Comparison of Different Grades of Innovative Tanyang Congou Black Tea (Minkehong) Based on Metabolomics and Sensory Evaluation

Abstract

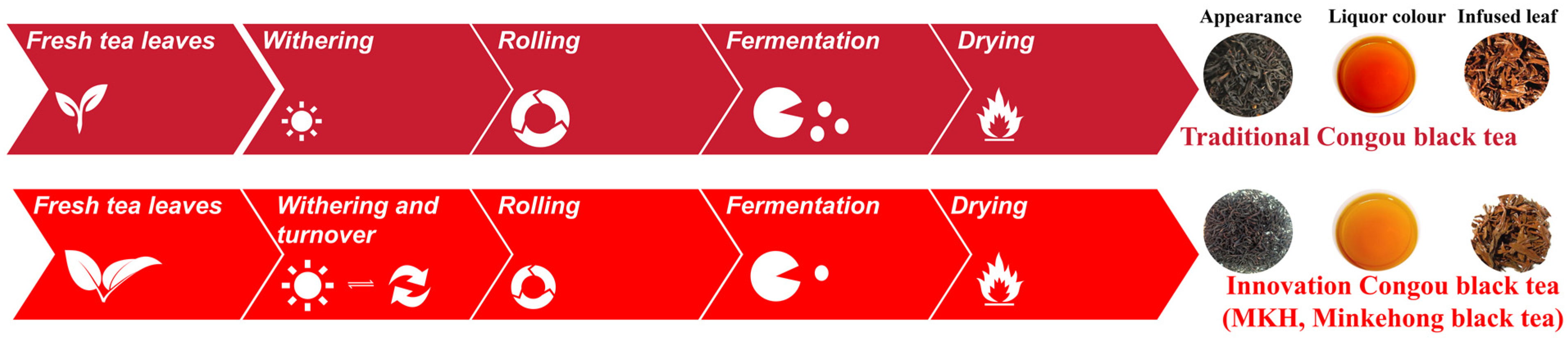

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Tea Samples

2.3. Sensory Evaluation

2.4. Liquor Chromaticity

2.5. Detection and Analysis of Non-Volatile Compounds by UPLC-MS

2.5.1. Catechin and Caffeine Analysis

2.5.2. Free Amino Acid Analysis

2.6. Detection and Analysis of Volatile Compounds by GC–MS

2.7. Statistical Analysis

3. Results

3.1. The Sensory Evaluation of Different Grades of MKH

3.2. The Analysis of Catechins and Caffeine Content among Different Grades of MKH

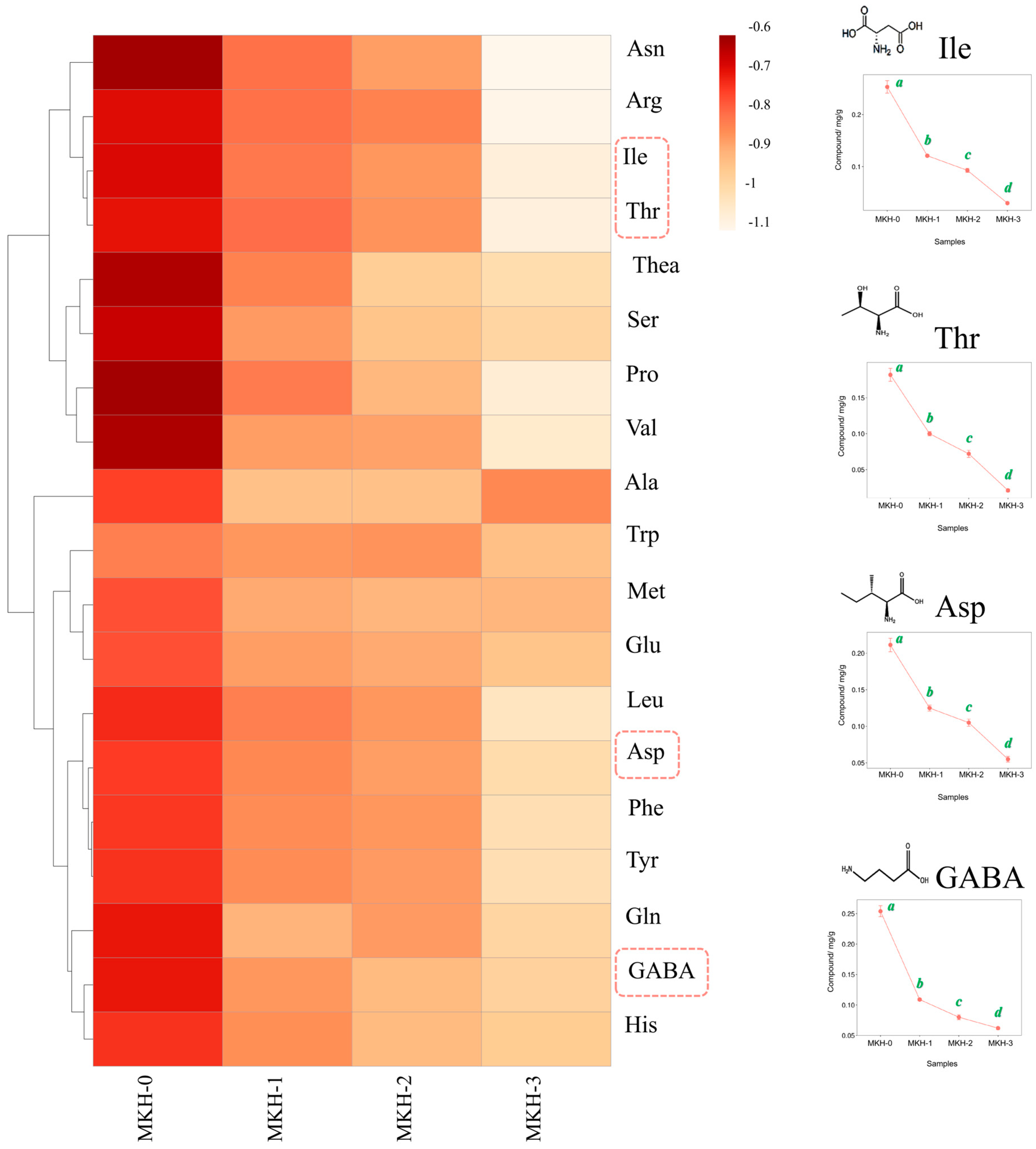

