Laser Additive Manufacturing of Fe-Based Magnetic Amorphous Alloys

Abstract

:1. Introduction

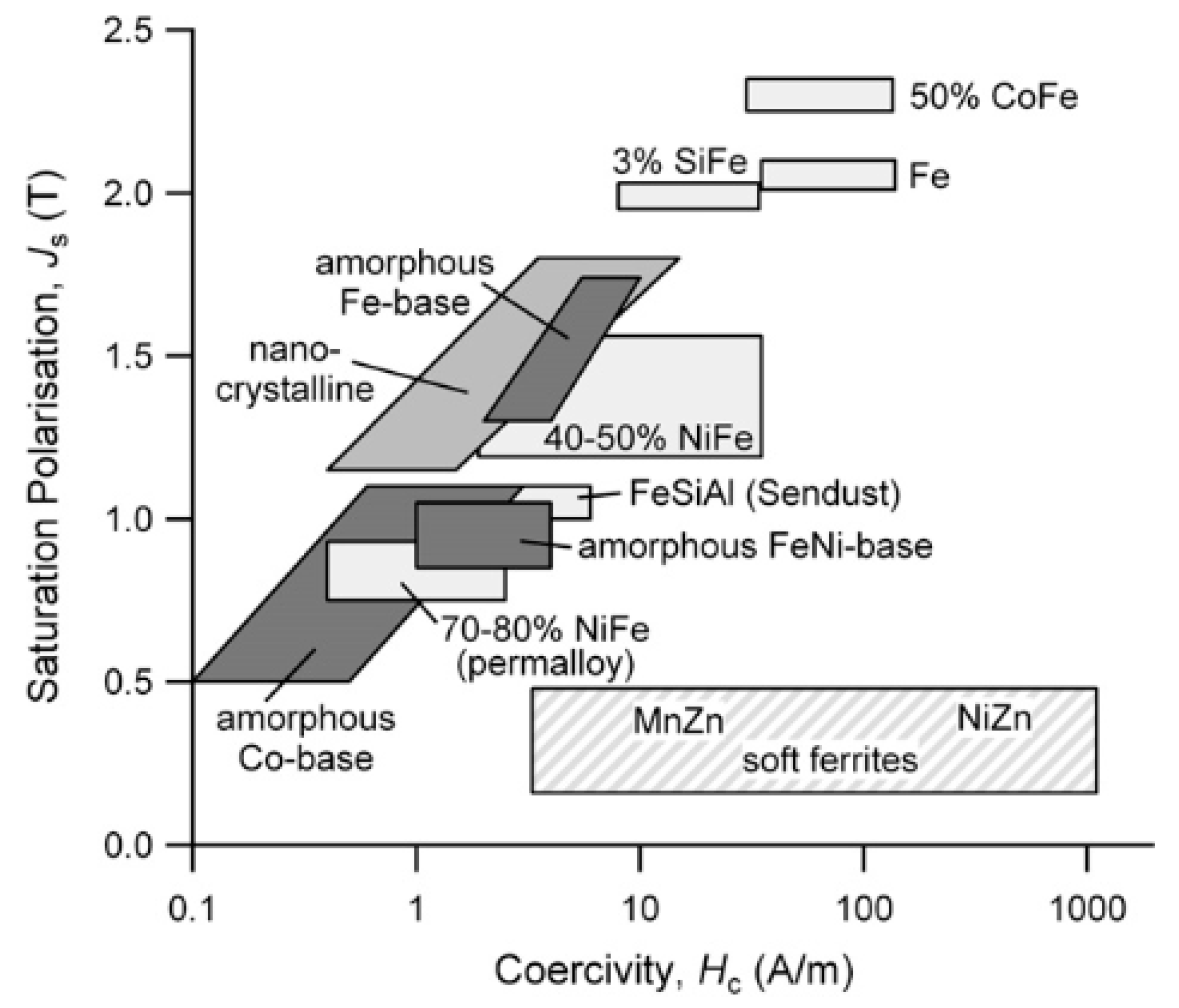

- For producing and utilising electromagnetic energy: due to their low cost and ecological reasons, the usage of soft magnetic materials comprises an important part of these applications because they have high magnetic permeability, low energy losses and high magnetic saturation. Fe-Si-based alloys are considered as the most representative materials for this area.

- For signal processing: Fe-Ni-based alloys are usually used in informatics, electronics, transducers, magnetic recording heads, microwave installations and so on [7].

