Abstract

Hydroponic agriculture, when combined with Internet of Things (IoT) technologies, provides a promising pathway to sustainable and efficient food production. This paper aims to systematically review and analyze recent advancements in IoT-based management for hydroponic systems, with a particular focus on assessing the technological maturity of current solutions, identifying existing gaps, and outlining promising directions for future research and development. Based on a review of 74 recent studies, the findings reveal a fragmented landscape characterized by custom-built solutions, predominantly relying on open-source microcontrollers and WiFi connectivity, but with limited adoption of standardized protocols and interoperable platforms. The majority of applications emphasize monitoring of core hydroponic parameters such as pH, EC, and temperature, while emerging uses of machine learning remain at an early stage. Few systems demonstrate readiness for commercial deployment or integration within broader smart agriculture ecosystems. By clarifying the current state of IoT-enabled hydroponics, this review highlights both the opportunities and the challenges in advancing from isolated prototypes toward robust, scalable systems capable of real-world application.

1. Introduction

Smart agriculture aims to address challenges related to climate change [] and population growth [] improving resource efficiency and reducing environmental impacts through IoT and AI technologies []. Within smart agriculture, controlled-environment farming, particularly greenhouses and soilless systems, has gained attention for enabling year-round production and optimal use of limited resources [,,]. Hydroponics, a key soilless technique where nutrients are delivered via nutrient solution (NS) without soil [,,], relies on precise management of parameters such as pH and EC to maintain crop yield and quality.

Hydroponic systems vary in nutrient delivery methods, including NFT, DFT (e.g., DWC, DRFT), ebb and flow, and aeroponics [,,]. Although each system presents unique benefits and limitations, all require effective NS management to sustain healthy root environments and ensure optimal plant growth.

Traditionally, NS parameters such as pH, EC, TDS, temperature, and dissolved oxygen were manually monitored, which is labor-intensive and prone to inaccuracies. IoT technologies have transformed NS management by enabling continuous sensing, automated control, data analytics, and remote access [,,]. These capabilities support advanced applications such as vertical farming and aquaponics in commercial and urban contexts.

However, despite these technological advantages, several challenges hinder the development of reliable, scalable, and interoperable IoT-based hydroponic systems.

Key technical challenges include long-term sensor reliability in humid, nutrient-rich environments [] and seamless integration of heterogeneous sensors and actuators into unified platforms. The increasing connectivity of agricultural systems also introduces security risks, raising concerns about data integrity, confidentiality, and operational stability []. Additionally, the development of cost-effective IoT solutions for small- and medium-scale growers and the optimization of energy consumption in continuous monitoring systems present ongoing challenges []. Further challenges include the role of edge computing in enabling real-time decision-making, the complexities of integrating heterogeneous data streams, such as environmental parameters, nutrient solution metrics, and crop imagery and the need for interpretable machine learning (ML) models to support informed agricultural decisions. Also, securing sensitive crop data and automated operations against cyber threats is essential to maintain system reliability and prevent unauthorized access []. Platforms focused on farms and agriculture management systems are advancing to enhance decision-making and optimize agricultural operations. However, a major challenge in the digital transformation of agriculture is the limited ability of current systems to work together. These isolated systems restrict data sharing and integration across different domains and platforms, preventing farmers from fully take advantage from collected data [,]. In addition, the lack of interoperability between devices, data formats, networks, and entire platforms remains a critical barrier faced by farmers and growers []. This ongoing issue continues to hinder the digitalization of agriculture and is widely recognized as a significant concern in both academic and industry circles [,].

This survey paper aims to analyze recent advancements in IoT-based NS management for hydroponic systems, focusing on understanding the technological maturity level of IoT in hydroponics, identifying existing gaps, and outlining promising directions for future research and development. By examining the latest studies and technological implementations, we aim to provide a comprehensive overview of the state of the art in IoT-enhanced hydroponics, offering insights into the potential for these technologies to transform modern agriculture. This research aims to enhance knowledge for both agricultural experts and computer science professionals. The analysis of the selected articles was conducted with the intent to characterize both agronomic aspects, such as sensors, actuators, and applications, and computer science dimensions, including communication protocols, data processing techniques, and interoperability challenges.

2. Literature Review and Methodology

To provide accurate and up-to-date examples of real-time monitoring IoT platforms for NS management in greenhouse crops, a comprehensive literature search was conducted using the Scopus and Web of Science databases. Scopus is one of the largest abstract and citation database with extensive coverage across computer science, engineering, and agriculture, which are disciplines central to this study. Web of Science was included for its rigorous indexing and strong representation of high-impact journals, providing a reliable complement to Scopus.

While integrating multiple databases (e.g., IEEE Xplore, Google Scholar) could potentially increase coverage, this review prioritizes methodological consistency and data quality over quantity. We used the following queries:

Scopus database Query:

“TITLE ((hydroponics OR nutrient*) AND (iot*)) AND DOCTYPE (ar OR cp) AND SRCTYPE (j OR p) AND SUBJAREA (comp OR engi OR agri) AND LANGUAGE (english) AND PUBYEAR > 2010”

This search targeted articles and conference papers in English, published in the last 15 years, focusing on IoT applications in hydroponic and nutrient solution management systems within the fields of computer science, engineering, and agriculture.

Web of Science database Query:

“TI = ((“hydroponics” AND “iot*”) OR (“nutrient solution*” AND “iot*”))”

In Web of Science, the search was adapted to the platform’s field codes and indexing system. The query was restricted to the title field (TI) for topical precision. To ensure methodological comparability with the Scopus query, document type filters were applied to include only journal articles and conference proceedings. Unlike Scopus, the publication year range had to be manually specified in Web of Science: results were limited to items published between 1 January 2010 and 2 October 2025, ensuring the same temporal coverage as the Scopus search.

2.1. Screening and Processing Retrieved Records and Exclusion Criteria

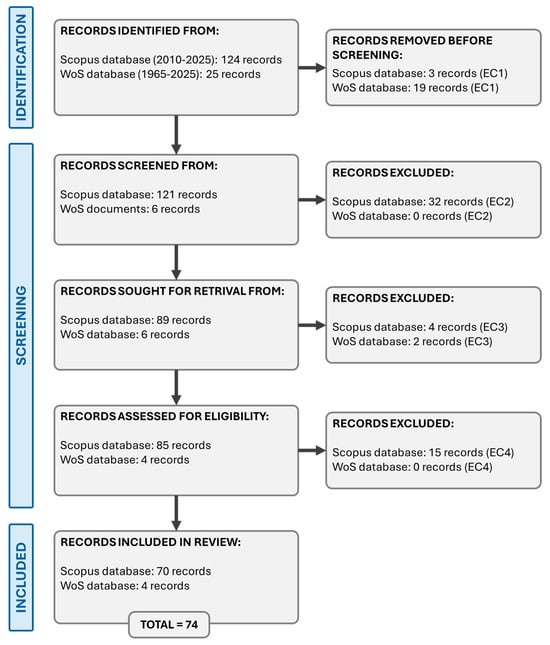

On 2 October 2025, a total of 124 documents resulted as the query output from Scopus database and only 25 documents resulted from Web of Science. To ensure all the included articles were relevant, a structured search strategy was developed to retrieve publications addressing the integration of advanced technologies within controlled-environment agriculture systems. The initial result set was exported and compiled for manual screening of titles, abstracts, and metadata to determine its potential relevance to the study’s objectives.

After the initial screening, the full texts of the retained publications were reviewed to confirm their eligibility. This step ensured that the selected works aligned with the scope of the review and provided substantive contributions to the topic under investigation. All publications meeting these criteria were logged into a shared document for structured evaluation, where metadata and key characteristics were systematically recorded.

Following the retrieval of the initial dataset, a careful screening process was implemented to ensure that only relevant and high-quality publications were included in the final analysis. This process was guided by a set of predefined exclusion criteria (EC) designed to filter out records that did not align with the scope, objectives, or methodological standards of the review. Each record was manually evaluated based on its title, abstract, and, where necessary, full text. The exclusion criteria were applied in a sequential and structured manner to maintain consistency across all assessments. The main criteria used for exclusion were as follows:

EC1: Duplicated records across venues or databases;

EC2: Papers not primarily focused on hydroponics/nutrient systems using IoT technologies;

EC3: Papers that were inaccessible or lacking essential information;

EC4: Conceptual surveys or tutorial papers not presenting original implementations.

After this checking, 74 relevant studies were selected and the workflow described is depicted in Figure 1.

Figure 1.

Identification, screening, and inclusion flow for documents using IoT in hydroponics according to PRISMA guidelines.

