Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications

Abstract

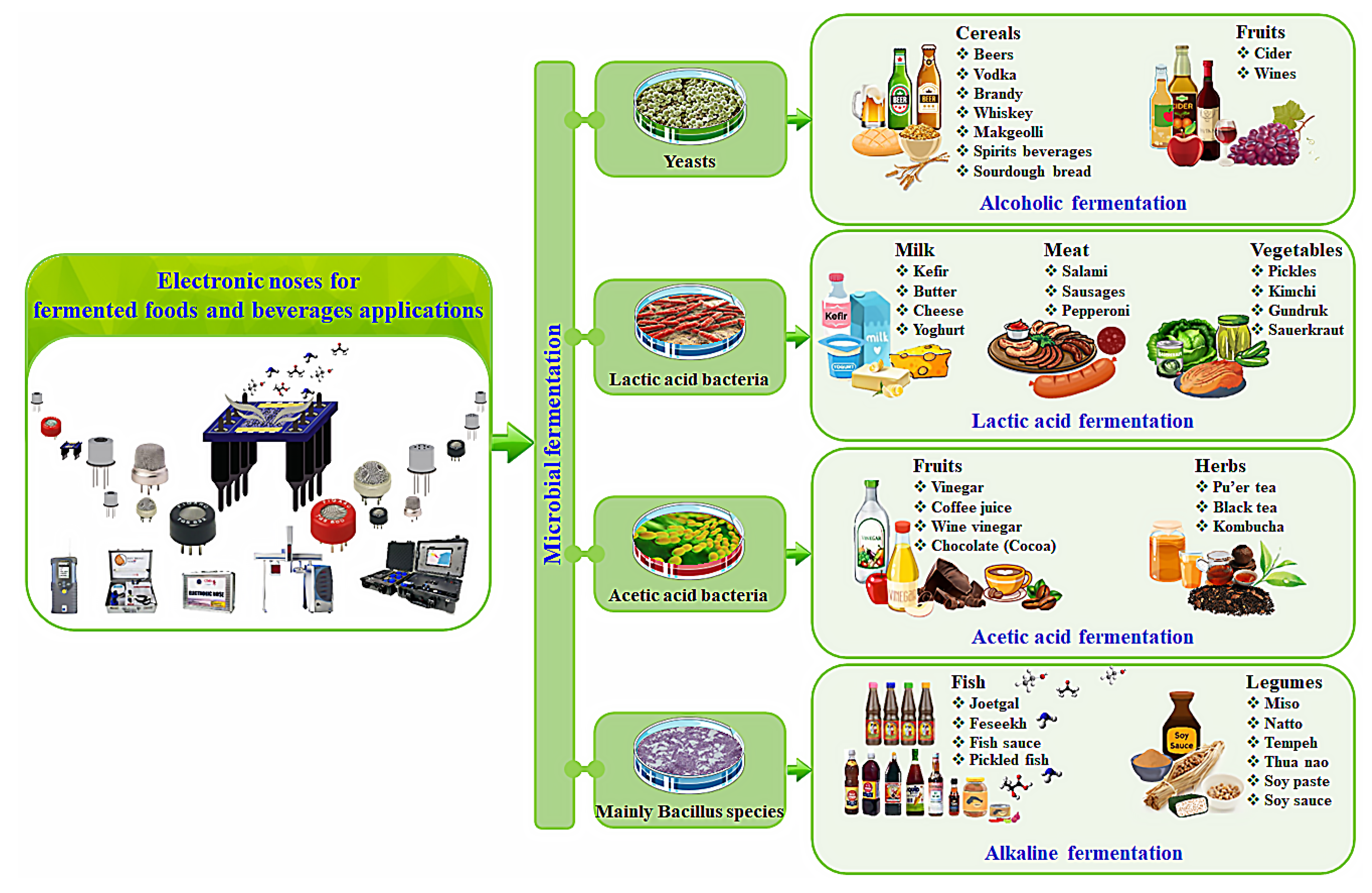

:1. Introduction

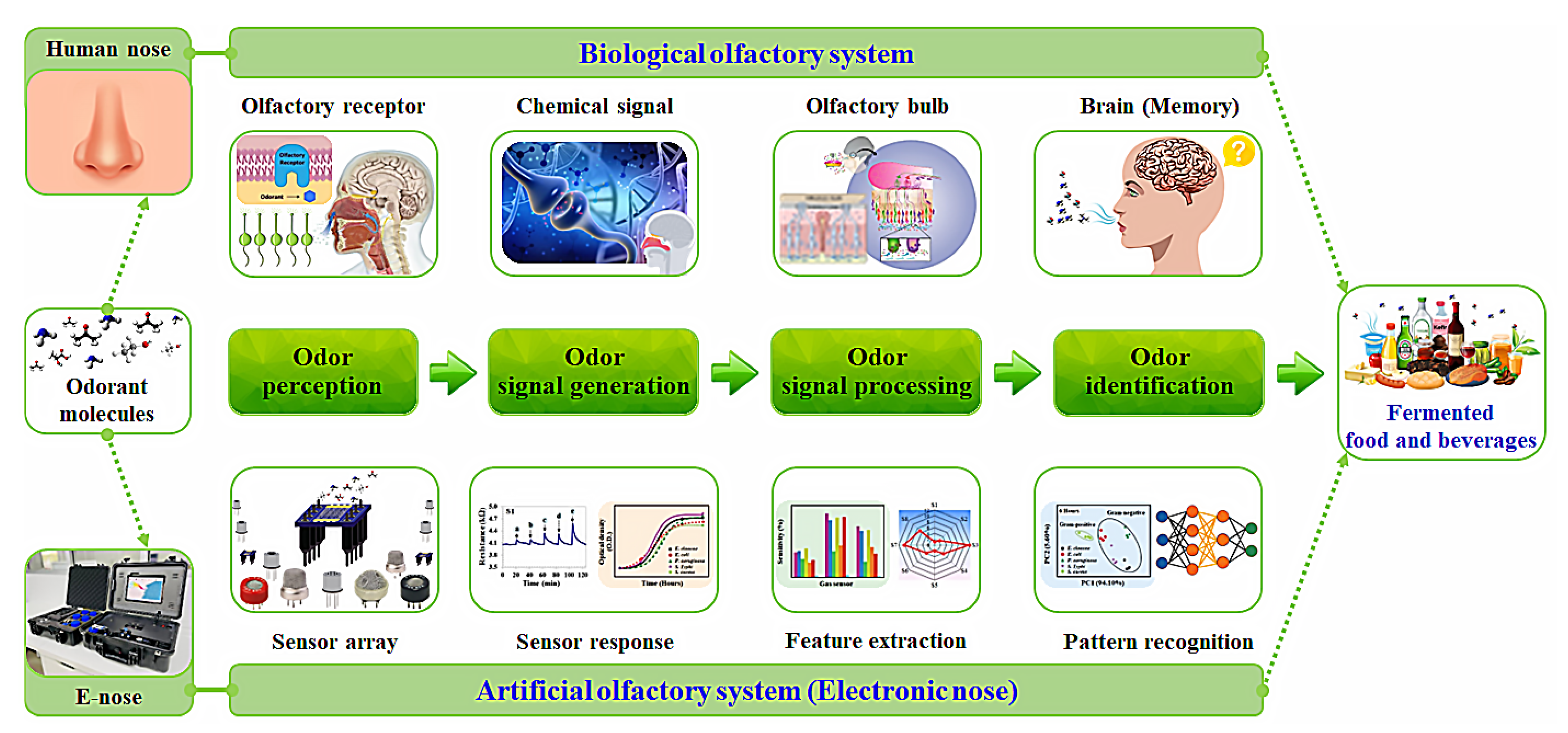

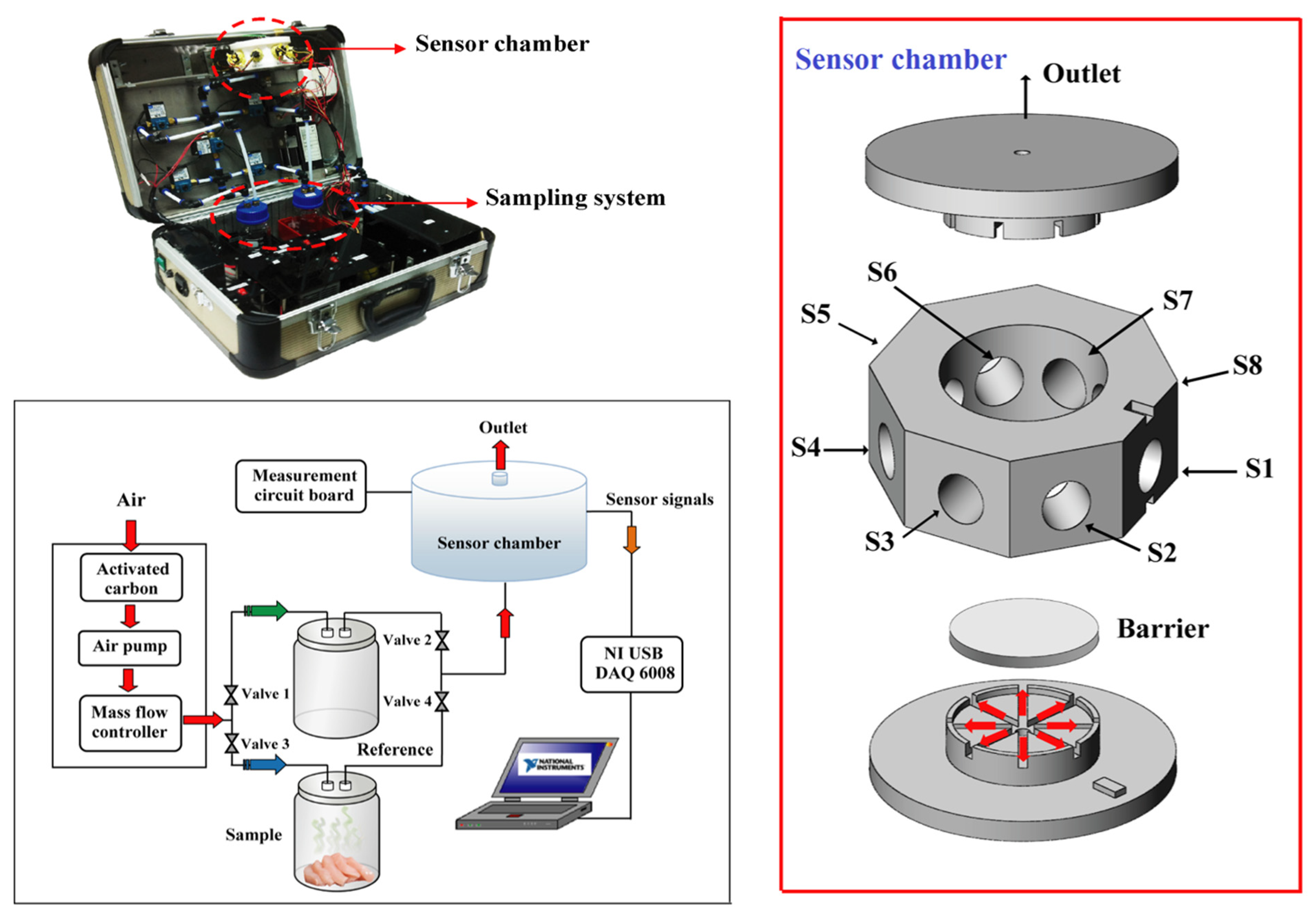

2. History and Basic Principle of E-Nose

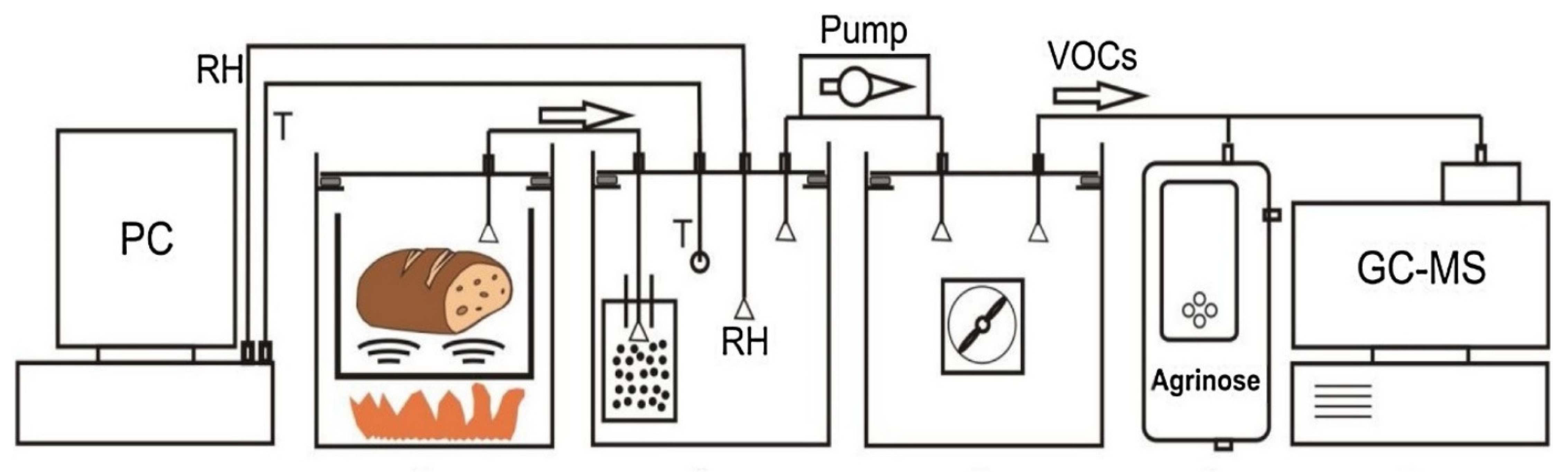

3. E-Nose for Alcoholic Fermentation

4. E-Nose for Lactic Acid Fermentation

5. E-Nose for Acetic Acid Fermentation

6. E-Nose for Alkaline Fermentation

7. Summary and Future Trends

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moretti, A.F.; Moure, M.C.; Quiñoy, F.; Esposito, F.; Simonelli, N.; Medrano, M.; León-Peláez, A. Water kefir, a fermented beverage containing probiotic microorganisms: From ancient and artisanal manufacture to industrialized and regulated commercialization. Future Foods 2022, 5, 100123. [Google Scholar] [CrossRef]

- Kesika, P.; Thangaleela, S.; Sivamaruthi, B.S.; Bharathi, M.; Chaiyasut, C. Fermented foods and their role in respiratory health: A mini-review. Fermentation 2022, 8, 162. [Google Scholar] [CrossRef]

- Song, Y.; Yu, J.; Song, J.; Wang, S.; Cao, T.; Liu, Z.; Gao, X.; Wei, Y. The antihypertensive effect and mechanisms of bioactive peptides from Ruditapes philippinarum fermented with Bacillus natto in spontaneously hypertensive rats. J. Funct. Foods 2021, 79, 104411. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Deng, J.; Wang, Y.; Hu, Q.; Li, C.; Liu, S. Dynamic profile of the microbiota during coconut water pre-fermentation for nata de coco production. LWT-Food Sci. Technol. 2017, 81, 87–93. [Google Scholar] [CrossRef]

- Tachibana, S.; Yasuda, M. Purification and characterization of heterogeneous glucoamylases from Monascus purpureus. Biosci. Biotechnol. Biochem. 2007, 71, 2573–2576. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, T.; Salauddin, M.; Kirtonia, K.; Pati, S.; Rebezov, M.; Khayrullin, M.; Panasenko, S.; Tretyak, L.; Temerbayeva, M.; Kapustina, N.; et al. A review on the commonly used methods for analysis of physical properties of food materials. Appl. Sci. 2022, 12, 2004. [Google Scholar] [CrossRef]

- Md Noh, M.F.; Gunasegavan, R.D.N.; Khalid, N.M.; Balasubramaniam, V.; Mustar, S.; Rashed, A.A. Recent techniques in nutrient analysis for food composition database. Molecules 2020, 25, 4567. [Google Scholar] [CrossRef]

- Bukhari, M.A.; Banasser, T.M.; El-Bali, M.; Bulkhi, R.A.; Qamash, R.A.; Trenganno, A.; Khayyat, M.; Kurdi, M.A.; Majrashi, A.A.; Bahewareth, F. Assessment of microbiological quality of food preparation process in some restaurants of Makkah city. Saudi J. Biol. Sci. 2021, 28, 5993–5997. [Google Scholar] [CrossRef]

- Mihafu, F.D.; Issa, J.Y.; Kamiyango, M.W. Implication of sensory evaluation and quality assessment in food product development: A review. Curr. Res. Nutr. Food Sci. 2020, 8, 690–702. [Google Scholar] [CrossRef]

- Drake, M.A. Encyclopedia of Dairy Sciences, 3rd ed.; Elsevier Science: Cambridge, MA, USA, 2022; pp. 572–576. [Google Scholar]

- Putri, S.; Malikul Ikram, M.M.; Sato, A.; Dahlan, H.D.; Rahmawati, D.; Ohto, Y.; Fukusaki, E. Application of gas chromatography-mass spectrometry-based metabolomics in food science and technology. J. Biosci. Bioeng. 2022, 133, 425–435. [Google Scholar] [CrossRef]

- Adebo, O.A.; Oyeyinka, S.A.; Adebiyi, J.A.; Feng, X.; Wilkin, J.D.; Kewuyemi, Y.O.; Abrahams, A.M.; Tugizimana, F. Application of gas chromatography–mass spectrometry (GC-MS)-based metabolomics for the study of fermented cereal and legume foods: A review. Food Sci. Technol. 2021, 56, 1514–1534. [Google Scholar] [CrossRef]

- Roy, M.; Yadav, B.K. Electronic nose for detection of food adulteration: A review. J. Food Sci. Technol. 2022, 59, 84–858. [Google Scholar] [CrossRef] [PubMed]

- Timsorn, K.; Wongchoosuk, C. Inkjet printing of room-temperature gas sensors for identification of formalin contamination in squids. J. Mater. Sci. Mater. Electron. 2019, 30, 4782–4791. [Google Scholar] [CrossRef]

- Timsorn, K.; Lorjaroenphon, Y.; Wongchoosuk, C. Identification of adulteration in uncooked Jasmine rice by a portable low-cost artificial olfactory system. Measurement 2017, 108, 67–76. [Google Scholar] [CrossRef]

- Timsorn, K.; Thoopboochagorn, T.; Lertwattanasakul, N.; Wongchoosuk, C. Evaluation of bacterial population on chicken meats using a briefcase electronic nose. Biosyst. Eng. 2016, 151, 116–125. [Google Scholar] [CrossRef]

- Wongchoosuk, C.; Wisitsoraat, A.; Tuantranont, A.; Kerdcharoen, T. Portable electronic nose based on carbon nanotube-SnO2 gas sensors and its application for detection of methanol contamination in whiskeys. Sens. Actuators B Chem. 2010, 147, 392–399. [Google Scholar] [CrossRef]

