Engineered Grain Boundary Enables the Room Temperature Solid-State Sodium Metal Batteries

Abstract

1. Introduction

2. Experimental Section

2.1. Synthesis of Na3Zr2Si2PO12-B2O3 Ceramics

2.2. Microstructure and Performance Characterization

2.3. Synthesis of the Composite Cathode

2.4. Assemble and Disassemble Cells

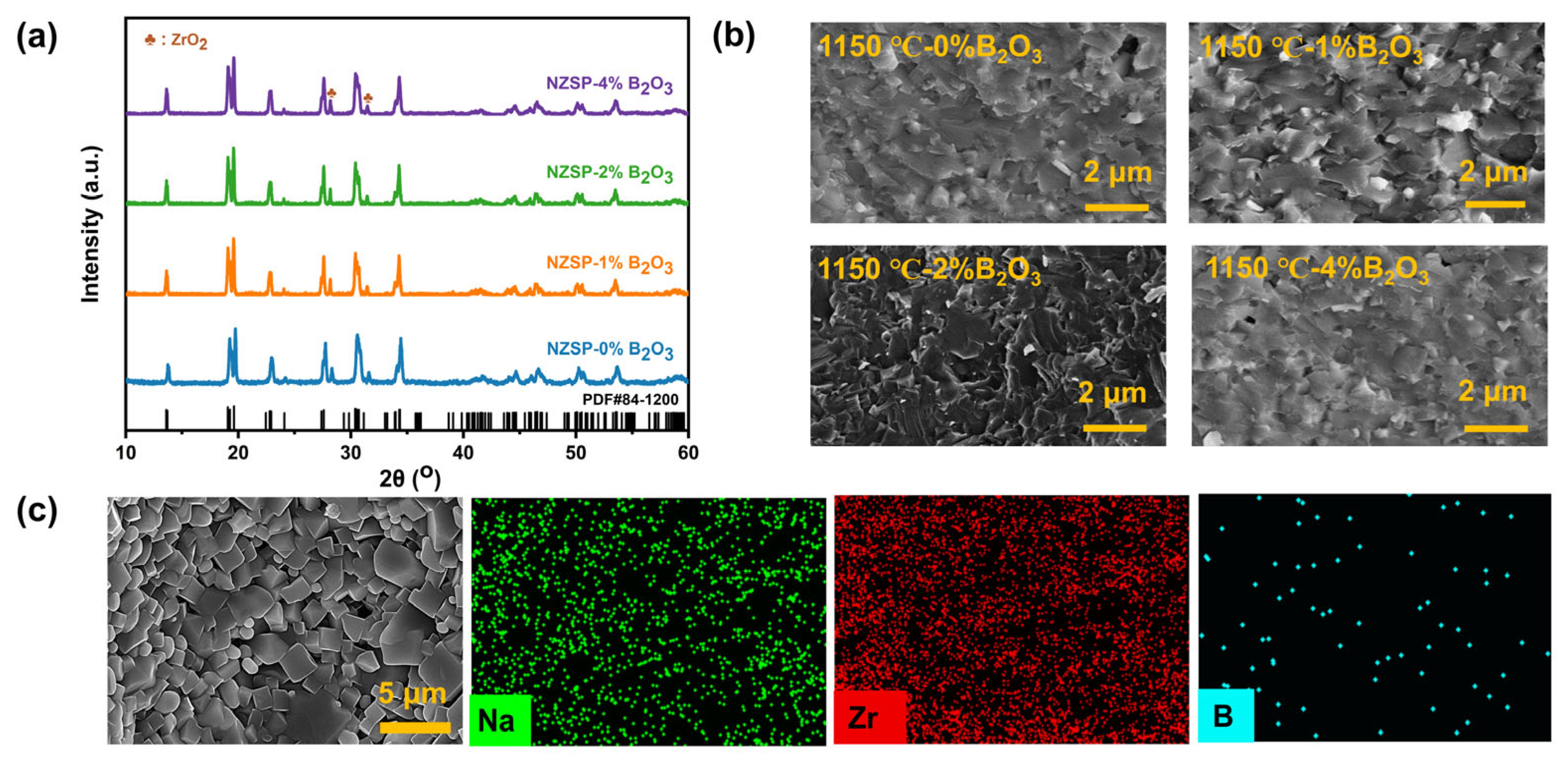

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sust. Energ. Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Olabi, A.G. Renewable energy and energy storage systems. Energy 2017, 136, 1–6. [Google Scholar] [CrossRef]