3.3. The Analysis of AA Content among Different Grades of MKH

3.4. The Analysis of Volatilesamong Different Grades of MKH

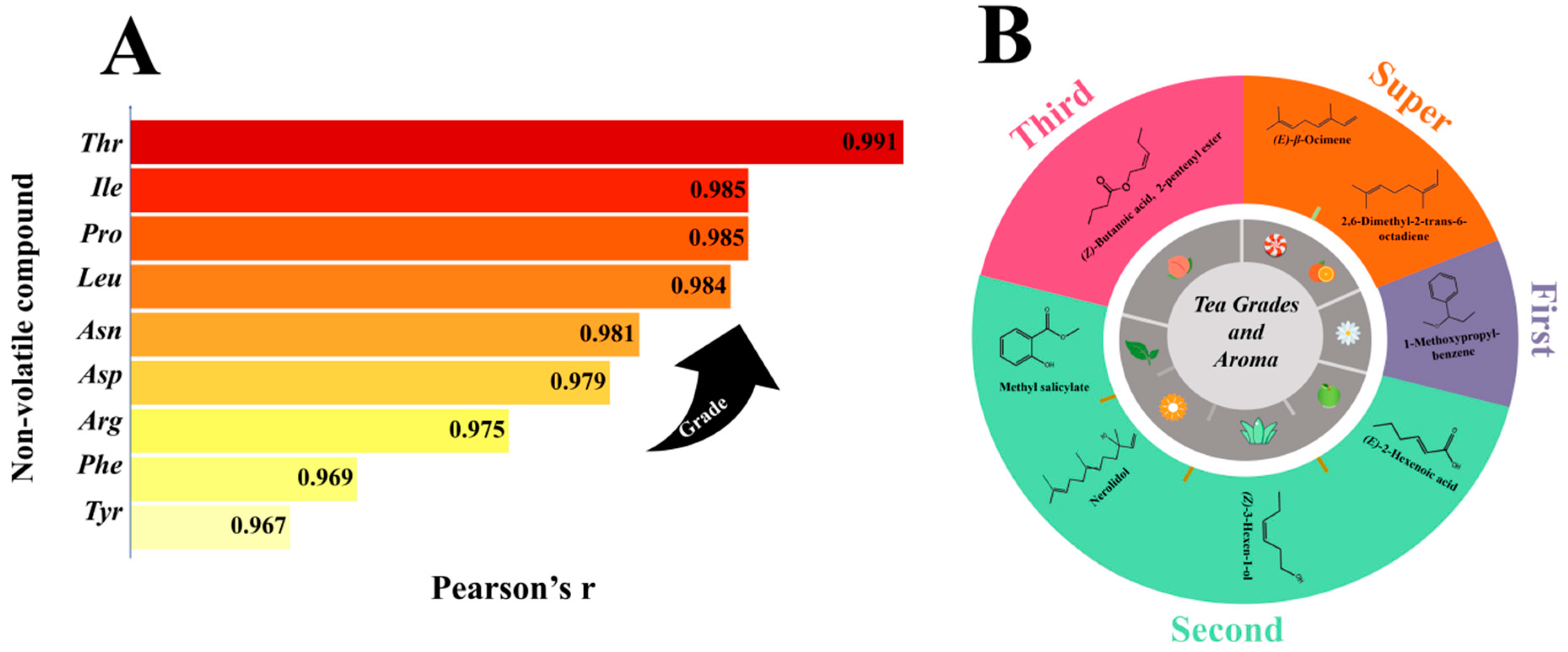

3.5. Association Analysis of Non-Volatile and Volatile Compounds among Different Grades of MKH

4. Discussion

4.1. The Selection of Non-Volatile Compounds and Their Correlation among Different MKH Grades

4.2. The Selection of Volatile Compounds and Their Correlation among Different MKH Grades

5. Conclusions

- (1)

- The MKH standard sample was generally positively correlated with the content of non-volatile compounds including AAs, catechins, and caffeine, and Ile, Thr, Asp, and GABA show significant differences between grades and are potential biomarker components for MKH.