- Hernández-Mesa, M.; Ropartz, D.; García-Campaña, A.M.; Rogniaux, H.; Dervilly-Pinel, G.; Bizec, B.L. Ion mobility spectrometry in food analysis: Principles, current applications and future trends. Molecules 2019, 24, 2706. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Chen, H.; Sun, B. Recent progress in food flavor analysis using gas chromatography–ion mobility spectrometry (GC–IMS). Food Chem. 2020, 315, 126158. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, T.; Yang, D.; Xie, J. Application of gas chromatography-ion mobility spectrometry in the analysis of food volatile components. Acta Chromatogr. 2022, 46, e13840. [Google Scholar] [CrossRef]

- Buratti, S.; Benedetti, S. Chapter 28—Alcoholic fermentation using electronic nose and electronic tongue. In Electronic Noses and Tongues in Food Science, 1st ed.; Rodríguez Méndez, M.L., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 291–299. [Google Scholar]

- Malakar, S.; Paul, S.K.; Jolvis Pou, K.R. The Science of Beverages. In Biotechnological Progress and Beverage Consumption, 1st ed.; Grumezescu, A.M., Holban, A.M., Eds.; Elsevier: Cambridge, MA, USA, 2020; Volume 19, pp. 1–37. [Google Scholar]

- Malo, P.; Urquhart, E.A. Fermented foods: Use of starter cultures. In Encyclopedia of Food and Health, 2nd ed.; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 681–685. [Google Scholar]

- Taylor, J.R.N.; Emmambux, M.N. 13-Products containing other speciality grains: Sorghum, the millets and pseudocereals. In Technology of Functional Cereal Products, 1st ed.; Hamaker, B.R., Ed.; Woodhead Publishing: Shaston, UK, 2008; pp. 281–335. [Google Scholar]

- Gomes, R.J.; Borges, M.D.F.; Rosa, M.D.F.; Castro-Gómez, R.J.H.; Spinosa, W.A. Acetic acid bacteria in the food industry: Systematics, characteristics and applications. Food Technol. Biotechnol. 2018, 56, 139–151. [Google Scholar] [CrossRef]

- Roos, J.D.; Vuyst, L.D. Acetic acid bacteria in fermented foods and beverages. Curr. Opin. Biotechnol. 2018, 49, 115–119. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Fung, D.Y.C. Alkaline-fermented foods: A review with emphasis on pidan fermentation. Crit. Rev. Microbiol. 1996, 22, 101–138. [Google Scholar] [CrossRef] [PubMed]

- Parkouda, C.; Nielsen, D.S.; Azokpota, P.; Ouoba, L.I.I.; Amoa-Awua, W.K.; Thorsen, L.; Hounhouigan, J.D.; Jensen, J.S.; Tano-Debrah, K.; Diawara, B.; et al. The microbiology of alkaline-fermentation of indigenous seeds used as food condiments in Africa and Asia. Crit. Rev. Microbiol. 2009, 35, 139–156. [Google Scholar] [CrossRef] [PubMed]

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355. [Google Scholar] [CrossRef]

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sens. Actuators B Chem. 1994, 18, 211–220. [Google Scholar] [CrossRef]

- Wilson, A.D.; Baietto, M. Applications and advances in electronic-nose technologies. Sensors 2009, 9, 5099–5148. [Google Scholar] [CrossRef]

- Buck, L.; Axel, R. A novel multigene family may encode odorant receptors: A molecular basis for odor recognition. Cell 1991, 65, 175–187. [Google Scholar] [CrossRef]

- Dunkel, A.; Steinhaus, M.; Kotthoff, M.; Nowak, B.; Krautwurst, D.; Schieberle, P.; Hofmann, T. Nature’s chemical signatures in human olfaction: A foodborne perspective for future biotechnology. Angew. Chem. Int. Ed. 2014, 53, 7124–7143. [Google Scholar] [CrossRef]

- Bushdid, C.; Magnasco, M.O.; Vosshall, L.B.; Keller, A. Humans can discriminate more than 1 trillion olfactory stimuli. Science 2014, 343, 1370–1372. [Google Scholar] [CrossRef] [Green Version]

- Calvi, E.; Quassolo, U.; Massaia, M.; Scandurra, A.; D’Aniello, B.; D’Amelio, P. The scent of emotions: A systematic review of human intra- and interspecific chemical communication of emotions. Brain Behav. 2020, 10, e01585. [Google Scholar] [CrossRef]

- Vieillard, S.; Ronat, L.; Baccarani, A.; Schaal, B.; Baudouin, J.Y.; Brochard, R. Age differences in olfactory affective responses: Evidence for a positivity effect and an emotional dedifferentiation. Aging Neuropsychol. Cogn. 2021, 28, 570–583. [Google Scholar] [CrossRef] [PubMed]

- Freemantle, A.W.J.; Stafford, L.D.; Wagstaff, C.R.D.; Akehurst, L. The relationship between olfactory function and emotional contagion. Chem. Percept. 2021, 1–11. [Google Scholar] [CrossRef]

- Seesaard, T.; Lorwongtragool, P.; Kerdcharoen, T. Development of fabric-based chemical gas sensors for use as wearable electronic noses. Sensors 2015, 15, 1885–1902. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seekaew, Y.; Lokavee, S.; Phokharatkul, D.; Wisitsoraat, A.; Kerdcharoen, T.; Wongchoosuk, C. Low-cost and flexible printed graphene–PEDOT:PSS gas sensor for ammonia detection. Org. Electron. 2014, 15, 2971–2981. [Google Scholar] [CrossRef]