- Ould Amrouche, S.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrog. Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Guney, M.S.; Tepe, Y. Classification and assessment of energy storage systems. Renew. Sust. Energ. Rev. 2017, 75, 1187–1197. [Google Scholar] [CrossRef]

- Olabi, A.G.; Onumaegbu, C.; Wilberforce, T.; Ramadan, M.; Abdelkareem, M.A.; Al-Alami, A.H. Critical review of energy storage systems. Energy 2021, 214, 118987. [Google Scholar] [CrossRef]

- Chen, K.F.; Xue, D.F. Materials chemistry toward electrochemical energy storage. J. Mater. Chem. A 2016, 4, 7522–7537. [Google Scholar] [CrossRef]

- Ragupathy, P.; Bhat, S.D.; Kalaiselvi, N. Electrochemical energy storage and conversion: An overview. WIREs Energy Environ. 2022, 12, e464. [Google Scholar] [CrossRef]

- Yang, Y.Q.; Bremner, S.; Menictas, C.; Kay, M. Battery energy storage system size determination in renewable energy systems: A review. Renew. Sust. Energ. Rev. 2018, 91, 109–125. [Google Scholar] [CrossRef]

- Vaalma, C.; Buchholz, D.; Weil, M.; Passerini, S. A cost and resource analysis of sodium-ion batteries. Nat. Rev. Mater. 2018, 3, 18013. [Google Scholar] [CrossRef]

- Hwang, J.-Y.; Myung, S.-T.; Sun, Y.-K. Sodium-ion batteries: Present and future. Chem. Soc. Rev. 2017, 46, 3529–3614. [Google Scholar] [CrossRef]

- Hou, D.W.; Xia, D.W.; Gabriel, E.; Russell, J.A.; Graff, K.; Ren, Y.; Sun, C.-J.; Lin, F.; Liu, Y.Z.; Xiong, H. Spatial and temporal analysis of sodium-ion batteries. ACS Energy Lett. 2021, 6, 4023–4054. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.G.; Li, J.; Lu, G.L.; Li, W.Y.; Tao, Q.Q.; Shi, C.H.; Huile, J.; Chen, G.; Wang, S. Fundamentals of electrolytes for solid-state batteries: Challenges and perspectives. Front. Mater. 2020, 7, 111. [Google Scholar] [CrossRef]

- Yu, X.Q.; Chen, R.S.; Gan, L.Y.; Li, H.; Chen, L.Q. Battery safety: From lithium-ion to solid-state batteries. Engineering 2022, 21, 9–14. [Google Scholar] [CrossRef]

- Zhao, Q.; Stalin, S.; Zhao, C.-Z.; Archer, L.A. Designing solid-state electrolytes for safe, energy-dense batteries. Nat. Rev. Mater. 2020, 5, 229–252. [Google Scholar] [CrossRef]

- Murgia, F.; Brighi, M.; Piveteau, L.; Avalos, C.E.; Gulino, V.; Nierstenhöfer, M.C.; Ngene, P.; Jongh, P.; CČerny, R. Enhanced room-temperature ionic conductivity of NaCB11H12 via high-energy mechanical milling. ACS Appl. Mater Inter. 2021, 13, 61346–61356. [Google Scholar] [CrossRef]

- Till, P.; Agne, M.T.; Kraft, M.A.; Courty, M.; Famprikis, T.; Ghidiu, M.; Krauskopf, T.; Masquelier, C.; Zeier, W.G. Two-dimensional substitution series Na3P1–xSbxS4–ySey: Beyond static description of structural bottlenecks for Na+ Transport. Chem. Mater. 2022, 34, 2410–2421. [Google Scholar] [CrossRef]

