High-Efficient Production of Cellulosic Ethanol from Corn Fiber Based on the Suitable C5/C6 Co-Fermentation Saccharomyces cerevisiae Strain

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials, Cellulase, and Reagents

2.2. Strains and Mediums

2.3. Composition Analysis of Corn Fiber

2.4. Pretreatment and Enzymolysis of Corn Fiber

2.5. Detoxification Methods

2.6. Oxygen-Limited Shake Flask and Batch Fermentation

2.7. Analytical Methods

3. Results and Discussions

3.1. Corn Fiber Is Considered an Excellent Feedstock for Cellulosic Ethanol Production

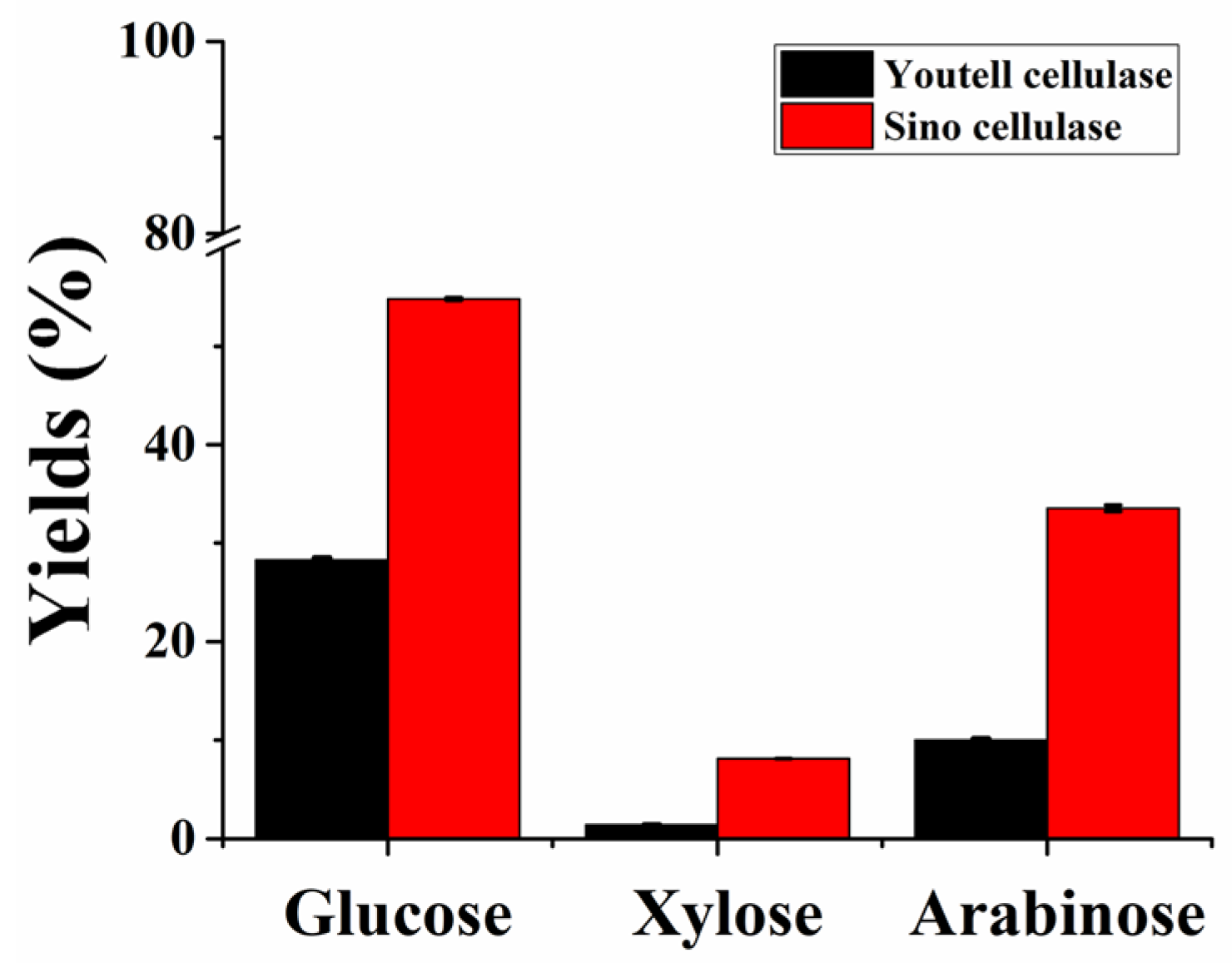

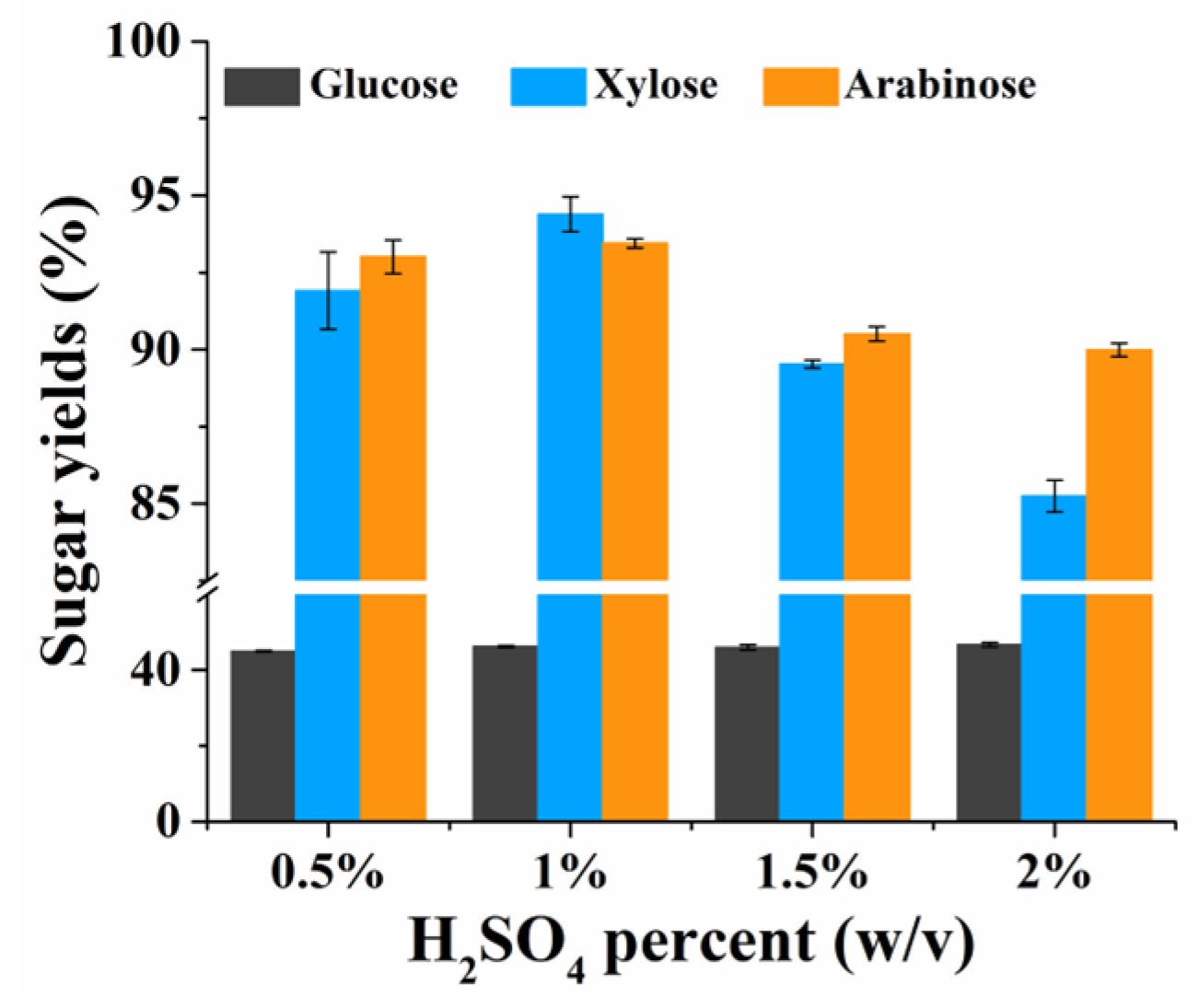

3.2. Optimization of Pretreatment and Enzymatic Hydrolysis Conditions of Corn Fiber

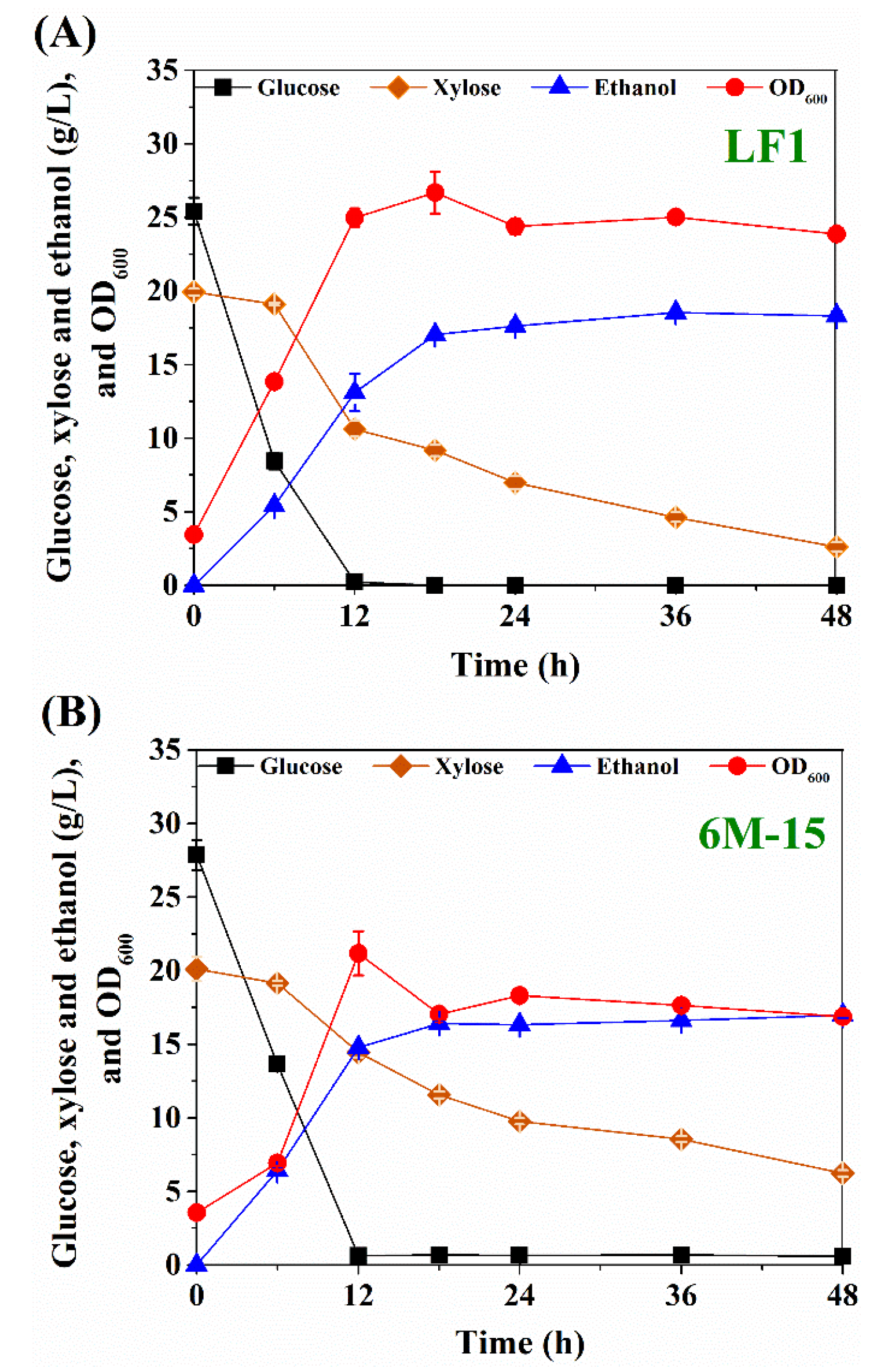

3.3. Ethanol Production from the Corn Fiber Hydrolysate by the C6/C5 Co-Fermenting S. Cerevisiae