- Kondee, S.; Arayawut, O.; Pon-On, W.; Wongchoosuk, C. Nitrogen-doped carbon oxide quantum dots for flexible humidity sensor: Experimental and SCC-DFTB study. Vacuum 2022, 195, 110648. [Google Scholar] [CrossRef]

- Seekaew, Y.; Arayawut, O.; Timsorn, K.; Wongchoosuk, C. Chapter nine—Synthesis, characterization, and applications of graphene and derivatives. In Carbon-Based Nanofillers and Their Rubber Nanocomposites, 1st ed.; Yaragalla, S., Mishra, R., Thomas, S., Kalarikkal, N., Maria, H.J., Eds.; Elsevier: Cambridge, MA, USA, 2019; pp. 259–283. [Google Scholar]

- Kerdcharoen, T.; Wongchoosuk, C. 11-Carbon nanotube and metal oxide hybrid materials for gas sensing. In Semiconductor Gas Sensors, 1st ed.; Jaaniso, R., Tan, O.K., Eds.; Woodhead Publishing: Shaston, UK, 2013; pp. 386–407. [Google Scholar]

- Traiwatcharanon, P.; Timsorn, K.; Wongchoosuk, C. Flexible room-temperature resistive humidity sensor based on silver nanoparticles. Mater. Res. Express 2017, 4, 085038. [Google Scholar] [CrossRef]

- Arayawut, O.; Kerdcharoen, T.; Wongchoosuk, C. Structures, electronic properties, and gas permeability of 3D pillared silicon carbide nanostructures. Nanomaterials 2022, 12, 1869. [Google Scholar] [CrossRef]

- Traiwatcharanona, P.; Siriwatcharapiboonb, W.; Jongprateep, O.; Wongchoosuk, C. Electrochemical paraquat sensor based on lead oxide nanoparticles. RSC Adv. 2022, 12, 16079–16092. [Google Scholar] [CrossRef]

- Chaloeipote, G.; Prathumwan, R.; Subannajui, K.; Wisitsoraat, A.; Wongchoosuk, C. 3D printed CuO semiconducting gas sensor for ammonia detection at room temperature. Mater. Sci. Semicond. Processing 2021, 123, 105546. [Google Scholar] [CrossRef]

- Chaloeipote, G.; Samarnwong, J.; Traiwatcharanon, P.; Kerdcharoen, T.; Wongchoosuk, C. High-performance resistive humidity sensor based on Ag nanoparticles decorated with graphene quantum dots. R. Soc. Open Sci. 2021, 8, 210407. [Google Scholar] [CrossRef]

- Seekaew, Y.; Pon-On, W.; Wongchoosuk, C. Ultrahigh selective room-temperature ammonia gas sensor based on tin–titanium dioxide/reduced graphene/carbon nanotube nanocomposites by the solvothermal method. ACS Omega 2019, 4, 16916–16924. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seesaard, T.; Thippakorn, C.; Kerdcharoen, T.; Kladsomboon, S. A hybrid electronic nose system for discrimination of pathogenic bacterial volatile compounds. Anal. Methods 2020, 12, 5671–5683. [Google Scholar] [CrossRef] [PubMed]

- Kladsomboon, S.; Thippakorn, C.; Seesaard, T. Development of organic-inorganic hybrid optical gas sensors for the non-invasive monitoring of pathogenic bacteria. Sensors 2018, 18, 3189. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grane, A.; Jach, A. Applications of principal component analysis (PCA) in food science and technology. In Mathematical and Statistical Methods in Food Science and Technology, 1st ed.; Granato, D., Ares, G., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 55–85. [Google Scholar]

- Ferraz da Silva Torres, E.A.; Garbelotti, M.L.; Moita Neto, J.M. The application of hierarchical clusters analysis to the study of the composition of foods. Food Chem. 2006, 99, 622–629. [Google Scholar] [CrossRef]

- Thanh-Blicharz, J.L.; Lewandowicz, J. Functionality of native starches in food systems: Cluster analysis grouping of rheological properties in different product matrices. Foods 2020, 9, 1073. [Google Scholar] [CrossRef]

- Kuti, T.; Hegyi, A.; Kemény, S. Analysis of sensory data of different food products by ANOVA. Chemom. Intell. Lab. Syst. 2004, 72, 253–257. [Google Scholar] [CrossRef]

- Kiselev, I.; Sysoev, V.; Kaikov, I.; Koronczi, I.; Adil Akai Tegin, R.; Smanalieva, J.; Sommer, M.; Ilicali, C.; Hauptmannl, M. On the temporal stability of analyte recognition with an e-nose based on a metal oxide sensor array in practical applications. Sensors 2018, 18, 550. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.; Li, Y.; Zhan, P.; Liu, P.; Tian, H.; Fan, J. Correlation of volatile compounds and sensory attributes of Chinese traditional sweet fermented flour pastes using hierarchical cluster analysis and partial least squares-discriminant analysis. J. Chem. 2017, 2017, 3213492. [Google Scholar] [CrossRef]

- Mazalan, N.M.; Idrus, Z.; Abdullah, N.A.S.; Ibrahim, Z. An overview of visualization techniques: A survey of food-related research. In Soft Computing in Data Science, 1st ed.; Berry, M., Yap, B., Mohamed, A., Köppen, M., Eds.; Springer: Singapore, 2019; Volume 1100, pp. 91–104. [Google Scholar]

- Buvé, C.; Saeys, W.; Rasmussen, M.A.; Neckebroeck, B.; Hendrickx, M.; Grauwet, T.; Loey, A.V. Application of multivariate data analysis for food quality investigations: An example-based review. Food Res. Int. 2022, 151, 110878. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Fuentes, S. Digital detection of olive oil rancidity levels and aroma profiles using near-infrared spectroscopy, a low-cost electronic nose and machine learning modelling. Chemosensors 2022, 10, 159. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Fuentes, S.; Hernandez-Brenes, C. Smart detection of faults in beers using near-infrared spectroscopy, a low-cost electronic nose and artificial intelligence. Fermentation 2021, 7, 117. [Google Scholar] [CrossRef]

- Summerson, V.; Gonzalez Viejo, C.; Torrico, D.D.; Pang, A.; Fuentes, S. Digital smoke taint detection in pinot grigio wines using an e-nose and machine learning algorithms following treatment with activated carbon and a cleaving enzyme. Fermentation 2021, 7, 119. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Fuentes, S. Low-cost methods to assess beer quality using artificial intelligence involving robotics, an electronic nose, and machine learning. Fermentation 2020, 6, 104. [Google Scholar] [CrossRef]

- Al-Marshadi, A.H.; Aslam, M. Statistical analysis for food quality in the presence of vague information. J. Food Qual. 2021, 2021, 7373620. [Google Scholar] [CrossRef]

- Wilson, A.D. Diverse applications of electronic-nose technologies in agriculture and forestry. Sensors 2013, 13, 2295–2348. [Google Scholar] [CrossRef] [Green Version]

- Seesaard, T.; Goel, N.; Kumar, M.; Wongchoosuk, C. Advances in gas sensors and electronic nose technologies for agricultural cycle applications. Comput. Electron. Agric. 2022, 193, 106673. [Google Scholar] [CrossRef]

- Jia, W.; Liang, G.; Jiang, Z.; Wang, J. Advances in electronic nose development for application to agricultural products. Food Anal. Methods 2019, 12, 2226–2240. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bandyopadhyay, R.; Bhattacharyya, N.; Pandey, R.A.; Jana, A. Application of electronic nose for industrial odors and gaseous emissions measurement and monitoring—An overview. Talanta 2015, 144, 329–340. [Google Scholar] [CrossRef]

- Wongchoosuk, C.; Subannajui, K.; Wang, C.; Yang, Y.; Güder, F.; Kerdcharoen, T.; Cimalla, V.; Zacharias, M. Electronic nose for toxic gas detection based on photostimulated core–shell nanowires. RSC Adv. 2014, 4, 35084–35088. [Google Scholar] [CrossRef]

- Wilson, A.D. Review of electronic-nose technologies and algorithms to detect hazardous chemicals in the environment. Procedia Technol. 2012, 1, 453–463. [Google Scholar] [CrossRef] [Green Version]

- Capelli, L.; Sironi, S.; Rosso, R.D. Electronic noses for environmental monitoring applications. Sensors 2014, 14, 19979–20007. [Google Scholar] [CrossRef]

- Young, R.C.; Buttner, W.J.; Linnell, B.R.; Ramesham, R. Electronic nose for space program applications. Sens. Actuators B 2003, 93, 7–16. [Google Scholar] [CrossRef]

- Ryan, M.A.; Manatt, K.S.; Gluck, S.; Shevade, A.V.; Kisor, A.K.; Zhou, H.; Lara, L.M.; Homer, M.L. The JPL electronic nose: Monitoring air in the U.S. Lab on the international space station. In Proceedings of the IEEE Sensors 2010, Waikoloa, HI, USA, 1–4 November 2010; pp. 1242–1247. [Google Scholar]

- Farraia, M.V.; Rufo, J.C.; Paciência, I.; Mendes, F.; Delgado, L.; Moreira, A. The electronic nose technology in clinical diagnosis: A systematic review. Porto Biomed. J. 2019, 4, e42. [Google Scholar] [CrossRef] [PubMed]

- Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses in medical diagnostics. Curr. Med. Chem. 2019, 26, 197–215. [Google Scholar] [CrossRef] [PubMed]

- Siyang, S.; Wongchoosuk, C.; Kerdcharoen, T. Diabetes diagnosis by direct measurement from urine odor using electronic nose. In Proceedings of the 5th 2012 Biomedical Engineering International Conference, Muang, Thailand, 5–7 December 2012; pp. 1–4. [Google Scholar]

- Wu, W.; Liu, T.; Haick, H. Electronic nose sensors in healthcare. In Reference Module in Biomedical Sciences, 1st ed.; Elsevier: Cambridge, MA, USA, 2021. [Google Scholar]

- Wongchoosuk, C.; Lutz, M.; Kerdcharoen, T. Detection and classification of human body odor using an electronic nose. Sensors 2009, 9, 7234–7249. [Google Scholar] [CrossRef] [Green Version]

- Wasilewski, T.; Migon, D.; Gebicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D. Electronic-nose applications in forensic science and for analysis of volatile biomarkers in the human breath. J. Forensic Sci. Criminol. 2014, 1, 1–21. [Google Scholar]

- Nagappan, P.G.; Subramaniam, S.; Wang, D.Y. Olfaction as a soldier– a review of the physiology and its present and future use in the military. Mil. Med. Res. 2017, 4, 9. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.H.; Feng, L.; Kemling, J.W.; Musto, C.J.; Suslick, K.S. An optoelectronic nose for the detection of toxic gases. Nat. Chem. 2009, 1, 562–567. [Google Scholar] [CrossRef] [Green Version]

- Jońca, J.; Pawnuk, M.; Arsen, A.; Sówka, I. Electronic noses and their applications for sensory and analytical measurements in the waste management plants—A review. Sensors 2022, 22, 1510. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Balaguru Rayappan, J.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Mamat, M.; Samad, S.A.; Hannan, M.A. An electronic nose for reliable measurement and correct classification of beverages. Sensors 2011, 11, 6435–6453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghasemi-Varnamkhasti, M.; Mohtasebi, S.S.; Rodriguez-Mendez, M.L.; Lozano, J.; Razavi, S.H.; Ahmadi, H. Potential application of electronic nose technology in brewery. Trends Food Sci. Technol. 2011, 22, 165–174. [Google Scholar] [CrossRef]

- Pinger, M.; Draf, J.; Lakner, T.; Ferdenzi, C.; Rouby, C.; Hummel, T.; Bensafi, M. Perceived utility of electronic noses in patients with loss of smell. Eur. Arch. Oto-Rhino-Laryngol. 2021, 278, 2155–2156. [Google Scholar] [CrossRef]

- Ramírez, H.L.; Soriano, A.; Gómez, S.; Iranzo, J.U.; Briones, A.I. Evaluation of the food sniffer electronic nose for assessing the shelf life of fresh pork meat compared to physicochemical measurements of meat quality. Eur. Food Res. Technol. 2018, 244, 1047–1055. [Google Scholar] [CrossRef]

- Ali, M.M.; Hashim, N.; Aziz, S.A.; Lasekan, O. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10. [Google Scholar]