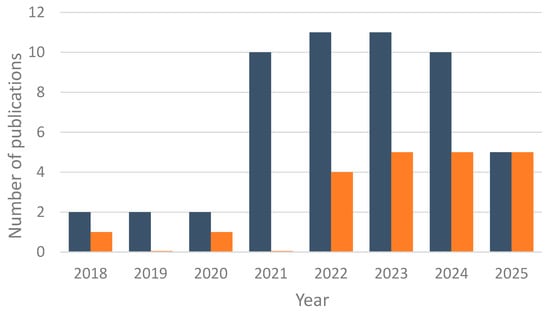

The distribution of publications by type and year over the analyzed period (2010–2025) is depicted in Figure 2. According to Figure 2, no relevant studies were identified before 2018, indicating that the application of IoT to hydroponics is a recent and emerging research area. This suggests that IoT use in hydroponics became a consistent and relevant topic only after 2017. The number of conference papers is consistently larger than journal articles throughout most of the period. After a modest number of publications between 2018 and 2020, there is a sharp increase in 2021 driven entirely by conference papers (10). From 2022 onward, journal articles begin to appear more regularly, reaching 4 in 2022 and increasing to 5 in both 2023 and 2024. The highest overall output is observed in 2023 (16 publications, 11 conference papers and 5 articles), followed closely by 2022 and 2024 (15 publications each). In 2025, despite being a partial year at the time of this survey, there are already 5 conference papers and 5 journal articles, indicating a growing balance between publication types and sustained research interest in the field.

Figure 2.

Annual distribution of publications by type (form 2010 to 2 October 2025). Blue bars represent conference papers; orange bars represent journal articles.

2.2. Aggregation

Each selected paper underwent a structured dual-review process to ensure the accuracy and consistency of feature characterization. One analyst was assigned to each paper, responsible for reading and extracting relevant information across predefined fields in a shared spreadsheet. Missing or ambiguous data were flagged with comments. A reviewer, different from the analyst, then validated this extraction by checking the source and suggesting corrections or additions. Any disagreements between the analyst and reviewer were resolved through direct discussion or escalated to the research group for consensus. All co-authors participated in both roles, ensuring that every paper was evaluated through diverse perspectives and strengthening the methodological coherence to ensure data extraction fidelity and standard interpretation across ambiguous cases.

2.3. Categories of Features Analyzed

To comprehensively evaluate studies conducted on IoT-based solutions in hydroponic and NS management systems, a set of features spanning across multiple technological and contextual layers were analyzed. Each selected study was reviewed and characterized according to its contributions across the physical, networking, service, and application layers. At the physical layer, we identified and classified the types of sensors and actuators employed for environmental and NS monitoring, distinguishing between common and advanced technologies. The networking layer involved the examination of network architectures and communication protocols used for data transmission, with attention to both standard and customized solutions.

The service layer focused on the presence of computational intelligence, including the application of ML and deep learning (DL) methods, as well as the underlying computing paradigms (e.g., cloud or edge computing) supporting data processing and decision-making. We also recorded the platforms used and whether these systems targeted specific domain applications, such as controlled environment agriculture or smart greenhouses. On the application layer, we evaluated the goal of each study, such as automation, resource optimization, or yield prediction. Additionally, we documented the specific hydroponic techniques implemented, the crop species cultivated, and the category of crop (e.g., leafy greens, fruit vegetables). Contextual metadata was also captured, including the availability of an open repository or dataset for reproducibility, the technology readiness level (TRL) indicating the maturity of the solution, and whether the system addressed aspects of interoperability and scalability, which are crucial for broader adoption and integration.

By systematically coding each of these dimensions, we aimed to enable a multidimensional analysis that highlights technological trends, identifies gaps in current approaches, and provides insight into the future development of smart hydroponic systems.

2.4. Limitations

Despite the structured and systematic nature of our review process, several limitations should be acknowledged. First, the main limitation of this review lies in its reliance on title-based searches. Restricting the query exclusively to the title field may have led to the exclusion of relevant studies in which key concepts were discussed only in the abstract, keywords, or main text. While this approach risks overlooking some valuable contributions due to variations in phrasing or terminology, it was deliberately chosen to ensure high topical precision. By focusing on works that explicitly mention both IoT and hydroponics in the title, the review prioritizes studies where the integration of these concepts is central rather than peripheral, thus aligning more closely with the objectives of this research. Additionally, the scope of our analysis was confined to publications indexed in two academic databases, thereby excluding literature from other repositories or non-indexed sources that may contain pertinent contributions. Our focus on English-language publications also introduces a potential bias, as important studies published in other languages were not considered. Furthermore, the review only covered works published from 2010 onward. This range was chosen to provide a comprehensive overview of developments over the past 15 years. However, it is important to note that the intersection of IoT and hydroponics, as indicated by publications explicitly mentioning both terms in their titles, only began to appear consistently after 2017 (Figure 2). Lastly, even though we employed a dual-review verification process to ensure accuracy and minimize bias, the classification and interpretation of features within each study involved an element of subjectivity, which could affect consistency across the dataset. While we sought to mitigate these risks through consensus and group discussions, some variation in judgment is inevitable in qualitative reviews of this nature.

3. A Review of IoT-Driven Hydroponics

The survey conducted includes an analysis of sensor and actuator usage across the 74 scientific publications with the aim to reveal insights on the common IoT setups in hydroponic research, highlighting current trends and identifying gaps in emerging technologies in the field. In the following sections, we categorize the main findings of this survey by analyzing sensor and parameter typologies, microcontroller boards, connection protocols, application layers, hydroponics techniques, and ML techniques. Finally, we conclude this section by discussing the open practices used, the interoperability level, and the technical readiness level reached. Additionally, the list of analyzed papers is made available in an open repository []. It is worth noting that the analysis does not describe each individual article in detail, but rather aims to identify the main findings in order to assess existing gaps and opportunities for future research.

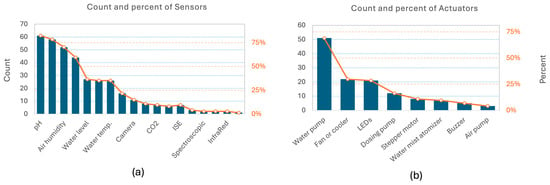

3.1. Sensor Typologies, Parameters Monitored, and Actuators Employed for Automation

We show the most common sensors used in hydroponics in Figure 3a. pH sensors are the most employed, featuring in over 82.4% of the studies. The substantial use of EC or TDS sensors (approximately 59.5%) underscores the emphasis on monitoring these two parameters of NS for ensuring quality in terms of salinity and nutrient availability. Indeed, many among the surveyed papers used these two sensors for automating NS salinity monitoring in open systems [,] or with recirculation provided [,]. Air temperature and relative humidity (RH) sensors are also widely utilized, appearing in approximately 78.4% and 70.3% of the studies, respectively, highlighting their relevance for plant growth, production, and ecosystem monitoring.

Figure 3.

(a) Count and percent of sensors usage across the survey paper. (b) Count and percent of actuator usage across the survey paper.

Water level, water temperature, and light radiation sensors are moderately used in IoT-based hydroponic systems, appearing in approximately 36.5% and 35.1% of the studies, respectively. These sensors play an important role in environmental control and nutrient solution management in automated systems. Soil moisture sensors, on the other hand, are found in about 21.6% of the papers. Although their presence may seem unusual in a soilless context, this is not entirely unexpected, as some systems adopt substrate-based or hybrid approaches where monitoring residual moisture remains relevant.

Despite cameras are used less frequently, appearing in approximately 14.9% of the analyzed papers, their application in visual monitoring, likely for assessing crop health and facilitating image-based analysis, signals the increasing integration of advanced technologies such as ML and DL in the field.

In addition to the widely used sensors mentioned above, there is a notable group of sensors that appears in approximately 9.5% of the surveyed publications, reflecting more specialized or emerging applications in IoT-based hydroponics research. Ion-selective electrode (ISE) sensors are present in a total of seven studies, likely used for targeted ion monitoring, which allow for specific nutrient control. For example, ref. [] utilizes a commercially available Vernier (Vernier Science and Education. Available online at: https://www.vernier.com/ (accessed on 21 March 2025)) device to measure Ca2+ and NH4+ levels, indicating that some research relies on off-the-shelf solutions rather than custom-built systems. ISEs combined with IoT were also compared with models and a standard ion analyzer for modeling K+, NO3−, and Ca2+, showing the potential for a real-time advanced monitoring in hydroponics systems []. One study conducted real-time advanced monitoring of essential nutrients such as (K+, NH4+, NO3−) using IoT-interfaced solid-contact ion-selective electrodes (SCISEs), demonstrating how continuous nutrient monitoring can significantly improve plant growth management []. The same IoT-interfaced SCISEs were employed in a real greenhouse study to assess lettuce nutrient (K+, NH4+, Ca2+) absorption efficiency under different conditions []. Moreover, IoT-based ISEs have been used to monitor and manage NS macronutrient (N-P-K) composition through ML algorithms for NS parameter optimization and overall crop quality improvement [,].

