Abstract

The global plastic production total has risen to more than 400 million tons per year; this number is mainly driven by industrial appliances. In the EU, where the annual production is about 30 million tons, only 32% of plastic waste is recycled. Therefore, a need for a robust and efficient waste management strategy has emerged. This study will introduce a novel logistic regression-based decision-making framework that focuses on the environment and the economy while also considering energy intensity and logistics. These factors reflect the use of Life Cycle Assessment (LCA) in this study, which is an approach that determines the selection of waste management strategies across different European countries. This study introduces a model with 94% sensitivity and 97% overall accuracy in order to compare pyrolysis and plastic waste recycling management methods. One of the main findings is the fact that pyrolysis demonstrated a maximum conversion efficiency of 88%; in comparison, the conversion efficiency for recycling was approximately 58%. Pyrolysis also generates by-products, such as syngas and pyrolytic oil, which are valuable. To conclude, this study is a tool for policymakers and industry leaders, so that they can make sustainable waste management decisions with data-driven and evidence-based reasoning.

1. Introduction

1.1. Background of Study

Plastic appliances are used in almost every industrial sector, so their waste management is a necessity. When plastics reach the end of their life cycles, they become a problem. The reason for this is that they resist natural degradation [1]. As the annual plastic production globally is currently 400 million tons, the prediction (bearing in mind that no intervention occurs) for 2050 is more than 800 million tons [1]. European industries produce more than 30 million tons of plastic waste each year, and only 32% of that is recycled, while the rest is incinerated, landfilled, or improperly disposed of [1,2].

Non-recycled plastic waste is abandoned everywhere, making it an environmental threat. When a large amount of waste starts degrading, microplastics emerge and are found everywhere, ranging from the oceans to food and human organs, which raises concern over the toxicological impact that they can have [3]. The energy demands for the plastic production and the waste management industries lead to the emission of greenhouse gasses, accounting for 3.8% of the total emissions [4].

1.1.1. Challenges in Plastic Waste Recycling

Recycling is thought to be the main solution, which is not the case. The reason for this is that recycling faces economic and technical challenges that decrease its efficiency. Some of these problems are contamination during collection and the degradation of plastic through multiple recycling cycles [5,6].

Plastic waste needs to be sorted by type, which is a complex procedure. For example, food packaging is made of multilayered plastic; in order to detect this type of waste, advanced technologies, such as optical sorting systems and chemical markers for proper segregation, are required [7]. These technologies are either expensive or not available, which is why much of the waste is misclassified or lost. Additionally, even if some of these technologies exist, they are not accessible in many regions that lack centralized facilities with a sufficient processing capacity, which means that less waste is recycled successfully [8].

Another problem down the line is consumer behavior. A lack of environmental awareness reduces the quality and quantity of recycled materials due to people improperly categorizing waste before it ends up in the trash [9]. Finally, when the end product is successfully recycled, some of its mechanical properties are weakened or even lost, making it inappropriate for industrial use [10]. Throughout this whole procedure, emissions are released that are potentially toxic and pose a threat to human health and the ecosystem [11].

1.1.2. The Need for a Comprehensive Framework

From the above introduction, it is clear that waste management is a multi-variant problem. Life Cycle Assessment (LCA) is a framework that can measure a product’s environmental footprint throughout its life cycle, from the day that the material is extracted to its disposal [12]. LCA can analyze the usage of each resource and the actual emissions and waste generated, making it an excellent sustainability measure [13,14].

Both recycling and pyrolysis are perceived as the dominant waste management solutions. By using LCA, every aspect of each procedure is considered, including its pollution potential [15]. Specifically, LCA allows for the evaluation of interconnected processes, such as upstream and downstream effects, making it an essential tool for analyzing complex waste management systems [13]. This framework is very useful, especially in Europe, where the circular economy and efficiency are key policies [16].

Pyrolysis by-products, such as syngas and pyrolytic oil, can be used for energy production, but its large-scale adoption can lead to immense capital costs [16]. On the other hand, recycling has a higher cost, but benefits from established infrastructure and strong regulatory support in many European countries [17]. Extended Producer Responsibility (EPR), which is a summation of the subsidies and campaigns that keep the public opinion aware, plays a critical role in increasing the recycling rates [14].

On the logistics side, pyrolysis centralized facilities can lead to increased transportational emissions and costs when recycling is dependent on decentralized networks that reduce them [12]. With that being said, recycling has better energy-intensive sorting and cleaning processes, which may circumvent some environmental benefits [15].

The Green Deal and the circular economy action plans are policies that aim to reduce emissions and improve resource efficiency [17]. Recycling is almost fully aligned with these goals because it supports material circularity, while reducing the need for new materials. Pyrolysis, though not favored between the two, is seen as a solution for managing plastics that are difficult to recycle, are contaminated, or are multilayered [13].

1.2. The State of the Art

- Pyrolysis as a plastic waste management solution

Data-driven sources claim that pyrolysis can achieve a high waste conversion efficiency that fluctuates between 70 and 90%. These fluctuations are dependent on the conditions of the process and the composition of the waste. This study emphasizes pyrolysis’ ability to convert mixed plastic waste into by-products of high value (syngas, pyrolytic oil and char) [15]. These by-products are then further refined into fuels or used in the industry, making it a promising technology for energy recovery.

Despite the above, there are challenges and limits as to how efficient pyrolysis is. The first concern is about the variability in output quality, because of the diversity of plastic waste. Environmentally, pyrolysis emits greenhouse gasses (GHGs), such as Nox (Nitrogen Oxides) and Sox (Sulfur Oxides) [9,10]. Also, there is a lack of economic and logistic constraints, which play a key role in large-scale adoption [10]. Additionally, pyrolysis facilities have high initial investment costs, while production costs are paid for by fuel production; the expense of building a pyrolysis site is significantly higher than that of a recycling facility [16]. A centralized pyrolysis facility is responsible for the transportation of the produced by-products; this adds to the logistic costs and emissions to and from the site [12]. These emissions may be decreased using carbon capture technologies or clean energy sources, making it a viable addition to recycling [14].

- Recycling: Challenges and Advancements

Traditional recycling is the process of sorting, cleaning, and reprocessing plastic waste that has already been used. This method is known as mechanical recycling. It has small energy requirements and well-established infrastructure [9]. However, its downsides are contamination, material degradation, and limited loops. Studies have highlighted that every recycling cycle gradually erodes a product’s mechanical properties; this results in the end product being less durable [10,11].

To overcome these challenges, chemical recycling can be of help. In this procedure, plastics are broken down to the molecular level, which allows the production of virgin-quality polymers. This type of recycling faces scalability issues, because chemical recycling requires significant amounts of energy. To produce that kind of energy, the need for sophisticated but not yet widely available infrastructure arises [11].

Countries that have a strong and well-developed waste management system are able to achieve higher recycling rates. On the other hand, countries with inadequate sorting and collection facilities are struggling to achieve a high recycling efficiency [8]. EPR policies and landfill bans are quite promising, yet their effectiveness varies significantly between different regions [11]. In conclusion, the procedure of recycling alone is not capable of handling the growing production rates of plastic waste, especially for multilayered packaging and contaminated plastics [13].

