Enzymatic Hydrolysis Strategies for Cellulosic Sugars Production to Obtain Bioethanol from Eucalyptus globulus Bark

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material and Pretreatment

2.2. Chemical Characterization of Pretreated Eucalyptus globulus Bark

2.3. Enzymatic Hydrolysis

2.3.1. Batch Enzymatic Hydrolysis—Effect of Additives

2.3.2. Batch Enzymatic Hydrolysis—Optimal Initial Solids Loading and Scale-Up

2.3.3. Fed-Batch Enzymatic Hydrolysis

2.4. Fermentation

2.5. Analytical Methods

2.5.1. pH

2.5.2. Cell Concentration

2.5.3. Glucose, Xylose and Ethanol Quantification

2.6. Calculations

2.6.1. Enzymatic Hydrolysis

2.6.2. Fermentation

3. Results and Discussion

3.1. Chemical Characterization of Raw Material

3.2. Enzymatic Hydrolysis of Kraft Pulp from Eucalyptus globulus Bark

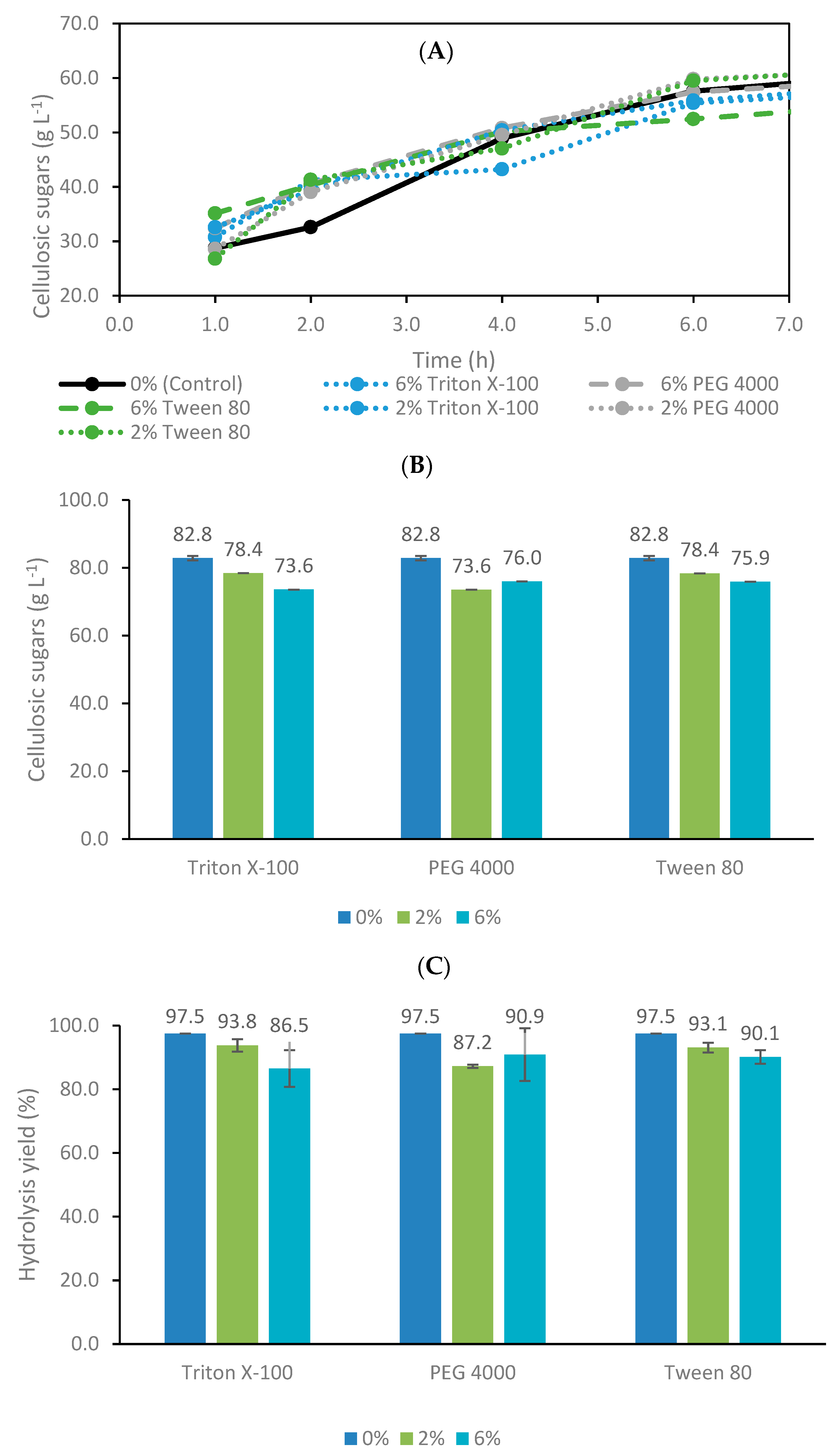

3.2.1. Effect of Additives on Enzymatic Hydrolysis

3.2.2. Optimal Initial Solids Loading and Scale-Up

3.2.3. Fed-Batch Enzymatic Hydrolysis

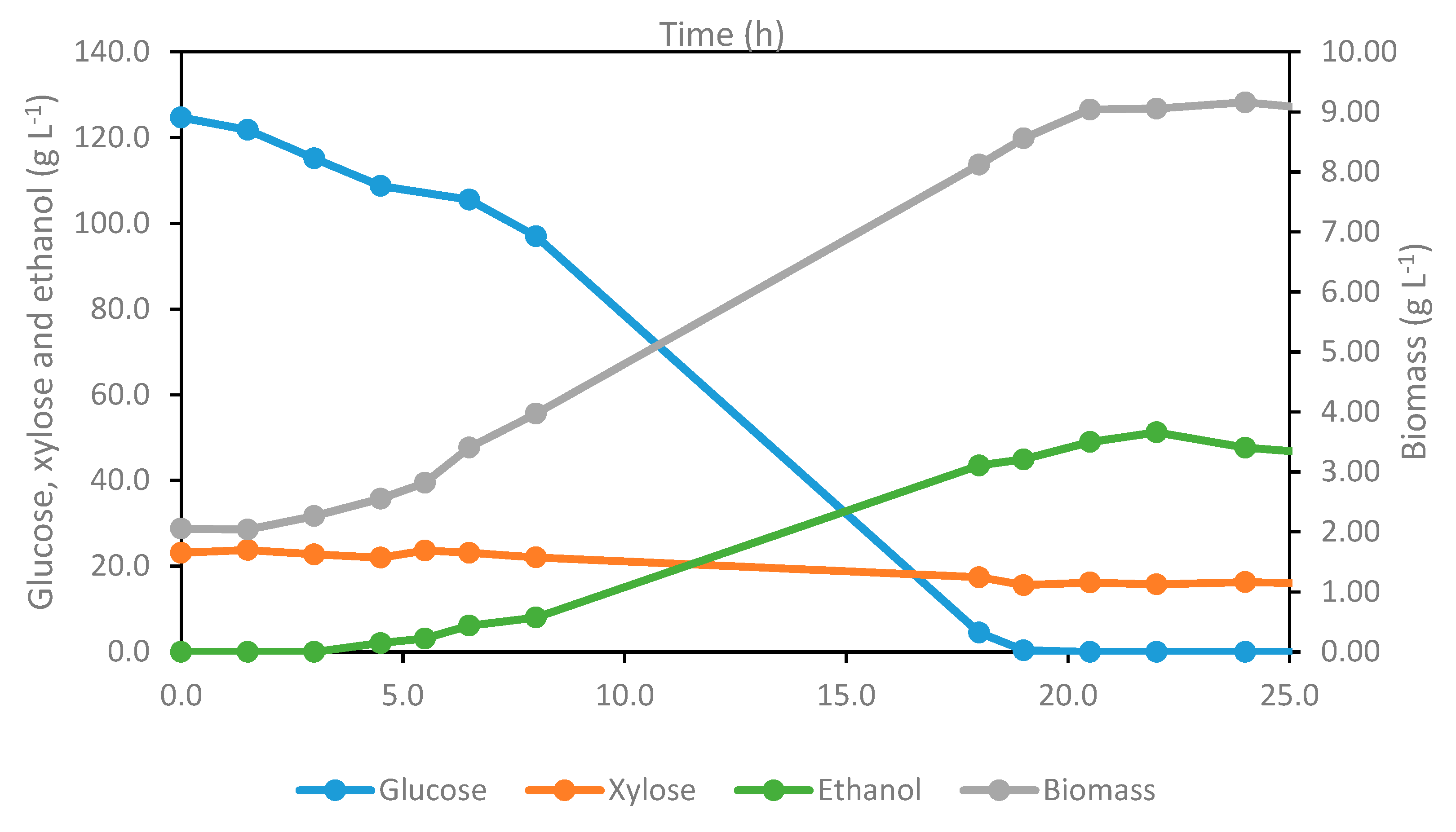

3.3. Fermentability of Hydrolysate Derived from Fed-Batch Strategy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Branco, R.; Serafim, L.; Xavier, A. Second Generation Bioethanol Production: On the Use of Pulp and Paper Industry Wastes as Feedstock. Fermentation 2019, 5, 4. [Google Scholar] [CrossRef]

