Microbial Fuel Cell Using a Novel Ionic Liquid-Type Membrane–Cathode Assembly for Animal Slurry Treatment and Fertilizer Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fuel and Chemicals

2.2. Synthesis of Copper and Cobalt Mixed Valence Oxides

2.3. Preparation of New Proton Exchange Membranes with Catalytic Activity Based on Ionic Liquids

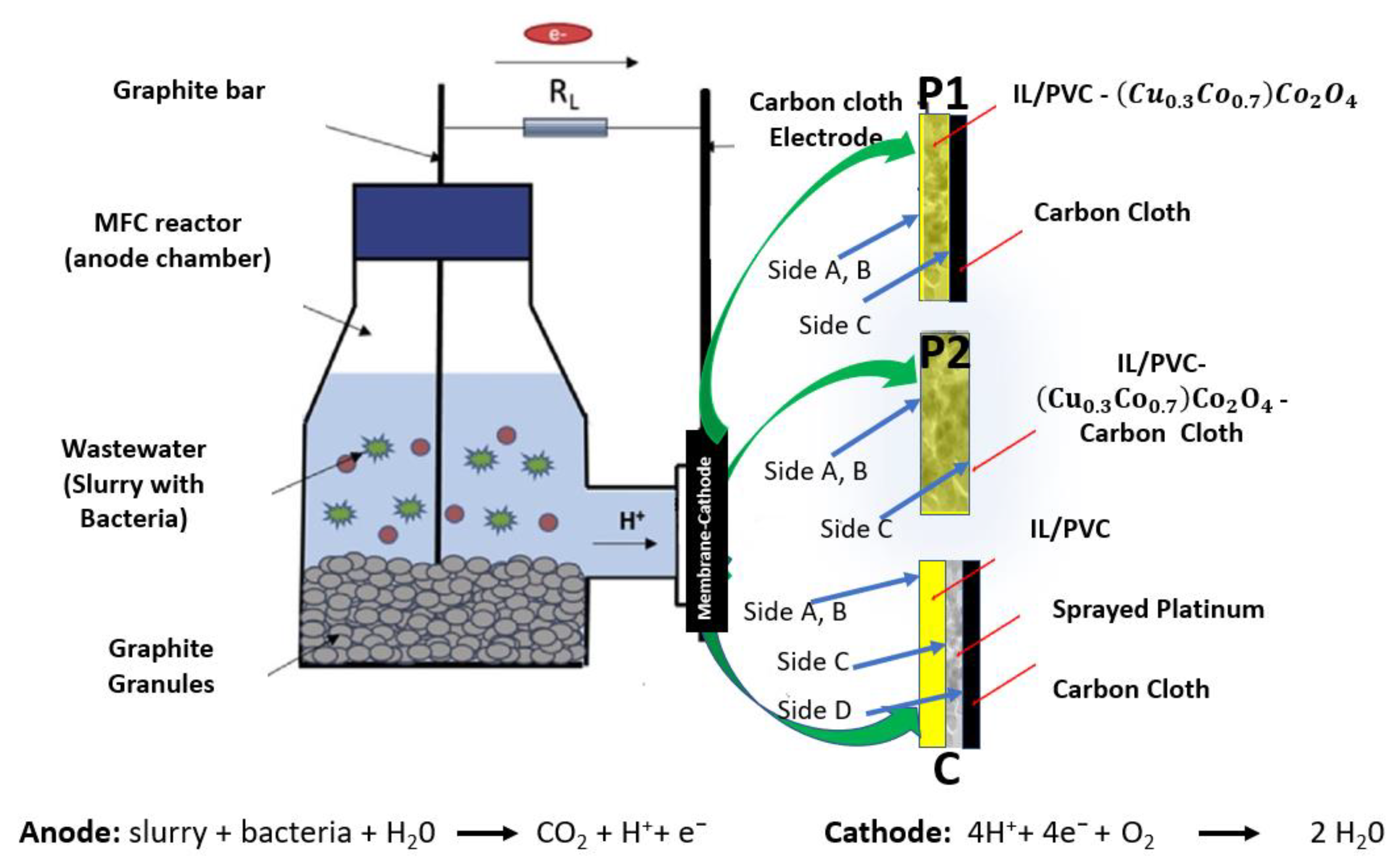

2.4. MFC Studies

2.5. Analytical Methods

2.5.1. Chemical Analysis

- COD (chemical oxygen demand): test conducted in COD 145541 Supelco cuvettes (Sigma-Aldrich). Procedure was according to DIN ISO 15705 and approved by the USEPA for wastewater. The relative standard deviation of the assay was found to be less than 3%, indicating a high degree of repeatability.