- The Need for a Hybrid Approach

As can be seen, both methods are bound to their limitations, so the need for a hybrid approach between the two arises. Mechanical recycling should be a priority for clean, homogeneous plastic streams, and, at the same time, pyrolysis can be used for non-recyclable and contaminated plastics [12]. The bridging role between the two is performed by chemical recycling, which has the potential for higher-quality material recovery and, at the same time, can significantly reduce the reliance on virgin plastic production [10,18].

1.3. Research Gaps and Objectives

This study explores the following objectives:

- Identify key drivers: the determination of the critical environmental (e.g., CO2 emissions, energy output), economic (e.g., operational costs, revenue potential), and logistical (e.g., transportation emissions, processing times) factors influencing scenario selection.

- Quantify trade-offs: the comparison of the environmental and economic trade-offs between pyrolysis and recycling to highlight the strengths and weaknesses of each approach.

- Predictive scenario selection: the development of a predictive model using logistic regression to estimate whether to choose pyrolysis or recycling under different conditions.

- Inform policy and practice: the provision of evidence-based recommendations for policymakers and industry leaders to optimize plastic waste management strategies in line with sustainability goals.

Previous studies have tried to focus on individual aspects (emissions, energy recovery, etc.), leaving the combination of these techniques aside [5,19]. This study complies with sustainability’s global agenda and with the Sustainable Development Goals (SDGs). This study supports Target 12, fostering effective resource use and waste management. It also supports Target 13 by taking into account the carbon footprint of a plastic waste management system [20]. Additionally, this study incorporates practical implications in Europe, where regulatory pressures and the public’s expectations about sustainability matter. This comprises key guidance for policymakers to aid in deciding which low emission technologies to subsidize and in which areas of infrastructure to invest, in order to achieve maximum energy capture. Lastly, this study makes a comparative analysis between pyrolysis and recycling, in order to compare the tradeoffs in these approaches.

2. Results

2.1. Data Analysis

2.1.1. Analysis Approach

The study utilizes a logistic regression model to determine the most efficient waste management scenario. The probability of selecting the preferred scenario was based on the following four different factors: environmental, economic, energy, and logistical. The validation of the data was carried out using several statistical tests. The analysis also included both quantitative results and visualizations to further emphasize the promising outcomes of pyrolysis in energy recovery, revenue generation, and operational efficiency as well.

2.1.2. Data Preprocessing

Handling missing values: in order to achieve a complete dataset, missing values of energy consumption and CO2 emissions were inputted using the mean.

Variable scaling: to make interpretation easier, operational costs and other variables with large ranges were normalized.

Categorical encoding: The dependent variable scenario numeric was coded as follows:

1 = pyrolysis; 2 = recycling.

Table 1 presents the summary metrics of the key variables of the study. The results show that, on a general basis, pyrolysis has a higher waste conversion efficiency and energy recovery potential than recycling.

Table 1.

Variable metrics (N = 40).

2.2. Model Fit

As a first indication, the chi-squared value was calculated using a likelihood-ratio test, simply by comparing two different models: a null model and a full model. The calculated value (x2 = 110.904, p < 0.001) indicates that the predictions can explain a significant portion of the variance in the dependent variable.

To gain deeper insight into the model’s performance, the Nagelkerke R2 value was used to estimate the proportion of variance explained by this model. The results showed that R2 = 1000, signifying a perfect fit of the data. However, despite the results of the test, because the pseudo R2 cannot directly translate to the traditional R2 linear regression values, no valid conclusions can be drawn using this test alone.

On top of this, the Hosmer–Lemeshow goodness-of-fit test was used to evaluate the alignment between predicted probabilities and observed data. As a result, the p-value > 0.05, showing that the model’s predictions are an appropriate fit for the data.

In the following evaluation, the model’s accuracy was assessed using the classification accuracy metric. The results were obtained by comparing predicted values to actual values in the dataset. The test successfully predicted pyrolysis and recycling scenarios with sensitivities of 94% and 98%, while achieving an excellent overall accuracy of 97%. As a next step, to improve the model’s stability and interpretability, variance inflation factor (VIF) values and Pearson correlation coefficients were used to identify multicollinearity within the independent variables. As a result, all the values with a factor (VIF > 10) were either excluded or combined.

As a final step to increase the model’s performance, a 10-fold cross-validation technique was used, showing a stable performance across folds, thereby indicating once more the model’s reliability.

The coefficients derived from the model are presented in Table 2 and provide key insights about the preferable waste management scenario by showing the influence of independent variables.

Table 2.

Logistic regression coefficients and statistical metrics for scenario selection.

The unstandardized coefficient (B) represents the change in the log-odds for a one-unit increase in the corresponding variable for the preferable waste management scenario. In this work, the coefficient for CO2 emissions (kg/ton) is B = −0.001 (p = 0.003), indicating that recycling is the preferable option, due to the higher amount of greenhouse gasses produced by pyrolysis. On the other hand, pyrolysis shows great energy recovery potential compared to recycling, with coefficient values of (B = 0.002, p < 0.001).

In order to obtain comparable results, the variables were normalized with the use of standardized coefficients (Beta). Among different factors, energy output (Beta = 0.311) and transportation emissions (KgCO2/ton) (Beta = 0.155, p < 0.001) seem to play a critical role.

For the further validation of the data, t-statistics and significance levels (Sig.) were used. Predictors like waste conversion efficiency (p = 0.0110), the average processing time (p = 0.032), and operational costs (B = -0.005, p = 0.029) highlight the influence of logistical and economic factors in favor of pyrolysis.

In conclusion, the logistic regression model that was used showed that economic, environmental, energy, and logistical factors are the contributing causes that influence waste management decisions. Both methods indicate advantages and disadvantages, with pyrolysis being favorable in terms of energy recovery, waste convention efficiency, transportation costs, and cost advantages in large-scale applications, while, on the other hand, recycling has a lower production rate of CO2 emissions and better material circularity, making it favorable for clean and homogeneous plastic waste streams.

2.3. Logistic Regression Results

The logistic regression revealed significant prediction evidence for selecting pyrolysis, as summarized in Table 3.

Table 3.

Summary of logistic regression results.

