Costs of Gasification Technologies for Energy and Fuel Production: Overview, Analysis, and Numerical Estimation

Abstract

1. Introduction

2. Overview of Capital and Operational Expenditures Associated with the Different Stages of Gasification

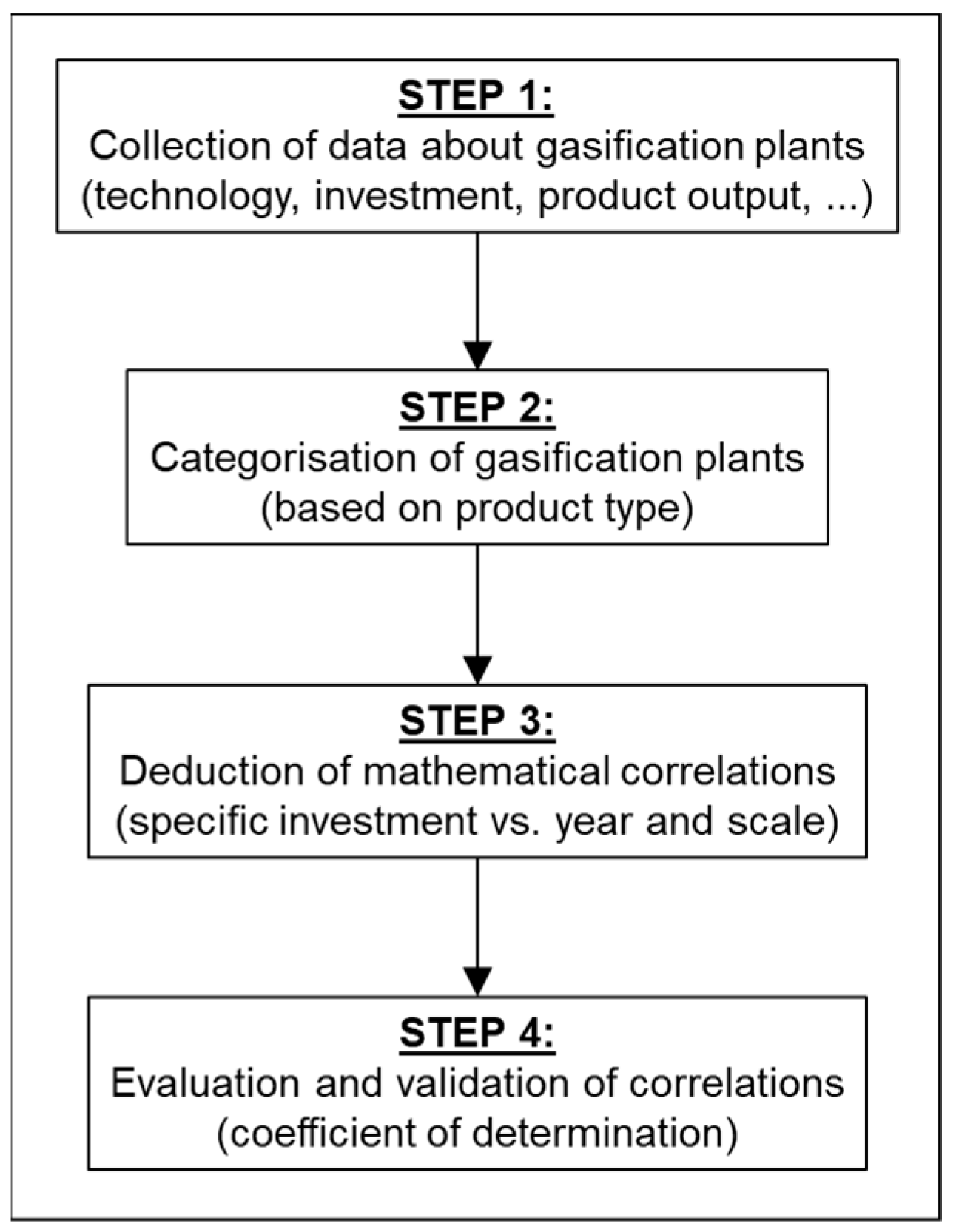

3. Description of Methodology Analysis

3.1. Survey of Information Regarding Real Gasification Plants Producing Energy or Renewable Fuels

3.2. Categorization of Gasification Plants According to the Final Product Type

3.3. Correlation Equations and Their Graphical Representations to Elucidate Evolutionary Trends of Plant Costs over Time, and Economy of Scale