- Biochemical oxygen demand at 5 days (BOD5): A system of six Velp Scientifica DBO sensors was used for the manometric determination of BOD, using dicyanamide as an inhibitor for nitrification and sodium hydroxide as alkali to capture CO2.

- Other parameters, including pH, conductivity, and temperature, were determined with a digital multimeter (sensION + MM150 from Hach Company; Loveland, CO, USA).

2.5.2. Electrochemical Analysis

Polarization Test

Internal Resistance

Coulombic Efficiency

2.6. SEM-EDX Characterization

3. Results and Discussion

3.1. Electrochemical Analysis

3.2. Slurry Wastewater Treatment Using Microbial Fuel Cell

3.3. Characterization of the Membrane–Catalyst Assembly

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Rossi, R.; Hur, A.Y.; Page, M.A.; Thomas, B.; Butkiewicz, J.J.; Jones, D.W.; Baek, G.; Saikaly, P.E.; Cropek, D.M.; Logan, B.E. Pilot scale microbial fuel cells using air cathodes for producing electricity while treating wastewater. Water Res. 2022, 215, 118208. [Google Scholar] [CrossRef]

- Walter, X.A.; Madrid, E.; Gajda, I.; Greenman, J.; Ieropoulos, I. Microbial fuel cell scale-up options: Performance evaluation of membrane (c-MFC) and membrane-less (s-MFC) systems under different feeding regimes. J. Power Sources 2022, 520, 230875. [Google Scholar] [CrossRef]

- Sevda, S.; Dominguez-Benetton, X.; Vanbroekhoven, K.; Wever, H.D.; Sreekrishnan, T.R.; Pant, D. High strength wastewater treatment accompanied by power generation using air cathode microbial fuel cell. Appl. Energy 2013, 105, 194–206. [Google Scholar] [CrossRef]

- Schmidt, A.; Sturm, G.; Lapp, C.J.; Siebert, D.; Saravia, F.; Horn, H.; Ravi, P.P.; Lemmer, A.; Gescher, J. Development of a production chain from vegetable biowaste to platform chemicals, Microb. Cell Factories 2018, 17, 90. [Google Scholar] [CrossRef] [PubMed]

- Galai, S.; de los Ríos, A.P.; Hernández-Fernández, F.J.; Kacem, S.H.; Mateo-Ramírez, F.; Quesada-Medina, J. Microbial Fuel Cell Application for Azoic Dye Decolorization with Simultaneous Bioenergy Production Using Stenotrophomonas sp. Chem. Eng. Technol. 2015, 38, 1511–1518. [Google Scholar] [CrossRef]

- Hernández-Fernández, F.J.; de los Ríos, A.P.; Salar-García, M.J.; Ortiz-Martínez, V.M.; Godínez, L.J.L.C.; Tomás-Alonso, F.; Quesada-Medina, J. Recent progress and perspectives in microbial fuel cells for bioenergy generation and wastewater treatment. Fuel Process. Technol. 2015, 138, 284–297. [Google Scholar] [CrossRef]

- Banerjee, A.; Calay, R.K.; Eregno, F.E. Role and Important Properties of a Membrane with Its Recent Advancement in a Microbial Fuel Cell. Energies 2022, 15, 444. [Google Scholar] [CrossRef]

- Lozano, L.J.; Godínez, C.; de los Ríos, A.P.; Hernández-Fernández, F.J.; Segado, S.S.; Alguacil, F.J. Recent advances in supported ionic liquid membrane technology. J. Membr. Sci. 2011, 376, 1–14. [Google Scholar] [CrossRef]

- Salar-García, M.J.; Santoroa, C.; Kodali, M.; Serovc, A.; Artyushkova, K.; Atanassov, P.; Ieropoulosa, I. Iron-streptomycin derived catalyst for efficient oxygen reduction reaction in ceramic microbial fuel cells operating with urine. J. Power Sources 2019, 425, 50–59. [Google Scholar] [CrossRef]

- Roche, I.; Katuri, K.; Scotthamber, K. A microbial fuel cell using manganese oxide oxygen reduction catalysts. J. Appl. Electrochem. 2010, 40, 13–21. [Google Scholar] [CrossRef]

- Touach, N.; Ortiz-Martínez, V.M.; Salar-García, M.J.; Benzaouak, A.; Hernández-Fernández, F.J.; de los Ríos, A.P.; Labjar, N.; Louk, S.; El Mahi, M.; Lotfi, E.M. Influence of the preparation method of MnO2-based cathodes on the performance of single-chamber MFCs using wastewater. Sep. Purif. Technol. 2016, 171, 174–181. [Google Scholar] [CrossRef]