2.4. Visualizations and Insights

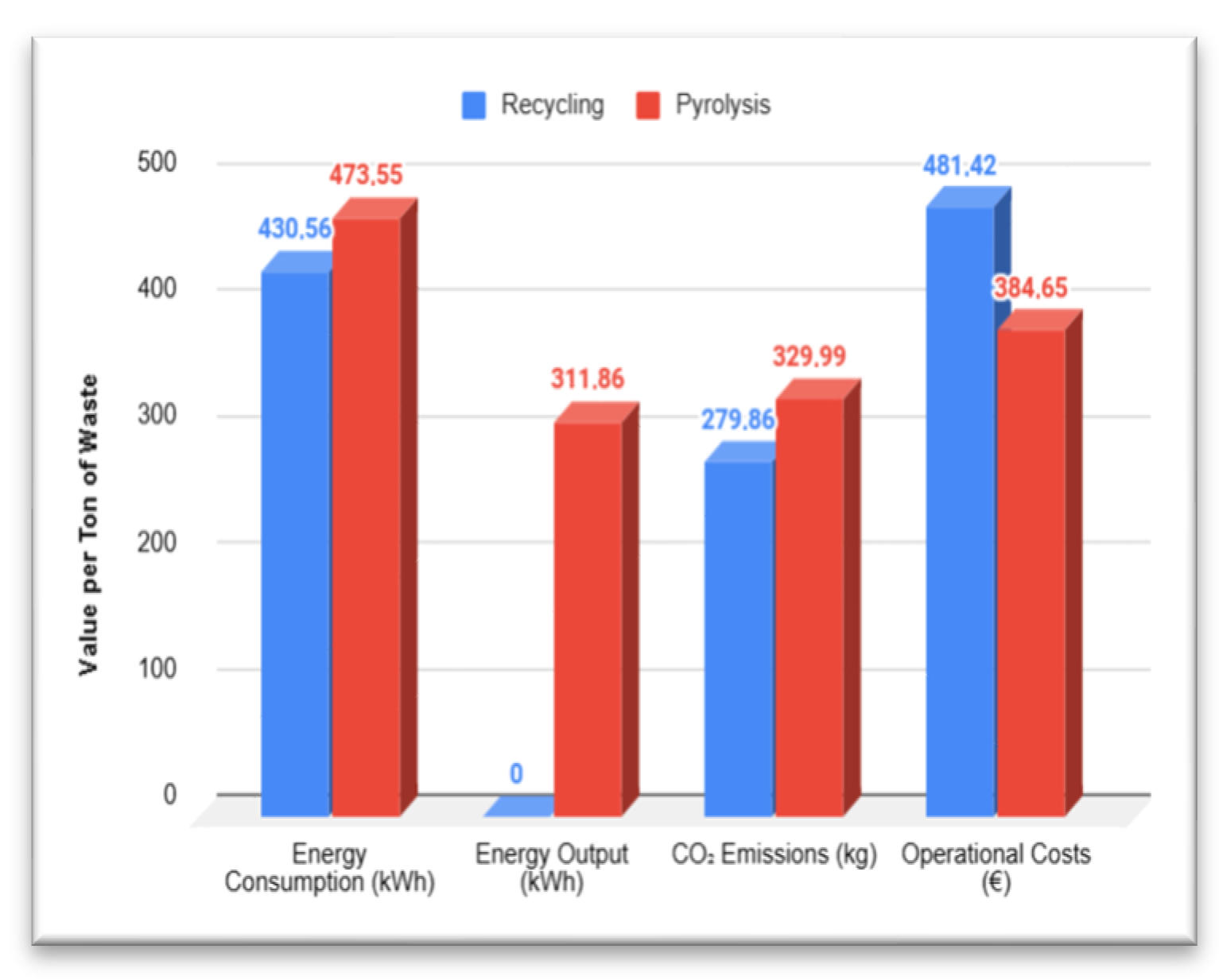

The following visualizations highlight pyrolysis’ advantages:

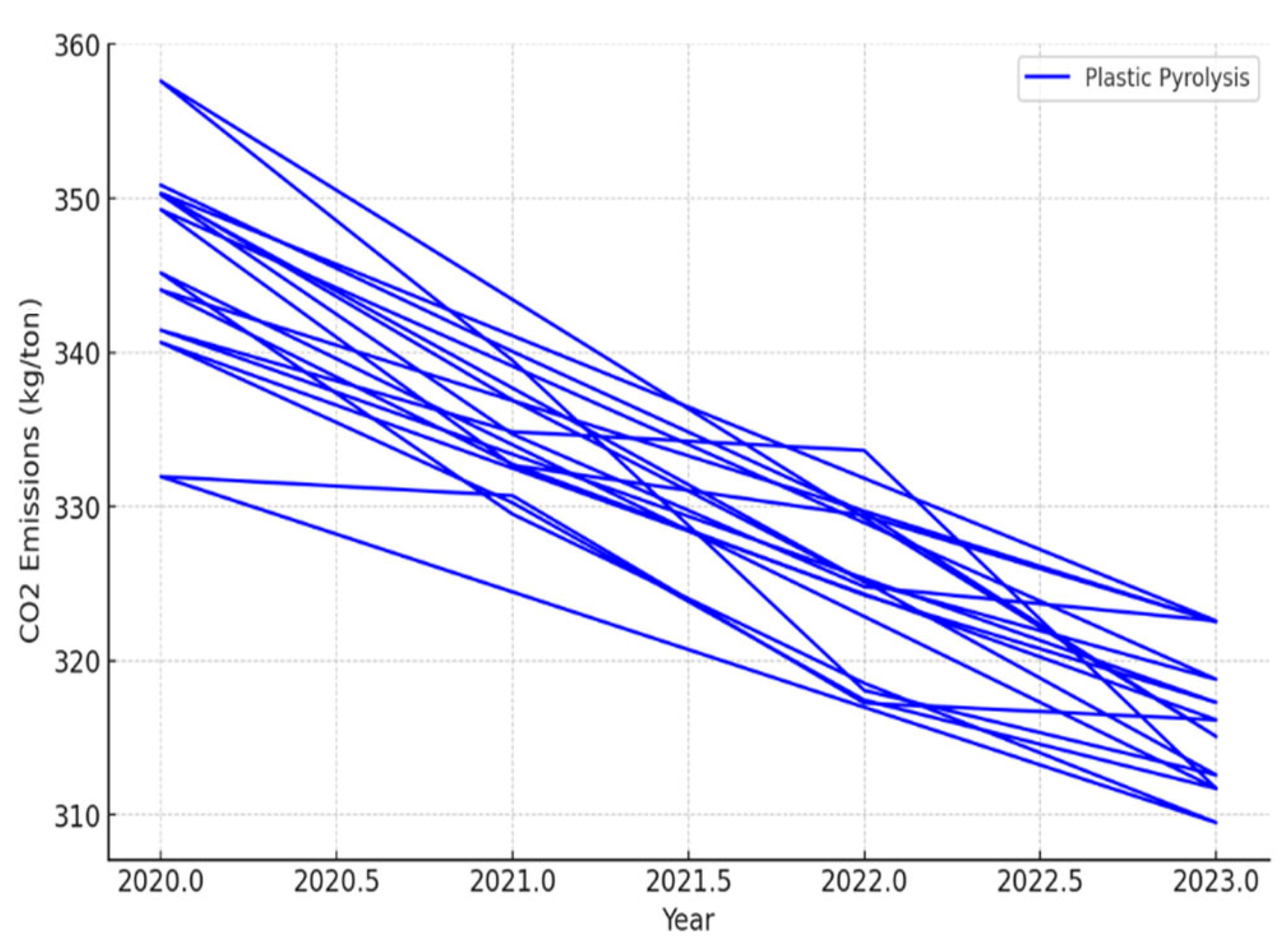

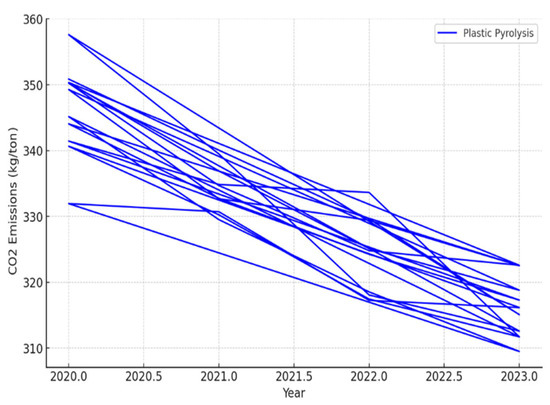

CO2 Emissions Over Time: pyrolysis produces higher CO2 emissions, but this has been declining over recent years as efficiency and carbon capture technologies have improved.