- Stoklosa, R.J.; Hodge, D.B. Integration of (Hemi)-Cellulosic Biofuels Technologies with Chemical Pulp Production. In Biorefineries; Qureshi, N., Hodge, D., Vertes, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 73–100. ISBN 9780444595041. [Google Scholar]

- Pinto, F.; Gominho, J.; André, R.N.; Gonçalves, D.; Miranda, M.; Varela, F.; Neves, D.; Santos, J.; Lourenço, A.; Pereira, H. Improvement of gasification performance of Eucalyptus globulus stumps with torrefaction and densification pre-treatments. Fuel 2017, 206, 289–299. [Google Scholar] [CrossRef]

- Souza, A.G.; Lima, G.F.; Rodrigues, R.C.L.B.; Cesarino, I.; Leão, A.L.; Rosa, D.S. A New Approach for Conversion of Eucalyptus Lignocellulosic Biomass into Cellulose Nanostructures: A Method that Can Be Applied in Industry. J. Nat. Fibers 2019, 18, 1501–1511. [Google Scholar] [CrossRef]

- Neiva, D.M.; Araújo, S.; Gominho, J.; Carneiro, A.C.; Pereira, H. Potential of Eucalyptus globulus industrial bark as a biorefinery feedstock: Chemical and fuel characterization. Ind. Crop. Prod. 2018, 123, 262–270. [Google Scholar] [CrossRef]

- Resquin, F.; Barrichelo, L.E.G.; da Silva, F.G.; Brito, J.O.; Sansigolo, C.A. Wood quality for kraft pulping of Eucalyptus globulus origins planted in Uruguay. Sci. For./For. Sci. 2006, 72, 57–66. [Google Scholar]

- Rodrigues, A.E.; Pinto, P.C.; Barreiro, M.F.; da Costa, C.E.; da Mota, M.F.; Fernandes, I. An Integrated Approach for Added-Value Products from Lignocellulosic Biorefineries: Vanillin, Syringaldehyde, Polyphenols and Polyurethane, 1st ed.; Springer: Cham, Switzerland, 2018; ISBN 978-3-319-99312-6. [Google Scholar]

- Ressel, J.B. Wood Yard Operations. In Handbook of Pulp; Sixta, H., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; Volume 1, pp. 69–107. ISBN 3527309993. [Google Scholar]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Pulping Chemistry and Technology. In Pulp and Paper Chemistry and Technology; Ek, M., Gellerstedt, G., Henriksson, G., Eds.; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2009; Volume 2. [Google Scholar]

- Biond-Forest Fibers from Portugal. Boletim Estatístico Biond 2021. Available online: https://www.biond.pt/publicacoes/boletim-estatistico-2021/ (accessed on 28 November 2022).

- Domingues, R.M.A.; Sousa, G.D.A.; Freire, C.S.R.; Silvestre, A.J.D.; Neto, C.P. Eucalyptus globulus biomass residues from pulping industry as a source of high value triterpenic compounds. Ind. Crop. Prod. 2010, 31, 65–70. [Google Scholar] [CrossRef]

- Neiva, D.M.; Luís, Â.; Gominho, J.; Domingues, F.; Duarte, A.P.; Pereira, H. Bark residues valorization potential regarding antioxidant and antimicrobial extracts. Wood Sci. Technol. 2020, 54, 559–585. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Robak, K.; Balcerek, M. Review of Second Generation Bioethanol Production from Residual Biomass. Food Technol. Biotechnol. 2018, 56, 174–187. [Google Scholar] [CrossRef]

- Aditiya, H.B.; Mahlia, T.M.I.; Chong, W.T.; Nur, H.; Sebayang, A.H. Second generation bioethanol production: A critical review. Renew. Sustain. Energy Rev. 2016, 66, 631–653. [Google Scholar] [CrossRef]

- Fatma, S.; Hameed, A.; Noman, M.; Ahmed, T.; Sohail, I.; Shahid, M.; Tariq, M.; Tabassum, R. Lignocellulosic Biomass: A Sustainable Bioenergy Source for Future. Protein Pept. Lett. 2018, 25, 148–163. [Google Scholar] [CrossRef]

- Pino, M.S.; Rodríguez-Jasso, R.M.; Michelin, M.; Flores-Gallegos, A.C.; Morales-Rodriguez, R.; Teixeira, J.A.; Ruiz, H.A. Bioreactor design for enzymatic hydrolysis of biomass under the biorefinery concept. Chem. Eng. J. 2018, 347, 119–136. [Google Scholar] [CrossRef]

- Huang, C.; Li, R.; Tang, W.; Zheng, Y.; Meng, X. Improve Enzymatic Hydrolysis of Lignocellulosic Biomass by Modifying Lignin Structure via Sulfite Pretreatment and Using Lignin Blockers. Fermentation 2022, 8, 558. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy. Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Kumar, A.; Naraian, R. Differential Expression of the Microbial β-1, 4-Xylanase, and β-1, 4-Endoglucanase Genes. In New and Future Developments in Microbial Biotechnology and Bioengineering; Singh, H.B., Gupta, V.K., Jogaiah, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 95–111. ISBN 9780444635037. [Google Scholar]