- Sharmilan, T.; Premarathne, I.; Wanniarachchi, I.; Kumari, S.; Wanniarachchi, D. Application of electronic nose to predict the optimum fermentation time for low-country Sri Lankan tea. J. Food Qual. 2022, 2022, 7703352. [Google Scholar] [CrossRef]

- Sanaeifar, A.; ZakiDizaji, H.; Jafari, A.; Guardia, M.D.L. Early detection of contamination and defect in foodstuffs by electronic nose: A review. Trends Anal. Chem. 2017, 97, 257–271. [Google Scholar] [CrossRef]

- Andre, R.S.; Facure, M.H.M.; Mercante, L.A.; Correa, D.S. Electronic nose based on hybrid free-standing nanofibrous mats for meat spoilage monitoring. Sens. Actuators B Chem. 2022, 353, 131114. [Google Scholar] [CrossRef]

- Feng, H.; Zhang, M.; Liu, P.; Liu, Y.; Zhang, X. Evaluation of IoT-enabled monitoring and electronic nose spoilage detection for salmon freshness during cold storage. Foods 2020, 9, 1579. [Google Scholar] [CrossRef]

- Vajdi, M.; Varidi, M.J.; Varidi, M.; Mohebbi, M. Using electronic nose to recognize fish spoilage with an optimum classifier. J. Food Meas. Charact. 2019, 13, 1205–1217. [Google Scholar] [CrossRef]

- Peris, M.; Escuder-Gilabert, L. Electronic noses and tongues to assess food authenticity and adulteration. Trends Food Sci. Technol. 2016, 58, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Falasconi, M.; Concina, I.; Gobbi, E.; Sberveglieri, V.; Pulvirenti, A.; Sberveglieri, G. Electronic nose for microbiological quality control of food products. Int. J. Electrochem. 2012, 2012, 715763. [Google Scholar] [CrossRef]

- Abdallah, S.A.; Al-Shatti, L.A.; Alhajraf, A.F.; Al-Hammad, N.; Al-Awadi, B. The detection of foodborne bacteria on beef: The application of the electronic nose. SpringerPlus 2013, 2, 687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xing, M.; Sun, K.; Liu, Q.; Pan, L.; Tu, K. Development of novel electronic nose applied for strawberry freshness detection during storage. Int. J. Food Eng. 2018, 14, 20180111. [Google Scholar] [CrossRef]

- Cozzolino, R.; Cefola, M.; Laurino, C.; Pellicano, M.P.; Palumbo, M.; Stocchero, M.; Pace, B. Electronic-nose as non-destructive tool to discriminate “Ferrovia” sweet cherries cold stored in air or packed in high CO2 modified atmospheres. Front. Nutr. 2021, 8, 720092. [Google Scholar] [CrossRef]

- Modesti, M.; Taglieri, I.; Bianchi, A.; Tonacci, A.; Sansone, F.; Bellincontro, A.; Venturi, F.; Sanmartin, C. E-nose and olfactory assessment: Teamwork or a challenge to the last data? The case of virgin olive oil stability and shelf life. Appl. Sci. 2021, 11, 8453. [Google Scholar] [CrossRef]

- Liu, L.; Li, X.; Li, Z.; Shi, Y. Application of electronic nose in detection of fresh vegetables freezing time considering odor identification technology. Chem. Eng. Trans. 2018, 68, 265–270. [Google Scholar]

- Sipos, L.; Kovacs, Z.; Szollosi, D.; Kókai, Z.; Dalmadi, I.; Fekete, A. Comparison of novel sensory panel performance evaluation techniques with e-nose analysis integration. J. Chemom. 2011, 25, 275–286. [Google Scholar] [CrossRef]

- Rizzolo, A.; Bianchi, G.; Vanoli, M.; Lurie, S.; Spinelli, L.; Torricelli, A. Electronic nose to detect volatile compound profile and quality changes in ‘Spring Belle’ peach (Prunus persica L.) during cold storage in relation to fruit optical properties measured by time-resolved reflectance spectroscopy. J. Agric. Food Chem. 2013, 61, 1671–1685. [Google Scholar] [CrossRef]

- Aleixandre, M.; Lozano, J.; Gutierrez, J.; Sayago, I.; Fernandez, M.J.; Horrillo, M.C. Portable e-nose to classify different kinds of wine. Sens. Actuators B 2008, 131, 71–76. [Google Scholar] [CrossRef]

- Men, H.; Shi, Y.; Fu, S.; Jiao, Y.; Qiao, Y.; Liu, J. Discrimination of beer based on e-tongue and e-nose combined with SVM: Comparison of different variable selection methods by PCA, GA-PLS and VIP. Preprints 2017, 2017050054. [Google Scholar]

- Quarto, A.; Soldo, D.; Di Lecce, F.; Giove, A.; Di Lecce, V.; Castronovo, A. Electronic nose for evaluating water use in beer production. In Proceedings of the 2017 ISOCS/IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Montreal, QC, Canada, 28–31 May 2017; pp. 1–3. [Google Scholar]

- Fujioka, K. Comparison of cheese aroma intensity measured using an electronic nose (e-nose) non-destructively with the aroma intensity scores of a sensory evaluation: A pilot study. Sensors 2021, 21, 8368. [Google Scholar] [CrossRef] [PubMed]

- Romano, A.; Cuenca, M.; Makhoul, S.; Biasioli, F.; Martinello, L.; Fugatti, A.; Scampicchio, M. Comparison of e-noses: The case study of honey. Ital. J. Food Sci. 2019, 28, 326–337. [Google Scholar]

- Rodríguez-Méndez, M.L.; De Saja, J.A.; González-Antón, R.; García-Hernández, C.; Medina-Plaza, C.; García-Cabezón, C.; Martín-Pedrosa, F. Electronic noses and tongues in wine industry. Front. Bioeng. Biotechnol. 2016, 4, 81. [Google Scholar] [CrossRef] [Green Version]

- Nimsuk, N. Improvement of accuracy in beer classification using transient features for electronic nose technology. J. Food Meas. Charact. 2018, 13, 656–662. [Google Scholar] [CrossRef]

- Rodríguez, J.; Durán, C.; Reyes, A. Electronic nose for quality control of Colombian coffee through the detection of defects in “Cup Tests”. Sensors 2010, 10, 36–46. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, W.; Wu, M.; Mao, J.; Sha, R. Application of e-nose combined with ANN modelling for qualitative and quantitative analysis of benzoic acid in cola-type beverages. J. Food Meas. Charact. 2021, 15, 5131–5138. [Google Scholar] [CrossRef]

- Gomes, M.T.S.R. Chapter 3—Electronic nose in dairy products. In Electronic Noses and Tongues in Food Science, 1st ed.; Rodríguez Méndez, M.L., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 21–30. [Google Scholar]

- Yakubu, H.G.; Kovacs, Z.; Toth, T.; Bazar, G. Trends in artificial aroma sensing by means of electronic nose technologies to advance dairy production—A review. Crit. Rev. Food Sci. Nutr. 2021, 1–15. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Zhao, J.; Ouyang, Q. Non-destructive evaluation of pork freshness using a portable electronic nose (E-nose) based on a colorimetric sensor array. Anal. Methods 2014, 6, 6271–6277. [Google Scholar] [CrossRef]

- Górska-Horczyczak, E.; Guzek, D.; Molęda, Z.; Wojtasik-Kalinowska, I.; Brodowska, M.; Wierzbicka, A. Applications of electronic noses in meat analysis. Food Sci. Technol. 2016, 36, 389–395. [Google Scholar] [CrossRef] [Green Version]

- Wojnowski, W.; Majchrzak, T.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses: Powerful tools in meat quality assessment. Meat Sci. 2017, 131, 119–131. [Google Scholar] [CrossRef] [PubMed]

- Raudiene, E.; Gailius, D.; Vinauskiene, R.; Eisinaite, V.; Balčiunas, G.; Dobiliene, J.; Tamkute, L. Rapid evaluation of fresh chicken meat quality by electronic nose. Czech J. Food Sci. 2018, 36, 420–426. [Google Scholar]

- Grassi, S.; Benedetti, S.; Opizzio, M.; Nardo, E.D.; Buratti, S. Meat and fish freshness assessment by a portable and simplified electronic nose system (Mastersense). Sensors 2019, 19, 3225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Güney, S.; Atasoy, A. Freshness classification of horse mackerels with e-nose system using hybrid binary decision tree structure. Int. J. Pattern Recognit. Artif. Intell. 2020, 34, 2050003. [Google Scholar] [CrossRef]

- Radi, R.; Wahyudi, E.; Adhityamurti, M.D.; Yuroto Putro, J.P.L.; Barokah, B.; Rohmah, D.N. Freshness assessment of Tilapia fish in traditional market based on an electronic nose. Bull. Electr. Eng. Inform. 2021, 10, 2466–2476. [Google Scholar] [CrossRef]

- Jiang, J.; Li, J.; Zheng, F.; Lin, H.; Hui, G. Rapid freshness analysis of mantis shrimps (Oratosquilla oratoria) by using electronic nose. Food Meas. 2016, 10, 48–55. [Google Scholar] [CrossRef]

- Srinivasan, P.; Robinson, J.; Geevaretnam, J.; Rayappan, J.B.B. Development of electronic nose (Shrimp-Nose) for the determination of perishable quality and shelf-life of cultured Pacific white shrimp (Litopenaeus Vannamei). Sens. Actuators B. Chem. 2020, 317, 128192. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, F.; Liu, S.; Dang, L.; Peng, X.; Yin, X. Chaotic time series prediction of E-nose sensor drift in embedded phase space. Sens. Actuators B Chem. 2013, 182, 71–79. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; He, Z.; Liu, J.; Deng, P.; Zhou, X. Anti-drift in E-nose: A subspace projection approach with drift reduction. Sens. Actuators B Chem. 2017, 253, 407–417. [Google Scholar] [CrossRef]

- Romain, A.C.; Nicolas, J. Long term stability of metal oxide-based gas sensors for e-nose environmental applications: An overview. Sens. Actuators B Chem. 2010, 146, 502–506. [Google Scholar] [CrossRef] [Green Version]

- Walker, G.M.; Stewart, G.G. Saccharomyces cerevisiae in the production of fermented beverages. Beverages 2016, 2, 30. [Google Scholar] [CrossRef]

- Jordan Voss, H.G.; Mendes Júnior, J.J.A.; Farinelli, M.E.; Stevan, S.L., Jr. A prototype to detect the alcohol content of beers based on an electronic nose. Sensors 2019, 19, 2646. [Google Scholar] [CrossRef] [Green Version]

- Berna, A.Z.; Trowell, S.; Cynkar, W.; Cozzolino, D. Comparison of metal oxide-based electronic nose and mass spectrometry-based electronic nose for the prediction of red wine spoilage. J. Agric. Food Chem. 2008, 56, 3238–3244. [Google Scholar] [CrossRef]

- Yan, B.; Sadiq, F.A.; Cai, Y.; Fan, D.; Zhang, H.; Zhao, J.; Chen, W. Identification of key aroma compounds in type I sourdough-based chinese steamed bread: Application of untargeted metabolomics analysis. Int. J. Mol. Sci. 2019, 20, 818. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farahmand, E.; Razavi, S.H.; Mohtasebi, S.S. Investigating effective variables to produce desirable aroma in sourdough using e-nose and sensory panel. J. Food Process Preserv. 2020, 45, e15157. [Google Scholar] [CrossRef]

- Taneyo Saa, D.L.; Nissen, L.; Gianotti, A. Metabolomic approach to study the impact of flour type and fermentation process on volatile profile of bakery products. Food Res. Int. 2019, 119, 510–516. [Google Scholar]

- Botre, B.A.; Gharpure, D. Analysis of volatile bread aroma for evaluation of bread freshness using an electronic nose (E-nose). Mater. Manuf. Processes 2006, 21, 279–283. [Google Scholar] [CrossRef]

- Rusinek, R.; Gancarz, M.; Nawrocka, A. Application of an electronic nose with novel method for generation of smellprints for testing the suitability for consumption of wheat bread during 4-day storage. LWT-Food Sci. Technol. 2020, 117, 108665. [Google Scholar] [CrossRef]

