Abstract

The increasing demand for sustainable materials in automotive applications, coupled with the critical need to address marine plastic pollution, presents an opportunity for innovative material development. This study explores composites made from recycled polyamide 6 (PA6) fishing nets reinforced with switchgrass fibers (0–30 wt%). The composite with 30 wt% switchgrass fibers increased tensile strength by 23% and Young’s modulus by 126% compared to unreinforced recycled PA6, achieving 93% of the tensile strength of commercial automotive-grade neat PA6 and surpassing another grade by 22%. However, higher fiber loading hindered processability, as evidenced by incomplete mold filling and reflected by a decrease in melt flow rate from 19.35 to 8.63 g/10 min. Thermal analysis revealed reduced crystallinity and crystallization temperatures with fiber addition, attributed to restricted polymer chain mobility. While dynamic mechanical analysis demonstrated improved stiffness below the glass transition temperature, scanning electron microscopy indicated optimal fiber-matrix adhesion at up to 20 wt% fiber loading, with aggregation at higher concentrations. These findings establish recycled fishing net-derived PA6/switchgrass fiber composites as a viable alternative to virgin materials in automotive applications, with mechanical properties comparable to commercial grades. Although the composites demonstrate enhanced mechanical strength and modulus, the significant reduction in ductility restricts their use to rigid, semi-structural components where flexibility is not critical. Future research should address processing challenges to enhance fiber dispersion and interfacial adhesion at higher loadings.

1. Introduction

Marine debris presents a significant global environmental challenge, with an estimated 6.4 million metric tons entering the oceans annually [1]. Among the various sources of this pollution, abandoned, lost, or discarded fishing nets are particularly concerning due to their substantial contribution to plastic waste in marine ecosystems. Historically, fishing nets were crafted from natural fibers such as cotton, jute, and hemp. However, since the 1950s, synthetic polymers have largely replaced these materials owing to their superior durability and resistance to water degradation [2]. As a result, modern nets persist in the marine environment for decades, compounding pollution levels.

Derelict fishing gear, including nets and ropes, constitutes a major component of marine plastic pollution. Studies indicate that such gear accounts for approximately 46% of the 79,000 metric tons of plastic waste in the Great Pacific Garbage Patch [3]. Additionally, a meta-analysis estimated that 5.7% of all fishing nets are lost to the marine environment annually [4]. Even after being discarded, these nets continue to harm marine organisms through a process known as “ghost fishing,” wherein entanglement leads to injury and mortality [5].

Fishing nets are predominantly manufactured from nylon (polyamides). Nylon, a semi-crystalline thermoplastic, is highly valued for its thermal stability, mechanical strength, abrasion resistance, and durability. These properties make it a preferred material not only for marine applications but also for advanced uses in the automotive industry [6].

In automotive manufacturing, the adoption of lightweight polymer materials has been driven by the need to reduce fuel consumption and minimize the carbon footprint of vehicles [7]. This trend is further supported by global regulatory frameworks. In the European Union, Regulation EU 2019/631 mandates that all new passenger cars achieve emissions of less than 49.5 g CO₂/km by 2030 [8]. Similarly, the United States Environmental Protection Agency (EPA) has set a target for new passenger cars to emit less than 73 g/mile of CO₂ by Model Year 2032 [9].

The automotive industry utilizes approximately 35% of all polyamide materials [10], with polyamide 6 (PA6) and polyamide 66 (PA66) being the most widely used. PA6 is commonly found in components like door handles, mirrors, fuel caps, wheel covers, gears, and bearings, while PA66 is often employed in under-the-hood applications including gears and leaf springs [6]. Both PA6 and PA66 are often reinforced, most notably with glass fibers or carbon fibers, to increase rigidity, enhance mechanical properties, and reduce overall weight [11,12,13,14]. Güler et al. [15] used a PA66 glass-fiber reinforced composite to manufacture an automobile hinge component and found that it satisfies the optimal dimensions of the component and reduces the weight of the component. Ishikawa et al. [16] used carbon-fiber reinforced PA6 composite to manufacture a chassis of a vehicle originally made of aluminum alloy.

Despite the many advantages of glass fibers in composite applications, their production is highly energy-intensive and relies heavily on fossil fuels [17]. Life cycle assessments reveal that manufacturing glass fibers can demand five to ten times more non-renewable energy than producing natural fibers [18,19]. Natural fibers are also less dense and often more cost-effective, providing additional benefits such as weight reduction [20]. However, incorporating these fibers into polyamides poses a challenge because the high melting temperatures of polymers like PA6 and PA66 can degrade the fibers, ultimately diminishing the composite’s mechanical properties [21].

Recycling polyamide 6 (PA6) from end-of-life fishing nets has gained increasing attention due to its potential to reduce plastic waste and provide a sustainable alternative to virgin polymers. Studies have demonstrated that recycled PA6 can retain rheological and mechanical properties comparable to those of virgin material, making it a viable option for high-performance applications [22]. To enhance the mechanical performance of recycled PA6, researchers have explored its reinforcement with both synthetic and natural fibers. For instance, carbon fiber reinforcement at 15 wt% has been shown to improve tensile modulus and impact toughness in PA6 composites [23]. Similarly, natural fiber reinforcements have been investigated as sustainable alternatives to synthetic fibers. Abdullah et al. [24] reported that kenaf fiber reinforcement in PA6 increased both storage and tensile moduli at a 10 wt% fiber loading due to enhanced stiffness. Moreover, Erbas Kiziltas et al. [25] demonstrated that hemp, flax, and kenaf fibers significantly improved the storage modulus of PA6, with a maximum increase of 68% at 20 wt% fiber loading.

Among the natural fibers of interest is switchgrass (Panicum virgatum L.), a warm-season grass native to North America and Mexico, known for thriving in poor soils and unfavorable conditions and reaching heights of up to 366 cm [26]. Switchgrass fibers stand out for their low cost, good quality, and sustainability, making them a promising reinforcement in polymer matrices [27]. As demonstrated by Van den Oever et al. [28], reinforcing polypropylene with 30 wt% switchgrass fibers yielded a 2.5-fold increase in flexural modulus. However, to our knowledge, no published studies have focused on using switchgrass fibers to reinforce PA6.

Simultaneously, the automotive sector has increasingly turned to recycled materials for more sustainable manufacturing. For instance, in 2021, Ford announced that its Bronco Sport features components made from 100% recycled ocean plastic [29], and in 2022, BMW announced the use of discarded fishing nets in both visible and non-visible interior and exterior trim pieces for its Neue Klasse electric car series, aiming for the recycled material to constitute 30% of the total material content by 2025 [30]. Similarly, Mercedes-Benz has incorporated recycled fishing nets into the production of floor coverings for its EQS electric vehicle [31]. Yet, no published investigations have explored composites composed solely of natural fibers and a 100% recycled fishing net matrix for automotive applications.

To address this research gap, this study investigates the mechanical and thermal properties of switchgrass fiber-reinforced composites fabricated from 100% recycled nylon fishing nets. By evaluating their mechanical behavior against commercial PA6 grades used in the automotive sector, this study aims to establish a more sustainable alternative to conventional PA6 composites. The following sections describe the materials and methods used for composite fabrication, the mechanical and thermal characterization techniques, and the results comparing the developed composites to commercially available PA6 materials.

2. Results

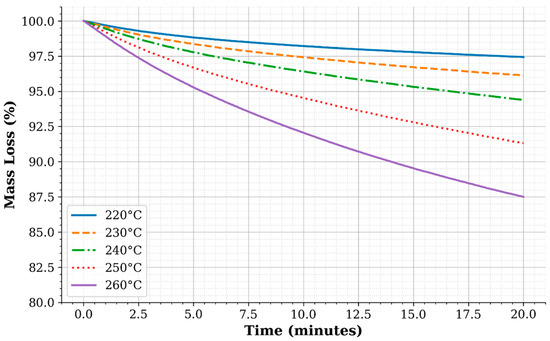

2.1. Isothermal TGA

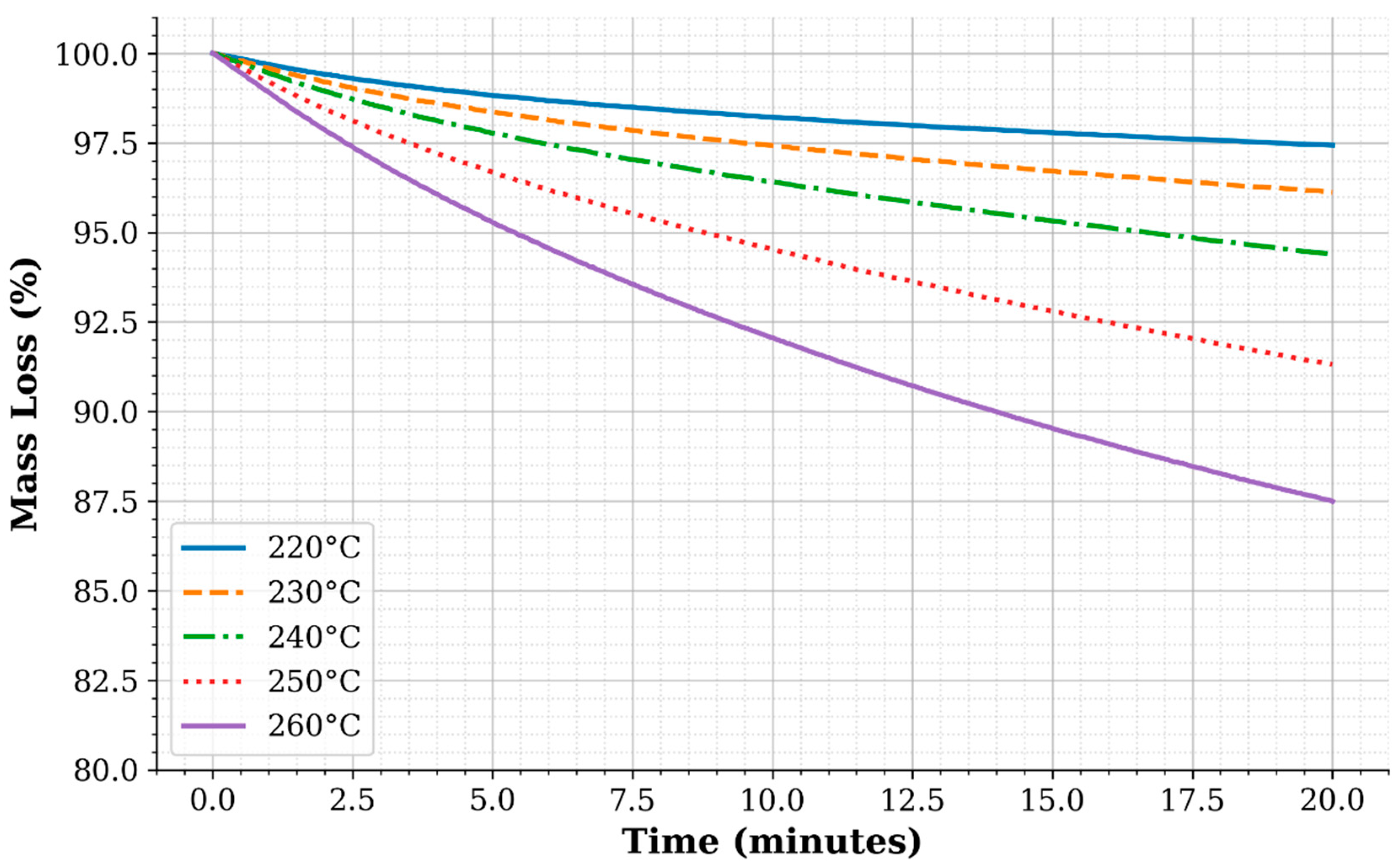

Figure 1 illustrates the isothermal thermogravimetric analysis (TGA) of switchgrass fibers at various temperatures. The results indicate that the degradation kinetics increase with temperature, as evidenced by the higher rate of mass loss observed between 260 °C and 250 °C compared to that between 250 °C and 240 °C. This behavior contrasts with the findings of Liang et al. [32], who reported a reduction in degradation kinetics for flax fibers under similar conditions. The observed increase in degradation kinetics for switchgrass fibers can be attributed to the thermal degradation of their structural components at higher temperatures. This degradation weakens the integrity of the cell wall, resulting in greater mass loss [33]. Notably, when compared to bark fibers, switchgrass fibers exhibit greater thermal stability. Gao et al. [34] reported a 23.3% mass loss at 260 °C after 20 min for bark fibers, whereas under the same conditions, our isothermal TGA measurements showed only a 12.5% mass loss for switchgrass.

