1. Introduction

Corn and soybean meal are the traditional component of poultry diets used to meet energy and protein requirements; however, the price continues to rise due to an imbalance between demand and production. Nutritional expenditure determines 50–70% of the cost of poultry production; an increase in the cost of feedstuff would lead to an increase in production costs, driving more public focus on cost-effective protein feedstuff [

1]. Studies have shown that many locally available ingredients can be used as soybean meal substitutes to meet the nutritional requirements of poultry, such as sunflower meal, rapeseed meal and cottonseed meal, which are commonly used [

2,

3,

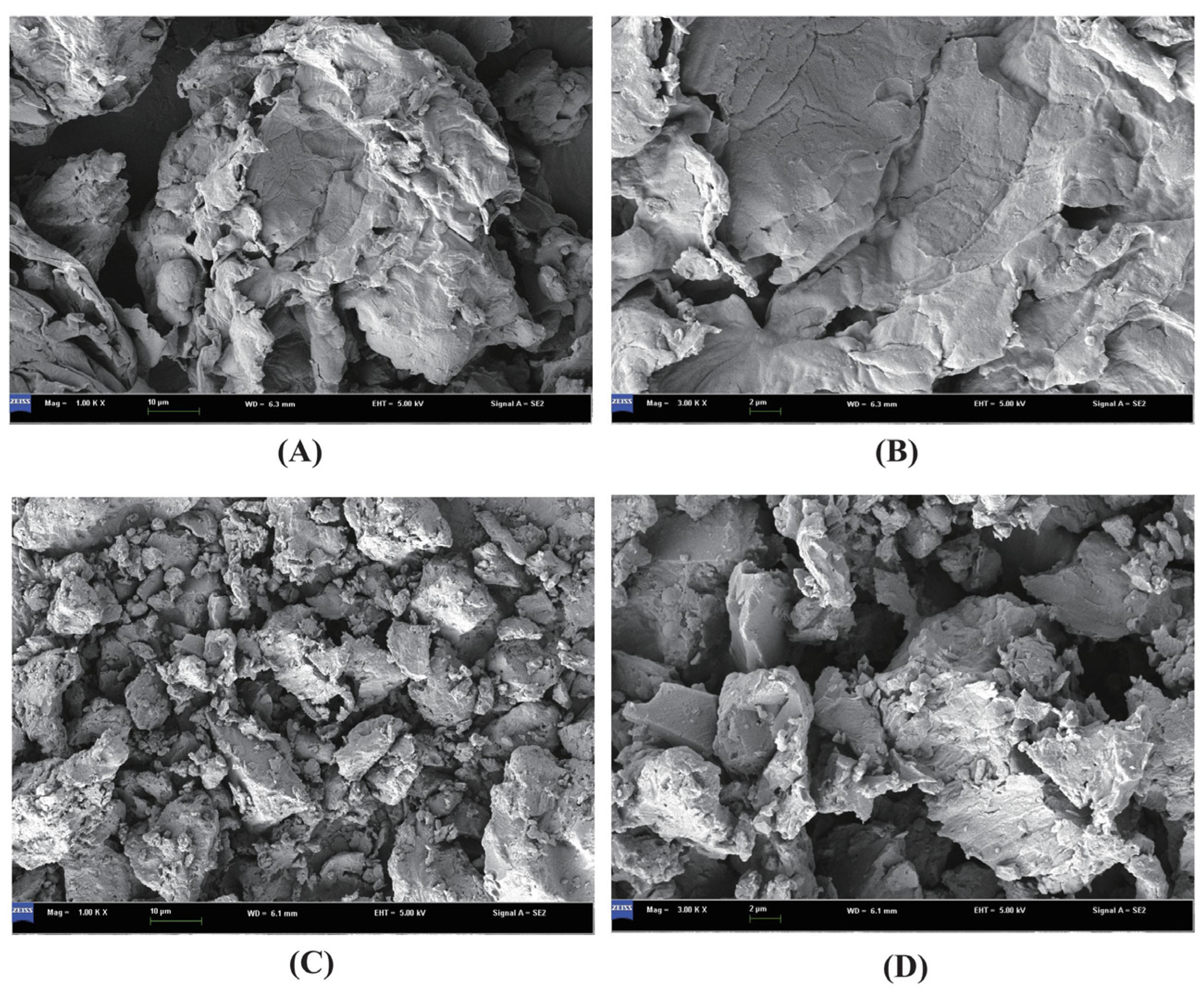

4]. Peanut meal (PNM) is a byproduct of peanut oil production by high temperature pressing, which is also a promising plant protein. It has a powdery or blocky morphology, with a strong peanut flavor that is comprised of 40.1–50.9% protein, 0.7–6.0% fat, 5.8–12.6% crude fiber, and also rich in vitamins, minerals, and antioxidant components (polyphenols, flavone). The nitrogen-corrected metabolic energy of broiler chickens is 9.6–12.6 MJ/kg [

5]. Although PNM can be fed to poultry directly, the imbalance in amino acid profiles limits its use in poultry feed, such as lower levels of lysine, threonine, and methionine and an excessively high arginine/lysine ratio (3.49), which is much higher than the National Research Council Nutrient Requirements of Poultry recommended ratio (1.10–1.18) [

6]. Studies have shown that excessive arginine may have negative effects on animal health and productivity [

7]. Additionally, phytic acid is the main anti-nutritional factor with a content of 1.50–2.00% in PNM, and it not only binds to metal ions, but connects to amino acid residues, which affects the absorption of nutrients by the organism [

8].

Aspergillus flavus and

Aspergillus parasiticus infections cause aflatoxin contamination in peanuts, which also limits the application of PNM in feed [

9].

Solid-state fermentation is the growth of microorganisms on solid materials under controlled conditions, which can also change the chemical or physical-chemical properties of the substrate [

10]. Recent studies have shown that solid-state fermentation of plant protein raw materials can improve nutritional properties. For instance, the contents of harmful compounds such as glucosinolates, non-starch polysaccharides, and phytates in rapeseed meal can be reduced by fermentation, and the indispensable nutrients are not lost in the process [

11,

12]. Jazi et al. [

