Prospective Use and Assessment of Recycled Plastic in Construction Industry

Abstract

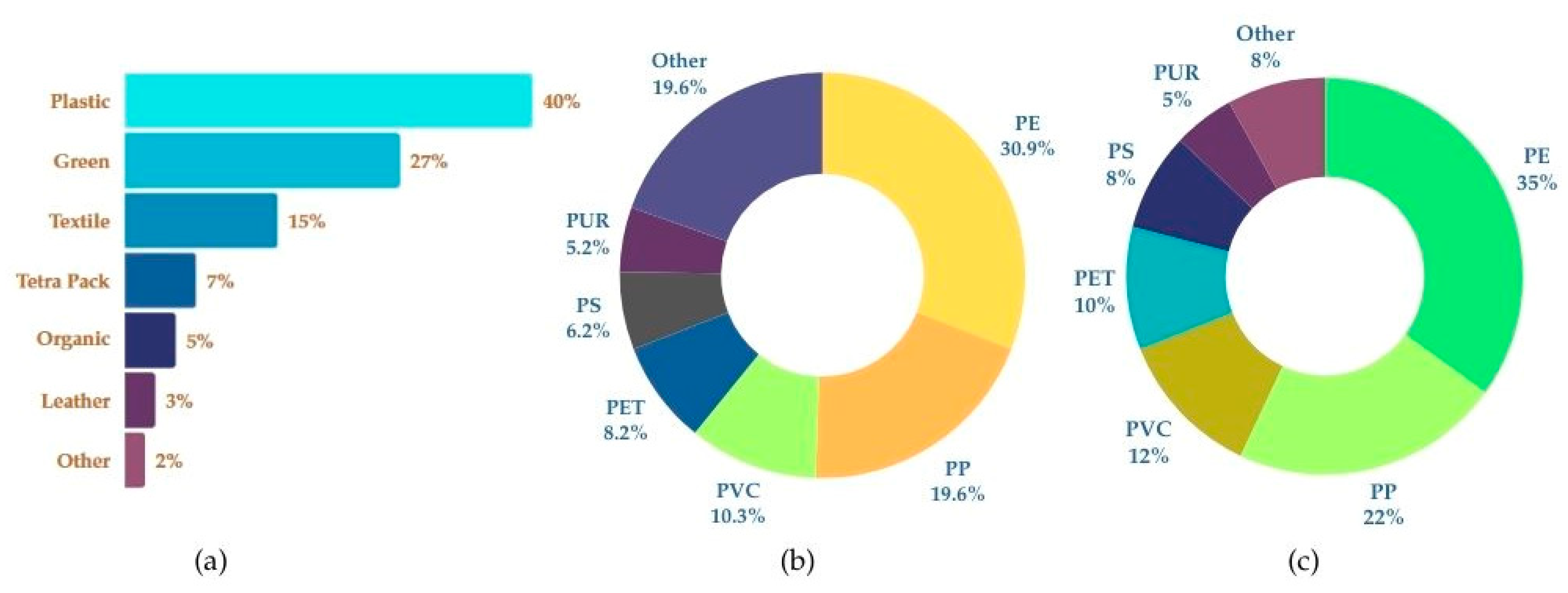

1. Introduction

1.1. Plastic Identification for Waste Plastic Recycling

1.2. Waste Plastic Recycling Methods and Products

1.3. Waste Plastic in the Construction Industry

| Waste Plastic Type | Purpose Used for | Matrix | Purpose | References |

|---|---|---|---|---|

| HDPE | FA, CA | Concrete | Additive | [35,36,37,38] |

| LDPE | FA, CA | Concrete | Additive | [36,39,40,41] |

| PET | Fiber Strips | Concrete | Reinforcement | [34,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56] |

| NM | Filler Material | Concrete | Flexibility | [57,58,59,60,61,62] |

| Melamine Formaldehyde | Fiber Strips | Concrete | Reinforcement | [63] |

| PVC | Fiber Strips | Concrete | Flexibility | [64,65,66] |

| PET&PC | Fiber Strips | Concrete | Reinforcement | [49] |

| GFRP | Fiber Strips | Concrete | Reinforcement | [67] |

| LDPE & PET | Filler Material | Concrete | Filler | [68] |

| ABS&PC | Filler Material | Concrete | Structural Support | [69] |

| PP | Fiber Strips | Concrete | Structural Support | [70,71] |

| Mixed Plastics (various) | FA, CA | Asphalt | Durability | [72,73,74,75] |

| PE | Fiber Strips | Asphalt | Reinforcement | [76,77] |

| PET | Filler Material | Asphalt | Flexibility | [78,79] |

| PP | FA, CA | Asphalt | Durability | [80,81] |

| HDPE | Fiber Strips | Asphalt | Durability | [82,83] |

| PVC | Filler Material | Asphalt | Reinforcement | [84,85] |

| PS | Filler Material | Asphalt | Flexibility | [86,87] |

| LDPE | FA, CA | Asphaltic Concrete | Tensile | [74,88] |

| PP | Fiber Strips | Soil | Soil Reinforcer | [89] |

| HDPE | Fiber Strips | Soil | Soil Reinforcer | [90] |

| PET | Filler Material | Soil | Soil Improvement | [91] |

| Waste Plastic Type | Mixed Proportion | Property Studied | References |

|---|---|---|---|

| HDPE | 100% HDPE | Tensile strength, elongation at break. | [92,93] |

| PP | 100% PP | Impact resistance, tensile modulus. | [93,94] |

| HDPE + LDPE | Diff. proportion HDPE, LDPE | Ductility, impact strength. | [93,95] |

| HDPE + PP | 50% HDPE, 50% PP | Tensile strength, elongation, thermal stability. | [96] |

| HDPE + SAM (samicanite) | Diff. proportion HDPE, SAM | Wear resistance. | [97] |

| HDPE + POL (polyolefin) | 60% HDPE, 40% POL | Elastic modulus, heat deflection temperature. | [98] |

| HDPE + V (virgin PE) | Diff. proportion HDPE, virgin PE | Stress cracking resistance, environmental resistance. | [99] |