- (2)

- (E)-β-Ocimene, 2,6-dimethyl-2-trans-6-octadiene, and 1-methoxypropyl-benzene were the most abundant volatile compounds in the higher grade of MKH, being conducive to the formation of the delicate sweet and floral aroma, while (Z)-3-hexen-1-ol, nerolidol, and (Z)-butanoic acid, 2-pentenyl ester were the most abundant volatile compounds in the second and third grade of MKH, being conducive to the formation of the rich fruity aroma.

- (3)

- The maturity of fresh tea leaf raw materials was negatively correlated with the grade of MKH, which was the main internal factor for the difference between volatile and non-volatile compounds in the sample grade.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shuai, M.; Peng, C.; Niu, H.; Shao, D.; Hou, R.; Cai, H. Recent techniques for the authentication of the geographical origin of tea leaves from Camellia sinensis: A review. Food Chem. 2022, 374, 131713. [Google Scholar] [CrossRef] [PubMed]

- Yong, L.; Song, Y.; Xiao, X.; Sui, H.X.; Xu, H.B.; Tan, R.; Yang, X.F.; Song, J.; Li, J.W.; Wei, S. Quantitative probabilistic assessment of caffeine intake from tea in Chinese adult consumers based on nationwide caffeine content determination and tea consumption survey. Food Chem. Toxicol. 2022, 165, 113102. [Google Scholar] [CrossRef]

- T/FACX-2018; Tanyang Gongfu Tea with Flowery-Fruity Flavour Minkehong Black Tea [Group standard]. Tea Industry Association of Fu’an City: Fu’an, China, 2018. (In Chinese)

- Wu, Q.Y.; Zhou, Z.W.; Zhang, Y.N.; Huang, H.Q.; Ou, X.X.; Sun, Y. Identification of key components responsible for the aromatic quality of Jinmudan black tea by means of molecular sensory science. Foods 2023, 12, 1794. [Google Scholar] [CrossRef]

- Li, J.; Hao, C.; Jia, H.; Zhang, J.; Wu, H.; Ning, J.; Wang, R.; Deng, W.W. Aroma characterization and their changes during the processing of black teas from the cultivar, Camellia sinensis (L.) O. Kuntze cv. Jinmudan. J. Food Compos. Anal. 2022, 108, 104449. [Google Scholar] [CrossRef]

- Lin, J.; Tu, Z.; Zhu, H.; Chen, L.; Wang, Y.; Yang, Y.; Lv, H.; Zhu, Y.; Yu, L.; Ye, Y. Effects of Shaking and Withering Processes on the Aroma Qualities of Black Tea. Horticulturae 2022, 8, 549. [Google Scholar] [CrossRef]

- Yin, X.; Xiao, Y.; Wang, K.; Wu, W.; Huang, J.; Liu, S.; Zhang, S. Effect of shaking manners on floral aroma quality and identification of key floral-aroma-active compounds in Hunan black tea. Food Res. Int. 2023, 174, 113515. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Wu, Q.; Yang, Y.; Hu, Q.; Wu, Z.; Huang, H.; Lin, H.; Lai, Z.; Sun, Y. The dynamic change in fatty acids during the postharvest process of oolong tea production. Molecules 2022, 27, 4298. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Fang, S.; Su, Y.; Xia, D.; Wu, Y.; Liu, Q.; Zou, L.; Lu, C.; Deng, W.; Ning, J. Insights into the mechanism of different withering methods on flavor formation of black tea based on target metabolomics and transcriptomics. LWT Food Sci. Technol. 2023, 189, 115537. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, Z.; Chen, Y.; Lu, C.; Deng, W.W.; Zhang, Z.; Ning, J. Visualizing chemical indicators: Spatial and temporal quality formation and distribution during black tea fermentation. Food Chem. 2022, 401, 134090. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, J.; Cheng, L.; Zhou, H.; Dong, Y.; Ma, H.; Zhou, J.; Yu, Y.; Xu, Q. Determination of tea aroma precursor gycosides: An efficient approach via liquid chromatography-tandem mass spectrometry. J. Agric. Food Chem. 2023, 71, 4083–4090. [Google Scholar] [CrossRef]

- Zeng, L.T.; Zhou, Y.; Gui, J.D.; Fu, X.M.; Mei, X.; Zhen, Y.P.; Ye, T.; Du, B.; Dong, F.; Naoharu, W.; et al. Formation of volatile tea constituent indole during the oolong tea manufacturing process. J. Agric. Food Chem. 2016, 64, 5011–5019. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Hu, Q.; Wu, Z.; Bi, W.; Chen, B.; Hao, Z.; Wu, L.; Ye, N.; Sun, Y. Volatile metabolomics and coexpression network analyses provide insight into the formation of the characteristic cultivar aroma of oolong tea (Camellia sinensis). LWT Food Sci. Technol. 2022, 164, 113666. [Google Scholar] [CrossRef]

- Zhou, Z.; Wu, Q.; Yao, Z.; Deng, H.; Liu, B.; Yue, C.; Sun, Y. Dynamics of ADH and related genes responsible for the transformation of C6-aldehydes to C6-alcohols during the postharvest process of oolong tea. Food Sci. Nutr. 2020, 8, 104–113. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Huang, J.; Huang, J.; Wu, W.; Tong, T.; Liu, S.; Zhou, L.; Liu, Z.; Zhang, S. Identification of volatile and odor-active compounds in Hunan black tea by SPME/GC-MS and multivariate analysis. LWT Food Sci. Technol. 2022, 164, 113656. [Google Scholar]