In Figure 1, every point represents a data instance in the dataset. The lines signify the fit of the logistic function that has been used. Some of the predictors that have been used are energy consumption, CO2 emissions, and operational costs, among others.

Figure 1.

Pyrolysis CO2 emissions in recent years.

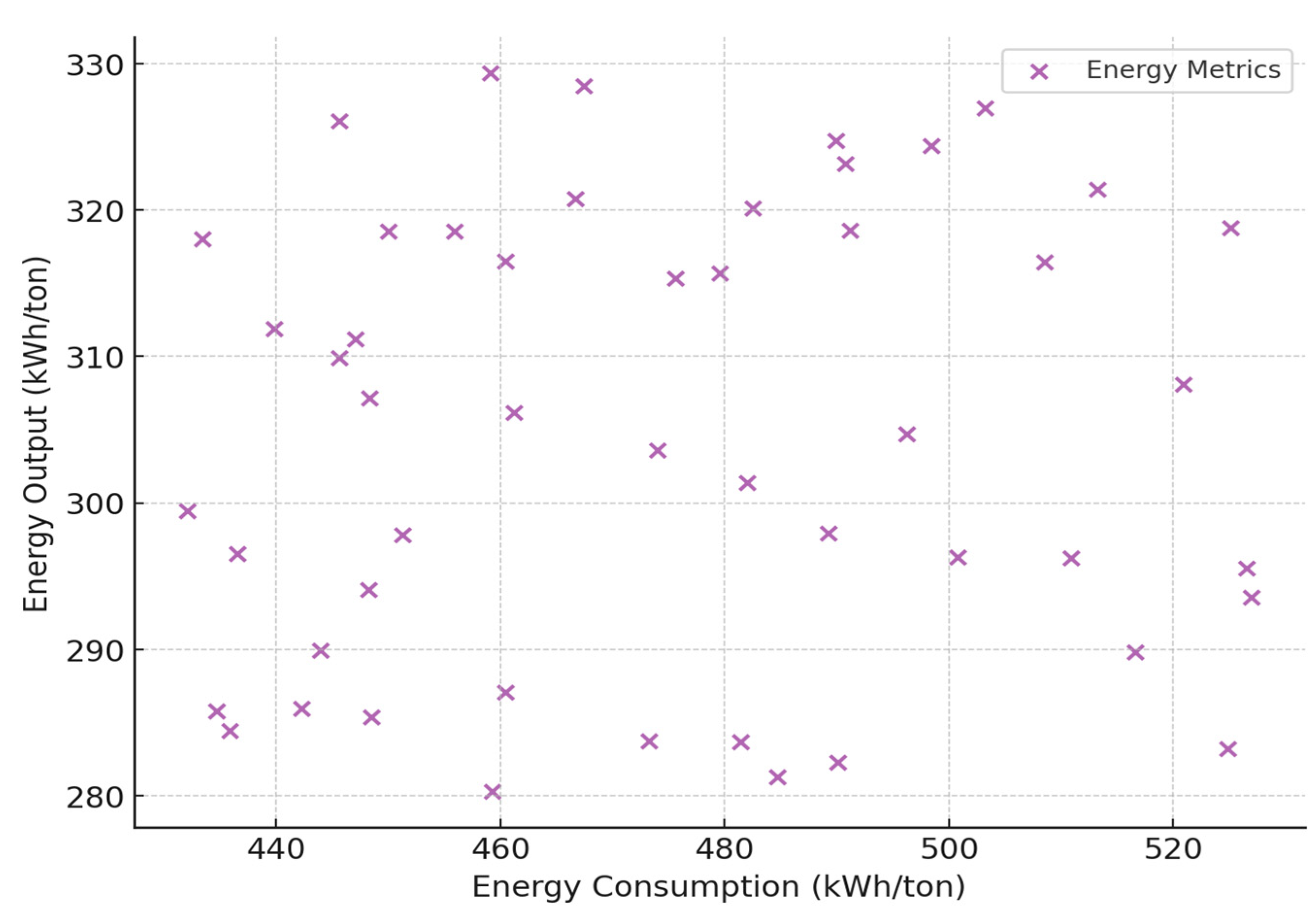

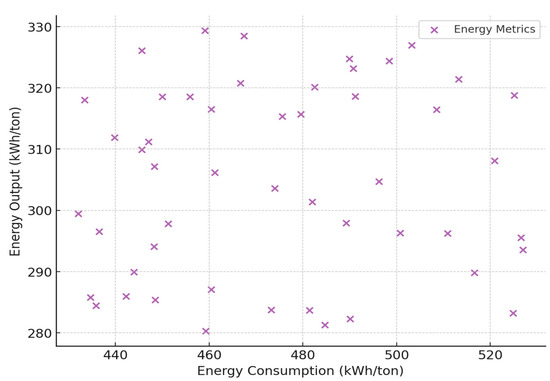

In Figure 2, the energy recovery vs. energy consumption (in kWh/ton) is presented for the pyrolysis scenario, and the reasons why a logistic regression model was chosen for these correlations are explained. This scatter plot captures the peak energy metrics of the data and provides insights into the trends and variations in energy performance within the pyrolysis process in the EU context.

Figure 2.

Energy efficiency of pyrolysis.