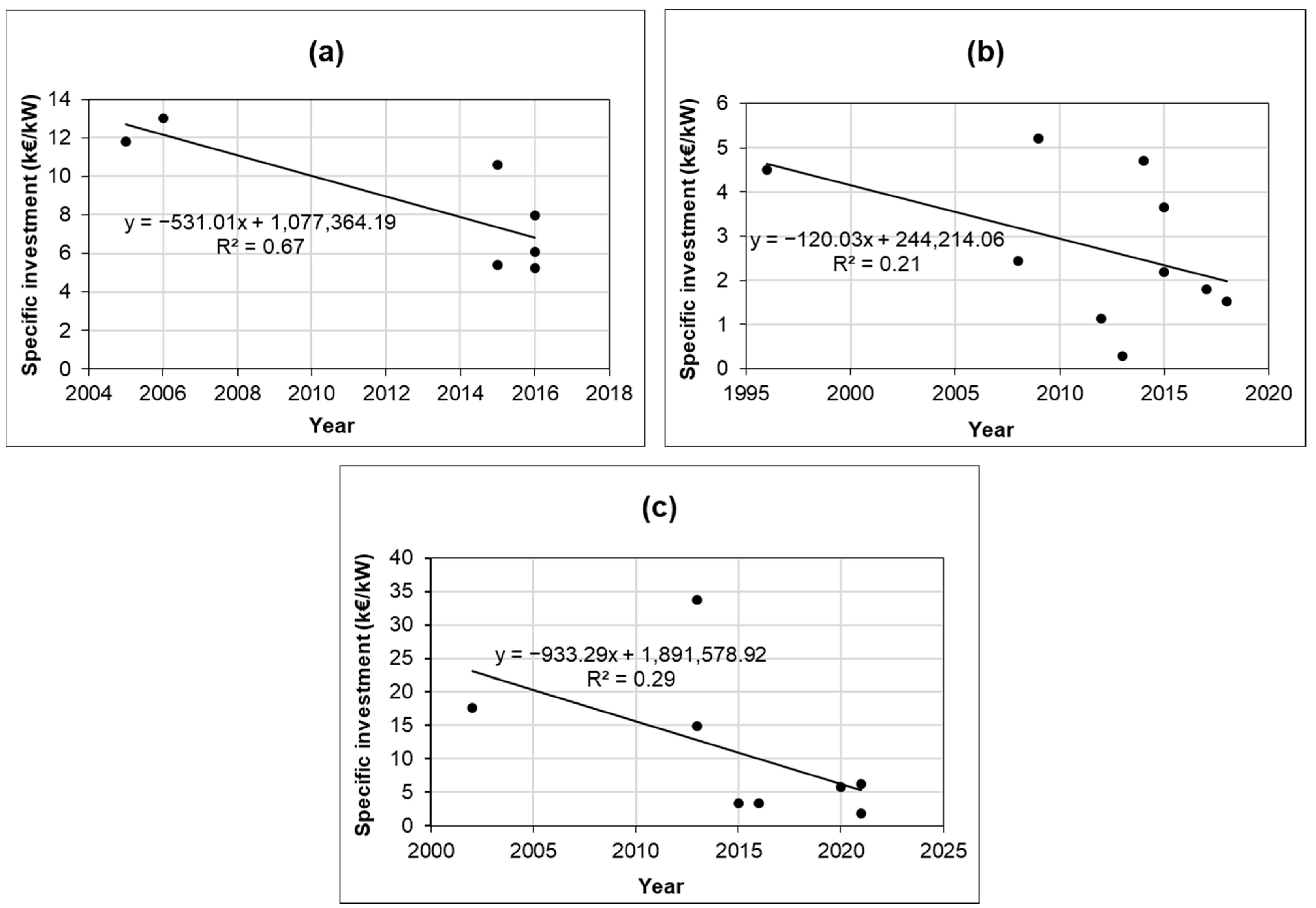

4. Analysis on the Evolutionary Trend of Gasification Plant Investments

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. The Commission Calls for a Climate Neutral Europe by 2050. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_18_6543 (accessed on 16 May 2023).

- Song, H.; Yang, G.; Xue, P.; Li, Y.; Zou, J.; Wang, S.; Yang, H.; Chen, H. Recent development of biomass gasification for H2 rich gas production. Appl. Energy Combust. Sci. 2022, 10, 100059. [Google Scholar] [CrossRef]

- Oliveira, M.; Ramos, A.; Ismail, T.M.; Monteiro, E.; Rouboa, A. A Review on Plasma Gasification of Solid Residues: Recent Advances and Developments. Energies 2022, 15, 1475. [Google Scholar] [CrossRef]

- Hanel, A.; Dieterich, V.; Bastek, S.; Spliethoff, H.; Fendt, S. Entrained flow gasification-based biomass-to-X processes: An energetic and technical evaluation. Energy Convers. Manag. 2022, 274, 116424. [Google Scholar] [CrossRef]