- Su, D.; He, J.J.; Zhou, Y.Z.; Li, Y.L.; Zhou, H.J. Aroma effects of key volatile compounds in Keemun black tea at different grades: HS-SPME-GC-MS, sensory evaluation, and chemometrics. Food Chem. 2022, 373, 131587. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, Q.; Wen, S.; Sun, L.; Chen, R.; Zhang, Z.; Cao, J.; Lai, Z.; Li, Z.; Lai, X.; et al. Metabolomics reveals the effects of different storage times on the acidity quality and metabolites of large-leaf black tea. Food Chem. 2023, 426, 136601. [Google Scholar] [CrossRef]

- Lan, T.; Zeng, Q.; Chen, L.; Tu, Z.; Ye, Y.; Liu, Y.; He, W. Comparison of volatile and nonvolatile metabolites in black tea under four second-drying methods using widely targeted metabolomics. Foods 2024, 13, 144. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Fang, T.; Li, W.; Jiang, Z.; Zhou, T.; Zhang, L.; Yu, Y. Widely targeted metabolomics using UPLC-QTRAP-MS/MS reveals chemical changes during the processing of black tea from the cultivar Camellia sinensis (L.) O. Kuntze cv. Huangjinya. Food Res. Int. 2022, 162, 112169. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, J.; Jiang, R.; Chen, H.; Liu, Q.; Yi, X.; Wen, S.; Huang, F.; Zhang, X.; Li, J.; Wen, H.; et al. Characterization of key odorants in ‘Baimaocha’ black teas from different regions. Food Chem. X 2024, 19, 101303. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Zhao, Y.; Zhu, M.; Li, J.; Wang, K. A meta-analysis of dynamic changes ofkey aroma compounds during black tea processing. Food Biosci. 2024, 58, 103784. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, Z.; He, J.; Zhao, S.; Ruan, S.; Liu, X.; Yu, S.; Sun, Y. Analysis of aroma precursors in Jinmudan fresh tea leaves and dynamic change of fatty acid volatile during black tea processing. Food Chem. X 2024, 21, 101155.23. [Google Scholar]

- Gu, H.W.; Yin, X.L.; Ma, Y.X.; Wang, J.; Yang, F.; Sun, W.; Ding, B.; Chen, Y.; Liu, Z. Differentiating grades of Xihu Longjing teas according to the contents of ten major components based on HPLC-DAD in combination with chemometrics. LWT Food Sci. Technol. 2020, 130, 109688. [Google Scholar] [CrossRef]

- Han, Z.; Wen, M.; Zhang, H.; Zhang, L.; Wan, X.; Ho, C.T. LC-MS based metabolomics and sensory evaluation reveal the critical compounds of different grades of Huangshan Maofeng green tea. Food Chem. 2022, 374, 131796. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Fu, Y.Q.; Liu, Y.Y.; Huang, J.S.; Chen, J.X.; Yin, J.F.; Jin, S.; Sun, W.J.; Xu, Y.Q. Comparative analysis of different grades of Tieguanyin oolong tea based on metabolomics and sensory evaluation. LWT Food Sci. Technol. 2023, 174, 114423. [Google Scholar] [CrossRef]

- Pang, X.M.; Chen, F.Y.; Liu, G.Y.; Zhang, Q.; Ye, J.H.; Lei, W.X.; Jia, X.L.; He, H.B. Comparative analysis on the quality of Wuyi Rougui (Camellia sinensis) tea with different grades. Food Sci. Technol. 2022, 42, 115321. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, E.; Niu, Y.; Zhu, J. Unraveling the contribution of aroma-active and chiral compounds to different grade of Yashi Xiang teas using stir bar sorptive extraction. J. Tea Sci. 2023, 88, 3302–3322. [Google Scholar] [CrossRef] [PubMed]

- Selim, D.A.; Shawky, E.; Abu El-Khair, R.M. Identification of the discriminatory chemical markers of different grades of Sri Lankan white, green and black tea (Camellia sinenesis L.) via metabolomics combined to chemometrics. J. Food Compos. Anal. 2022, 109, 104473. [Google Scholar] [CrossRef]

- GB/T24710-2009; Production of Geographical Indication_Tanyang Congou Black Tea [Geographical Indication]. Standards Press of China: Beijing, China, 2009. (In Chinese)

- GB/T8313-2018; Methodology for Sensory Evaluation of Tea [National Standard]. Standards Press of China: Beijing, China, 2018. (In Chinese)

- Chen, S.; Li, M.; Zheng, G.; Wang, T.; Lin, J.; Wang, S.; Wang, X.; Chao, Q.; Cao, S.; Yang, Z.; et al. Metabolite Profiling of 14 Wuyi Rock Tea Cultivars Using UPLC-QTOF MS and UPLC-QqQ MS Combined with Chemometrics. Molecules 2018, 23, 104. [Google Scholar] [CrossRef] [PubMed]

