Real-Time Discrimination and Quality Evaluation of Black Tea Fermentation Quality Using a Homemade Simple Machine Vision System

Abstract

:1. Introduction

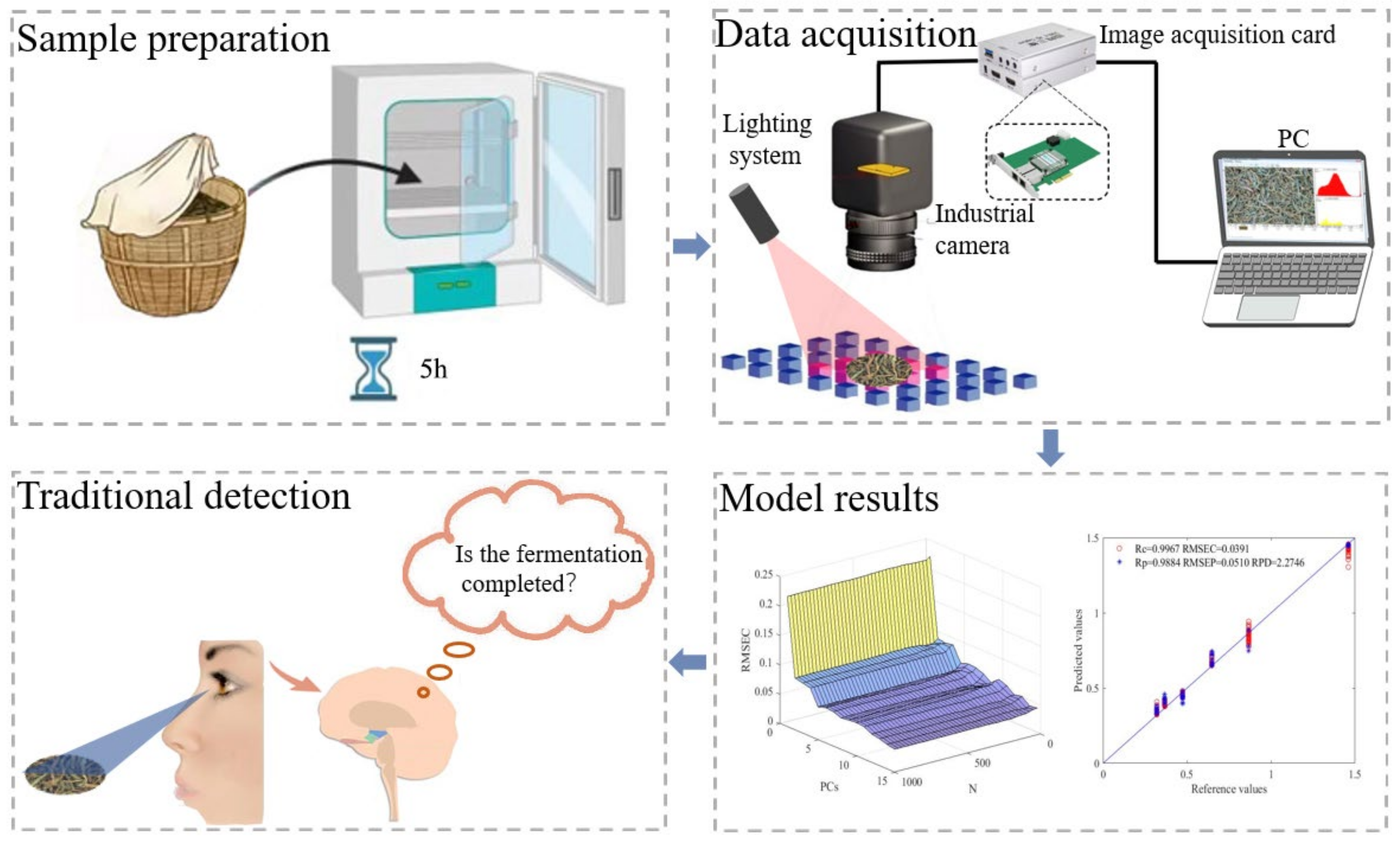

2. Materials and Methods

2.1. Sample Preparation

2.2. Detection of Catechin Components and Thearubigin Content

2.3. Machine Vision System Construction and Data Acquisition