Figure 1.

Isothermal TGA of switchgrass fibers at various temperatures.

Natural fibers are composed of three primary components: cellulose, hemicellulose, and lignin. Cellulose exhibits thermal stability and degrades predominantly between 300 °C and 375 °C. Hemicellulose, being the most heat-sensitive component, decomposes in the range of 200 °C to 275 °C. Lignin begins to degrade at approximately 200 °C but persists as the last component to decompose, with degradation extending up to around 500 °C [35,36]. The decomposition of hemicellulose and lignin disrupts the fibril network within the fiber, compromising its structural integrity. This degradation adversely impacts the mechanical properties of the fibers, subsequently reducing the mechanical performance of composite materials reinforced with switchgrass fibers [21]. Given that the switchgrass fibers remain in the extruder and injection molding machine for 3–5 min for each composite formulation, the mass loss is expected to remain below 5%. Therefore, although some thermal degradation of the natural fibers may occur during processing, it is unlikely to significantly compromise the fiber–matrix interface or the overall mechanical properties of the resulting composites.

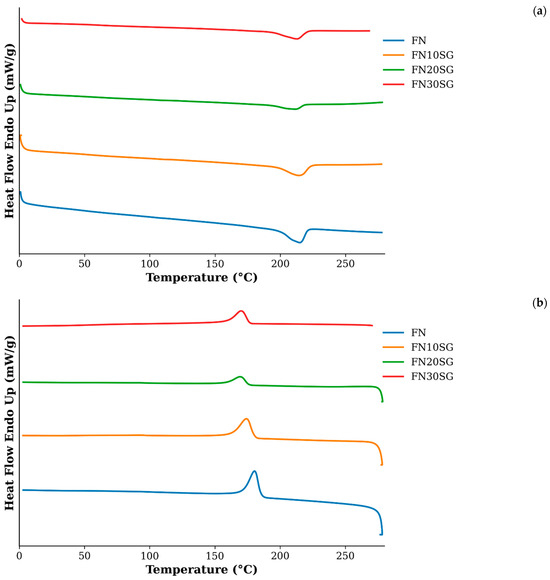

2.2. DSC

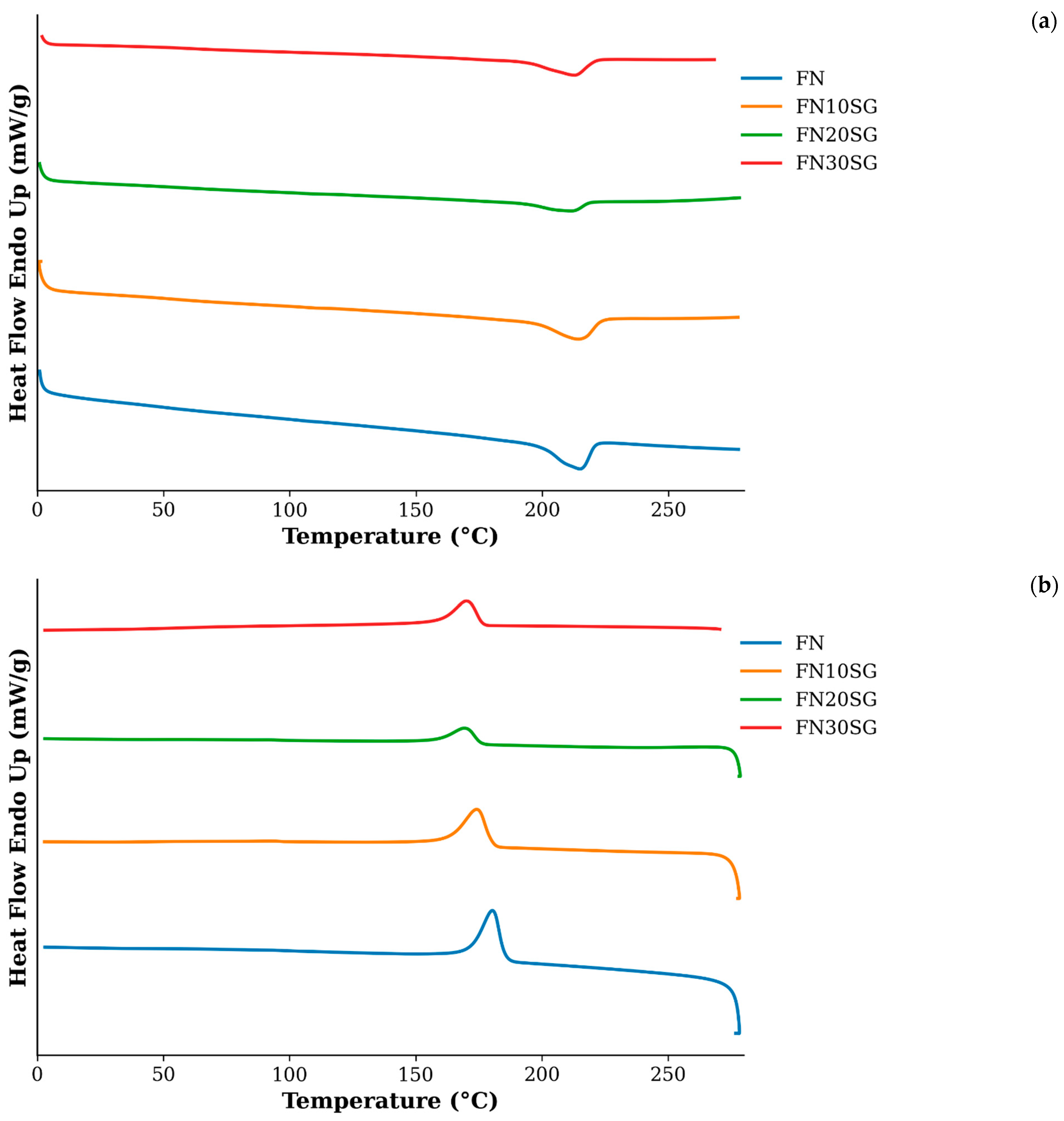

Figure 2 and Table 1 illustrate the DSC curves and thermal analysis data for the four formulations. The material exhibits a broad melting endotherm ranging from 197 °C to 225 °C, indicative of the presence of both α and γ crystalline forms of PA6. The α-form, being thermodynamically stable, melts at approximately 220 °C, while the γ-form, which is thermodynamically metastable, melts around 214 °C [37]. For FN, the γ-form appears as a distinct shoulder in the DSC curve; however, this shoulder becomes less pronounced as the content of switchgrass fibers increases.

Figure 2.

(a) DSC Heating curves of the formulations; (b) DSC Cooling curves of the formulations.

Table 1.

Melting enthalpy (ΔHm,PA6), degree of crystallinity (XPA6), melting temperature (Tm,PA6), and crystallization temperature (Tc,PA6) for PA6 of the four formulations.

A minor reduction in melting temperature (Tm) was observed upon incorporating switchgrass (SG) fibers into the polymer matrix. However, the absence of a clear correlation between fiber content and Tm suggests that this decrease is negligible and more likely attributable to experimental variation rather than any intrinsic influence of the fibers on PA6’s thermal behavior. This finding aligns with the work of Abdullah et al. [38] who reported no effect of wood flour on PA6’s melting temperature.

Notably, the crystallization temperature showed a consistent decrease with increasing switchgrass fiber content in the composite. This trend indicates that, rather than acting as heterogeneous nucleating agents, the switchgrass fibers impeded the crystallization process, resulting in delayed crystallization and consequently lower crystallization temperatures. This result is in accordance with Huang et al. (2017) [39] who showed in their study that increasing straw fibers decreased the crystallization temperature of PA6. Furthermore, the enthalpy of melting (ΔHm) decreased significantly from 51 J/g for neat PA6 to 24 J/g for composites containing 20% and 30% switchgrass fibers. This reduction was also reflected in the degree of crystallinity (X) of the PA6 matrix, which decreased from 26.84% for the neat polymer to 15.79% for FN20SF, which is due to fibers restricting the mobility of PA6 chains, which impairs the ability of polymer chains to arrange into ordered crystalline structures, and the disruption of crystal growth [40]. Interestingly, FN30SF exhibited a slight increase in crystallinity to 18.04%. This unexpected behavior may be attributed to the high fiber content creating confined spaces between fibers, where restricted polymer chain movement could lead to localized crystallization, thereby increasing the overall crystallinity of the polymer matrix.