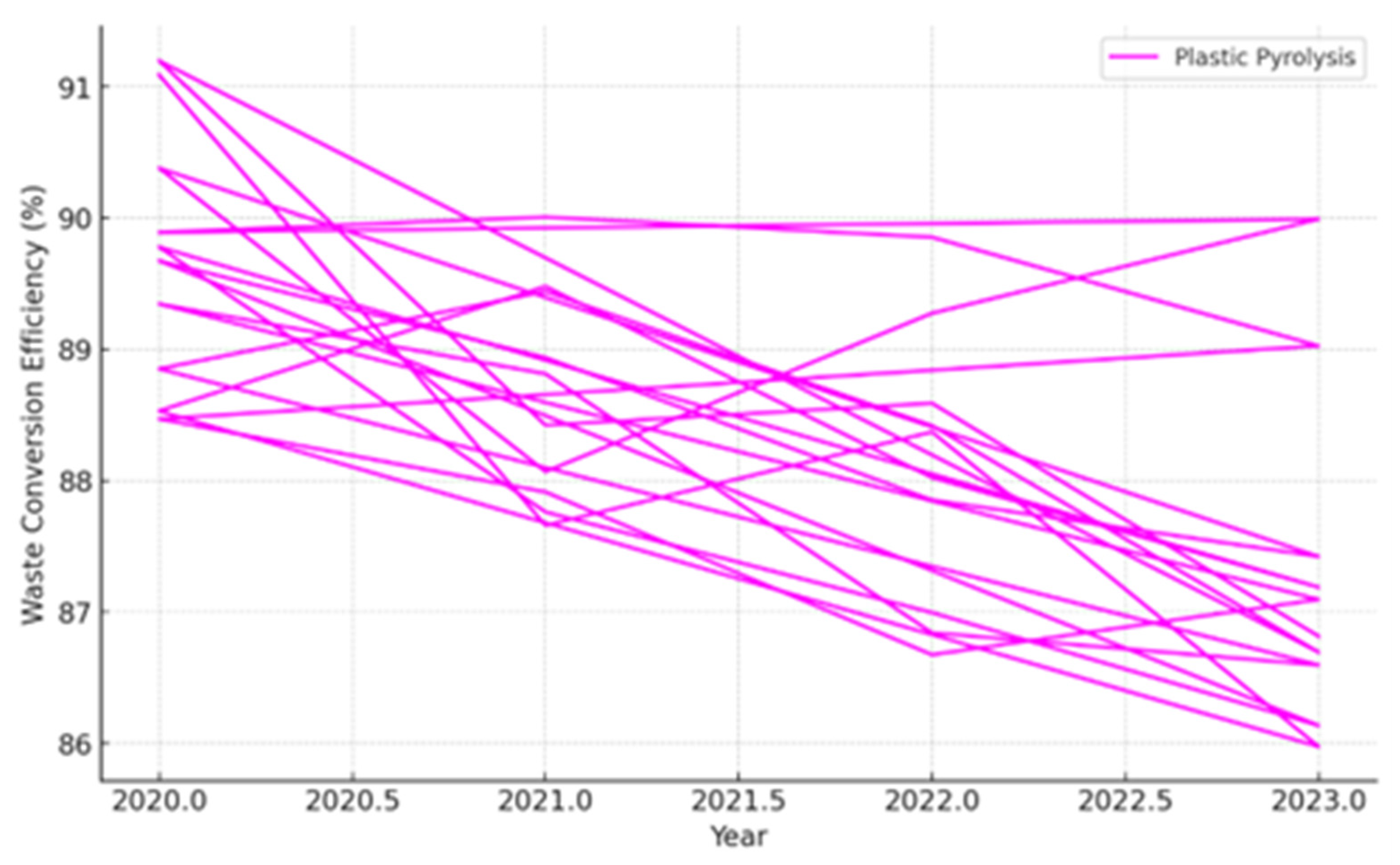

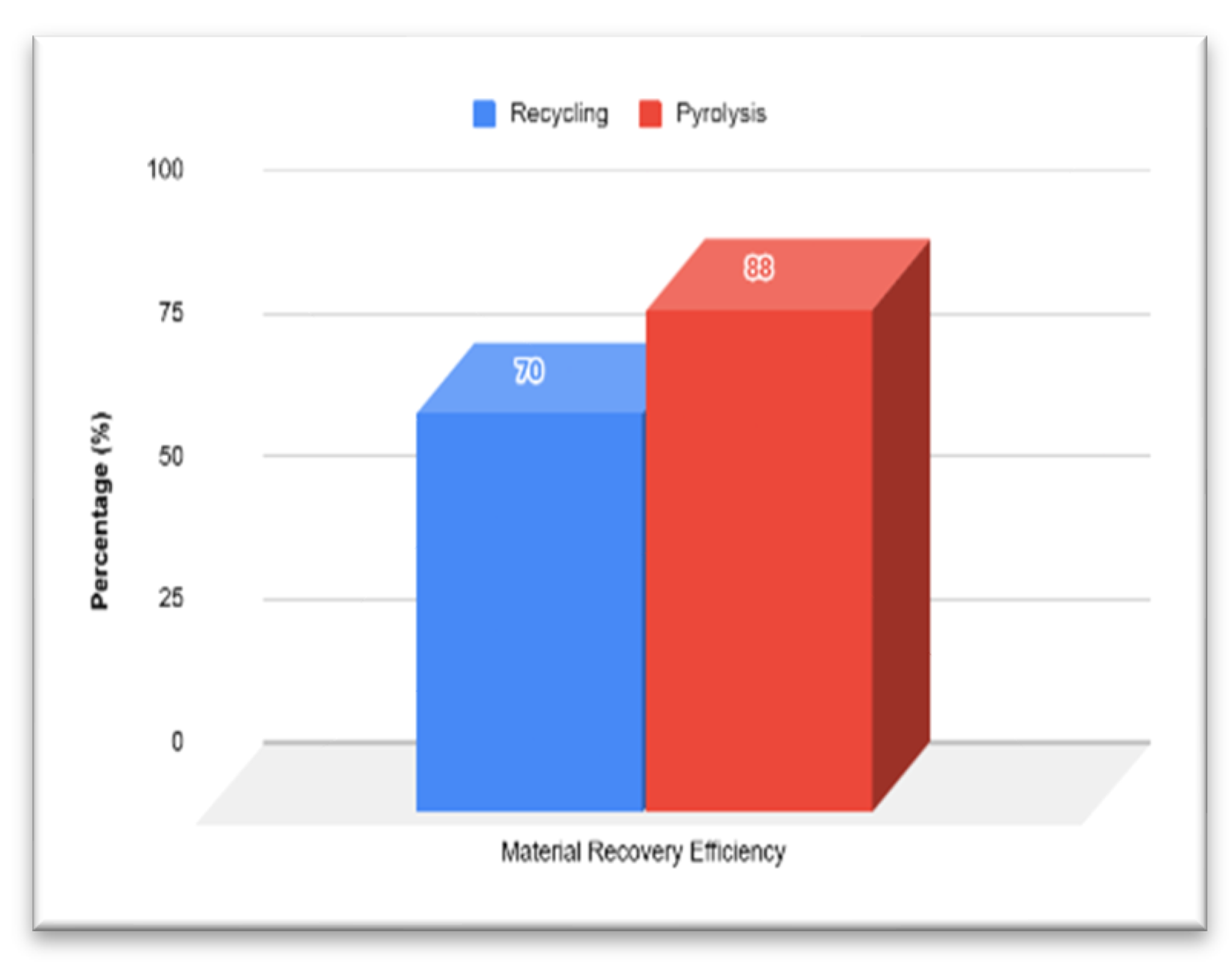

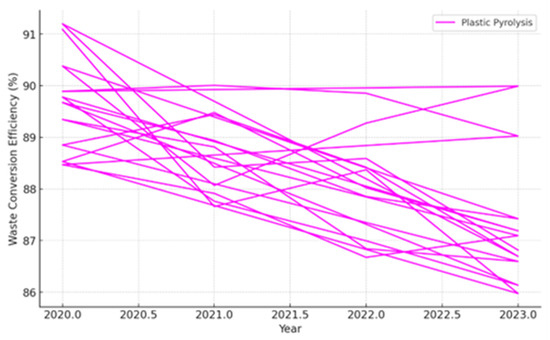

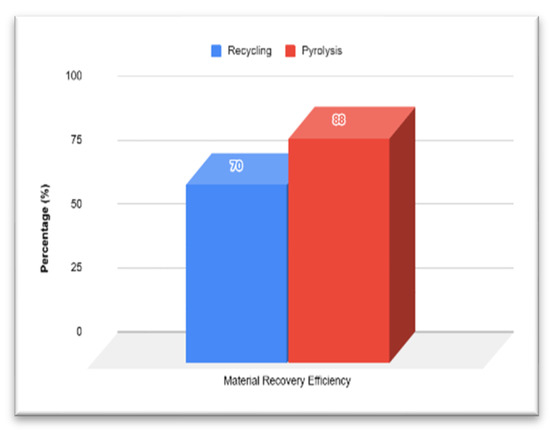

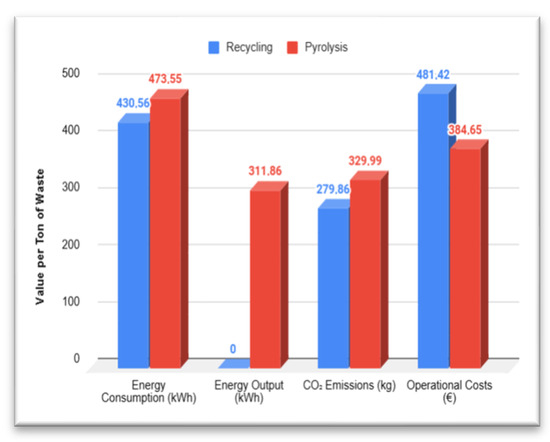

Figure 3 presents the further environmental and economic benefits of the pyrolysis method. The data show that conversion rates are as high as 88% (Figure 4); this complies with European policies like the EU Circular Economy Action Plan.