- Padella, M.; O’Connell, A.; Prussi, M. What is still Limiting the Deployment of Cellulosic Ethanol? Analysis of the Current Status of the Sector. Appl. Sci. 2019, 9, 4523. [Google Scholar] [CrossRef]

- Qiao, J.; Cui, H.; Wang, M.; Fu, X.; Wang, X.; Li, X.; Huang, H. Integrated biorefinery approaches for the industrialization of cellulosic ethanol fuel. Bioresour. Technol. 2022, 360, 127516. [Google Scholar] [CrossRef]

- Alhammad, A.; Adewale, P.; Kuttiraja, M.; Christopher, L.P. Enhancing enzyme-aided production of fermentable sugars from poplar pulp in the presence of non-ionic surfactants. Bioprocess Biosyst. Eng. 2018, 41, 1133–1142. [Google Scholar] [CrossRef]

- Rocha-Martín, J.; Martinez-Bernal, C.; Pérez-Cobas, Y.; Reyes-Sosa, F.M.; García, B.D. Additives enhancing enzymatic hydrolysis of lignocellulosic biomass. Bioresour. Technol. 2017, 244, 48–56. [Google Scholar] [CrossRef]

- Börjesson, J.; Peterson, R.; Tjerneld, F. Enhanced enzymatic conversion of softwood lignocellulose by poly(ethylene glycol) addition. Enzyme Microb. Technol. 2007, 40, 754–762. [Google Scholar] [CrossRef]

- Reis, C.E.R.; Libardi Junior, N.; Bento, H.B.S.; de Carvalho, A.K.F.; de Souza Vandenberghe, L.P.; Soccol, C.R.; Aminabhavi, T.M.; Chandel, A.K. Process strategies to reduce cellulase enzyme loading for renewable sugar production in biorefineries. Chem. Eng. J. 2023, 451, 138690. [Google Scholar] [CrossRef]

- Li, X.; Zheng, Y. Lignin-enzyme interaction: Mechanism, mitigation approach, modeling, and research prospects. Biotechnol. Adv. 2017, 35, 466–489. [Google Scholar] [CrossRef]

- Florencio, C.; Badino, A.C.; Farinas, C.S. Addition of Soybean Protein Improves Saccharification and Ethanol Production from Hydrothermally Pretreated Sugarcane Bagasse. Bioenergy Res. 2019, 12, 81–93. [Google Scholar] [CrossRef]

- Brondi, M.G.; Vasconcellos, V.M.; Giordano, R.C.; Farinas, C.S. Alternative Low-Cost Additives to Improve the Saccharification of Lignocellulosic Biomass. Appl. Biochem. Biotechnol. 2019, 187, 461–473. [Google Scholar] [CrossRef] [PubMed]

- Mesquita, J.F.; Ferraz, A.; Aguiar, A. Alkaline-sulfite pretreatment and use of surfactants during enzymatic hydrolysis to enhance ethanol production from sugarcane bagasse. Bioprocess Biosyst. Eng. 2016, 39, 441–448. [Google Scholar] [CrossRef]

- Cheng, J.; Yu, Y.; Zhu, M. Enhanced biodegradation of sugarcane bagasse by Clostridium thermocellum with surfactant addition. Green Chem. 2014, 16, 2689–2695. [Google Scholar] [CrossRef]

- He, L.; Han, Q.; Jameel, H.; Chang, H.M.; Phillips, R.; Wang, Z. Comparison of One-Stage Batch and Fed-Batch Enzymatic Hydrolysis of Pretreated Hardwood for the Production of Biosugar. Appl. Biochem. Biotechnol. 2018, 184, 1441–1452. [Google Scholar] [CrossRef]

- Zhang, J.; Chu, D.; Huang, J.; Yu, Z.; Dai, G.; Bao, J. Simultaneous saccharification and ethanol fermentation at high corn stover solids loading in a helical stirring bioreactor. Biotechnol. Bioeng. 2010, 105, 718–728. [Google Scholar] [CrossRef]

- Gomes, A.C.; Moysés, D.N.; Santa Anna, L.M.M.; Castro, A.M. Fed-batch strategies for saccharification of pilot-scale mild-acid and alkali pretreated sugarcane bagasse: Effects of solid loading and surfactant addition. Ind. Crop. Prod. 2018, 119, 283–289. [Google Scholar] [CrossRef]

- Ferreira, J.A.; Taherzadeh, M.J. Improving the economy of lignocellulose-based biorefineries with organosolv pretreatment. Bioresour. Technol. 2020, 299, 122695. [Google Scholar] [CrossRef]