- Prieto, N.; Rodriguez-Méndez, M.L.; Leardi, R.; Oliveri, P.; Hernando-Esquisabel, D.; Iniguez-Crespo, M.; de Saja, J.A. Application of multi-way analysis to UV–visible spectroscopy, gas chromatography and electronic nose data for wine ageing evaluation. Anal. Chim. Acta 2012, 719, 43–51. [Google Scholar] [CrossRef]

- Kang, B.S.; Lee, J.E.; Park, H.J. Qualitative and quantitative prediction of volatile compounds from initial amino acid profiles in Korean rice wine (makgeolli) model. J. Food Sci. 2014, 79, C1106–C1116. [Google Scholar] [CrossRef] [PubMed]

- Wiśniewska, P.; Śliwińska, M.; Namieśnik, J.; Wardencki, W.; Dymerski, T. The verification of the usefulness of electronic nose based on ultra-fast gas chromatography and four different chemometric methods for rapid analysis of spirit beverages. J. Anal. Methods Chem. 2016, 2016, 8763436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gancarz, M.; Malaga-Toboła, U.; Oniszczuk, A.; Tabor, S.; Oniszczuk, T.; Gawrysiak-Witulska, M.; Rusinek, R. Detection and measurement of aroma compounds with the electronic nose and a novel method for MOS sensor signal analysis during the wheat bread making process. Food Bioprod. Processing 2021, 127, 90–98. [Google Scholar] [CrossRef]

- Wiśniewska, P.; Śliwińska, M.; Dymerski, T.; Wardencki, W.; Namieśnik, J. Comparison of an electronic nose based on ultrafast gas chromatography, comprehensive two-dimensional gas chromatography, and sensory evaluation for an analysis of type of whisky. J. Chem. 2017, 2017, 2710104. [Google Scholar] [CrossRef]

- Phetchakul, T.; Sutthinet, C. Monitoring of draft beer fermentation process by electronic nose. Adv. Mater. Res. 2014, 911, 297–301. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Fuentes, S.; Godbole, A.; Widdicombe, B.; Unnithan, R.R. Development of a low-cost e-nose to assess aroma profiles: An artificial intelligence application to assess beer quality. Sens. Actuators B Chem. 2020, 308, 127688. [Google Scholar] [CrossRef]

- Blanco-Rodríguez, A.; Campo, F.; Morales, O.M.; Valiente, R.; Lambert, B.; Becherán, L.; Garcia-Ramirez, A.; Lisboa, H.D.M.; Durán, A. Development of an electronic nose to identify and classify odours from spirits beverages. Chem. Eng. Trans. 2016, 54, 337–342. [Google Scholar]

- Summerson, V.; Gonzalez Viejo, C.; Pang, A.; Torrico, D.D.; Fuentes, S. Assessment of volatile aromatic compounds in smoke tainted cabernet sauvignon wines using a low-cost e-nose and machine learning modelling. Molecules 2021, 26, 5108. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Viejo, C.; Fuentes, S. Digital assessment and classification of wine faults using a low-cost electronic nose, near-infrared spectroscopy and machine learning modelling. Sensors 2022, 22, 2303. [Google Scholar] [CrossRef]

- Rombouts, J.L.; Kranendonk, E.M.M.; Regueira, A.; Weissbrodt, D.G.; Kleerebezem, R.; Maria van Loosdrecht, M.C. Selecting for lactic acid producing and utilising bacteria in anaerobic enrichment cultures. Biotechnol Bioeng. 2020, 117, 1281–1293. [Google Scholar] [CrossRef]

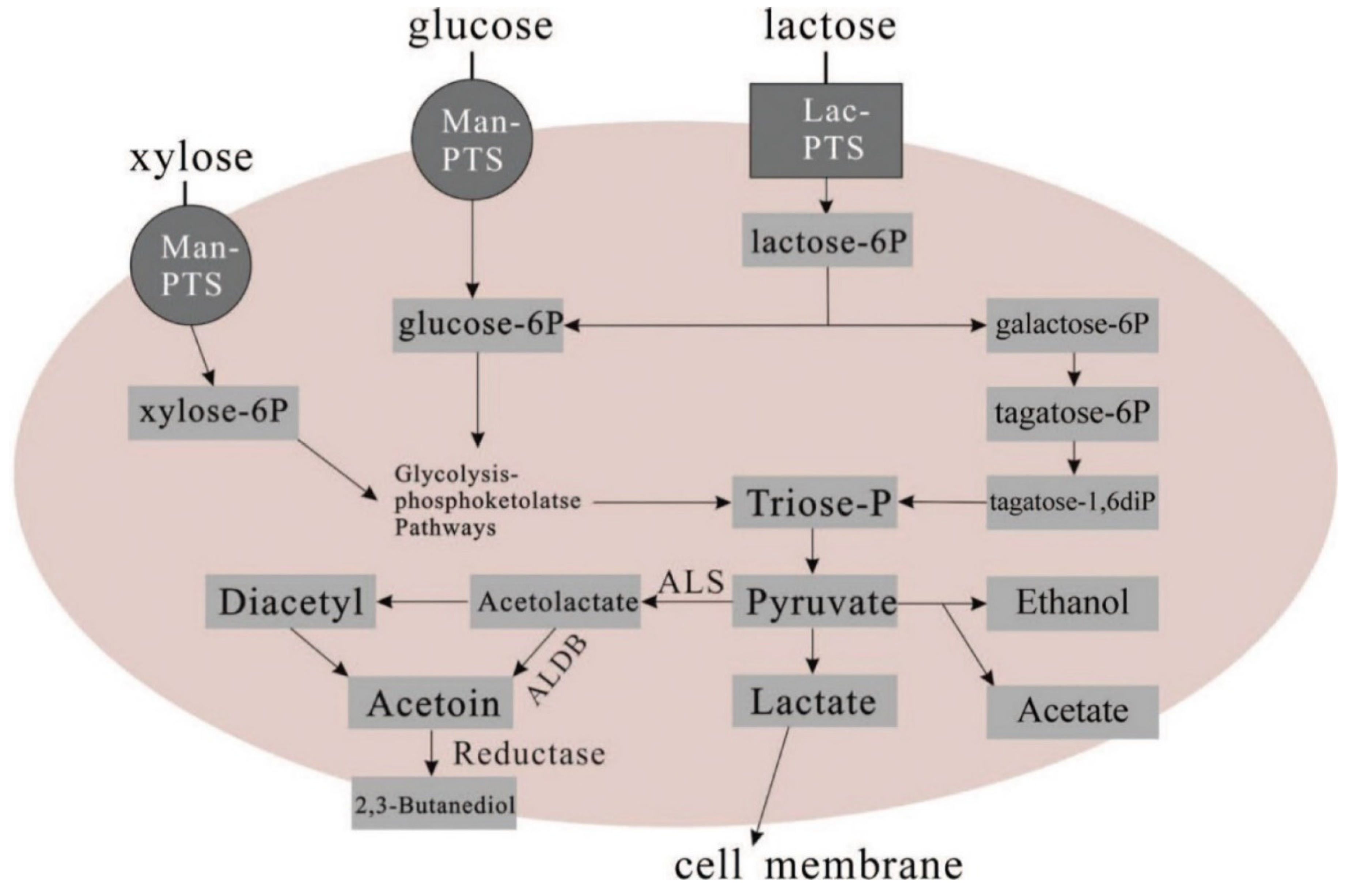

- Pan, D.D.; Wu, Z.; Peng, T.; Zeng, X.Q.; Li, H. Volatile organic compounds profile during milk fermentation by Lactobacillus pentosus and correlations between volatiles flavor and carbohydrate metabolism. J. Dairy Sci. 2014, 97, 624–631. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stiles, M.E.; Holzapfel, W.H. Lactic acid bacteria of foods and their current taxonomy. Int. J. Food Microbiol. 1997, 36, 1–29. [Google Scholar] [CrossRef]

- Abu-Khalaf, N.; Masoud, W. Electronic nose for differentiation and quantification of yeast species in white fresh soft cheese. Appl. Bionics Biomech. 2022, 2022, 8472661. [Google Scholar] [CrossRef] [PubMed]

- Kovacs, Z.; Bodor, Z.; Zinia Zaukuu, J.L.; Kaszab, T.; Bazar, G.; Tóth, T.; Mohácsi-Farkas, C. Electronic nose for monitoring odor changes of Lactobacillus species during milk fermentation and rapid selection of probiotic candidates. Foods 2020, 9, 1539. [Google Scholar] [CrossRef]

- Drake, M.A.; Gerard, P.D.; Kleinhenz, J.P.; Harper, W.J. Application of an electronic nose to correlate with descriptive sensory analysis of aged Cheddar cheese. LWT-Food Sci. Technol. 2003, 36, 13–20. [Google Scholar] [CrossRef]

- Štefániková, J.; Nagyová, V.; Hynšt, M.; Vietoris, V.; Martišová, P.; Nagyová, L. Application of electronic nose for determination of Slovak cheese authentication based on aroma profile. Potravinarstvo Slovak. J. Food Sci. 2019, 13, 262–267. [Google Scholar]

- Trihaas, J.; Vognsen, L.; Nielsen, P.V. Electronic nose: New tool in modelling the ripening of Danish blue cheese. Int. Dairy J. 2005, 15, 679–691. [Google Scholar] [CrossRef]

- Li, S.; Ma, C.; Liu, Z.; Gong, G.; Xu, Z.; Xu, A.; Hua, B. Flavour analysis of stirred yoghurt with Cheddar cheese adding into milk. Food Sci. Technol. Res. 2014, 20, 939–946. [Google Scholar] [CrossRef]

- Tian, H.; Liu, H.; He, Y.; Chen, B.; Xiao, L.; Fei, Y.; Wang, G.; Yu, H.; Chen, C. Combined application of electronic nose analysis and back-propagation neural network and random forest models for assessing yogurt flavor acceptability. J. Food Meas. Charact. 2020, 14, 573–583. [Google Scholar] [CrossRef]

- Olivares, A.; Navarro, J.L.; Flores, M. Characterization of volatile compounds responsible for the aroma in naturally fermented sausages by gas chromatography-olfactometry. Food Sci. Technol. Int. 2015, 21, 110–123. [Google Scholar] [CrossRef] [Green Version]

- Gu, X.; Sun, Y.; Tu, K.; Pan, L. Evaluation of lipid oxidation of Chinese-style sausage during processing and storage based on electronic nose. Meat Sci. 2017, 133, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Gao, H.; Zhang, Y.; Liao, Y.; Zeng, Q.; He, X.; Xu, K.; He, J. Optimizing conditions of electronic nose for rapid detection of flavor substances in Ningxiang pork. J. Food Process Eng. 2021, 44, e13758. [Google Scholar] [CrossRef]

- Chen, Q.; Hu, Y.; Wen, R.; Wang, Y.; Qin, L.; Kong, B. Characterisation of the flavour profile of dry fermented sausages with different NaCl substitutes using HS-SPME-GC-MS combined with electronic nose and electronic tongue. Meat Sci. 2021, 172, 108338. [Google Scholar] [CrossRef]

- Yin, X.; Lv, Y.; Wen, R.; Wang, Y.; Chen, Q.; Kong, B. Characterization of selected Harbin red sausages on the basis of their flavour profiles using HS-SPME-GC/MS combined with electronic nose and electronic tongue. Meat Sci. 2021, 172, 108345. [Google Scholar] [CrossRef]

- Taurino, A.M.; Dello Monaco, D.; Capone, S.; Epifani, M.; Rella, R.; Siciliano, P.; Ferrara, L.; Maglione, G.; Basso, A.; Balzarano, D. Analysis of dry salami by means of an electronic nose and correlation with microbiological methods. Sens. Actuators B Chem. 2003, 95, 123–131. [Google Scholar] [CrossRef]

- Yang, X.; Hu, W.; Xiu, Z.; Jiang, A.; Yang, X.; Sarengaowa; Ji, Y.; Guan, Y.; Feng, K. Microbial dynamics and volatilome profiles during the fermentation of Chinese northeast sauerkraut by Leuconostoc mesenteroides ORC 2 and Lactobacillus plantarum HBUAS 51041 under different salt concentrations. Food Res. Int. 2020, 130, 108926. [Google Scholar] [CrossRef]

- Cai, W.; Tang, F.; Wang, Y.; Zhang, Z.; Xue, Y.; Zhao, X.; Guo, Z.; Shan, C. Bacterial diversity and flavor profile of Zha-Chili, a traditional fermented food in China. Food Res. Int. 2021, 141, 110112. [Google Scholar] [CrossRef]

