2.7. Assessment of Storage Stability of NPV Powder

Microbial Counts

2.8. Statistical Analysis

3. Results and Discussion

3.1. Effects of Spray Drying Conditions

3.1.1. Yield of NPV Powder

3.1.2. Bulk Density

3.1.3. Moisture Content and Water Activity

3.1.4. Total Soluble Solids

3.1.5. Color

3.2. Optimization of Design

3.3. Nutritional Characteristics

3.4. Sensory Acceptance

3.5. Product Stability during Storage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheablam, O.; Chanklap, B. Sustainable nipa palm (Nypa fruticans Wurmb.) product utilization in Thailand. Scientifica 2020, 2020, 3856203. [Google Scholar] [CrossRef] [PubMed]

- Hamilton, L.S.; Murphy, D.H. Use and management of Nipa palm (Nypa fruticans, arecaceae): A review. Econ. Bot. 1988, 42, 206–213. [Google Scholar] [CrossRef]

- Tsuji, K.; Ghazalli, M.N.F.; Ariffin, Z.; Nordin, M.S.; Khaidizar, M.I.; Dulloo, M.E.; Sebastian, L.S. Biological and ethnobotanical characteristics of Nipa Palm (Nypa fructicans Wurmb.): A review. Sains Malays. 2011, 40, 1407–1412. [Google Scholar]

- Senghoi, W.; Klangbud, W.K. Antioxidants, inhibits the growth of foodborne pathogens and reduces nitric oxide activity in LPS-stimulated RAW 264.7 cells of nipa palm vinegar. PeerJ 2021, 9, e12151. [Google Scholar] [CrossRef]

- Laklaeng, S.-N.; Kwanhian, W. Immunomodulation effect of Nypa fruticans palm vinegar. Walailak J. Sci. Technol. 2020, 17, 1200–1210. [Google Scholar] [CrossRef]

- Francisco-Ortega, J.; Zona, S. Sweet sap from palms, a source of beverages, alcohol, vinegar, syrup, and sugar. Vieraea 2013, 41, 91–113. [Google Scholar] [CrossRef]

- Yusoff, N.A.; Ahmad, M.; Al Hindi, B.; Widyawati, T.; Yam, M.F.; Mahmud, R.; Razak, K.N.; Asmawi, M.Z. Aqueous extract of Nypa fruticans Wurmb. vinegar alleviates postprandial hyperglycemia in normoglycemic rats. Nutrients 2015, 7, 7012–7026. [Google Scholar] [CrossRef] [PubMed]

- Chatatikun, M.; Kwanhian, W. Phenolic profile of nipa palm vinegar and evaluation of its antilipidemic activities. Evid. Based Complement. Alternat. Med. 2020, 2020, 6769726. [Google Scholar] [CrossRef]

- Santos, D.; Maurício, A.C.; Sencadas, V.; Santos, J.D.; Fernandes, M.H.; Gomes, P.S. Spray drying: An overview. Biomater. Phys. Chem. -New Ed. 2017, 9–35. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Chen, W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 2017, 65, 49–67. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Hassan, N.D.; Mamat, S.N.; Nawi, N.M.; Rashid, W.A.; Tan, N.A. Extraction technologies and solvents of phytocompounds from plant materials: Physicochemical characterization and identification of ingredients and bioactive compounds from plant extract using various instrumentations. In Ingredients Extraction by Physicochemical Methods in Food; Grumezescu, A.M., Holban, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 523–560. [Google Scholar] [CrossRef]

- Braga, V.; Guidi, L.R.; de Santana, R.C.; Zotarelli, M.F. Production and characterization of pineapple-mint juice by spray drying. Powder Technol. 2020, 375, 409–419. [Google Scholar] [CrossRef]

- Mishra, P.; Mishra, S.; Mahanta, C.L. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 2014, 92, 252–258. [Google Scholar] [CrossRef]

- Abd Hashib, S.; Abd Rahman, N.; Suzihaque, M.; Ibrahim, U.K.; Hanif, N.E. Effect of slurry concentration and inlet temperature towards glass temperature of spray dried pineapple powder. Procedia Soc. Behav. Sci. 2015, 195, 2660–2667. [Google Scholar] [CrossRef]

- Oberoi, D.P.S.; Sogi, D.S. Effect of drying methods and maltodextrin concentration on pigment content of watermelon juice powder. J. Food Eng. 2015, 165, 172–178. [Google Scholar] [CrossRef]