2. Amorphous Fe-Based Magnetic Alloys

3. Additive Manufacturing of Amorphous Fe-Based Magnetic Alloys

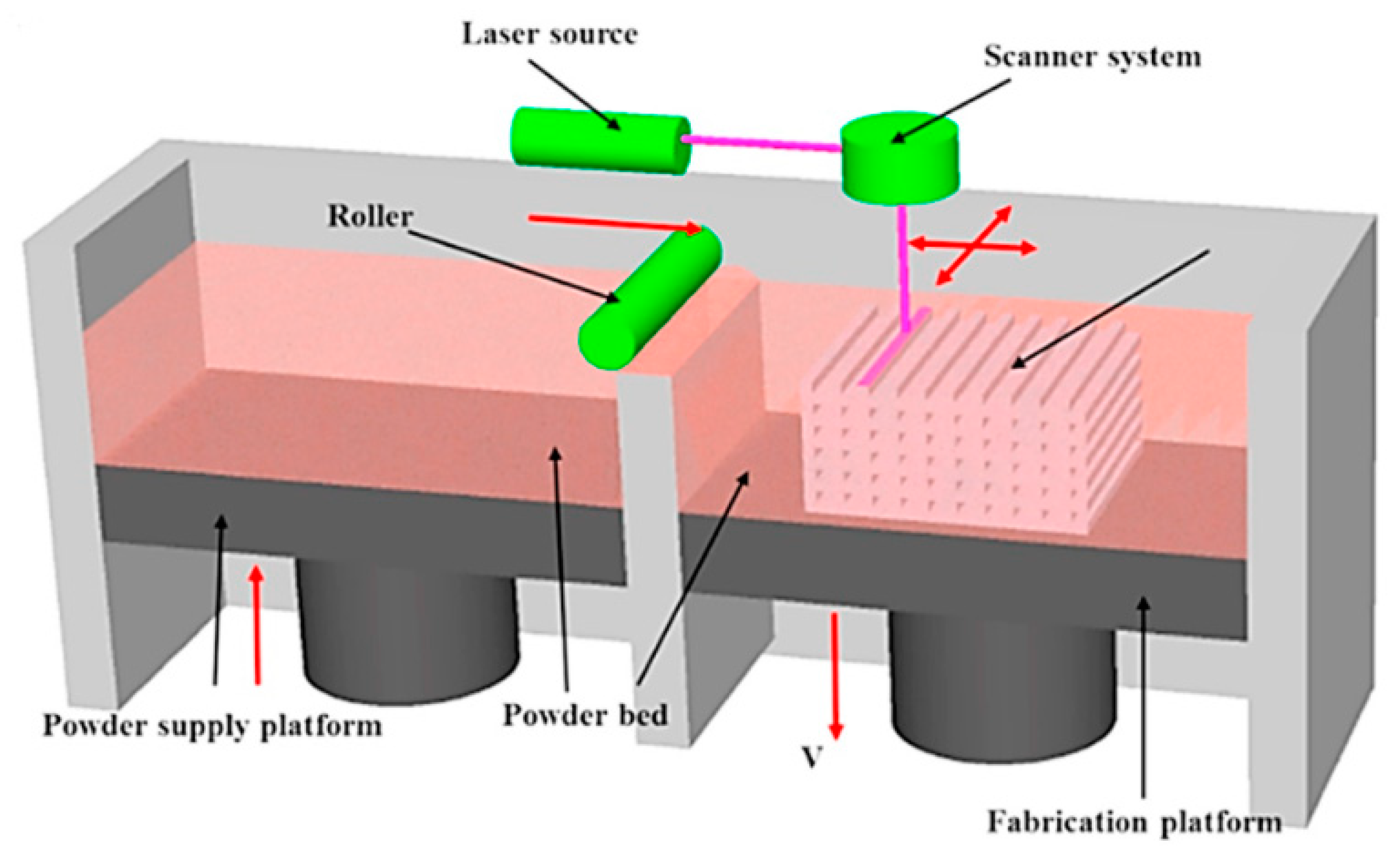

3.1. Powder-Bed Fusion

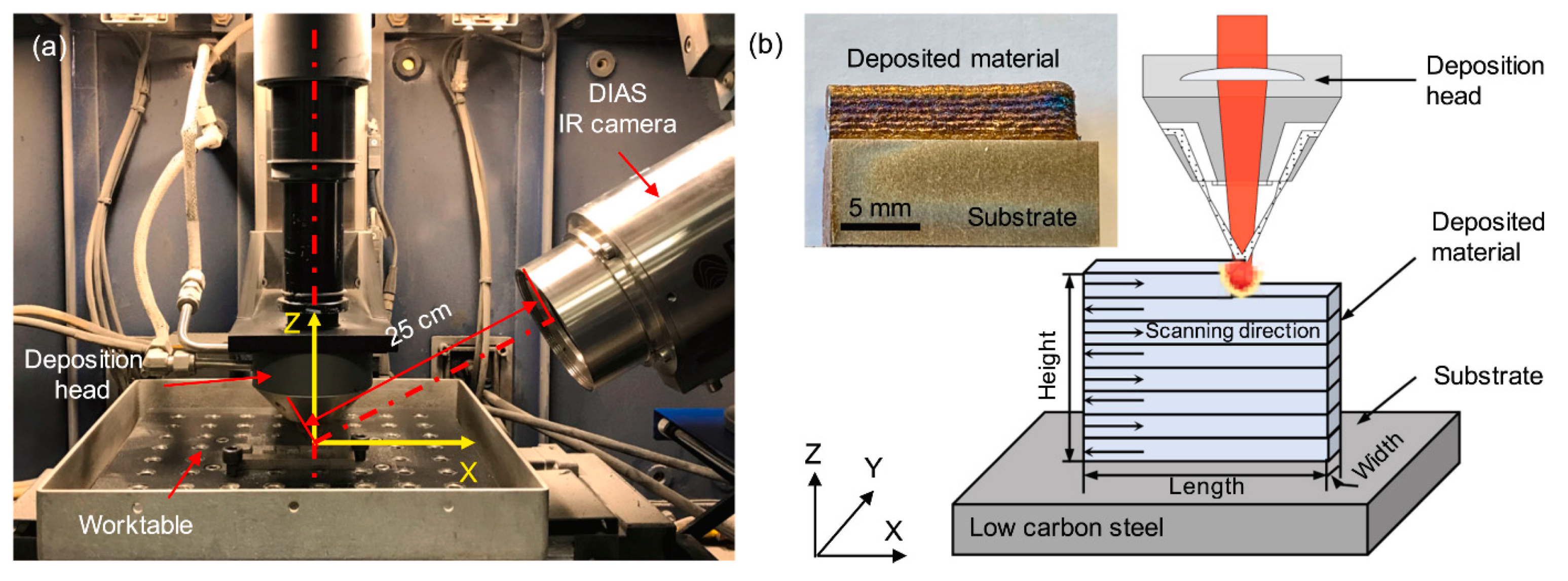

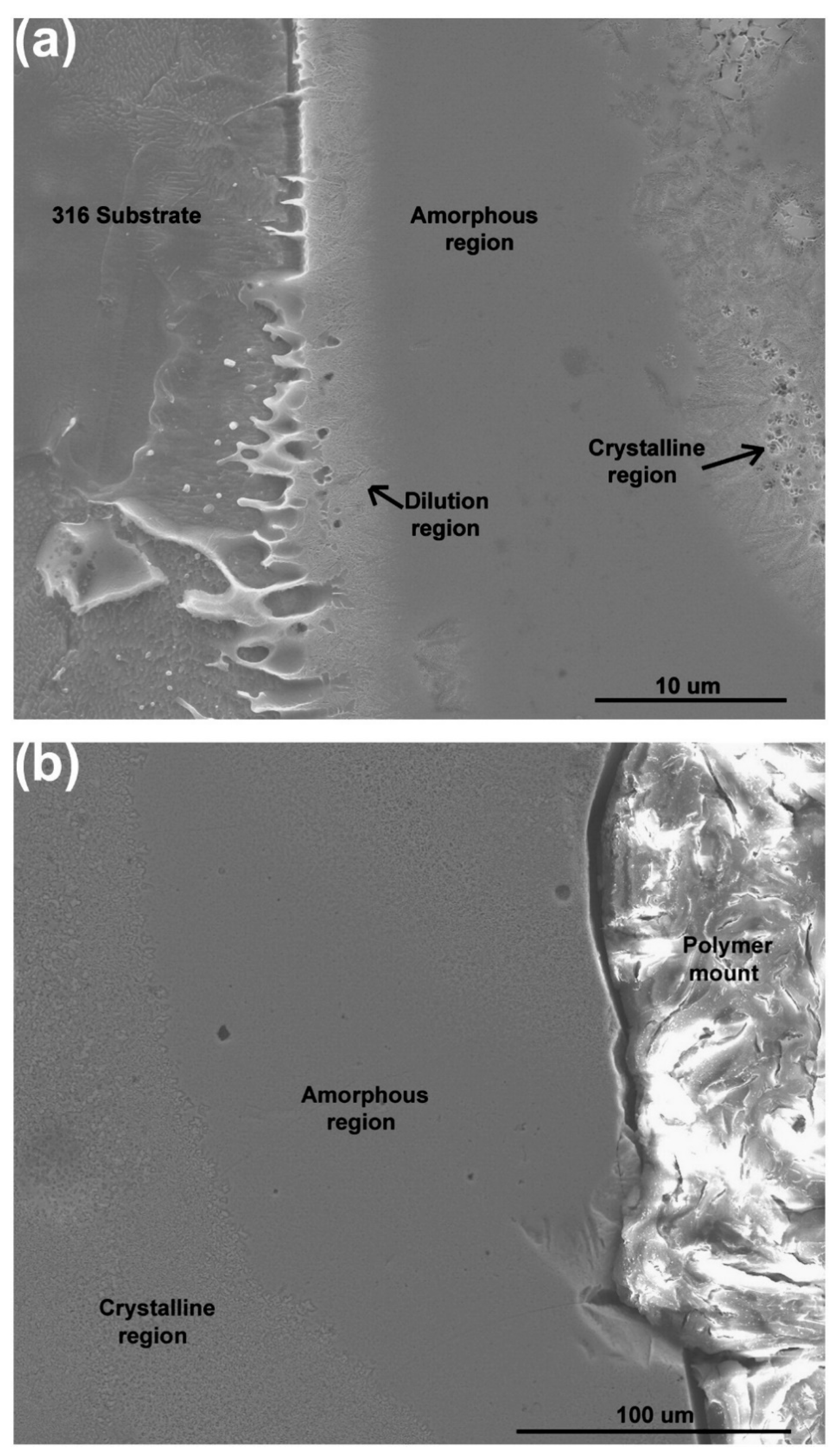

3.2. Direct Energy Deposition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Périgo, E.; Jacimovic, J.; Ferré, F.G.; Scherf, L. Additive manufacturing of magnetic materials. Addit. Manuf. 2019, 30, 100870. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.; Ipus, J.; Law, J.; Moreno-Ramírez, L.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar] [CrossRef]

- Smith, C.; Katakam, S.; Nag, S.; Zhang, Y.R.; Law, J.Y.; Ramanujan, R.V.; Dahotre, N.B.; Banerjee, R. Comparison of the Crystallization Behavior of Fe-Si-B-Cu and Fe-Si-B-Cu-Nb-Based Amorphous Soft Magnetic Alloys. Met. Mater. Trans. A 2014, 45, 2998–3009. [Google Scholar] [CrossRef]

- Wan, F.; He, A.; Zhang, J.; Song, J.; Wang, A.; Chang, C.T.; Wang, X. Development of FeSiBNbCu Nanocrystalline Soft Magnetic Alloys with High B s and Good Manufacturability. J. Electron. Mater. 2016, 45, 4913–4918. [Google Scholar] [CrossRef]

- Borkar, T.; Conteri, R.; Chen, X.; Ramanujan, R.; Banerjee, R. Laser additive processing of functionally-graded Fe–Si–B–Cu–Nb soft magnetic materials. Mater. Manuf. Process. 2017, 32, 1581–1587. [Google Scholar] [CrossRef]

- Yang, X.; Cui, X.; Jin, G.; Liu, J.; Chen, Y.; Liu, Z. Soft magnetic property of (Fe 60 Co 35 Ni 5) 78 Si 6 B 12 Cu 1 Mo 3 alloys by laser additive manufacturing. J. Magn. Magn. Mater. 2018, 466, 75–80. [Google Scholar] [CrossRef]

- Gavrila, H.; Ionita, V. Crystalline and Amorphous Soft Magnetic Materials and Their Applications—Status of Art and Challenges. J. Optoelectron. Adv. Mater. 2002, 4, 173–192. [Google Scholar]

- Jung, H.Y.; Choi, S.J.; Prashanth, K.G.; Stoica, M.; Scudino, S.; Yi, S.; Kühn, U.; Kim, D.H.; Kim, K.B.; Eckert, J. Fabrication of Fe-based bulk metallic glass by selective laser melting: A parameter study. Mater. Des. 2015, 86, 703–708. [Google Scholar] [CrossRef]