- He, Y.; Bagley, D.M.; Leung, K.T.; Liss, S.N.; Liao, B.Q. Recent advances in membrane technologies for biorefining and bioenergy production. Biotechnol. Adv. 2012, 30, 817–858. [Google Scholar] [CrossRef]

- Guerrero, M. Portugal Biofuel Market Outlook 2017; USDA Foreign Agricultural Service: Global Agricultural Information Network: Madrid, Spain, 2017. [Google Scholar]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Lignocellulosic Biorefineries in Europe: Current State and Prospects. Trends Biotechnol. 2019, 37, 231–234. [Google Scholar] [CrossRef] [PubMed]

- Guigou, M.; Cabrera, M.N.; Vique, M.; Bariani, M.; Guarino, J.; Ferrari, M.D.; Lareo, C. Combined pretreatments of eucalyptus sawdust for ethanol production within a biorefinery approach. Biomass Convers. Biorefinery 2019, 9, 293–304. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Laboratory Analytical Procedure (LAP): Determination of Structural Carbohydrates and Lignin in Biomass. Available online: https://www.nrel.gov/docs/gen/fy13/42618.pdf (accessed on 27 October 2021).

- Adney, B.; Baker, J. Laboratory Analytical Procedure (LAP): Measurement of Cellulase Activities. Available online: https://www.nrel.gov/docs/gen/fy08/42628.pdf (accessed on 30 June 2019).

- Branco, R.H.R.; Amândio, M.S.T.; Serafim, L.S.; Xavier, A.M.R.B. Ethanol production from hydrolyzed kraft pulp by mono- and co-cultures of yeasts: The challenge of C6 and C5 sugars consumption. Energies 2020, 13, 744. [Google Scholar] [CrossRef]

- Raj, K.; Krishnan, C. Improved high solid loading enzymatic hydrolysis of low-temperature aqueous ammonia soaked sugarcane bagasse using laccase-mediator system and high concentration ethanol production. Ind. Crop. Prod. 2019, 131, 32–40. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, J.; Yuan, Z.; Zhang, Y.; Liu, Y.; Liang, C. Optimization of fed-batch enzymatic hydrolysis from alkali-pretreated sugarcane bagasse for high-concentration sugar production. Bioresour. Technol. 2014, 167, 41–45. [Google Scholar] [CrossRef]

- Kang, Q.; Appels, L.; Tan, T.; Dewil, R. Bioethanol from lignocellulosic biomass: Current findings determine research priorities. Sci. World J. 2014, 2014, 298153. [Google Scholar] [CrossRef]

- Oliveira, R.J.; Santos, B.; Mota, M.J.; Pereira, S.R.; Branco, P.C.; Pinto, P.C.R. The impact of acid hydrolysis conditions on carbohydrate determination in lignocellulosic materials: A case study with Eucalyptus globulus bark. Holzforschung 2021, 75, 957–967. [Google Scholar] [CrossRef]

- Pinto, P.C.R.; Oliveira, C.; Costa, C.A.E.; Rodrigues, A.E. Performance of Side-Streams from Eucalyptus Processing as Sources of Polysaccharides and Lignins by Kraft Delignification. Ind. Eng. Chem. Res. 2016, 55, 516–526. [Google Scholar] [CrossRef]

- Monrroy, M.; García, J.-R.; Mendonça, R.T.; Baeza, J.; Freer, J. Kraft pulping of Eucalyptus globulus as a pretreatment for bioethanol production by simultaneous saccharification and fermentation. J. Chil. Chem. Soc. 2012, 57, 1113–1117. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef]

- Ko, C.H.; Wang, Y.N.; Chang, F.C.; Chen, J.J.; Chen, W.H.; Hwang, W.S. Potentials of lignocellulosic bioethanols produced from hardwood in Taiwan. Energy 2012, 44, 329–334. [Google Scholar] [CrossRef]

- Buzała, K.P.; Kalinowska, H.; Małachowska, E.; Przybysz, P. The utility of selected kraft hardwood and softwood pulps for fuel ethanol production. Ind. Crop. Prod. 2017, 108, 824–830. [Google Scholar] [CrossRef]

- Troncoso, E.; Castillo, R.; Valenzuela, R.; Reyes, P.; Freer, J.; Norambuena, M.; Rodríguez, J.; Parra, C. Chemical and microstructural changes in Eucalyptus globulus fibers subjected to four different pretreatments and their influence on the enzymatic hydrolysis. J. Chil. Chem. Soc. 2017, 62, 3442–3446. [Google Scholar] [CrossRef]