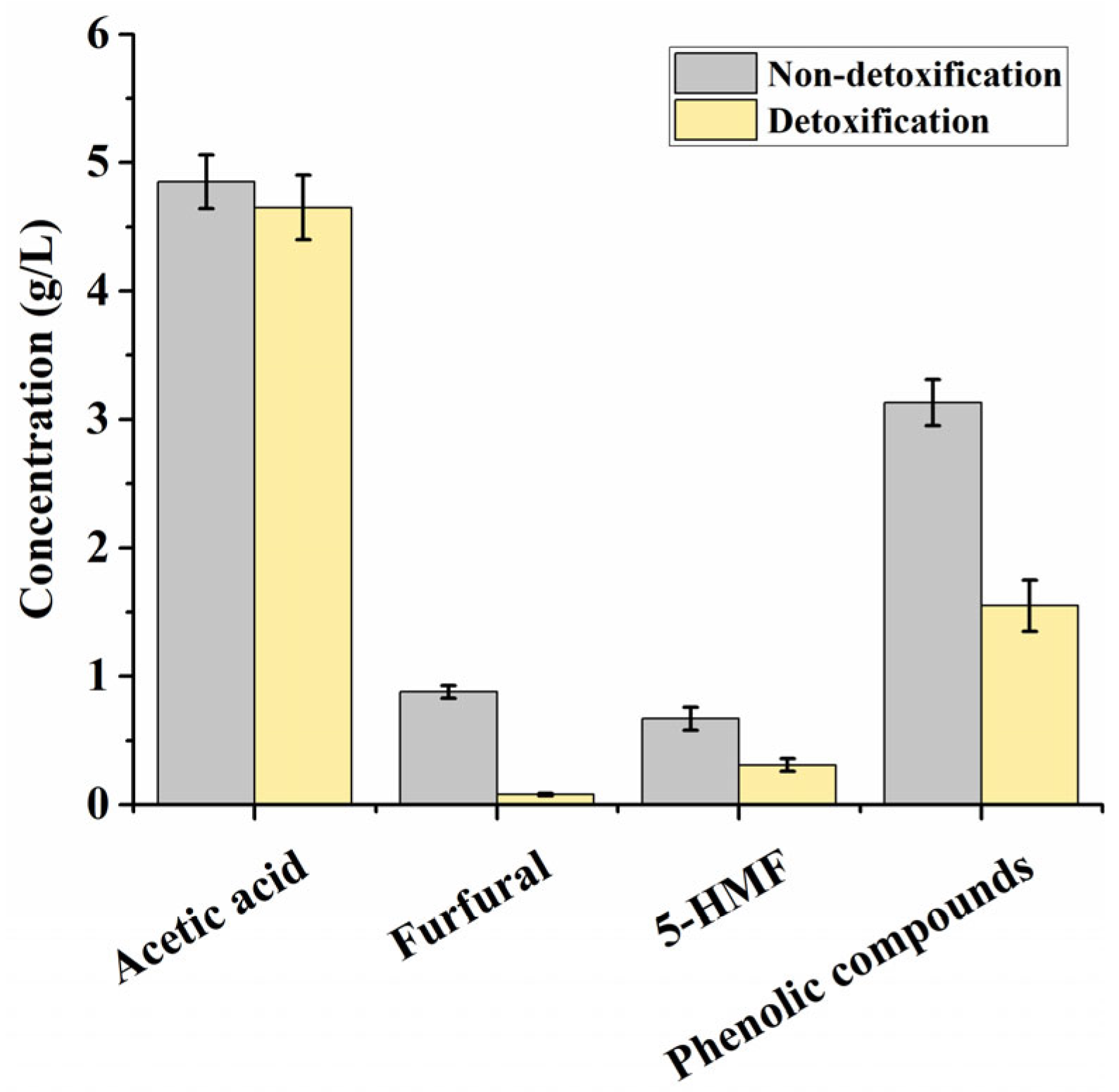

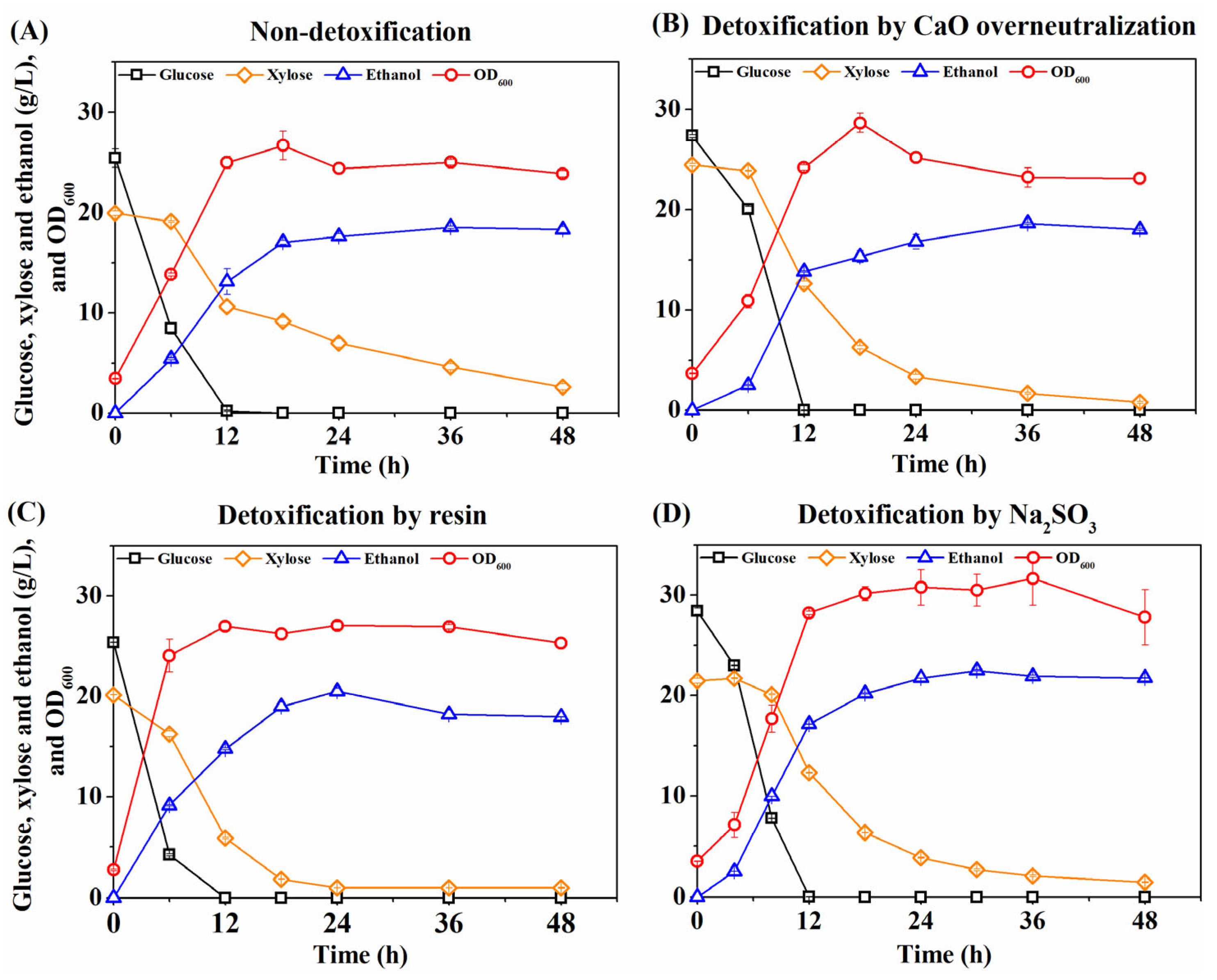

3.4. Different Detoxification Strategies Employed to Improve Fermentation Efficiency of Corn Fiber Hydrolysate

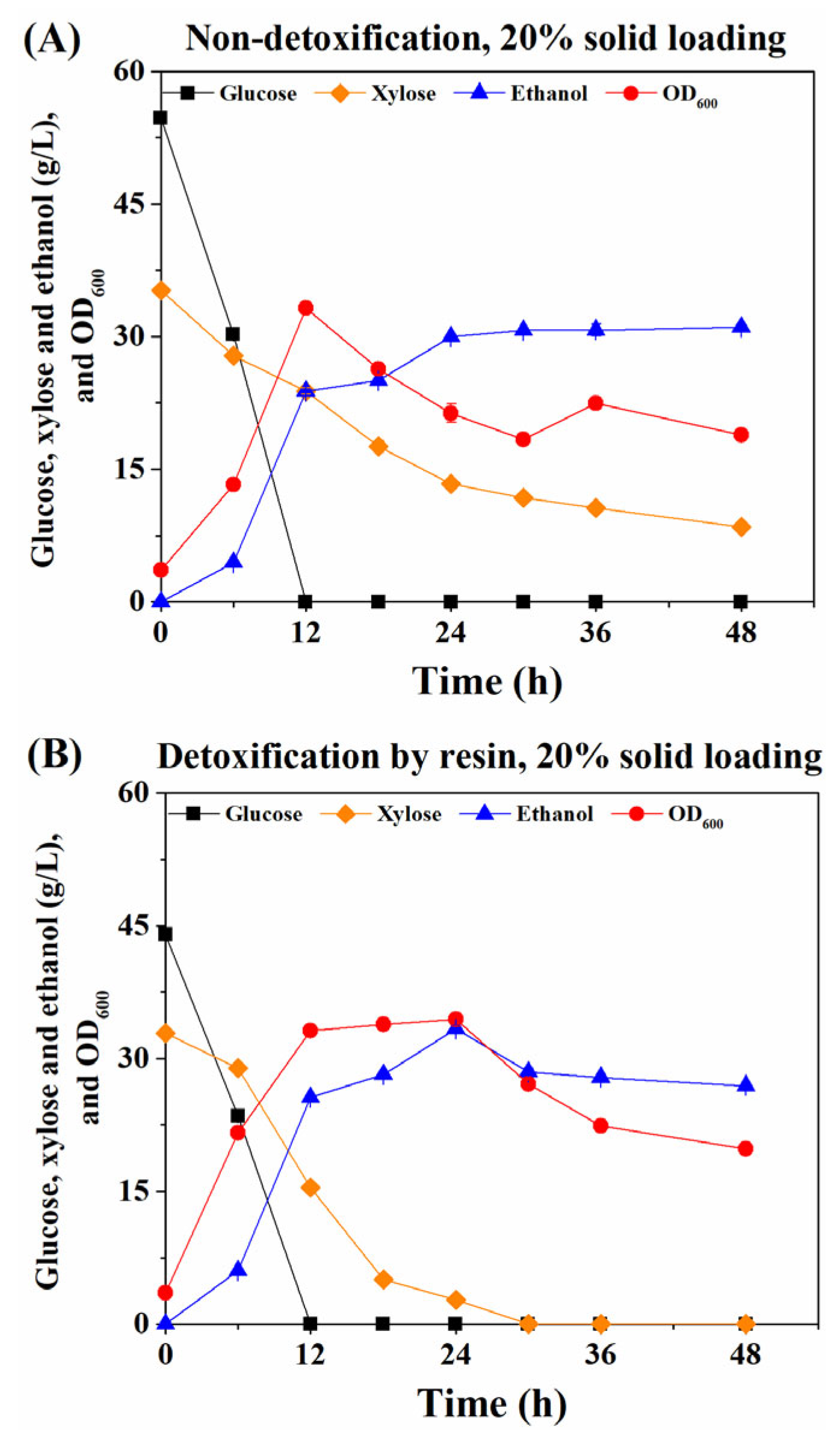

3.5. Increasing Solid Loading Leads to Higher Toxicity and Its Counteraction Strategies

3.6. 50 L Batch Fermentation of Corn Fiber Hydrolysate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Yildirim, O.; Ozkaya, B.; Altinbas, M.; Demir, A. Statistical optimization of dilute acid pretreatment of lignocellulosic biomass by response surface methodology to obtain fermentable sugars for bioethanol production. Int. J. Energy Res. 2021, 45, 8882–8899. [Google Scholar] [CrossRef]

- Ujor, V.C.; Okonkwo, C.C. Microbial detoxification of lignocellulosic biomass hydrolysates: Biochemical and molecular aspects, challenges, exploits and future perspectives. Front. Bioeng. Biotechnol. 2022, 10, 1061667. [Google Scholar] [CrossRef]

- Deshavath, N.N.; Mohan, M.; Veeranki, V.D.; Goud, V.V.; Pinnamaneni, S.R.; Benarjee, T. Dilute acid pretreatment of sorghum biomass to maximize the hemicellulose hydrolysis with minimized levels of fermentative inhibitors for bioethanol production. 3 Biotech. 2017, 7, 139. [Google Scholar] [CrossRef] [PubMed]