- Wang, J.; Li, R.; Hua, N.; Huang, L.; Zhang, T. Ternary Fe–P–C bulk metallic glass with good soft-magnetic and mechanical properties. Scr. Mater. 2011, 65, 536–539. [Google Scholar] [CrossRef]

- Shi, M.; Liu, Z.; Zhang, T. Effects of metalloid B addition on the glass formation, magnetic andmechanical properties of FePCB bulkmetallic glasses. J. Mater. Sci. Technol. 2015, 31, 493–497. [Google Scholar] [CrossRef]

- Li, Z.; Wang, A.; Chang, C.; Wang, Y.; Dong, B.; Zhou, S. FeSiBPNbCu alloys with high glass-forming ability and good soft magnetic properties. Intermetallics 2014, 54, 225–231. [Google Scholar] [CrossRef]

- Alvarez, K.L.; Martín, J.M.; Ipatov, M.; Gonzalez, J. Soft magnetic amorphous alloys (Fe-rich) obtained by gas atomisation technique. J. Alloy. Compd. 2018, 735, 2646–2652. [Google Scholar] [CrossRef]

- Jeziorski, L.; Nabialek, M.; Szota, M.; Dospial, M. Method of continuous casting of amorphous metallic materials based on iron. Arch. Foundry Eng. 2011, 11, 69–72. [Google Scholar]

- Nabialek, M.; Pietrusiewicz, P.; Dospial, M.; Szota, M.; Błoch, K.; Gruszka, K.; Ozga, K.; Garus, S. Effect of manufacturing method on the magnetic properties and formation of structural defects in Fe61Co10Y8Zr1B20 amorphous alloy. J. Alloy. Compd. 2014, 615, S51–S55. [Google Scholar] [CrossRef]

- Zhang, M.; Kong, F.; Wang, A.; Chang, C. Softmagnetic properties of bulk FeCoMoPCBSi glassy core prepared by copper mold casting. J. Appl. Phys. 2012, 111, 07A312. [Google Scholar] [CrossRef]

- Kim, Y.; Jang, D.; Seok, H.; Kim, K. Fabrication of Fe–Si–B based amorphous powder cores by cold pressing and their magnetic properties. Mater. Sci. Eng. A 2007, 449, 389–393. [Google Scholar] [CrossRef]

- Ishihara, S.; Zhang, W.; Kimura, H.; Omori, M.; Inoue, A. Consolidation of Fe–Co–Nd–Dy–B glassy powders by spark-plasma sintering andmagnetic properties of the consolidated alloys. Mater. Trans. 2003, 44, 138–143. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, S.; Mizushima, T.; Makino, A.; Inoue, A. Structure and soft magnetic properties of bulk Fe–Al–Ga–P–C–B–Si glassy alloys prepared by consolidating amorphous powders. Mater. Sci. Eng. A 2001, 1, 1019–1022. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Cahn, R. Rapidly Solidified Alloys; Marcel Dekker Inc.: New York, NY, USA, 1993. [Google Scholar]

- Davies, H.; Gibbs, M. Handbook of Magnetism and Advanced Materials; John Wiley and Sons: London, UK, 2007; Volume 4. [Google Scholar]

- Boll, R.; Hilzinger, H.; Warlimont, H. The Magnetic, Chemical and Structural Properties of Glassy Metallic Alloys; CRC Press: Boca Raton, FL, USA, 1983. [Google Scholar]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Katakam, S.; Hwang, J.; Paital, S.; Banerjee, R.; Vora, H.; Dahotre, N. Laser-induced thermal and spatial nanocrystallization of amorphousFe–Si–B alloy. Scr. Mater. 2012, 66, 538–541. [Google Scholar] [CrossRef]

- Elhajjar, R.F.; Law, C.-T.; Pegoretti, A. Magnetostrictive polymer composites: Recent advances in materials, structures and properties. Prog. Mater. Sci. 2018, 97, 204–229. [Google Scholar] [CrossRef]

- Na, S.; Galuardi, J.; Flatau, A. Consolidation of magnetostrictive (001)-oriented Fe-Ga flakes for 3D printing powder materials. In Proceedings of the 2017 IEEE International Magnetics Conference (INTERMAG), Dublin, Ireland, 24–28 April 2017; p. 1. [Google Scholar]

- Al-Taher, A.; Reiss, R.; Lafferty, A.; Hayes, S.; Lupu, N.; Murgulescu, I.; Morley, N. Magnetostrictive Materials for aerospace applications. J. Phys. Conf. Ser. 2017, 903, 012010. [Google Scholar] [CrossRef]

- Hathaway, K.; Clark, A. Magnetostrictive Materials. Mater. Res. Soc. Bull. 1993, 4, 34–41. [Google Scholar] [CrossRef]

- Moron, C.; Cabrera, C.; Moron, A.; Garcia, A.; Gonzalez, M. Magnetic Sensors Based on Amorphous Ferromagnetic Materials: A Revie. Sensors 2015, 15, 28340–28366. [Google Scholar] [CrossRef] [Green Version]

- Jiles, D. Introduction to Magnetism and Magnetic Materials, 3rd ed.; CRC Press, Taylor and Francis Group: New York, NY, USA, 2016. [Google Scholar]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef]

- Lee, J.M.; Yeong, W.Y. Design and Printing Strategies in 3D Bioprinting of Cell-Hydrogels: A Review. Adv. Health Mater. 2016, 5, 2856–2865. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Campbell, T.; Williams, C.; Ivanona, O.; Garrett, B. Could 3D Printing Change the World. In Technologies, Potential, and Implications of Additive Manufacturing; Atlantic Council: Washington, DC, USA, 2011. [Google Scholar]

- Goh, G.D.; Agarwala, S.; Goh, G.L.; Dikshit, V.; Sing, S.L.; Yeong, W.Y. Additive manufacturing in unmanned aerial vehicles (UAVs): Challenges and potential. Aerosp. Sci. Technol. 2017, 63, 140–151. [Google Scholar] [CrossRef]

- Taylor, A.P.; Velez, C.; Arnold, D.P.; Velásquez-García, L.F. Fully 3D-Printed, Monolithic, Mini Magnetic Actuators for Low-Cost, Compact Systems. J. Microelectromechanical Syst. 2019, 28, 481–493. [Google Scholar] [CrossRef]

- Patton, M.V.; Ryan, P.; Calascione, T.; Fischer, N.; Morgenstern, A.; Stenger, N.; Nelson-Cheeseman, B.B.; Ryan, P. Manipulating magnetic anisotropy in fused filament fabricated parts via macroscopic shape, mesoscopic infill orientation, and infill percentage. Addit. Manuf. 2019, 27, 482–488. [Google Scholar] [CrossRef]

- Díaz-García, Á.; Law, J.; Cota, A.; Bellido-Correa, A.; Ramírez-Rico, J.; Schäfer, R.; Franco, V. Novel procedure for laboratory scale production of composite functional filaments for additive manufacturing. Mater. Today Commun. 2020, 24, 101049. [Google Scholar] [CrossRef]

- Bollig, L.M.; Patton, M.V.; Mowry, G.S.; Nelson-Cheeseman, B.B. Effects of 3-D Printed Structural Characteristics on Magnetic Properties. IEEE Trans. Magn. 2017, 53, 1–6. [Google Scholar] [CrossRef]

- Arbaoui, Y.; Agaciak, P.; Chevalier, A.; Laur, V.; Maalouf, A.; Ville, J.; Roquefort, P.; Aubry, T.; Queffelec, P. 3D printed ferromagnetic composites for microwave applications. J. Mater. Sci. 2017, 52, 4988–4996. [Google Scholar] [CrossRef]

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef] [Green Version]

- Chaudhary, V.; Mantri, S.; Ramanujan, R.; Banerjee, R. Additive manufacturing of magnetic materials. Prog. Mater. Sci. 2020, 114, 100688. [Google Scholar] [CrossRef]

- Zhang, B.; Fenineche, N.-E.; Zhu, L.; Liao, H.; Coddet, C. Studies of magnetic properties of permalloy (Fe–30%Ni) prepared by SLM technology. J. Magn. Magn. Mater. 2012, 324, 495–500. [Google Scholar] [CrossRef]

- Mikler, C.V.; Chaudhary, V.; Borkar, T.; Soni, V.; Jaeger, D.; Chen, X.; Contieri, R.; Ramanujan, R.V.; Banerjee, R. Laser Additive Manufacturing of Magnetic Materials. JOM 2017, 69, 532–543. [Google Scholar] [CrossRef] [Green Version]

- Kustas, A.; Susan, D.; Johnson, K.; Whetten, S.; Rodriguez, M.; Dagel, D.; Micheal, J.; Keicher, D.; Argibay, N. Characterization of the Fe-Co-1.5V soft magnetic alloy processed by laser engineered net shaping (LENS). Addit. Manuf. 2018, 21, 41–52. [Google Scholar]