Flow meters, CO2 sensors, and dissolved oxygen (DO) sensors are less frequently used, appearing in approximately 10.8%, 9.5%, and 8.1% of the studies, respectively. Flow meters and DO sensors highlight the need to regulate water circulation and maintain adequate oxygen availability in the root zone, which is essential in closed-loop systems [,] and aquaponics systems [,]. CO2 sensors, although relatively recent in adoption, appear mainly in the most recent publications (particularly in 2025). Their emergence reflects the growing interest in VF [,] and fully indoor controlled environments, where atmospheric CO2 becomes a critical factor for productivity.

Among the different types of actuators used, depicted in Figure 3b, water pumps were the most used actuators, making up more than 68.9% of the total actuators mentioned. Water pumps play a crucial role in circulating nutrient solutions throughout hydroponic systems, ensuring not only the delivery of water and nutrients but also enabling precise adjustments to pH and EC. Their widespread use highlights the efficiency and ease of automating water flow management in hydroponics, which is vital for maintaining optimal plant health.

Within the 51 papers mentioning the usage of water pumps, two types of devices were employed: (i) inflow pumps (the majority) with the aim of supplying NS into the system, and (ii) outflow pumps which are used in some specific hydroponic systems such as ebb and flow (E&F) and DWC to remove excess water or nutrient solution to prevent oversaturation or to recycle the water [,]. In many of these automated systems, pumps were accompanied by electrovalves and stepper motors, which enabled different levels of control. Fans and LEDs are the second most frequent type of actuator, mentioned, respectively, in 29.7% and 28.4% of the studies. Fans are essential for regulating the airflow and temperature in controlled environments, preventing excessive humidity. LEDs provide specific wavelengths of light that plants need for photosynthesis []. The usage of LEDs suggests a focus on optimizing light conditions, especially in indoor or VF systems where natural sunlight is limited []. Dosing pumps, though used less frequently, 16.2% of the total, are critical for aquaponics systems, used for feeding fish or adding eventual supplements to the system, reflecting the system’s dual focus on both plant and aquatic life management [,]. Air pumps are essential for providing oxygen to the water in systems like DWC or aquaponics, but used also in much common systems like NFT []. They help oxygenate the NS tanks, promoting root health and preventing stagnation, which can lead to anaerobic conditions harmful to plant growth.

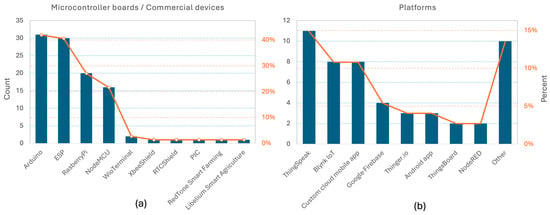

3.2. Microcontroller Boards

Another component of the physical layer is represented by microcontroller boards. The 74 papers were analyzed to understand the physical layer of the IoT managing system. This analysis demonstrates that most of the research is focused on proof-of-concept implementations rather than fully developed, commercialized solutions. The predominance of microcontroller boards such as Arduino (present on 31 publications), ESP (30 publications), and Raspberry Pi (20 publications) suggests not only that researchers are engaged in exploratory or experimental studies, but also that these platforms are favored due to their low cost and open-source designs. This focus on prototyping-grade platforms is further underscored by the limited presence of commercially available nodes. Indeed, among the 74 studies, only 2 employed commercial devices such as the RedTone Smart Farming system (REDtone Smart Farming. Available online at: https://www.redtone.com/smart-farming/ (accessed on 21 March 2025)) [] and Libelium Smart Agriculture Xtreme (Libelium Smart Agriculture. Available online at: https://www.libelium.com/ (accessed on 21 March 2025)) [], highlighting the scarcity of commercially viable solutions in the literature. Figure 4a depicts the microcontroller boards found in the present survey.

Figure 4.

(a) Count and percent of microcontroller boards usage across the surveyed papers. (b) Count and percent of platform usage across the surveyed papers.

This scarcity reflects a broader challenge within the field: the difficulty of sourcing commercially available devices and nodes designed specifically for smart hydroponic systems. Although platforms such as RedTone, Libelium, and Dragino (Dragino. Available online at: https://www.dragino.com/ (accessed on 21 March 2025)) offer Arduino-compatible nodes that could be adapted for hydroponic monitoring, they are not widely utilized, likely due to limited availability or high cost. This lack of readily accessible commercial solutions suggests that while proof-of-concept studies are essential for advancing research, the transition to scalable, market-ready IoT systems for hydroponics remains underdeveloped. Consequently, further efforts are needed to bridge the gap between research prototypes and commercially deployable solutions in smart hydroponics.

3.3. Connection and Protocols

The surveyed papers revealed that WiFi is the most common connection type with 60 studies using it, underscoring its widespread adoption possibly due to its ease of setup and robust data transfer capabilities. Bluetooth Low Energy and Zigbee are utilized in five and three works, respectively, suggesting that these technologies might be preferred for more niche applications or specific scenarios where energy efficiency and network topology require low-power solutions. GSM and GPRS connections were found in nine publications, indicating their importance in scenarios requiring remote connectivity, especially in areas lacking WiFi infrastructure.

Moreover, only 16 papers out of 74 surveyed specified the protocols used, which might suggest either a lack of standardization in reporting or a focus on the connection types rather than the protocols themselves in the surveyed literature. TCP/IP show limited usage with only one mention, perhaps indicating their application in specific contexts where simple request/response models or fundamental internet protocols are sufficient. HTTP and MQTT appear to be not commonly used, with only seven and eight papers reporting protocols, respectively, although MQTT is suitable for lightweight messaging and is effective in IoT environments where minimal bandwidth usage and efficient data transmission are crucial. Also, MQTT is associated with papers with the most robust scientific designs and setups. In [], a stress-test comparison between HTTP and MQTT highlights clear differences in efficiency and reliability. Overall, MQTT proved to be more resource-efficient than HTTP, requiring less than one-third of the CPU usage under equal client loads as well as when handling the same number of messages. In addition, MQTT demonstrated a much faster transfer time, making it particularly well-suited for hydroponic IoT scenarios that rely on real-time monitoring and rapid sensor–actuator communication. However, this efficiency comes with a trade-off: while HTTP was able to reliably receive a high number of messages without losses, MQTT experienced payload losses under high-throughput conditions, suggesting its use is more appropriate in hydroponic systems with fault-tolerant architectures or where occasional data loss is acceptable in favor of faster, lightweight communication.

3.4. Platforms and Application Layer

Among the platforms surveyed for IoT system management in hydroponics, ThingSpeak (Thingspeak: https://thingspeak.mathworks.com/ (accessed on 21 March 2025)) emerges as the most frequently utilized, appearing in 11 publications (Figure 4b). This indicates a preference for its specialized capabilities in handling real-time data streaming and analysis, which are crucial for monitoring variables such as nutrient levels and environmental conditions in hydroponic systems. Following ThingSpeak, generic cloud mobile apps and the Blink IoT platform are also commonly used, both with eight mentions each. However, the diversity of platforms, including Thingsboard, thinger.io, Google Firebase, and others, with only one mention each suggests there is no standardization in the platforms used for IoT in hydroponics. This diversity reflects a fragmented domain where users often choose platforms based on specific needs, availability or familiarity, rather than a unified approach across the field. All these platforms being free also highlights the accessibility and low barrier for entry in adopting IoT solutions in hydroponic agriculture. The fragmentation and lack of standardized approach is a well-known problem. Indeed, ref. [] identified more than 300 IoT platforms available in the market promoting their own IoT infrastructure, protocols data formats, and so on.