- Buzała, K.; Przybysz, P.; Rosicka-Kaczmarek, J.; Kalinowska, H. Production of glucose-rich enzymatic hydrolysates from cellulosic pulps. Cellulose 2015, 22, 663–674. [Google Scholar] [CrossRef]

- Novozhilov, E.V.; Sinel’nikov, I.G.; Aksenov, A.S.; Chukhchin, D.G.; Tyshkunova, I.V.; Rozhkova, A.M.; Osipov, D.O.; Zorov, I.N.; Sinitsyn, A.P. Biocatalytic conversion of kraft pulp using cellulase complex of Penicillium verruculosum. Catal. Ind. 2016, 8, 95–100. [Google Scholar] [CrossRef]

- Pettersson, K.; Mahmoudkhani, M.; Schenck, A. Opportunities for Biorefineries in the Pulping Industry. In Systems Perspectives on Biorefineries; Sandén, B., Pettersson, K., Eds.; Chalmers University of Technology: Göteborg, Sweden, 2014; pp. 68–80. [Google Scholar]

- Chen, Y.-A.; Zhou, Y.; Qin, Y.; Liu, D.; Zhao, X. Evaluation of the action of Tween 20 non-ionic surfactant during enzymatic hydrolysis of lignocellulose: Pretreatment, hydrolysis conditions and lignin structure. Bioresour. Technol. 2018, 269, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Zhang, J.; Zhang, Y.; Guo, Y.; Xu, H.; Xu, J.; Wang, Z. Enhancement of high-solids enzymatic hydrolysis efficiency of alkali pretreated sugarcane bagasse at low cellulase dosage by fed-batch strategy based on optimized accessory enzymes and additives. Bioresour. Technol. 2019, 292, 121993. [Google Scholar] [CrossRef]

- Madadi, M.; Song, G.; Sun, F.; Sun, C.; Xia, C.; Zhang, E.; Karimi, K.; Tu, M. Positive role of non-catalytic proteins on mitigating inhibitory effects of lignin and enhancing cellulase activity in enzymatic hydrolysis: Application, mechanism, and prospective. Environ. Res. 2022, 215, 114291. [Google Scholar] [CrossRef]

- Saini, J.K.; Himanshu; Hemansi; Kaur, A.; Mathur, A. Strategies to enhance enzymatic hydrolysis of lignocellulosic biomass for biorefinery applications: A review. Bioresour. Technol. 2022, 360, 127517. [Google Scholar] [CrossRef]

- da Silva, A.S.; Espinheira, R.P.; Teixeira, R.S.S.; de Souza, M.F.; Ferreira-Leitão, V.; Bon, E.P.S. Constraints and advances in high-solids enzymatic hydrolysis of lignocellulosic biomass: A critical review. Biotechnol. Biofuels 2020, 13, 58. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, W.; Paice, M.G.; Saddler, J.N. High consistency enzymatic hydrolysis of hardwood substrates. Bioresour. Technol. 2009, 100, 5890–5897. [Google Scholar] [CrossRef] [PubMed]

- Singhania, R.; Patel, A.; Raj, T.; Tsai, M.-L.; Chen, C.-W.; Dong, C.-D. Advances and Challenges in Biocatalysts Application for High Solid-Loading of Biomass for 2nd Generation Bio-Ethanol Production. Catalysts 2022, 12, 615. [Google Scholar] [CrossRef]

- Chen, H.Z.; Liu, Z.H. Enzymatic hydrolysis of lignocellulosic biomass from low to high solids loading. Eng. Life Sci. 2017, 17, 489–499. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, Y.-Y.; Xu, J.-L.; Yuan, Z.-H.; Qi, W.; Zhuang, X.-S.; He, M.-C. High solid and low enzyme loading based saccharification of agricultural biomass. Bioresources 2012, 7, 345–353. [Google Scholar] [CrossRef]

- Shiva; Climent Barba, F.; Rodríguez-Jasso, R.M.; Sukumaran, R.K.; Ruiz, H.A. High-solids loading processing for an integrated lignocellulosic biorefinery: Effects of transport phenomena and rheology—A review. Bioresour. Technol. 2022, 351, 127044. [Google Scholar] [CrossRef]

- Hsieh, C.W.C.; Cannella, D.; Jørgensen, H.; Felby, C.; Thygesen, L.G. Cellulase inhibition by high concentrations of monosaccharides. J. Agric. Food Chem. 2014, 62, 3800–3805. [Google Scholar] [CrossRef]

- Xiao, Z.; Zhang, X.; Gregg, D.J.; Saddler, J.N. Effects of Sugar Inhibition on Cellulases and β-Glucosidase During Enzymatic Hydrolysis of Softwood Substrates. In Proceedings of the Twenty-Fifth Symposium on Biotechnology for Fuels and Chemicals, Applied Biochemistry and Biotechnology, Breckenridge, CO, USA, 4–7 May 2003; Humana Press: Totowa, NJ, USA, 2004; Volume 113–116, pp. 1115–1126. [Google Scholar]