- Goll, D.; Schuller, D.; Martinek, G.; Kunert, T.; Schurr, J.; Sinz, C.; Schubert, T.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive manufacturing of soft magnetic materials and components. Addit. Manuf. 2019, 27, 428–439. [Google Scholar] [CrossRef]

- Kang, N.; El Mansori, M.; Guittonneau, F.; Liao, H.; Fu, Y.; Aubry, E. Controllable mesostructure, magnetic properties of soft magnetic Fe-Ni-Si by using selective laser melting from nickel coated high silicon steel powder. Appl. Surf. Sci. 2018, 455, 736–741. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Zhai, W.; Huang, R.; Fu, J.; Fu, M.; Li, F. Metal-Based 3D-Printed Micro Parts & Structures. Ref. Modul. Mater. Sci. Mater. Eng. 2020. [Google Scholar] [CrossRef]

- Utela, B.; Storti, D.; Anderson, R.; Ganter, M. A review of process development steps for new material systems in three dimensional printing (3DP). J. Manuf. Process. 2008, 10, 96–104. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Pauly, S.; Löber, L.; Petters, R.; Stoica, M.; Scudino, S.; Kühn, U.; Eckert, J. Processing metallic glasses by selective laser melting. Mater. Today 2013, 16, 37–41. [Google Scholar] [CrossRef]

- Zheng, B.; Zhou, Y.; Smugeresky, J.E.; Lavernia, E.J. Processing and Behavior of Fe-Based Metallic Glass Components via Laser-Engineered Net Shaping. Met. Mater. Trans. A 2009, 40, 1235–1245. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Khan, M.; Dickens, P. Selective Laser Melting (SLM) of pure gold. Gold Bull. 2010, 43, 114–121. [Google Scholar] [CrossRef] [Green Version]

- Dayal, R. Numerical Modelling of Processes Governing Selective Laser Sintering. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2014. [Google Scholar]

- Yuan, P.; Gu, D. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: Simulation and experiments. J. Phys. D Appl. Phys. 2015, 48, 035303. [Google Scholar] [CrossRef]

- Luborsky, F. Amorphous Metal Alloys; Butterworths: London, UK, 1983. [Google Scholar]

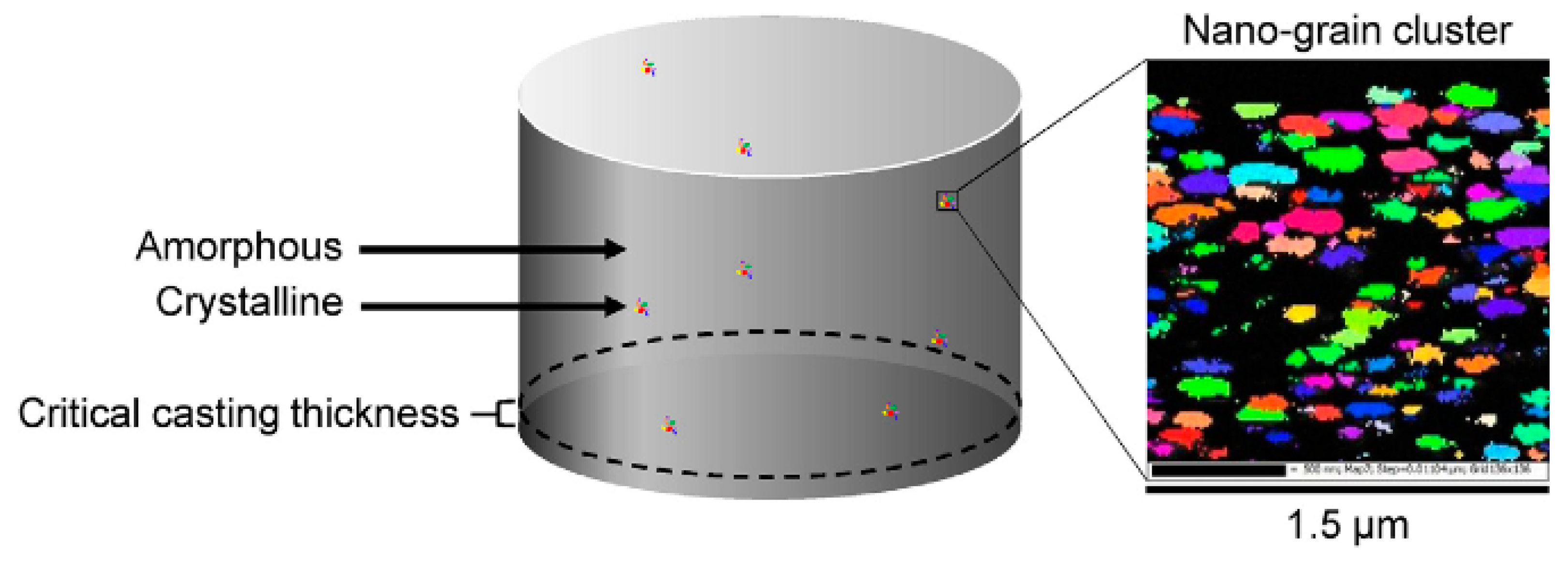

- Mahbooba, Z.; Thorsson, L.; Unosson, M.; Skoglund, P.; West, H.; Horn, T.; Rock, C.; Vogli, E.; Harryson, O. Additive manufacturing of an iron-based bulk metallic glass larger than thecritical casting thickness. Appl. Mater. Today 2018, 11, 264–269. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inone, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Efimov, Y.; Mukhin, G.; Lazarev, E.; Korotkov, N.; Ryabtsev, L.; Dmitriev, V.; Frolova, T. The structure of rapidly hardened Fe-Si-B alloys. Russ. Metall. 1986, 4, 167–173. [Google Scholar]

- Haginaro, M.; Inonue, A.; Masu, T. Mechanical properties of FeSiB amorphous wires produced by in-rotating-water spinning method. Metall. Mater. Trans. A 1982, 13, 373–382. [Google Scholar]

- Suwa, Y.; Agatsuma, S.; Hashi, S.; Ishiyama, K. Study of strain sensor using FeSiB magnetoresistive thin films. IEEE Trans. Magn. 2010, 46, 666–669. [Google Scholar] [CrossRef]

- Li, S.; Horikawa, S.; Park, M.-K.; Chai, Y.; Vodyanoy, V.J.; Chin, B.A. Amorphous metallic glass biosensors. Intermetallics 2012, 30, 80–85. [Google Scholar] [CrossRef]

- Inoue, A.; Komuro, M.; Masumoto, T. Fe-Si-B amorphous alloys with high silicon concentration. J. Mater. Sci. 1984, 19, 4125–4132. [Google Scholar] [CrossRef]