| LDPE | 100% LDPE | Tensile strength, environmental stress cracking. | [97] |

1.4. Environmental Aspects and Hazards of Waste Plastics

1.5. Research Significance

2. Experimental Procedure

2.1. Recycling Through an Environmentally Friendly Approach

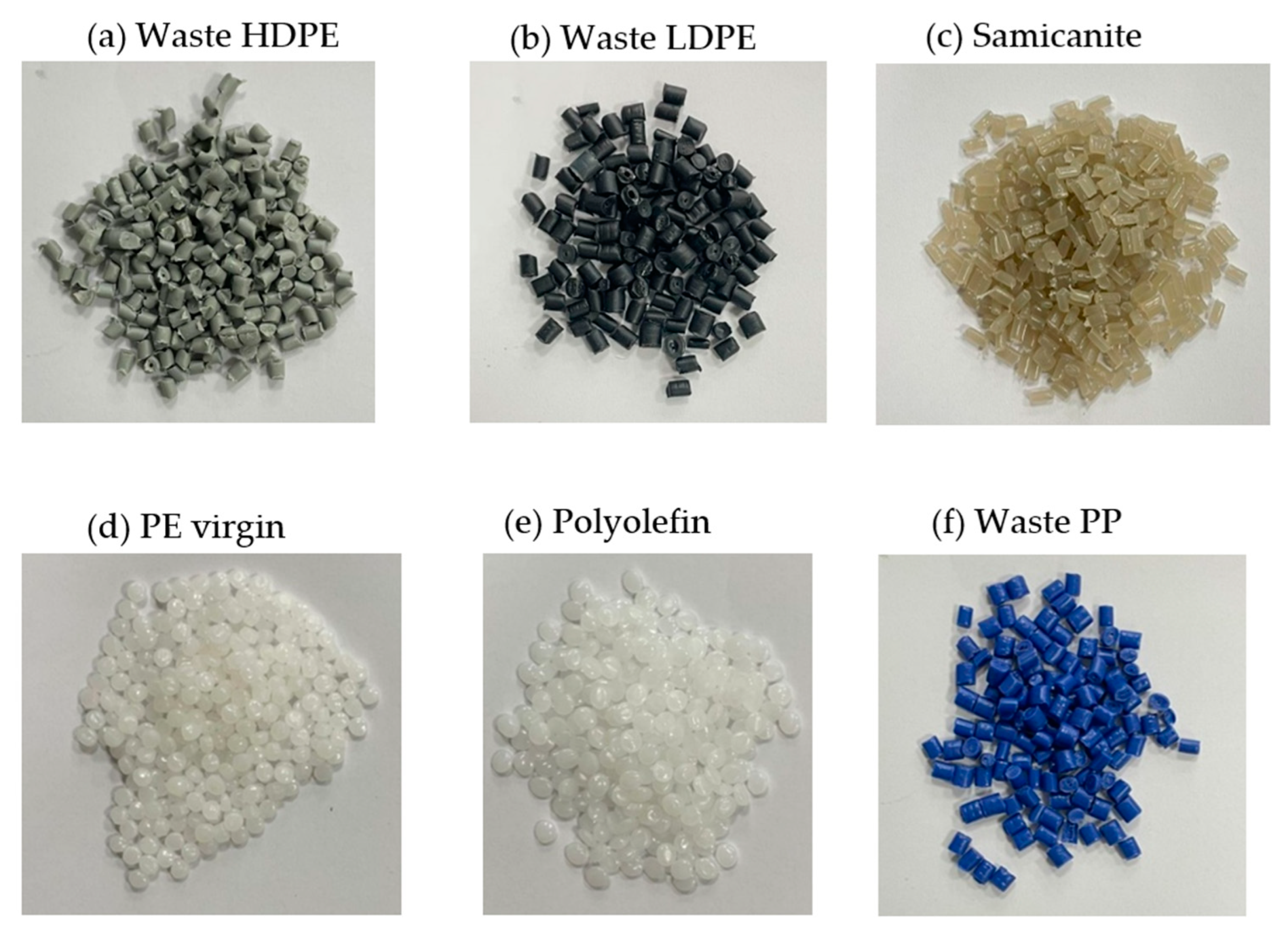

2.1.1. Collection of Raw Material and Material Identification

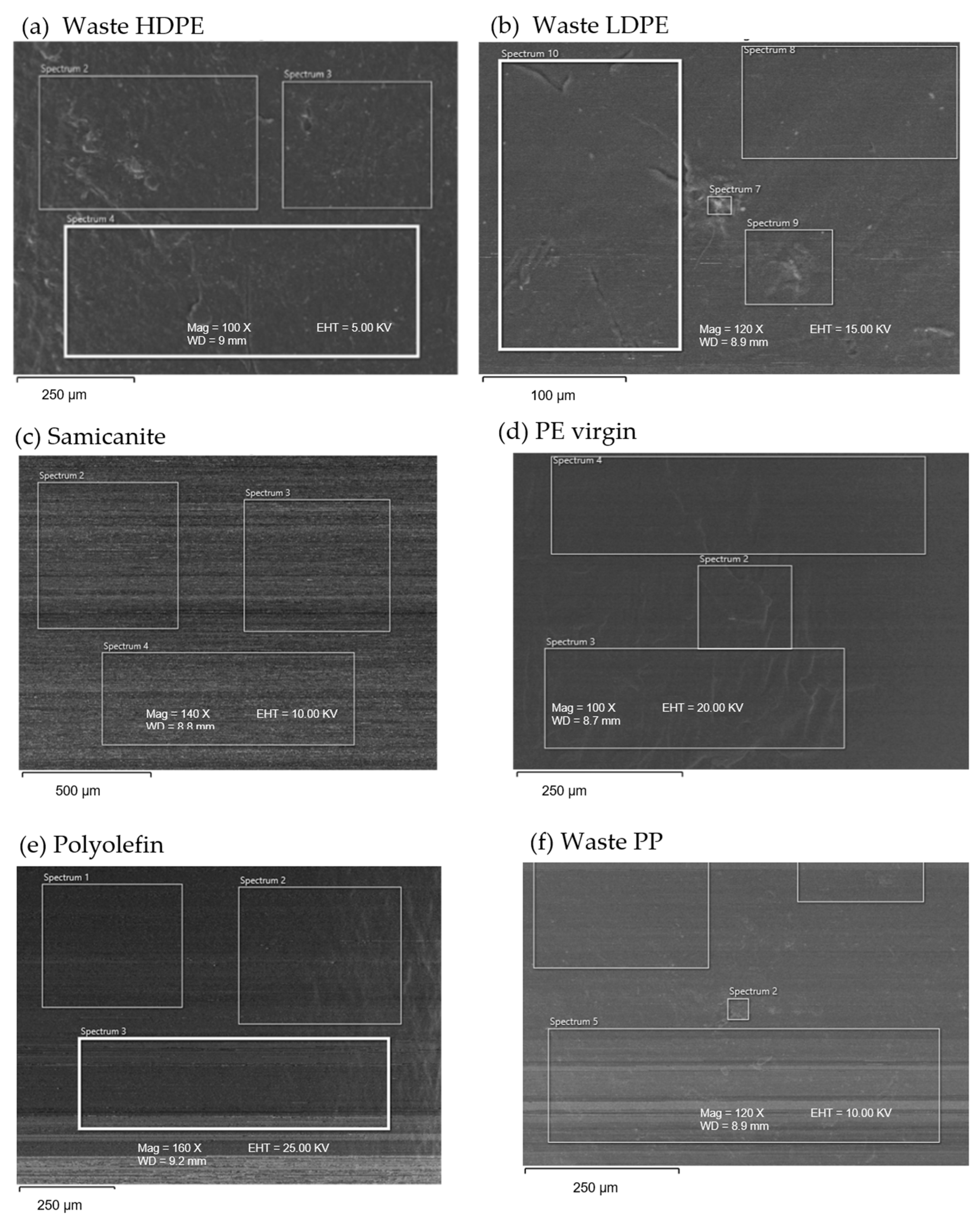

- SEM and the detection of impurities

- b.

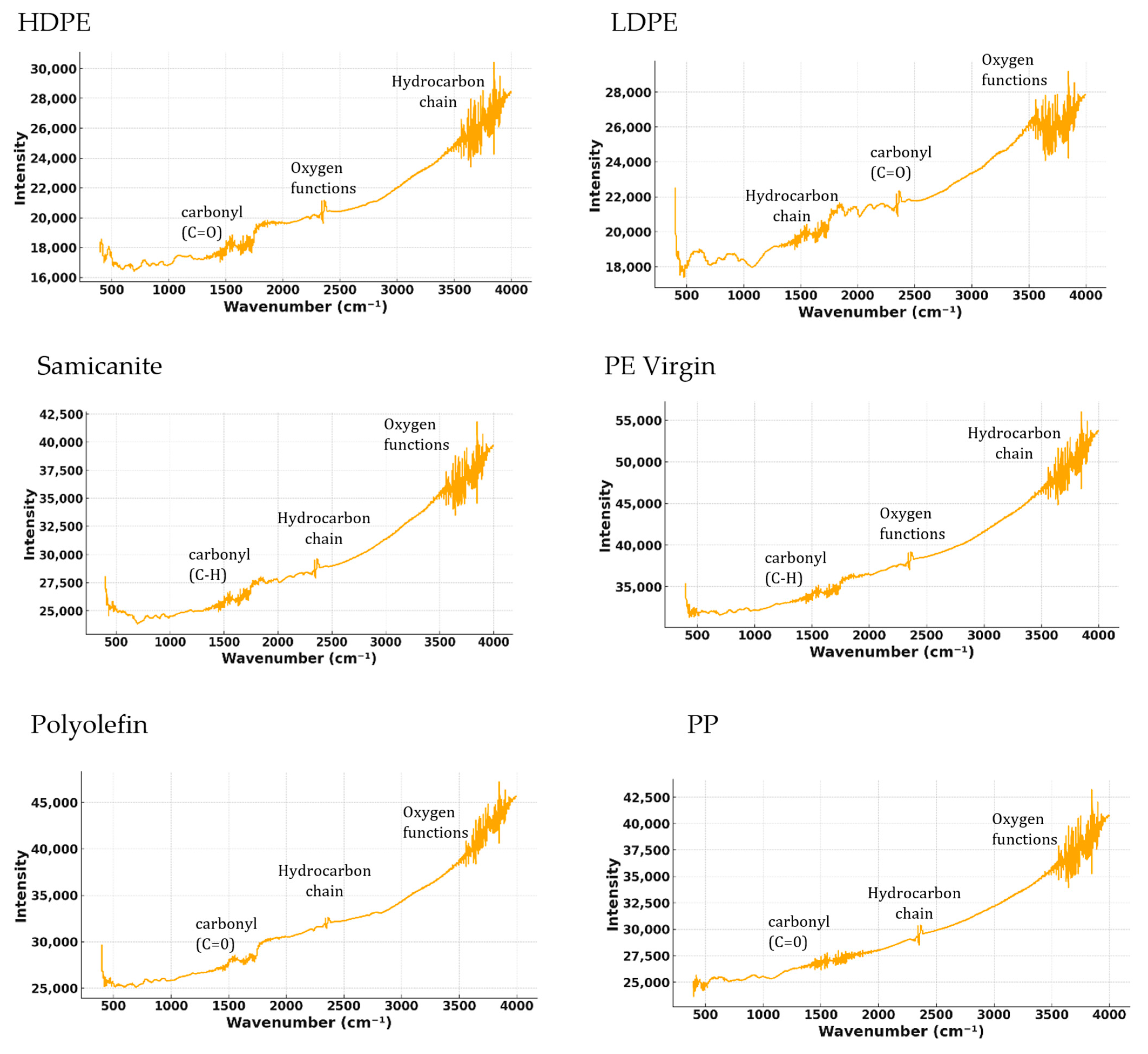

- FTIR of Raw Material

- c.