13] also revealed crude fiber and free cotton phenol in cottonseed meal could be degraded by fermentation. Shi et al. [

14] reported that solid-state fermentation of corn-soybean meal mixed diets reduced the concentration of anti-nutritional factors β-soybean globulin and phytic acid while increasing the content of soluble protein. Li et al. [

15] reported the total amino acids content of fermented soybean meal increased by 2.56%, crude fiber and trypsin inhibitor decreased by 7.56% and 67.80%, respectively, and the standardized ileal digestibility (SID) of amino acids of broiler chickens increased significantly. Regarding PNM, previous studies found that solid-state fermentation improved the nutrient composition, and also degraded aflatoxin B

1 (AFB

1) [

16,

17]. Specifically, we hope to tackle the problem of imbalance in amino acid and anti-nutritional factors in PNM via solid-state fermentation, which requires the fermentation bacteria to have the capacity to hydrolyze proteins and depolymerize phytates. In our laboratory’s previous work,

Bacillus velezensis LB-Y-1 and

Pediococcus acidilactici LC-9-1 were screened out, and they have potential in this regard [

18].

As far as we know, few investigations have been performed on the nutritional value evaluation of FPNM in broiler chickens. In order to better understand the potential application of FPNM in broiler diets, it is necessary to comprehensively evaluate the nutritional value of it. Therefore, the purpose of this study is to analyze the changes of nutritional composition of PNM after solid-state fermentation. Additionally, we hypothesize that fermentation can improve the SID of amino acid and apparent metabolizable energy (AME) of PNM.

4. Discussion

China is currently the largest producer, consumer, and exporter of peanuts in the world. According to the report of the Food and Agriculture Organization of the United Nations of 2020, the annual peanut production was about 18 million tons in China, of which more than 50% (9 million tons) was used for crushing, which produced about 4.5–5.9 million tons of PNM [

29,

30]. In early studies, some negative effects of PNM were found, which limit its application. Costa et al. [

31] found that, due to the imbalance of amino acids, broilers fed on corn-peanut meal diets required additional supplementation of lysine, threonine, and methionine to achieve the same growth performance as corn-soybean meal diets. Xia et al. [

32] also found that replacing soybean meal with peanut meal in the diet reduced the egg production and antioxidant capacity of egg ducks.