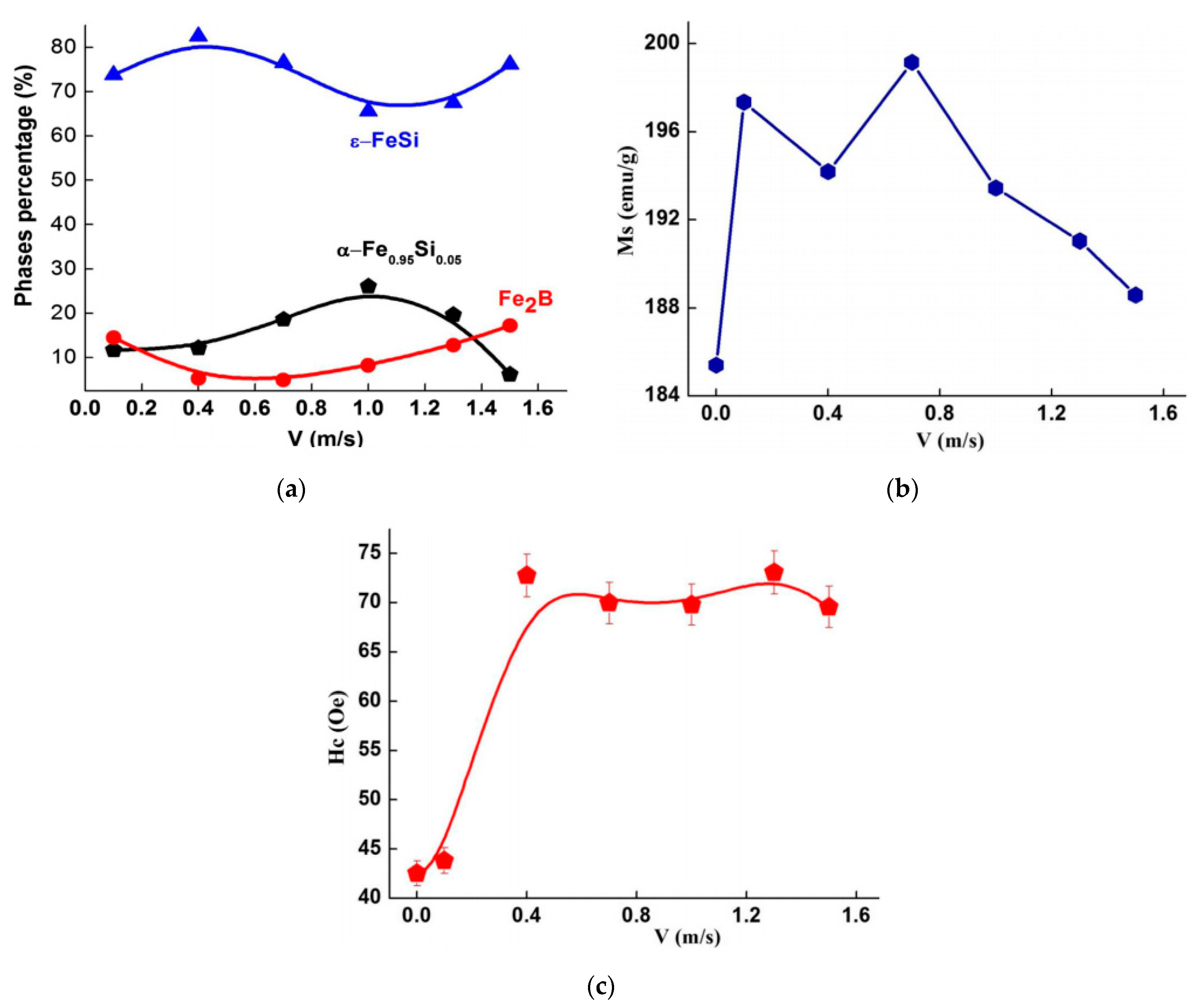

- Alleg, S.; Drablia, R.; Fenineche, N. Effect of the Laser Scan Rate on the Microstructure, Magnetic Properties, and Microhardness of Selective Laser-Melted FeSiB. J. Supercond. Nov. Magn. 2018, 31, 3565–3577. [Google Scholar] [CrossRef]

- de Boer, F.; Boom, R.; Mattens, W.; Miedema, A.; Niessen, A. Cohesion in Metals; North-Holland: Amsterdam, The Netherlands, 1988. [Google Scholar]

- Dong, S.; Song, B.; Zhang, X.; Deng, C.; Fenineche, N.; Hansz, B.; Liao, H.; Coddet, C. Fabrication of FeSiB magnetic coatings with improved saturation magnetization by plasma spray and dry-ice blasting. J. Alloy. Compd. 2014, 584, 254–260. [Google Scholar] [CrossRef]

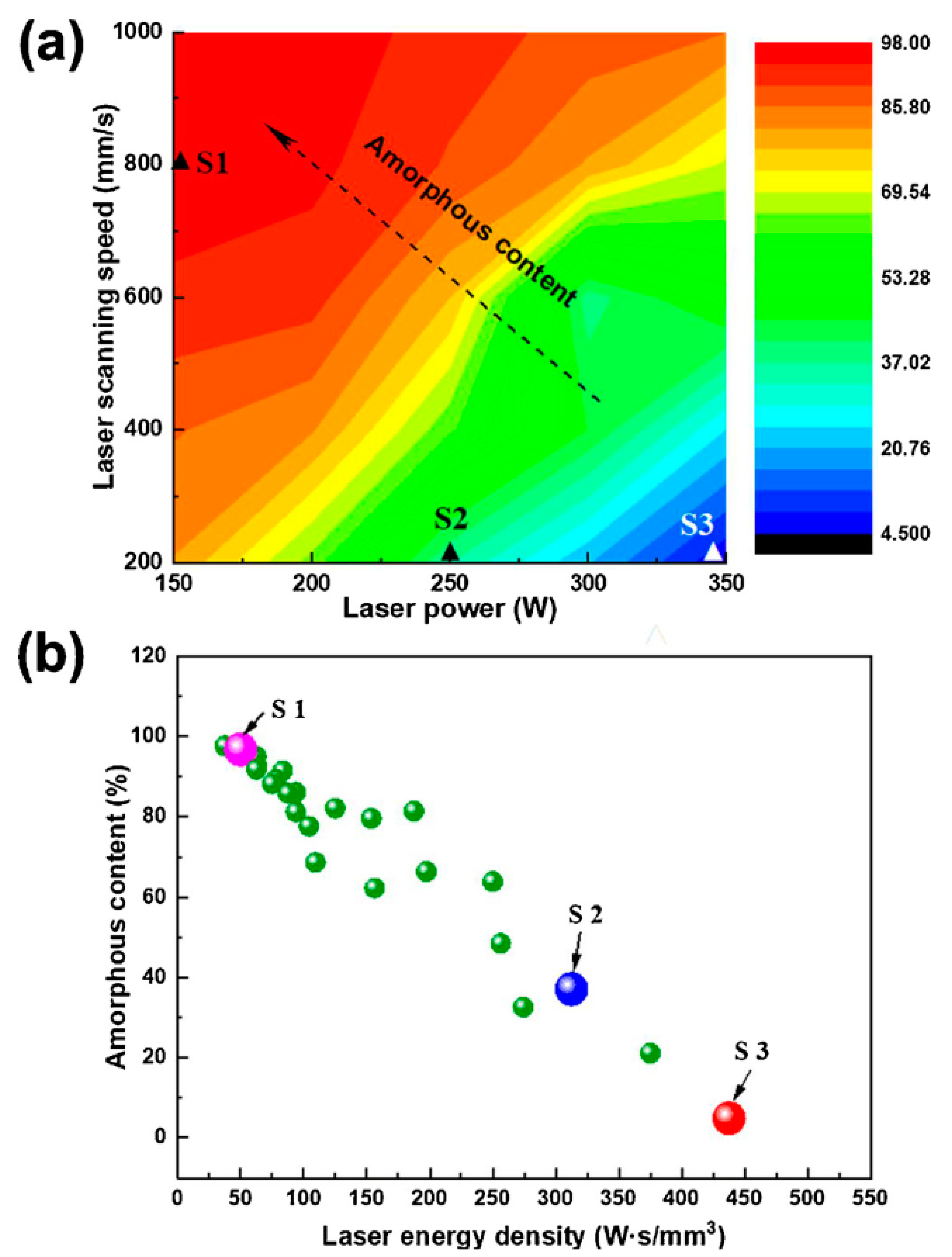

- Ouyang, D.; Xing, W.; Li, N.; Li, Y.; Liu, L. Structural evolutions in 3D-printed Fe-based metallic glass fabricated by selective laser melting. Addit. Manuf. 2018, 23, 246–252. [Google Scholar] [CrossRef]

- Pauly, S.; Schricker, C.; Scudino, S.; Deng, L.; Kühn, U. Processing a glass-forming Zr-based alloy by selective laser melting. Mater. Des. 2017, 135, 133–141. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef] [Green Version]

- Carter, L.; Wang, X.; Read, N. Process optimization of selective laser melting using energy density model for nickel based superalloys. Mater. Sci. Technol. 2015, 32, 1–5. [Google Scholar]