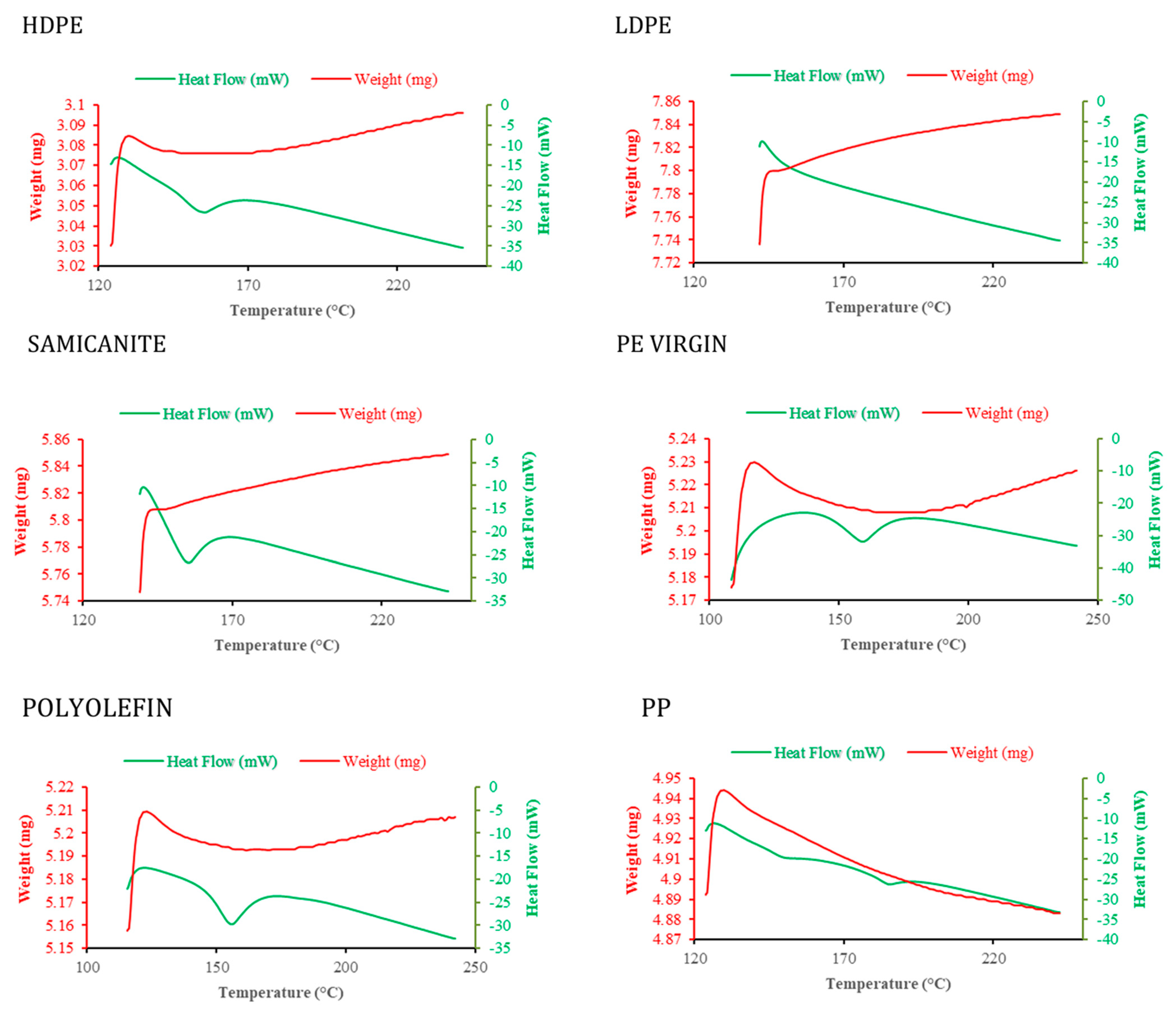

- TGA and DSC of Raw Waste Plastic and Materials

2.1.2. Mechanical Extrusion Process

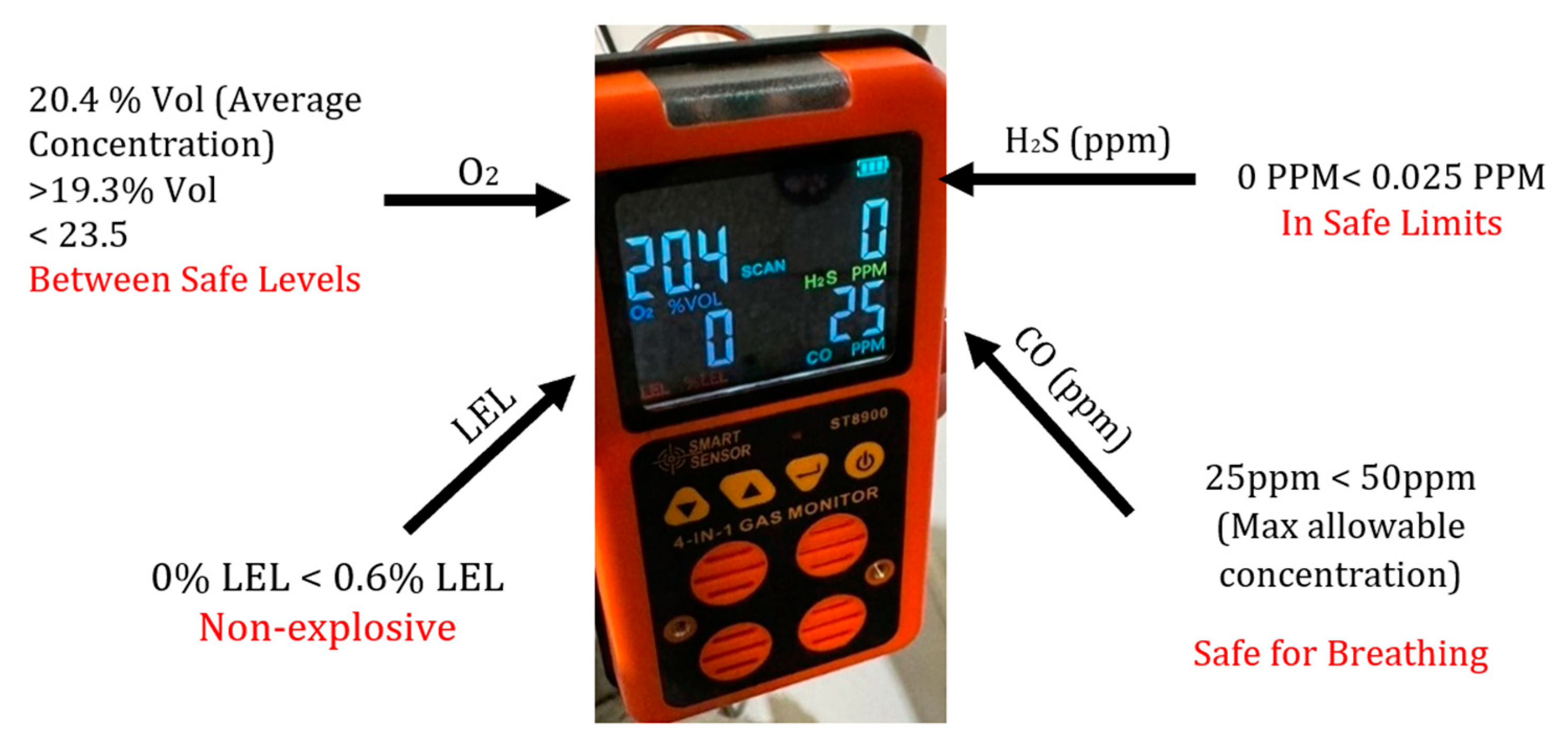

2.1.3. Gas Emissions Detection and Monitoring

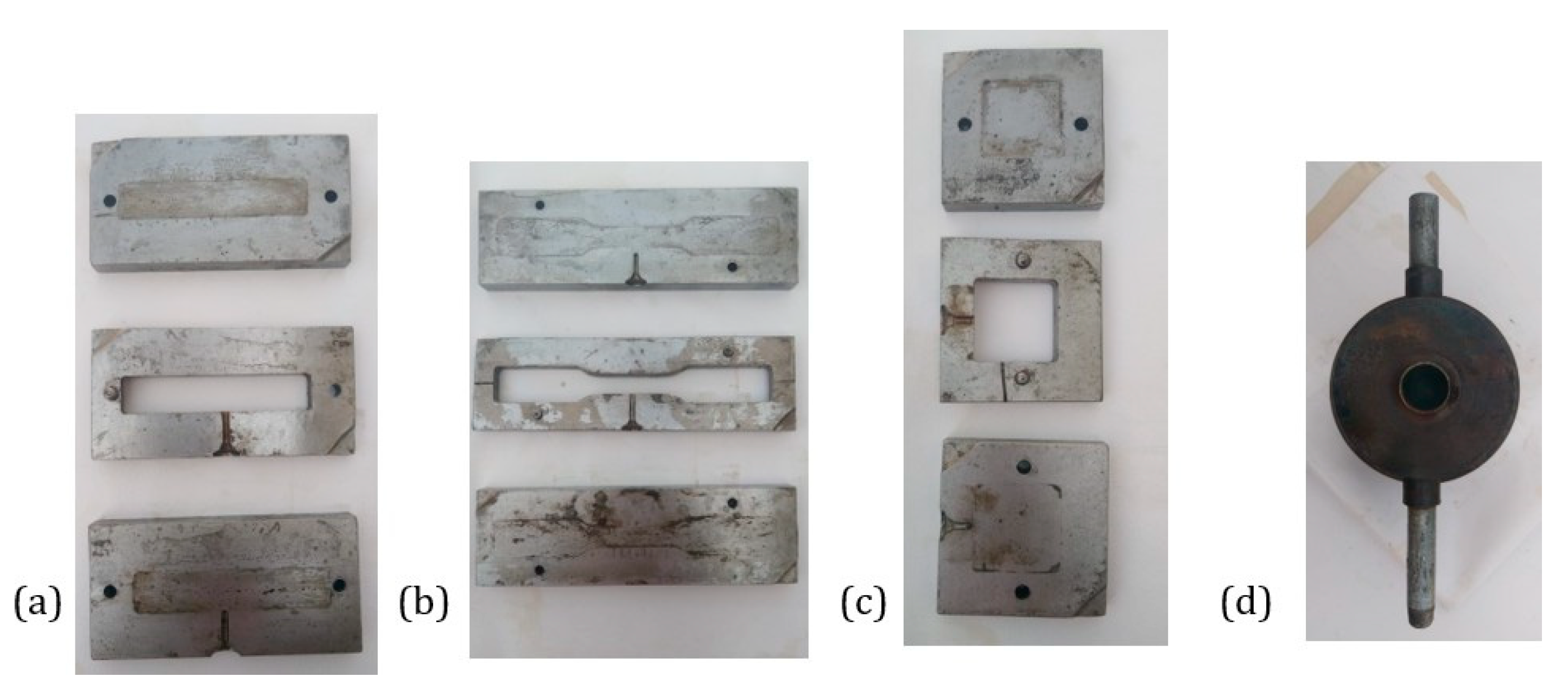

2.2. Preparation of Samples

2.3. Testing

2.3.1. Mechanical Testing

- Shear

- b.

- Tensile

- c.

- Compression

- d.

- Flexure

2.3.2. Microstructure Analysis

- SEM analysis

- b.