- Gajda, I.; Greenman, J.; Santoro, C.; Serov, A.; Melhuish, C.; Atanassov, P.; Ieropoulos, I.A. Improved power and long term performance of microbial fuel cell with Fe-N-C catalyst in air-breathing cathode. Energy 2018, 144, 1073–1079. [Google Scholar] [CrossRef]

- Benzaouak, A.; Touach, N.; Ortiz-Martínez, V.M.; Salar-García, M.J.; Hernández-Fernández, F.J.; de los Ríos, A.P.; El Mahi, M.; Lotfi, E.M. Ferroelectric LiTaO3 as novel photo-electrocatalyst in microbial fuel cells, Environ. Prog. Sustain. 2017, 36, 1568–1574. [Google Scholar] [CrossRef]

- Santoro, C.; Artyushkova, K.; Babanova, S.; Atanassov, P.; Ieropoulos, I.; Grattieri, M.; Cristiani, P.; Trasatti, S.; Li, B.; Schuler, A.J. Parameters characterization and optimization of activated carbon (AC) cathodes for microbial fuel cell application. Bioresour. Technol. 2014, 163, 54–63. [Google Scholar] [CrossRef]

- Kacem, S.H.; Galai, S.; de los Ríos, A.P.; Fernández, F.J.H.; Smaali, I. New efficient laccase immobilization strategy using ionic liquids for biocatalysis and microbial fuel cells applications. J. Chem. Technol. Biotechnol. 2018, 93, 174–183. [Google Scholar] [CrossRef]

- Blázquez, E.; Gabriel, D.; Baeza, J.A.; Guisasola, A.; Ledezma, P.; Freguia, S. Implementation of a sulfide–air fuel cell coupled to a sulfate-reducing biocathode for elemental sulfur recovery. Inter. J. Environ. Res. Public Health 2021, 18, 5571. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Zhang, H.; Zhang, C.; Zhang, G.; Yang, F.; Yuan, G.; Gao, F. Simultaneous nitrogen and carbon removal in a single chamber microbial fuel cell with a rotating biocathode. Process Biochem. 2013, 48, 893–900. [Google Scholar] [CrossRef]

- Gancarz, P.; Zorębski, E.; Dzida, M. Influence of experimental conditions on the electrochemical window. Case study on bis(trifluoromethylsulfonyl)imide-based ionic liquids. Electrochem. Commun. 2021, 130, 107107. [Google Scholar] [CrossRef]

- Baicha, Z.; Salar-García, M.J.; Ortiz-Martínez, V.M.; Hernández-Fernández, F.J.; de los Ríos, A.P.; Marín, D.P.M.; Collado, J.A.; Tomás-Alonso, F.; El Mahi, M. On the selective transport of nutrients through polymer inclusion membranes based on ionic liquids. Processes 2019, 7, 544. [Google Scholar] [CrossRef]

- Hernández-Fernández, F.J.; de los Ríos, A.P.; Mateo-Ramírez, F.; Godinez, C.; Lozano-Blanco, L.J.; Moreno, J.I.; Tomas-Alonso, F. New application of supported ionic liquids membranes as proton exchange membranes in microbial fuel cell for wastewater treatment. J. Chem. Eng. 2015, 279, 115–119. [Google Scholar] [CrossRef]

- Hernández-Fernández, F.J.; de los Ríos, A.P.; Mateo-Ramírez, F.; Juárez, M.D.; Lozano-Blanco, L.J.; Godinez, C. New application of polymer inclusion membrane based on ionic liquids as proton exchange membrane in microbial fuel cell. Sep. Purif. Technol. 2016, 160, 51–58. [Google Scholar] [CrossRef]

- Ortiz-Martínez, V.M.; Salar-García, M.J.; Hernández-Fernández, F.J.; de los Ríos, A.P. Development and characterization of a new embedded ionic liquid based membrane-cathode assembly for its application in single chamber microbial fuel cells. Energy 2015, 93, 1748–1757. [Google Scholar] [CrossRef]

- Marszałek, M.; Kowalski, Z.; Makara, A. Physicochemical and microbiological characteristics of pig slurry. Tech. Trans. Chemical. 2014, 111, 81–91. [Google Scholar]

- Cong, H.N.; El Abbassi, K.; Chartier, P. Electrocatalysis of Oxygen Reduction on Polypyrrole/Mixed Valence Spinel Oxide Nanoparticles. J. Electrochem. Soc. 2002, 149, A525. [Google Scholar] [CrossRef]