- Liao, L.; Zheng, J.; Li, C.; Liu, R.; Zhang, Y. Thermodynamic modeling modification and experimental validation of entrained-flow gasification of biomass. J. Energy Inst. 2022, 103, 160–168. [Google Scholar] [CrossRef]

- Di Carlo, A.; Savuto, E.; Foscolo, P.U.; Papa, A.A.; Tacconi, A.; Del Zotto, L.; Aydin, B.; Bocci, E. Preliminary Results of Biomass Gasification Obtained at Pilot Scale with an Innovative 100 kWth Dual Bubbling Fluidized Bed Gasifier. Energies 2022, 15, 4369. [Google Scholar] [CrossRef]

- Kang, P.; Zhang, G.; Ge, Z.; Zha, Z.; Zhang, H. Three-dimensional modelling and optimization of an industrial dual fluidized bed biomass gasification decoupling combustion reactor. Appl. Energy 2022, 311, 118619. [Google Scholar] [CrossRef]

- Teixeira, P.; Bacariza, C.; Correia, P.; Pinheiro, C.I.C.; Cabrita, I. Hydrogen Production with In Situ CO2 Capture at High and Medium Temperatures Using Solid Sorbents. Energies 2022, 15, 4039. [Google Scholar] [CrossRef]

- Parvez, A.M.; Hafner, S.; Hornberger, M.; Schmid, M.; Scheffknecht, G. Sorption enhanced gasification (SEG) of biomass for tailored syngas production with in-situ CO2 capture: Current status, process scale-up experiences and outlook. Renew. Sustain. Energy Rev. 2021, 141, 110756. [Google Scholar] [CrossRef]

- Hafner, S.; Schmid, M.; Scheffknecht, G. Parametric study on the adjustability of the syngas composition by sorption-enhanced gasification in a dual-fluidized bed pilot plant. Energies 2021, 14, 399. [Google Scholar] [CrossRef]

- Greencorn, M.J.; Jackson, S.D.; Hargreaves, J.S.J.; Datta, S.; Paul, M.C. Enhancement of gasification in oxyfuel BECCS cycles employing a direct recycling CO2 utilisation process. Energy Convers. Manag. 2023, 277, 116601. [Google Scholar] [CrossRef]

- Pandey, B.; Sheth, P.N.; Prajapati, Y.K. Air-CO2 and oxygen-enriched air-CO2 biomass gasification in an autothermal downdraft gasifier: Experimental studies. Energy Convers. Manag. 2022, 270, 116216. [Google Scholar] [CrossRef]

- Schmid, M.; Schmidberger, C.; Scheffknecht, G. Modelling and simulation of fluidized bed steam-oxygen gasification of sewage sludge using thermochemical equilibrium and experimental data. Fuel 2023, 341, 127595. [Google Scholar] [CrossRef]

- Zhang, R.; Ku, X.; Yang, S. Study of air-steam gasification of spherocylindrical biomass particles in a fluidized bed by using CFD-DEM coupling with the multi-sphere model. Energy Convers. Manag. 2023, 276, 116561. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y. Sorption-enhanced steam gasification of biomass for H 2 -rich gas production and in-situ CO2 capture by CaO-based sorbents: A critical review. Appl. Energy Combust. Sci. 2023, 14, 100124. [Google Scholar] [CrossRef]

- Hunt, J.D.; Nascimento, A.; Nascimento, N.; Vieira, L.W.; Romero, O.J. Possible pathways for oil and gas companies in a sustainable future: From the perspective of a hydrogen economy. Renew. Sustain. Energy Rev. 2022, 160, 112291. [Google Scholar] [CrossRef]

- Oki, Y.; Inumaru, J.; Hara, S.; Kobayashi, M.; Watanabe, H.; Umemoto, S.; Makino, H. Development of oxy-fuel IGCC system with CO2 recirculation for CO2 capture. Energy Procedia 2011, 4, 1066–1073. [Google Scholar] [CrossRef]

- Alves, O.; Garcia, B.; Rijo, B.; Lourinho, G.; Nobre, C. Market Opportunities in Portugal for the Water-and-Waste Sector Using Sludge Gasification. Energies 2022, 15, 6600. [Google Scholar] [CrossRef]

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste biomass valorization for the production of biofuels and value-added products: A comprehensive review of thermochemical, biological and integrated processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Sajid, M.; Raheem, A.; Ullah, N.; Asim, M.; Ur Rehman, M.S.; Ali, N. Gasification of municipal solid waste: Progress, challenges, and prospects. Renew. Sustain. Energy Rev. 2022, 168, 112815. [Google Scholar] [CrossRef]

- Madanikashani, S.; Vandewalle, L.A.; De Meester, S.; De Wilde, J.; Van Geem, K.M. Multi-Scale Modeling of Plastic Waste Gasification: Opportunities and Challenges. Materials 2022, 15, 4215. [Google Scholar] [CrossRef]