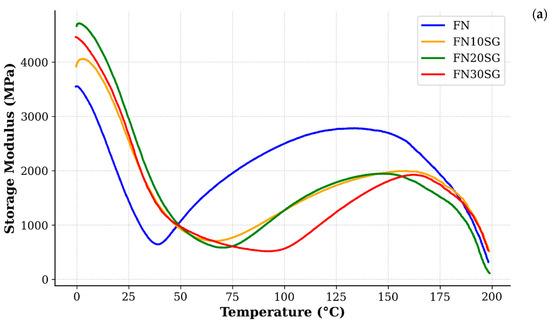

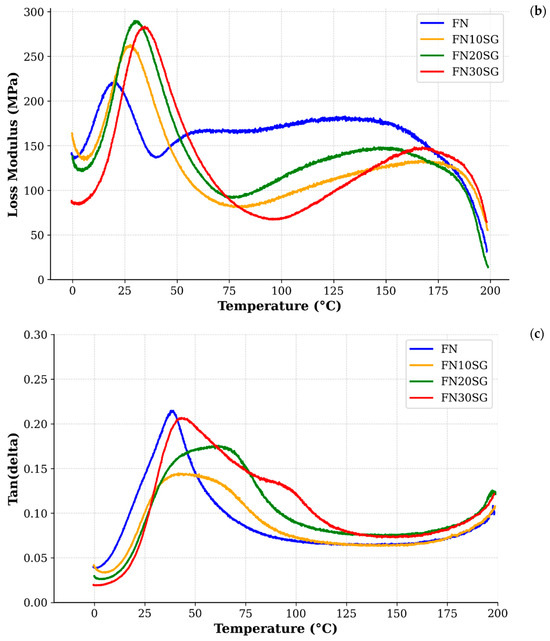

2.3. Dynamic Mechanical Analysis

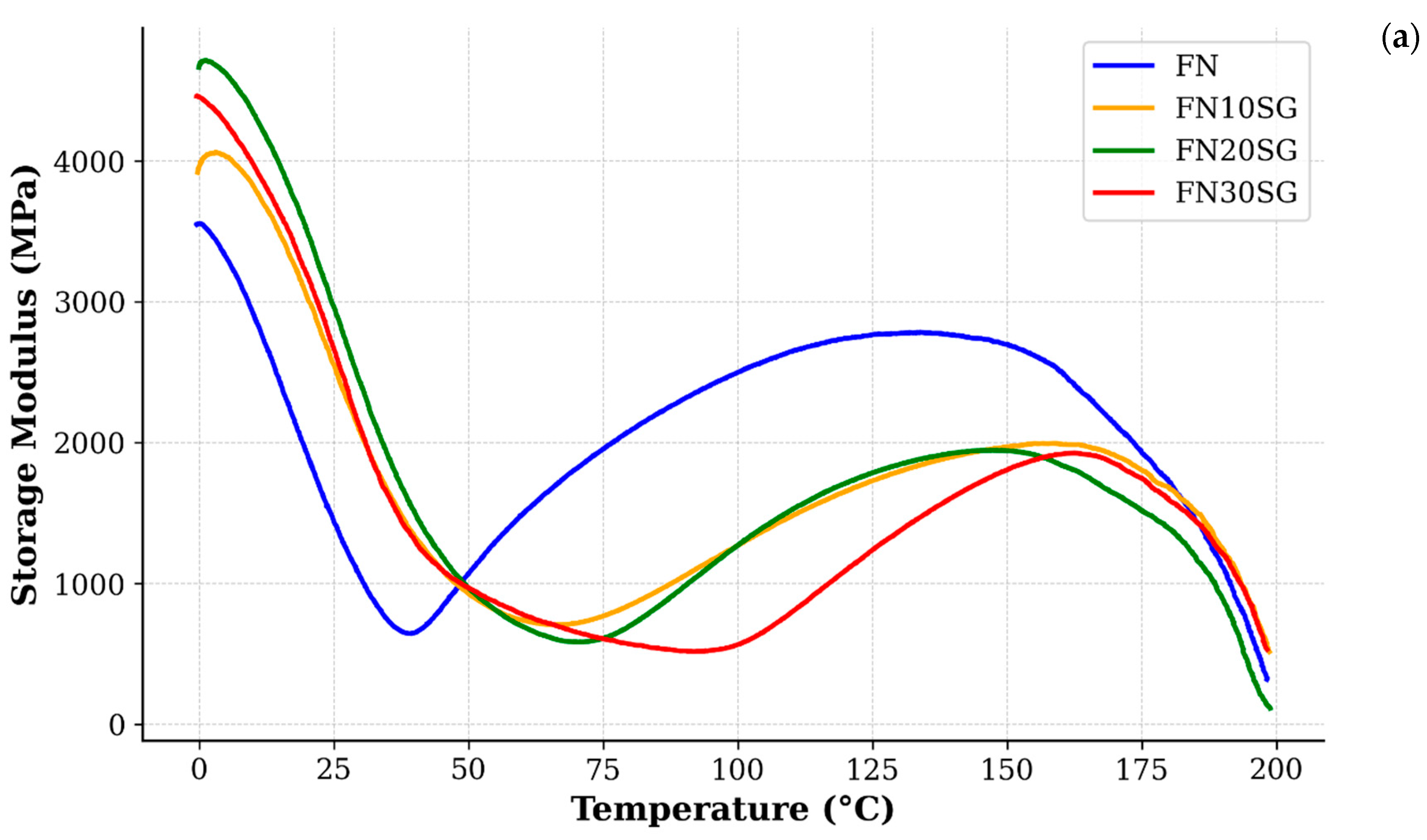

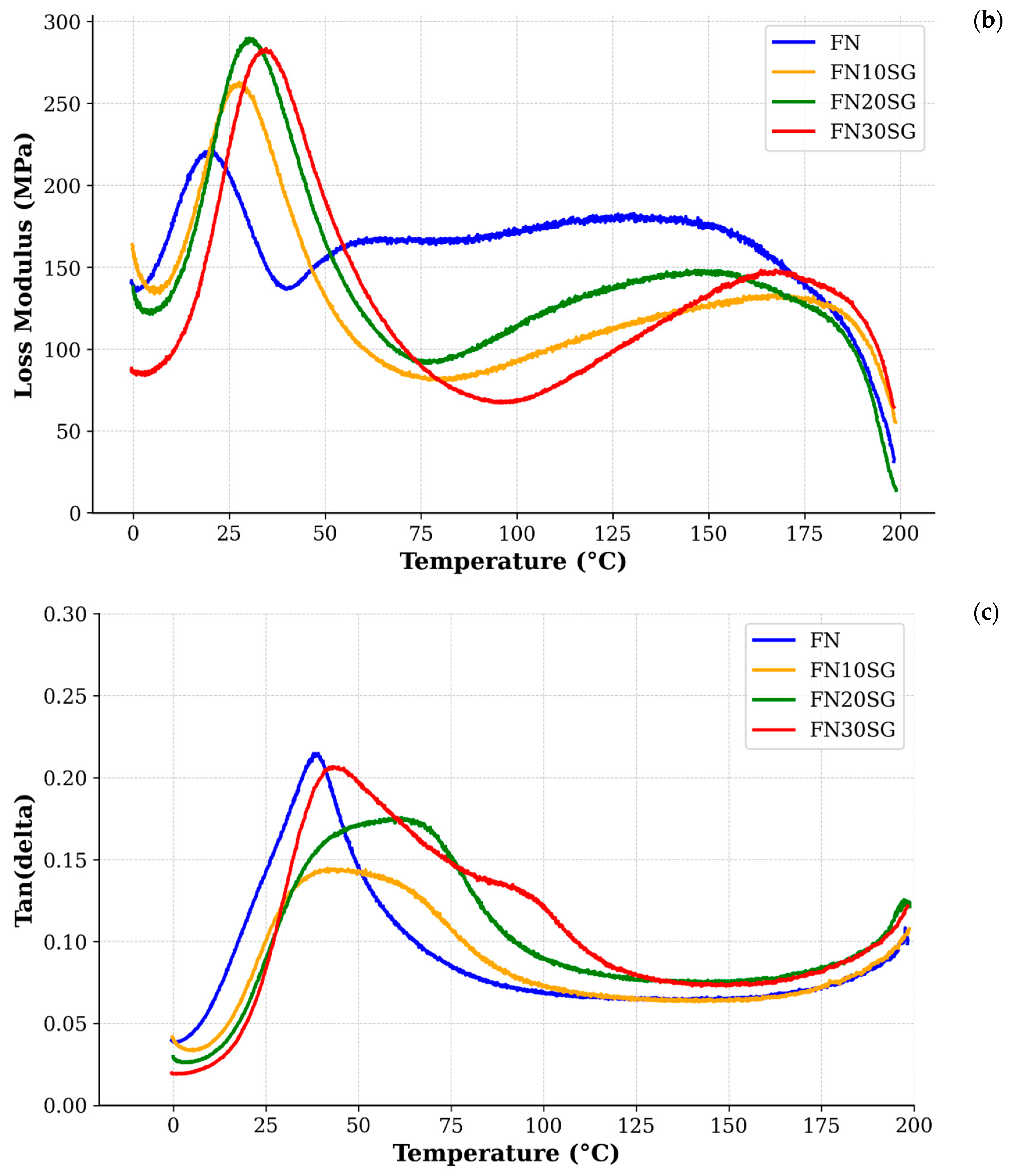

Figure 3 presents the dynamic mechanical analysis (DMA) results for the composites. The storage modulus of all formulations exhibits a marked decrease with rising temperature, with the most pronounced decline occurring between 25°C and 60 °C. This region corresponds to the glass transition temperature (T) of PA6 [41], after which it sharply increases above T. This behavior is attributed to the cold-crystallization phenomenon, where polymer chains, initially quenched into a highly disordered state, gain mobility upon heating above T, allowing them to reorganize into crystallites [42]. This reorganization leads to increased stiffness, as reflected by the sharp rise in the modulus. This phenomenon was observed by Cristea et al. [43] for PLA and by Codou et al. [44] for PET.

Figure 3.

(a) Storage modulus of the formulations; (b) Loss modulus of the formulations; (c) Tan (δ) of the formulations.