- Thibert, V.; Legeay, P.; Chapuis-Hugon, F.; Valérie, P. Molecularly imprinted polymer for the selective extraction of cocaine and its metabolites, benzoylecgonine and ecgonine methyl ester, from biological fluids before LC–MS analysis. J. Chromatogr. B 2014, 949–950, 16–23. [Google Scholar] [CrossRef]

- Lyu, F.; Han, F.; Ge, C.; Mao, W.; Chen, L.; Hu, H.; Chen, G.; Lang, Q.; Fang, C. OmicStudio: A composable bioinformatics cloud platform with real-time feedback that can generate high-quality graphs for publication. iMeta 2023, 2, e85. [Google Scholar] [CrossRef]

- Liu, Z.; Ran, Q.; Li, Q.; Yang, T.; Dai, Y.; Zhang, T.; Fang, S.; Pan, K.; Long, L. Interaction between major catechins and umami amino acids in green tea based on electronic tongue technology. J. Food Sci. 2023, 88, 2339–2352. [Google Scholar] [CrossRef]

- Deng, S.; Zhou, X.; Dong, H.; Xu, Y.; Gao, Y.; Wang, B.; Liu, X. Mellow and thick taste of Pu-Erh ripe tea based on chemical properties by sensory-directed flavor analysis. Foods 2022, 11, 2285. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Wu, Q.; Rao, H.; Cai, L.; Zheng, S.; Sun, Y. The dynamic change in aromatic compounds and their relationship with CsAAAT genes during the post-harvest process of oolong tea. Metabolites 2023, 13, 868. [Google Scholar] [CrossRef]

- Elideth, F.R.; Nemesio, V.R.; Diego, H.M.; Moisés, R.M.; Reinaldo, M.A.; Rodolfo, V.V.L.; Gerardo, Z.V.; Nury, P.H.; Elvia, B.M. 1 H NMR-based fingerprinting of eleven Mexican Capsicum annuum cultivars. Food Res. Int. 2019, 121, 12–19. [Google Scholar]

- Wei, F.; Luo, L.; Zeng, L. Characterization of key sweet taste compounds in Camellia nanchuanica black tea. LWT Food Sci. Technol. 2023, 182, 114858. [Google Scholar] [CrossRef]

- Xue, J.; Liu, P.; Guo, G.; Wang, W.; Zhang, J.; Wang, W.; Le, T.; Yin, J.; Ni, D.; Jiang, H. Profiling of dynamic changes in non-volatile metabolites of shaken black tea during the manufacturing process using targeted and non-targeted metabolomics analysis. LWT-Food Sci. Technol. 2022, 156, 113010. [Google Scholar] [CrossRef]

- Ma, Q.; Qin, M.; Song, L.; Sun, H.; Zhang, H.; Wu, H.; Ren, Z.; Liu, H.; Duan, G.; Wang, Y.; et al. Molecular link in flavonoid and amino acid biosynthesis contributes to the flavor of Changqing tea in different seasons. Foods 2022, 11, 2289. [Google Scholar] [CrossRef]

- Huang, D.; Li, M.; Wang, H.; Fu, M.; Hu, S.; Wan, X.; Wang, Z.; Chen, Q. Combining gas chromatography-ion mobility spectrometry and olfactory analysis to reveal the effect of filled-N2 anaerobic treatment duration on variation in the volatile profiles of gabaron green tea. LWT Food Sci. Technol. 2023, 179, 114630. [Google Scholar] [CrossRef]

- Sullivan, R.C.; Nottage, S.; Makinwa, F.; Oruna-Concha, M.J.; Fagan, C.C.; Parker, J.K. Characterisation of cooked cheese flavour: Non-volatile components. Foods 2023, 12, 3794. [Google Scholar] [CrossRef]

- Sonntag, T.; Kunert, C.; Dunkel, A.; Hofmann, T. Sensory-guided identification of N-(1-methyl-4-oxoimidazolidin-2-ylidene)-α-amino acids as contributors to the thick-sour and mouth-drying orosensation of stewed beef juice. J. Agric. Food Chem. 2010, 58, 6341–6350. [Google Scholar] [CrossRef]

- Pu, D.; Shan, Y.; Wang, J.; Sun, B.; Xu, Y.; Zhang, W.; Zhang, Y. Recent trends in aroma release and perception during food oral processing: A review. Crit. Rev. Food Sci. 2022, 3, 11–17. [Google Scholar] [CrossRef] [PubMed]

- Hou, Z.W.; Wang, Y.J.; Xu, S.S.; Wei, Y.M.; Bao, G.H.; Dai, Q.Y.; Deng, W.W.; Ning, J.M. Effects of dynamic and static withering technology on volatile and nonvolatile components of Keemun black tea using GC-MS and HPLC combined with chemometrics. LWT Food Sci. Technol. 2020, 130, 109547. [Google Scholar] [CrossRef]

- Wu, S.M.; Yu, Y.Q.; Zhu, J.Y.; Hua, J.J.; Shen, S.; Jiang, Y.W.; Yuan, H.B.; Li, J. Analysis of the effect of rolling speed on the Congou black tea quality using electronic tongue and metabolomics. Food Sci. 2023, 44, 301–310. (In Chinese) [Google Scholar]