- Chen, J.-C.; Zheng, B.-D.; Zhao, Y.-Y.; Xu, J.; Wu, J.-J.; Luo, C.; Pang, J.; He, G.-Q. Hypolipidemic effects on lipid metabolism and lipase inhibition by black vinegar powder. J. Biobased Mater. Bioenergy 2012, 6, 634–639. [Google Scholar] [CrossRef]

- Chen, J.; Tian, J.; Ge, H.; Liu, R.; Xiao, J. Effects of tetramethylpyrazine from Chinese black vinegar on antioxidant and hypolipidemia activities in HepG2 cells. Food Chem. Toxicol. 2017, 109, 930–940. [Google Scholar] [CrossRef]

- Othaman, M.A.; Sharifudin, S.A.; Mansor, A.; Kahar, A.; Long, K. Coconut water vinegar: New alternative with improved processing technique. J. Eng. Sci. Technol. 2014, 9, 293–302. [Google Scholar]

- Yu, L.; Peng, Z.; Dong, L.; Wang, S.; Ding, L.; Huo, Y.; Wang, H. Bamboo vinegar powder supplementation improves the antioxidant ability of the liver in finishing pigs. Livest. Sci. 2018, 211, 80–86. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Spray drying of tomato pulp in dehumidified air: II. The effect on powder properties. J. Food Eng. 2005, 66, 35–42. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International, 21st ed.; AOAC International: Rockville, MD, USA, 2019. [Google Scholar]

- AOAC International. Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Rockville, MD, USA, 2000. [Google Scholar]

- Palachum, W.; Choorit, W.; Manurakchinakorn, S.; Chisti, Y. Guava pulp fermentation and processing to a vitamin B12-enriched product. J. Food Process. Preserv. 2020, 44, e14566. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, B.; Yao, S. High-performance liquid chromatography/electrospray ionization-mass spectrometry for simultaneous determination of taurine and 10 water-soluble vitamins in multivitamin tablets. Anal. Chim. Acta 2006, 569, 169–175. [Google Scholar] [CrossRef]

- Sullivan, D.M.; Carpenter, D.E. Methods of Analysis for Nutrition Labeling; AOAC International: Rockville, MD, USA, 1993. [Google Scholar]

- Palachum, W.; Choorit, W.; Chisti, Y. Nutritionally enhanced probioticated whole pineapple juice. Fermentation 2021, 7, 178. [Google Scholar] [CrossRef]

- FDA. Bacteriological Analytical Manual: Chapter 3: Aerobic Plate Count; US Food and Drug Administration: Silver Spring, MD, USA, 2001. Available online: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-3-aerobic-plate-count (accessed on 5 April 2022).

- Tan, S.L.; Sulaiman, R.; Rukayadi, Y.; Ramli, N.S. Physical, chemical, microbiological properties and shelf life kinetic of spray-dried cantaloupe juice powder during storage. LWT 2021, 140, 110597. [Google Scholar] [CrossRef]

- Saavedra-Leos, M.Z.; Leyva-Porras, C.; López-Martínez, L.A.; González-García, R.; Martínez, J.O.; Compeán Martínez, I.; Toxqui-Terán, A. Evaluation of the spray drying conditions of blueberry juice-maltodextrin on the yield, content, and retention of quercetin 3-D-galactoside. Polymers 2019, 11, 312. [Google Scholar] [CrossRef] [PubMed]

- Şahin-Nadeem, H.; Torun, M.; Özdemir, F. Spray drying of the mountain tea (Sideritis stricta) water extract by using different hydrocolloid carriers. LWT 2011, 44, 1626–1635. [Google Scholar] [CrossRef]

- Şahin-Nadeem, H.; Dinçer, C.; Torun, M.; Topuz, A.; Özdemir, F. Influence of inlet air temperature and carrier material on the production of instant soluble sage (Salvia fruticosa Miller) by spray drying. LWT 2013, 52, 31–38. [Google Scholar] [CrossRef]

- Lee, K.-C.; Yoon, Y.S.; Li, F.-Z.; Eun, J.-B. Effects of inlet air temperature and concentration of carrier agents on physicochemical properties, sensory evaluation of spray-dried mandarin (Citrus unshiu) beverage powder. Appl. Biol. Chem. 2017, 60, 33–40. [Google Scholar] [CrossRef]

- Ribeiro, C.M.C.M.; Magliano, L.C.d.S.A.; Costa, M.M.A.d.; Bezerra, T.K.A.; Silva, F.L.H.d.; Maciel, M.I.S. Optimization of the spray drying process conditions for acerola and seriguela juice mix. Food Sci. Technol. 2019, 39, 48–55. [Google Scholar] [CrossRef]