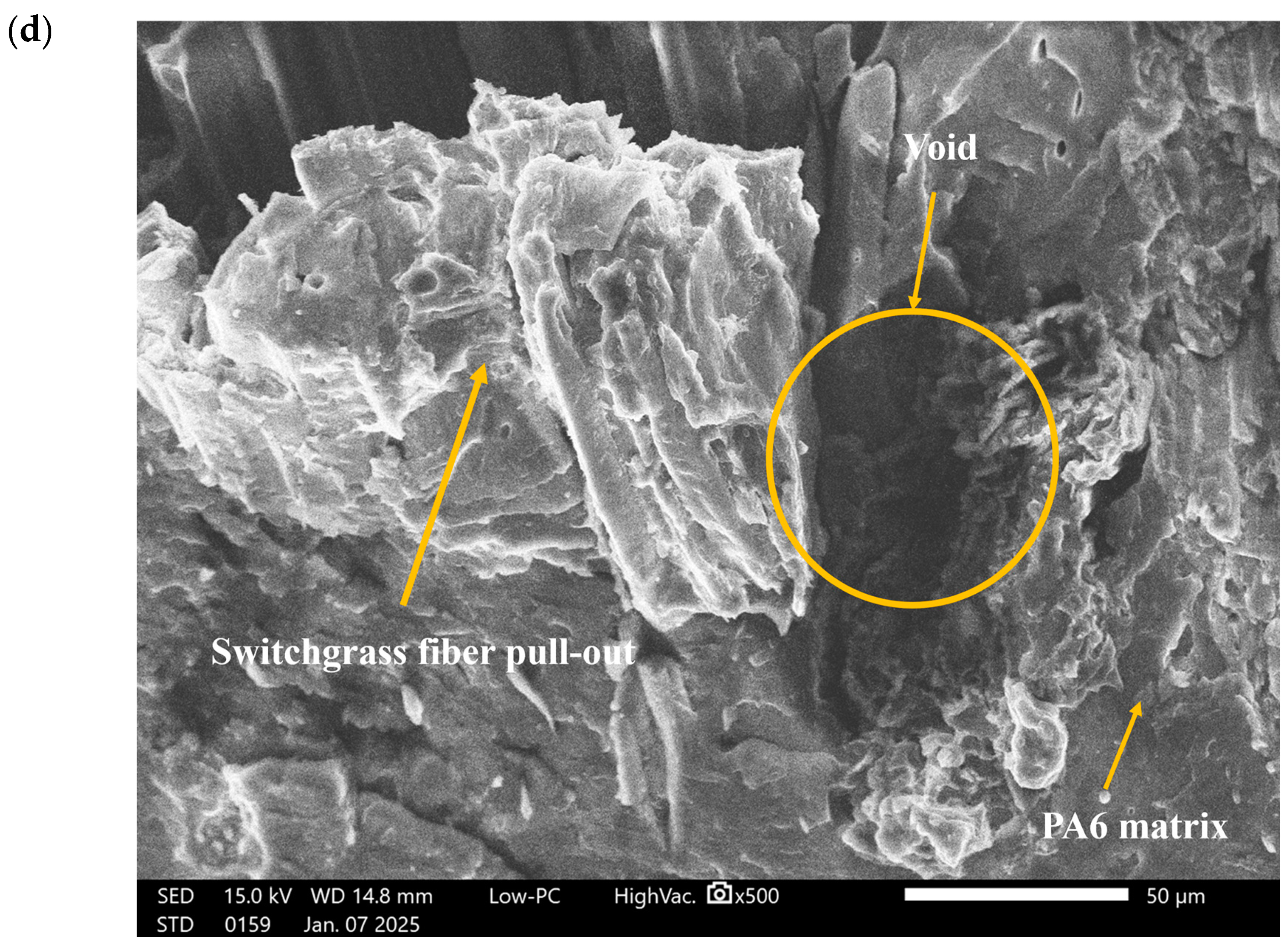

However, the addition of switchgrass fibers reduces this stiffness increase above T. At 130 °C, the FN30SG formulation exhibits a storage modulus 47% lower than that of FN, likely due to the fibers hindering the polymer’s crystallization process, resulting in fewer crystallites and subsequently lower stiffness. Below T, the storage modulus increases with the addition of switchgrass fibers. This enhancement in stiffness is attributed to the reinforcing effect of the fibers, which improve stress transfer at the interface with the polymer matrix. Notably, the FN20SG composite, containing 20% switchgrass fibers, exhibits the most significant increase in storage modulus—a 31% improvement compared to the FN formulation. In contrast, the FN30SG composite, with a higher fiber content of 30%, shows a smaller increase of 25.5% relative to FN. Despite the additional reinforcing fibers, the expected proportional improvement in stiffness is not observed. This discrepancy is likely due to the formation of fiber aggregates at higher loadings, which create weak points in the composite, leading to poor interfacial bonding and reduced efficiency in stress transfer [45].

A similar trend is observed with the loss modulus. The peak value increases when fibers are added to the polymer, which is attributable to the fibers restricting the motion of the polymer chain segments [46,47]. The decreased peak for FN30SG compared to FN20SG may result from poor interfacial bonding, leading to less restriction of the molecular mobility of the polymer chains. This causes lower frictional resistance and, consequently, reduced energy dissipation, which decreases the height of the E′′ peak [46,47]. Additionally, the loss modulus peak broadens with the increase of switchgrass fibers, which could be due to an inhibition of the relaxation processes within the composites. This effect arises from the restricted mobility of chain segments upon filler addition, leading to a wider distribution of relaxation times [48]. The glass transition temperature (T), identified from the temperature at the maximum loss modulus peak, increases with higher fiber content, rising from 16.9 °C for FN to 30.8 °C for FN30SG. This increase is attributed to the restricted molecular mobility of polymer chains due to the presence of fibers, requiring a higher temperature for the transition to the rubbery state [49].

The analysis of tan(δ) revealed that fiber incorporation reduced peak heights across all composites, as fibers restricted the movement of polymer chains. Interestingly, the composite with the lowest fiber content (FN10SG) showed the greatest reduction in peak height. This can be attributed to enhanced fiber-matrix interfacial bonding at lower fiber concentrations, which more effectively hinders polymer chain mobility, leading to reduced molecular motion and consequently lower damping properties [50]. At higher fiber loadings, the increased viscosity of the composite impedes the flow of the polymer matrix, preventing it from fully encapsulating the fibers. This could result in the formation of voids and microcracks, which serve as localized sites of molecular mobility and energy dissipation, ultimately increasing the tan(δ) peak.

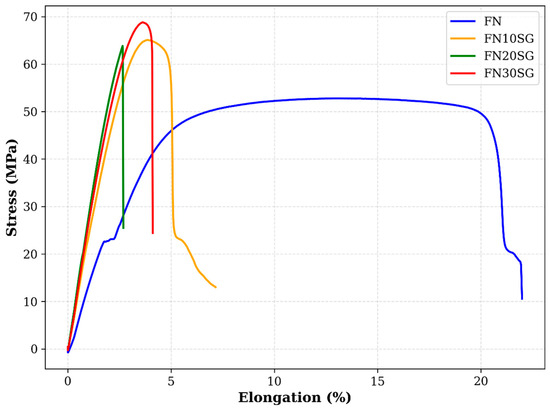

2.4. Tensile Tests

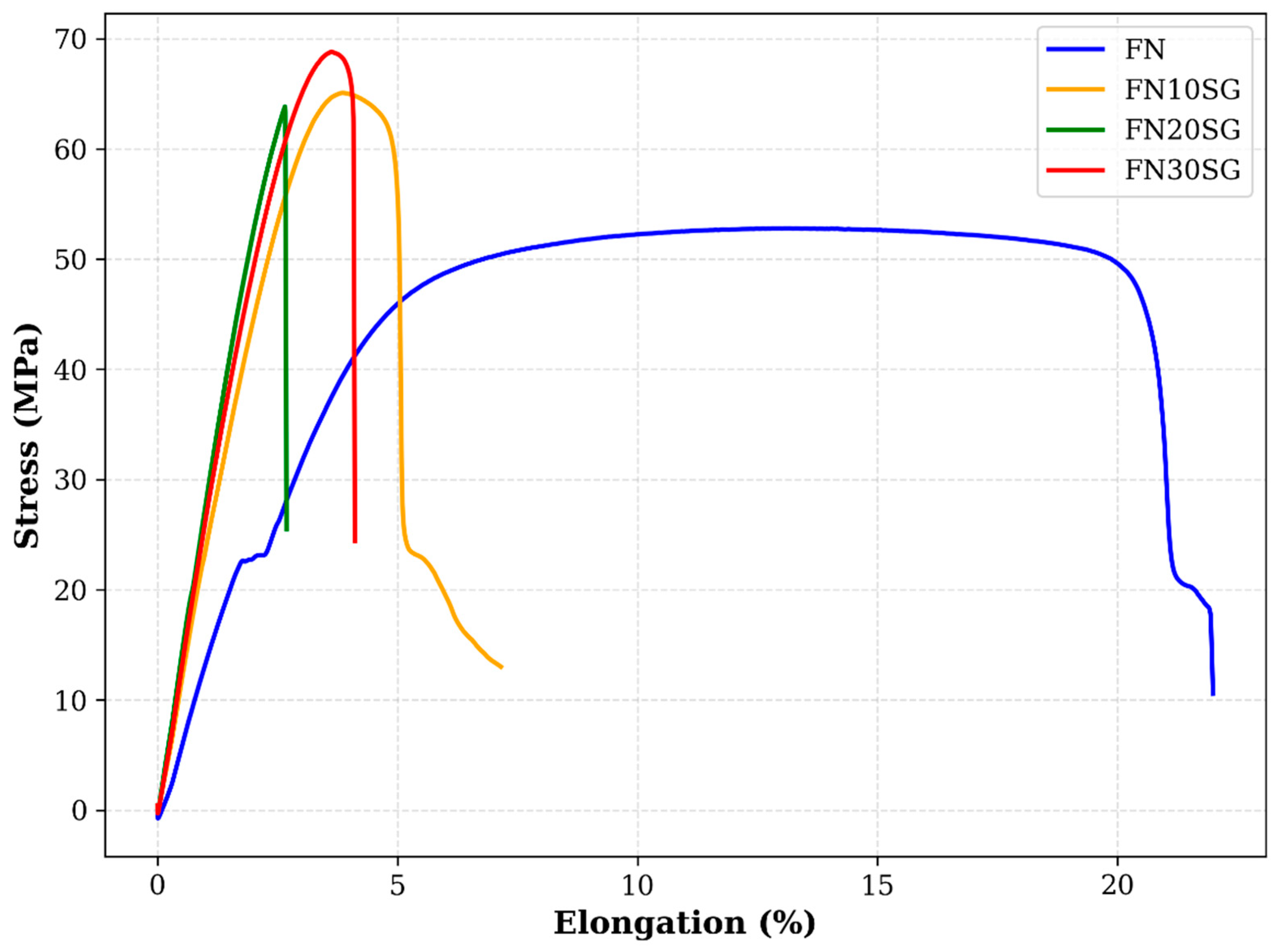

The tensile test results are illustrated in Figure 4. The baseline FN formulation demonstrated an average tensile strength of 54.58 MPa. Upon incorporating switchgrass fibers into the composite formulations, the tensile strength remained relatively steady up until the FN30SG composition. At this 30% switchgrass fiber loading, a notable increase in tensile strength was observed, reaching 67.22 MPa. This observed increase may be attributed to the higher degree of crystallinity indicated by the DSC results for this formulation. A more pronounced enhancement was observed in the tensile modulus. The FN material exhibited a tensile modulus of 1.09 GPa, which increased substantially to approximately 2.6 GPa in the FN20SG and FN30SG formulations. This significant increase is attributed to the strong interfacial adhesion between the fibers and the FN matrix, which facilitates efficient stress transfer and enhances stiffness. Interestingly, the modulus plateaued beyond 20% fiber content, suggesting that higher loadings may lead to fiber agglomeration. This agglomeration likely reduces the effective load transfer between fibers and the matrix due to localized poor adhesion, thereby limiting further stiffness increases [51].

Figure 4.

Stress-Strain curves of the formulations.

The incorporation of switchgrass fibers also resulted in a dramatic reduction in elongation at break. For FN10SG, a 92% decrease was observed compared to the neat FN formulation, primarily due to the restricted mobility of polymer chains imposed by the rigid fiber phase and the intrinsically low elongation of the switchgrass fibers relative to the polymer matrix [52]. An unexpected trend emerged in the FN30SG formulation, which exhibited the highest elongation at break among the composites. This behavior may be explained by the formation of fiber aggregates at higher loadings, leading to regions of poor dispersion that partially alleviate the restriction on polymer chain mobility.

These mechanical property trends align with previous studies on natural fiber-reinforced polyamide 6 composites. Panyasart et al. [53] reported similar behavior in composites reinforced with 40% pineapple leaf fibers, observing improvements of 10.11% and 77.57% in tensile strength and modulus, respectively, accompanied by an 89% reduction in elongation at break. Similarly, Alonso-Montemayor et al. [54] demonstrated that incorporating 30% bleached hemp fibers into polyamide 6 resulted in a 41% increase in tensile strength, a 98% enhancement in tensile modulus, and a 61% decrease in elongation at break.