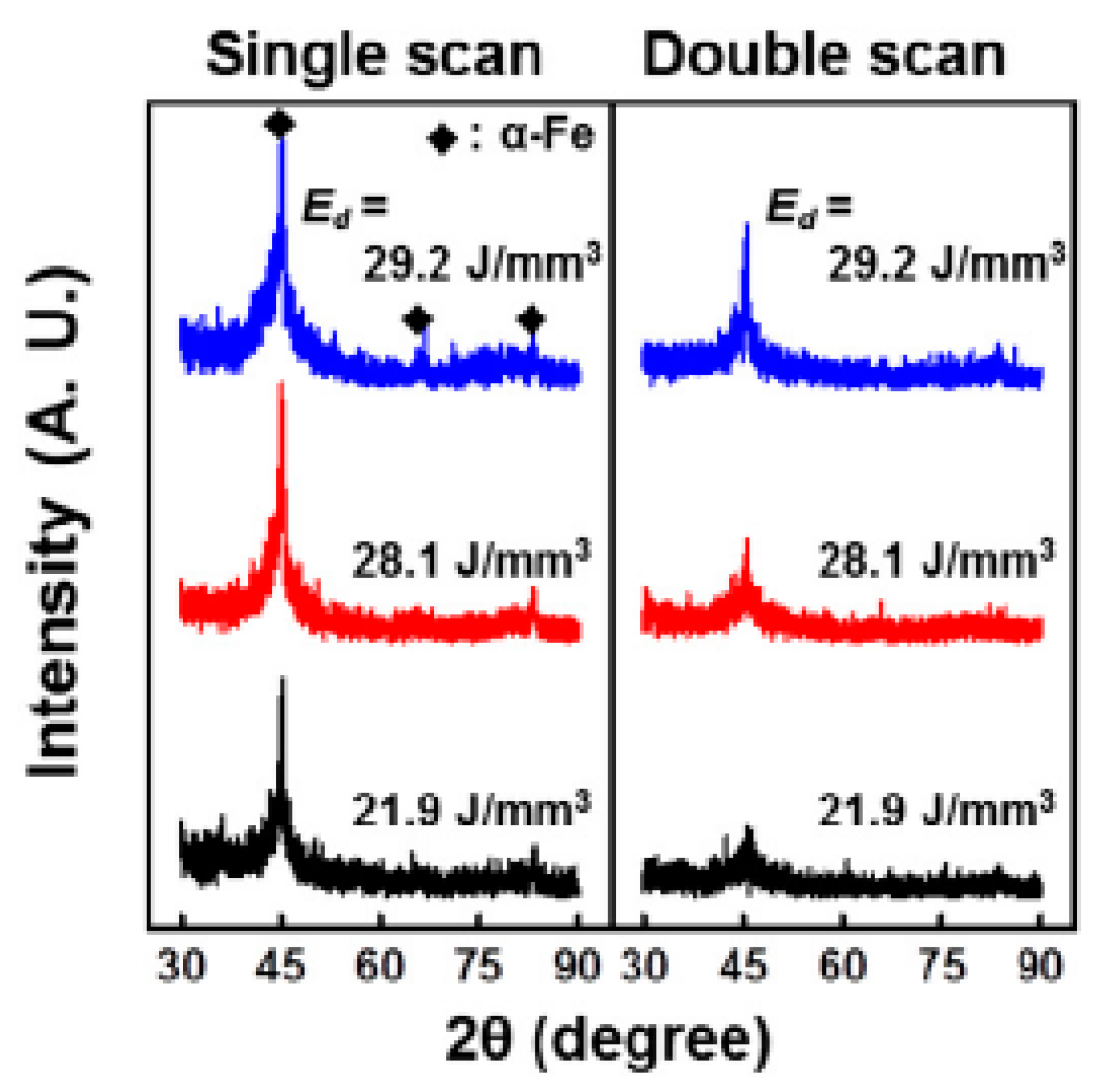

- Nam, Y.G.; Koo, B.; Chang, M.S.; Yang, S.; Yu, J.; Park, Y.H.; Jeong, J.W. Selective laser melting vitrification of amorphous soft magnetic alloys with help of double-scanning-induced compositional homogeneity. Mater. Lett. 2020, 261, 127068. [Google Scholar] [CrossRef]

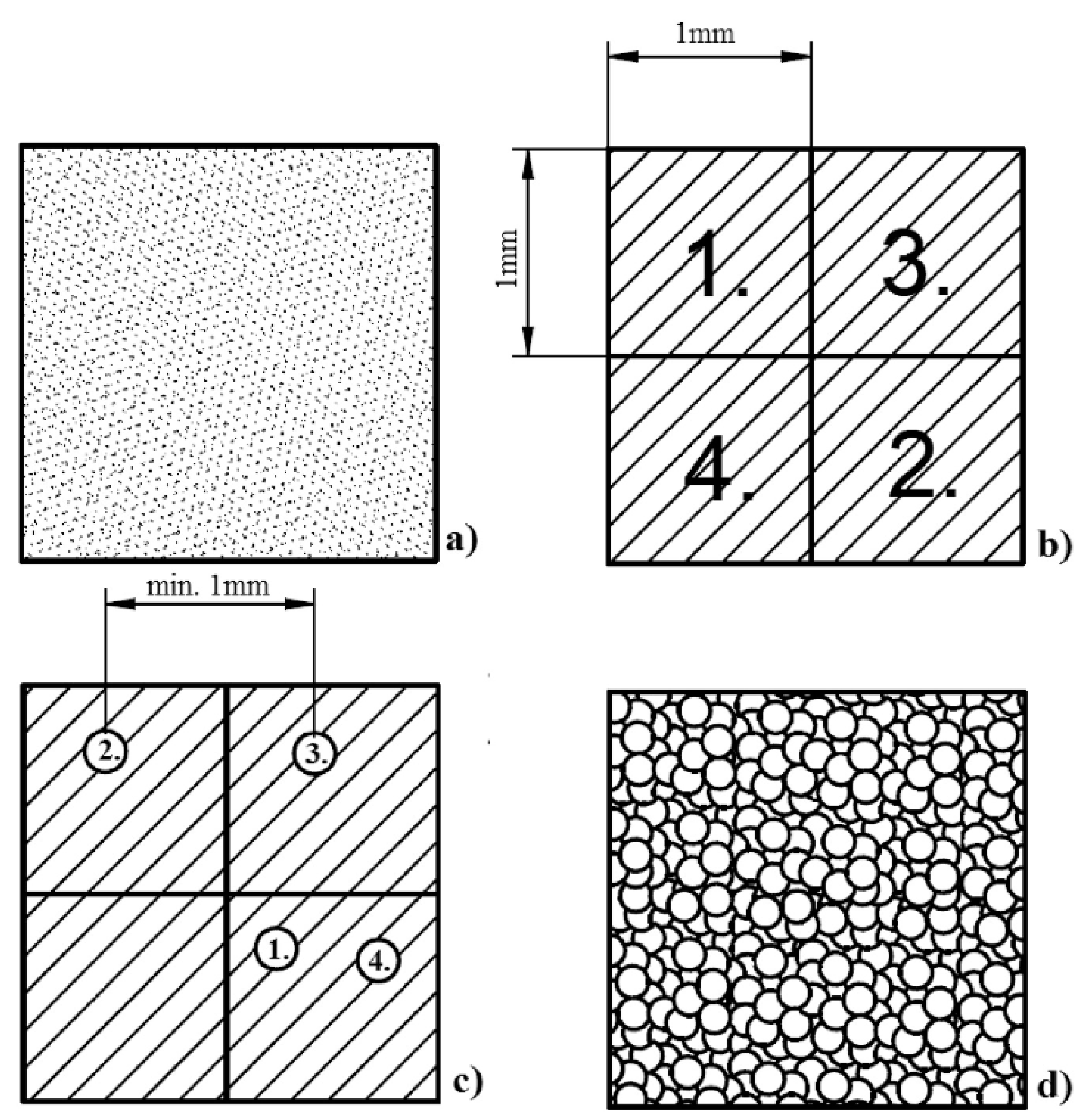

- Żrodowski, Ł.; Wysocki, B.; Wróblewski, R.; Krawczyńska, A.; Adamczyk-Cieślak, B.; Zdunek, J.; Błyskun, P.; Ferenc, J.; Leonowicz, M.; Święszkowski, W. New approach to amorphization of alloys with low glass forming ability via selective laser melting. J. Alloy. Compd. 2019, 771, 769–776. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Directed energy deposition processes. In Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015; pp. 245–268. [Google Scholar]

- Zhang, Z.; Liu, Z.; Wu, D. Prediction of melt pool temperature in directed energy deposition using machine learning. Addit. Manuf. 2021, 37, 101692. [Google Scholar] [CrossRef]

- Hofmeister, W.; Griffith, M.; Ensz, M.; Smugeresky, J. Solidification in direct metal deposition by LENS processing. J. Miner. Met. Mater. Soc. 2001, 53, 30–34. [Google Scholar] [CrossRef]