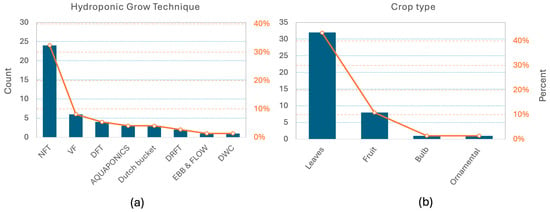

3.5. Hydroponic Techniques and Crops

Figure 5a presents an overview of the most common hydroponic techniques alongside the types of crops typically cultivated using these methods. While not all surveyed papers provided explicit details, NFT emerged as the most popular, with 24 instances noted. The preference for NFT is primarily due to its efficient and straightforward operational design, which optimizes the delivery of nutrients directly to plant roots while ensuring optimal root oxygenation []. Additionally, the system’s use of a continuous or intermittent flow of nutrient-rich water keeps the roots constantly exposed to necessary nutrients, effectively reducing the risk of water stress []. This setup negates the need for precise water management in irrigation practices. NFT’s space efficiency and its compatibility with VF structures make it particularly suitable for urban areas and locations with limited space [,,,]. Furthermore, NFT has been extensively utilized in research focused on various agricultural challenges, including salinity, NS management, greenhouse cultivation of diverse crops, and studies on nutrient uptake, as explored by [].

Figure 5.

(a) Count and percentage of hydroponics techniques employed among the surveyed papers. (b) Count and percentage of crops used in trials among the surveyed papers.

Among the articles surveyed, most NFT systems were developed primarily to explore the potential of IoT for real-time monitoring and automation of one of several aspects. These tests were generally conducted in laboratory or home settings. In certain scenarios, smart NFT systems were specifically deployed in urban contexts with limited space and resources [,]. However, the use of small areas was often due to the experimental nature of the research, most of the time aiming to demonstrate IoT potential and not a real use case scenario.

Conversely, ref. [,] applied IoT technologies in commercial greenhouse environments, focusing on enhancing the precision and efficiency of hydroponic agriculture. Ref. [] focused on developing an automated system to monitor TDS in hydroponic solutions, ensuring optimal quality of NS for plant health. Furthermore, an additional investigation applied IoT for both monitoring and controlling nutrient solutions and utilized ML to predict growth rates in leafy vegetables []. These applications of IoT in hydroponics show how advanced technologies can lead to more precise control and better prediction of plant growth outcomes, contributing to more sustainable and efficient agricultural practices.

Some studies provided tangible evidence of using IoT for sustainable practices, such as close hydroponic systems providing NS recirculation to optimize crop production [] and for integrating and monitoring solar energy [,].

VF was found in six studies, indicating that this technique and its terminology are gaining traction within the scientific community, likely due to its demonstrated effectiveness, growing recognition in the literature, and consistency in methodological application. Other methods like DFT, Dutch Bucket, and aquaponics were found in four (DFT) and three (Dutch Bucket and aquaponics) studies, respectively. These techniques are chosen for specific plant needs or scalability considerations. Techniques such as DRFT, ebb and flow, and DWC have lower counts, possibly indicating higher complexities or specific requirements. Additionally, only five of these papers included trials on NS recirculation, specifically three on DFT, one on VF, and one on NFT.

Figure 5b shows the types of crops studied among the papers of the survey. Leafy vegetables are the most common vegetables used in hydroponics in general, and the results of this survey corroborate this trend. Indeed, 32 of these studies used leafy vegetables, reflecting their suitability for hydroponic systems, which can efficiently support their growth requirements. Among the leafy vegetables, lettuce (Lactuca sativa) is the most cultivated, with fourteen studies using them in their trials, followed by six studies each based on general leafy vegetables and brassicaceae such as Chinese cabbage Brassica rapa subsp. pekinensis, Pak choi Brassica rapa subsp. chinensis, kale (Brassica oleracea var acephala), arugula (Eruca sativa), and mustard (Brassica juncea), followed by spinach (Spinacia oleracea) with three.

It is well known that leafy vegetables are the most suited for hydroponics systems because of their high-water use efficiency (WUE), which is the amount of water transformed into product. Moreover, four of the trials were conducted on aromatic leafy species some of them highlighting how the use of IoT ease the growth of some difficult and valuable species such as holy basil (Ocimum tenuiflorum) [].

Fruit vegetables are present as well, though less prevalent, with a count of eight papers in total. Their lower representation could be due to the greater nutritional and demands and operations typical of fruit-bearing crops compared to leafy vegetables. In the category of fruit vegetables, cucumbers (Cucumis sativus), peppers (Capsicum annuum) and tomatoes (Solanum lycopersicum) are the most frequent, each recorded three and two times, respectively, followed by eggplants (Solanum melongena) with one study each, showcasing a variety of fruits that can also be adapted to hydroponic cultivation despite their higher resource requirements.

Bulb and ornamental plants both have a count of one study each. Their minimal presence might be attributed to their less frequent use in hydroponic setups, which are primarily optimized for more commonly grown hydroponic plants like leafy greens and herbs.

3.6. Machine Learning Techniques

The survey results highlight that IoT technologies were commonly employed to monitor crop growth parameters, while AI techniques were applied to assess crop health, growth status, and nutrient concentrations. Several studies specifically utilized ML techniques to optimize crop management processes.

In greenhouse environments, where pathogens can spread rapidly, disease and nutrient deficiency detection becomes a critical component of crop management. For this task, DL techniques demonstrated higher performance compared to ML approaches [,]. DL methods were primarily used to classify disease symptoms and identify nutrient deficiencies on crop leaves through image analysis.

For example, Deepika et al. [] evaluated four transfer learning models to determine the general health status of plant leaves, while Mosaad et al. [] implemented a convolutional neural network (CNN) and a YOLO (You Only Look Once) model to predict and detect the health status of mint leaves. This last study integrated DL techniques with IoT technologies to provide recommendations for vertical hydroponic growing systems. In addition, Khare et al. [] developed a solar-powered, automated hydroponic system capable of precisely regulating growth parameters. Their system utilized DL techniques for optimal nutrient level prediction and plant disease classification.

Accurately predicting crop growth stages and yield is critical for optimizing resource use and maximizing production in greenhouses and hydroponic systems. ML combined with IoT technology been successfully used for this task in hydroponic contexts. Promwee et al. [] demonstrated the efficiency of smart hydroponic systems that leverage IoT for precise monitoring and control. Their study reported improvements in plant height, width, weight, and chlorophyll content. Furthermore, they utilized ML models on the Amazon Web Services (AWS) cloud to predict plant growth and crop quality while ensuring optimal resource management through an automated control system.

Similarly, Budiman et al. [] and Mapari et al. [] implemented IoT systems to gather accurate, real-time data, which was then used in ML models to control nutrient supply and predict crop growth rates. These techniques enhanced decision-making and helped maintain ideal growing conditions for crops. Mamatha and Kavitha employed IoT to monitor essential environmental parameters and applied a Random Forest (RF) algorithm to predict and estimate crop yield. The results were made accessible to farmers through a user-friendly web application, providing them with actionable insights to optimize production and improve profitability.

Srinidhi et al. [] developed a mobile application that integrates hydroponic systems with ML algorithms, specifically K-Nearest Neighbors (KNN) and Lasso Regression. Their models predict the nutritional value of each plant, while a multiple-leaf detection feature allows users to input additional data and receive customized insights, supporting more informed cultivation decisions. Efficient NS management is another critical task of hydroponic systems, as maintaining the balance of nutrients according to plant needs requires constant monitoring and adjustments. The combination of IoT and ML offer real-time monitoring and automated control of nutrient delivery systems solutions to growers. Smart NS management not only ensures the sustainability of these systems but also minimizes manual intervention, making them highly scalable and efficient. Studies on smart NS management were identified in the present survey. For instance, Mehare and Gaikwad [] developed an intelligent management system using supervised classification and regression-based approaches to optimize resource allocation based on specific crop requirements. Similarly, Dhal et al. [] designed a smart nutrient solution management system for aquaponics, utilizing machine learning techniques to maintain nutrient balance. By analyzing key parameters such as pH and EC, they applied feature selection methods to identify the most relevant factors influencing nutrient levels. Their system provided data-driven suggestions to maintain nutrient solutions at optimal concentrations, ensuring healthier crops and more efficient resource use.

The study in [] introduced the CRL-SHS reinforcement learning and metaheuristic algorithm, which enables dynamic adaptation of hydroponic parameters and achieved substantial performance gains over several state-of-the-art ML/DL models. With 99.11% accuracy and consistently high precision, recall, and F1 scores across multiple datasets, this work demonstrates the effectiveness of adaptive and intelligent control strategies in hydroponic automation. Meanwhile, ref. [] broadened the focus from system control to crop growth and disease detection by implementing a Dynamic Graph Neural Network (DGNN-GDD) integrated with computational fluid dynamics (CFD) analysis and statistical validation. Achieving a 93% weighted F1 score, this study illustrates a significant shift in hydroponics research toward the fusion of predictive AI, physical process modeling, and biological understanding, marking a new stage of sophistication in smart agriculture.