- Yan, Z.; Zhou, Z.; Jiao, Y.; Huang, J.; Yu, Z.; Zhang, D.; Chen, Y.; Ni, D. Hot-air drying significantly improves the quality and functional activity of orange black tea compared with traditional sunlight drying. Foods 2023, 12, 1913. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Liu, Y.; Yang, J.; Wang, H.; Zhou, H.; Lei, P. Manufacturing process differences give Keemun black teas their distinctive aromas. Food Chem. X 2023, 19, 100865. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Yang, L.; Luo, X.; Huang, R.; Jiao, W.; Zhong, X.; Li, L.; Wang, Q.; Liu, M.; Liu, K. Aroma formation and dynamic changes during Sichuan black tea processing by GC-MS-sabsed metabolomics. Fermentation 2023, 9, 686. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, J.; Fu, Y.; Yin, J.; Shi, J.; Xu, Y. Chemical composition, sensory properties and bioactivities of Castanopsis lamontii buds and mature leaves. Food Chem. 2020, 316, 126370. [Google Scholar] [CrossRef]

- Wu, Z.R. Effect of Sun Withering on the Quality of Black Tea. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2023; p. 83. (In Chinese). [Google Scholar]

| Compound/mg/g | MKH-0 | MKH-1 | MKH-2 | MKH-3 |

|---|---|---|---|---|

| C | 8.991 ± 0.570 a | 6.448 ± 0.254 b | 5.408 ± 0.102 c | 5.490 ± 0.122 c |

| EC | 12.105 ± 1.471 a | 6.701 ± 0.449 b | 3.521 ± 0.236 c | 4.932 ± 0.222 bc |

| EGC | 76.807 ± 4.638 a | 57.608 ± 2.281 b | 29.617 ± 2.653 c | 25.538 ± 1.098 c |

| EGCG | 133.316 ± 8.235 a | 83.953 ± 1.394 b | 33.508 ± 3.130 c | 33.732 ± 4.198 c |

| ECG | 25.650 ± 1.199 a | 16.652 ± 0.857 b | 7.993 ± 0.355 d | 11.597 ± 1.377 c |

| Caffeine | 24.455 ± 1.416 a | 22.576 ± 0.598 ab | 21.081 ± 1.081 b | 22.427 ± 1.357 ab |

| No | Compounds | CAS Number | Class | NIST RI | Odor Description | Relative Mean Content (μg/g) | |||

|---|---|---|---|---|---|---|---|---|---|

| MKH-0 | MKH-1 | MKH-2 | MKH-3 | ||||||

| v1 | 6-Methyl-3-(1-methylethyl)-7-oxabicyclo [4.1.0]heptan-2-one | 5286-38-4 | Ketone | 1256 | - | 0.999 ± 0.146 | 0.629 ± 0.050 | 0.552 ± 0.017 | 0.373 ± 0.090 |

| v2 | Methyl salicylate | 119-36-8 | Ester | 1192 | Wintergreen, minty | 1.000 ± 0.081 | 0.652 ± 0.036 | 0.493 ± 0.013 | 0.483 ± 0.055 |

| v3 | Linalyl acetate | 115-95-7 | Terpenoids | 1257 | Orange | 0.270 ± 0.046 | 0.165 ± 0.013 | 0.143 ± 0.005 | 0.096 ± 0.024 |

| v4 | (Z)-2-Decenal | 115-95-7 | Terpenoids | 1257 | Citrus, floral | 0.253 ± 0.040 | 0.153 ± 0.012 | 0.129 ± 0.004 | 0.083 ± 0.023 |

| v5 | 2-Methyl-7-exo-vinylbicyclo [4.2.0]oct-1(2)-ene | 107914-89-6 | Hydrocarbons | 1112 | - | 0.440 ± 0.044 | 0.499 ± 0.031 | 0.628 ± 0.013 | 0.612 ± 0.061 |

| v6 | (Z)-Butanoic acid, 2-pentenyl ester | 42125-13-3 | Ester | 1091 | Fruity, honey | 0.190 ± 0.007 | 0.101 ± 0.006 | 0.069 ± 0.002 | 0.084 ± 0.005 |

| v7 | Ethanone | 1122-62-9 | Heterocyclic compound | 1034 | Balsamic, coffee | 0.199 ± 0.015 | 0.163 ± 0.010 | 0.147 ± 0.002 | 0.113 ± 0.009 |

| v8 | Ascaridole | 512-85-6 | Terpenoids | 1244 | - | 0.097 ± 0.020 | 0.052 ± 0.006 | 0.043 ± 0.002 | 0.024 ± 0.010 |

| v9 | Pyrazinamide | 98-96-4 | Heterocyclic compound | 1250 | bitter | 0.061 ± 0.020 | 0.039 ± 0.005 | 0.026 ± 0.009 | 0.020 ± 0.011 |

| v10 | Tetrahydro-6-pentyl-2H-pyran-2-one | 705-86-2 | Ester | 1497 | Coconut, creamy | 0.046 ± 0.017 | 0.119 ± 0.011 | 0.116 ± 0.003 | 0.123 ± 0.049 |

| v11 | (E)-2-Hexenoic acid | 13419-69-7 | Acid | 982 | Fruity | 0.057 ± 0.002 | 0.088 ± 0.008 | 0.102 ± 0.002 | 0.114 ± 0.007 |