- Bukhari, N.A.; Luthfi, A.A.I.; Rahim, N.A.; Nasrin, A.B.; Sukiran, M.A.; Loh, S. Biomass Deacetylation at Moderate Solid Loading Improves Sugar Recovery and Succinic Acid Production. Fermentation 2023, 9, 235. [Google Scholar]

- Iqbal, Z.; Siddiqua, A.; Anwar, Z.; Munir, M. Valorization of Delonix regia Pods for Bioethanol Production. Fermentation 2023, 9, 289. [Google Scholar]

- Saini, J.K.; Himanshu; Hemansi; Kaur, A.; Mathur, A. Strategies to enhance enzymatic hydrolysis of lignocellulosic biomass for biorefinery applications: A review. Bioresour. Technol. 2022, 360, 127517. [Google Scholar] [CrossRef] [PubMed]

- Cui, P.; Ye, Z.; Chai, M.; Yuan, J.; Xiong, Y.; Yang, H.; Yao, L. Effective fractionation of lignocellulose components and lignin valorization by combination of deep eutectic solvent with ethanol. Front. Bioeng. Biotechnol. 2023, 10, 1115469. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chen, Y.; Gao, Y.; Mo, Y.; Long, T.; Yao, B.; Li, Y. Engineering Trichoderma reesei for the hyperproduction of cellulose induced protein 1 (Cip1) on a sophorose-containing inducer to efficiently saccharify alkali-pretreated corn stover. Prep. Biochem. Biotechnol. 2022, 53, 880–890. [Google Scholar] [CrossRef]

- Liu, T.; Huang, S.; Geng, A. Recombinant Diploid Saccharomyces cerevisiae Strain Development for Rapid Glucose and Xylose Co-Fermentation. Fermentation 2018, 4, 59. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Alriksson, B.; Nilvebrant, N.-O. Bioconversion of lignocellulose: Inhibitors and detoxification. Biotechnol. Biofuels 2013, 6, 16. [Google Scholar] [CrossRef]

- Stovicek, V.; Dato, L.; Almqvist, H.; Schöpping, M.; Chekina, K.; Pedersen, L.E.; Koza, A.; Figueira, D.; Tjosås, F.; Ferreira, B.S.; et al. Rational and evolutionary engineering of Saccharomyces cerevisiae for production of dicarboxylic acids from lignocellulosic biomass and exploring genetic mechanisms of the yeast tolerance to the biomass hydrolysate. Biotechnol. Biofuels Bioprod. 2022, 15, 22. [Google Scholar] [CrossRef]

- Anil, K.; Alexander, R.; Gotthard, K.; Sanjeev, K.; Davender, S.; Bijender, S. Multifarious pretreatment strategies for the lignocellulosic substrates for the generation of renewable and sustainable biofuels: A review. Renew. Energy 2020, 160, 1228–1252. [Google Scholar]

- Guo, Y.; Huang, J.; Xu, N.; Jia, H.; Li, X.; Zhao, J.; Qu, Y. A Detoxification-Free Process for Enhanced Ethanol Production from Corn Fiber Under Semi-Simultaneous Saccharification and Fermentation. Front. Microbiol. 2022, 13, 861918. [Google Scholar] [CrossRef]

- Manish, G.; Karen, K.; Michael, R.L.; Robert, H.; Rodney, J.B. Assessment of ethanol production options for corn products. Bioresour. Technol. 1996, 58, 253–264. [Google Scholar]

- Bothast, R.J.; Schlicher, M.A. Biotechnological processes for conversion of corn into ethanol. Appl. Microbiol. Biotechnol. 2005, 67, 19–25. [Google Scholar] [CrossRef]

- Bura, R.; Mansfield, S.D.; Saddler, J.N.; Bothast, R.J. SO2-catalyzed steam explosion of corn fiber for ethanol production. Appl. Biochem. Biotechnol. 2002, 98–100, 59–72. [Google Scholar] [CrossRef]

- Juneja, A.; Noordam, B.; Pel, H.; Basu, R.; Appeldoorn, M.; Singh, V. Optimization of two-stage pretreatment for maximizing ethanol production in 1.5G technology. Bioresour. Technol. 2021, 320, 124380. [Google Scholar] [CrossRef] [PubMed]

- Buruiană, C.T.; Georgescu, L.; Isticioaia, S.F.; Constantin, O.E.; Vizireanu, C.; Dinică, R.M.; Furdui, B. Insights on Monosaccharides and Bioethanol Production from Sweet Sorghum Stalks Using Dilute Acid Pretreatment. Processes 2020, 8, 1486. [Google Scholar] [CrossRef]

- Liu, S.; Yu, Y.; Xu, Z.; Chen, S.; Shen, G.; Yuan, X.; Deng, Q.; Shen, W.; Yang, S.; Zhang, C.; et al. Efficient Corncob Biorefinery for Ethanol Initiated by a Novel Pretreatment of Densifying Lignocellulosic Biomass with Sulfuric Acid. Fermentation 2022, 8, 661. [Google Scholar] [CrossRef]