- Both, E.; Boom, R.; Schutyser, M. Particle morphology and powder properties during spray drying of maltodextrin and whey protein mixtures. Powder Technol. 2020, 363, 519–524. [Google Scholar] [CrossRef]

- Sinija, V.R.; Mishra, H.N. Moisture sorption isotherms and heat of sorption of instant (soluble) green tea powder and green tea granules. J. Food Eng. 2008, 86, 494–500. [Google Scholar] [CrossRef]

- Solval, K.M.; Sundararajan, S.; Alfaro, L.; Sathivel, S. Development of cantaloupe (Cucumis melo) juice powders using spray drying technology. LWT 2012, 46, 287–293. [Google Scholar] [CrossRef]

- Quek, S.Y.; Chok, N.K.; Swedlund, P. The physicochemical properties of spray-dried watermelon powders. Chem. Eng. Process. Process Intensif. 2007, 46, 386–392. [Google Scholar] [CrossRef]

- Han, N.S.; Ahmad, W.; Ishak, W.R.W. Quality characteristics of Pleurotus sajor-caju powder: Study on nutritional compositions, functional properties and storage stability. Sains Malays. 2016, 45, 1617–1623. [Google Scholar]

| Product | Condition | Y (%) | BD (g mL−1) | MC (% w/w) | aw | TSS (°Bx) | Color | |||

|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | MD (%) | L* | a* | b* | ||||||

| NPVp-1 | 150 | 15 | 53.37 ± 0.14 | 0.46 ± 0.00 | 2.56 ± 0.06 | 0.31 ± 0.01 | 19.50 ± 0.71 | 91.75 ± 0.06 | 0.18 ± 0.01 | 7.91 ± 0.01 |

| NPVp-2 | 150 | 20 | 56.31 ± 0.44 | 0.47 ± 0.00 | 3.05 ± 0.07 | 0.36 ± 0.01 | 24.10 ± 0.14 | 91.95 ± 0.06 | −0.27 ± 0.00 | 5.53 ± 0.04 |

| NPVp-3 | 170 | 15 | 53.62 ± 0.11 | 0.47 ± 0.00 | 2.08 ± 0.04 | 0.23 ± 0.00 | 20.00 ± 0.00 | 93.57 ± 0.62 | 0.38 ± 0.01 | 10.12 ± 0.12 |

| NPVp-4 | 170 | 20 | 58.29 ± 0.05 | 0.48 ± 0.01 | 3.03 ± 0.05 | 0.24 ± 0.00 | 23.70 ± 0.42 | 92.80 ± 0.13 | 0.49 ± 0.01 | 10.28 ± 0.02 |

| NPVp-5 | 190 | 15 | 47.04 ± 0.44 | 0.43 ± 0.00 | 2.63 ± 0.04 | 0.23 ± 0.00 | 20.00 ± 0.00 | 91.53 ± 0.04 | −0.09 ± 0.00 | 6.29 ± 0.03 |

| NPVp-6 | 190 | 20 | 50.72 ± 0.02 | 0.46 ± 0.00 | 3.02 ± 0.03 | 0.24 ± 0.01 | 24.00 ± 0.00 | 92.14 ± 0.06 | 0.54 ± 0.00 | 6.21 ± 0.01 |

| Source of Variation | Y | BD | MC | aw | TSS | Color | ||

|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | ||||||

| Model | 31.94 ** | 0.0005 ** | 0.2966 ** | 0.0054 ** | 10.19 ** | 1.16 ** | 0.2132 ** | 8.58 ** |

| Inlet temperature (X1) | 57.9 ** | 0.0008 ** | 0.094 ** | 0.0122 ** | 0.0433 NS | 35.19 ** | 0.2295 ** | 18.59 ** |

| Maltodextrin concentration (X2) | 42.41 ** | 0.0007 ** | 1.12 ** | 0.0015 ** | 50.43 ** | 0.0099 NS | 0.029 ** | 1.76 ** |