2.4. Data Processing

2.5. The Model Evaluation Indicators

3. Results and Discussion

3.1. Results of Physicochemical and Correlation Analysis of Samples

3.2. Response of Color Variables in the Black Tea Fermentation Process

3.3. Data Preprocessing Results and PCA

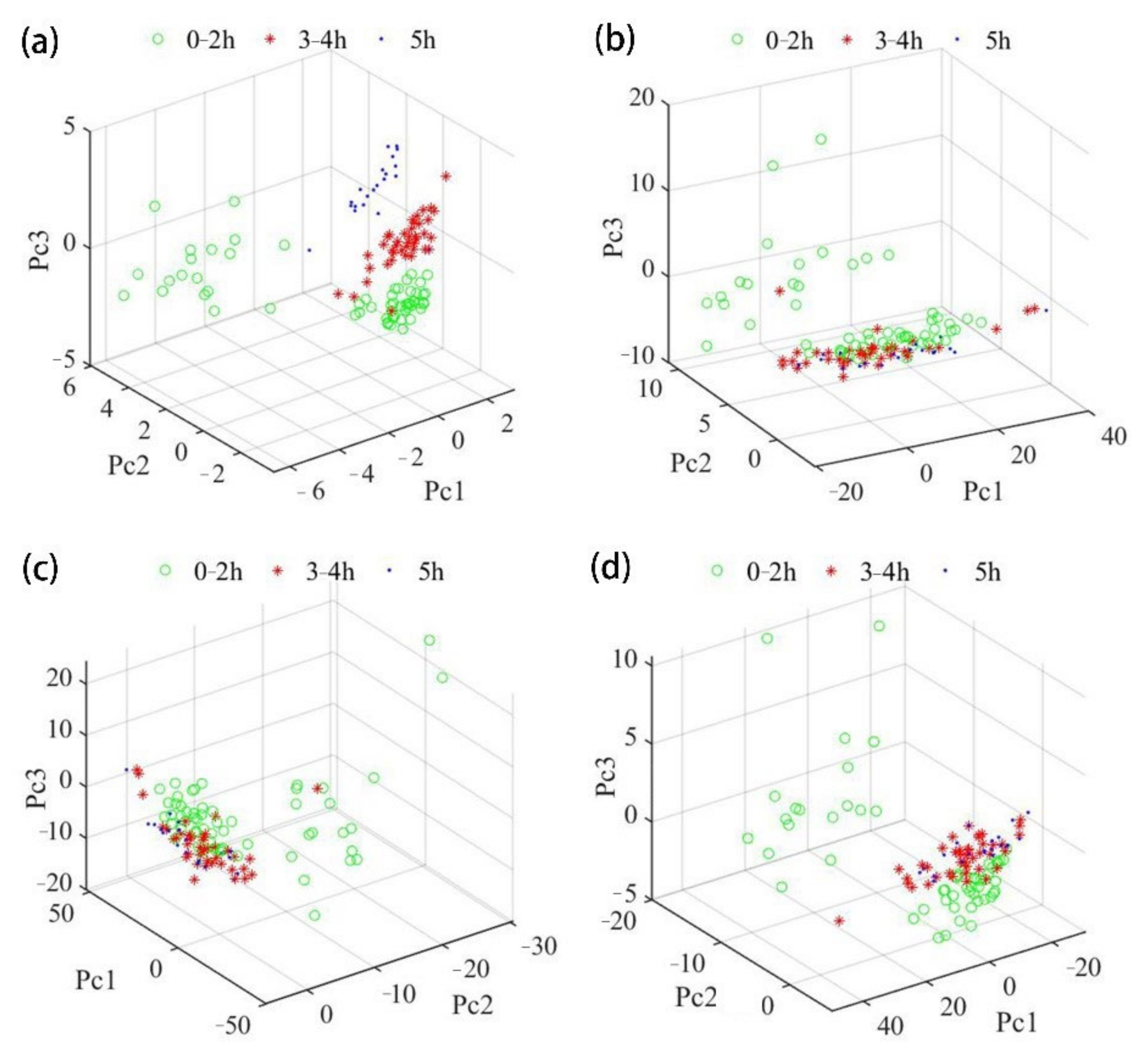

3.4. KNN and RF Model Discrimination Results