- FTIR analysis

2.4. Optimization Procedure

3. Results

3.1. Mechanical Performance of Recycled Plastic

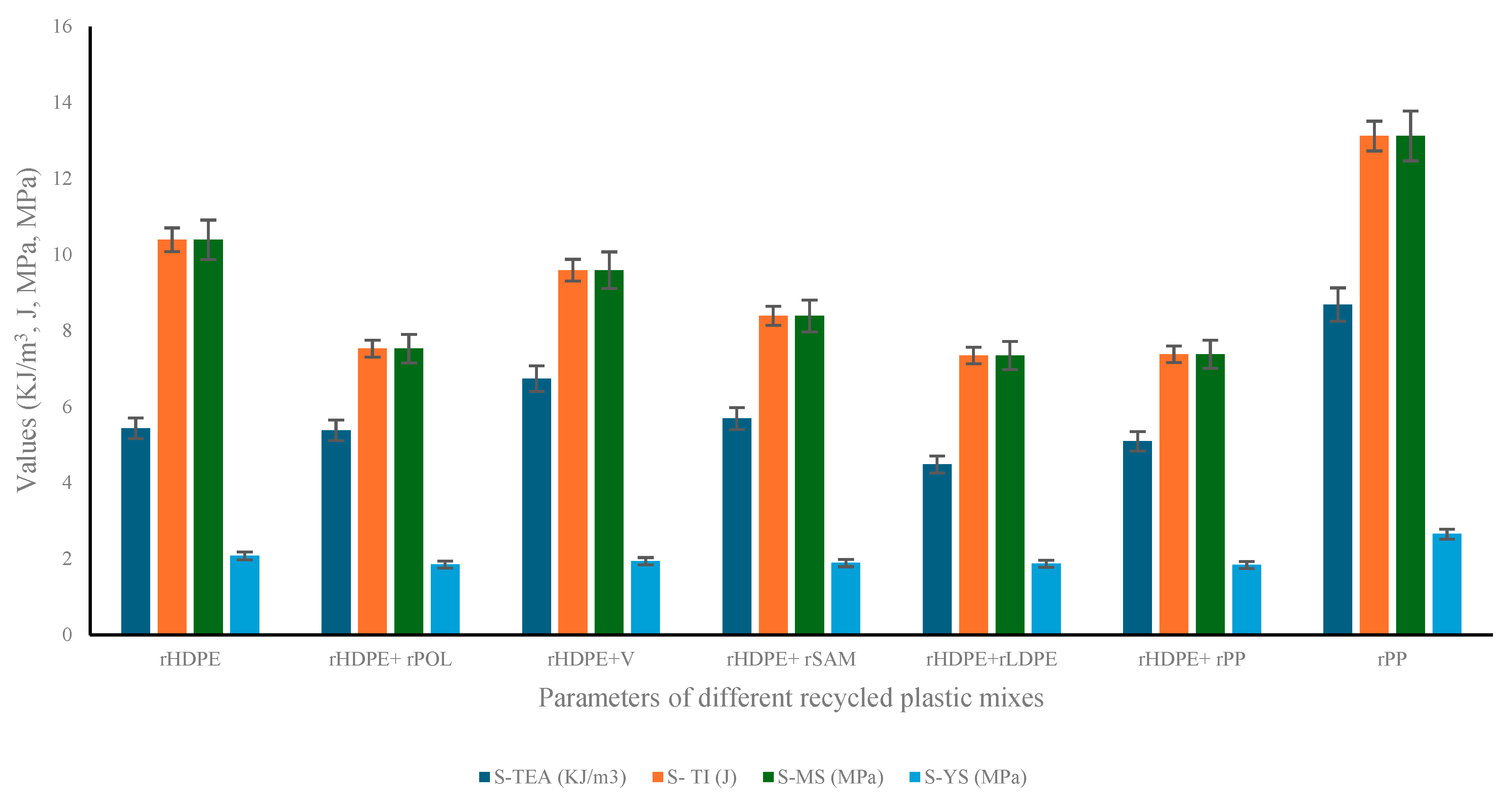

3.1.1. Shear Behavior

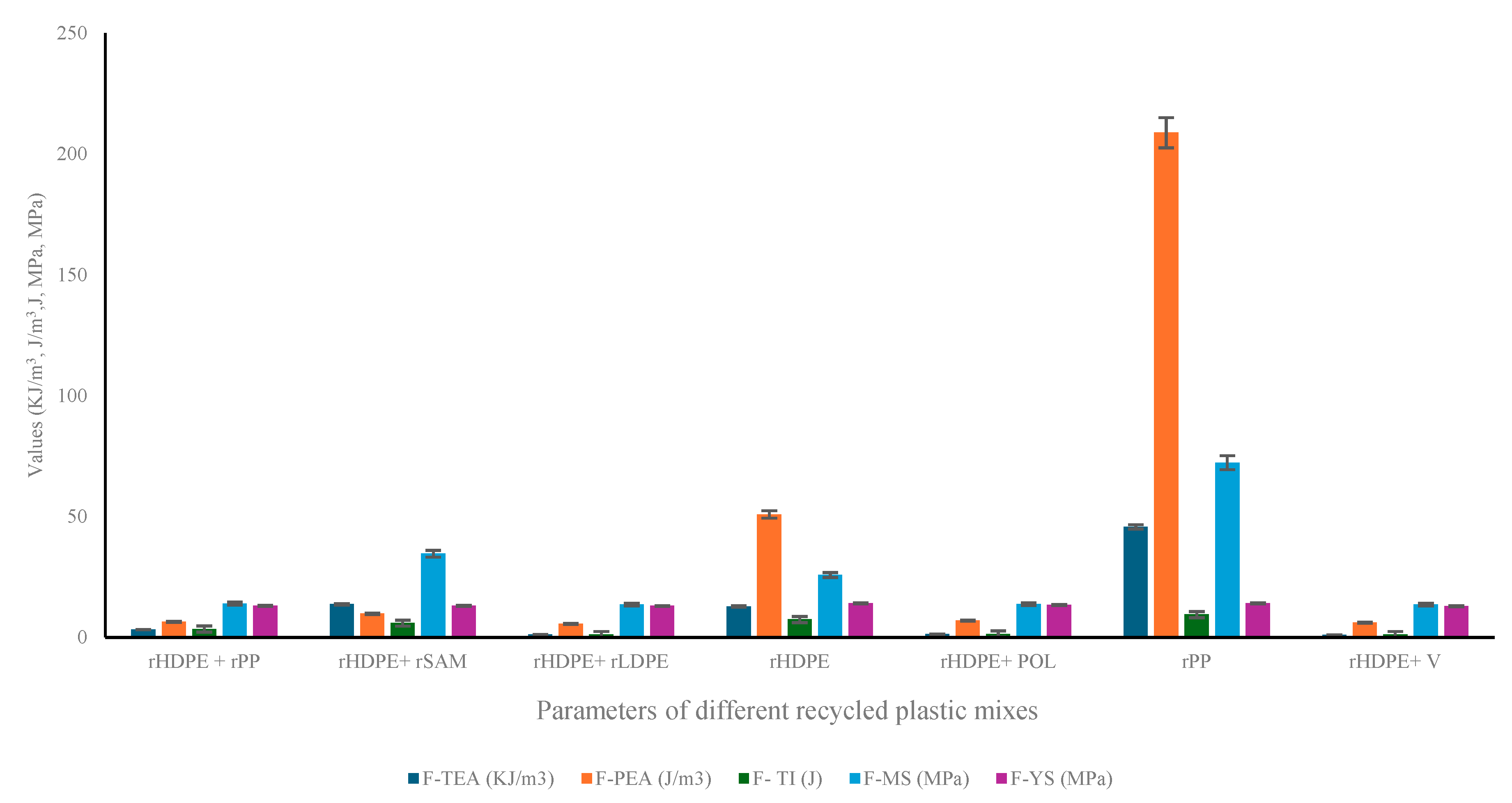

3.1.2. Flexural Behavior

3.1.3. Compression Behavior

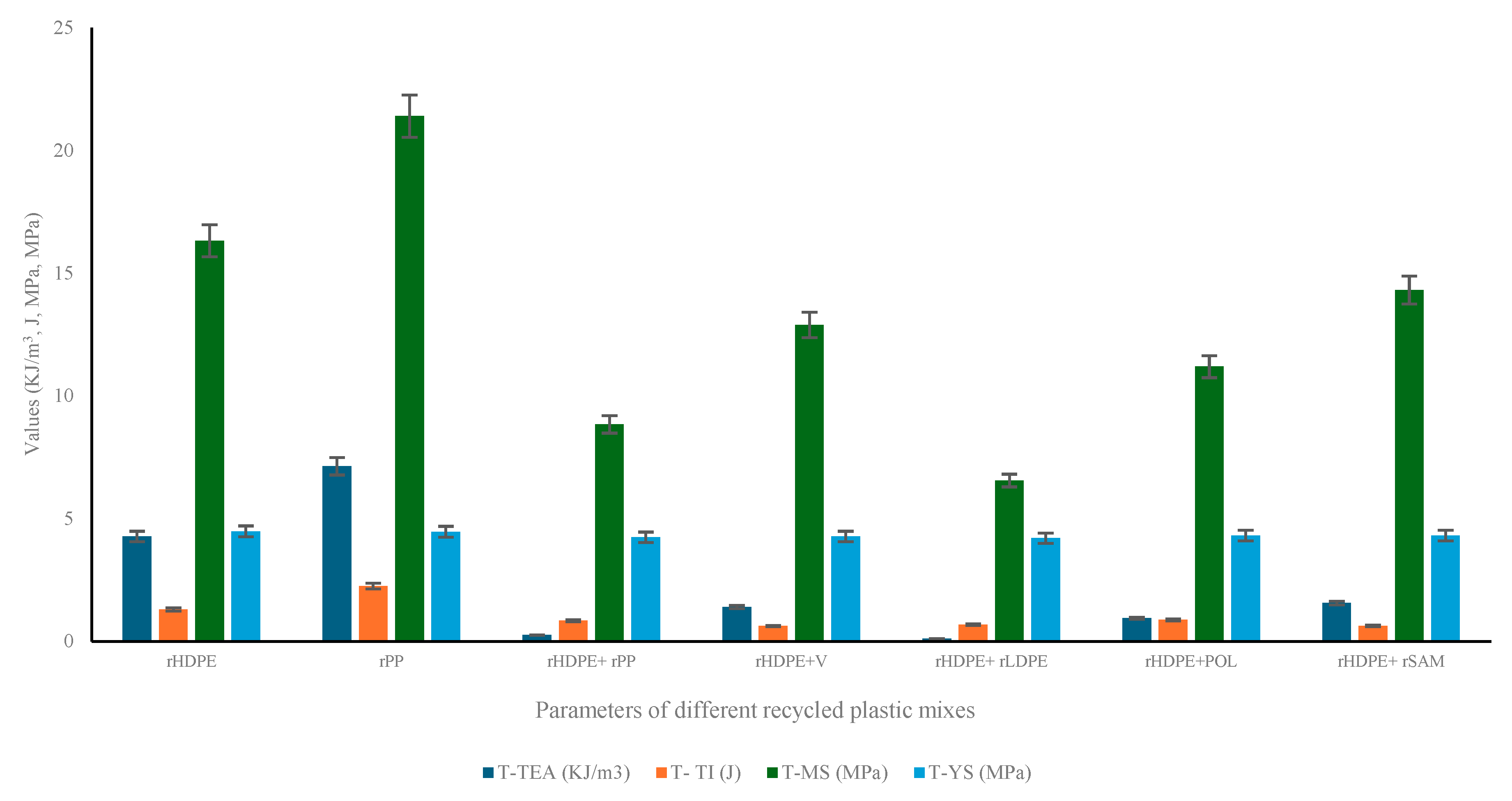

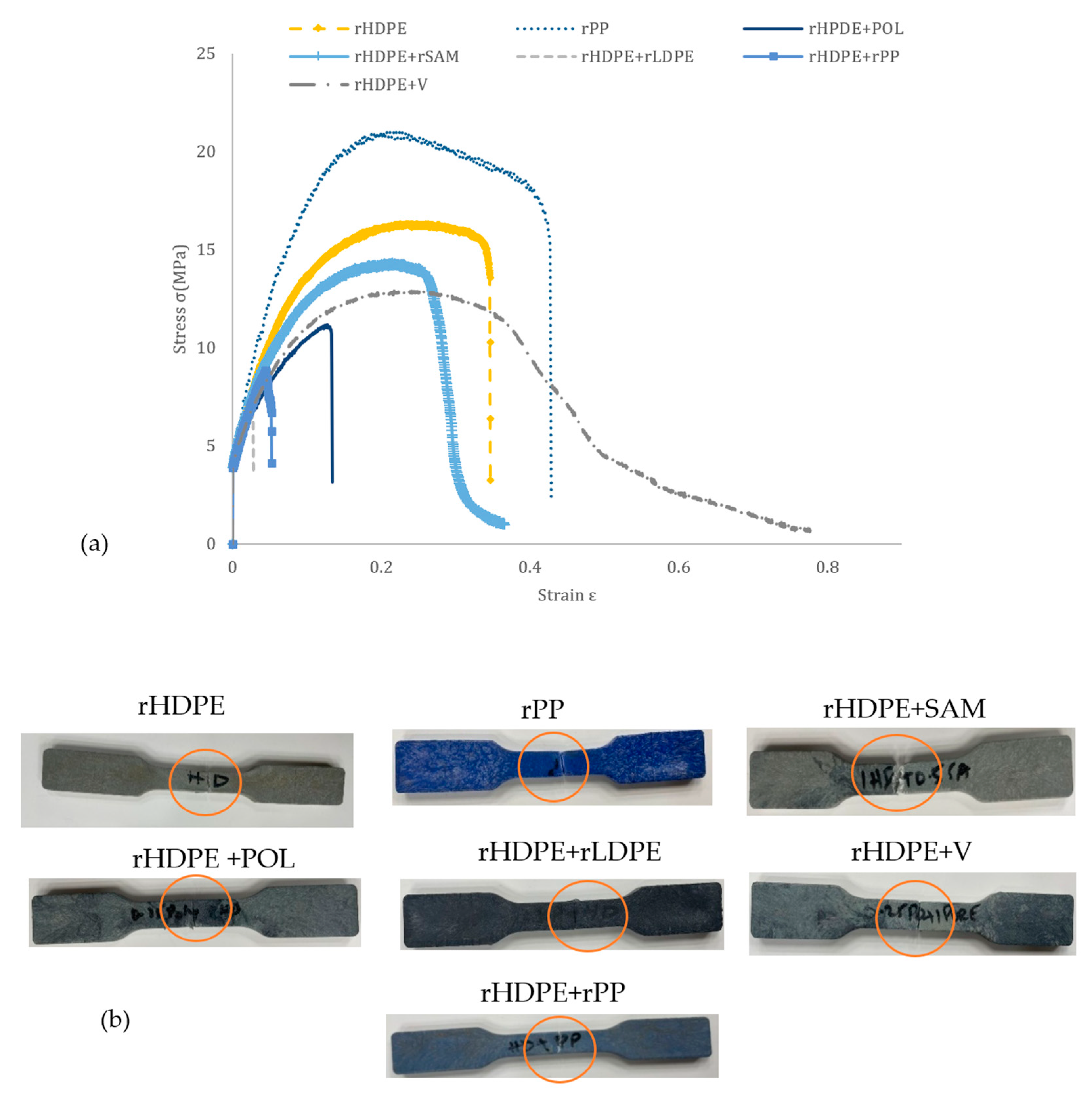

3.1.4. Tensile Behavior

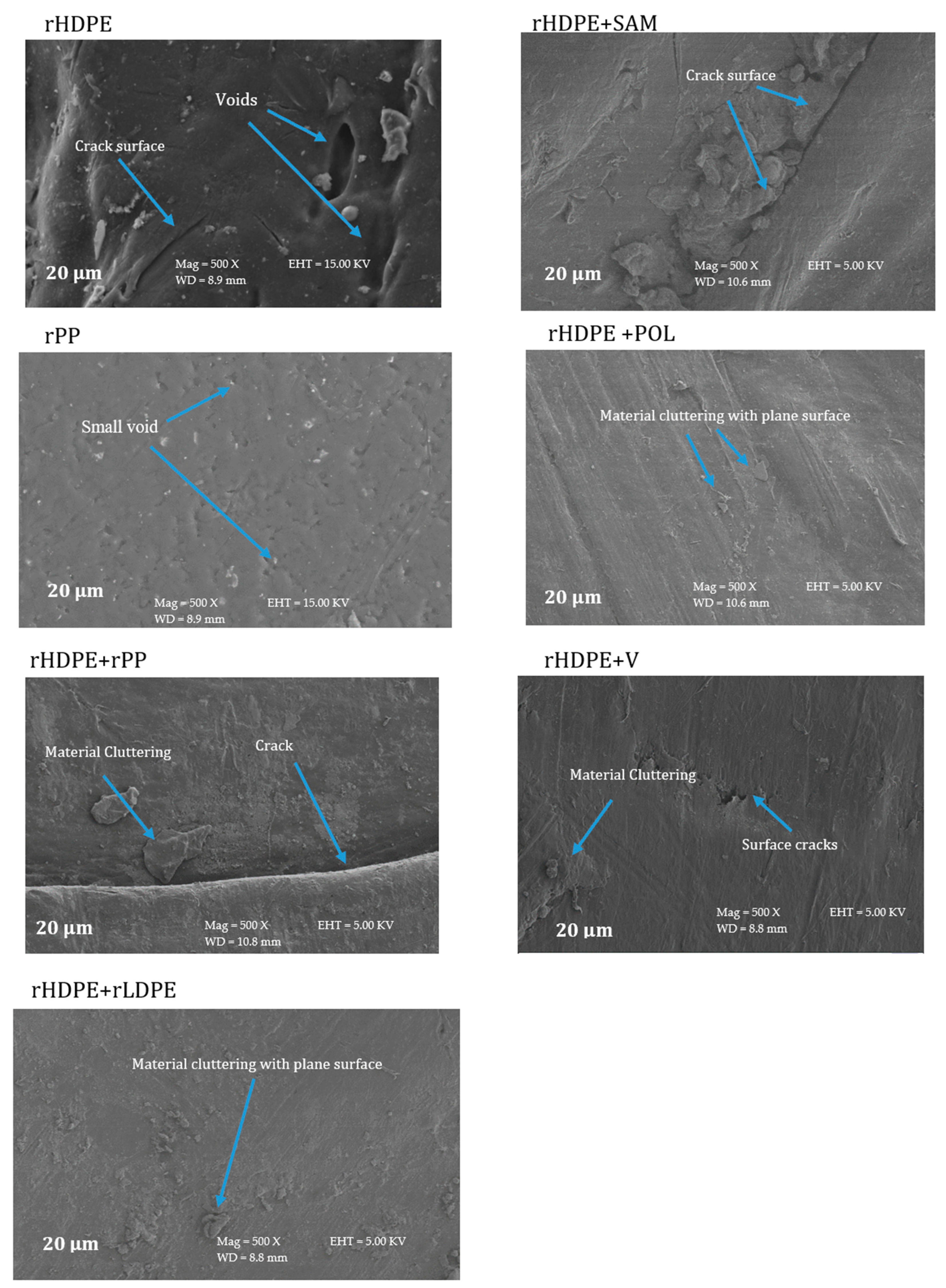

3.2. Microstructure Analysis

3.2.1. SEM Analysis of Damaged Surfaces of Specimens

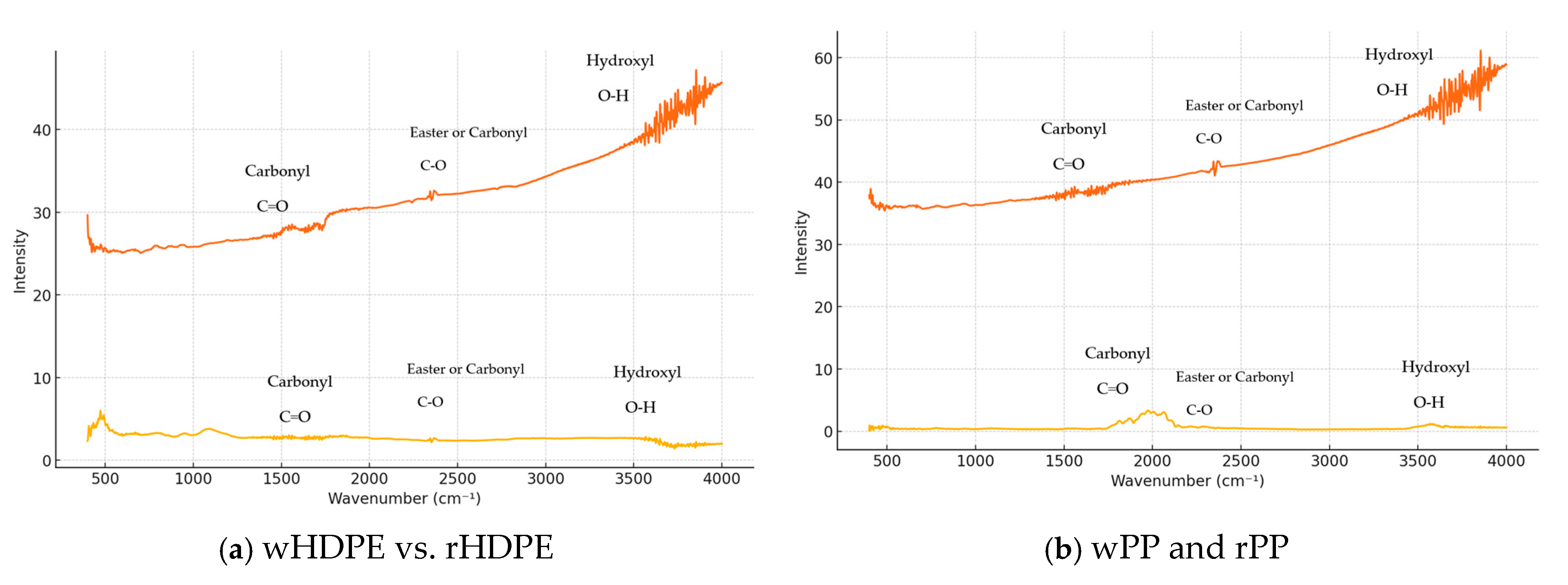

3.2.2. FTIR

3.3. Optimization

4. Perspective Use of Recycled Plastic Waste in Construction Industry

5. Conclusions

- The SEM and TGA results of the raw materials indicate that there are impurities. The raw materials are thermally stable, and their low weight confirms that the decomposition does not release hazardous gases. The materials are easily moldable in the temperature ranges defined in this study.

- The materials’ behaviors for use in construction were tested by subjecting the materials to different loading conditions, and the performance of the polymers was reasonable.

- ▪

- Shear behavior testing revealed that rHDPE had almost the same ranging shear energy as rPP. Based on optimization, blends are also recommended for energy absorbing capabilities in shear intensive applications.

- ▪

- The flexural behavior test revealed that rHDPE + rSAM performed well for bearing loads. However, rPP exhibited the highest F-PEA of 208.81 J/m3. This behavior was unmatched by the rHDPE blends.

- ▪

- The compressive parameters of rHDPE+POL and rHDPE+rSAM indicate that these two would be useful for structural applications, although rHDPE and rPP showed the lowest energy absorption during compression compared to the blends.

- ▪

- The tensile behavior of rPP had the highest energy absorption (T-TEA: 7.13 KJ/m3) and thus proved to be the toughest under tensile loads, while rHDPE had a balanced performance between strength and ductility. Mixed compositions like rHDPE + rLDPE exhibited poor results, which is probably due to the incompatibility of the polymers.

- The SEM and FTIR of the polymer confirm improvement in chemical cross linking.

- ▪

- Through the SEM analysis of the materials after failures appeared, voids, material cluttering, the cleavage of the failure surface, and the ductile tearing and energy dissipative behavior of rHDPE under stress was confirmed, with its toughness and reliability for load-bearing applications being affirmed.

- ▪

- Polymer extrusion induces significant chemical changes due to heat, shearing, and pressure, leading to chain scission, oxidative modifications, and new functional groups becoming detectable in FTIR spectra. High temperatures and mechanical stress can also cause crosslinking, the recombination of fragments, and reactions with additives, further altering the material’s composition.

- It has been found that rHDPE and rPP behave significantly well in tensile and ductility tests. Such properties make them suitable for application in load-bearing components, reinforcements, and protective barriers in construction.

- Recycled HDPE and PP are recommended for the construction industry, and the recycling process is feasible and is compatible with the concepts of the circular economy, which promotes the use of recycled materials instead of raw ones and drastically decreases the carbon footprint of construction materials like concrete and steel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PET | polyethylene terephthalate |