- Du, J.; Liang, J.; Gao, X.; Liu, G.; Qu, Y. Optimization of an artificial cellulase cocktail for high-solids enzymatic hydrolysis of cellulosic materials with different pretreatment methods. Bioresour. Technol. 2020, 295, 122272. [Google Scholar] [CrossRef]

- Peng, B.; Shen, Y.; Li, X.; Chen, X.; Hou, J.; Bao, X. Improvement of xylose fermentation in respiratory-deficient xylose-fermenting Saccharomyces cerevisiae. Metab. Eng. 2011, 14, 9–18. [Google Scholar] [PubMed]

- Wei, F.; Li, M.; Wang, M.; Li, H.; Li, Z.; Qin, W.; Wei, T.; Zhao, J.; Bao, X. A C6/C5 co-fermenting Saccharomyces cerevisiae strain with the alleviation of antagonism between xylose utilization and robustness. GCB Bioenergy 2020, 13, 83–97. [Google Scholar]

- Li, H.; Shen, Y.U.; Wu, M.; Hou, J.; Jiao, C.; Li, Z.; Liu, X.; Bao, X. Engineering a wild-type diploid Saccharomyces cerevisiaestrain for second-generation bioethanol production. Bioresour. Bioprocess. 2016, 3, 51. [Google Scholar] [PubMed]

- Du, J.; Cao, Y.; Liu, G.; Zhao, J.; Li, X.; Qu, Y. Identifying and overcoming the effect of mass transfer limitation on decreased yield in enzymatic hydrolysis of lignocellulose at high solid concentrations. Bioresour. Technol. 2017, 229, 88–95. [Google Scholar]

- Liu, G.; Qin, Y.; Li, Z.; Qu, Y. Improving lignocellulolytic enzyme production with Penicillium: From strain screening to systems biology. Biofuels 2013, 4, 523–534. [Google Scholar]

- Leif, J.J.; Carlos, M. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar]

- Beri, D.; York, W.S.; Lynd, L.R.; Peña, M.J.; Herring, C.D. Development of a thermophilic coculture for corn fiber conversion to ethanol. Nat. Commun. 2020, 11, 1937. [Google Scholar]

- Cámara, E.; Olsson, L.; Zrimec, J.; Zelezniak, A.; Geijer, C.; Nygård, Y. Data mining of Saccharomyces cerevisiae mutants engineered for increased tolerance towards inhibitors in lignocellulosic hydrolysates. Biotechnol. Adv. 2022, 57, 107947. [Google Scholar]

- Björn, A.; Adnan, C.; Leif, J.J. Improving the fermentability of enzymatic hydrolysates of lignocellulose through chemical in-situ detoxification with reducing agents. Bioresour. Technol. 2010, 102, 1254–1263. [Google Scholar]

- Adnan, C.; Leif, J.J. Detoxification of lignocellulosic hydrolysates using sodium borohydride. Bioresour. Technol. 2013, 136, 368–376. [Google Scholar]

- Nilvebrant, N.-O.; Persson, P.; Reimann, A.; De, S.F.; Gorton, L.; Jönsson, L.J. Limits for alkaline detoxification of dilute-acid lignocellulose hydrolysates. Appl. Biochem. Biotechnol. 2003, 105–108, 615–628. [Google Scholar] [CrossRef]

- Yang, Y.; Lew, P.C. Detoxification of hemicellulose-rich poplar hydrolysate by polymeric resins for improved ethanol fermentability. Fuel 2017, 203, 187–196. [Google Scholar]

- Zhang, B.; Zhan, B.; Bao, J. Reframing biorefinery processing chain of corn fiber for cellulosic ethanol production. Ind. Crop. Prod. 2021, 170, 113791. [Google Scholar] [CrossRef]

- Myat, L.; Ryu, G.-H. Characteristics of destarched corn fiber extrudates for ethanol production. J. Cereal Sci. 2014, 60, 289–296. [Google Scholar]

- Shrestha, P.; Khanal, S.K.; Pometto, A.L., III; Hans van Leeuwen, J. Ethanolproduction via in situ fungal saccharification and fermentation of mild alkali andsteam pretreated corn fiber. Bioresour. Technol. 2010, 101, 8698–8705. [Google Scholar] [CrossRef] [PubMed]

| Components | Composition Contents (%, w/w) | |

|---|---|---|

| Raw corn fiber | Cellulose | 26.34 ± 1.29 |

| Hemicellulose | 37.64 ± 1.01 | |

| Starch | 17.28 ± 1.77 | |

| Crude protein | 10.68 ± 0.32 | |

| Lipids | 2.11 ± 0.36 | |

| Lignin | 2.06 ± 0.11 | |

| Ash | 0.19 ± 0.08 | |

| Others | 3.70 ± 0.22 | |

| Main sugars of the completely acid-treated corn fiber * | Glucose | 35.62 ± 0.11 |