| X1 × X2 | 0.7493 ** | 0.0002 ** | 0.0892 ** | 0.0006 ** | 0.21 NS | 7.41 ** | 0.289 ** | 1.97 ** |

| R2 | 0.9974 | 0.9814 | 0.9903 | 0.9940 | 0.9864 | 0.9342 | 0.9999 | 0.9996 |

| Test Item | Unit/100 g a,b | NPVp-3 Powder | Commercial Vinegar Powder d |

|---|---|---|---|

| Energy | kcal | 366.16 ± 3.92 | 380.9 |

| Protein | g | 1.33 ± 0.01 | 0.05 |

| Crude fat | g | 0.96 ± 0.013 | 0.1 |

| Cholesterol | mg | Not detected | 0 |

| Carbohydrate | g | 88.05 ± 1.88 | 96.2 |

| Total sugars | g | 14.16 ± 0.85 | 3.5 |

| Total dietary fiber | g | 0 ± 0.00 | 0.22 |

| Ash | g | 3.03 ± 0.01 | - |

| Minerals | |||

| Calcium (Ca) | mg | 30.92 ± 0.71 | 25 |

| Iron (Fe) | mg | 0.54 ± 0.00 | 0.41 |

| Sodium (Na) | mg | 268.56 ± 0.12 | 79 |

| Potassium (K) | mg | 883.90 ± 0.35 | - |

| Phosphorous (P) | mg | 35.90 ± 0.03 | - |

| Magnesium (Mg) | mg | 21.50 ± 0.13 | - |

| Zinc (Zn) | mg | 0.26 ± 0.00 | - |

| Vitamins | |||

| Vitamin A | μg | 0.00 ± 0.00 | 0.54 |

| Vitamin B1 | mg | Not detected | - |

| Vitamin B2 | mg | Not detected | - |

| Vitamin C | mg | 12.68 ± 0.10 | 0.27 |

| Other constituents | |||

| Total phenolics content | μg GAE c g−1 | 1049.76 ± 20.03 | - |

| Acetic acid | % w/v | 5.13 | 12 |

| Property | Storage Duration (Days) A | |||||

|---|---|---|---|---|---|---|

| 0 | 30 | 60 | 90 | 120 | 180 | |

| Appearance |  |  |  |  |  |  |

| pH | 3.20 ± 0.01 ab | 3.18 ± 0.01 a | 3.18 ± 0.01 a | 3.21 ± 0.01 b | 3.21 ± 0.00 b | 3.21 ± 0.00 b |

| Moisture (% w/w) | 2.61 ± 0.01 a | 2.62 ± 0.02 a | 2.61 ± 0.01 a | 2.61 ± 0.01 a | 2.62 ± 0.02 a | 2.62 ± 0.01 a |

| Water activity | 0.23 ± 0.00 a | 0.23 ± 0.00 a | 0.23 ± 0.00 a | 0.23 ± 0.00 a | 0.24 ± 0.00 a | 0.24 ± 0.00 a |

| Color | ||||||

| L* | 94.13 ± 0.18 a | 95.07 ± 0.13 bc | 95.04 ± 0.05 bc | 94.94 ± 0.07 bc | 94.87 ± 0.04 bc | 94.64 ± 0.07 b |

| a* | 0.37 ± 0.03 a | 0.36 ± 0.01 a | 0.42 ± 0.06 ab | 0.49 ± 0.04 ab | 0.54 ± 0.03 bc | 0.58 ± 0.02 c |

| b* | 10.03 ± 0.04 a | 10.26 ± 0.20 ab | 10.44 ± 0.15 abc | 10.53 ± 0.02 bc | 10.67 ± 0.01 bc | 10.78 ± 0.11 c |

| Molds (CFU g−1) | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a |

| Yeasts (CFU g−1) | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a | 00.00 ± 0.00 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palachum, W.; Klangbud, W.K.; Chisti, Y. Spray-Dried Nipa Palm Vinegar Powder: Production and Evaluation of Physicochemical, Nutritional, Sensory, and Storage Aspects. Fermentation 2022, 8, 272. https://doi.org/10.3390/fermentation8060272

Palachum W, Klangbud WK, Chisti Y. Spray-Dried Nipa Palm Vinegar Powder: Production and Evaluation of Physicochemical, Nutritional, Sensory, and Storage Aspects. Fermentation. 2022; 8(6):272. https://doi.org/10.3390/fermentation8060272

Chicago/Turabian StylePalachum, Wilawan, Wiyada Kwanhian Klangbud, and Yusuf Chisti. 2022. "Spray-Dried Nipa Palm Vinegar Powder: Production and Evaluation of Physicochemical, Nutritional, Sensory, and Storage Aspects" Fermentation 8, no. 6: 272. https://doi.org/10.3390/fermentation8060272

APA StylePalachum, W., Klangbud, W. K., & Chisti, Y. (2022). Spray-Dried Nipa Palm Vinegar Powder: Production and Evaluation of Physicochemical, Nutritional, Sensory, and Storage Aspects. Fermentation, 8(6), 272. https://doi.org/10.3390/fermentation8060272