| v12 | Isopentyl hexanoate | 2198-61-0 | Ester | 1250 | Fruity, apple | 0.071 ± 0.015 | 0.037 ± 0.005 | 0.029 ± 0.001 | 0.014 ± 0.008 |

| v13 | Methyl 2,2,3-trimethylcyclopentyl-ketone | 17983-22-1 | Ketone | 1092 | - | 0.071 ± 0.003 | 0.034 ± 0.002 | 0.023 ± 0.001 | 0.028 ± 0.002 |

| v14 | 1-Methyl-4-cyclohexanol | 586-81-2 | Terpenoids | 1197 | Camphor | 0.063 ± 0.007 | 0.034 ± 0.003 | 0.021 ± 0.001 | 0.020 ± 0.005 |

| v15 | 1-Methoxypropyl-benzene | 59588-12-4 | Aromatics | 1104 | Floral | 0.059 ± 0.003 | 0.025 ± 0.002 | 0.013 ± 0.001 | 0.019 ± 0.002 |

| v16 | 2-Hydroxy-2,6,6-trimethyl-bicyclo [3.1.1]heptan-3-one | 10136-65-9 | Ketone | 1256 | Minty | 0.057 ± 0.012 | 0.029 ± 0.004 | 0.022 ± 0.001 | 0.010 ± 0.007 |

| v17 | 1-Ethyl-3-methyl-benzene | 620-14-4 | Aromatics | 957 | Aromatic | 0.104 ± 0.004 | 0.124 ± 0.005 | 0.163 ± 0.002 | 0.142 ± 0.007 |

| v18 | α-Farnesene | 40716-66-3 | Terpenoids | 1564 | Floral, woody | 0.006 ± 0.007 | 0.038 ± 0.006 | 0.045 ± 0.001 | 0.052 ± 0.020 |

| v19 | p-Menth-8-en-3-ol acetate | 89-49-6 | Ester | 1259 | Sweet, woody, minty | 0.037 ± 0.009 | 0.015 ± 0.003 | 0.011 ± 0.001 | 0.002 ± 0.005 |

| v20 | Benzeneacetic acid ethyl ester | 101-97-3 | Ester | 1247 | Floral, sweet | 0.040 ± 0.009 | 0.019 ± 0.002 | 0.014 ± 0.001 | 0.005 ± 0.005 |

| v21 | (E)-2-Butenoic acid, 2-methyl-2-methylpropyl ester | 61692-84-0 | Ester | 1093 | Fruity | 0.035 ± 0.002 | 0.015 ± 0.002 | 0.009 ± 0.001 | 0.012 ± 0.001 |

| v22 | N,N-Dimethyl-1,2,3-trithian-5-amine | 31895-21-3 | Heterocyclic compound | 1491 | - | 0.016 ± 0.009 | 0.050 ± 0.005 | 0.049 ± 0.002 | 0.052 ± 0.024 |

| v23 | (E)-Linalool oxide | 34995-77-2 | Heterocyclic compound | 1086 | Floral, woody, camphor | 0.313 ± 0.012 | 0.255 ± 0.012 | 0.255 ± 0.004 | 0.290 ± 0.015 |

| v24 | 2-Nitroethyl-Benzene | 6125-24-2 | Aromatics | 1304 | Bitter, almond | 0.009 ± 0.006 | 0.047 ± 0.005 | 0.049 ± 0.002 | 0.036 ± 0.014 |

| v25 | (E)-β-Ocimene | 3779-61-1 | Terpenoids | 1049 | Sweet, herbal | 0.029 ± 0.010 | 0.010 ± 0.002 | 0.008 ± 0.001 | 0.004 ± 0.002 |

| v26 | 1-Methyl-4-(1-methylethylidene)-cyclohexene | 586-62-9 | Terpenoids | 1088 | Citrus, woody, sweet | 0.232 ± 0.012 | 0.189 ± 0.010 | 0.186 ± 0.004 | 0.210 ± 0.012 |

| v27 | 1,10-Undecadiene | 13688-67-0 | Hydrocarbons | 1095 | - | 0.024 ± 0.001 | 0.007 ± 0.001 | 0.001 ± 0.000 | 0.003 ± 0.001 |

| v28 | 2,6-Dimethyl-2-trans-6-octadiene | 2609-23-6 | Terpenoids | 993 | Citrus | 0.022 ± 0.008 | 0.006 ± 0.002 | 0.003 ± 0.001 | 0.000 ± 0.002 |

| v29 | 3,5-Dimethyl-1H-pyrazole-1-carboximidamide | 22906-75-8 | Heterocyclic compound | 1096 | - | 0.036 ± 0.002 | 0.022 ± 0.002 | 0.020 ± 0.001 | 0.019 ± 0.002 |

| v30 | 2-Propenal | 623-30-3 | Heterocyclic compound | 1111 | Pungent | 0.028 ± 0.005 | 0.033 ± 0.003 | 0.046 ± 0.002 | 0.044 ± 0.006 |

| v31 | p-Mentha-1,5-dien-8-ol | 1686-20-0 | Terpenoids | 1167 | - | 0.015 ± 0.002 | 0.021 ± 0.003 | 0.036 ± 0.002 | 0.026 ± 0.003 |