- Mateo-Ramírez, F.; Addi, H.; Hernández-Fernández, F.J.; Godínez, C.; de los Rios, A.P.; El Lotfi, M.; El Mahi, M.; Blanco, L.J.L. Air breathing cathode-microbial fuel cell with separator based on ionic liquid applied to slaughterhouse wastewater treatment and bio-energy production. J. Chem.Technol. Biotechnol. 2017, 92, 642–648. [Google Scholar] [CrossRef]

- Garrido, Y.; Tudela, J.A.; Marín, A.; Allende, A.; Gil, M.I. Reconditioning of Wash Water for the Fresh-Cut Industry. Adv. Food Process Technol. 2020, 3, 126. [Google Scholar]

- Fu, J.; Lee, W.N.; Coleman, C.; Nowack, K.; Carter, J.; Huang, C.H. Removal of disinfection byproduct (DBP) precursors in water by two-stage biofiltration treatment. Water Res. 2017, 123, 224–235. [Google Scholar] [CrossRef]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Keller, U.S.J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial Fuel Cells: Methodology and Technology. Environ. Sci. Technol. 2006, 40, 5181–5191. [Google Scholar] [CrossRef]

- Kiely, P.D.; Cusick, R.; Call, D.F.; Selembo, P.A.; Regan, J.M.; Logan, B.E. Anode microbial communities produced by changing from microbial fuel cell to microbial electrolysis cell operation using two different wastewaters. Bioresour. Technol. 2011, 102, 388–394. [Google Scholar] [CrossRef]

- Yokoyama, H.; Ohmori, H.; Ishida, M.; Waki, M.; Tanaka, Y. Treatment of cow-waste slurry by a microbial fuel cell and the properties of the treated slurry as a liquid manure. Anim. Sci. J. 2006, 77, 634–638. [Google Scholar] [CrossRef]

- Tomás-Alonso, F.; Rubio, A.M.; Giménez, A.; de los Ríos, A.P.; Salar-García, M.J.; Ortiz-Martínez, V.M.; Hernández-Fernández, F.J. Influence of ionic liquid composition on the stability of polyvinyl chloride-based ionic liquid inclusion membrnes in aqueous solution. AIChE J. 2017, 63, 770–780. [Google Scholar] [CrossRef]

- You, J.; Greenman, J.; Melhuish, C.; Ieropoulos, I. Electricity generation and struvite recovery from human urine using microbial fuel cells. J. Chem. Technol. Biotechnol. 2016, 91, 647–654. [Google Scholar] [CrossRef]

- Doyle, J.D.; Parsons, S.A. Struvite formation control and recovery. Water Res. 2002, 36, 3925–3940. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Harnisch, F.; Schrder, U.; Scholz, F.; Bogdanoff, P.; Herrmann, I. Challenges and constraints of using oxygen cathodes in microbial fuel cells. Environ. Sci. Technol. 2006, 40, 5193–5199. [Google Scholar] [CrossRef] [PubMed]

- Ichihashi, O.; Hirooka, K. Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour. Technol. 2012, 114, 303–307. [Google Scholar] [CrossRef]

| Absorbance at 254 nm (Dilution 1:10) | |||

|---|---|---|---|

| MFC | |||

| P1 | 0.847 | 0.3465 | 59.09 |

| P2 | 0.847 | 0.269 | 68.24 |

| C | 0.847 | 0.393 | 53.60 |

| PEM–Catalyst Assembly (P1) ([MTOA+][Cl−]-PVC-) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Peak Element | Weight % A | Atomic % A | Weight % B | Atomic % B | Weight % B* | Atomic % B* | Weight % C | Atomic % C |