- Sánchez, R.; Martín-Tornero, E.; Lozano, J.; Boselli, E.; Arroyo, P.; Meléndez, F.; Martín-Vertedor, D. E-nose discrimination of abnormal fermentations in Spanish-style green olives. Molecules 2021, 26, 5353. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Yang, X.; Ji, Y.; Guan, Y. Effect of starter cultures mixed with different autochthonous lactic acid bacteria on microbial, metabolome and sensory properties of Chinese northeast sauerkraut. Food Res. Int. 2021, 148, 110605. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.H.; Oh, I.M.; Choi, S.; Park, J.T. Classification of geographical origin of kimchi by volatile compounds analysis using an electronic nose. Food Sci. Biotechnol. 2021, 30, 1313–1319. [Google Scholar] [CrossRef]

- Dai, C.; Huang, X.; Sun, J.; Tian, X.; Aheto, J.H.; Niu, S. Development of a portable electronic nose for in-situ detection of submerged fermentation of Tremella aurantialba. J. Food Saf. 2021, 41, e12902. [Google Scholar] [CrossRef]

- Štefániková, J.; Martišová, P.; Árvay, J.; Jankura, E.; Kačániová, M.; Gálová, J.; Vietoris, V. Comparison of electronic systems with sensory analysis for the quality evaluation of parenica cheese. Czech J. Food Sci. 2020, 38, 273–279. [Google Scholar] [CrossRef]

- Guan, B.; Zhao, J.; Cai, M.; Lin, H.; Yao, L.; Sun, L. Analysis of volatile organic compounds from Chinese vinegar substrate during solid-state fermentation using a colorimetric sensor array. Anal. Methods 2014, 6, 9383–9391. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, S.; Xie, C.; Zeng, D.; Fan, C.; Li, D.; Bai, Z. Characterization of Chinese vinegars by electronic nose. Sens. Actuators B Chem. 2006, 119, 538–546. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, S.; Xie, C.; Fan, C.; Bai, Z. ‘Sensory analysis’ of Chinese vinegars using an electronic nose. Sens. Actuators B Chem. 2008, 128, 586–593. [Google Scholar] [CrossRef]

- Jo, D.; Kim, G.R.; Yeo, S.H.; Jeong, Y.J.; Noh, B.S.; Kwon, J.H. Analysis of aroma compounds of commercial cider vinegars with different acidities using SPME/GC-MS, electronic nose, and sensory evaluation. Food Sci. Biotechnol. 2013, 22, 1559–1565. [Google Scholar] [CrossRef]

- Zhou, H.B. Identification of vinegar flavor using electronic nose. Res. J. Appl. Sci. Eng. Technol. 2017, 13, 154–160. [Google Scholar] [CrossRef]

- Taştan, M.; Gökozan, H. Real-Time Monitoring of Indoor Air Quality with Internet of Things-Based E-Nose. Appl. Sci. 2019, 9, 3435. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, J.; Wu, J.; Sun, B.; Zhang, Y.; Lan, X. Evaluation of Chinese vinegar by electronic nose. Appl. Mech. Mater. 2014, 490–491, 1497–1502. [Google Scholar] [CrossRef]

- Men, H.; Wang, L.; Zhang, H. Electronic nose for the vinegar quality evaluation by an incremental RBF network. J. Comput. 2012, 7, 2276–2282. [Google Scholar] [CrossRef]

- Wu, X.H.; Zhu, J.; Wu, B.; Huang, D.P.; Sun, J.; Dai, C.X. Classification of Chinese vinegar varieties using electronic nose and fuzzy Foley–Sammon transformation. J. Food Sci. Technol. 2020, 57, 1310–1319. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Huang, X.; Wang, C.; Aheto, J.H.; Chang, X.; Yu, S.; Zhang, X.; Wang, Y. Coupling electronic nose with GC–MS improves flavor recognition and grade differentiation of Zhenjiang aromatic vinegar. J. Food Process Eng. 2021, 44, e13806. [Google Scholar] [CrossRef]

- Jo, Y.; Chung, N.; Park, S.W.; Noh, B.S.; Jeong, Y.J.; Kwon, J.H. Application of E-tongue, E-nose, and MS-E-nose for discriminating aged vinegars based on taste and aroma profiles. Food Sci. Biotechnol. 2016, 25, 1313–1318. [Google Scholar] [CrossRef] [PubMed]

- Tozlu, B.H.; İbrahim Okumuş, H. A new approach to automation of black tea fermentation process with electronic nose. Automatika 2018, 59, 373–381. [Google Scholar] [CrossRef]

- Zheng, X.Q.; Li, Q.S.; Xiang, L.P.; Liang, Y.R. Recent advances in volatiles of teas. Molecules 2016, 21, 338. [Google Scholar] [CrossRef]

- Park, J.; Thomasson, J.A.; Gale, C.C.; Sword, G.A.; Lee, K.M.; Herrman, T.J.; Suh, C.P.C. Adsorbent-SERS technique for determination of plant VOCs from live cotton plants and dried teas. ACS Omega 2020, 5, 2779–2790. [Google Scholar] [CrossRef] [Green Version]

- Siyang, S.; Seesaard, T.; Lorwongtragool, P.; Kerdcharoen, T. E-nose based on metallo-tetraphenylporphyrinl SWNT-COOH for alcohol detection. In Proceedings of the 2013 IEEE International Conference of Electron Devices and Solid-State Circuits (EDSSC), Hong Kong, China, 3–5 June 2013. [Google Scholar]

- Chen, Q.; Zhao, J.; Chen, Z.; Lin, H.; Zhao, D.A. Discrimination of green tea quality using the electronic nose technique and the human panel test, comparison of linear and nonlinear classification tools. Sens. Actuators B Chem. 2011, 159, 294–300. [Google Scholar] [CrossRef]

- Torri, L.; Rinaldi, M.; Chiavaro, E. Electronic nose evaluation of volatile emission of Chinese teas: From leaves to infusions. Int. J. Food Sci. Technol. 2014, 49, 1315–1323. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, J.; Wu, B.; Zhao, C.; Sun, J.; Dai, C. Discrimination of Chinese liquors based on electronic nose and fuzzy discriminant principal component analysis. Foods 2019, 8, 38. [Google Scholar] [CrossRef] [Green Version]

- Anal, A.K. Quality ingredients and safety concerns for traditional fermented foods and beverages from Asia: A review. Fermentation 2019, 5, 8. [Google Scholar] [CrossRef] [Green Version]

- Diez-Simon, C.; Eichelsheim, C.; Mumm, R.; Hall, R.D. Chemical and sensory characteristics of soy sauce: A review. J. Agric. Food Chem. 2020, 68, 11612–11630. [Google Scholar] [CrossRef] [PubMed]

- Chukeatirote, E.; Eungwanichayapant, P.D.; Kanghae, A. Determination of volatile components in fermented soybean prepared by a coculture of Bacillus subtilis and Rhizopus oligosporus. Food Res. 2017, 1, 225–233. [Google Scholar] [CrossRef]

- Park, S.W.; Lee, S.J.; Sim, Y.S.; Choi, J.Y.; Park, E.Y.; Noh, B.S. Analysis of ethanol in soy sauce using electronic nose for halal food certification. Food Sci. Biotechnol. 2017, 26, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.Y.; Kwak, H.S.; Kim, M.J.; Kim, Y.; Kim, K.O.; Kim, S.S. Comparison of a descriptive analysis and instrumental measurements (electronic nose and electronic tongue) for the sensory profiling of Korean fermented soybean paste (doenjang). J. Sens. Stud. 2017, 32, e12282. [Google Scholar] [CrossRef]

- Hidayat, S.N.; Nuringtyas, T.R.; Triyana, K. Electronic nose coupled with chemometrics for monitoring of Tempeh fermentation process. In Proceedings of the 2018 4th International Conference on Science and Technology (ICST), Yogyakarta, Indonesia, 7–8 August 2018. [Google Scholar]

- Ravi, R.; Taheri, A.; Khandekar, D.; Millas, R. Rapid profiling of soybean aromatic compounds using electronic nose. Biosensors 2019, 9, 66. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.; Huang, X.; Wang, L.; Ren, Y.; Zhang, X.; Wang, Y. Characterization of selected Chinese soybean paste based on flavor profiles using HS-SPME-GC/MS, E-nose and E-tongue combined with chemometrics. Food Chem. 2022, 375, 131840. [Google Scholar] [CrossRef]

- Narzary, Y.; Das, S.; Goyal, A.K.; Lam, S.S.; Sarma, H.; Sharma, D. Fermented fish products in South and Southeast Asian cuisine: Indigenous technology processes, nutrient composition, and cultural significance. J. Ethn. Foods 2021, 8, 33. [Google Scholar] [CrossRef]

- Shivanne Gowda, S.G.; Narayan, B.; Gopal, S. Bacteriological properties and health-related biochemical components of fermented fish sauce: An overview. Food Rev. Int. 2016, 32, 203–229. [Google Scholar] [CrossRef]

- Yang, X.; Xie, W.; Zhang, C.; Wu, H.; Li, S.; Yang, L. Identification of sensory quality of rapid fermented fish using electronic nose. In Proceedings of the 2009 International Conference on Information Engineering and Computer Science, Wuhan, China, 19–20 December 2009. [Google Scholar]

- Wang, Y.; Wu, Y.; Shen, Y.; Li, C.; Zhao, Y.; Qi, B.; Li, L.; Chen, Y. Metabolic footprint analysis of volatile organic compounds by gas chromatography-ion mobility spectrometry to discriminate Mandarin fish (Siniperca chuatsi) at different fermentation stages. Front. Bioeng. Biotechnol. 2021, 9, 805364. [Google Scholar] [CrossRef]

- Nimsuk, N. Application of electronic nose for classification of fish sauces using transient responses and learning vector quantization algorithm. Adv. Mater. Res. 2014, 931–932, 1582–1586. [Google Scholar] [CrossRef]

- Nakano, M.; Sagane, Y.; Koizumi, R.; Nakazawa, Y.; Yamazaki, M.; Ikehama, K.; Yoshida, K.; Watanabe, T.; Takano, K.; Sato, H. Clustering of commercial fish sauce products based on an e-panel technique. Data Brief 2018, 16, 515–520. [Google Scholar] [CrossRef] [PubMed]

| Time | Country | Local Name (Objectives) | Type of E-nose (Pattern Recognition) | Target VOCs | Ref. |

|---|---|---|---|---|---|

| Fermented cereal and grain products | |||||

| 2014 | Thailand | Draft beer (To monitor the draft beer fermentation process) | 7 MOS Model: Lab-made E-nose (PCA) | General combustible, alcohol, natural, methane, LPG, propane, carbon monoxide, air contaminants | [139] |

| 2019 | Brazil | Beer (To detect the alcohol content of beers) | 13 MOS Model: Lab-made E-nose (MLR, ELM, RF, MNLR) | Ethanol, propane, butane, methane, isobutane, benzene, NH3, toluene, CH4, hexane, LPG, CO, H2, H2S, methyl mercaptan, trimethylamine | [127] |

| 2020 | Australia | Beer (To assess beer quality) | 9 MOS Model: Lab-made E-nose (ANN) | Ethanol, methane, carbon monoxide, hydrogen, hydrogen sulfide, ammonia, benzene/alcohol/ammonia, carbon dioxide | [140] |

| 2021 | Australia | Beer (To detect beer faults in the brewing process) | 9 MOS Model: Lab-made E-nose (ANN) | Alcohol, methane (CH4), carbon monoxide (CO), hydrogen (H2), ammonia/alcohol/benzene, hydrogen sulfide (H2S), ammonia, carbon dioxide (CO2) | [60] |

| 2014 | Korea | Korean rice wine (makgeolli) (To detect volatile compounds from initial amino acid profiles in Korean rice wine (makgeolli) model) | MS-EN Model: SMart Nose 300 (PCA, PLSR) | Isobutanol, isoamyl alcohol, 2-methyl butanol, 2-phenylethanol, isobutyl acetate, isoamyl acetate, 2-methylbutyl acetate, 2-phenylethyl acetate, ethyl caproate, ethyl caprylate, ethyl caprate | [135] |