Solid-state fermentation has been studied and applied in the food and feed industry for a long time. Its application can improve the nutritional value of the substrate, as well as produce organic acids, enzymes, and other beneficial metabolites in the body [

10,

33]. The present study found that fermentation changed the chemical composition of PNM. Yang et al. [

16] reported that the CP content increased by 6.96% after fermentation with

Bacillus licheniformis, which is close to 6.70% in this study. However, this was not an actual increase in protein content since no additional nitrogen sources were supplemented during fermentation. Hu et al. [

12] considered that the increase in CP content was mainly associated with a decrease in the concentration of non-structural carbohydrates, and the proportion of CP that was compensated for increased due to a decrease in dry matter content. Additionally, except for proteases, strains of

Bacillus spp. produce fiber-degrading enzymes, such as cellulases, hemicellulases, and β-glucanases [

34]. The decrease in CF content may be related to the fiber-degrading enzymes secreted by the bacteria used for fermentation.

TCA-SP is a parameter that indicates the degree of protein decomposition, mainly including small peptides with molecular weight less than 10 kDa; free amino acids; and small amounts of non-protein nitrogen compounds [

35]. Yang et al. [

16] reported that the content of TCA-SP in fermented PNM was increased by 400.37%, which was consistent with our findings. The positive effect of fermentation on protein of PNM facilitated protein utilization, and amino acids in the form of small molecular peptides were more easily transported by intestinal epithelial cells than their free form. The increase of L-latic acid content can lower the pH value of raw materials and resist the proliferation of mold and harmful microorganisms, which can prolong the storage time of the product and solve the problem that PNM is not easy to store [

36]. PNM contains many anti-nutritional factors such as phytic acid, trypsin inhibitor and plant hemagglutinin, among which phytic acid is an important factor for inhibiting the utilization of nutrients in PNM.

Bacillus subtilis,

Bacillus cereus, and other

Bacillus spp. can secrete phytase, which can hydrolyze phytic acid into inositol and phytate, and release nutrients such as amino acids and mineral elements combined with phytic acid in the process of enzymatic hydrolyzation, thus improving the utilization rate of nutrients in raw materials [

37,

38]. Our study found that the level of phytic acid in PNM was significantly reduced after the solid-state fermentation, which may be related to the production of phytase by microorganism. The study of Castro-Alba et al. [

39] showed that the fermentation of pseudocereal flours by

Lactobacillus degraded phytic acid and thus improved the utilization of mineral elements. Concomitantly, researchers also reported that phytase produced by microorganisms was selective for the degradation of phytic acid, and not all raw materials can achieve the same degradation efficiency, which suggested that we need to use effective microorganisms for fermentation. In this study, the degradation of phytic acid by microorganisms was not only due to the phytase, but also because the L-lactic acid produced by the

Pediococcus acidilactici reduced the pH value of PNM, and the change in pH value can provide conditions for the activation of microbial phytase and endogenous plant phytase [

40]. AFB

1 is the most carcinogenic of all natural toxins, and with a detection rate of nearly 100% in PNM [

41]. Through our experiments, we found that fermentation of PNM by

Bacillus velezensis and

Pediococcus acidilactici significantly reduced the level of AFB

1 in PNM and improved the quality of PNM. Probiotics generally clear AFB

1 by inhibiting spore formation of

Aspergillus flavus and

Aspergillus parasiticus, which produces AFB

1, or by enzymatic cleavage of the lactone ring of AFB

1 [

42,

43]

. For this study, both effects may be present simultaneously. Wang et al. [

44] have reported that

Bacillus velezensis has great potential as a feed additive to remove mycotoxins in animal feed. What’s more, the fermentation strain

Pediococcus acidilactici LC-9-1 used in this experiment has the function of inhibiting the proliferation of some pathogenic microorganisms [

18].