| C K | 56.25 | 74.46 | 53.87 | 75.30 | 16.69 | 33.55 | 40.16 | 65.15 |

| N K | 1.57 | 1.78 | −0.43 | −0.51 | 3.11 | 5.36 | 2.45 | 3.40 |

| O K | 8.23 | 8.18 | 3.62 | 3.81 | - | - | 4.38 | 5.34 |

| Na K | 1.82 | 1.26 | 4.54 | 3.32 | 22.75 | 23.89 | - | - |

| S K | - | - | 0.79 | 0.41 | 0.49 | 0.37 | 1.64 | 1.00 |

| Cl K | 31.65 | 14.20 | 34.22 | 16.22 | 51.03 | 34.76 | 37.88 | 20.82 |

| K K | - | - | 0.80 | 0.34 | 0.44 | 0.27 | - | - |

| Ca K | - | - | 2.13 | 0.89 | 0.84 | 0.51 | 2.16 | 2.05 |

| Co K | 0.36 | 0.10 | 0.38 | 0.11 | 0.37 | 0.15 | 6.49 | 2.15 |

| Cu K | 0.13 | 0.03 | 0.07 | 0.02 | 0.07 | 0.03 | 0.62 | 0.9 |

| Zr K | - | - | - | - | 4.22 | 1.12 | 4.22 | 0.9 |

| PEM–Catalyst Assembly (P2) ([MTOA+][Cl−]-PVC-)-Carbon Cloth | ||||||

|---|---|---|---|---|---|---|

| Peak Element | Weight % A | Atomic % A | Weight % B | Atomic % B | Weight % C | Atomic % C |

| C K | 68.46 | 86.56 | 74.92 | 90.76 | 52.08 | 75.34 |

| N K | 1.88 | 2.04 | −3.17 | −3.29 | 0.46 | 0.57 |

| F K | - | - | 5.85 | 4.48 | - | - |

| O K | - | - | - | - | 2.84 | 3.09 |

| Si K | - | - | - | - | 0.62 | 0.38 |

| S K | - | - | 0.29 | 0.13 | 1.10 | 0.59 |

| Cl K | 23.51 | 10.07 | 15.41 | 6.32 | 39.43 | 19.39 |

| Ca K | - | - | 2.22 | 0.80 | - | - |

| Co K | 3.02 | 0.78 | 0.69 | 0.17 | 0.47 | 0.14 |

| Cu K | 0.41 | 0.10 | 0.27 | 0.06 | −0.10 | −0.03 |

| Zr K | 2.72 | 0.45 | 3.53 | 0.56 | 3.09 | 0.59 |

| Control System (C) [MTOA+][Cl−]-PVC-Pt-Carbon Cloth | ||||||||

|---|---|---|---|---|---|---|---|---|

| Peak Element | Weight % A | Atomic % A | Weight % B | Atomic % B | Weight % C | Atomic % C | Weight % D | Atomic % D |

| C K | 64.53 | 83.05 | 46.31 | 74.12 | 55.82 | 77.85 | 71.91 | 80.45 |

| N K | 2.22 | 2.44 | −3.98 | −5.47 | 1.17 | 1.40 | 0.73 | 0.70 |

| F K | - | - | - | - | - | - | 26.54 | 18.77 |

| OK | - | - | - | - | 4.26 | 4.46 | - | - |

| S K | - | - | 2.87 | 1.72 | 2.10 | 1.10 | - | - |

| Cl K | 33.25 | 14.50 | 53.09 | 28.79 | 31.15 | 14.42 | 0.06 | 0.02 |

| K K | - | - | 1.72 | 0.85 | - | - | - | |

| Pt M | - | - | - | - | 5.51 | 4.47 | 0.75 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iniesta-López, E.; Hernández-Fernández, A.; Garrido, Y.; Ieropoulos, I.A.; Hernández-Fernández, F.J. Microbial Fuel Cell Using a Novel Ionic Liquid-Type Membrane–Cathode Assembly for Animal Slurry Treatment and Fertilizer Production. Fermentation 2023, 9, 844. https://doi.org/10.3390/fermentation9090844

Iniesta-López E, Hernández-Fernández A, Garrido Y, Ieropoulos IA, Hernández-Fernández FJ. Microbial Fuel Cell Using a Novel Ionic Liquid-Type Membrane–Cathode Assembly for Animal Slurry Treatment and Fertilizer Production. Fermentation. 2023; 9(9):844. https://doi.org/10.3390/fermentation9090844

Chicago/Turabian StyleIniesta-López, Eduardo, Adrián Hernández-Fernández, Yolanda Garrido, Ioannis A. Ieropoulos, and Francisco José Hernández-Fernández. 2023. "Microbial Fuel Cell Using a Novel Ionic Liquid-Type Membrane–Cathode Assembly for Animal Slurry Treatment and Fertilizer Production" Fermentation 9, no. 9: 844. https://doi.org/10.3390/fermentation9090844

APA StyleIniesta-López, E., Hernández-Fernández, A., Garrido, Y., Ieropoulos, I. A., & Hernández-Fernández, F. J. (2023). Microbial Fuel Cell Using a Novel Ionic Liquid-Type Membrane–Cathode Assembly for Animal Slurry Treatment and Fertilizer Production. Fermentation, 9(9), 844. https://doi.org/10.3390/fermentation9090844