Figure 3.

Waste conversion efficiency in recent years.

Figure 4.

Comparative results of scenarios in an EU context per percentage.

Figure 5.

Comparative results of scenarios in an EU context per ton of waste.

- Environmental Factors:

While recycling is related to lower CO2 emissions, pyrolysis shows a promising future for emission reduction by applying carbon capture technologies and renewable energy integration.

Transportation emissions positively influence the preference for pyrolysis, given centralized infrastructure and mass processing.

- Economic Factors:

Pyrolysis benefits from lower operational costs in large-scale facilities, and, at the same time, it shows high revenue potential from fuel and chemical by-products.

- Energy Metrics:

Pyrolysis offers high energy recovery efficiency compared to recycling.

- Logistical Strengths:

Pyrolysis’s advantage in processing contaminated and mixed waste streams highlights its operational efficiency compared to recycling.

The model’s high accuracy underscores its reliability in predicting pyrolysis as the preferred option, as follows:

- Overall accuracy = 97%;

- Sensitivity (pyrolysis detection) = 94%;

- Specificity (recycling detection) = 98%.

The high classification accuracy reinforces pyrolysis’s advantages in scenarios involving mixed waste, high energy demands, and operational cost considerations.

3. Materials and Methods

3.1. Data Sources

This study utilized secondary data collected from European databases and academic sources. The key data sources included the following:

- Reports from Plastics Europe on waste production, recycling rates, and energy recovery.

- European Commission datasets related to emissions and waste management efficiency.

- Published empirical studies providing metrics for pyrolysis and recycling from the years 2020–2023 to ensure relevance to current waste management practices and technologies [21,22].

3.2. Methodology

3.2.1. Data Interpretation

In this study, the trade-offs of pyrolysis and recycling are analyzed by comparing the energy and environmental impacts of these waste management techniques. Firstly, regarding energy consumption, measured in kwh/ton, it is observed that the two methods have highest energy requirements at different stages of their processes; on the one hand, recycling needs more energy when it comes to the pre-treatment stage, such as, for example, for the sorting and cleaning of plastic waste [13]. On the other hand, pyrolysis uses large amounts of energy during processing, due to the use of thermal decomposition. However, the possibility of a net recovery of the lost energy, resulting from the production of fuels such as syngas and pyrolytic oil, has the potential to offset the energy cost of this process [16].

As far as the energy production sector is concerned, it can be said that, due to the ability of pyrolysis to recover the energy incorporated in plastic waste, it can be considered a highly viable option for energy-intensive industries, since 70–90% of the material entering the industry ends up being converted into energy products that can be reused [16]. On the other hand, recycling, which cannot convert the respective materials into energy but focuses instead on their recovery, can contribute to resource conservation in the sense of delaying direct energy production.

Considering the issue of greenhouse gas emissions, measured in kg CO2/ton, once again the use of thermal decomposition during pyrolysis is found to produce higher carbon dioxide emissions, especially when using fossil fuels as the main energy source [13].

In the context of the pollution potential of the two methods, namely the production of sulfur oxide (SOx) and nitrogen oxide (NOx), as well as the release of volatile organic compounds (VOCs), it is found that pyrolysis produces significant amounts of the first two types of pollutants, which in turn can lead to the formation of smog and acidification [13,16]. Recycling, on the other hand, is more closely linked to the release of VOCs during processing [15].

In terms of material recovery efficiency, in the case of recycling, the conversion of plastic waste into reusable materials is highly successful (up to 70%), as long as the streams are clean and homogeneous. However, if the waste is contaminated or mixed, this percentage is greatly reduced. In the case of contaminated waste, however, the pyrolysis process does not seem to be affected; it maintains a success rate for material recovery of 88%. It is therefore a preferable option when it comes to recyclable plastics that are more difficult to process [13,16].

Finally, the economic costs of the two procedures also vary according to the stages at which the costs are assessed. Thus, the pyrolysis option is characterized by a high initial cost, which can be offset during the process by the revenue it generates, due to the production of fuel, coal, and other by-products. In contrast, recycling may not be as costly at the outset, since the infrastructure used for it is already in place, but the subsequent challenges mentioned above, such as its difficulty in managing contamination in an efficient way, increase its cost, among other things [15].

3.2.2. Hypotheses Development

- Environmental Factors

Waste management is becoming more environmentally sustainable, considering greenhouse gas (GHG) emissions. Pyrolysis releases more GHGs than recycling; however, it may not be as environmentally destructive in some contexts [23,24]. However, pyrolysis has some advantages over the management of non-recyclable plastics. Therefore, the following hypotheses have been developed.

H1:

The likelihood of choosing pyrolysis over recycling is negatively associated with higher CO2 emissions.

H2:

The likelihood of choosing pyrolysis over recycling is positively associated with higher transport emissions due to the possibility of additional logistics emerging for centralized pyrolysis facilities.

- Economic Factors

Operational costs and revenue generation determine the procedure of scenario selection. Pyrolysis is also capable of generating revenue from fuel and chemical by-products, which makes it a potentially profitable option for some waste streams [25]. On the other hand, recycling usually results in higher operational costs, as a result of contamination problems and a complicated sorting process [26]. Thus, the following hypotheses have been developed:

H3:

The likelihood of choosing pyrolysis over recycling is negatively associated with higher operational costs.

H4:

Pyrolysis is more likely to be selected as the waste conversion output for a given facility when there is a higher revenue potential associated with the outputs.

- Energy Efficiency Factors

When analyzing waste management decisions, one must know that they are dependent on energy efficiency. Pyrolysis energy recovery is preferred when converting plastics to high-value fuels [27]. In contrast, the high energy contents of plastic makes recycling an energy-intensive method [22]. Therefore, the following hypotheses have been developed:

H5:

The likelihood of selecting pyrolysis over recycling is positively (and largely) correlated with the higher energy output.

H6:

A negative association between energy consumption during processing and the selection of pyrolysis vs. recycling is observed.

- Logistical Factors

Logistics can be improved by taking into account several factors, including the mass of the waste, the average processing time, etc. As previously mentioned, for contaminated waste, pyrolysis is preferred [22]. Recycling has a shorter processing time if the waste is homogeneous and can be recycled [28]. Therefore, the following hypotheses have been developed:

H7:

The likelihood of selecting pyrolysis over recycling is positively associated with waste conversion efficiency.