| HDPE | high-density polyethylene |

| LDPE | Low-Density Polyethylene |

| PVC | Polyvinyl Chloride |

| uPVC | Un-plasticized Polyvinyl Chloride |

| PP | Polypropylene |

| PS | Polystyrene |

| SAM | Samicanite |

| POL | Polyolefin |

| V | Virgin |

| r-PVC | Recycled Polyvinyl Chloride |

| FTIR | Fourier Transform Infrared Spectroscopy |

| TGA | Thermogravimetric Analysis |

| TEA | total energy absorption |

| TI | toughness index |

| YS | yield stress |

| MS | maximum stress |

| PEA | peak energy absorption |

| F | Flexural |

| T | Tensile |

| S | Shear |

| C | Compression |

| R | Recycled |

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2023, 9, 1005. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, M. Nanomaterial-Based Modifications for Improving the Thermal Stability of Recycled Plastics. J. Polym. Sci. 2024, 62, 301–319. [Google Scholar]

- Khan, H.; Raza, M. Enhancing the Mechanical Properties of Waste Plastics through Advanced Recycling Techniques. Mater. Sci. Adv. 2024, 45, 192–211. [Google Scholar]

- Liang, Y. An Analysis of the Plastic Waste Trade and Management in Asia. Waste Manag. 2021, 119, 242–253. [Google Scholar] [CrossRef]

- Al-Maadeed, M. An Overview of Solid Waste Management and Plastic Recycling in Qatar. J. Polym. Environ. 2012, 20, 186–194. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. National Overview: Facts and Figures on Materials, Wastes and Recycling; U.S. Environmental Protection Agency: Washington, DC, USA, 2021. [Google Scholar]

- Shen, L. Open-Loop Recycling: A LCA Case Study of PET Bottle-to-Fibre Recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Gopinath, K.P. A Critical Review on the Influence of Energy, Environmental, and Economic Factors on Plastic Waste Recycling. J. Clean. Prod. 2020, 274, 123031. [Google Scholar] [CrossRef]

- Thompson, R.C.; Swan, S.H.; Moore, C.J.; vom Saal, F.S. Our Plastic Age. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1973–1976. [Google Scholar] [CrossRef]

- Yussuf, A.A.; Al-Saleh, M.A.; Al-Enezi, S.T.; Abraham, G. Synthesis and Characterization of Conductive Polypyrrole: The Influence of the Oxidants and Monomer on the Electrical, Thermal, and Morphological Properties. Int. J. Polym. Sci. 2018, 2018, 4191747. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, M. Potential Applications of Different Forms of Recycled Plastics as Construction Materials—A Review. Eng. Proc. 2023, 53, 5. [Google Scholar] [CrossRef]

- Lubongo, C.; Daej, M.A.B.; Alexandridis, P. Recent Developments in Technology for Sorting Plastic for Recycling: The Emergence of Artificial Intelligence and the Rise of the Robots. Recycling 2024, 9, 59. [Google Scholar] [CrossRef]

- Ignatyev, I.A.; Thielemans, W.; Beke, B.V. Recycling of Polymers: A Review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef]

- Prabowo, J.; Lai, L.; Chivers, B.; Burke, D.; Dinh, A.H.; Ye, L.; Wang, Y.; Wang, Y.; Wei, L.; Chen, Y. Solid Carbon Co-Products from Hydrogen Production by Methane Pyrolysis: Current Understandings and Recent Progress. Carbon 2024, 216, 118507. [Google Scholar] [CrossRef]

- Tanner, J.; Wilson, K.; Huang, Y. Circular Economy Strategies for Enhancing Waste Plastic Recycling. J. Environ. Policy 2024, 51, 22–44. [Google Scholar]