The tensile properties of FN30SG were evaluated by comparing them to commercial polyamide 6 (PA6) grades commonly used in automotive applications (Table 2). The tensile strength of FN30SG was competitive, achieving 93.4% of Nylon 6 Unfilled Natural NXH-01 NC and surpassing ESTOPLAST XU150BB01 by 22.0%. However, it was 23.6% lower than Nylatron MC 907. Similarly, the Young’s modulus of FN30SG reached 79.4% of NXH-01 NC and 68.3% of Nylatron MC 907. In contrast, the elongation at break for FN30SG was significantly reduced, achieving only 6.9% of NXH-01 NC and 16.6% of Nylatron MC 907, though it reached 41.4% of ESTOPLAST XU150BB01. Despite this reduction in ductility, FN30SG’s combination of stiffness and tensile strength makes it suitable for automotive applications where flexibility is not critical, such as dashboard supports, overhead console frames, and seat bases.

Table 2.

Tensile properties of experimental PA6 composites and neat commercial PA6 grades used in automotive applications.

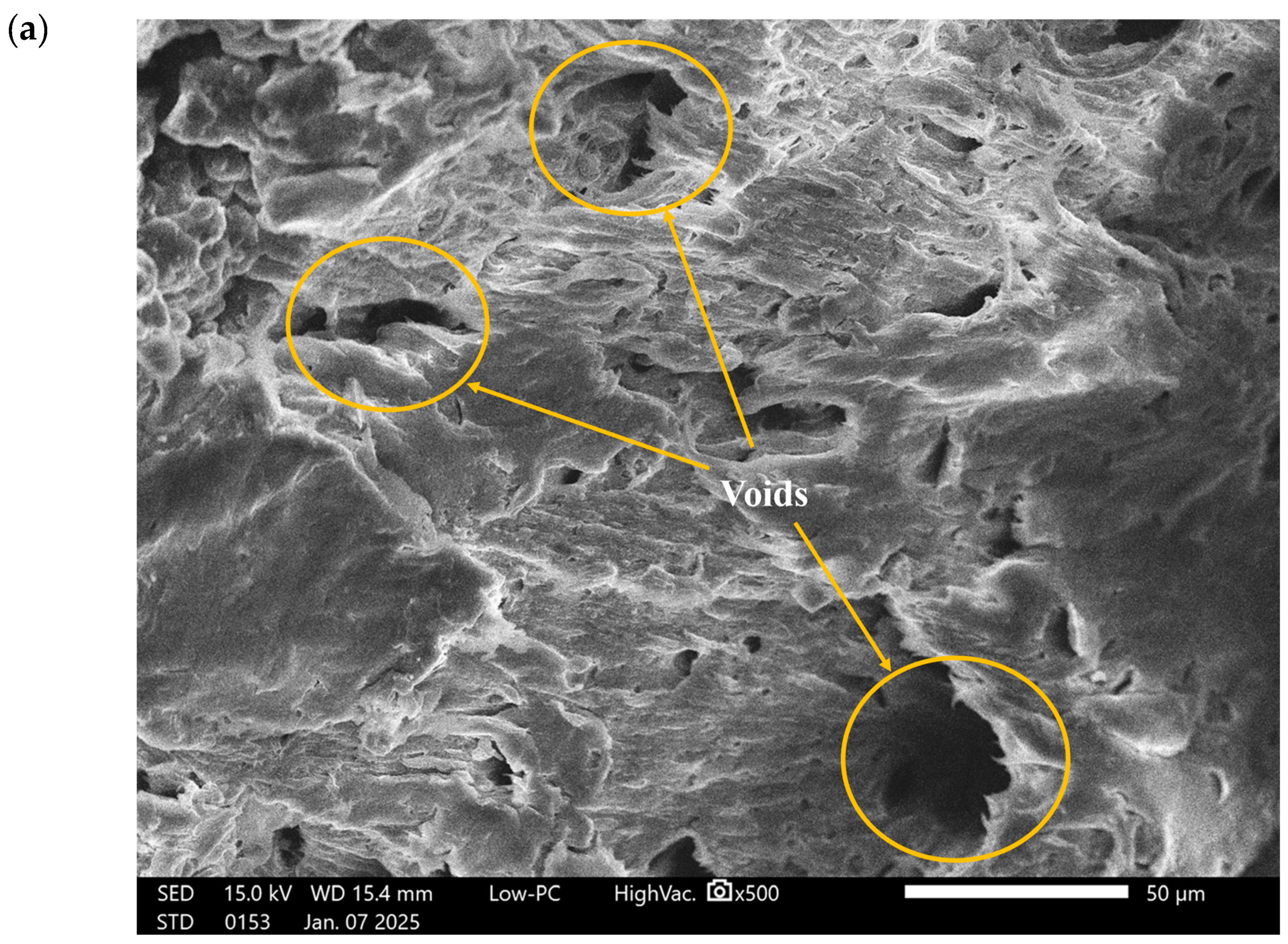

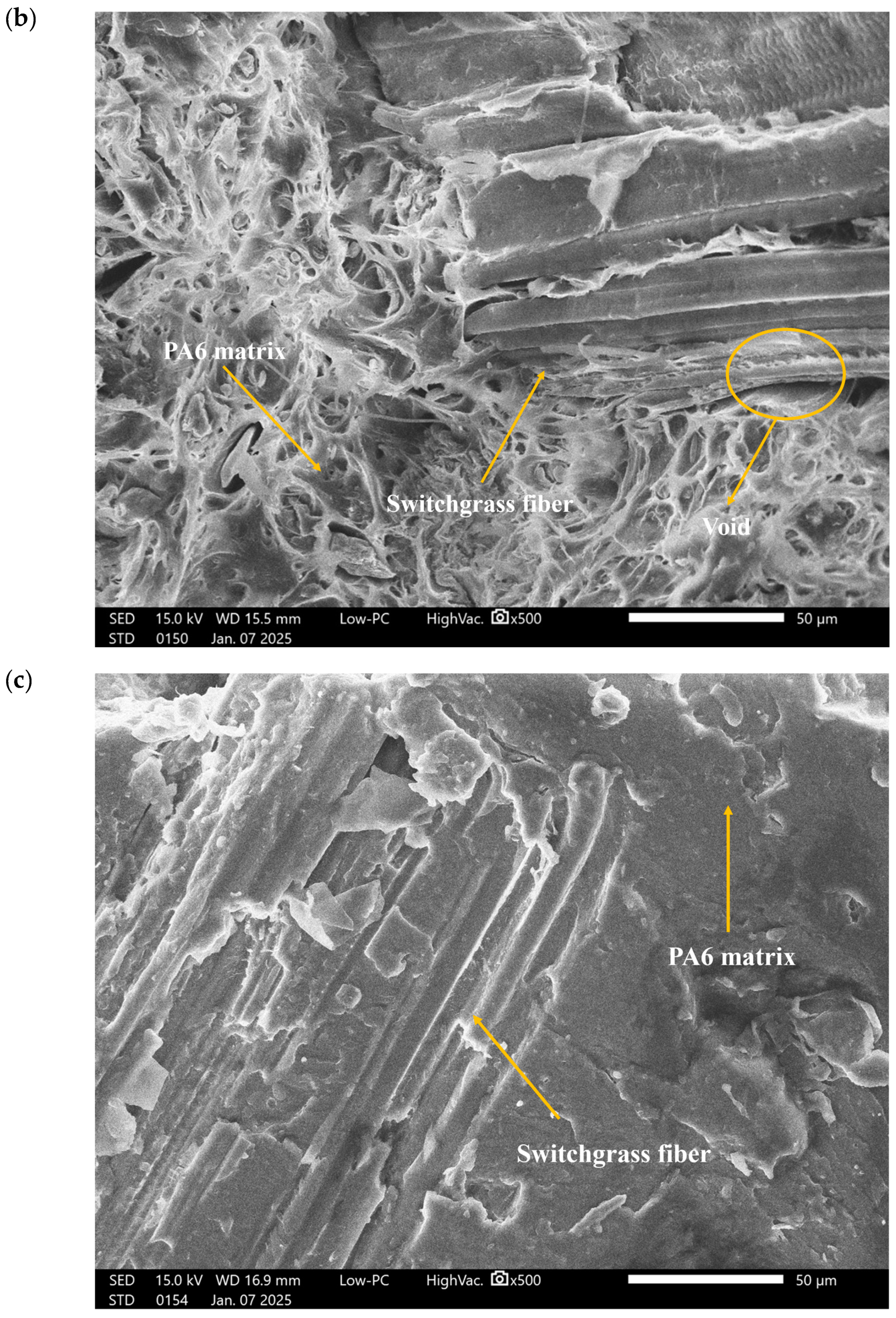

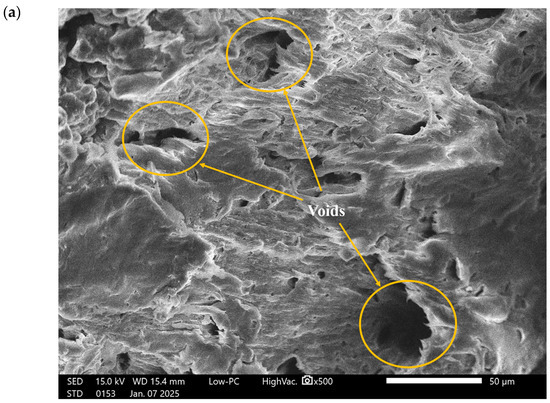

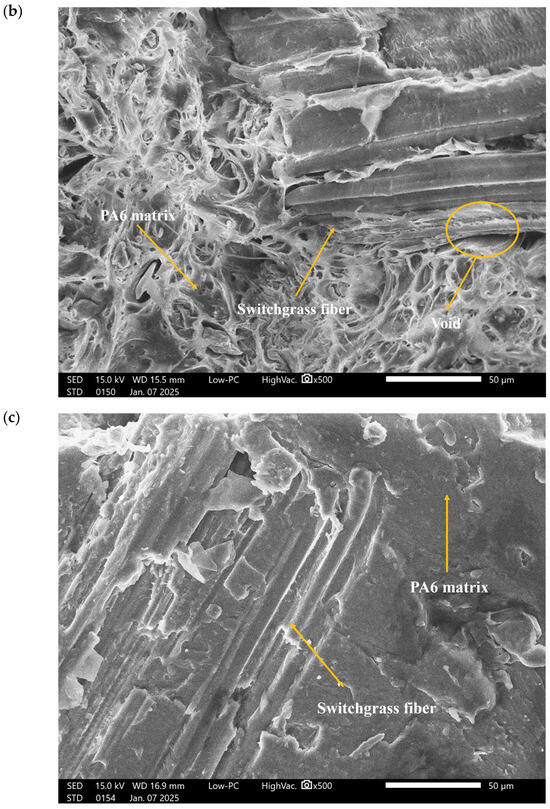

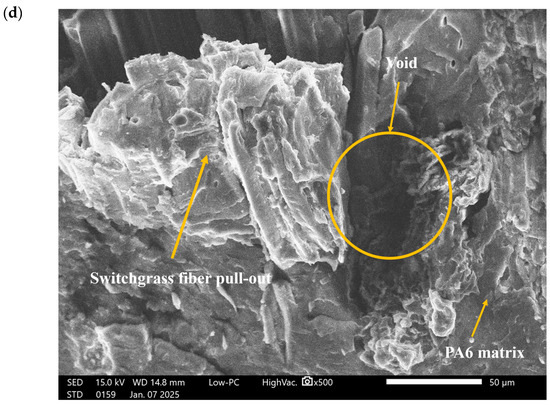

Figure 5 displays SEM micrographs (500× magnification) of the fracture surfaces for the four formulations. The fracture surface of FN exhibits an irregular and rough morphology with voids, indicating significant stretching prior to failure, which aligns with its high elongation at break observed in the tensile results. The composite formulations FN10SG and FN20SG show less surface stretching, consistent with their reduced elongation at break. The strong interfacial adhesion between the matrix and fibers, demonstrated by the absence of fiber pull-out and minimal voids, enhances stress transfer and is reflected in the notable increase in Young’s modulus for these formulations. Conversely, FN30SG shows evidence of weaker interfacial bonding, as indicated by fiber pull-out and increased voids at the interface. This reduced adhesion contributes to the plateau in Young’s modulus beyond 20% fiber content and the limited tensile strength improvement. The poorer interfacial quality might also explain the slightly higher elongation at break compared to FN20SG, as discussed earlier.