H8:

The likelihood of selecting pyrolysis over recycling will increase with longer average processing times.

3.2.3. Conceptual Framework

In the illustrations below, a robust conceptual framework that has been developed to address logistical, environmental, economic, and energy factors is shown.

The dependent variable is the selection of a scenario.

The binary variable is coded as follows: 1 = pyrolysis; 2 = recycling.

The factors are as follows:

Environmental factors: CO2 emissions (H1) and transportation emissions (H2);

Economic factors: operational costs (H3) and revenue from outputs (H4);

Energy metrics: energy output (H5) and energy consumption (H6);

Logistical factors: waste conversion efficiency (H7) and processing time (H8).

The independent variables are given below:

Environmental factors: CO2 emissions in kg per ton and transportation emissions in kg CO2 per km;

Economic factors: operational costs in Euros per ton and revenue from outputs in Euros per ton;

Energy metrics: energy consumption in kWh per ton and energy output in kWh per ton;

Logistical factors: waste conversion efficiency in percentage and average processing time in hours per ton.

- Logistic Regression

The main analytical tool that this study uses is binary logistic regression. This makes the selection between pyrolysis (1) or recycling (2) a function of the studied independent variables. Logistic regression works well as a predictor because it is well suited to categorical dependent variables. Our predictors include continuous variables and percentage-based variables.

The key outputs are as follows:

Odds Ratios (Exp(B)): these report the effect of every independent variable on the likelihood of choosing pyrolysis.

Significance Levels (p-values): these report the variables that have a significant impact on the selection of a scenario, based on the results.

3.3. Validation Steps

To determine the reliability of the logistic regression model, several steps are carried out to assess the model’s performance on the data and the stability of the model across different conditions.

The steps examined for this issue are as follows:

- (a)

- The training and testing split;

- (b)

- The classification metrics;

- (c)

- The Hosmer–Lemeshow goodness-of-fit test;

- (d)

- The cross-validation method;

- (e)

- The multicollinearity diagnostics method.

The first step is splitting the data. Specifically, 70% of the data were used for the training of the model and 30% for the testing. As a result, the model was not purely trained on these data, which makes it easier to generalize in other similar situations.

Regarding the classification metrics section, the model had an accuracy of 97%, a sensitivity of 94%, and a specificity of 98%. Therefore, it can be claimed that this model is able to choose between the pyrolysis and recycling scenarios to a very large extent and provide a high overall prediction accuracy.

Subsequently, the model’s predictions underwent the Hosmer–Lemeshow goodness-of-fit test and the p-value was found to be greater than 0.05, which means that this model fits the data in a satisfactory manner; therefore, the overfitting that may be required in other cases is not needed when using this model.

To increase the robustness of the model, cross-validation was performed; the model was validated over several iterations, using a 10-fold cross-validation of previous results. This procedure was carried out by dividing the dataset into ten parts, using nine of them for training and the tenth for testing, and then repeating this process until all data had been tested. It was therefore clear that, in every area of the results, they were consistent and in agreement with the initial findings, thus supporting the validity of the analysis model used.

VIF values and Pearson correlation coefficients were used to assess the possibility of multicollinearity among the independent variables. To ensure the stability of the regression coefficients, VIF values greater than 10 were dropped and, in some cases, combined to enhance the explanatory power of the model.

All the above methods were used to measure the reliability of the model as a universal predictor, and it was concluded that this is actually a very reliable model for identifying waste management scenarios, considering factors such as possible environmental, economic, energy, or logistical factors. Since the verification was divided into the above steps, it is safe to assume that this model can be applied in real conditions and that it is scientifically significant.

- Limitations

There are some limitations in this study regarding the generalizability and the quality of the results derived from the data and, as a result, the hypothesis acceptability. It is essential to mention that this study has utilized only European regional data considering such policies and infrastructure. It may therefore be unable to be implemented in other areas because of the specific factors used, which vary and can, in some cases, hinder adoption. In addition, since secondary data were used, questions about their quality may be raised concerning the reliability of the original data sources, which are not part of this analysis. Finally, it is important to note that, since logistic regression assumes that linearity exists between the logit of the dependent and independent variables, there are cases wherein more complex interactions cannot be captured in a comprehensive manner.

4. Conclusions

4.1. Comparative Conclusions

After establishing the reliability of this data analysis, the following conclusions can be extracted and summarized, with a high level of certainty.

- The benefits of pyrolysis are as follows:

Energy recovery: pyrolysis provides high energy recovery rates, making it ideal for applications requiring high energy outputs.

Economic viability: lower operational costs and higher revenue potential make pyrolysis a cost-effective choice.

Logistical versatility: pyrolysis can process mixed and contaminated waste streams with a higher efficiency than recycling.

- The benefits of recycling are as follows:

CO2 emissions: recycling generates fewer emissions, aligning with carbon neutrality goals.

Decentralized infrastructure: recycling benefits from decentralized networks that reduce logistical burdens.

4.2. Policy Recommendations

This study’s findings can be used as a springboard for specific policy recommendations to enhance plastic waste management. Besides general policies like the European Green Deal and the Circular Economy Action Plan, focusing on resource efficiency and carbon neutrality can also help support these recommendations [16,17].

- Extended Producer Responsibility (EPR) programs:

Germany’s Packaging Act involves the producers paying for the collection, sorting, and recycling of packaging materials, and Germany has achieved one of the highest recycling rates in Europe, at 67% [8]. If EPR is extended to include incentives for using recycled content, then both recycling and pyrolysis integration can be enhanced.

- Subsidies for pyrolysis technologies:

Financial incentives for implementing pyrolysis technologies can be used to mitigate the high initial capital costs of building these facilities. Subsidies for thermal treatment technologies such as pyrolysis have been introduced in Denmark, which has resulted in enhanced energy recovery from non-recyclable waste [9]. It can thus be argued that subsidies may be used to promote the application of pyrolysis for contaminated plastics while gradually phasing out the use of landfills. Therefore, the treatment of contaminated plastics using the pyrolysis process is feasible and can be optimized by controlling the operating conditions and quality of input materials. The detailed analysis of the yield, product properties, and market potential of pyrolysis by-products offers valuable information for decision-making processes regarding the commercialization of these products, while the careful consideration of their environmental and economic impacts is essential for assessing the sustainability of this waste management strategy.

- Carbon emission regulations:

Policies like the EU ETS (Emissions Trading System) are a form of regulation that penalizes carbon intensive operations, forcing industries to pay for their environmental impact. Pyrolysis plants in countries with stricter ETS caps have started to integrate renewable energy sources and carbon capture technologies to reduce emissions, moving towards more sustainable practices, driven by the very regulations meant to limit their business [10]. In addition to this, the improvements made in the pyrolysis process make it more consistent with the overall sustainability objectives.

- Waste segregation policies:

It has been found that effective waste segregation policies are quite important in improving recycling quality. For instance, Sweden has strict policies on waste management that include segregation at the household level, accompanied by public awareness campaigns, which have led to low levels of contamination of the recyclables streams and therefore higher recycling efficiency [11]. Adopting similar policies across Europe could address the challenges of contamination and sorting in recycling processes [29].