- Onyenokporo, N.C.; Beizaee, A.; Adekeye, O.F.; Oyinlola, M.A. The Bottle House: Upcycling Plastic Bottles to Improve the Thermal Performance of Low-Cost Homes. Sustainability 2024, 16, 1360. [Google Scholar] [CrossRef]

- Xanthos, M. PET Recycling: Processes and Applications. J. Polym. Environ. 2023, 31, 11–29. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, A.R.; Garciá, J.M. Chemical Recycling of Waste Plastics for New Materials Production. Nat. Rev. Chem. 2017, 1, 0046. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical Recycling: Compatibilization of Mixed Thermoplastic Wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Ahmad, H.; Rodrigue, D. Crosslinked Polyethylene: A Review on the Crosslinking Techniques, Manufacturing Methods, Applications, and Recycling. Polym. Eng. Sci. 2022, 62, 2376–2401. [Google Scholar] [CrossRef]

- Sharma, K.; Patel, N. Surface Modification Techniques for Improving the Performance of Recycled Plastics. Adv. Mater. Res. 2024, 58, 87–106. [Google Scholar]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of Landfill Wastes (Tyres, Plastics and Glass) in Construction—A Review on Global Waste Generation, Performance, Application and Future Opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Schade, A.; Melzer, M.; Zimmermann, S.; Schwarz, T.; Stoewe, K.; Kuhn, H. Plastic Waste Recycling—A Chemical Recycling Perspective. ACS Sustain. Chem. Eng. 2024, 12, 12270–12288. [Google Scholar] [CrossRef]

- Kabirifar, K. Waste Management Factors Contributing to Reuse and Recycle Strategies. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Phanisankar, M.; Das, R.; Rao, S. Pyrolysis and Gasification of Plastic Waste: A Sustainable Approach to Waste Management. Energy Environ. Res. 2023, 41, 145–162. [Google Scholar]

- Shi, L.; Zhu, L. Recent Advances and Challenges in Enzymatic Depolymerization and Recycling of PET Wastes. ChemBioChem 2024, 25, 202300578. [Google Scholar] [CrossRef]

- Engeland, J.V. Strategic Network Optimization Models in Waste Supply Chains. Omega 2020, 91, 102012. [Google Scholar] [CrossRef]

- Drain, K.F.; Murphy, W.R.; Otterburn, M.S. Polymer Waste-Resource Recovery. Conserv. Recycl. 1981, 4, 201–218. [Google Scholar] [CrossRef]

- Mansour, S.A.; Mohammed, A.; Khalid, R. PET Plastic Aggregates in Sustainable Concrete Production: A Critical Review. J. Clean. Prod. 2022, 362, 132112. [Google Scholar]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.; Levett, P. Evaluation of Concrete Performance with Different Types of Recycled Plastic Waste for Kerb Application. Constr. Build. Mater. 2021, 293, 123477. [Google Scholar] [CrossRef]

- Chen, X.-F.; Jiao, C.-J. Effect of Physical Properties of Construction Wastes Based Composite Photocatalysts on the Sulfur Dioxide Degradation: Experimental Investigation and Mechanism Analysis. Case Stud. Constr. Mater. 2022, 17, e01237. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of Concrete Prepared with Crushed Fine Stone, Furnace Bottom Ash and Fine Recycled Aggregate as Fine Aggregates. Constr. Build. Mater. 2022, 325, 126856. [Google Scholar] [CrossRef]

- Saxena, R.; Siddique, S.; Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact Resistance and Energy Absorption Capacity of Concrete Containing Plastic Waste. Constr. Build. Mater. 2018, 176, 415–421. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of Recycled Plastic in Concrete: A Review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Tamrin; Nurdiana, J. The Effect of Recycled HDPE Plastic Additions on Concrete Performance. Recycling 2021, 6, 18. [Google Scholar] [CrossRef]

- Naik, T.R.; Singh, S.S.; Huber, C.O.; Brodersen, B.S. Use of Post-Consumer Waste Plastics in Cement-Based Composites. Cem. Concr. Res. 1996, 26, 1489–1492. [Google Scholar] [CrossRef]

- Jassim, A.K. Recycling of Polyethylene Waste to Produce Plastic Cement. Procedia Manuf. 2016, 8, 635–642. [Google Scholar] [CrossRef]

- Sule, J. Use of Waste Plastics in Cement-Based Composite for Lightweight Concrete Production. Int. J. Res. Eng. Technol. 2017, 2, 44–54. [Google Scholar]

- Choudhary, A.K.; Jha, J.N.; Gill, K.S.; Shukla, S.K. Utilization of Fly Ash and Waste Recycled Product Reinforced with Plastic Wastes as Construction Materials in Flexible Pavement. In Proceedings of the Geo-Congress 2014: Geo-Characterization and Modeling for Sustainability, Atlanta, GA, USA, 23–26 February 2014; pp. 3890–3902. [Google Scholar]

- Mashaan, N.S.; Ouano, C.A.E. An Investigation of the Mechanical Properties of Concrete with Different Types of Waste Plastics for Rigid Pavements. Appl. Mech. 2025, 6, 9. [Google Scholar] [CrossRef]

- Simon, N.; Raubenheimer, K.; Urho, N.; Unger, S.; Azoulay, D.; Farrelly, T.; Sousa, J.; van Asselt, H.; Carlini, G.; Sekomo, C.; et al. A Binding Global Agreement to Address the Life Cycle of Plastics. Science 2021, 373, 43–47. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of Post-Consumer Waste Plastic in Cementitious Concrete Composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.W.; Moon, D.J.; Chung, J.S.; Cho, S.K. Effects of Waste PET Bottles Aggregate on the Properties of Concrete. Cem. Concr. Res. 2009, 39, 33–38. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of Content and Particle Size of Waste PET Bottles on Concrete Behavior at Different w/c Ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef] [PubMed]

- Frigione, M. Recycling of PET Bottles as Fine Aggregate in Concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Ramadevi, K.K.; Manju, R. Experimental Investigation on the Properties of Concrete With Plastic PET (Bottle) Fibres as Fine Aggregates. J. Emerg. Technol. Adv. Eng. 2012, 2, 42–46. [Google Scholar]

- Silva, R.V.; Brito, J.D.; Saikia, N. Influence of Curing Conditions on the Durability-Related Performance of Concrete Made with Selected Plastic Waste Aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Hannawi, K.; Kamali-Bernard, S.; Prince, W. Physical and Mechanical Properties of Mortars Containing PET and PC Waste Aggregates. Waste Manag. 2010, 30, 2312–2320. [Google Scholar] [CrossRef]

- Juki, M.I. Relationship between Compressive, Splitting Tensile and Flexural Strength of Concrete Containing Granulated Waste Polyethylene Terephthalate (PET) Bottles as Fine Aggregate. Adv. Mater. Res. 2013, 795, 356–359. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J.D. Waste Polyethylene Terephthalate as an Aggregate in Concrete. Mater. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef]

- Correia, J.R.; Lima, J.S.; Brito, J.D. Post-Fire Mechanical Performance of Concrete Made with Selected Plastic Waste Aggregates. Cem. Concr. Compos. 2014, 53, 187–199. [Google Scholar] [CrossRef]

- Mohammed, A.A. Flexural Behavior and Analysis of Reinforced Concrete Beams Made of Recycled PET Waste Concrete. Constr. Build. Mater. 2017, 155, 593–604. [Google Scholar] [CrossRef]

- Shubbar, S.D.A.; Al-Shadeedi, A.S. Utilization of Waste Plastic Bottles As Fine Aggregate in Concrete. Kufa J. Eng. 2017, 8, 132–146. [Google Scholar] [CrossRef]

- Bandodkar, Y.P.G.L.R.; Gaonkar, A.A.; Gaonkar, N.D. Pulverised PET Bottles as Partial Replacement for Sand. Int. J. Earth Sci. Eng. 2011, 4, 1009–1012. [Google Scholar]

- Safi, B.; Saidi, M.; Aboutaleb, D.; Maallem, M. The Use of Plastic Waste as Fine Aggregate in the Self-Compacting Mortars: Effect on Physical and Mechanical Properties. Constr. Build. Mater. 2013, 43, 436–442. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of Selected Waste Materials in Concrete Mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef] [PubMed]

- Rai, B.; Rushad, S.T.; Kr, B.; Duggal, S.K. Study of Waste Plastic Mix Concrete with Plasticizer. ISRN Civ. Eng. 2012, 2012, 469272. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Safi, B.; Chaid, R. Use of Recycled Plastic Bag Waste in the Concrete. Mater. Process. Environ. 2009, 8, 480–487. [Google Scholar]

- Jaivignesh, B.; Sofi, A. Study on Mechanical Properties of Concrete Using Plastic Waste as an Aggregate. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 80. [Google Scholar]

- Aldahdooh, M.A.A.; Jamrah, A.; Alnuaimi, A.; Martini, M.I.; Ahmed, M.S.R.; Ahmed, A.S.R. Influence of Various Plastics-Waste Aggregates on Properties of Normal Concrete. J. Build. Eng. 2018, 17, 13–22. [Google Scholar] [CrossRef]

- Akinyele, J.O.; Ajede, A. The Use of Granulated Plastic Waste in Structural Concrete. Afr. J. Sci. Technol. Innov. Dev. 2018, 10, 169–175. [Google Scholar] [CrossRef]

- Dweik, H.S.; Ziara, M.M.; Hadidoun, M.S. Enhancing Concrete Strength and Thermal Insulation Using Thermoset Plastic Waste. Int. J. Polym. Mater. Polym. Biomater. 2008, 57, 635–656. [Google Scholar] [CrossRef]

- Kou, S.C.; Lee, G.; Poon, C.S.; Lai, W.L. Properties of Lightweight Aggregate Concrete Prepared with PVC Granules Derived from Scraped PVC Pipes. Waste Manag. 2009, 29, 621–628. [Google Scholar] [CrossRef] [PubMed]

- Haghighatnejad, N.; Mousavi, S.Y.; Khaleghi, S.J.; Tabarsa, A.; Yousefi, S. Properties of Recycled PVC Aggregate Concrete under Different Curing Conditions. Constr. Build. Mater. 2016, 126, 943–950. [Google Scholar] [CrossRef]

- Aciu, C.; Ilutiu-Varvara, D.A.; Manea, D.L.; Orban, Y.A.; Babota, F. Recycling of Plastic Waste Materials in the Composition of Ecological Mortars. Procedia Manuf. 2018, 22, 274–279. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A. Improvement of the Mechanical Properties of Glass Fibre Reinforced Plastic Waste Powder Filled Concrete. Constr. Build. Mater. 2010, 24, 448–460. [Google Scholar] [CrossRef]

- Galvão, J.C.A.; Portella, K.F.; Joukoski, A.; Mendes, R.; Ferreira, E.S. Use of Waste Polymers in Concrete for Repair of Dam Hydraulic Surfaces. Constr. Build. Mater. 2011, 25, 1049–1055. [Google Scholar] [CrossRef]

- Liu, F.; Yan, Y.; Li, L.; Lan, C.; Chen, G. Performance of Recycled Plastic-Based Concrete. J. Mater. Civ. Eng. 2015, 27, A4014004. [Google Scholar] [CrossRef]

- Chandni, T.J.; Anand, K.B. Utilization of Recycled Waste as Filler in Foam Concrete. J. Build. Eng. 2018, 19, 154–160. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Pokorný, J.; Jankovský, O.; Pavlík, Z.; Černý, R. Structural, Mechanical and Hygrothermal Properties of Lightweight Concrete Based on the Application of Waste Plastics. Constr. Build. Mater. 2018, 180, 1–11. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of Structural Concrete with Recycled Plastic Waste as a Partial Replacement for Sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of Waste Plastic Materials for Road Construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Vasudevan, R.; Saravanavel, S.; Rajasekaran, S.; Thirunakkarasu, D. Utilisation of Waste Plastics in Construction of Flexible Pavement. Indian Highw. 2006, 34, 5–20. [Google Scholar]