- Rastogi, M.; Shrivastava, S. Recent advances in second generation bioethanol production: An insight to pretreatment, saccharification and fermentation processes. Renew. Sustain. Energy Rev. 2017, 80, 330–340. [Google Scholar] [CrossRef]

- Yang, M.; Li, W.; Liu, B.; Li, Q.; Xing, J. High-concentration sugars production from corn stover based on combined pretreatments and fed-batch process. Bioresour. Technol. 2010, 101, 4884–4888. [Google Scholar] [CrossRef]

- Liu, Z.H.; Chen, H.Z. Periodic peristalsis releasing constrained water in high solids enzymatic hydrolysis of steam exploded corn stover. Bioresour. Technol. 2016, 205, 142–152. [Google Scholar] [CrossRef]

- Hernández-Beltrán, J.U.; Hernández-Escoto, H. Enzymatic hydrolysis of biomass at high-solids loadings through fed-batch operation. Biomass Bioenergy 2018, 119, 191–197. [Google Scholar] [CrossRef]

- Wang, W.; Zhuang, X.; Yuan, Z.; Yu, Q.; Qi, W.; Wang, Q.; Tan, X. High consistency enzymatic saccharification of sweet sorghum bagasse pretreated with liquid hot water. Bioresour. Technol. 2012, 108, 252–257. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.H.; Park, H.M.; Kim, D.H.; Yang, J.; Kim, K.H. Fed-Batch Enzymatic Saccharification of High Solids Pretreated Lignocellulose for Obtaining High Titers and High Yields of Glucose. Appl. Biochem. Biotechnol. 2017, 182, 1108–1120. [Google Scholar] [CrossRef] [PubMed]

- Kossatz, H.L.; Rose, S.H.; Viljoen-Bloom, M.; van Zyl, W.H. Production of ethanol from steam exploded triticale straw in a simultaneous saccharification and fermentation process. Process. Biochem. 2017, 53, 10–16. [Google Scholar] [CrossRef]

- Demeke, M.M.; Dietz, H.; Li, Y.; Foulquié-Moreno, M.R.; Mutturi, S.; Deprez, S.; Den Abt, T.; Bonini, B.M.; Liden, G.; Dumortier, F.; et al. Development of a D-xylose fermenting and inhibitor tolerant industrial Saccharomyces cerevisiae strain with high performance in lignocellulose hydrolysates using metabolic and evolutionary engineering. Biotechnol. Biofuels 2013, 6, 89. [Google Scholar] [CrossRef]

- Fernandes-Klajn, F.; Romero-García, J.M.; Díaz, M.J.; Castro, E. Comparison of fermentation strategies for ethanol production from olive tree pruning biomass. Ind. Crop. Prod. 2018, 122, 98–106. [Google Scholar] [CrossRef]

- Amândio, M.S.T.; Rocha, J.M.S.; Serafim, L.S.; Xavier, A.M.R.B. Cellulosic Bioethanol from Industrial Eucalyptus globulus Bark Residues Using Kraft Pulping as a Pretreatment. Energies 2021, 14, 2185. [Google Scholar] [CrossRef]

- Malik, K.; Sharma, P.; Yang, Y.; Zhang, P.; Zhang, L.; Xing, X.; Yue, J.; Song, Z.; Nan, L.; Yujun, S.; et al. Lignocellulosic biomass for bioethanol: Insight into the advanced pretreatment and fermentation approaches. Ind. Crop. Prod. 2022, 188, 115569. [Google Scholar] [CrossRef]

- Cunha, J.T.; Soares, P.O.; Baptista, S.L.; Costa, C.E.; Domingues, L. Engineered Saccharomyces cerevisiae for lignocellulosic valorization: A review and perspectives on bioethanol production. Bioengineered 2020, 11, 883–903. [Google Scholar] [CrossRef]

- Díaz, M.J.; Moya, M.; Castro, E. Bioethanol Production from Steam-Exploded Barley Straw by Co-Fermentation with Escherichia coli SL100. Agronomy 2022, 12, 874. [Google Scholar] [CrossRef]

- Kemppainen, K.; Inkinen, J.; Uusitalo, J.; Nakari-Setälä, T.; Siika-aho, M. Hot water extraction and steam explosion as pretreatments for ethanol production from spruce bark. Bioresour. Technol. 2012, 117, 131–139. [Google Scholar] [CrossRef]