3.7. Open Science Practices, Interoperability, and Technical Readiness Level

All 74 papers were surveyed to determine whether they provided open repositories and to assess the level of interoperability in IoT solutions.

The findings reveal that only 4 out of 74 papers included open repositories, highlighting a significant gap in publicly available datasets or software components. Specifically, ref. [] shared an open repository containing data on nutrient monitoring in NS through an IoT-connected spectroscopic system; however, no source code was made available. Similarly, ref. [] included a data statement indicating that datasets would be provided upon request. These datasets are more likely related to cabbage improvement rather than code or software for IoT applications. Moreover, ref. [] tested ML models on public dataset for NS parameter prediction (https://doi.org/10.15482/USDA.ADC/1503971, (accessed on 30 October 2025)) and disease detection (https://www.kaggle.com/datasets/emmarex/plantdisease, (accessed on 30 October 2025)) and ref. [] used public dataset to train a reinforcement learning model on a lettuce growth days dataset (https://www.kaggle.com/jjayfabor/datasets, (accessed on 30 October 2025)), a hydroponic plant nutrition dataset (https://www.kaggle.com/datasets/chalimmufidah/hydroponic-plants-nutrition-data/, (accessed on 30 October 2025)), a hydroponic and soil compound dataset (https://www.kaggle.com/datasets/abtabm/plant-growthhydroponics-and-soil-compound-dataset, (accessed on 30 October 2025)), a nutrient solution and Pak choi dataset (https://figshare.com/articles/dataset/Nutrient_solution_and_pakchoi/5740269, (accessed on 30 October 2025)), and on a vertical farming dataset (https://www.kaggle.com/datasets/midouazerty/work-for-parmavir, (accessed on 30 October 2025)).

This limited availability of open data aligns with the general lack of free datasets in both the academic literature and online repositories. Despite the scarcity of open datasets in surveyed papers, some relevant datasets were found in online repositories. For example, ref. [] published a dataset on NS management and growth analysis in soilless tomato crops, covering dry matter content, nutrient solution consumption, and plant tissue composition. Additional datasets were identified on Kaggle, primarily image datasets for training ML and DL models for nutrient deficiency detection (https://www.kaggle.com/datasets/baronn/lettuce-npk-dataset, (accessed on 30 October 2025)). Other Kaggle datasets contained general environmental parameters (https://www.kaggle.com/datasets/pranav941/hydroponics-feed, (accessed on 30 October 2025)), soil and substrate information (https://www.kaggle.com/datasets/abtabm/plant-growthhydroponics-and-soil-compound-dataset, (accessed on 30 October 2025)), and aquaponics-related data (https://www.kaggle.com/datasets/udcdse/aquaponics-dataset, (accessed on 30 October 2025)).

Interoperability, while slightly better, remains a significant challenge, with only 17 papers (23%) addressing it. This means that the vast majority (57 papers) do not consider interoperability, potentially leading to fragmented IoT ecosystems where devices and platforms struggle to communicate effectively. The lack of standardized protocols and the prevalence of vendor-specific architectures may contribute to this issue, limiting the scalability and integration of IoT systems across different domains. Improving interoperability is crucial for ensuring seamless data exchange and fostering innovation in IoT solutions.

The evaluation of scalability and technology readiness level (TRL) across the 74 surveyed papers highlights significant gaps in both aspects. Most papers exhibit low scalability (38 papers, about 51.4%) and low TRL (49 papers, about 66.2%), indicating that many IoT solutions remain in early development stages or are designed for small-scale applications without clear pathways for large-scale deployment. A medium scalability level is observed in 27 papers (about 36.5%), while 21 papers (about 28.4%) have a medium TRL, suggesting that some solutions show potential for expansion but are not yet fully mature. Notably, only one paper achieves high scalability and none reaches a high TRL, emphasizing the lack of fully developed and widely deployable IoT solutions. These results suggest that research efforts primarily focus on conceptual frameworks or small-scale implementations rather than mature, market-ready technologies. Enhancing scalability and TRL is mandatory for transitioning IoT-based agricultural solutions from experimental phases to real-world applications. Additionally, we examine the platform’s scalability by comparing state-of-the-art solutions available in the literature. These developments highlight the increasing interest in digital platforms for incorporating advanced sensing technologies and AI to enhance the precision and efficiency of hydroponic systems. The integration of AI enables predictive analytics and machine learning capabilities, which can further optimize growing conditions and resource management.

However, few of these platforms can seamlessly integrate with other systems via standard communication protocols and, in general, their technical readiness level is low. The interoperability capability is crucial for creating smart agricultural, and specifically hydroponics, systems that can interact with various devices and platforms. Furthermore, we observed a significant lack of open-source code, data, and models, as no works reference a public repository, emphasizing the need for greater transparency and community access. Open-source initiatives could accelerate innovation and adoption by allowing researchers and practitioners to build upon existing work.

By addressing key challenges such as scalability, interoperability, and transparency, the platform has the potential to significantly impact the future of sustainable agriculture in diverse contexts, from small-scale urban farms to large commercial operations.

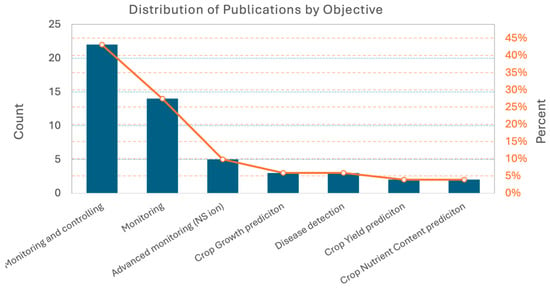

3.8. Analysis of the Objectives

Each publication analyzed in this survey presents a unique goal aligned with its specific research context and technological implementation. However, to facilitate comparison and synthesis across the literature, we categorized these objectives into broader functional groups based on domain applications, which are depicted in Figure 6.

Figure 6.

Number of publications per each domain application.

Monitoring refers to studies in which IoT systems were used solely for data acquisition and real-time observation of hydroponic setups, without direct intervention capabilities. In contrast, monitoring and controlling encompasses works that included actuation components such as irrigation systems, notification mechanisms, fans, or cooling systems allowing for remote or automated system responses based on sensor input.

The category of advanced monitoring includes studies that incorporated ion-selective electrodes or other specialized sensors. These tools, increasingly popular in hydroponics due to their compatibility with IoT technologies, allow for more precise nutrient solution analysis.

Additional objectives covered more complex tasks involving ML and DL techniques. These studies focused on the prediction of crop parameters, such as growth stage, yield, or nutrient content, or on disease detection, aiming to support proactive crop management and enhance system intelligence.

The analysis of application domains across the reviewed literature reveals emphasis on core functionalities such as monitoring and control within IoT-based hydroponic systems. The most prevalent category focused on both monitoring and controlling providing the integration of sensor feedback with automated actuation mechanisms. Following closely, monitoring alone suggests that many systems still prioritize data acquisition over full automation.

More specialized objectives were addressed less frequently. For instance, advanced monitoring, particularly with nutrient solution ion analysis, appeared in only five studies, indicating a growing but still limited interest in more complex sensing capabilities. Predictive capabilities such as growth stage prediction, yield estimation, and nutrient content prediction were explored in just a few publications, reflecting the emerging role of machine learning in this domain.

Lastly, disease detection, although a critical aspect of crop health management, was the focus of only three papers, highlighting a significant gap and a potential direction for future research. Overall, while most current efforts emphasize real-time environmental management, the relatively low number of studies focused on prediction and health diagnostics suggests that the field is still maturing and transitioning toward more intelligent and autonomous systems.

4. Discussion

The current landscape emerged from the 74 surveyed papers is predominantly characterized by exploratory, proof-of-concept research rather than mature, market-ready technologies. This is evident in the widespread use of open-source microcontroller platforms which appear in the majority of surveyed studies. While these platforms provide accessible and flexible tools for experimental implementations, the scarcity of commercial IoT nodes tailored for hydroponics underscores how underdeveloped the market is for practical, ready-to-deploy solutions in this field. This reliance on non-commercial hardware limits the ability to scale solutions beyond controlled experimental environments and highlights a gap between research prototypes and deployable systems. A comprehensive analysis of the microcontroller boards used across the literature [] confirms this technological immaturity: most studies rely on versatile but non-industrial platforms, which vary widely in features, sensors, and integration strategies. While this diversity enables experimentation, it prevents aggregation or standardization at the hardware level. Importantly, the challenge in this domain is not the choice of board itself, but rather the lack of scalability and large-scale data integration, which are essential for real-world deployment. As shown in Figure 2, IoT adoption in hydroponics has only recently gained momentum and the field remains in a prototyping and research-grade phase. Commercial, ready-to-use devices are still rare and often lack technical readiness or robust data collection capabilities. However, as prototyping efforts mature, it is expected that standardized, scalable, commercial-grade IoT solutions will naturally emerge, enabling broader deployment and integration with existing agricultural infrastructure.