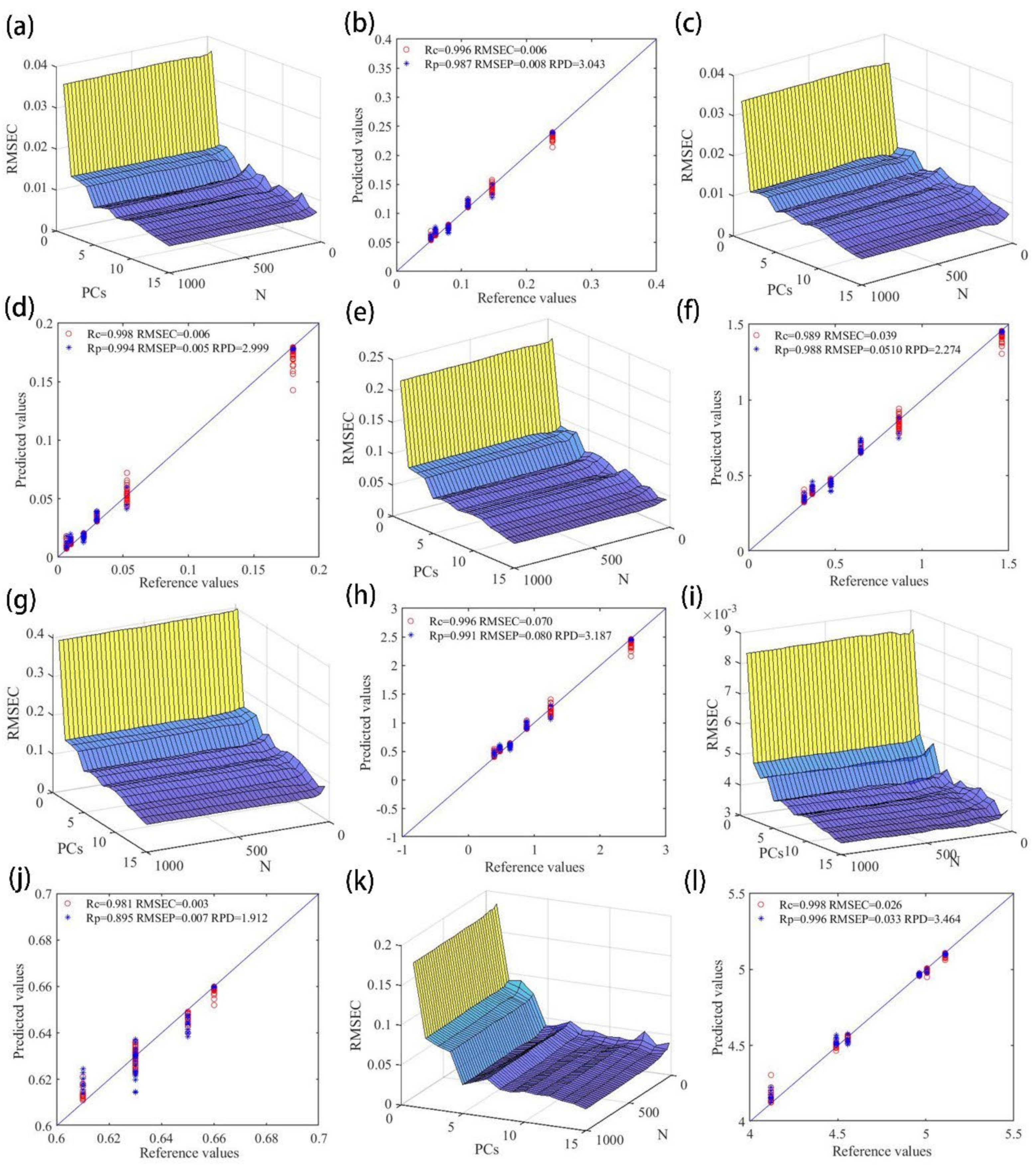

3.5. Prediction Results of the Catechin Fraction and Thearubigin Content by the PLS and RF Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C.-S.; Dong, C.-W.; Jiang, Y.-W.; An, T.; Zhao, Y. A Method for Judging the Fermentation Quality of Congou Based on Hyperspectral. Spectrosc. Spectr. Anal. 2021, 41, 1320–1328. [Google Scholar]