- Frankó, B.; Galbe, M.; Wallberg, O. Influence of bark on fuel ethanol production from steam-pretreated spruce. Biotechnol. Biofuels 2015, 8, 15–25. [Google Scholar] [CrossRef] [PubMed]

| Chemical Characterization (%, Dry Weight Basis) 1 | ||||

|---|---|---|---|---|

| Cellulose | Hemicelluloses | Klason Lignin | Acid-Soluble Lignin | Ashes |

| 79.8 ± 3.8 | 15.5 ± 0.6 | 1.5 ± 0.2 | 1.1 ± 0.1 | 2.1 ± 0.1 |

| Experiment | Sugars Concentration (g L−1) | Conversion Efficiency (%) |

|---|---|---|

| 8% (w/v) solids loading, 1 L | 82.0 | 96.4 |

| 11% (w/v) solids loading, 1 L | 106.0 | 90.7 |

| 14% (w/v) solids loading, 1 L | 124.1 | 83.4 |

| 11% (w/v) solids loading, 3 L | 101.1 | 85.8 |

| Fed-batch, 20% (w/v) solids loading, 3 L | 161.6 | 76.0 |

| Raw Material | Pretreatment | Enzymatic Consortium | Enzymatic Dosage | Solids Feeding (w/v) | Feeding Times (h) | Total Solids Loading (%) | Operation Time (h) | EH Conversion Efficiency (%) | Glucose (g L−1) | Xylose (g L−1) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| E. globulus bark | Kraft pulping | Cellic® CTec2 | 25 FPU gCH−1 | 11% + 3% + 3% + 3% | 0, 2, 4, 6 | 20 | 24 | 76.0 | 136.4 | 25.2 | This work |

| Sugarcane bagasse | Aqueous ammonia soaked | Cellic® CTec2 + Laccase + 1-HBT | 10 FPU gdry biomass−1 + 200 U gdry biomass−1 + 25 mg gdry biomass−1 | 12% + 8% + 5% + 5% + 5% + 5% | 0, 3, 8, 12, 24 | 40 | 96 | ~60 a | 157.65 | 57.12 | [43] |

| Sugarcane bagasse | Alkali | Cellic® CTec3 | 10 FPU gsubstrate−1 | 10% + 5% + 4% + 3% | 0, 8, 12, 16 | 22 | 72 | 82 * | 125 ± 1.8 | N.R. | [57] |

| Sugarcane bagasse | Alkali | Cellic® CTec2 | 10 FPU gsubstrate−1 | 12% + 7% + 7% + 7% | 0, 6, 12, 24 | 33 | 120 | ~60 | 129.50 | 56.03 | [44] |

| Sugarcane bagasse | NaOH | Accellerase® 1500 | 9.6 FPU gsolids−1 | 9% + 8% + 7% + 6% | 0, 8, 24, 48 | 30 | 144 | 55.07 * | 125.97 | 8.66 | [64] |

| Wheat straw | NaOH | Accellerase® 1500 | 9.6 FPU gsolids−1 | 9% + 8% + 7% + 6% | 0, 8, 24,48 | 30 | 144 | 39.38 * | 81.99 | 20.30 | [64] |

| Rice straw | Dilute maleic acid | Cellic® CTec2 | 15 FPU gglucan−1 | 10% + 10% + 10% | 0, 12, 24 | 30 | 60 | 76 * | 132.6 | N.R. | [73] |

| Corn stover | Steam explosion + NaOH-H2O2 | Cellulase from Trichoderma reesi | 20 FPU gsolids−1 | 12% + 6% + 6% + 6% | 0, 12, 36, 60 | 30 | 144 | 60 | 175 | 20 | [69] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amândio, M.S.T.; Rocha, J.M.S.; Xavier, A.M.R.B. Enzymatic Hydrolysis Strategies for Cellulosic Sugars Production to Obtain Bioethanol from Eucalyptus globulus Bark. Fermentation 2023, 9, 241. https://doi.org/10.3390/fermentation9030241

Amândio MST, Rocha JMS, Xavier AMRB. Enzymatic Hydrolysis Strategies for Cellulosic Sugars Production to Obtain Bioethanol from Eucalyptus globulus Bark. Fermentation. 2023; 9(3):241. https://doi.org/10.3390/fermentation9030241

Chicago/Turabian StyleAmândio, Mariana S. T., Jorge M. S. Rocha, and Ana M. R. B. Xavier. 2023. "Enzymatic Hydrolysis Strategies for Cellulosic Sugars Production to Obtain Bioethanol from Eucalyptus globulus Bark" Fermentation 9, no. 3: 241. https://doi.org/10.3390/fermentation9030241

APA StyleAmândio, M. S. T., Rocha, J. M. S., & Xavier, A. M. R. B. (2023). Enzymatic Hydrolysis Strategies for Cellulosic Sugars Production to Obtain Bioethanol from Eucalyptus globulus Bark. Fermentation, 9(3), 241. https://doi.org/10.3390/fermentation9030241