Figure 5.

SEM micrographs at 500× magnification of (a) FN; (b) FN10SG; (c) FN20SG; (d) FN30SG.

2.5. Melt Flow Rate

MFR has an inverse relationship with melt viscosity; higher MFR values suggest improved flow characteristics and lower viscosity when stress is applied. In automotive manufacturing, precise control over material flow is crucial due to the complex shapes of components [58]. The optimization of MFR is essential for achieving complete mold filling while maintaining the desired mechanical properties of the final parts.

The MFR data in Table 3 shows a significant decline as switchgrass fiber content in polyamide 6 increases. The MFR drops from 19.64 g/10 min for pure polyamide 6 (FN) to 8.63 g/10 min for the composite with 30% fiber (FN30SG). This drop is due to the rigid switchgrass fibers hindering the mobility of the nylon 6 chains, thereby increasing melt viscosity. A comparable finding was reported by Ozen et al. [59], who noted a 68% reduction in MFR for polyamide 6 composites containing a 20% fiber blend. However, the MFR seems to stabilize after a 20% fiber addition, with no notable decrease beyond this point. This suggests that at a fiber content of 30%, fiber aggregation may occur, potentially reducing the fibers’ ability to further restrict the polymer’s flow.

Table 3.

Melt Flow Rate (MFR) of Experimental and Commercial Fiber-Reinforced Polyamide Composites.

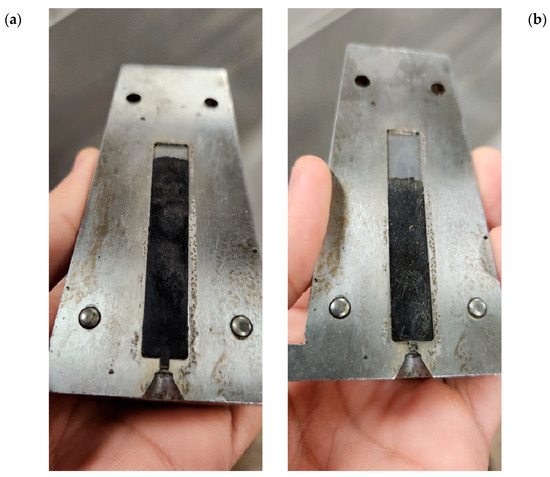

Mold-filling behavior demonstrated a clear correlation with fiber content (Figure 6). While neat polyamide 6 filled the mold readily, increasing fiber content progressively complicated the process. At 20% fiber content, successful filling occurred in half the trials, while at 30% loading, only one in four attempts succeeded. However, this challenge manifested differently across sample types—DMA specimens experienced filling difficulties, while tensile samples filled successfully in all trials, likely due to their greater thickness and consequently larger mold opening, which enhanced material flow despite increased fiber content. Testing was conducted using only those samples that were successfully molded.

Figure 6.

Incomplete mold filling observed for (a) FN20SG and (b) FN30SG.

Direct comparison with commercial PA6 composites was challenging due to differences in resin grades, fiber types (glass vs. switchgrass), and processing conditions, including variations in testing temperature, applied load, and testing standards (e.g., ASTM D1238 vs. ISO 1133 [64,65]) as shown in Table 3.

3. Materials and Methods

3.1. Materials

The fishing nets used in this study were sourced from discarded lobster cages in Îles-de-la-Madeleine (Quebec, QC, Canada), and collected with support from local fishermen and port authorities. The nets were manually removed by detaching securing rings and carefully cutting them away from the cage structures.

Switchgrass fibers were sourced from the Coopérative de solidarité Agroénergie de l’Est (Bas–Saint-Laurent, QC, Canada). The raw material was mechanically crushed and subsequently sieved to obtain a controlled particle size distribution of 0.85–1.75 mm. This specific size range was selected to minimize variability in fiber dimensions, thereby promoting more uniform mechanical properties in the resulting composites. The chemical composition of switchgrass is presented in the Table 4 [66].

Table 4.

Chemical composition of switchgrass fiber.

3.2. Preparation of Specimens

Initially, the fishing nets were cut into 1–2 cm pieces using scissors and extruded to form filaments, which were then pelletized into 2 mm pellets. These pellets, along with the switchgrass fibers, were dried in an oven at 80 °C for 8 h to remove moisture before blending according to the proportions specified in Table 5. This drying step is crucial because moisture has been shown to adversely affect the properties of the PA6 matrix [67].

Table 5.

Formulations by weight in percentage.

Subsequently, the blend underwent a second extrusion, after which the resulting material was processed using injection molding to produce specimens for characterization. The parameters for both the extrusion and injection molding processes are detailed in Table 6.

Table 6.

Extrusion and injection molding processes.

3.3. Characterization Techniques

3.3.1. Isothermal Thermogravimetric Analysis (TGA)

Isothermal TGA was performed to evaluate switchgrass fiber thermal degradation during processing. Five samples (10–15 mg) were maintained at constant temperatures (220–260 °C, 10 °C intervals) for 20 min under nitrogen atmosphere using a TGA 2000 instrument (Dupont, Wilmington, DE, USA). Prior to the isothermal hold, the temperature was ramped at 15 °C/min to reach the target temperature.

3.3.2. Differential Scanning Calorimetry (DSC)

DSC was used to investigate how switchgrass fiber content affects the crystallization and melting behavior of the polymer matrix using a DSC Q2000 instrument (TA Instruments, Newcastle, DE, USA). Approximately 15 mg samples were subjected to a thermal cycle, with three samples tested per formulation. This cycle included an initial heating from 0 °C to 280 °C, followed by a 1-min isothermal hold. Subsequently, the samples were cooled to 0 °C and then reheated to 280 °C, before a final cooling to 0 °C. A heating and cooling rate of 10 °C/min was used throughout these ramps. The first heating and cooling cycles were performed to eliminate any prior thermal history of the samples.

The degree of crystallinity of PA6 in the formulations was calculated using Equation (1):

where is the melting enthalpy of PA6, is the melting enthalpy of 100% crystalline PA6 which is equal to 230 J/g [68], and wPA6 is the weight fraction of PA6 in the formulation.

3.3.3. Dynamic Mechanical Analysis (DMA)

DMA was employed to study the effect of switchgrass fiber loading on the viscoelastic properties of the composites. The analysis was performed using a DMA Q850 instrument (TA Instruments, Newcastle, DE, USA) with a dual cantilever setup. Rectangular specimens measuring 60 × 10 × 1 mm were tested over a temperature range of 0 to 200 °C, with a heating rate of 2 °C/min and a constant frequency of 1 Hz. The storage modulus (E′), loss modulus (E″), and damping factor (tan δ) were monitored as functions of temperature. Three samples were tested for each formulation.