Connectivity remains largely dominated by WiFi, favored for its robustness and ease of use, though niche applications employ low-power technologies like Bluetooth and Zigbee. Protocol adoption is uneven, with MQTT used infrequently despite its advantages, possibly reflecting limited standardization and varying design priorities across studies. This fragmented approach to communication technologies complicates efforts to build interoperable systems that can seamlessly exchange data and function cohesively across heterogeneous devices and platforms.

Indeed, interoperability emerges as a critical bottleneck in advancing IoT for hydroponics, pointing to a widespread issue of fragmented ecosystems driven by vendor-specific architectures and a lack of standardized protocols. Without interoperable frameworks, scaling IoT solutions for hydroponics remains challenging, as devices and systems struggle to communicate effectively, limiting integration potential and hindering broader adoption. This fragmentation is further reflected in the diverse but uncoordinated use of IoT platforms, where no single platform dominates and users select tools based on availability or familiarity rather than compatibility or standardization. The prevalent use of free, open platforms lowers barriers to entry but inadvertently perpetuates ecosystem fragmentation, undermining efforts toward unified, scalable solutions.

From a technical maturity perspective, the TRL and scalability of current IoT hydroponic solutions remain largely low. Most studies focus on small-scale or laboratory implementations, with limited consideration for practical deployment at the commercial scale. This is compounded by a significant lack of open repositories or publicly shared datasets and codebases hindering reproducibility, validation, and collaborative improvement across the field. Without accessible, standardized datasets and software components, the pathway from experimental proof-of-concept to reliable, scalable commercial systems becomes arduous.

Functionally, IoT applications have largely concentrated on monitoring and basic control of hydroponic environments, such as sensor data acquisition and actuation of irrigation or climate control devices. Advanced monitoring techniques, including ISE for NS monitoring and predictive analytics using ML and DL remain underrepresented. Although AI methods show promise, they are applied in only a small subset of studies, showing an early stage of integration between IoT and intelligent data analytics in hydroponics. This gap indicates a need for greater focus on developing intelligent, autonomous systems that can not only monitor but also predict and optimize crop conditions, thereby improving resource use efficiency and crop yields sustainably.

The dominance of NFT hydroponics and leafy vegetables such as lettuce in the surveyed research further points to a research focus on relatively simpler and well-understood crop systems. While this is a logical starting point, scaling IoT solutions for a wider variety of crops and hydroponic techniques, including those with greater complexity, will be necessary to realize the full potential of IoT-enabled smart agriculture.

5. Conclusions

In conclusion, the IoT landscape for hydroponic systems is promising but immature. The heavy reliance on open-source microcontrollers and free platforms facilitates experimentation but also limits scalability and commercialization. Critical barriers, especially interoperability, lack of standardized protocols, low TRL, limited scalability, and scarce open resources must be addressed to transition from research prototypes to deployable technologies. Overall, this review reveals that IoT-based hydroponic systems are still in an early stage of technological development, marked by diverse but fragmented research efforts. Most studies remain at proof-of-concept level, relying on open-source hardware and non-standardized communication protocols, which limits scalability and interoperability. Connectivity solutions are dominated by WiFi, while more efficient or standardized alternatives remain underexplored. Data management and system integration are hindered by the absence of shared datasets and open platforms, reducing reproducibility and slowing collective progress. Functionally, current implementations focus primarily on monitoring and basic control, with limited integration of AI-driven analytics or predictive capabilities. These patterns collectively highlight a research field rich in innovation but lacking consolidation, standardization, and real-world deployment readiness. Future efforts should emphasize developing interoperable, scalable systems with higher TRL, supported by open datasets and shared software to accelerate innovation. Furthermore, integrating advanced AI-driven predictive analytics and expanding the scope beyond leafy vegetables will be pivotal in advancing smart hydroponics from niche research to practical, sustainable agricultural solutions.

Author Contributions

Conceptualization, P.B., A.C. and M.B.; methodology, M.S. and A.C.; validation, A.C., M.S., D.L.R. and M.B.; formal analysis, M.S.; A.C. and D.L.R.; investigation, M.S. and A.C.; resources, P.B.; data curation, M.S.; A.C. and D.L.R.; writing—original draft preparation, M.S.; writing—review and editing, D.P.-M. and M.S.; visualization, D.L.R.; supervision, A.C.; project administration, P.B., A.C. and M.B.; funding acquisition, P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original data presented in the study are openly available in [] at https://doi.org/10.5281/zenodo.15835814.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Morchid, A.; Et-taibi, B.; Oughannou, Z.; El Alami, R.; Qjidaa, H.; Jamil, M.O.; Boufounas, E.-M.; Abid, M.R. IoT-enabled smart agriculture for improving water management: A smart irrigation control using embedded systems and Server-Sent Events. Sci. Afr. 2025, 27, e02527. [Google Scholar] [CrossRef]

- Rathor, A.S.; Choudhury, S.; Sharma, A.; Nautiyal, P.; Shah, G. Empowering vertical farming through IoT and AI-Driven technologies: A comprehensive review. Heliyon 2024, 10, e34998. [Google Scholar] [CrossRef]

- Rudrakar, S.; Rughani, P. IoT based Agriculture (Ag-IoT): A detailed study on Architecture, Security and Forensics. Inf. Process. Agric. 2024, 11, 524–541. [Google Scholar] [CrossRef]

- Elsherbiny, O.; Gao, J.; Ma, M.; Guo, Y.; Tunio, M.H.; Mosha, A.H. Advancing lettuce physiological state recognition in IoT aeroponic systems: A meta-learning-driven data fusion approach. Eur. J. Agron. 2024, 161, 127387. [Google Scholar] [CrossRef]

- Iglesias, A.; Garrote, L. Adaptation strategies for agricultural water management under climate change in Europe. Agric. Water Manag. 2015, 155, 113–124. [Google Scholar] [CrossRef]

- Gebreegziher, W.G. Soilless culture technology to transform vegetable farming, reduce land pressure and degradation in drylands. Cogent Food Agric. 2023, 9, 2265106. [Google Scholar] [CrossRef]

- Park, Y.; Williams, K.A. Organic hydroponics: A review. Sci. Hortic. 2024, 324, 112604. [Google Scholar] [CrossRef]

- Chowdhury, M.E.H.; Khandakar, A.; Ahmed, S.; Al-Khuzaei, F.; Hamdalla, J.; Haque, F.; Reaz, M.B.I.; Al Shafei, A.; Al-Emadi, N. Design, construction and testing of iot based automated indoor vertical hydroponics farming test-bed in qatar. Sensors 2020, 20, 5637. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Palmitessa, O.D.; Signore, A.; Santamaria, P. Advancements and future perspectives in nutrient film technique hydroponic system: A comprehensive review and bibliometric analysis. Front. Plant Sci. 2024, 15, 1504792. [Google Scholar] [CrossRef]

- Samba, N.; Nunomura, O.; Nakano, A.; Tsukagoshi, S. Effective Training Methods for Cucumber Production in Newly Developed Nutrient Film Technique Hydroponic System. Horticulturae 2023, 9, 478. [Google Scholar] [CrossRef]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef]

- Rahman, M.A.; Chakraborty, N.R.; Sufiun, A.; Banshal, S.K.; Tajnin, F.R. An AIoT-based hydroponic system for crop recommendation and nutrient parameter monitorization. Smart Agric. Technol. 2024, 8, 100472. [Google Scholar] [CrossRef]

- Dhal, S.B.; Jungbluth, K.; Lin, R.; Sabahi, S.P.; Bagavathiannan, M.; Braga-Neto, U.; Kalafatis, S. A Machine-Learning-Based IoT System for Optimizing Nutrient Supply in Commercial Aquaponic Operations. Sensors 2022, 22, 3510. [Google Scholar] [CrossRef]