- Dong, C.; Yang, C.; Liu, Z.; Zhang, R.; Yan, P.; An, T.; Li, Y. Nondestructive Testing and Visualization of Catechin Content in Black Tea Fermentation Using Hyperspectral Imaging. Sensors 2021, 21, 8051. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; Ye, Y.; Yang, C.; An, T.; Jiang, Y.; Ye, Y.; Yang, Y. Rapid detection of catechins during black tea fermentation based on electrical properties and chemometrics. Food Biosci. 2021, 40, 100855. [Google Scholar] [CrossRef]

- An, T.; Li, Y.; Tian, X.; Fan, S.; Duan, D.; Zhao, C.; Dong, C. Evaluation of aroma quality using multidimensional olfactory information during black tea fermentation. Sens. Actuators B-Chem. 2022, 371, 132518. [Google Scholar] [CrossRef]

- Jia, H.; Yuan, W.; Ren, Z.; Ning, J.; Xu, Y.-Q.; Wang, Y.; Deng, W.-W. Cost-effective and sensitive indicator-displacement array (IDA) assay for quality monitoring of black tea fermentation. Food Chem. 2023, 403, 134340. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Gouda, M.; Perumal, A.B.; Huang, Z.; Lin, L.; Tang, Y.; Dong, C. Using surface-enhanced Raman spectroscopy combined with chemometrics for black tea quality assessment during its fermentation process. Sens. Actuators B-Chem. 2022, 373, 132680. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, Y.; An, T.; Liu, Z.; Jiang, Y.; Li, Y.; Dong, C. Quantitative prediction and visualization of key physical and chemical components in black tea fermentation using hyperspectral imaging. LWT-Food Sci. Technol. 2021, 141, 110975. [Google Scholar] [CrossRef]

- Wang, Z.; Ahmad, W.; Zhu, A.; Geng, W.; Kang, W.; Ouyang, Q.; Chen, Q. Identification of volatile compounds and metabolic pathway during ultrasound-assisted kombucha fermentation by HS-SPME-GC/MS combined with metabolomic analysis. Ultrason. Sonochemistry 2023, 94, 106339. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, Z.; Chen, Y.; Lu, C.; Deng, W.W.; Zhang, Z.; Ning, J. Visualizing chemical indicators: Spatial and temporal quality formation and distribution during black tea fermentation. Food Chem. 2023, 401, 134090. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, R.; Yang, C.; Hu, B.; Luo, X.; Li, Y.; Dong, C. Research on moisture content detection method during green tea processing based on machine vision and near-infrared spectroscopy technology. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2022, 271, 120921. [Google Scholar] [CrossRef]

- Ren, G.; Wu, R.; Yin, L.; Zhang, Z. Intelligent Evaluation of the Appearance Modality of Black Tea Based on Machine Vision and Hyperspectral Imaging. Anal. Lett. 2023, 22, 1706. [Google Scholar] [CrossRef]

- Huang, Z.; Sanaeifar, A.; Tian, Y.; Liu, L.; Zhang, D.; Wang, H.; Li, X. Improved generalization of spectral models associated with Vis-NIR spectroscopy for determining the moisture content of different tea leaves. J. Food Eng. 2021, 293, 110374. [Google Scholar] [CrossRef]

- Sanaeifar, A.; Li, X.; He, Y.; Huang, Z.; Zhan, Z. A data fusion approach on confocal Raman microspectroscopy and electronic nose for quantitative evaluation of pesticide residue in tea. Biosyst. Eng. 2021, 210, 206–222. [Google Scholar] [CrossRef]

- Xu, J.; Qu, F.; Shen, B.; Huang, Z.; Li, X.; Weng, H.; Wu, R. Rapid Detection of Tea Polyphenols in Fresh Tea Leaves Based on Fusion of Visible/Short-Wave and Long-Wave near Infrared Spectroscopy and Its Device Development. Appl. Sci. 2023, 13, 1739. [Google Scholar] [CrossRef]

- Zhao, S.; Adade, S.Y.-S.S.; Wang, Z.; Wu, J.; Jiao, T.; Li, H.; Chen, Q.X. On-line monitoring of total sugar during kombucha fermentation process by near-infrared spectroscopy: Comparison of linear and non-linear multiple calibration methods. Food Chem. 2023, 423, 136208. [Google Scholar] [CrossRef]

- Dai, F.; Shi, J.; Yang, C.; Li, Y.; Zhao, Y.; Liu, Z.; Dong, C. Detection of anthocyanin content in fresh Zijuan tea leaves based on hyperspectral imaging. Food Control. 2023, 152, 109839. [Google Scholar] [CrossRef]