3.3.4. Tensile Tests

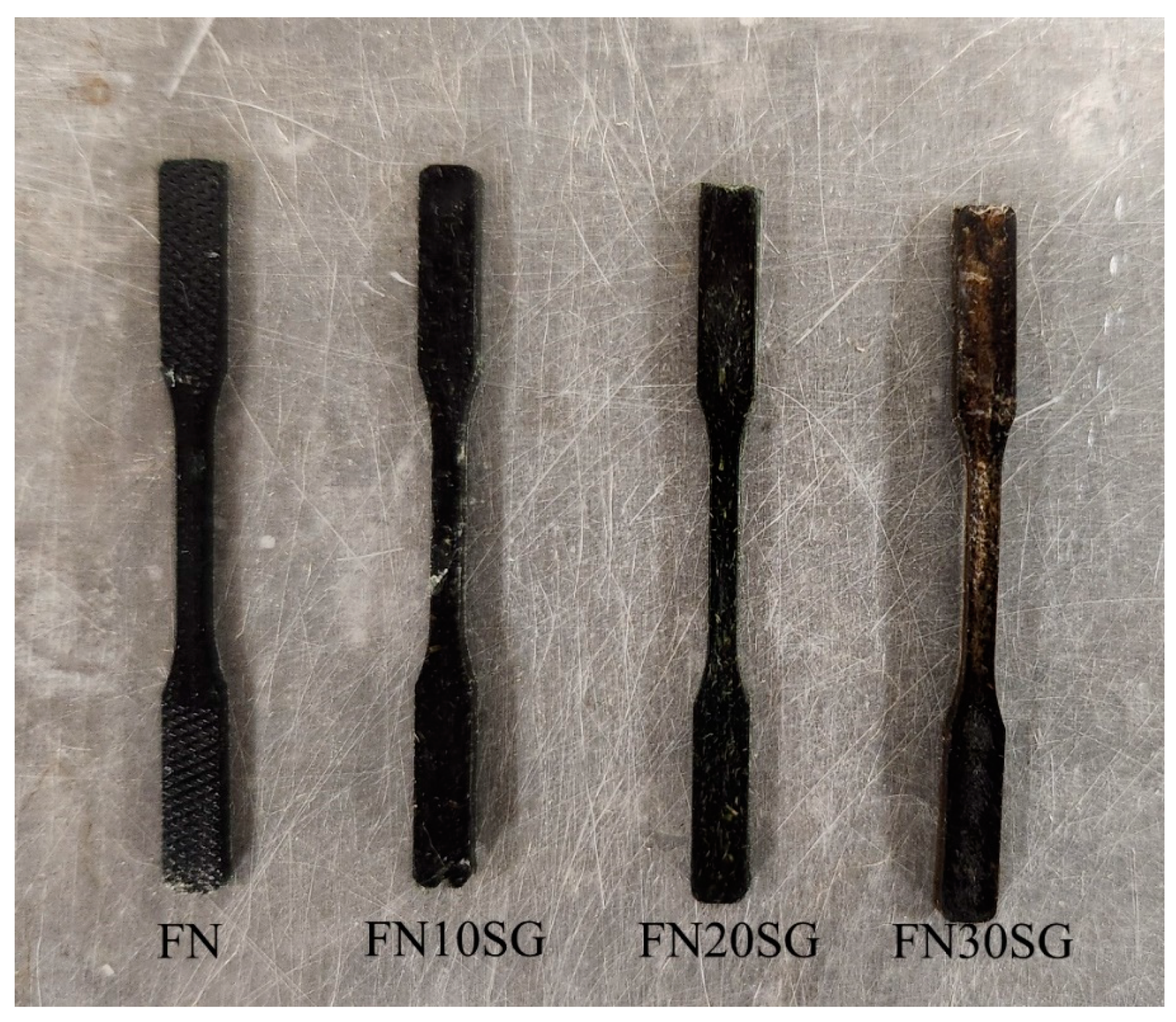

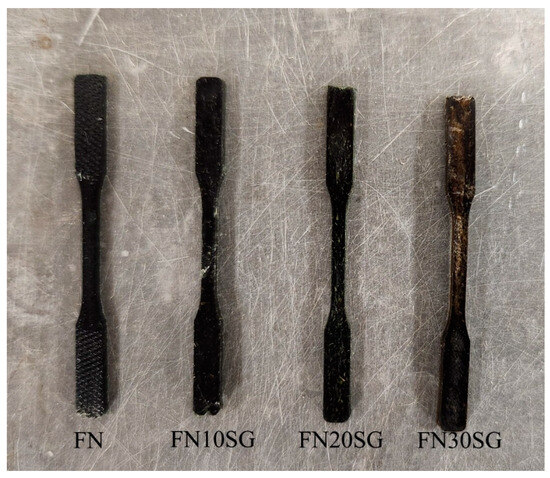

Tensile tests were conducted on the formulations using a Z050 universal testing machine (Zwick/Roell, Ulm, Badem-Wurttemberg, Germany) at a crosshead speed of 1.4 mm/min, following ISO 527-2 guidelines for 1BB specimens [69]. Five samples were tested for each formulation. The tests were performed at room temperature, and the Young’s modulus (E), tensile stress at break, and strain at break were determined from the resulting stress-strain curves. The samples corresponding to the four formulations are shown in Figure 7.

Figure 7.

Tensile samples according to ISO 527-2.

3.3.5. Scanning Electron Microscopy (SEM)

The fracture surface morphology of the tensile samples was analyzed using a JCM-7000 SEM (JEOL NeoScope, Easton, MD, USA) operating at 15 kV, with a magnification of 500×.

3.3.6. Melt Flow Rate (MFR)

The melt flow rate (MFR) measurements were conducted according to ASTM D1238-23 [64] using a Cflow plastometer (Zwick/Roell, Ulm, Badem-Wurttemberg, Germany). The tests were conducted at a temperature of 235 °C with a standard load of 2.16 kg. Three measurements were performed for each composition, and the results were averaged to obtain the final MFR value. The MFR was reported in grams per 10 min.

4. Conclusions

This study demonstrates the successful development of sustainable composites using recycled fishing net-derived PA6 reinforced with switchgrass fibers for automotive applications. Incorporating switchgrass fibers up to 30 wt% improves mechanical properties significantly. Compared to unreinforced PA6, the FN30SG composite shows a 23% rise in tensile strength and a 126% increase in Young’s modulus, making it competitive with commercial PA6 grades, especially for applications where stiffness is more critical than ductility.

Melt flow rate (MFR) measurements reveal a notable decrease in flow with higher fiber content, dropping from 19.35 g/10 min for neat PA6 to 8.63 g/10 min for FN30SG. This reduction in flow indicates increased melt viscosity, which can complicate processing due to reduced mold-filling efficiency. However, beyond 20 wt% fiber content, MFR values level off, suggesting that fiber aggregation may limit further viscosity increases.

Thermal analysis shows that switchgrass fibers affect the crystallization of PA6, as DSC results indicate lower crystallization temperatures and overall crystallinity at higher fiber loadings. DMA confirms that the storage modulus is enhanced below the matrix glass transition temperature. SEM images demonstrate strong fiber-matrix adhesion up to 20 wt% fiber, with some interfacial deterioration at 30 wt% loading. Alongside the plateau in mechanical properties and processing difficulties, these results suggest an optimal performance range of 20–30 wt% fiber.

Overall, recycled fishing net-derived PA6/switchgrass fiber composites offer a promising, more sustainable alternative to virgin PA6, particularly for automotive components needing high stiffness and moderate strength. Future work should focus on refining processing conditions and exploring surface treatments to further improve fiber-matrix adhesion at higher fiber content.

Author Contributions

Conceptualization, Z.B.; methodology, Z.B.; software, Z.B.; validation, Z.B.; formal analysis, Z.B.; investigation, Z.B.; resources, M.R. and Z.B.; data curation, Z.B.; writing—original draft preparation, Z.B.; writing—review and editing, M.R., P.C. and S.E.; visualization, Z.B.; supervision, M.R., P.C. and S.E.; project administration, M.R. and Z.B.; funding acquisition, M.R. and S.E. All authors have read and agreed to the published version of the manuscript.

Funding

Research was funded by MITACS, grant number IT39206.

Data Availability Statement

The original contributions of this study are included in the article. For further information, please contact the corresponding author.

Acknowledgments

The authors gratefully acknowledge the Rassemblement des Pêcheurs et Pêcheuses des Côtes des Îles (RPPCÎ) and the CERMIM for providing the fishing nets utilized in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Macfadyen, G.; Huntington, T.; Cappell, R. Abandoned, lost or otherwise discarded fishing gear. In UNEP Regional Seas Reports and Studies No. 185; FAO Fisheries and Aquaculture Technical Paper No. 523; UNEP/FAO: Rome, Italy, 2009; Available online: https://www.researchgate.net/publication/242491383_Abandoned_Lost_or_Otherwise_Discarded_Fishing_Gear (accessed on 3 June 2024).

- U.S. Commission on Ocean Policy. U.S. Ocean Action Plan: The Bush Administration’s Response to the U.S. Commission on Ocean Policy. 2004. Available online: https://www.ncei.noaa.gov/data/oceans/coris/library/NOAA/other/us_ocean_action_plan_2004.pdf (accessed on 31 December 2024).

- Lebreton, L.; Slat, B.; Ferrari, F.; Sainte-Rose, B.; Aitken, J.; Marthouse, R.; Hajbane, S.; Cunsolo, S.; Schwarz, A.; Levivier, A.; et al. Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci. Rep. 2018, 8, 4666. [Google Scholar] [CrossRef] [PubMed]

- Richardson, K.; Hardesty, B.D.; Wilcox, C. Estimates of fishing gear loss rates at a global scale: A literature review and meta-analysis. Fish Fish. 2019, 20, 1218–1231. [Google Scholar] [CrossRef]

- Breen, P.A. Report of the working group on ghost fishing. In Proceedings of the Second International Conference on Marine Debris, NOAA Technical Memorandum NMFS-TM-NMFS-SWFSC-154, Shomura, Honolulu, HI, USA, 2–7 April 1989; pp. 571–599. [Google Scholar]

- Kondo, M.Y.; Montagna, L.S.; Morgado, G.F.d.M.; de Castilho, A.L.G.; Batista, L.A.P.d.S.; Botelho, E.C.; Costa, M.L.; Passador, F.R.; Rezende, M.C.; Ribeiro, M.V. Recent advances in the use of Polyamide-based materials for the automotive industry. Polímeros 2022, 32, e2022023. [Google Scholar] [CrossRef]

- Nguyen-Tran, H.-D.; Hoang, V.-T.; Do, V.-T.; Chun, D.-M.; Yum, Y.-J. Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts. Materials 2018, 11, 429. [Google Scholar] [CrossRef] [PubMed]

- European Commission. CO2 Emission Performance Standards for Cars and Vans. Available online: https://climate.ec.europa.eu/eu-action/transport/road-transport-reducing-co2-emissions-vehicles/co2-emission-performance-standards-cars-and-vans_en?u (accessed on 31 December 2024).

- Multi-Pollutant Emissions Standards for Model Years 2027 and Later Light-Duty and Medium-Duty Vehicles. Available online: https://www.govinfo.gov/content/pkg/FR-2024-04-18/pdf/2024-06214.pdf (accessed on 31 December 2024).

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2022, 35, 1169–1209. [Google Scholar] [CrossRef]

- Uematsu, H.; Kawasaki, T.; Koizumi, K.; Yamaguchi, A.; Sugihara, S.; Yamane, M.; Kawabe, K.; Ozaki, Y.; Tanoue, S. Relationship between crystalline structure of polyamide 6 within carbon fibers and their mechanical properties studied using Micro-Raman spectroscopy. Polymer 2021, 223, 123711. [Google Scholar] [CrossRef]

- Zaldua, N.; Maiz, J.; de la Calle, A.; García-Arrieta, S.; Elizetxea, C.; Harismendy, I.; Tercjak, A.; Müller, A.J. Nucleation and Crystallization of PA6 Composites Prepared by T-RTM: Effects of Carbon and Glass Fiber Loading. Polymers 2019, 11, 1680. [Google Scholar] [CrossRef]

- Mosey, S.; Korkees, F.; Rees, A.; Llewelyn, G. Investigation into fibre orientation and weldline reduction of injection moulded short glass-fibre/polyamide 6-6 automotive components. J. Thermoplast. Compos. Mater. 2020, 33, 1603–1628. [Google Scholar] [CrossRef]

- Caputo, F.; Lamanna, G.; De Luca, A.; Armentani, E. Thermo-Mechanical Investigation on an Automotive Engine Encapsulation System Made of Fiberglass Reinforced Polyamide PA6 GF30 Material. Macromol. Symp. 2020, 389, 1900100. [Google Scholar] [CrossRef]

- Güler, T.; Demirci, E.; Yıldız, A.R.; Yavuz, U. Lightweight design of an automobile hinge component using glass fiber polyamide composites. Mater. Test. 2018, 60, 306–310. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Patel, M.; Bastioli, C.; Marini, L.; Würdinger, E. Life-cycle Assessment of Bio-based Polymers and Natural Fiber Composites. In Biopolymers Online; Steinbüchel, A., Ed.; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Laban, B.G.; Lundquist, L.; Leterrier, Y.; Månson, J.-A.E.; Jolliet, O. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Foulk, J.A.; Akin, D.E.; Dodd, R.B. New Low Cost Flax Fibers for Composites; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Thomason, J.L.; Rudeiros-Fernández, J.L. Thermal degradation behaviour of natural fibres at thermoplastic composite processing temperatures. Polym. Degrad Stab. 2021, 188, 109594. [Google Scholar] [CrossRef]

- Mondragon, G.; Kortaberria, G.; Mendiburu, E.; González, N.; Arbelaiz, A. Thermomechanical recycling of polyamide 6 from fishing nets waste. J. Appl. Polym.Sci. 2020, 137, 48442. [Google Scholar] [CrossRef]

- Pasciucco, F.; Rossi, D.; Maccaferri, E.; Pecorini, I.; Giorgini, L.; Seggiani, M. Recycling polyamide 6 fishing nets and carbon fibers for the development of novel sustainable composites: Properties and LCA process analysis. J. Clean. Prod. 2025, 486, 144634. [Google Scholar]