- Ascher, S.; Wang, X.; Watson, I.; Sloan, W.; You, S. Interpretable machine learning to model biomass and waste gasification. Bioresour. Technol. 2022, 364, 128062. [Google Scholar] [CrossRef] [PubMed]

- Vamvuka, D.; Afthentopoulos, E.; Sfakiotakis, S. H2-rich gas production from steam gasification of a winery waste and its blends with industrial wastes. Effect of operating parameters on gas quality and efficiency. Renew. Energy 2022, 197, 1224–1232. [Google Scholar] [CrossRef]

- Tangri, N.; Wilson, M. Waste Gasification & Pyrolysis: High Risk, Low Yield Processes for Waste Management. Available online: https://www.no-burn.org/wp-content/uploads/Waste-Gasification-and-Pyrolysis-high-risk-low-yield-processes-march-2017.pdf (accessed on 16 May 2023).

- Beşirli, S.; Erdem, A.; Doğru, M.; Keskinler, B. Development of Intensive Hot Syngas Clean-up System for Biomass Gasification. In Proceedings of the 5th EurAsia Waste Management Symposium, Istanbul, Turkey, 26–28 October 2020; pp. 2–6. [Google Scholar]

- Binte Mohamed, D.K.; Veksha, A.; Ha, Q.L.M.; Chan, W.P.; Lim, T.T.; Lisak, G. Advanced Ni tar reforming catalysts resistant to syngas impurities: Current knowledge, research gaps and future prospects. Fuel 2022, 318, 123602. [Google Scholar] [CrossRef]

- Chan, W.P.; Veksha, A.; Lei, J.; Da Oh, W.; Dou, X.; Giannis, A.; Lisak, G.; Lim, T.T. A hot syngas purification system integrated with downdraft gasification of municipal solid waste. Appl. Energy 2019, 237, 227–240. [Google Scholar] [CrossRef]

- Zeng, X.; Ueki, Y.; Yoshiie, R.; Naruse, I.; Wang, F.; Han, Z.; Xu, G. Recent progress in tar removal by char and the applications: A comprehensive analysis. Carbon Resour. Convers. 2020, 3, 1–18. [Google Scholar] [CrossRef]

- Frilund, C.; Tuomi, S.; Kurkela, E.; Simell, P. Small- to medium-scale deep syngas purification: Biomass-to-liquids multi-contaminant removal demonstration. Biomass Bioenergy 2021, 148, 106031. [Google Scholar] [CrossRef]

- de Fournas, N.; Wei, M. Techno-economic assessment of renewable methanol from biomass gasification and PEM electrolysis for decarbonization of the maritime sector in California. Energy Convers. Manag. 2022, 257, 115440. [Google Scholar] [CrossRef]

- AlNouss, A.; Shahbaz, M.; Mckay, G.; Al-Ansari, T. Bio-methanol production from palm wastes steam gasification with application of CaO for CO2 capture: Techno-economic-environmental analysis. J. Clean. Prod. 2022, 341, 130849. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Yang, A.; Sun, S.; Shen, W.; Ren, J. Developing a novel gasification-based sludge-to-methanol utilization process and exergy-economic-environmental (3E) analysis. Energy Convers. Manag. 2022, 260, 115600. [Google Scholar] [CrossRef]

- Gómez, L.; Grasa, G.; Martínez, I.; Murillo, R. Performance study of a methanation process for a syngas obtained from a sorption enhanced gasification process. Chem. Eng. Sci. 2023, 267, 118291. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.L.; Zhao, X.Y.; Cao, J.P. Methanation of syngas from biomass gasification: An overview. Int. J. Hydrogen Energy 2020, 45, 4223–4243. [Google Scholar] [CrossRef]

- Gabbrielli, R.; Barontini, F.; Frigo, S.; Bressan, L. Numerical analysis of bio-methane production from biomass-sewage sludge oxy-steam gasification and methanation process. Appl. Energy 2022, 307, 118292. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Alam, M.T.; Krishna, B.B.; Bhaskar, T.; Perkins, G. A review on the production of renewable aviation fuels from the gasification of biomass and residual wastes. Bioresour. Technol. 2020, 312, 123596. [Google Scholar] [CrossRef] [PubMed]

- IEA Bioenergy. Status Report on Thermal Gasification of Biomass and Waste 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/03/Status-Report2021_final.pdf (accessed on 16 May 2023).

- International Renewable Energy Agency. Renewable Power Generations Costs in 2018. Available online: https://www.irena.org/publications/2019/May/Renewable-power-generation-costs-in-2018 (accessed on 16 May 2023).