- Zhang, K.; Xiong, J.; Ruiz, C.; Zhang, J. Design and Performance Assessment of Sustainable Road Pothole Patching Materials Using Waste Cooking Oil, Plastic, and Reclaimed Asphalt Pavement. Constr. Build. Mater. 2024, 429, 136426. [Google Scholar] [CrossRef]

- Pallavi, M.L.; Dey, S.; Veerendra, G.T.; Padavala, S.S.; Manoj, A.V. Optimizing the Bituminous Pavement Constructions with Waste Plastic Materials Improved the Road Constructions Performance and Their Future Applications. AI Civ. Eng. 2024, 3, 16. [Google Scholar] [CrossRef]

- Vasudevan, R.; Sekar, A.R.C.; Sundarakannan, B.; Velkennedy, R. A Technique to Dispose Waste Plastics in an Ecofriendly Way—Application in Construction of Flexible Pavements. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Priyanka, A.; NarasimhaReddy, K.; Balaji, N. Analysis in the Application of Plastic Waste as a Constructive Material in Flexible Pavement. Math. Educ. 2021, 12, 166–170. [Google Scholar]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using Waste Plastic Bottles as Additive for Stone Mastic Asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Giustozzi, F. Polymer-Modified Pervious Concrete for Durable and Sustainable Transportation Infrastructures. Constr. Build. Mater. 2016, 111, 502–512. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Tan, Y.Q. Mechanistic Approach for Polypropylene-Modified Flexible Pavements. Mater. Des. 2009, 30, 1133–1140. [Google Scholar] [CrossRef]

- Dandge, A.L. Utilization of Waste Plastic Materials in Road Construction. J. Adv. Res. Mech. Civ. Eng. 2016, 3, 1–9. [Google Scholar]

- Gawande, A.; Zamare, G.; Renge, V.C.; Tayde, S.; Bharsakale, G. An Overview on Waste Plastic Utilization in Asphalting of Roads. J. Eng. Res. Stud. 2012, 3, 1–5. [Google Scholar]

- Chavan, M.A. Use of Plastic Waste in Flexible Pavements. Int. J. Appl. Innov. Eng. Manag. 2013, 2, 540–552. [Google Scholar]

- Mishra, B.; Mishra, R.S. A Study on Use of Industrial Wastes in Rural Road Construction. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 10387–10398. [Google Scholar] [CrossRef]

- Oliveira, J.R.M. Developing Enhanced Modified Bitumens with Waste Engine Oil Products Combined with Polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a Recycled Polymer Modified Binder for Use in Stone Mastic Asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Punith, V.S.; Veeraragavan, A. Behavior of Asphalt Concrete Mixtures with Reclaimed Polyethylene as Additive. J. Mater. Civ. Eng. 2007, 19, 500–507. [Google Scholar] [CrossRef]

- Suriya, P.A.; Sangeetha, S.P.; Abirami, R.; Subathra, P. Stabilization of Red Soil Using Polypropylene. Mater. Today Proc. 2021, 46, 5881–5884. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Ayatollahi, M.R.; Hashemi, M.M. Influences of Silica Fume Particles and Polyethylene Terephthalate Fibers on the Mechanical Characteristics of Cement-Treated Sandy Soil Using Ultrasonic Pulse. Constr. Build. Mater. 2022, 81, 14. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, M.K. Effect of NaOH Treated Polyethylene Terephthalate (PET) Plastic Bottle Strips on Stabilization of Soil. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2023; Volume 1273, p. 012013. [Google Scholar]

- Drozdov, A.D.; Jermiin, R.H.; Christiansen, J.D. Lifetime Predictions for Virgin and Recycled High-Density Polyethylene under Creep Conditions. arXiv 2024, arXiv:2404.10336. [Google Scholar]

- Tesfaw, S.; Bogale, T.M.; Fatoba, O. Evaluation of Tensile and Flexural Strength Properties of Virgin and Recycled High-Density Polyethylene (HDPE) for Pipe Fitting Application. Mater. Today Proc. 2022, 62, 3103–3113. [Google Scholar] [CrossRef]

- Kamalian, P.; Khorasani, S.N.; Abdolmaleki, A.; Karevan, M.; Khalili, S.; Shirani, M.; Neisiany, R.E. Toward the Development of Polyethylene Photocatalytic Degradation. J. Polym. Eng. 2020, 40, 181–191. [Google Scholar] [CrossRef]

- Cho, K.Y.; Lee, B.H.; Hwang, K.M.; Lee, H.; Choe, S. Rheological and Mechanical Properties in Polyethylene Blends. Polym. Eng. Sci. 1998, 38, 1969–1975. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Hindle, C.S.; Kalloudis, M.; Koutsos, V. Thermomechanical Properties of Virgin and Recycled Polypropylene—High-Density Polyethylene Blends. Polymers 2023, 15, 4200. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Kalloudis, M.; Koutsos, V. High-Density Polyethylene–Polypropylene Blends: Examining the Relationship Between Nano/Microscale Phase Separation and Thermomechanical Properties. Polymers 2025, 17, 166. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.-O.; Oh, Y.-H.; Jeong, S.-I.; Park, J.-S. Optimization of the Physical Properties of HDPE/PU Blends through Improved Compatibility and Electron Beam Crosslinking. Polymers 2022, 14, 3607. [Google Scholar] [CrossRef]

- Cestari, S.P.; Martin, P.J.; Hanna, P.R.; Kearns, M.P.; Mendes, L.C.; Millar, B. Use of Virgin/Recycled Polyethylene Blends in Rotational Moulding. J. Polym. Eng. 2021, 41, 509–516. [Google Scholar] [CrossRef]

- Klingenberg, P.; Brüll, R.; Fell, T.; Barton, B.; Soll, M.; Emans, T.; Bakker, F.; Geertz, G. Quality Comparison of Plastic Packaging Waste from Different Separation Systems: Result Enhancement with Non-Negative Matrix Factorization of FTIR Spectra. Waste Manag. 2024, 178, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Gu, F. From Waste Plastics to Industrial Raw Materials. Sci. Total Environ. 2017, 601–602, 1192–1207. [Google Scholar] [CrossRef]

- ASTM-D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-D695-23; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D732-24; Standard Test Method for Shear Strength of Plastics by Punch Tool. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Jiang, P. Social Media and Household Waste Management. Resour. Conserv. Recycl. 2021, 164, 105146. [Google Scholar] [CrossRef]

- Graziano, A.; Jaffer, S.; Sain, M. Review on Modification Strategies of Polyethylene/Polypropylene Immiscible Thermoplastic Polymer Blends for Enhancing Their Mechanical Behavior. J. Elastomers Plast. 2019, 51, 291–336. [Google Scholar] [CrossRef]

- Zhang, J.; Hirschberg, V.; Rodrigue, D. Blending Recycled High-Density Polyethylene HDPE (rHDPE) with Virgin (vHDPE) as an Effective Approach to Improve the Mechanical Properties. Recycling 2023, 8, 2. [Google Scholar] [CrossRef]

- Hanna, E.G. Recycling of Waste Mixed Plastics Blends (PE/PP). J. Eng. Sci. Technol. Rev. 2019, 12, 87–92. [Google Scholar] [CrossRef]

- Liu, S.Q.; Gong, W.G.; Zheng, B.C. The Effect of Peroxide Cross-Linking on the Properties of Low-Density Polyethylene. J. Macromol. Sci. Part B 2014, 53, 67–77. [Google Scholar] [CrossRef]

- Gavande, V.; Jeong, M.; Lee, W.-K. On the Mechanical, Thermal, and Rheological Properties of Polyethylene/Ultra-High Molecular Weight Polypropylene Blends. Polymers 2023, 15, 4236. [Google Scholar] [CrossRef] [PubMed]

| SPI Symbol/Code | Structure | General Properties of the Material | Recyclable? | Density (gm/cm3) |

|---|---|---|---|---|

|  | Impermeable ability: good. Solvent resistance. Hard. Clear. Microwave transparency. High heat resistant. | Widely recycled | 1.38–1.40 |

| Polyethylene Terephthalate: PET | ||||

|  | Impermeable ability: excellent. Chemical repellent. Strong, semi-flexible. Waxy surface. | Widely recycled | 0.93–0.97 |

| High-Density Polyethylene: HDPE | ||||

|  | Excellent transparency. Chemical repellent. Rigid. Good resistance to weathering. Impermeable ability: good. Stable. | It is often not recyclable; the only problem is the chemicals that might alter the polymer | 1.10–1.45 |

| Polyvinyl Chloride: PVC | ||||

|  | Waxy on surface. Flexible. Good transparency. Impermeable ability: good. Low melting point. | Not recycled; fails under stress | 0.91–0.94 |

| Low-Density Polyethylene: LDPE | ||||

|  | Chemical repellent. Hard. Flexible. High melting point. Translucent. Waxy on surface. Strong. | Rarely recycled | 0.90–0.92 |

| Polypropylene: PP | ||||

|  | Clear. Glassy. Rigid. Brittle. Hard. Good clarity. Fats and solvents can affect. | Rarely recycled | 1.04–1.11 For Expanded Polystyrene 0.016–0.64 |

| Polystyrene: PS | ||||

| Others | Includes numbers 7–19, usually polyamides, ABS, PC mixed polymers, etc. | Not recycled due to diverse risk of contamination | Varies |

| File Name | Max Weight (mg) (Temperature °C) | Min Weight (mg) (Temperature °C) | Weight (mg) | % Weight Loss | Max Heat Flow (mW) (Temperature °C) | Min Heat Flow (mW) (Temperature °C) |

|---|---|---|---|---|---|---|

| Waste HPDE | 3.10 (240.50) | 3.03 (124.09) | 0.07 | 2.18 | −13.14 (126.64) | −35.37 (242.05) |

| Waste LDPE | 7.85 (241.15) | 7.74 (141.85) | 0.11 | 1.45 | −9.90 (142.62) | −34.45 (242.17) |

| Samicanite | 5.85 (242.07) | 5.75 (139.08) | 0.10 | 1.78 | −10.46 (140.41) | −32.79 (242.24) |

| PE virgin | 5.23 (117.35) | 5.18 (108.34) | 0.05 | 1.05 | −22.86 (135.68) | −43.52 (108.34) |

| Polyolefin | 5.21 (123.09) | 5.16 (115.48) | 0.05 | 1.01 | −17.49 (121.69) | −32.95 (242.16) |

| Waste PP | 4.94 (129.90) | 4.88 (240.66) | 0.06 | 1.25 | −11.23 (126.31) | −33.34 (242.21) |

| Parameter | Recycled Plastic Mixes | |||||||

|---|---|---|---|---|---|---|---|---|

| rHDPE | rPP | rHDPE + rPP | rHD + V | rHDPE + rLDPE | rHDPE + POL | rHDPE + rSAM | ||

| Material content by weight | rPP | 100% | 50% | |||||

| rHDPE | 100% | 50% | 50% | 50% | 80% | 80% | ||

| Other plastics (V, LDPE, SAM, POL) | 50% | 50% | 20% | 20% | ||||

| Mechanical test samples | Shear Test (S) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Flexure Test (F) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Tensile Test (T) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Compression Test (C) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Parameter | Recycled Plastic Mixes | ||||||