- Abdullah, N.; Abdan, K.; Roslim, M.H.M.; Radzuan, M.N.; Shafi, A.R.; Hao, L.C. Properties of kenaf fiber-reinforced polyamide 6 composites. e-Polymers 2024, 24, 20228112. [Google Scholar] [CrossRef]

- Kiziltas, E.E.; Yang, H.-S.; Kiziltas, A.; Boran, S.; Ozen, E.; Gardner, D.J. Thermal Analysis of Polyamide 6 Composites Filled by Natural Fiber Blend. BioResources 2016, 11, 4758–4769. [Google Scholar] [CrossRef]

- Falasca, S.; Pitta-Alvarez, S.; Del Fresno, C.M. Possibilities for Growing Switch-grass (Panicum virgatum) as Second Generation Energy Crop in Dry-subhumid, Semiarid and Arid Regions of the Argentina. J. Cent. Eur. Agric. 2017, 18, 95–116. [Google Scholar] [CrossRef]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Biocomposites From Switchgrass and Lignin Hybrid and Poly(butylene succinate) Bioplastic: Studies on Reactive Compatibilization and Performance Evaluation. Macromol. Mater. Eng. 2014, 299, 178–189. [Google Scholar] [CrossRef]

- van den Oever, M.J.A.; Elbersen, H.W.; Keijsers, E.R.P.; Gosselink, R.J.A.; de Klerk-Engels, B. Switchgrass (Panicum virgatum L.) as a reinforcing fibre in polypropylene composites. J. Mater. Sci. 2003, 38, 3697–3707. [Google Scholar] [CrossRef]

- Ford. Ford Bronco Sport Becomes First Vehicle to Feature Parts Made of 100% Recycled Ocean Plastic. Available online: https://media.ford.com/content/fordmedia/fna/us/en/news/2021/12/08/ford-bronco-sport-recycled-ocean-plastic.html (accessed on 24 January 2025).

- BMW. Recycled Fishing Nets for the Neue Klasse. Available online: https://www.bmwgroup.com/en/news/general/2022/recycled-plastics.html (accessed on 1 January 2025).

- Mercedes Benz. Innovative Materials for Sustainable Luxury. Available online: https://group.mercedes-benz.com/sustainability/resources-circularity/materials/sustainable-materials.html (accessed on 27 February 2025).

- Liang, S.; Nouri, H.; Lafranche, E. Thermo-compression forming of flax fibre-reinforced polyamide 6 composites: Influence of the fibre thermal degradation on mechanical properties. J. Mater. Sci. 2015, 50, 7660–7672. [Google Scholar] [CrossRef]

- Cui, J.; Fu, D.; Mi, L.; Li, L.; Liu, Y.; Wang, C.; He, C.; Zhang, H.; Chen, Y.; Wang, Q. Effects of Thermal Treatment on the Mechanical Properties of Bamboo Fiber Bundles. Materials 2023, 16, 1239. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Wang, X.-M.; Wan, H.; Brunette, G. Binderless panels made with black spruce bark. BioResources 2011, 6, 3960–3972. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of wood part 1. J. Anal. Appl. Pyrolysis 2006, 77, 28–34. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of wood part 2. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Klata, E.; Van de Velde, K.; Krucińska, I. DSC investigations of polyamide 6 in hybrid GF/PA 6 yarns and composites. Polym. Test. 2003, 22, 929–937. [Google Scholar] [CrossRef]

- Abdullah, N.; Abdan, K.; Lee, C.H.; Roslim, M.H.M.; Radzuan, M.N.; Shafi, A.R. Thermal properties of wood flour reinforced polyamide 6 biocomposites by twin screw extrusion. Phys. Sci. Rev. 2023, 8, 5153–5164. [Google Scholar] [CrossRef]

- Huang, Z.; Yin, Q.; Wang, Q.; Wang, P.; Liu, T.; Qian, L. Mechanical properties and crystallization behavior of three kinds of straws/nylon 6 composites. Int. J. Biol. Macromol. 2017, 103, 663–668. [Google Scholar] [CrossRef]

- Zhu, S.; Guo, Y.; Chen, Y.; Liu, S. Low Water Absorption, High-Strength Polyamide 6 Composites Blended with Sustainable Bamboo-Based Biochar. Nanomaterials 2020, 10, 1367. [Google Scholar] [CrossRef]

- Sambale, A.; Kurkowski, M.; Stommel, M. Determination of moisture gradients in polyamide 6 using StepScan DSC. Thermochim. Acta 2019, 672, 150–156. [Google Scholar]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, Mechanical and Thermal Properties of Polyphenylene Sulfide and Polysulfone Impregnated Carbon Fiber Composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef] [PubMed]

- Cristea, M.; Ionita, D.; Iftime, M.M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [Google Scholar] [CrossRef] [PubMed]

- Codou, A.; Moncel, M.; van Berkel, J.G.; Guigo, N.; Sbirrazzuoli, N. Glass transition dynamics and cooperativity length of poly(ethylene 2,5-furandicarboxylate) compared to poly(ethylene terephthalate). Phys. Chem. Chem. Phys. 2016, 18, 16647–16658. [Google Scholar]

- Mohammed, M.; Rasidi, M.; Mohammed, A.; Rahman, R.; Osman, A.; Adam, T.; Betar, B.; Dahham, O. Interfacial bonding mechanisms of natural fibre-matrix composites: An overview. BioResources 2022, 17, 7031–7090. [Google Scholar] [CrossRef]

- Bahlouli, S.; Belaadi, A.; Makhlouf, A.; Alshahrani, H.; Khan, M.K.A.; Jawaid, M. Effect of Fiber Loading on Thermal Properties of Cellulosic Washingtonia Reinforced HDPE Biocomposites. Polymers 2023, 15, 2910. [Google Scholar] [CrossRef]

- Sreenivasan, V.S.; Rajini, N.; Alavudeen, A.; Arumugaprabu, V. Dynamic mechanical and thermo-gravimetric analysis of Sansevieria cylindrica/polyester composite: Effect of fiber length, fiber loading and chemical treatment. Compos. B Eng. 2015, 69, 76–86. [Google Scholar] [CrossRef]

- Hameed, N.; Sreekumar, P.A.; Francis, B.; Yang, W.; Thomas, S. Morphology, dynamic mechanical and thermal studies on poly(styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2422–2432. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Neves, R.M.; Monticeli, F.M.; Thomas, S. Modeling of dynamic mechanical curves of kenaf/polyester composites using surface response methodology. J. Appl. Polym.Sci. 2022, 139, e52078. [Google Scholar]

- Tham, M.W.; Fazita, M.N.; Khalil, H.A.; Zuhudi, N.Z.M.; Jaafar, M.; Rizal, S.; Haafiz, M.M. Tensile properties prediction of natural fibre composites using rule of mixtures: A review. J. Reinf. Plast.Compos. 2019, 38, 211–248. [Google Scholar] [CrossRef]

- Bakar, N.; Chee, C.Y.; Abdullah, L.C.; Ratnam, C.T.; Azowa, N. Effect of methyl methacrylate grafted kenaf on mechanical properties of polyvinyl chloride/ethylene vinyl acetate composites. Compos. Part A Appl. Sci. Manuf. 2014, 63, 45–50. [Google Scholar] [CrossRef]

- Panyasart, K.; Chaiyut, N.; Amornsakchai, T.; Santawitee, O. Effect of Surface Treatment on the Properties of Pineapple Leaf Fibers Reinforced Polyamide 6 Composites. Energy Procedia 2014, 56, 406–413. [Google Scholar] [CrossRef]

- Alonso-Montemayor, F.J.; Tarrés, Q.; Oliver-Ortega, H.; Espinach, F.X.; Narro-Céspedes, R.I.; Castañeda-Facio, A.O.; Delgado-Aguilar, M. Enhancing the Mechanical Performance of Bleached Hemp Fibers Reinforced Polyamide 6 Composites: A Competitive Alternative to Commodity Composites. Polymers 2020, 12, 1041. [Google Scholar] [CrossRef]

- Mitsubishi Chemical Group. Nylatron MC 907/Ertalon 6 PLA PA6. Available online: https://www.mcam.com/mam/54356/GEP-Ertalon%E2%84%A2%206PLA%20PA6_en_US.pdf (accessed on 8 January 2025).

- Celanese Corporation. Nylon 6 Unfilled Natural NXH-01 NC. Available online: https://materials.ulprospector.com/en/document?e=235763 (accessed on 8 January 2025).

- Ester Industries Ltd. Product Data Sheet ESTOPLAST XU150BB01 [PA6-UF] Compound. Available online: https://www.esterindustries.com/sites/default/files/ep-products/XU150BB01.pdf (accessed on 8 January 2025).

- Li, J.; Liu, H.; Wang, Y.; Wang, L.; Liu, G.; Chen, C.; Wei, L.; Li, H. Strength-plasticity synergetic CF/PEEK composites obtained by adjusting melt flow rate. Polymer 2024, 305, 127186. [Google Scholar] [CrossRef]

- Ozen, E.; Kiziltas, A.; Kiziltas, E.E.; Gardner, D.J. Natural fiber blend—nylon 6 composites. Polym. Compos. 2013, 34, 544–553. [Google Scholar] [CrossRef]

- Sinopec. Sinopec Low Viscosity Nylon 6 Chips (BL3240) with High Quality and Best Price. Available online: https://sinopecgt.en.made-in-china.com/product/gmsRyieufSWv/China-Sinopec-Low-Viscosity-Nylon-6-Chips-Bl3240-with-High-Quality-and-Best-Price.html (accessed on 9 January 2025).

- Plastcom. SLOVAMID® 6 GF 10. Available online: https://materials.ulprospector.com/en/document?e=141876. (accessed on 9 January 2025).

- MatWeb. Polyplastic Compounds Armamid® PA6 GF 20-3FR Nylon 6, 20% Glass Fiber Reinforced. Available online: https://www.matweb.com/search/datasheettext.aspx?matguid=6077e0d67eb3495999df024838db5f6f (accessed on 9 January 2025).

- MatWeb. Aclo Accutech Nylon 6 NY0730G20L Glass Reinforced. Available online: https://www.matweb.com/search/datasheet.aspx?matguid=c98f04130fdc4d529a360729abe5655d (accessed on 9 January 2025).

- ASTM D1238; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM: West Conshohocken, PA, USA, 2013.

- ISO 1133; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics. International Organization for Standardization: Geneva, Switzerland, 2022.

- Bonfiglio, F.; Cagno, M.; Yamakawa, C.K.; Mussatto, S.I. Production of xylitol and carotenoids from switchgrass and Eucalyptus globulus hydrolysates obtained by intensified steam explosion pretreatment. Ind. Crops Prod. 2021, 170, 113800. [Google Scholar]

- Stan, D.V. Considerations on the drying of the raw material and consequences on the quality of the injected products. Mater. Plast. 2020, 57, 46–56. [Google Scholar]

- Blaine, R.L. Polymer Heats of Fusion; Thermal Applications Note TN048; TA Instruments: New Castle, DE, USA, 1990. [Google Scholar]

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion. ISO: Geneva, Switzerland, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).