- Goddek, S.; Joyce, A.; Kotzen, B.; Burnell, G.M. Aquaponics Food Production Systems: Combined Aquaculture and Hydroponic Production Technologies for the Future; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Toke, I.A.; Rahman, M.M.F.; Monir, M.F.; Ahmed, T.; Rabbani, K.A. IoT Driven Smart Greenhouse: A Cost-Effective and User-Centric Automation Solution For Agriculture. In Proceedings of the 2023 IEEE International Conference on Advanced Networks and Telecommunications Systems (ANTS), Jaipur, India, 17–20 December 2023; IEEE: New York, NY, USA, 2023; pp. 503–508. [Google Scholar] [CrossRef]

- Ait Oussous, S.; Bajit, A.; Achour, Y.; Morino, I.; Zejli, D.; Elbouayadi, R. Applying Computational Intelligence, Visual Optimization Tools, and Synchronized PAYLOAD’s Handshaking to Enhance Greenhouses ECC Cyber Security-based Agriculture IoT’s Properties. In Proceedings of the 2023 9th International Conference on Optimization and Applications (ICOA), AbuDhabi, United Arab Emirates, 5–6 October 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Sportelli, M.; Bonzi, L.; Brunori, G.; Hamouda, F.; Puig-Sirera, A.; Marasco, S.; Rallo, G. Current State of Irrigation Decision Support Systems (IDSS) in Italy: Critical insights. In Proceedings of the 2023 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Pisa, Italy, 6–8 November 2023; pp. 131–136. [Google Scholar] [CrossRef]

- Sportelli, M.; Crivello, A.; Bacco, M.; Rallo, G.; Brunori, G. Public irrigation decision support systems (IDSS) in Italy: Description, evaluation and national context overview. Smart Agric. Technol. 2024, 9, 100564. [Google Scholar] [CrossRef]

- Sportelli, M.; Crivello, A.; La Rosa, D.; Bacco, M.; Incrocci, L.; Barsocchi, P. An IoT Platform for Smart Hydroponics: Building Blocks and Open Challenges. In Proceedings of the 2024 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Padua, Italy, 29–31 October 2024; pp. 112–117. [Google Scholar] [CrossRef]

- Ferrari, A.; Bacco, M.; Gaber, K.; Jedlitschka, A.; Hess, S.; Kaipainen, J.; Koltsida, P.; Toli, E.; Brunori, G. Drivers, barriers and impacts of digitalisation in rural areas from the viewpoint of experts. Inf. Softw. Technol. 2022, 145, 106816. [Google Scholar] [CrossRef]

- Roussaki, I.; Doolin, K.; Skarmeta, A.; Routis, G.; Lopez-Morales, J.A.; Claffey, E.; Mora, M.; Martinez, J.A. Building an interoperable space for smart agriculture. Digit. Commun. Netw. 2023, 9, 183–193. [Google Scholar] [CrossRef]

- Sportelli, M.; La Rosa, D.; Crivello, A.; Pineda Medina, D.; Bacco, F.M.; Barsocchi, P. Beyond Prototypes: What is missing to fill the Gap in IoT-Enabled Hydroponics Platform. Zenodo 2025. [Google Scholar] [CrossRef]

- Sulaiman, S.F.; Kassim, A.H.A.; Samsudin, S.I.; Sulaiman, N.A.; Sunar, N. IoT-based monitoring system for hydroponics. Prz. Elektrotechniczny 2023, 2023, 135–140. [Google Scholar] [CrossRef]

- Pawar, S.; Tembe, S.; Khan, S. Design of an affordable pH module for IoT Based pH level control in hydroponics applications. In Proceedings of the 2020 International Conference on Convergence to Digital World—Quo Vadis, ICCDW 2020, Mumbai, India, 18–20 February 2020. [Google Scholar] [CrossRef]

- Bhandari, N.S.; Bhandari, N.; Agarwal, R.; Sharma, P.K. An Insight on Artificial Intelligence (AI) and Internet of Things (IoT) driven Hydroponics Farming. In Proceedings of the 2024 5th International Conference on Image Processing and Capsule Networks, ICIPCN 2024, Dhulikhel, Nepal, 3–4 July 2024; pp. 496–501. [Google Scholar] [CrossRef]

- Agbayani, L.S.T.; Villaverde, J.F. Effect of Lettuce on Different Recirculation Intervals of an IoT-Based Hydroponics System Using Deep Flow Technique. In Proceedings of the 2022 IEEE Region 10 Symposium, TENSYMP 2022, Mumbai, India, 1–3 July 2022. [Google Scholar] [CrossRef]

- Sherubha, P.; Bharathipriya, C.; Iqbal, M.M.; Ganesh, P.; Sasirekha, S.P. A Real Time IoT Measurement System for Hydroponics Cultivation. In Proceedings of the 2022 2nd International Conference on Computing and Information Technology, ICCIT 2022, Tabuk, Saudi Arabia, 25–27 January 2022; pp. 432–435. [Google Scholar] [CrossRef]

- Wu, Y.M.; Liu, S.Y.; Shi, B.Y.; Peng, J.Y.; Kao, Z.W.; Chen, Y.Y.; Hsieh, T.Y.; Chung, H.Y.; Lin, C.Y.; Fang, W.; et al. IoT-interfaced solid-contact ion-selective electrodes for cyber-monitoring of element- specific nutrient information in hydroponics. Comput. Electron. Agric. 2023, 214, 108266. [Google Scholar] [CrossRef]

- Wu, Y.M.; Liu, S.Y.; Shi, B.Y.; Peng, J.Y.; Kao, Z.W.; Chung, H.Y.; Lin, C.Y.; Fang, W.; Chen, L.C. Field Study Correlating Nutrient Absorption and Transpiration in Lettuce Hydroponics Using an IoT-Interfaced Solid-State Ion Sensor Array. IEEE Sens. Lett. 2024, 8, 1–4. [Google Scholar] [CrossRef]

- Brindha, G.; Kumaragurubaran, T.; Dhanush, S.; Devadharshini, D. Automating Hydroponics: Enhance the Crop Cultivation and Monitoring Using IOT and ML. In Proceedings of the 2025 Global Conference in Emerging Technology (GINOTECH), Pune, India, 9–11 May 2025; IEEE: New York, NY, USA, 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Raju, S.V.S.R.; Dappuri, B.; Varma, P.R.K.; Yachamaneni, M.; Verghese, D.M.G.; Mishra, M.K. Design and Implementation of Smart Hydroponics Farming Using IoT-Based AI Controller with Mobile Application System. J. Nanomater. 2022, 2022, 4435591. [Google Scholar] [CrossRef]

- Tatas, K.; Al-Zoubi, A.; Antoniou, A.; Zolotareva, D. IPONICS: IoT Monitoring and Control for Hydroponics. In Proceedings of the 2021 10th International Conference on Modern Circuits and Systems Technologies, MOCAST 2021, Thessaloniki, Greece, 5–7 July 2021. [Google Scholar] [CrossRef]

- Boopathy, S.; Anand, K.R.G.; Priya, E.L.D.; Sharmila, A.; Pasupathy, S.A. IoT based Hydroponics based Natural Fertigation System for Organic Veggies Cultivation. In Proceedings of the 2021 Third International Conference on Intelligent Communication Technologies and Virtual Mobile Networks (ICICV), Tirunelveli, India, 4–6 February 2021; IEEE: New York, NY, USA, 2021; pp. 404–409. [Google Scholar] [CrossRef]

- Raman, R.; Vasmatkar, A. IoT-Enabled Aquaponics and Hydroponics for Efficient Indoor Farming Systems with Cloud Computing. In Proceedings of the 2024 International Conference on Advances in Data Engineering and Intelligent Computing Systems, ADICS 2024, Chennai, India, 18–19 April 2024. [Google Scholar] [CrossRef]

- Sridevi, A.; Devadharshini, K.; Deepika, B.; Elakkiya, K.V.; Bharathi, G. Smart Aquaponics and Hydroponics Monitoring Using IoT. In Proceedings of the 2nd International Conference on Artificial Intelligence and Machine Learning Applications: Healthcare and Internet of Things, AIMLA 2024, Namakkal, India, 15–16 March 2024. [Google Scholar] [CrossRef]

- Duangpakdee, K.; Sukpancharoen, S. Vertical Smart Farm System for off-Season Crop Production using Hydroponics and IoT-based Environmental Control. In Proceedings of the 2024 International Conference on Advanced Robotics and Mechatronics (ICARM), Tokyo, Japan, 8–10 July 2024; IEEE: New York, NY, USA, 2024; pp. 284–289. [Google Scholar] [CrossRef]

- Bhat, A.G.; Hasan, M.; Singh, D.K.; Sahoo, R.N.; Yeasin, M.; S, V.K. Design, Development and Testing of an IoT-Based Smart Vertical Hydroponic System for Optimized Nutrient Management in a Controlled Environment. Irrig. Drain. 2025, ird.4002. [Google Scholar] [CrossRef]