- Anejionu, O.C.D.; Woods, J. Preliminary farm-level estimation of 20-year impact of introduction of energy crops in conventional farms in the UK. Renew. Sustain. Energy Rev. 2019, 116, 109407. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C. Industrial gasification systems (>3 MWth) for bioenergy in Europe: Current status and future perspectives. Renew. Sustain. Energy Rev. 2021, 145, 111108. [Google Scholar] [CrossRef]

- Abadie, L.M.; Chamorro, J.M. The economics of gasification: A market-based approach. Energies 2009, 2, 662–694. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C.; Pinto, R.G.; Matos, M.A.A.; Frade, J.R.; Yaremchenko, A.; Mishra, G.S.; Pinto, P.C.R. Low-cost catalysts for in-situ improvement of producer gas quality during direct gasification of biomass. Energy 2018, 165, 442–454. [Google Scholar] [CrossRef]

- Heidenreich, S.; Foscolo, P.U. New concepts in biomass gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- Pio, D.T.; Gomes, H.G.M.F.; Tarelho, L.A.C.; Ruivo, L.C.M.; Matos, M.A.A.; Pinto, R.G.; Frade, J.R.; Lemos, F.M.S. Ilmenite as low-cost catalyst for producer gas quality improvement from a biomass pilot-scale gasifier. Energy Rep. 2020, 6, 325–330. [Google Scholar] [CrossRef]

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic assessment of advanced biofuel production via gasification using cost data from the GoBiGas plant. Energy Sci. Eng. 2018, 7, 217–229. [Google Scholar] [CrossRef]

- Larsson, A.; Kuba, M.; Berdugo Vilches, T.; Seemann, M.; Hofbauer, H.; Thunman, H. Steam gasification of biomass—Typical gas quality and operational strategies derived from industrial-scale plants. Fuel Process. Technol. 2021, 212, 106609. [Google Scholar] [CrossRef]

- Waldheim, L. Gasification of Waste for Energy Carriers—A Review. Available online: https://www.ieabioenergy.com/blog/publications/gasification-of-waste-for-energy-carriers-a-review/ (accessed on 16 May 2023).

- International Renewable Energy Agency. Renewable Energy Technologies: Cost Analysis Series—Biomass for Power Generation. Available online: https://www.irena.org/publications/2012/Jun/Renewable-Energy-Cost-Analysis---Biomass-for-Power-Generation (accessed on 16 May 2023).

- Menin, L.; Benedetti, V.; Patuzzi, F.; Baratieri, M. Techno-economic modeling of an integrated biomethane-biomethanol production process via biomass gasification, electrolysis, biomethanation, and catalytic methanol synthesis. Biomass Convers. Biorefinery 2020, 13, 977–998. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Air Pollution Control Technology—Fact Sheet. Available online: https://www3.epa.gov/ttncatc1/dir1/fwespwpi.pdf (accessed on 16 May 2023).

- Hengston, H. Air Pollution Control: Wet Scrubbers. Available online: https://www.cedengineering.com/userfiles/C05-021%20-%20Air%20Pollution%20Control%20-%20Wet%20Scrubbers%20-%20US.pdf (accessed on 16 May 2023).

- Boerrigter, H.; van Paasen, S.V.B.; Bergman, P.C.; Könemann, J.W.; Emmen, R.; Wijnands, A. “OLGA” Tar Removal Technology—Proof-of-Concept (PoC) for Application in Integrated Biomass Gasification Combined Heat and Power (CHP) Systems. Available online: https://www.osti.gov/etdeweb/biblio/20767409 (accessed on 16 May 2023).

- European Commission. Eurostat—Your Key to European Statistics. Available online: https://ec.europa.eu/eurostat (accessed on 30 August 2022).

- US Department of Energy, U.S. Gasification Projects. Available online: https://www.netl.doe.gov/sites/default/files/netl-file/US-Gasification-Database.xlsx (accessed on 13 October 2021).

- Energy & Environmental Research Center Energy & Environmental Research Center. Available online: https://undeerc.org/ (accessed on 13 October 2021).

- CoGen CoGen—Delivering Waste + Energy Solutions. Available online: https://www.cogenuk.com/ (accessed on 13 October 2021).

- Aravossis, K.; Brebbia, C.A.; Kakaras, E.; Kungolos, A.G. Environmental Economics and Investment Assessment; WIT Press: Southampton, UK, 2006. [Google Scholar]

- Heeb, R. B&W Vølund—Up-Date on the Gasification Technology. Available online: https://task32.ieabioenergy.com/wp-content/uploads/sites/24/2017/03/08-Volund.pdf (accessed on 16 May 2023).

- Hrbek, J. Status Report on Thermal Gasification of Biomass and Waste 2019. Available online: https://www.ieabioenergy.com/blog/publications/new-publication-2019-status-report-on-thermal-gasification-of-biomass-and-waste/ (accessed on 16 May 2023).