- Yin, H.; Ma, F.; Wang, D.; He, X.; Yin, Y.; Song, C.; Zhao, L. Establishing a Prediction Model for Tea Leaf Moisture Content Using the Free-Space Method’s Measured Scattering Coefficient. Agriculture 2023, 13, 1136. [Google Scholar] [CrossRef]

- Geng, D.; Chen, X.; Lu, D.; Chen, B. Discrimination of different edible vegetable oils based on GC-IMS and SIMCA. Cyta-J. Food 2023, 21, 49–56. [Google Scholar] [CrossRef]

- Wu, J.; Zareef, M.; Chen, Q.; Ouyang, Q. Application of visible-near infrared spectroscopy in tandem with multivariate analysis for the rapid evaluation of matcha physicochemical indicators. Food Chem. 2023, 421, 136185. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.; Ye, Y.; Wang, Y.; Xu, P. Structural insight into polyphenol oxidation during black tea fermentation. Food Chem.-X 2023, 17, 100615. [Google Scholar] [CrossRef]

- Liu, C.; Lin, H.; Wang, K.; Zhang, Z.; Huang, J.; Liu, Z. Study on the Trend in Microbial Changes during the Fermentation of Black Tea and Its Effect on the Quality. Foods 2023, 12, 1944. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Wang, Y.; Cui, Q.; Liu, Y.; Ning, J.; Zhang, Z. Qualitative and quantitative quality evaluation of black tea fermentation through noncontact chemical imaging. J. Food Compos. Anal. 2022, 106, 104300. [Google Scholar] [CrossRef]

- Liang, G.; Dong, C.; Hu, B.; Zhu, H.; Yuan, H.; Jiang, Y.; Hao, G. Prediction of Moisture Content for Congou Black Tea Withering Leaves Using Image Features and Nonlinear Method. Sci. Rep. 2018, 8, 7854. [Google Scholar] [CrossRef]

- Bhargava, A.; Bansal, A.; Goyal, V.; Shukla, A. Machine learning & computer vision-based optimum black tea fermentation detection. Multimed. Tools Appl. 2023, 15453. [Google Scholar] [CrossRef]

- Flores-Vidal, P.; Gomez, D.; Castro, J.; Montero, J. New Aggregation Approaches with HSV to Color Edge Detection. Int. J. Comput. Intell. Syst. 2022, 15, 78. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, Z.; Zhang, Y.; Huang, H.; Ou, X.; Sun, Y. Identification of Key Components Responsible for the Aromatic Quality of Jinmudan Black Tea by Means of Molecular Sensory Science. Foods 2023, 12, 1794. [Google Scholar] [CrossRef]

- Li, L.; Li, M.; Cui, Q.; Liu, Y.; Chen, Y.; Wang, Y.; Ning, J. Rapid monitoring of black tea fermentation quality based on a solution-phase sensor array combined with UV-visible spectroscopy. Food Chem. 2022, 377, 131974. [Google Scholar] [CrossRef]

- Dos Santos Freitas, M.M.; Barbosa, J.R.; dos Santos Martins, E.M.; da Silva Martins, L.H.; Farias, F.d.S.; Henriques Lourenco, L.d.F.; da Silva e Silva, N. KNN algorithm and multivariate analysis to select and classify starch films. Food Packag. Shelf Life 2022, 34, 100976. [Google Scholar] [CrossRef]

- Chen, J.; Liu, H.; Li, T.; Wang, Y. Edibility and species discrimination of wild bolete mushrooms using FT-NIR spectroscopy combined with DD-SIMCA and RF models. LWT-Food Sci. Technol. 2023, 180, 114701. [Google Scholar] [CrossRef]

- Akram, U.; Sahar, A.; Sameen, A.; Muhammad, N.; Ahmad, M.H.; Khan, M.I.; Rahman, H.U.U. Use of Fourier transform infrared spectroscopy and multi-variant analysis for detection of butter adulteration with vegetable oil. Int. J. Food Prop. 2023, 26, 167–178. [Google Scholar] [CrossRef]

- Putri, L.A.; Rahman, I.; Puspita, M.; Hidayat, S.N.; Dharmawan, A.B.; Rianjanu, A.; Wasisto, H.S. Rapid analysis of meat floss origin using a supervised machine learning-based electronic nose towards food authentication. NPJ Sci. Food 2023, 7, 31. [Google Scholar] [CrossRef] [PubMed]