- Liu, L.M.; Liang, D.S.; Zhou, X.L.; Liu, Y.J.; Su, J.W.; Xu, Y.; Peng, J.S. Enhancing Na-ion conducting capacity of NASICON ceramic electrolyte Na3.4Zr2Si2.4P0.6O12 by NaF sintering aid. J. Mater. Sci. 2022, 57, 11774–11782. [Google Scholar] [CrossRef]

- Oh, J.A.S.; He, L.C.; Plewa, A.; Morita, M.; Zhao, Y.; Sakamoto, T.; Song, X.; Zhai, W.; Zeng, K.Y.; Lu, L. Composite NASICON (Na3Zr2Si2PO12) solid-state electrolyte with enhanced Na+ ionic conductivity: Effect of liquid phase sintering. Acs App. Mater. Interfaces 2019, 11, 40125–40133. [Google Scholar] [CrossRef]

- Grady, Z.; Fan, Z.M.; Ndayishimiye, A.; Randall, C.A. Design and sintering of all-solid-state composite cathodes with tunable mixed conduction properties via the cold sintering process. ACS Appl. Mater. Interfaces 2021, 13, 48071–48087. [Google Scholar] [CrossRef]

- Leng, H.Y.; Huang, J.J.; Nie, J.Y.; Luo, J. Cold sintering and ionic conductivities of Na3.256Mg0.128Zr1.872Si2PO12 solid electrolytes. J. Power Sources 2018, 391, 170–179. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Sun, Z.; Ni, Q.; Jin, H.B.; Zhao, Y.J. Recent advance on NASICON electrolyte in solid-state sodium metal batteries. Energy Storage Mater. 2023, 56, 582–599. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.X.; Wen, J.W.; Wang, Y.; Li, N.; Wang, J.; Fan, L.J. Improvement of ionic conductivity and densification of Na3Zr2Si2PO12 solid electrolyte rapidly prepared by microwave sintering. Ceram. Int. 2022, 48, 18999–19005. [Google Scholar] [CrossRef]

- Fuentes, R.O.; Figueiredo, F.M.; Marques, F.M.B.; Franco, J.I. Processing and electrical properties of NASICON prepared from yttria-doped zirconia precursors. J. Eur. Ceram. Soc. 2001, 21, 737–743. [Google Scholar] [CrossRef]

- Krok, F. Influence of sintering conditions on chemical composition of NASICON. Solid State Ion. 1987, 24, 21–28. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Z.; Sun, C.; Jin, H.B.; Zhao, Y.J. Exploring the origin of ZrO2 phase in Na3Zr2Si2PO12 ceramic electrolyte. Ceram. Int. 2023, 49, 3094–3098. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Gao, X.W.; Gao, H.C.; Jin, H.B.; Goodenough, J.B. Three electron reversible redox reaction in sodium vanadium chromium phosphate as a high-energy-density cathode for sodium-ion batteries. Adv. Funct. Mater. 2020, 30, 1908680. [Google Scholar] [CrossRef]

- Sun, C.; Zhao, Y.J.; Ni, Q.; Sun, Z.; Yuan, X.Y.; Li, J.B.; Jin, H.B. Reversible multielectron redox in NASICON cathode with high energy density for low-temperature sodium-ion batteries. Energy Storage Mater. 2022, 49, 291–298. [Google Scholar] [CrossRef]

- Zheng, C.J.; Lu, Y.; Su, J.M.; Song, Z.; Xiu, T.P.; Jin, J.; Badding, M.E.; Wen, Z.Y. Grain boundary engineering enabled high-performance garnet-type electrolyte for lithium dendrite free lithium metal batteries. Small Methods 2022, 6, e2200667. [Google Scholar] [CrossRef]

- Thokchom, J.S.; Kumar, B. The effects of crystallization parameters on the ionic conductivity of a lithium aluminum germanium phosphate glass-ceramic. J. Power Sources 2010, 195, 2870–2876. [Google Scholar] [CrossRef]

- Zhao, X.C.; Luo, Y.S.; Zhao, X.J. Effect of TeO2 sintering aid on the microstructure and electrical properties of Li1.3Al0.3Ti1.7(PO4)3 solid electrolyte. J. Alloy. Compd. 2022, 927, 167019. [Google Scholar] [CrossRef]