- Spanner Re2 GmbH Spanner Re2. Available online: https://www.holz-kraft.com/en/ (accessed on 13 October 2021).

- Veredict Media Limited Vaasa Bio-Gasification Plant. Available online: https://www.power-technology.com/projects/vaasa-plant/ (accessed on 14 October 2021).

- Boston Alternative Energy Facility Boston Alternative Energy Facility. Available online: https://www.bostonaef.co.uk/ (accessed on 14 October 2021).

- IEA Bioenergy Technology Collaboration Programme—Facilities. Available online: https://www.ieabioenergy.com/installations/ (accessed on 13 October 2021).

- Engie Gaya Project. Available online: https://www.projetgaya.com/en/ (accessed on 13 October 2021).

- International Renewable Energy Agency. Innovation Outlook—Renewable Methanol. Available online: https://www.irena.org/publications/2021/Jan/Innovation-Outlook-Renewable-Methanol (accessed on 16 May 2023).

- VarmlandsMethanol, A.B. Available online: https://www.varmlandsmetanol.se/ (accessed on 13 October 2021).

- Engie. One Mission, One Biomethane, One Industrial Project for a New Energy Generation. Available online: https://www.projetgaya.com/wp-content/uploads/2017/08/Gaya-AN-new_08_2017-4.pdf (accessed on 16 May 2023).

- Tuomi, S.; Kurkela, E.; Hannula, I.; Berg, C.G. The impact of biomass drying on the efficiency of a gasification plant co-producing Fischer-Tropsch fuels and heat—A conceptual investigation. Biomass Bioenergy 2019, 127, 105272. [Google Scholar] [CrossRef]

- Spyrakis, S.; Panopoulos, K.D.; Fryda, L.; Kakaras, E. Synthesis, modelling and exergy analysis of atmospheric air blown biomass gasification for Fischer-Tropsch process. In Proceedings of the ECOS 2008—Proceedings of the 21st International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Cracow-Gliwice, Poland, 24–27 June 2008; Volume 12, pp. 1311–1318. [Google Scholar]

- Snehesh, A.S.; Mukunda, H.S.; Mahapatra, S.; Dasappa, S. Fischer-Tropsch route for the conversion of biomass to liquid fuels—Technical and economic analysis. Energy 2017, 130, 182–191. [Google Scholar] [CrossRef]

- Im-orb, K.; Simasatitkul, L.; Arpornwichanop, A. Techno-economic analysis of the biomass gasification and Fischer-Tropsch integrated process with off-gas recirculation. Energy 2016, 94, 483–496. [Google Scholar] [CrossRef]

- Bolívar Caballero, J.J.; Zaini, I.N.; Yang, W. Reforming processes for syngas production: A mini-review on the current status, challenges, and prospects for biomass conversion to fuels. Appl. Energy Combust. Sci. 2022, 10, 100064. [Google Scholar] [CrossRef]

- van den Oever, A.E.M.; Costa, D.; Cardellini, G.; Messagie, M. Systematic review on the energy conversion efficiency of biomass-based Fischer-Tropsch plants. Fuel 2022, 324, 124478. [Google Scholar] [CrossRef]

- dos Santos, R.G.; Alencar, A.C. Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer Tropsch synthesis: A review. Int. J. Hydrogen Energy 2020, 45, 18114–18132. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; Del Olmo, O.A. Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Wilen, C.; Kurkela, E. Gasification of Biomass for Energy Production: State of Technology in Finland and Global Market Perspectives; Technical Research Centre of Finland: Espoo, Finland, 1997. [Google Scholar]

- Cerone, N.; Zimbardi, F.; Villone, A.; Strjiugas, N.; Kiyikci, E.G. Gasification of Wood and Torrefied Wood with Air, Oxygen, and Steam in a Fixed-Bed Pilot Plant. Energy Fuels 2016, 30, 4034–4043. [Google Scholar] [CrossRef]

- Long, H.A., III; Arnold, B.; Brown, B.; Crouse, D.; Gangwal, S.; Knudsen, S.; Munson, C.; Shilling, N.; Slettehaugh, B.; Sorensen, J.; et al. Guidelines/Handbook for the Design of Modular Gasification Systems. Available online: https://netl.doe.gov/sites/default/files/2022-07/Gasification%20Handbook.pdf (accessed on 16 May 2023).

- Peterson, D.; Haase, S. Market Assessment of Biomass Gasification and Combustion Technology for Small- and Medium-Scale Applications. Available online: https://www.nrel.gov/docs/fy09osti/46190.pdf (accessed on 16 May 2023).