| Xylose | 24.15 ± 0.09 | |

| Arabinose | 14.26 ± 0.21 |

| Components | Contents (g/L) for Different Reaction Times | ||

|---|---|---|---|

| 90 min | 120 min | 150 min | |

| Glucose * | 8.89 ± 0.52 | 13.54 ± 0.21 | 12.03 ± 0.32 |

| Xylose | 18.09 ± 0.64 | 22.20 ± 1.25 | 21.98 ± 0.98 |

| Arabinose | 11.15 ± 0.98 | 12.36 ± 0.54 | 12.27 ± 0.34 |

| Acetic acid | 2.13 ± 0.09 | 2.63 ± 0.21 | 2.72 ± 0.24 |

| Furfural * | 0.45 ± 0.07 | 0.53 ± 0.07 | 0.76 ± 0.04 |

| 5-HMF | 0.06 ± 0.02 | 0.08 ± 0.02 | 0.13 ± 0.03 |

| Pretreatment Stage | Enzymolysis Stage | Fermentation Stage | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pretreatment Conditions | Solid Loading (%) | Sugar Concentration (g/L) | Sugar Yield (%, w/w) | Dosage of Enzymes (per Gram Dry Matter) | Sugar Concentration (g/L) | Sugar yield (%, w/w) | Detoxification | Sugar Metabolic Rate (g L −1 h −1) | Ethanol Yield (g/g) | References |

| 8% Citric acid (w/w); 165 °C; 2 min | 25 | Glucose ~5.00, xylose ~12.75 | Glucose 6.40, xylose 68.90 | 10 FPU CTec 2.0 | Glucose 94.10, xylose 30.90 | Biodetoxification | 1.60 | ~0.44 | [33] | |

| Extrusion; melt temperature 140 °C | ~7 | Glucose 10.04, xylose 15.10 | Glucose 12.76, xylose 68.90 | ~5.9 FPU celluclast; 38 CBU β-glucosidase; 1 FBG viscozyme L | None | ~0.88 | 0.45 | [34] | ||

| 0.5% H2SO4 (w/v); 105 °C; 43 min | 20 | Glucose 4.60, xylose 3.92 | Glucose 10.5, xylose 38.3 | 10 FPU MCAX | Glucose ~54.00, xylose ~22.00 | Glucose 95.50, xylose 72.40 | None | ~0.70 | 0.41 | [13] |

| 2% NaOH (w/w); 30 °C; 2 h; | 20 | Glucose ~10.20, xylose ~1.60 | Glucose ~16.41, xylose ~3.61 | ~15 FPU spezyme CP | Glucose ~23.40, xylose ~2.36 | Glucose ~37.64, xylose ~5.32 | Water washing | ~0.18 | ~0.21 | [35] |

| Hot water; 180 °C; 10 min; wet disk milling | 20 | Glucose ~7.00, xylose ~12.00 | Glucose 88.50, xylose 41.00 | 0.05 g cellulase | Glucose ~46.44, xylose ~27.08 | Glucose 94.90, xylose 74.20 | None | ~0.37 | [17] | |

| 0.5% H2SO4 (w/v); 115 °C; 120 min | 10 | Glucose 13.54, xylose 20.72 | Glucose 43.56, xylose 93.38 | 10 FPU Youtell | Glucose 28.03, xylose 21.07 | Glucose 90.19 xylose 94.95 | 5 mM Na2SO3 | 1.57 | 0.48 | This study |

| 0.5% H2SO4 (w/v); 115 °C; 120 min | 20 | Glucose 18.15, xylose 35.88 | Glucose 29.20, xylose 80.85 | 10 FPU Youtell | Glucose 52.13, xylose 37.19 | Glucose 83.86, xylose 83.80 | Ion exchange resin | 2.24 | 0.47 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Xu, F.; Zhao, Y.; Sun, D.; Liu, J.; Yin, X.; Li, Z.; Zhao, J.; Li, H.; Bao, X. High-Efficient Production of Cellulosic Ethanol from Corn Fiber Based on the Suitable C5/C6 Co-Fermentation Saccharomyces cerevisiae Strain. Fermentation 2023, 9, 743. https://doi.org/10.3390/fermentation9080743

Li M, Xu F, Zhao Y, Sun D, Liu J, Yin X, Li Z, Zhao J, Li H, Bao X. High-Efficient Production of Cellulosic Ethanol from Corn Fiber Based on the Suitable C5/C6 Co-Fermentation Saccharomyces cerevisiae Strain. Fermentation. 2023; 9(8):743. https://doi.org/10.3390/fermentation9080743

Chicago/Turabian StyleLi, Menglei, Fadi Xu, Yuping Zhao, Dongming Sun, Jiao Liu, Xiaolong Yin, Zailu Li, Jianzhi Zhao, Hongxing Li, and Xiaoming Bao. 2023. "High-Efficient Production of Cellulosic Ethanol from Corn Fiber Based on the Suitable C5/C6 Co-Fermentation Saccharomyces cerevisiae Strain" Fermentation 9, no. 8: 743. https://doi.org/10.3390/fermentation9080743

APA StyleLi, M., Xu, F., Zhao, Y., Sun, D., Liu, J., Yin, X., Li, Z., Zhao, J., Li, H., & Bao, X. (2023). High-Efficient Production of Cellulosic Ethanol from Corn Fiber Based on the Suitable C5/C6 Co-Fermentation Saccharomyces cerevisiae Strain. Fermentation, 9(8), 743. https://doi.org/10.3390/fermentation9080743