- He, S.N.; Xu, Y.L.; Chen, Y.J.; Ma, X.N. Enhanced ionic conductivity of an F−-assisted Na3Zr2Si2PO12 solid electrolyte for solid-state sodium batteries. J. Mater. Chem. A 2020, 8, 12594–12602. [Google Scholar] [CrossRef]

- Naqash, S.; Ma, Q.; Tietz, F.; Guillon, O. Na3Zr2(SiO4)2(PO4) prepared by a solution-assisted solid state reaction. Solid State Ion. 2017, 302, 83–91. [Google Scholar] [CrossRef]

- Park, H.; Jung, K.; Nezafati, M.; Kim, C.-S.; Kang, B. Sodium ion diffusion in Nasicon (Na3Zr2Si2PO12) solid electrolytes: Effects of excess sodium. ACS Appl. Mater. Interfaces 2016, 8, 27814–27824. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.J.; Zhong, G.M.; Lu, Y.X.; Liu, L.L.; Zhao, C.L.; Zhang, Q.Q.; Hu, Y.-S.; Yang, Y.; Chen, L.Q. A novel NASICON-based glass-ceramic composite electrolyte with enhanced Na-ion conductivity. Energy Storage Mater. 2019, 23, 514–521. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Wang, C.Z.; Dai, Y.J.; Jin, H.B. Homogeneous Na+ transfer dynamic at Na/Na3Zr2Si2PO12 interface for all solid-state sodium metal batteries. Nano Energy 2021, 88, 106293. [Google Scholar] [CrossRef]

- Aslam, M.K.; Niu, Y.B.; Hussain, T.; Tabassum, H. How to avoid dendrite formation in metal batteries: Innovative strategies for dendrite suppression. Nano Energy 2021, 86, 106142. [Google Scholar] [CrossRef]

- Gao, Z.H.; Yang, J.Y.; Li, G.C.; Ferber, T.; Feng, J.R.; Li, Y.Y.; Fu, H.Y.; Jaegermann, W.; Monroe, C.W.; Huang, Y.H. TiO2 as second phase in Na3Zr2Si2PO12 to suppress dendrite growth in sodium metal solid-state batteries. Adv. Energy Mater. 2022, 12, 2103607. [Google Scholar] [CrossRef]

- Wang, X.X.; Chen, J.J.; Mao, Z.Y.; Wang, D.J. Effective resistance to dendrite growth of NASICON solid electrolyte with lower electronic conductivity. Chem. Eng. J. 2022, 427, 130899. [Google Scholar] [CrossRef]

- Oh, J.A.S.; He, L.C.; Chua, B.; Zeng, K.Y.; Lu, L. Inorganic sodium solid-state electrolyte and interface with sodium metal for room-temperature metal solid-state batteries. Energy Storage Mater. 2021, 34, 28–44. [Google Scholar] [CrossRef]

- Ruan, Y.L.; Guo, F.; Liu, J.J.; Song, S.D.; Jiang, N.Y.; Cheng, B.W. Optimization of Na3Zr2Si2PO12 ceramic electrolyte and interface for high performance solid-state sodium battery. Ceram. Inter. 2019, 45, 1770–1776. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Sun, Z.; Jin, H.; Zhao, Y. Engineered Grain Boundary Enables the Room Temperature Solid-State Sodium Metal Batteries. Batteries 2023, 9, 252. https://doi.org/10.3390/batteries9050252

Li Y, Sun Z, Jin H, Zhao Y. Engineered Grain Boundary Enables the Room Temperature Solid-State Sodium Metal Batteries. Batteries. 2023; 9(5):252. https://doi.org/10.3390/batteries9050252

Chicago/Turabian StyleLi, Yang, Zheng Sun, Haibo Jin, and Yongjie Zhao. 2023. "Engineered Grain Boundary Enables the Room Temperature Solid-State Sodium Metal Batteries" Batteries 9, no. 5: 252. https://doi.org/10.3390/batteries9050252

APA StyleLi, Y., Sun, Z., Jin, H., & Zhao, Y. (2023). Engineered Grain Boundary Enables the Room Temperature Solid-State Sodium Metal Batteries. Batteries, 9(5), 252. https://doi.org/10.3390/batteries9050252