- Langholtz, M.; Stokes, B.; Eaton, L. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy (Executive Summary). Ind. Biotechnol. 2016, 12, 282–289. [Google Scholar] [CrossRef]

- Sanjaya, E.; Abbas, A. Plasma Gasification as an Alternative Energy-from-Waste (EFW) Technology for the Circular Economy: An Environmental Review. Resour. Conserv. Recycl. 2023, 189, 106730. [Google Scholar] [CrossRef]

- Ramos, A.; Berzosa, J.; Espí, J.; Clarens, F.; Rouboa, A. Life Cycle Costing for Plasma Gasification of Municipal Solid Waste: A Socio-Economic Approach. Energy Convers. Manag. 2020, 209, 112508. [Google Scholar] [CrossRef]

- Sumitomo SHI/FW. Energy from Waste. Available online: https://www.shi-fw.com/our-solutions/energy-from-waste/ (accessed on 3 March 2023).

- Silva Ortiz, P.; Maier, S.; Dietrich, R.-U.; Pinto Mariano, A.; Maciel Filho, R.; Posada, J. Comparative Techno-Economic and Exergetic Analysis of Circulating and Dual Bed Biomass Gasification Systems. Front. Chem. Eng. 2021, 3, 1–12. [Google Scholar] [CrossRef]

- Hanchate, N.; Ramani, S.; Mathpati, C.S.; Dalvi, V.H. Biomass Gasification Using Dual Fluidized Bed Gasification Systems: A Review. J. Clean. Prod. 2021, 280, 123148. [Google Scholar] [CrossRef]

- Hadi Jafari, P.; Wingren, A.; Hellström, J.G.I.; Gebart, B.R. Effect of Process Parameters on the Performance of an Air-Blown Entrained Flow Cyclone Gasifier. Int. J. Sustain. Energy 2020, 39, 21–40. [Google Scholar] [CrossRef]

- Rizzo, J. Evaluation of a Combined Cyclone & Gas Filtration System for Particulate Removal in the Gasification Process. Available online: https://www.osti.gov/servlets/purl/1090272 (accessed on 16 May 2023).

- Baasel, W.D. Capital and Operating Costs of Wet Scrubbers: Installed on Coal-Fired Utilities Impacting the East Coast. J. Air Pollut. Control Assoc. 1988, 38, 327–332. [Google Scholar] [CrossRef]

- Fleisch, T. Associated Gas Monetization via MiniGTL Conversion of Flared Gas into Liquid Fuels & Chemicals. Available online: https://openknowledge.worldbank.org/entities/publication/b51afa19-51bd-59c6-9d91-3e80ebfdd0e8 (accessed on 16 May 2023).

- Nyári, J. Techno-Economic Feasibility Study of a Methanol Plant Using Carbon Dioxide and Hydrogen. Master Thesis, KTH School of Industrial Engineering and Management, Stockholm, Sweden, 2018. [Google Scholar]

- Balas, M.; Lisy, M.; Kubicek, J.; Pospisil, J. Syngas Cleaning by Wet Scrubber. WSEAS Trans. Heat Mass Transf. 2014, 9, 195–204. [Google Scholar]

- Danaci, D.; Webley, P.A.; Petit, C. Guidelines for Techno-Economic Analysis of Adsorption Processes. Front. Chem. Eng. 2021, 2, 1–11. [Google Scholar] [CrossRef]

- Lepage, T.; Kammoun, M.; Schmetz, Q.; Richel, A. Biomass-to-Hydrogen: A Review of Main Routes Production, Processes Evaluation and Techno-Economical Assessment. Biomass Bioenergy 2021, 144, 105920. [Google Scholar] [CrossRef]

- Milne, T.A.; Elam, C.C.; Evans, R.J. Hydrogen from Biomass—State of the Art and Research Challenges. Available online: https://www.nrel.gov/docs/legosti/old/36262.pdf (accessed on 16 May 2023).

- Tan, R.S.; Tuan Abdullah, T.A.; Johari, A.; Md Isa, K. Catalytic Steam Reforming of Tar for Enhancing Hydrogen Production from Biomass Gasification: A Review. Front. Energy 2020, 14, 545–569. [Google Scholar] [CrossRef]

- Gómez-Rueda, Y. Syngas Purification by Plasma Tar Cracking. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2021. [Google Scholar]

- Nunnally, T.; Tsangaris, A.; Rabinovich, A.; Nirenberg, G.; Chernets, I.; Fridman, A. Gliding Arc Plasma Oxidative Steam Reforming of a Simulated Syngas Containing Naphthalene and Toluene. Int. J. Hydrogen Energy 2014, 39, 11976–11989. [Google Scholar] [CrossRef]

- Evangelisti, S.; Tagliaferri, C.; Clift, R.; Lettieri, P.; Taylor, R.; Chapman, C. Integrated Gasification and Plasma Cleaning for Waste Treatment: A Life Cycle Perspective. Waste Manag. 2015, 43, 485–496. [Google Scholar] [CrossRef] [PubMed]

- Evans, G. Targeting New and Cleaner Uses for Wastes and Biomass Using Gasification. Available online: https://ukerc.rl.ac.uk/ETI/PUBLICATIONS/Targeting-new-and-cleaner-uses-for-wastes-and-biomass-using-gasification.pdf (accessed on 16 May 2023).