- Stevens, J.D.; Murray, D.; Diepeveen, D.; Toohey, D. Development and Testing of an IoT Spectroscopic Nutrient Monitoring System for Use in Micro Indoor Smart Hydroponics. Horticulturae 2023, 9, 185. [Google Scholar] [CrossRef]

- Fenitha, J.R.; Mirudhula, S.; Subhashini, K.; Sriharidha, R. Hydroponic Nutrient Solution for Optimized Greenhouse with IOT. In Proceedings of the 2022 International Conference on Advanced Computing Technologies and Applications, ICACTA 2022, Coimbatore, India, 4–5 March 2022. [Google Scholar] [CrossRef]

- Rao, P.B.S.; Venkatesh, R.T.; Murthy, S.G.; Negavadi, S.B.; Srinivasulu, T.; Nataraj, Y.B.; Satish, V.; Balenahalli, V.K. Automated IoT Solutions for Efficient Hydroponic Farming: Nutrients, PH and Lighting Management. J. Eur. Systèmes Autom. 2024, 57, 1273–1283. [Google Scholar] [CrossRef]

- Pragathi, B.; Satyanarayana, P.E.; Kumar, S.; Murthy, A.S.D.; Suman, J.V. Development of an IoT Based Automated Hydroponics System for Efficient and Sustainable Indoor Plant Cultivation. In Proceedings of the 2024 IEEE Silchar Subsection Conference (SILCON 2024), Agartala, India, 15–17 November 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Ardina, A.M.S.; Maceda, D.D.M.C.; Borromeo, C.E.B.; Cruz, J.D.; Fedeluz, J.M.; Mauricio, A.M.F. IoT-Based Solar-powered Smart Hydroponics system with Real-Time Monitoring and Control System. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management, HNICEM 2022, Boracay Island, Philippines, 1–4 December 2022. [Google Scholar] [CrossRef]

- Singh, N.K.; Bhatt, P.; Vala, B. Automatic nutrient delivery IoT based hydroponic by self-monitoring parameter. IET Conf. Proc. 2025, 2025, 661–667. [Google Scholar] [CrossRef]

- Rus, R.C.; Salisu, M.A.; Usaizan, N.; Nashir, I.M.; Yusuff, O.; Sulaiman, Z.; Hammed, A. Influence of Composition of Soilless Substrates Monitored with Iot Sensor Nodes on the Growth, Nutrient and Fruit Quality of Rockmelons (Cucumis melo Var. Cantalupensis). Indian J. Agric. Res. 2023, 57, 211–217. [Google Scholar] [CrossRef]

- Nugraha, I.R.; Putra, W.H.N.; Setiawan, E. A Comparative Study of HTTP and MQTT for IoT Applications in Hydroponics. J. RESTI Rekayasa Sist. Dan Teknol. Inf. 2024, 8, 119–126. [Google Scholar] [CrossRef]

- Noura, M.; Atiquzzaman, M.; Gaedke, M. Interoperability in Internet of Things: Taxonomies and Open Challenges. Mob. Netw. Appl. 2019, 24, 796–809. [Google Scholar] [CrossRef]

- Al-Maskri, A.; Al-Kharusi, L.; Al-Miqbali, H.; Khan, M.M. Effects of Salinity Stress on Growth of Lettuce (Lactuca sativa) under Closed-recycle Nutrient Film Technique. Int. J. Agric. Biol. 2010, 12, 377–380. [Google Scholar]

- Treftz, C.; Omaye, S.T. Hydroponics: Potential for augmenting sustainable food production in non-arable regions. Nutr. Food Sci. 2016, 46, 672–684. [Google Scholar] [CrossRef]

- Awal, M.A.; Pio, A.S.; Mim, M.J.; Partha, P.K.P.; Kafi, M.A.A.; Farha, S. A smart IoT-based hydroponics system for small-scale household in Bangladesh. Smart Agric. Technol. 2025, 12, 101163. [Google Scholar] [CrossRef]

- Budiman, M.; Partogi, E.; Kristi, A.; Anggara, P.; Aminah, N.S. Study of the Effect of Physical Parameters on Commercial Hydroponics Based on Internet of Things (IoT): A Case Study of Bok Coy Plants (Brassica rapa) and Water Spinach (Ipomoea Aquatica). J. Math. Fundam. Sci. 2022, 54, 275. [Google Scholar] [CrossRef]

- Promwee, A.; Nijibulat, S.; Nguyen, H.H. Enhancing Chinese Cabbage Production and Quality through IoT-Based Smart Farming in NFT-Hydroponics. Agronomy 2024, 14, 579. [Google Scholar] [CrossRef]

- Faustino, A.R.B.; Ibia, A.H.; Koch, C.K.S.; Madrid, A.L.; Pacis, M.C.; Chua, E. A Solar Powered Hydroponics System for Condominium Buildings with Internet of Things (IoT) Monitoring System. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management, HNICEM 2022, Boracay Island, Philippines, 1–4 December 2022. [Google Scholar] [CrossRef]

- Fadilla, R.M.; Oktafiandini, N.S.D.; Adha, M.; Kamelia, L.; Firdaus, D.F.; Akmaliyah, A. The Prototype of Smart Garden Fertigation System with Solar Photovoltaic System Based on IoT. In Proceedings of the 2021 7th International Conference on Wireless and Telematics (ICWT), Bandung, Indonesia, 19–20 August 2021; IEEE: New York, NY, USA, 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Kumaragurubaran, T.; Chiranjeevi, R.; K, D.K. Intelligent growth of holy basil: An iot-based hydroponics system empowered by the CRL-SHS Algorithm. Earth Sci. Inform. 2025, 18, 426. [Google Scholar] [CrossRef]

- Deepika, V.; Kalaiselvi, A.; Dhivyaarthi, G. Monitoring of Hydroponics Plant and Prediction of Leaf Disease using IOT. In Proceedings of the 2021 International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation, ICAECA 2021, Coimbatore, India, 8–9 October 2021. [Google Scholar] [CrossRef]

- Mosaad, B.; Abdulla, R.; Rana, M.E. Recommendations for a Vertical Farming System Using Hydroponics, Machine Learning and IoT. In Proceedings of the 2023 4th International Conference on Data Analytics for Business and Industry, ICDABI 2023, Bahrain, 25–26 October 2023; pp. 373–378. [Google Scholar] [CrossRef]

- Khare, P.; Koti, A.; Khare, A. Solar-smart hydroponics farming with IoT-based AI controller with mobile app. In Proceedings of the 2023 IEEE Sustainable Smart Lighting World Conference and Expo, LS18 2023, Mumbai, India, 8–10 June 2023. [Google Scholar] [CrossRef]

- Mapari, R.G.; Tiwari, H.; Bhangale, K.B.; Jagtap, N.; Gujar, K.; Sarode, Y.; Mahajan, A. IOT Based Vertical Farming Using Hydroponics for Spectrum Management & Crop Quality Control. In Proceedings of the 2022 2nd International Conference on Intelligent Technologies, CONIT 2022, Hubli, India, 24–26 June 2022. [Google Scholar] [CrossRef]

- Srinidhi, H.K.; Shreenidhi, H.S.; Vishnu, G.S. Smart Hydroponics system integrating with IoT and Machine learning algorithm. In Proceedings of the 5th IEEE International Conference on Recent Trends in Electronics, Information and Communication Technology, RTEICT 2020, Bangalore, India, 12–13 November 2020; pp. 261–264. [Google Scholar] [CrossRef]

- Mehare, J.P.; Gaikwad, A. Secured Framework for Smart Farming in Hydroponics with Intelligent and Precise Management based on IoT with Blockchain Technology. Int. J. Recent Innov. Trends Comput. Commun. 2023, 11, 244–254. [Google Scholar] [CrossRef]

- Bovas Herbert Bejaxhin, A.; Brucely, Y.; Rose, D.D.; Mahesh, G.; Sharma, S.; Singh, R.; Kumar, A.; Abbas, M. Revolutionizing agriculture: A comprehensive research on IoT controlled fluid circulation in hydroponics using plumbed PVC planting pipes for enhanced crop growth and disease detection with CFD analysis. Environ. Fluid Mech. 2024, 24, 1235–1262. [Google Scholar] [CrossRef]

- Signore, A.; Serio, F.; Santamaria, P. Growth Analysis and Nutrient Solution Management of a Soil-Less Tomato Crop in a Mediterranean Environment. Data 2019, 4, 38. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).