4.3. Comparison with Existing Research

This work agrees with previous research, showing promising results, by stating the findings’ environmental implications [21] and how they can be effectively applied in the management of non-recyclable plastics [25,28]. Furthermore, this study adopts a more holistic perspective by involving economic and logistical aspects together with environmental concerns, revealing pyrolysis as a cheaper and more flexible process in terms of operation, while at the same time showing that it can compete with recycling in the treatment of streams.

4.3.1. Areas for Future Research

To further explore the potential of pyrolysis in waste management, several key areas for future research can be identified, as follows:

- Longitudinal studies, including the evaluation of the long-term performance and the potential for scalability of the pyrolysis plants in various regions.

- Hybrid systems, specifically applied studies about the combination of pyrolysis and recycling technologies to enhance waste management systems.

- Economic modeling, including cost–benefit analyses for market dynamics and policy changes.

- Technological innovations, including assessing the role of present technologies and the role of emerging technologies, like artificial intelligence-based sorting and renewable energy, in improving pyrolysis’s efficiency [26].

4.3.2. Limitations

The study’s findings are based on data from European contexts and may not fully represent regions with different waste compositions and policy frameworks. The study uses secondary data, and this may have introduced biases if the source data were incomplete or inconsistent. Future research can address these limitations by including primary data collection and region-specific analyses.

5. Discussion

This publication aims to compare pyrolysis and the recycling of plastic waste as waste management strategies, taking into account environmental, economic, energy, and logistical factors. The results show that pyrolysis can be considered applicable and complementary to recycling, especially in cases where energy recovery or the treatment of mixed or contaminated plastics is needed. Although pyrolysis is more carbon-intense than recycling, recent developments in carbon capture technology may negate this disadvantage. Furthermore, the creation of value added by products such as syngas and pyrolytic oil has proven to be a viable option for large waste management systems.

On the other hand, recycling scores high in reducing carbon emissions and helping to circulate materials but, at the same time, has higher operating costs, due to contamination and difficulties in sorting through complex waste streams. These factors, when taken into account, seem to hinder the model’s efficiency. This research study concludes that pyrolysis and recycling could be combined to offer a more holistic approach to the problem of plastic waste on a global scale.

Author Contributions

Conceptualization, C.V.; methodology, D.-A.K.; investigation, D.-A.K.; data curation, D.-A.K. and A.T.; writing—original draft preparation, D.-A.K.; validation, S.P.; writing—review and editing, A.T. and S.P.; supervision, C.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe. Plastics—The Facts 2021: An Analysis of European Plastics Production, Demand, and Waste Data. 2021. Available online: https://plasticseurope.org (accessed on 31 December 2024).

- Rochman, C.M.; Hoh, E.; Kurobe, T.; Teh, S.J. Ingested plastic transfers hazardous chemicals to fish and induces hepatic stress. Sci. Rep. 2013, 3, 3263. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef] [PubMed]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Gasde, J.; Woidasky, J.; Moesslein, J.; Lang-Koetz, C. Plastics Recycling with Tracer-Based-Sorting: Challenges of a Potential Radical Technology. Sustainability 2020, 13, 258. [Google Scholar] [CrossRef]

- Maitlo, G.; Ali, I.; Maitlo, H.A.; Ali, S.; Unar, I.N.; Ahmad, M.B.; Bhutto, D.K.; Karmani, R.K.; Naich, S.U.R.; Sajjad, R.U.; et al. Plastic Waste Recycling, Applications, and Future Prospects for a Sustainable Environment. Sustainability 2022, 14, 11637. [Google Scholar] [CrossRef]

- Oke, A.; McDonald, S.; Korobilis-Magas, E.; Osobajo, O.A.; Awuzie, B.O. Reframing Recycling Behaviour through Consumers’ Perceptions: An Exploratory Investigation. Sustainability 2021, 13, 13849. [Google Scholar] [CrossRef]

- Gao, P.; Krantz, J.; Ferki, O.; Nieduzak, Z.; Perry, S.; Sobkowicz, M.J.; Masato, D. Thermo-mechanical recycling via ultrahigh-speed extrusion of film-grade recycled LDPE and injection molding. Sustain. Mater. Technol. 2023, 38, e00719. [Google Scholar] [CrossRef]

- Ziani, K.; Ioniță-Mîndrican, C.-B.; Mititelu, M.; Neacșu, S.M.; Negrei, C.; Moroșan, E.; Drăgănescu, D.; Preda, O.-T. Microplastics: A Real Global Threat for Environment and Food Safety: A State of the Art Review. Nutrients 2023, 15, 617. [Google Scholar] [CrossRef]

- Ravikumar, D.; Keoleian, G.A.; Walzberg, J.; Heath, G.; Heller, M.C. Advancing environmental assessment of the circular economy: Challenges and opportunities. Resour. Conserv. Recycl. Adv. 2024, 21, 200203. [Google Scholar] [CrossRef]

- Xayachak, T.; Haque, N.; Parthasarathy, R.; King, S.; Emami, N.; Lau, D.; Pramanik, B.K. Pyrolysis for plastic waste management: An engineering perspective. J. Environ. Chem. Eng. 2022, 10, 108865. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. The zero waste index: A performance measurement tool for waste management systems in a ‘zero waste city’. J. Clean. Prod. 2013, 50, 123–132. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- European Commission. A European Green Deal: Striving to Be the First Climate-Neutral Continent. 2020. Available online: https://ec.europa.eu (accessed on 31 December 2024).

- Rajmohan, K.V.S.; Ramya, C.; Viswanathan, M.R.; Varjani, S. Plastic pollutants: Waste management for pollution control and abatement. Curr. Opin. Environ. Sci. Health 2019, 12, 72–84. [Google Scholar] [CrossRef]

- Rahimi, A.; García, J.M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 2017, 1, 0046. [Google Scholar] [CrossRef]

- United Nations. The 17 Goals. United Nations Sustainable Development Goals. Available online: https://sdgs.un.org/goals (accessed on 4 February 2025).

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent advances in the gasification of waste plastics. A critical overview. Renew. Sustain. Energy Rev. 2018, 82, 576–596. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. An overview of the challenges and trade-offs in closing the loop of post-consumer plastic waste (PCPW): Focus on recycling. J. Hazard. Mater. 2019, 380, 120887. [Google Scholar] [CrossRef]

- Lazarevic, D.; Aoustin, E.; Buclet, N.; Brandt, N. Plastic waste management in the context of a European recycling society: Comparing results and uncertainties in a life cycle perspective. Resour. Conserv. Recycl. 2010, 55, 246–259. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Wang, Y.-C.; Lu, S.-C.; Hsieh, Y.-F.; Chien, C.-H.; Tsai, S.-B.; Dong, W. An empirical research on customer satisfaction study: A consideration of different levels of performance. SpringerPlus 2016, 5, 1577. [Google Scholar] [CrossRef] [PubMed]

- Almeida, D.; Marques, M.F. Thermal and catalytic pyrolysis of plastic waste. Polímeros 2016, 26, 44–51. [Google Scholar] [CrossRef]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, S.; Laner, D. The environmental performance of plastic packaging waste management in Germany: Current and future key factors. J. Ind. Ecol. 2023, 27, 1447–1460. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Vlachokostas, C. Closing the loop between energy production and waste management: A conceptual approach towards sustainable development. Sustainability 2020, 12, 5995. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).