| v32 | (E)-Nerolidol | 7212-44-4 | Terpenoids | 1563 | Floral, citrus | 0.006 ± 0.007 | 0.038 ± 0.006 | 0.045 ± 0.001 | 0.052 ± 0.020 |

| v33 | 5-Methyl-4-hexen-3-one | 13905-10-7 | Ketone | 1080 | Floral | 0.075 ± 0.003 | 0.058 ± 0.003 | 0.058 ± 0.001 | 0.068 ± 0.004 |

| v34 | 6-Camphenone | 55659-42-2 | Ketone | 1114 | - | 0.005 ± 0.002 | 0.007 ± 0.001 | 0.015 ± 0.000 | 0.013 ± 0.003 |

| v35 | 4-Ethyl-(E)-3-nonen-5-yne | 74744-60-8 | Hydrocarbons | 1117 | - | 0.008 ± 0.003 | 0.010 ± 0.002 | 0.017 ± 0.001 | 0.016 ± 0.003 |

| v36 | 2,7-Dimethyl-3,6-bis(methylene)-1,7-octadiene | 16714-60-6 | Hydrocarbons | 1083 | - | 0.058 ± 0.003 | 0.045 ± 0.003 | 0.044 ± 0.001 | 0.052 ± 0.003 |

| v37 | β-Ionone | 14901-07-6 | Terpenoids | 1491 | Dry, powdery, floral | 0.109 ± 0.029 | 0.146 ± 0.010 | 0.154 ± 0.004 | 0.116 ± 0.033 |

| v38 | (Z)-3-Hexen-1-ol | 928-96-1 | Alcohol | 858 | Fresh, green, leafy | 0.016 ± 0.001 | 0.001 ± 0.001 | 0.013 ± 0.001 | 0.042 ± 0.004 |

| v39 | (E)-2-Methylbut-2-en-1-yl methacrylate | 88142-95-4 | Ester | 1088 | - | 0.041 ± 0.002 | 0.031 ± 0.002 | 0.031 ± 0.001 | 0.035 ± 0.003 |

| v40 | Dihydroactinidiolide | 17092-92-1 | Heterocyclic compound | 1532 | Ripe, apricot, fruity | 0.019 ± 0.009 | 0.041 ± 0.004 | 0.039 ± 0.001 | 0.027 ± 0.013 |

| v41 | 1H-Imidazole-4-methanol | 822-55-9 | Heterocyclic compound | 1080 | - | 0.049 ± 0.003 | 0.038 ± 0.003 | 0.037 ± 0.001 | 0.044 ± 0.003 |

| v42 | 2-Methylpropyl-pyrazine | 29460-92-2 | Heterocyclic compound | 1074 | Fruity | 0.119 ± 0.005 | 0.103 ± 0.006 | 0.121 ± 0.002 | 0.141 ± 0.007 |

| v43 | 6-Ethenyltetrahydro-2,2,6-trimethyl-2H-Pyran-3-ol | 14049-11-7 | Heterocyclic compound | 1173 | Floral, honey | 0.109 ± 0.008 | 0.100 ± 0.006 | 0.137 ± 0.001 | 0.113 ± 0.010 |

| v44 | 2,6-Dimethyl-7-octen-2-ol | 18479-58-8 | Terpenoids | 1064 | Citrus | 0.106 ± 0.005 | 0.093 ± 0.005 | 0.108 ± 0.002 | 0.126 ± 0.007 |

| v45 | Tetrahydro-4,6,6-trimethyl-2H-Pyran-2-one | 20628-36-8 | Heterocyclic compound | 1141 | - | 0.018 ± 0.003 | 0.017 ± 0.001 | 0.016 ± 0.001 | 0.010 ± 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.-W.; Wu, Q.-Y.; Chen, L.-Q.; Ruan, S.-L.; Yang, Z.-Y.; Sun, Y.; Aikebaier, R. Comparison of Different Grades of Innovative Tanyang Congou Black Tea (Minkehong) Based on Metabolomics and Sensory Evaluation. Horticulturae 2024, 10, 374. https://doi.org/10.3390/horticulturae10040374

Zhou Z-W, Wu Q-Y, Chen L-Q, Ruan S-L, Yang Z-Y, Sun Y, Aikebaier R. Comparison of Different Grades of Innovative Tanyang Congou Black Tea (Minkehong) Based on Metabolomics and Sensory Evaluation. Horticulturae. 2024; 10(4):374. https://doi.org/10.3390/horticulturae10040374

Chicago/Turabian StyleZhou, Zi-Wei, Qing-Yang Wu, Li-Qin Chen, Shu-Ling Ruan, Zi-Yu Yang, Yun Sun, and Reheman Aikebaier. 2024. "Comparison of Different Grades of Innovative Tanyang Congou Black Tea (Minkehong) Based on Metabolomics and Sensory Evaluation" Horticulturae 10, no. 4: 374. https://doi.org/10.3390/horticulturae10040374

APA StyleZhou, Z.-W., Wu, Q.-Y., Chen, L.-Q., Ruan, S.-L., Yang, Z.-Y., Sun, Y., & Aikebaier, R. (2024). Comparison of Different Grades of Innovative Tanyang Congou Black Tea (Minkehong) Based on Metabolomics and Sensory Evaluation. Horticulturae, 10(4), 374. https://doi.org/10.3390/horticulturae10040374