|---|---|---|---|---|---|---|---|

| rHDPE | rHDPE + rPOL | rHDPE + V | rHDPE + rSAM | rHDPE + rLDPE | rHDPE + rPP | rPP | |

| S-TEA (KJ/m3) | 5.43 ± 0.13 (9.96) | 5.38 ± 0.03 (3.39) | 6.74 ± 0.10 (8.15) | 5.69 ± 0.10 (8.64) | 4.48 ± 0.03 (4.84) | 5.09 ± 0.09 (14.03) | 8.69 ± 0.09 (5.06) |

| S- TI (J) | 10.39±0.03 (4.90) | 7.53 ± 0.07 (14.40) | 9.59 ± 0.03 (4.79) | 8.39 ± 0.04 (7.25) | 7.35 ± 0.01 (9.29) | 7.38 ± 0.06 (17.54) | 13.12 ± 0.04 (4.61) |

| S-MS (MPa) | 10.39±0.47 (6.14) | 7.53 ± 0.95 (18.19) | 9.59 ± 0.51 (7.28) | 8.39 ± 0.30 (4.84) | 7.35 ± 0.65 (12.40) | 7.38 ± 0.45 (11.45) | 13.12 ± 0.34 (3.39) |

| S-YS (MPa) | 2.08±0.06 (3.18) | 1.85 ± 0.14 (8.60) | 1.94 ± 0.01 (0.77) | 1.89 ± 0.04 (2.07) | 1.87 ± 0.25 (15.32) | 1.84 ± 0.08 (5.40) | 2.65 ± 0.02 (0.89) |

| Parameter | Recycled Plastic and Mixes | ||||||

|---|---|---|---|---|---|---|---|

| rHDPE + rPP | rHDPE + rSAM | rHDPE + rLDPE | rHDPE | rHDPE + POL | rPP | rHDPE + V | |

| F-TEA (KJ/m3) | 3.24 ± 0.28 (9) | 13.66 ± 1.83 (13) | 1.11 ± 0.50 (5) | 12.80 ± 1.97 (15) | 1.27 ± 0.18 (14) | 45.74 ± 7.64 (17) | 1.05 ± 0.13 (13) |

| F-PEA (J/m3) | 6.44 ± 0.69 (11) | 9.82 ± 2.54 (26) | 5.56 ± 0.06 (1) | 50.79 ± 6.40 (13) | 7.00 ± 1.97 (28) | 208.81 ± 7.00 (3) | 6.09 ± 1.31 (21) |

| F-TI (J) | 3.45 ± 0.37 (11) | 5.87 ± 1.52 (26) | 1.15 ± 0.01 (1) | 7.37 ± 0.93 (13) | 1.39 ± 0.39 (28) | 9.42 ± 0.32 (3) | 1.15 ± 0.25 (21) |

| F-MS (MPa) | 13.99 ± 1.21 (9) | 34.61 ± 4.63 (13) | 13.60 ± 0.06 (1) | 25.83 ± 3.97 (15) | 13.66 ± 1.91 (14) | 72.23 ± 12.07 (17) | 13.60 ± 1.71 (13) |

| F-YS (MPa) | 13.12 ± 0.15 (1) | 13.12 ± 0.20 (2) | 12.98 ± 0.17 (1) | 14.05 ± 0.16 (1) | 13.36 ± 0.23 (2) | 14.14 ± 0.14 (1) | 12.92 ± 0.22 (2) |

| Parameter | Recycled Plastic and Mixes | ||||||

|---|---|---|---|---|---|---|---|

| rHDPE | rPP | rHDPE + V | rHDPE + rLDPE | rHDPE + POL | rHDPE + rSAM | rHDPE + rPP | |

| C-TEA (KJ/m3) | 0.55 ± 0.06 (11) | 0.77 ± 0.02 (3) | 3.22 ± 0.41 (13) | 3.60 ± 0.32 (9) | 4.23 ± 0.41 (10) | 3.90 ± 0.27 (7) | 3.17 ± 0.18 (6) |

| C-TI (J) | 0.37 ± 0.04 (11) | 0.27 ± 0.02 (7) | 1.88 ± 0.11 (6) | 2.21 ± 0.21 (9) | 2.78 ± 0.09 (3) | 2.38 ± 0.07 (3) | 3.17 ± 0.09 (3) |

| C-MS (MPa) | 6.97 ± 0.12 (2) | 8.77 ± 1.12 (13) | 20.68 ± 3.4 (16) | 23.98 ± 2.4 (10) | 27.47 ± 4.8 (17) | 24.21 ± 1.22 (5) | 18.33 ± 0.76 (4) |

| Parameter | Recycled Plastic and Mixes | ||||||

|---|---|---|---|---|---|---|---|

| rHDPE | rPP | rHDPE + rPP | rHDPE + V | rHDPE + rLDPE | rHDPE + POL | rHDPE + rSAM | |

| T-TEA (KJ/m3) | 4.27 ± 0.65 (16) | 7.13 ± 2.00 (17) | 0.25 ± 0.03 (8) | 1.40 ± 0.60 (17) | 0.10 ± 0.00 (0) | 0.94 ± 0.10 (9) | 1.56 ± 0.50 (14) |

| T-TI (J) | 1.30 ± 0.65 (14.91) | 2.25 ± 1.30 (10.98) | 0.84 ± 0.03 (8.17) | 0.62 ± 0.40 (10.87) | 0.68 ± 0.00 (0.48) | 0.87 ± 0.10 (8.85) | 0.63 ± 0.60 (16.34) |

| T-MS (MPa) | 16.32 ± 0.83 (5) | 21.4 ± 0.51 (2) | 8.84 ± 0.23 (3) | 12.89 ± 0.25 (2) | 6.55 ± 0.29 (5) | 11.19 ± 0.58 (5) | 14.31 ± 0.66 (5) |

| T-YS (MPa) | 4.48 ± 0.12 (2.80) | 4.46 ± 0.09 (2.14) | 4.24 ± 0.06 (1.43) | 4.27 ± 0.05 (1.11) | 4.20 ± 0.00 (0.00) | 4.31 ± 0.02 (0.49) | 4.31 ± 0.05 (1.12) |

| Parameter | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Behavior | Compression Behavior | Flexural Behavior | Shear Behavior | ||||||||||||

| T-TEA (KJ/m3) | T-TI (J) | T-MS (MPa) | T-YS (MPa) | C-TEA (KJ/m3) | C-TI (J) | C-MS (MPa) | F-TEA (KJ/m3) | F-PEA (J/m3) | F-TI (J) | F-MS (MPa) | F-YS (MPa) | S-TEA (KJ/m3) | S-TI (J) | S-MS (MPa) | S-YS (MPa) |

| Materials with highest performance | |||||||||||||||

| rPP | rHDPE | rHDPE + POL | rHDPE + rPP | rHDPE + POL | rPP | rPP | |||||||||

| 7.13 ± 2.00 (17) | 2.25 ± 1.30 (10.98) | 21.4 ± 0.51 (2) | 4.48 ± 0.12 (2.80) | 4.23 ± 0.41 (10) | 3.17 ± 0.09 (3) | 27.47 ± 4.8 (17) | 45.74 ± 7.64 (17) | 208.81 ± 7.00 (28) | 9.42 ± 0.32 (3) | 72.23 ± 12.07 (17) | 14.14 ± 0.14 (1) | 8.69 ± 0.09 (5.06) | 13.12 ± 0.04 (4.61) | 13.12 ± 0.34 (3.39) | 2.65 ± 0.02 (0.89) |

| Materials with second highest performance | |||||||||||||||

| rHDPE | rPP | rHDPE + SAM | rHDPE + POL | rHDPE + SAM | rHDPE + SAM | rHDPE | rHDPE + SAM | rHDPE | rHDPE + V | rHDPE | |||||

| 4.27 ± 0.65 (16) | 1.30 ± 0.65 (14.91) | 16.32 ± 0.83 (5) | 4.46 ± 0.09 (2.14) | 3.90 ± 0.27 (7) | 2.78 ± 0.09 (3) | 24.21 ± 1.22 (5) | 13.66 ± 1.83 (13) | 50.79 ± 6.40 (13) | 7.37 ± 0.93 (13) | 34.61 ± 4.63 (13) | 14.05 ± 0.16 (1) | 6.74 ± 0.10 (8.15) | 10.39 ± 0.03 (4.90) | 10.39 ± 0.47 (6.14) | 2.08 ± 0.06 (3.18) |

| Materials with poorest performance | |||||||||||||||

| rHDPE + rLDPE | rHDPE | rPP | rHDPE | rHDPE + rLDPE | rHDPE + rLDPE | ||||||||||

| 0.10 ± 0.00 (0) | 0.68 ± 0.00 (0.48) | 6.55 ± 0.29 (5) | 4.20 ± 0.00 (0.00) | 0.55 ± 0.06 (11) | 0.27 ± 0.02 (7) | 6.97 ± 0.12 (2) | 1.11 ± 0.50 (5) | 5.56 ± 0.06 (1) | 1.15 ± 0.01 (1) | 13.60 ± 0.06 (1) | 12.98 ± 0.17 (1) | 4.48 ± 0.03 (4.84) | 7.35 ± 0.01 (9.29) | 7.35 ± 0.65 (12.4) | 1.87 ± 0.25 (15.32) |

| Recommended material for construction products | |||||||||||||||

| First priority: rPP (from strength and toughness point of view) | |||||||||||||||

| 7.13 ± 2.00 (17) | 2.25 ± 1.30 (10.98) | 21.4 ± 0.51 (2) | 4.46 ± 0.09 (2.14) | 0.77 ± 0.02 (3) | 0.27 ± 0.02 (7) | 8.77 ± 1.12 (13) | 45.74 ± 7.64 (17) | 208.8 ± 7.00 (3) | 9.42 ± 0.32 (3) | 72.23 ± 12.07 (17) | 14.14 ± 0.14 (1) | 8.69 ± 0.09 (5.06) | 13.12 ± 0.04 (4.61) | 13.12 ± 0.34 (3.39) | 2.65 ± 0.02 (0.89) |

| Second priority: rHDPE (from yield strength, performance, and recyclability point of view) | |||||||||||||||

| 4.27 ± 0.65 (16) | 1.30 ± 0.65 (14.91) | 16.32 ± 0.83 (5) | 4.48 ± 0.12 (2.80 | 0.55 ± 0.06 (11) | 0.37 ± 0.04 (11) | 6.97 ± 0.12 (2) | 12.80 ± 1.97 (15) | 50.79 ± 6.40 (13) | 7.37 ± 0.93 (13) | 25.83 ± 3.97 (15) | 14.05 ± 0.16 (1) | 5.43 ± 0.13 (9.96) | 10.39 ± 0.03 (4.90) | 10.39 ± 0.47 (6.14) | 2.08 ± 0.06 (3.18) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, A.J.; Ali, M. Prospective Use and Assessment of Recycled Plastic in Construction Industry. Recycling 2025, 10, 41. https://doi.org/10.3390/recycling10020041

Das AJ, Ali M. Prospective Use and Assessment of Recycled Plastic in Construction Industry. Recycling. 2025; 10(2):41. https://doi.org/10.3390/recycling10020041

Chicago/Turabian StyleDas, Aaroon Joshua, and Majid Ali. 2025. "Prospective Use and Assessment of Recycled Plastic in Construction Industry" Recycling 10, no. 2: 41. https://doi.org/10.3390/recycling10020041

APA StyleDas, A. J., & Ali, M. (2025). Prospective Use and Assessment of Recycled Plastic in Construction Industry. Recycling, 10(2), 41. https://doi.org/10.3390/recycling10020041