| 2016 | Brazil | Spirit beverages (To classify odors from alcoholic beverages, as well as butanol and methanol vapors) | 5 MOS Model: Lab-made E-nose (PCA, MLP, SOM, CA) | Aguardiente, butanol, tequilas, vodkas, whiskey, methanol | [141] |

| 2016 | Poland | Spirit beverages (To discriminate raw spirits, vodkas and whisky samples) | Fast GC e-nose Model: Alpha MOS (PCA, DFA, SIMCA) | tert-Butylmethylether, ethyl acetate, 2-methyl-1-butanol, 2-methyl-1- propanol, n-butanol, 2,3-pentanedione, methyl butanoate, pentanol, 1-hexanol, (Z)-4-heptenal | [136] |

| 2017 | Poland | Whisky (To analyze and evaluate type of whisky) | MOS Model: Alpha MOS (PLS-DA) | 2-Propanol, n-butanol, furfural, ethyl isovalerate, alpha-pinene, decanal, eugenol, geosmin, gamma-decalactone, 12-methyltridecanal | [138] |

| 2006 | India | Bread (To cluster bread odor data according to the state of freshness of bread) | 4 MOS Model: Lab-made E-nose (SOM network) | Methane, butane, propane, alcohol, toluene, xylene, LP-gas/propane, CO, CO2, H | [132] |

| 2019 | Italy | Bakery products (To investigate the volatilome of different bakery products, obtained from mature and immature grains and transformed by sourdough) | 10 MOS Model: PEN2 (CAP analysis) | Ethyl alcohol, 3-hydroxy-2-butanone, acetic acid, octanoic acid, heptanoic acid, 3-methyl butanoic acid, heptanal, acetophenone, ethylbenzene, 2-methyl-3-decen-5-one, 2,4-bis (1-methylethyl) phenol, heptanal | [131] |

| 2019 | China | Sourdough-based Chinese steamed bread (To identify a key aroma compound in type I sourdough-based Chinese steamed bread) | 14 MOS Model: ISENSO INTELLIGENT (PCA, PLS-DA) | Ethyl acetate (fruity), ethyl lactate (caramel-like), hexyl acetate (fruity), (E)-2-nonenal (fatty) and 2-pentylfuran (fruity), acetic acid, 2-methyl-1-propanol, ethanol, 1-pentanol, pentanal, (E)-2-octenal, hexanal | [129] |

| 2020 | Iran | Sourdough (To investigate effective variables to produce desirable aroma in sourdough) | 6 MOS Model: Lab-made E-nose (LSD test) | Alcohol, LPG, natural gas, carbon monoxide, ammonia, sulfide, benzene, H2S, toluene, acetone, hydrogen | [130] |

| 2020 | Poland | Bread (To test the suitability of bread for consumption during four-day storage) | 8 MOS Model: Lab-made E-nose (PCA) | Ketones, acids, aromatic comp., terpenoids, sulfur comp., esters, alcohols, hydrocarbons | [133] |

| Fermented fruit products | |||||

| 2008 | Australia | Wine (To predict red wine spoilage) | 12 MOS Model: FOX-3000, Alpha MOS (PLS regression, RMSECV) | Ethanol, 3-methylbutanol, 4-ethylphenol, 4-ethylguaiacol | [128] |

| 2012 | Spain | Wine (To identify the aging of red wines) | 9 MOS Model: Lab-made E-nose (PCA, Tucker3 analysis) | 2-Furaldehyde, guaiacol, eugenol, cis- and trans-whiskeylactone | [134] |

| 2021 | Australia | Wine (To assess volatile aromatic compounds in smoke-taintedcabernet sauvignon wines) | 9 MOS Model: Lab-made E-nose (LSD, PCA, ANN) | Ethanol, methane, carbon monoxide, hydrogen sulfide, ammonia, alcohol, benzene, carbon dioxide, hydrogen | [142] |

| 2021 | Australia | Wine (To detect smoke taint in Pinot Grigio wines) | 9 MOS Model: Lab-made E-nose (LSD, PCA, ANN) | Ammonia, alcohol, benzene, carbon dioxide, hydrogen, ethanol, methane, carbon monoxide, hydrogen sulfide, | [61] |

| 2022 | Australia | Wine (To assess and classify flaws and faults in wine) | 9 MOS Model: Lab-made E-nose (HSD, SE) | Alcohol, methane, hydrogen, ammonia, benzene, carbon dioxide, hydrogen sulfide | [143] |

| Time | Country | Local Name (Objectives) | Type of E-nose (Pattern Recognition) | Target VOCs | Ref. |

|---|---|---|---|---|---|

| Fermented milk products | |||||

| 2003 | USA | Cheddar cheese (To evaluate the differentiation of aged Cheddar cheese aroma) | E-nose based on GC (Kenner, LA, USA) Model: Lab-made E-nose (CA, PCA) | 4-Mercapto-4-methyl-pentan-2-one | [149] |

| 2005 | Denmark | Danish blue cheese (To detect the ripening of Danish blue cheese) | 12 MOS Model: FOX-3000, Alpha MOS (PCA, PLS-R) | 2-Methyl ketones, benzaldehyde, 3-methyl-butanal, 2-hexanol | [151] |

| 2014 | China | Yogurt (To analyze stirred yogurt with cheddar cheese added to milk) | 18 MOS Model: FOX-4000, Alpha MOS (PCA) | Pentanal, dimethyl trisulfide, ethyl butanoate, methanethiol, dimethyl disulfide | [152] |

| 2019 | Slovakia | Slovak cheese (To characterize steamed cheese and assess quality decay of steamed cheese during storage) | E-nose with two FID detectors Model: Heracles II, Alpha M.O.S. (PCA) | Acetaldehyde, 1-propanal, propanoic acid, ethyl hexanoate, furfural, butan-2-one, isovaleric acid, 1-hexanol or α-pinene | [150] |

| 2020 | China | Yogurt (To detect unsatisfactory products for the quality control of yogurt) | 18 MOS Model: FOX-4000, Alpha MOS (PCA, BPNN, RF) | Satisfactorily favored yogurt samples and three subsets of yogurt samples with unsatisfactory favors (cooked, lack of yogurt favor, vinegarish) | [153] |

| 2020 | Hungary | Milk (To monitor odor changes during milk fermentation with Lactobacillus species) | Heracles GC e-nose Model: Heracles Neo 300 ultra-fast GC analyzer (LDA, ANOVA tests, Tukey HSD test) | 2-octanol (expressing fatty or oily aroma), decane (sweet aroma), 2,4-heptadienal (fatty aroma), compound of pyridine, 2-pentyl (fatty and tallowy aroma) | [148] |

| 2020 | Slovakia | Parenica cheese (To investigate the quality of smoked and unsmoked Parenica cheeses after seven days of storage) | GC-FID e-nose Model: Heracles II; Alpha M.O.S. (PCA) | Carboxylic acids, alcohols, aldehydes, ketones, esters, sulfur compounds, furans/furanones, phenols, terpenes | [166] |

| 2021 | Japan | Cheese (To classify cheese types, production areas and cheese ages) | POLFA odor sensor Model: POLFA, Karumoa Co., Ltd. (Tukey’s HSD test) | VOCs from five kinds of processed cheeses (two types of normal processed cheese, one type containing aged cheese, two types containing blue cheese, one type of natural cheese) | [106] |

| 2022 | Palestine | White fresh soft cheese (To identify and quantify four yeast species in white fresh soft cheese) | 8 MOS Model: Lab-made E-nose (PCA, PLS) | Four species of yeast (Pichia anomala, Pichia kluyveri, Hanseniaspora uvarum, and Debaryomyces hansenii) | [147] |

| Fermented meat products | |||||

| 2003 | Italy | Salami (To analyze and discriminate different Mediterranean salami) | 5 sensors based on SnO2 sol–gel thin films Model: Lab-made E-nose (PCA) | β-Pinene, α-pinene, limonene, hexanal, benzaldehyde, 1-hexanol, 2-ethyl, 2-heptanone | [159] |

| 2017 | China | Chinese-style sausage (To evaluate lipid oxidation of Chinese-style sausage during processing and storage) | 10 MOS Model: PEN3 (SVM, ANN, HCA) | Aromatic compounds, nitrogen oxides, ammonia, benzene, hydrogen, methane, sulfur compound, alcohols | [155] |

| 2021 | China | Ningxiang pork (To detect flavor substances in Ningxiang pork) | 10 MOS Model: PEN3 (PCA, LDA) | Aldehydes, alcohols, ketones, olefins, nitrogen oxides, methyl compounds, aldol, sulfur compounds, aromatic hydrocarbons | [156] |

| 2021 | China | Dry fermented sausage (To detect the flavor profiles of dry fermented sausages with different NaCl substitutes) | 10 MOS Model: PEN3 (PCA, HCA) | Aldehydes, ketones, alcohols, acids, esters, terpenes | [157] |

| 2021 | China | Harbin red sausages (To study volatile profiles and taste properties of Harbin red sausages prepared with traditional and conventional processing methods) | 10 MOS Model: PEN3 (PCA, PLS) | Hexanol, furfuryl alcohol, hexanal, furfural, 5-methyl furfural, 2-methyl-2-cyclopenten-1-one, 3-methyl-2-cyclopenten-1-one, 3-ethyl-2-hydroxy-2-cyclopenten-1-one, 1-indanone, guaiacol, 2-methoxy-4-methylphenol, 2,3,5-trimethyphenol, o-cresol, 4-ethyl-2-methoxyphenol, 2,5-dimethylphenol, 2,4-dimethylphenol, 2-methoxy-4-propylphenol, octane, naphthalene, heptanoic acid, 1-octen-3-ol, 2-nonanone, methyl 2-furoate | [158] |

| Fermented vegetable products | |||||

| 2021 | China | Zha-chili (To detect the bacterial diversity during fermentation process and flavor quality of zha-chili samples) | 10 MOS Model: PEN3 (PCA, PCoA, CA, ANOSIM) | Ammonia, aromatic compounds, aldehydes, ketones, methane, sulfur compounds, terpenes, organic sulfur compounds, alcohols, ketones | [161] |

| 2021 | Spain | Green olives (To assess abnormal fermentation defects of Spanish-style table olives) | 11 MOS Model: Lab-made E-nose (PCA, PLS-DA) | VOCs from five types of table olives (control, zapateria, putrid, butyric and musty), carboxylic acids, alcohols, phenols, esters | [162] |

| 2021 | Korea | Kimchi (To classify geographical origin of kimchi by volatile compound analysis) | Smart Nose SA, Marin-Epagnier, Switzerland Model: Lab-made E-nose (PCA, DFA) | Total of 69 kinds of kimchi samples (Korean and Chinese kimchi) | [164] |

| 2021 | China | Chinese northeast sauerkraut (To investigate lactic acid bacteria for fermentation of Chinese northeast sauerkraut) | 10 MOS Model: PEN3 (PCA, HCA) | 2-Ethylhexanol, 3,5-dimethylbenzaldehyde, 3,5-ditert-butylphenol, alcohols (2-nonanol, 2-heptanol), esters (ethyl crotonate, ethyl butanoate, ethyl lactate, ethylhexanoate, ethyl 3-phenylpropanoate and ethyl acetate), terpenes (geraniol, nerolidol, dihydrocarveol), polyphenols, nitriles, lactones, isobutanol, methyl acetate, 2-methylpentaldehyde | [163] |

| 2021 | China | Tremella aurantialba (To detect saponin in submerged fermentation with Tremellaaurantialba (T. aurantialba)) | 8 MOS Model: Lab-made E-nose (PLSR) | Saponin compounds, aldehydes, esters, alcohols, heterocyclic, aromatic compounds, ketones | [165] |

| Time | Country | Local Name (Objectives) | Type of E-nose (Pattern Recognition) | Target VOCs | Refs. |

|---|---|---|---|---|---|

| Fermented fruits products | |||||

| 2006 | China | Chinese vinegars (To establish a gas-sensing fingerprint database of Chinese vinegars for quality control) | Nine nano ZnO thick film gas sensors Model: Lab-made E-nose (PCA, CA, LVQ) | Acetic acid and vinegar samples (aromatic vinegar, mature vinegar, rice vinegar, white vinegar, fruit vinegar) | [168] |