- Xiao, M.; Chen, Y.; Zheng, F.; An, Q.; Xiao, M.; Wang, H.; Dai, Q. Predicting the storage time of green tea by myricetin based on surface-enhanced Raman spectroscopy. NPJ Sci. Food 2023, 7, 28. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; An, T.; Zhu, H.; Wang, J.; Hu, B.; Jiang, Y.; Li, J. Rapid Sensing of Key Quality Components in Black Tea Fermentation Using Electrical Characteristics Coupled to Variables Selection Algorithms. Sci. Rep. 2020, 10, 1598. [Google Scholar] [CrossRef] [PubMed]

| The Models’ Ferment Quality NC | The Discrimination Results of the Correction Set | NP | The Discrimination Results of the Prediction Set | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Discrimination/% | 1 | 2 | 3 | Discrimination/% | ||||

| KNN | 1 | 48 | 47 | 1 | 0 | 96.88% | 12 | 11 | 1 | 0 | 91.65% |

| 2 | 32 | 30 | 1 | 1 | 8 | 7 | 1 | 0 | |||

| 3 | 16 | 0 | 0 | 16 | 4 | 4 | 0 | 0 | |||

| RF | 1 | 48 | 48 | 0 | 0 | 100% | 12 | 12 | 0 | 0 | 100% |

| 2 | 32 | 0 | 32 | 0 | 8 | 0 | 8 | 0 | |||

| 3 | 16 | 0 | 1 | 16 | 4 | 0 | 0 | 4 | |||

| Quality Index | Methods | VariableNumber | PCs | Calibration Set | Prediction Set | |||

|---|---|---|---|---|---|---|---|---|

| Rc | RMSECV | Rp | RMSEP | RPD | ||||

| C | Zscore-PLS | 18 | 8 | 0.875 | 0.047 | 0.837 | 0.055 | 1.475 |

| Zscore-RF | 18 | 6 | 0.996 | 0.006 | 0.987 | 0.008 | 3.043 | |

| EC | Zscore-PLS | 18 | 7 | 0.910 | 0.028 | 0.898 | 0.032 | 1.541 |

| Zscore-RF | 18 | 7 | 0.998 | 0.006 | 0.994 | 0.005 | 2.999 | |

| ECG | Zscore-PLS | 18 | 6 | 0.902 | 0.113 | 0.885 | 0.169 | 1.411 |

| Zscore-RF | 18 | 3 | 0.989 | 0.039 | 0.988 | 0.051 | 2.274 | |

| EGCG | Zscore-PLS | 18 | 4 | 0.898 | 0.341 | 0.852 | 0.447 | 1.243 |

| Zscore-RF | 18 | 3 | 0.996 | 0.070 | 0.991 | 0.080 | 3.187 | |

| EGC | Zscore-PLS | 18 | 6 | 0.934 | 0.052 | 0.847 | 0.086 | 1.227 |

| Zscore-RF | 18 | 3 | 0.981 | 0.003 | 0.895 | 0.007 | 1.912 | |

| Thearubigin | Zscore-PLS | 18 | 10 | 0.957 | 0.076 | 0.914 | 0.134 | 2.574 |

| Zscore-RF | 18 | 9 | 0.998 | 0.026 | 0.996 | 0.033 | 3.464 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; An, T.; Qi, D.; Yuan, C.; Dong, C. Real-Time Discrimination and Quality Evaluation of Black Tea Fermentation Quality Using a Homemade Simple Machine Vision System. Fermentation 2023, 9, 814. https://doi.org/10.3390/fermentation9090814

Yang C, An T, Qi D, Yuan C, Dong C. Real-Time Discrimination and Quality Evaluation of Black Tea Fermentation Quality Using a Homemade Simple Machine Vision System. Fermentation. 2023; 9(9):814. https://doi.org/10.3390/fermentation9090814

Chicago/Turabian StyleYang, Chongshan, Ting An, Dandan Qi, Changbo Yuan, and Chunwang Dong. 2023. "Real-Time Discrimination and Quality Evaluation of Black Tea Fermentation Quality Using a Homemade Simple Machine Vision System" Fermentation 9, no. 9: 814. https://doi.org/10.3390/fermentation9090814