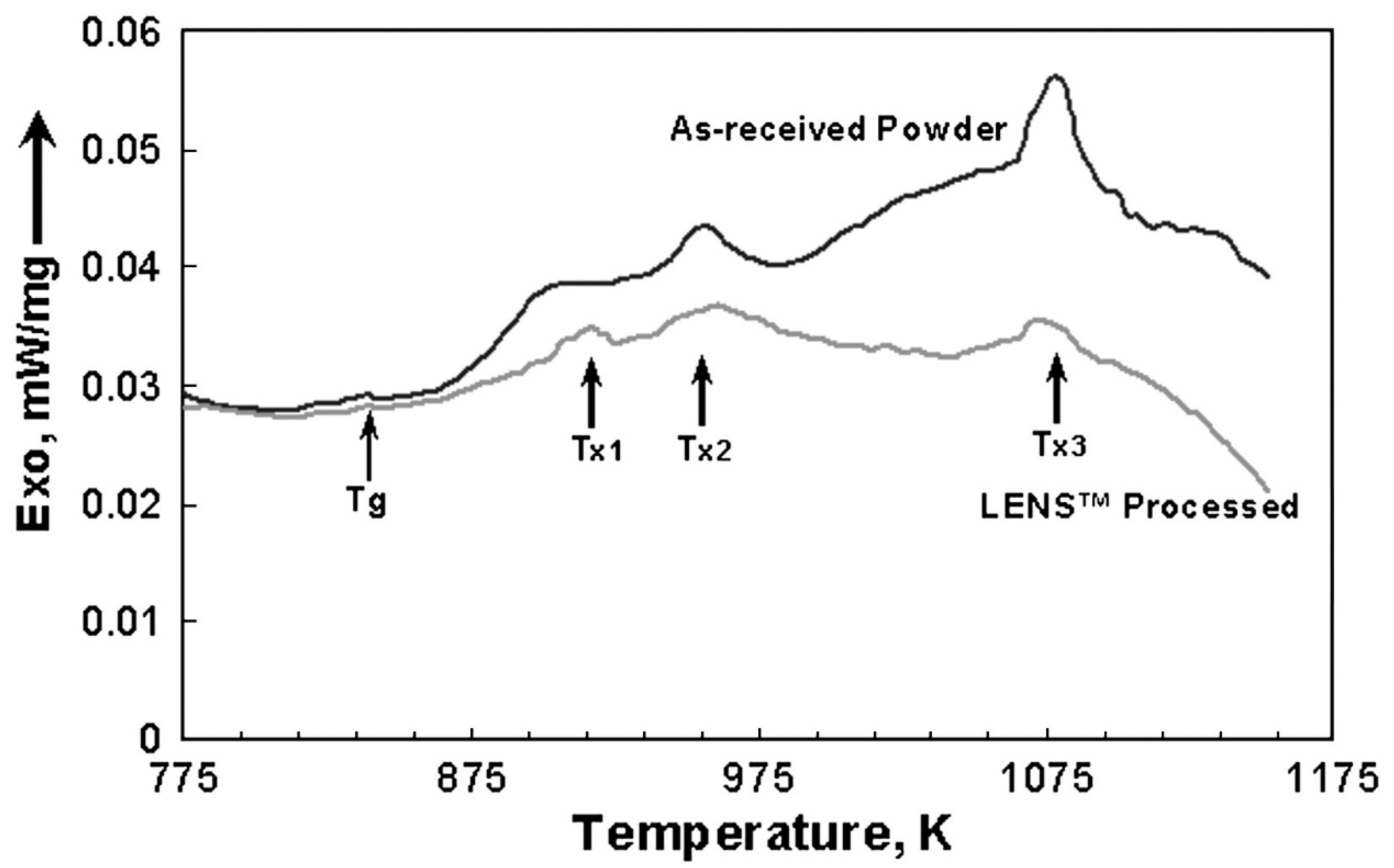

- Balla, V.K.; Bandyopadhyay, A. Laser processing of Fe-based bulk amorphous alloy. Surf. Coat. Technol. 2010, 205, 2661–2667. [Google Scholar] [CrossRef]

- Mazumder, J.; Schifferer, A.; Choi, J. Direct materials deposition: Designed macro and microstructure. Mater. Res. Innov. 1999, 3, 118–131. [Google Scholar] [CrossRef]

- Kurz, W.; Bezençon, C.; Gäumann, M. Columnar to equiaxed transition in solidification processing. Sci. Technol. Adv. Mater. 2001, 2, 185–191. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.; Kobryn, P.A.; Fraser, H.L. Thermal process maps for predicting solidification microstructure in laser fabrication of thin-wall structures. J. Mater. Process. Technol. 2006, 178, 135–142. [Google Scholar] [CrossRef]

- Gäumann, M.; Henry, S.; Cléton, F.; Wagnière, J.-D.; Kurz, W. Epitaxial laser metal forming: Analysis of microstructure formation. Mater. Sci. Eng. A 1999, 271, 232–241. [Google Scholar] [CrossRef]

- Farmer, J.; Haslam, J.; Day, S.; Lian, T.; Saw, C.; Hailey, P.; Choi, J.-S.; Rebak, R.B.; Yang, N.; Payer, J.; et al. Corrosion resistance of thermally sprayed high-boron iron-based amorphous-metal coatings: Fe49.7Cr17.7Mn1.9Mo7.4W1.6B15.2C3.8Si2.4. J. Mater. Res. 2007, 22, 2297–2311. [Google Scholar] [CrossRef]

- Vilar, R. Laser Alloying and Laser Cladding. Mater. Sci. Forum 1999, 301, 229–252. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Zhang, Y.; Ramanujan, R. The effect of niobium alloying additions on the crystallization of a Fe–Si–B–Nb alloy. J. Alloy. Compd. 2005, 403, 197–205. [Google Scholar] [CrossRef]

- Zhang, Y.; Ramanujan, R. Characterization of the effect of alloying additions on the crystallization of an amorphous Fe73.5Si13.5B9Nb3Cu1 alloy. Intermetalics 2006, 14, 710–714. [Google Scholar] [CrossRef]

- Zhang, Y.; Ramanujan, R.V. A study of the crystallization behavior of an amorphous Fe77.5Si13.5B9 alloy. Mater. Sci. Eng. A 2006, 416, 161–168. [Google Scholar] [CrossRef]

- Xie, F.; Chen, Q.; Gao, J.; Li, Y. Laser 3D Printing of Fe-Based Bulk Metallic Glass: Microstructure Evolution and Crack Propagation. J. Mater. Eng. Perform. 2019, 28, 3478–3486. [Google Scholar] [CrossRef]

- Chen, Q.; Shen, J.; Zhang, D.; Fan, H.; Sun, J. Mechanical performance and fracture behavior of Fe41Co7Cr15Mo14Y2C15B6 bulk metallic glass. J. Mater. Res. 2006, 22, 358–363. [Google Scholar] [CrossRef]

- Dehghanghadikolaei, A.; Namdari, N.; Mohammadian, B.; Fotovvati, B. Additive Manufacturing Methods: A Brief Overview. J. Sci. Eng. Res. 2018, 5, 123–131. [Google Scholar]

- Wong, K.; Hernandez, A. A Review of Additive Manufacturing. Int. Sch. Res. Netw. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

| As Cast | Annealed | ||||||

|---|---|---|---|---|---|---|---|

| Alloy | Shape | Hc (A/m) | Mr/Ms | µmax (103) | Hc (A/m) | Mr/Ms | µmax (103) |

| Fe80B20 | Toroid | 6.4 | 0.51 | 100 | 3.2 | 0.77 | 300 |

| Fe40Ni40P14B6 | Toroid | 4.8 | 0.45 | 58 | 1.6 | 0.71 | 275 |

| Fe29Ni44P14B6Si2 | Toroid | 4.6 | 0.54 | 46 | 0.88 | 0.70 | 310 |

| Fe4.7Co70.3Si15B10 | Strip | 1.04 | 0.36 | 190 | 0.48 | 0.63 | 700 |

| (Fe0.8Ni0.2)78Si8B14 | Strip | 1.44 | 0.41 | 300 | 0.48 | 0.95 | 2000 |

| Fe80P16C3B | Toroid | 4.96 | 0.4 | 96 | 4.0 | 0.42 | 130 |

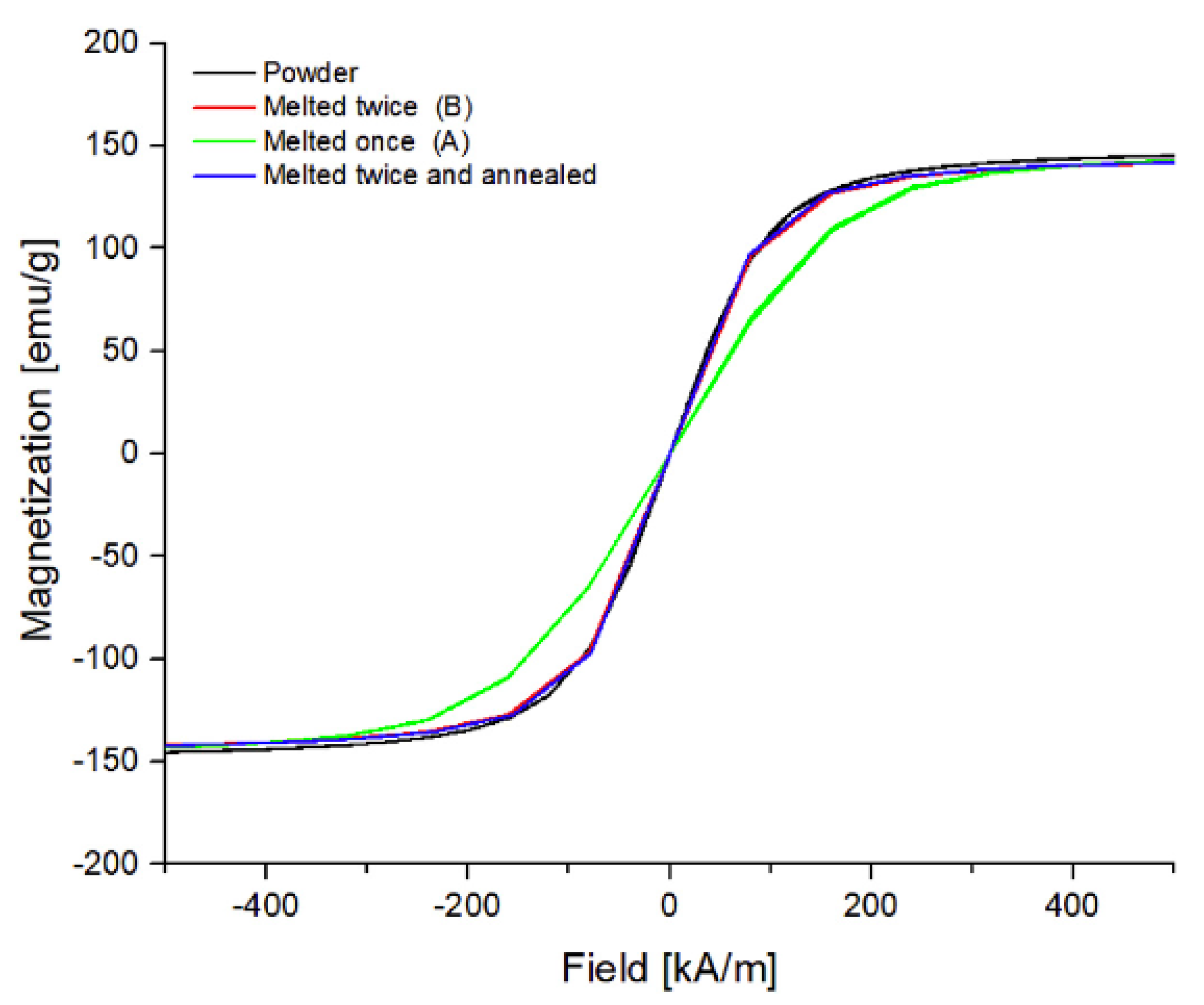

| Sample | Coercivity (A/m) |

|---|---|

| Powder | 99 |

| Melted once | 1032 |

| Melted twice | 397 |

| Melted twice and annealed | 238 |

| Process Parameters | Magnetic Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Alloy | Powder Size (µm) | Technique | P (W) | v (m/s) | Amorphous Content (%) | Ms | Hc (A/m) | Hardness (HV) | Reference |

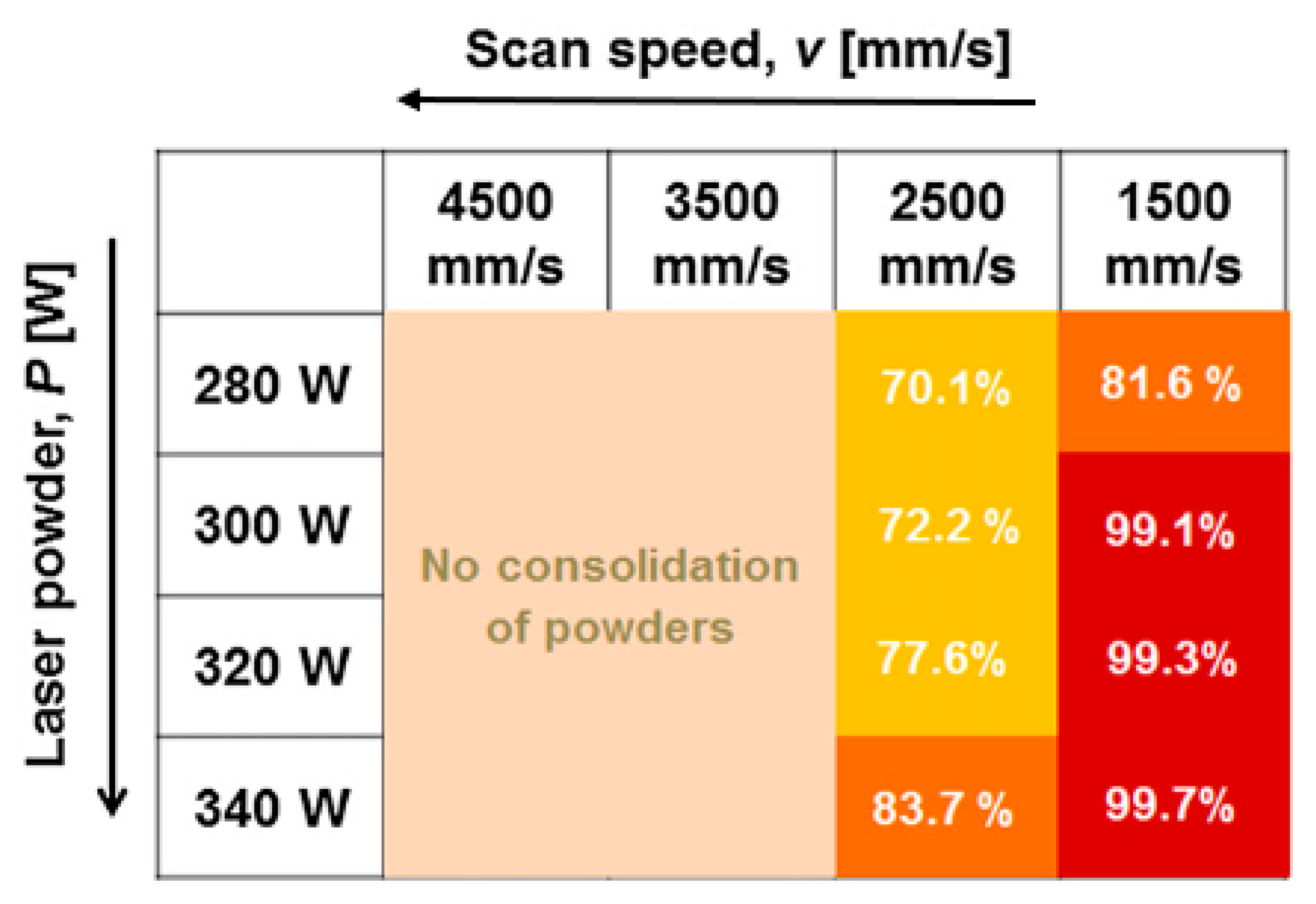

| Fe68.3C6.9 Si2.5B6.7P8.7Cr2.3Mo2.5Al2.1 | <150 | SLM | 340 | 1.5, 2.5 | Unknown | 102.8, 103.6 Am2/kg | 27.9 31.6 | - | [8] |

| FeCrMoCB | <80 | SLM | 80–200 | 0.8–5 | 100 a | - | - | 902 | [61] |

| Fe92.4Si3.1B4.5 | < 30 | SLM | 90 | 0.1–1.5 | 70–80 | 188.6–199 Am2/kg | 3485.5–5809.2 | 1654–2273 | [68] |

| Fe43.7Co7.3Cr14.7Mo12.6C15.5B4.3Y1.9 (at.%) | < 33 | SLM | 150–350 | 0.2–1 | 4.96–100 | - | - | - | [71] |

| Fe71Si10C6Cr2 (at.%) | ~24.5 | SLM | Max 120 | - | 89.6 | ~150 Am2/kg | 238 | - | [76] |

| Fe73.7Si11B11C2Cr2.28 | ~25 | SLM | 50, 70, 90 | 1.2, 1.6 | 47 | 1.22 T (kg/s2A) | 1591.5–2387.3 | - | [75] |

| Fe-Si-B-Nb-Cu | <150 | LENS | - | - | - | 118–150 Am2/kg | 1273.2–3819.7 | - | [5] |

| Cr<25Mo<15W<10C<3Mn<5Si<2B<5Febalance (at.%) | <180 | LENS | 250 | 0.02 | - | - | - | 1421 ± 101 | [80] |

| Fe41Co7Cr15Mo14C15B6Y2 (at.%) | - | LENS | 300, 600, 900 | 0.005, 0.01 | - | - | - | 1263.7 | [91] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozden, M.G.; Morley, N.A. Laser Additive Manufacturing of Fe-Based Magnetic Amorphous Alloys. Magnetochemistry 2021, 7, 20. https://doi.org/10.3390/magnetochemistry7020020

Ozden MG, Morley NA. Laser Additive Manufacturing of Fe-Based Magnetic Amorphous Alloys. Magnetochemistry. 2021; 7(2):20. https://doi.org/10.3390/magnetochemistry7020020

Chicago/Turabian StyleOzden, Merve G., and Nicola A. Morley. 2021. "Laser Additive Manufacturing of Fe-Based Magnetic Amorphous Alloys" Magnetochemistry 7, no. 2: 20. https://doi.org/10.3390/magnetochemistry7020020

APA StyleOzden, M. G., & Morley, N. A. (2021). Laser Additive Manufacturing of Fe-Based Magnetic Amorphous Alloys. Magnetochemistry, 7(2), 20. https://doi.org/10.3390/magnetochemistry7020020