In this study, fermentation significantly increased the concentration of free amino acids in PNM, excluding arginine. The increase is based on the activity of peptidases, and is highly dependent on the microorganisms involved in fermentation [

45]. However, we also found a decrease in the concentration of serine and arginine as hydrolyzed amino acids, which may be related to the utilization of microorganisms. Similar to our results, in a study on solid-state fermentation of soybean meal, serine and arginine decreased by 22.04% and 21.73%, respectively [

15]. Compared to fish meal (0.76) and soybean meal (1.15), the ratio of arginine to lysine in PNM is 3.01, which is seriously imbalanced [

46]. Excessive arginine will lead to the antagonism of amino acids in animals and inhibit the absorption of lysine, and affect the normal growth and development of animals. We found that the lysine content of hydrolyzed amino acids in the FPNM was significantly increased by probiotics fermentation and the ratio of arginine to lysine was reduced to 1.6, making the amino acid composition of FPNM closer to the ideal amino acid composition.

The endogenous amino acid losses in broilers were corrected by the classical NFD method, and the result was similar to that in the report of Barua et al. [

47], which proved that the method was reasonable. Our experiment showed that the proportion of main endogenous amino acids such as glutamate, aspartic, threonine, and serine in ileum increased in broilers fed with FPNM [

48]. There are limited studies on the effect of FPNM on ileal amino acid digestibility in broiler chickens, but we have found in other studies on plant-based protein feedstuffs that rapeseed meal and soybean meal fermented by probiotics increase the AID and SID of most amino acids in broiler chickens, which is similar to our research in which the AID and SID of partial essential and non-essential amino acid were both increased in broilers fed FPNM [

15,

27]. Additionally, it was found that the digestibility of dry matter of PNM in vitro was increased by 10.18% after fermentation by

Bacillus licheniformis [

16]. The reason for the increase in amino acid digestibility may be related to the improvement of protein molecules in PNM after fermentation; more peptides and free amino acids were absorbed by the animal intestine, and the peptides also promoted the utilization of amino acids by the animal intestine [

49]. Furthermore, the fermentation by probiotics reduced the interference of crude fiber on the absorption of nutrients in PNM; specific manifestations include the decreased viscosity of digesta and better binding between digestive enzymes and substrates. These also promoted the digestibility of amino acids [

50]. Additionally, the decrease in the phytic acid level can also promote the digestion of amino acids. It’s well known that phytic acid combines with endogenous proteases (such as pepsin and trypsin) to form complexes that reduce amino acids digestibility, especially the AID of cysteine, aspartic acid and glycine, ultimately leading to lower feed conversion rates [

51,

52,

53]. As the limiting amino acids in livestock diets, the improvement in the digestibility of methionine and lysine can promote amino acid balance and utilization efficiency in diets [

54]. Moreover, amino acids balance can accurately predict the nutritional value of feedstuff and reduce the impact of unnecessary nitrogen emissions on environmental pollution, and also provide a new theory and method for the study of low protein diets. In this study, we obtained an AME of 10.68 MJ/kg for PNM, which was close to the value of 10.88 MJ/kg published in the Chinese Feed Composition and Nutritional Value (2019 version) [

55]. However, no significant difference was derived between PNM and FPNM for AME and ARGE. Similar to our results, Li et al. [

15] did not find a significant difference in AME between soybean meal and fermented soybean meal in broilers. The availability of energy in PNM and FPNM mainly depends on the balance of energy-yielding components in the feed and the factors that inhibit its utilization. Reduction in CF and anti-nutritional factors would favor the utilization of nutrients, and degraded CF was converted into disaccharides and eventually into glucose, which was more readily utilized by the body [

56,

57,

58]. However, fermentation itself is an energy-consuming process, in which the microorganisms consume carbon sources such as monosaccharides, disaccharides, oligosaccharides, starch, and cellulose from the substrate for proliferation and biotransformation [

59]. Thus, the energy that can be utilized by the body may not increase, which we believe has led to the absence of any difference in the AME of PNM and FPNM.