- Fahlén, E.; Ahlgren, E.O. Assessment of Integration of Different Biomass Gasification Alternatives in a District-Heating System. Energy 2009, 34, 2184–2195. [Google Scholar] [CrossRef]

- Börjesson, M.; Ahlgren, E.O. Biomass Gasification in Cost-Optimized District Heating Systems—A Regional Modelling Analysis. Energy Policy 2010, 38, 168–180. [Google Scholar] [CrossRef]

- Romeu, P.M. Design of a Raw Syngas Post-Combustor for a 30 KW Entrained Flow Biomass Gasifier. Bachelor Thesis, Luleå University of Technology, Luleå, Sweden, 2021. [Google Scholar]

- Wei, L.; Pordesimo, L.O.; Filip To, S.D.; Herndon, C.W.; Batchelor, W.D. Evaluation of Micro-Scale Syngas Production Costs through Modeling. Trans. ASABE 2009, 52, 1649–1659. [Google Scholar] [CrossRef]

- Rey, J.R.C.; Pio, D.T.; Tarelho, L.A.C. Biomass Direct Gasification for Electricity Generation and Natural Gas Replacement in the Lime Kilns of the Pulp and Paper Industry: A Techno-Economic Analysis. Energy 2021, 237, 121562. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C.; Matos, M.A.A. Characteristics of the Gas Produced during Biomass Direct Gasification in an Autothermal Pilot-Scale Bubbling Fluidized Bed Reactor. Energy 2017, 120, 915–928. [Google Scholar] [CrossRef]

- Copa, J.R.; Tuna, C.E.; Silveira, J.L.; Boloy, R.A.M.; Brito, P.; Silva, V.; Cardoso, J.; Eusébio, D. Techno-Economic Assessment of the Use of Syngas Generated from Biomass to Feed an Internal Combustion Engine. Energies 2020, 13, 3097. [Google Scholar] [CrossRef]

- Briones-Hidrovo, A.; Copa, J.; Tarelho, L.A.C.; Gonçalves, C.; Pacheco da Costa, T.; Dias, A.C. Environmental and Energy Performance of Residual Forest Biomass for Electricity Generation: Gasification vs. Combustion. J. Clean. Prod. 2021, 289. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Pezzola, L.; Mussi, R.; Bromberg, L.; Heywood, J.; Kasseris, E. A Novel Low-Cost Tar Removal Technology for Small-Scale Biomass Gasification to Power. Biomass Bioenergy 2021, 149, 106085. [Google Scholar] [CrossRef]

- Colantoni, A.; Villarini, M.; Monarca, D.; Carlini, M.; Mosconi, E.M.; Bocci, E.; Rajabi Hamedani, S. Economic Analysis and Risk Assessment of Biomass Gasification CHP Systems of Different Sizes through Monte Carlo Simulation. Energy Rep. 2021, 7, 1954–1961. [Google Scholar] [CrossRef]

- Chang, C.T.; Costa, M.; La Villetta, M.; Macaluso, A.; Piazzullo, D.; Vanoli, L. Thermo-Economic Analyses of a Taiwanese Combined CHP System Fuelled with Syngas from Rice Husk Gasification. Energy 2019, 167, 766–780. [Google Scholar] [CrossRef]

- Aguado, R.; Vera, D.; Jurado, F.; Beltrán, G. An Integrated Gasification Plant for Electric Power Generation from Wet Biomass: Toward a Sustainable Production in the Olive Oil Industry. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Kheiri, R.; Khoshbakhti Saray, R.; Omidi Kashani, B. Thermo-Economic-Environmental Analysis of a New Tri-Generation Seasonal System with Gas Turbine Prime Mover Based on Municipal Solid Waste Gasification. Energy Convers. Manag. 2022, 265, 115755. [Google Scholar] [CrossRef]

- Karellas, S.; Boukis, I.; Kontopoulos, G. Development of an Investment Decision Tool for Biogas Production from Agricultural Waste. Renew. Sustain. Energy Rev. 2010, 14, 1273–1282. [Google Scholar] [CrossRef]

- Corrêa, P.S.P.; Zhang, J.; Lora, E.E.S.; Andrade, R.V.; de Mello e Pinto, L.R.; