Lithium-Ion Capacitor Safety Testing for Commercial Application

Abstract

:1. Introduction

2. Experimental Method

3. Electrochemical–Thermal Reaction Mechanisms Governing Equation

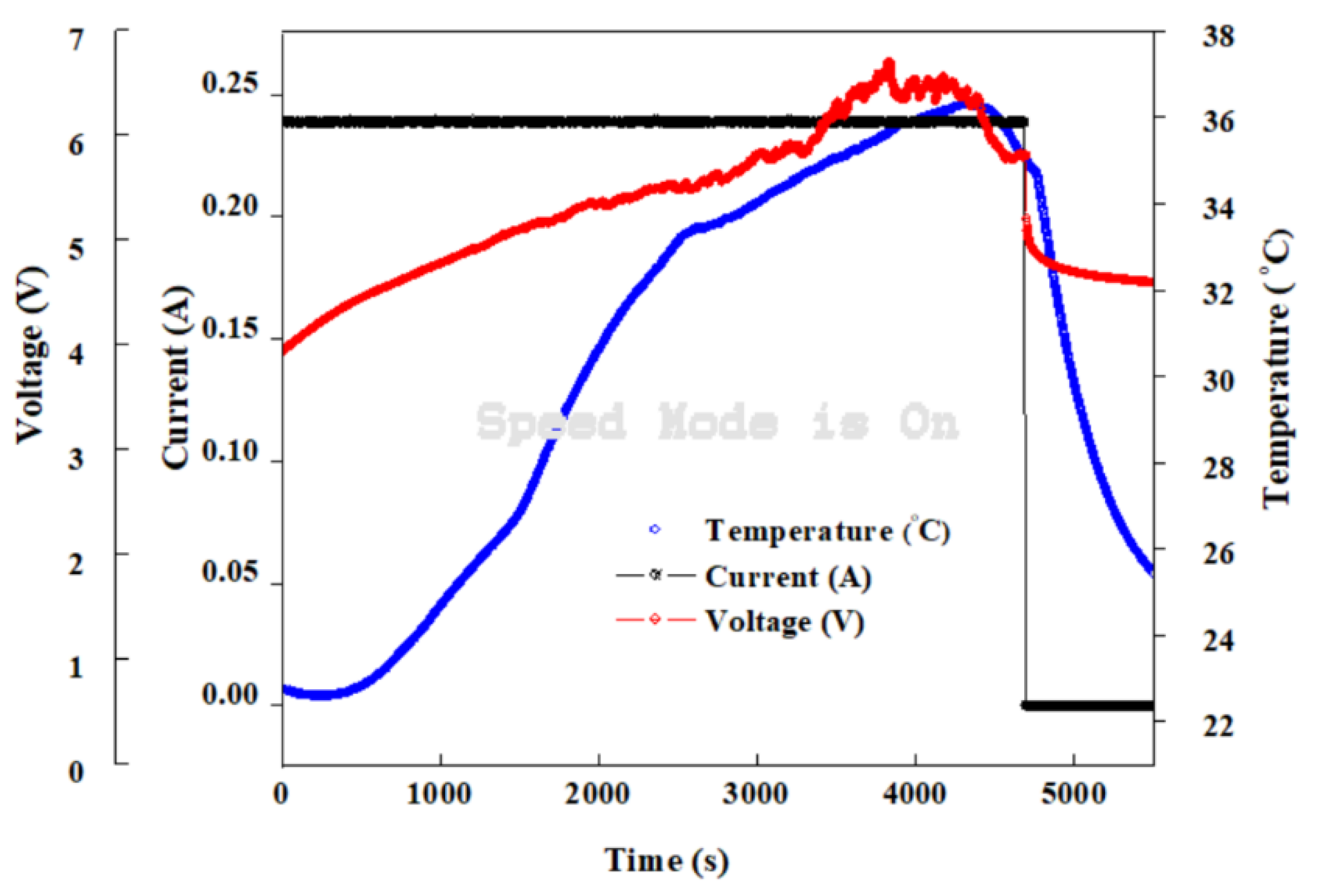

4. Result and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cao, W.J.; Zheng, J.P. The effect of cathode and anode potentials on the cycling performance of Li-Ion capacitors. J. Electrochem. Soc. 2013, 160, A1572–A1576. [Google Scholar] [CrossRef]

- Zheng, J.P. The limitations of energy density of battery/double-layer capacitor asymmetric cells. J. Electrochem. Soc. 2003, 150, A484–A492. [Google Scholar] [CrossRef]

- Zheng, J.P. Theoretical energy density for electrochemical capacitors with intercalation electrodes. J. Electrochem. Soc. 2005, 152, A1864–A1869. [Google Scholar] [CrossRef]

- Zheng, J.P. High energy density electrochemical capacitors without consumption of electrolyte. J. Electrochem. Soc. 2009, 156, A500–A505. [Google Scholar] [CrossRef]

- Cao, W.J.; Zheng, J.P. Li-ion capacitors with carbon cathode and hard carbon/stabilized lithium metal powder anode electrodes. J. Power Sour. 2012, 213, 180–185. [Google Scholar] [CrossRef]

- Gao, X.; Zhan, C.; Yu, X.; Liang, Q.; Lv, R.; Gai, G.; Shen, W.; Kang, F.; Huang, Z.H. A high performance lithium-ion capacitor with both electrodes prepared from Sri Lanka graphite ore. Materials 2017, 10, 414. [Google Scholar] [CrossRef]

- Adelowo, E.; Baboukani, A.; Chen, C.; Wang, C. Electrostatically sprayed reduced graphene oxide-carbon nanotubes electrodes for lithium-ion capacitors. J. Carbon Res. 2018, 4, 31. [Google Scholar] [CrossRef] [Green Version]

- Belov, D.; Yang, M.H. Failure mechanism of Li-ion battery at overcharge conditions. J. Sol. State Electrochem. 2008, 12, 885–894. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, U.S.; Sim, C.B. Modelling of the thermal behaviour of an ultracapacior for a 42-V automotive electrical system. J. Power Sour. 2008, 175, 664–668. [Google Scholar] [CrossRef]

- Gualous, H.; Louahlia-Gualous, H.; Gallay, R.; Miraoui, A. Supercapacitor thermal modelling and characterization in transient state for industrial applications. IEEE Trans. Ind. Appl. 2009, 45, 1035–1044. [Google Scholar] [CrossRef]

- Monzer Al, S.; Gualous, H.; Van Mierlo, J.; Culcu, H. Thermal modeling and heat management of supercapacitor modules for vehicle applications. J. Power Sour. 2009, 194, 581–587. [Google Scholar]

- Zubieta, L.; Bonert, R. Characterization of double-layer capacitors for power electronics applications. IEEE Trans. Ind. Appl. 2000, 36, 199–205. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, Z.B.; Zhang, R.; Bin, Y.Z.; Qiu, J.S. Polymer casting of ultralight graphene aerogels for the production of conductive nanocomposites with low filling Content. J. Mater. Chem. A 2014, 2, 3756–3760. [Google Scholar] [CrossRef]

- Song, Z.; Sun, K. Adaptive backstepping sliding mode control with fuzzy monitoring strategy for a kind of mechanical system. ISA Trans. 2014, 53, 125–133. [Google Scholar] [CrossRef]

- Guo, G.; Bo, L. Three-dimensional thermal finite element modeling of lithium-ion battery in thermal abuse application. J. Power Sour. 2010, 195, 2393–2398. [Google Scholar] [CrossRef]

- Wang, K.; Li, L.; Zhang, T.; Liu, Z. Nitrogen-doped graphene for supercapacitor with long-term electrochemical stability. Energy 2014, 70, 612–617. [Google Scholar] [CrossRef]

- Finegan, D.P.; Tjaden, B.; Heenan, T.M.; Jervis, R.; Di Michiel, M.; Rack, A.; Hinds, G.; Brett, D.J.; Shearing, P.R. Tracking internal temperature and structural dynamics during nail penetration of lithium-ion cells. J. Electrochem. Soc. 2017, 164, A3285–A3291. [Google Scholar] [CrossRef]

- Wang, K.; Li, L.; Yin, H.; Zhang, T.; Wan, W. Thermal modelling analysis of spiral wound supercapacitor under constant-current cycling. PLoS ONE 2015, 10, e0138672. [Google Scholar] [CrossRef] [Green Version]

- Al-zubaidi, A.; Ji, X.; Yu, J. Thermal charging of supercapacitors: A perspective. Sustain. Energy Fuels 2017, 1, 1457–1474. [Google Scholar] [CrossRef]

- Kermani, G.; Sahraei, E. Characterization and modeling of the mechanical properties of lithium-ion batteries. Energies 2017, 10, 1730. [Google Scholar] [CrossRef] [Green Version]

- Larsson, F.; Mellander, B. Abuse by external heating, overcharge and short circuiting of commercial lithium-ion battery cells. J. Electrochem. Soc. 2014, 161, A1611–A1617. [Google Scholar] [CrossRef]

- Lee, C.W.; Venkatachalapathy, R.; Prakash, J. A Novel Flame-Retardant Additive for Lithium Batteries. Electrochem. Sol. State Lett. 2000, 3, 63–65. [Google Scholar] [CrossRef]

- Cappetto, A.; Cao, W.J.; Luo, J.F.; Hagen, M.; Adams, D.; Shelikeri, A.; Xu, K.; Zheng, J.P. Performance of wide temperature range electrolytes for Li-Ion capacitor pouch cells. J. Power Sour. 2017, 359, 205–214. [Google Scholar] [CrossRef]

- Arora, A.; Medora, N.K.; Livernois, T.; Swart, J. Safety of Lithium-Ion Batteries for Hybrid Electric Vehicles. In Electric and Hybrid Vehicle; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Spotnitz, R.; Franklin, J. Abuse Behavior of High-Power, Lithium-Ion Cells. J. Power Sour. 2003, 113, 81–100. [Google Scholar] [CrossRef]

- Tobishima, S.; Yamaki, J. A consideration of Lithium Cell Safety. J. Power Sour. 1999, 81–82, 882–886. [Google Scholar] [CrossRef]

- Biensan, P.; Simon, B.; Peres, J.P. On Safety of Lithium-Ion Cells. J. Power Sour. 1999, 81–82, 906–912. [Google Scholar] [CrossRef]

- Saito, Y.; Takano, K.; Negishi, A. Thermal behaviors of lithium-ion cells during overcharge. J. Power Sour. 2001, 97–98, 693–696. [Google Scholar] [CrossRef]

- Leising, R.A.; Palazzo, M.J.; Takeuchi, E.S.; Takeuchi, K.J. Abuse Testing of Lithium-Ion Batteries: Characterization of the Overcharge Reaction of LiCoO2/Graphite Cells. J. Electrochem. Soc. 2001, 148, A838. [Google Scholar] [CrossRef]

- Leising, R.A.; Palazzo, M.J.; Takeuchi, E.S.; Takeuchi, K.J. A study of the overcharge reaction of lithium-ion batteries. J. Power Sour. 2001, 97–98, 681–683. [Google Scholar] [CrossRef]

- Abada, S.; Marlair, G.; Lecocq, A.; Petit, M.; Sauvant-Moynot, V.; Huet, F. Safety Focused Modeling of Lithium-Ion Batteries: A Review. J. Power Sour. 2016, 306, 178–192. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Sour. 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Zavalis, T.G.; Behm, M.; Lindbergh, G. Investigation of Short-Circuit Scenarios in a Lithium-Ion Battery Cell. J. Electrochem. Soc. 2012, 159, A848. [Google Scholar] [CrossRef]

- Ouyang, D.; Chen, M.; Huang, Q.; Weng, J.; Wang, Z.; Wang, J. A review on the thermal hazards of the lithium-ion battery and the corresponding countermeasures. Appl. Sci. 2019, 9, 2483. [Google Scholar] [CrossRef] [Green Version]

- Yamauchi, T.; Mizushima, K.; Satoh, Y.; Yamada, S. Development of a simulator for both property and safety of a lithium secondary battery. J. Power Sour. 2004, 136, 99–107. [Google Scholar] [CrossRef]

- Melcher, A.; Ziebert, C.; Lei, B.; Zhao, W.; Luo, J.; Rohde, M.; Seifert, H.J. Modeling and Simulation of Thermal Runaway in Cylindrical 18650 Lithium-Ion Batteries. In Meeting Abstracts the Electrochemical Society; The Electrochemical Society: Pennington, NJ, USA, 2016; p. 425. [Google Scholar]

- Matula, R.A. Electrical resistivity of copper, gold, palladium and silver. J. Phys. Chem. 1979, 8, 1147. [Google Scholar] [CrossRef] [Green Version]

- Benger, R.; Wenzl, H.; Beck, H.; Jiang, M.; Ohms, D.; Schaedlich, G. 2009 Electrochemical thermal modeling of lithium-ion cells for use in HEV or EV application. World Electr. Veh. J. 2009, 3, 342. [Google Scholar] [CrossRef] [Green Version]

- Jeon, D.H.; Baek, S.M. Thermal modeling of cylindrical lithium ion battery during discharge cycle. Energy Convers. Manag. 2011, 52, 2973–2981. [Google Scholar] [CrossRef]

- Wang, F.; Li, M. Thermal performance analysis of the Lithium-ion Batteries. In Proceedings of the 2010 International Conference on Parallel and Distributed Computing, Applications and Technologies (PDCAT), Wuhan, China, 8–11 December 2010; pp. 483–486. [Google Scholar]

- Soltani, M.; Ronsmans, J.; Kakihara, S.; Jaguemont, J.; Van den Bossche, P.; van Mierlo, J.; Omar, N. Hybrid battery/lithium-ion capacitor energy storage system for a pure electric bus for an urban transportation application. Appl. Sci. 2018, 8, 1176. [Google Scholar] [CrossRef] [Green Version]

- Onda, K.; Ohshima, T.; Nakayama, M.; Fukuda, K.; Araki, T. Thermal behavior of small lithium-ion battery during rapid charge and discharge cycles. J. Power Sour. 2006, 158, 535–542. [Google Scholar] [CrossRef]

- Ismail, N.H.F.; Toha, S.F.; Azubir, N.A.M.; Ishak, N.H.M.; Hassan, M.K.; Ibrahim, B.S.K. Simplified heat generation model for lithium ion battery used in electric vehicle. IOP Conf. Ser. Mater. Sci. Eng. 2013, 53, 012014. [Google Scholar] [CrossRef]

- Aurbach, D.; Zinigrad, E.; Cohen, Y.; Teller, H. A short review of failure mechanism of lithium metal and lithiated graphite anodes in liquid electrolyte solutions. Sol. State Ion. 2002, 148, 405–416. [Google Scholar] [CrossRef]

- Dahn, J.R.; Fuller, E.W.; Obrovac, M.; Von Sacken, U. Thermal stability of LixCoO2, LixNiO2 and λ-MnO2 and consequences for the safety of Li-ion cells. Sol. State Ion. 1994, 69, 265–270. [Google Scholar] [CrossRef]

- Chen, Y.; Evans, J.W. Thermal analysis of lithium-ion batteries. J. Electrochem. Soc. 1996, 143, 2708–2712. [Google Scholar] [CrossRef]

- Kriston, A.; Pfrang, A.; Döring, H.; Fritsch, B.; Ruiz, V.; Adanouj, I.; Kosmidou, T.; Ungeheuer, J.; Boon-Brett, L. External short circuit performance of Graphite-LiNi1/3Co1/3Mn1/3O2 and Graphite-LiNi0.8Co0.15Al0.05O2 cells at different external. J. Power Sour. 2017, 361, 170–181. [Google Scholar] [CrossRef]

- Orendorff, C.J. The Role of Separators in Lithium-Ion Cell Safety. Electrochem. Soc. Interface 2012, 21, 61–65. [Google Scholar] [CrossRef]

- Jiang, J.R.D.J.; Dahn, J.R. ARC studies of the thermal stability of three different cathode materials: LiCoO2; Li [Ni0.1Co0.8Mn0.1]O2; and LiFePO4, in LiPF6 and LiBoB EC/DEC electrolytes. Electrochem. Commun. 2004, 6, 39–43. [Google Scholar] [CrossRef]

| Parameters | Specification |

|---|---|

| Dimension | Thickness = 4.5 mm, Heights = 58 mm, Width = 48 mm |

| Weight | 16 g |

| Specific Power | 6 kW/kg |

| Specific Energy | 14 Wh/g |

| Voltage Range | 2.2–3.8 V |

| Maximum Voltage | 4.0 V |

| Capacitance | 200 F |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolufawi, O.; Shellikeri, A.; Zheng, J.P. Lithium-Ion Capacitor Safety Testing for Commercial Application. Batteries 2019, 5, 74. https://doi.org/10.3390/batteries5040074

Bolufawi O, Shellikeri A, Zheng JP. Lithium-Ion Capacitor Safety Testing for Commercial Application. Batteries. 2019; 5(4):74. https://doi.org/10.3390/batteries5040074

Chicago/Turabian StyleBolufawi, Omonayo, Annadanesh Shellikeri, and Jim P. Zheng. 2019. "Lithium-Ion Capacitor Safety Testing for Commercial Application" Batteries 5, no. 4: 74. https://doi.org/10.3390/batteries5040074

APA StyleBolufawi, O., Shellikeri, A., & Zheng, J. P. (2019). Lithium-Ion Capacitor Safety Testing for Commercial Application. Batteries, 5(4), 74. https://doi.org/10.3390/batteries5040074