| 2008 | China | Chinese vinegars (To establish a gas-sensing fingerprint database of Chinese vinegars and identify them individually for their quality control) | Nine doped nano-ZnO thick film gas sensors Model: Lab-made E-nose (BP-ANNs, KNN) | Aromatic vinegar (Hengshun Xiangcu, Beigushan Xiangcu, Yanhui Xiangcu, Jinyou Xiangcu, ZhengjiangXiangcu, Longmen Xiangcu and Weichunyun Xiangcu), maturevinegar (Shuita Chencu, Donghu Chencu, Beigushan Chencu, Zhengjiang Chencu and Weichunyuan Chencu), Rice vinegar (Jinbiao Micu and Longmen Micu), white vinegar (Meiweixia Baicu and Longmen Baicu), fruit vinegar (Haitian Pingguocu) | [169] |

| 2012 | China | Vinegar (To identify vinegar online) | 6 MOS Model: Lab-made E-nose (RBF, K-means) | Five kinds of Chinese vinegar (vinegarriver white city, river city rice vinegar, Liubiju vinegar, apple vinegar, Zilin old vinegar | [174] |

| 2013 | Korea | Cider vinegars (To determine the volatile profiles of cider vinegars) | Surface acoustic wave (SAW) sensor Model: zNose (PCA) | Acetic acid, ethyl alcohol, 1-hexanol, furfural, benzaldehyde, ethyl acetate, n-butyl acetate, isobutyl acetate, isoamyl acetate, hexyl acetate | [170] |

| 2014 | China | Vinegar (To evaluate the aroma of vinegars and control their quality) | 10 MOS Model: PEN3 (La, LDA, PCA) | Volatile components in vinegars (acids, esters, aromatics compounds, alcohols, sulfur compounds, alkenes) | [173] |

| 2016 | Korea | Vinegar (To discriminate aged vinegars based on taste and aroma profiles) | MS-E-nose Model: SMart Nose300; Alpha M.O.S. (PCA) | Aroma profiles of aged vinegars (Chinese Shanxi extra-aged vinegar, Japanese black vinegar, Italian balsamic vinegar) | [177] |

| 2017 | China | Vinegar (To discriminate different flavors of vinegar) | 8 MOS Model: Lab-made E-nose (PCA, LDA, MLP) | Five different flavors of vinegar (white vinegar, mature vinegar, rice vinegar, balsamic vinegar and apple vinegar) | [171] |

| 2020 | China | Chinese vinegar (To identify Chinese vinegar varieties) | 10 MOS Model: Lab-made E-nose (PCA, SNV, LDA, KNN) | VOCs from five different kinds of Chinese vinegars (Zhenjiangxiangcu, Zhenjiangchencu, Baoningcu, Hengshunxiangcu and Shanxichencu) | [175] |

| 2021 | China | Zhenjiang aromatic vinegar (To differentiate different grades of Zhenjiang aromatic vinegar (ZAV)) | 10 MOS Model: PEN3 (PCA, PLS-DA) | Furfural, acetic acid, tetramethylpyrazine, phenethyl acetate, phenylethyl alcohol, acetic acid, isobutyric acid, ethyl phenylacetate, 3-hydroxy-2-butanone, 2,3-butanedione, 2-acetylfuran | [176] |

| Fermented herb products | |||||

| 2011 | China | Green tea (To discriminate the green tea quality) | 8 MOS Model: Lab-made E-nose (PCA, KNN, ANN) | Hexenols, pentanal, hexanol, pinene | [182] |

| 2014 | Italy | Chinese teas (To discriminate the tealeaf quality) | 10 MOS Model: Win Muster v.16 (PCA, CA, LSD) | Aromatic compounds, broad-range compounds, polar compounds, nitrogen oxides and ozone, ammonia, aromatic compounds, aldehydes, ketones, hydrogen, alkanes, less polar compounds, methane, sulfur compounds, terpenes, alcohols | [183] |

| 2016 | China | Pu-erh teas (To discriminate two types of Pu-erh teas) | 12 MOS Model: Agrinose (PCA) | Alcohol, methoxyphenlic compounds, | [137] |

| 2018 | Turkey | Black tea (To monitor the quality control in black tea during fermentation process) | 13 MOS Model: Lab-made E-nose (LDA, Bayes, KNN-3 methods) | (E)-2-hexenal, hexenal, (E)-geraniol, linalool, linalool oxide II (cis, furanoid), benzeneacetaldehyde, linalool oxide I (trans, furanoid), 3,7-dimethyl-1,5,7-octatrien-3-ol, benzaldehyde, methyl salicylate | [178,179] |

| 2019 | China | Chinese liquors (To discriminate Chinese liquors) | 10 MOS Model: Lab-made E-nose (FDPCA, DPCA, PCA, KNN) | Six types of Chinese liquors (Maotai, Gujinggongjiu, Yingjiagongjiu, Haizhilan, Fenjiu, Kouzijiao) | [184] |

| 2022 | Sri Lanka | Sri Lankan tea (To monitor the fermentation process of Sri Lankan low-country tea) | 4 MOS Model: Digi-Nose (PCA, SVM) | Diethyl phthalate, dimethyl phthalate, Diisononyl phthalate, 2-hydroxyisobutyric acid, 3-penten-2-ol | [89,180] |

| Time | Country | Local Name (Objectives) | Type of E-nose (Pattern Recognition) | Target VOCs | Ref. |

|---|---|---|---|---|---|

| Fermented fish products | |||||

| 2009 | China | Fermented fish (To analyze traditional fermented fish flavor) | 18 MOS Model: FOX-4000, Alpha MOS (PCA, SQC) | VOCs from traditional fermented fish | [195] |

| 2014 | Thailand | Fish sauce (To classify fish sauce based on the level of total nitrogen content) | 6 MOS Model: Lab-made E-nose (PCA, LVQ) | Nitrogen content from fish sauce | [197] |

| 2018 | Japan | Fish sauce (To classify different smells from 46 commercially available fish sauce products) | 18 MOS Model: FOX-4000, Alpha MOS (CA) | VOCs from 46 fish sauce products in several countries (Japan, Thailand, Vietnam, China, Philippines, Italy) | [198] |

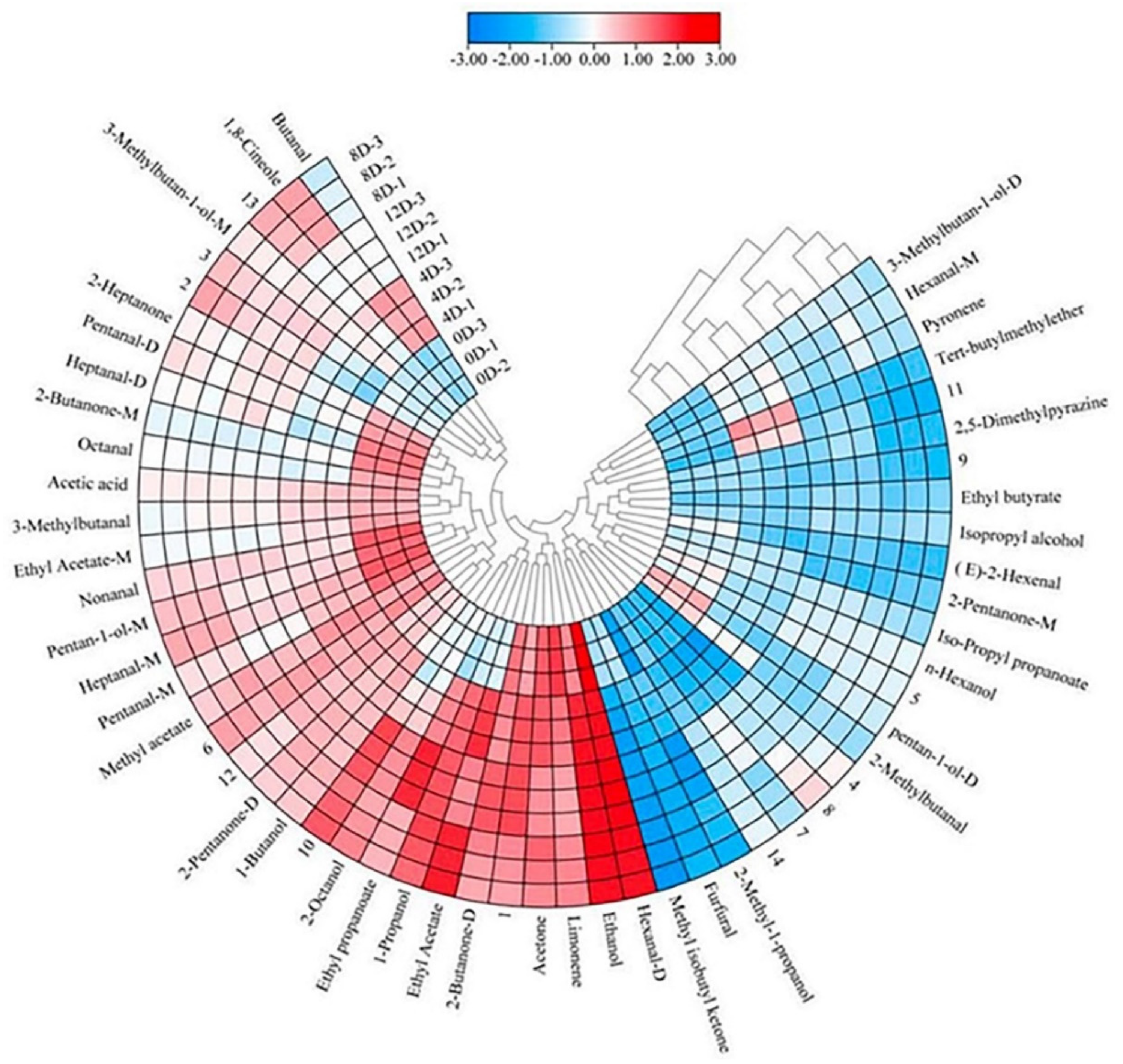

| 2021 | China | Chinese fermented Mandarin fish (To establish the volatile fingerprint of fermented mandarin fish at different fermentation stages) | 18 MOS Model: FOX-4000, Alpha MOS (PCA, PLS-DA, HCA) | Hexanal-D, nonanal, limonene | [196] |

| Fermented legumes products | |||||

| 2018 | Indonesia | Tempeh (To monitor the fermentation process of tempeh) | 8 MOS Model: Lab-made E-nose (PCA, LDA, SVM, KNN) | CO, methane, ethanol, propane, isobutane, hydrogen, ethanol, ammonia, ethanol, toluene, hydrogen sulfide | [190] |

| 2017 | Korea | Soy sauce (To analyze ethanol content in soy sauce for halal food certification) | Model: Smart Nose 300 (DFA) | Ethanol in 24 different kinds of soy sauce | [188] |

| 2017 | Korea | Soybean paste (To investigate the sensory profiling of fermented soybean paste (doenjang)) | Model: Heracles II, Alpha MOS (PCA) | Ethanol, ethyl acetate, ethyl iso-butyrate, pyridine, ethyl 2-methylbutyrate, 1-hydroxy-2-propanone, 1-penten-3-one, 2-ethylfuran, ethyl furan, ethyl butyrate, ethyl isovalerate, 2-methyl-1-butano | [189] |

| 2019 | USA | Soybean (To determine the quantity and quality of volatile compounds in soybean varieties) | Model: HERCALES GC Flash electronic nose (PCA) | Ethyl-2-methyl butyrate, 2-methyl propanal, 2-propanol | [191] |

| 2022 | China | Chinese soybean paste (To select Chinese soybean paste based on flavor profiles) | Model: HS-SPME-GC/MS with E-nose (LDA, PLSR, SVR) | Esters, total acids, reducing sugar, salinity, amino acid nitrogen | [192] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seesaard, T.; Wongchoosuk, C. Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications. Fermentation 2022, 8, 302. https://doi.org/10.3390/fermentation8070302

Seesaard T, Wongchoosuk C. Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications. Fermentation. 2022; 8(7):302. https://doi.org/10.3390/fermentation8070302

Chicago/Turabian StyleSeesaard, Thara, and Chatchawal Wongchoosuk. 2022. "Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications" Fermentation 8, no. 7: 302. https://doi.org/10.3390/fermentation8070302

APA StyleSeesaard, T., & Wongchoosuk, C. (2022). Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications. Fermentation, 8(7), 302. https://doi.org/10.3390/fermentation8070302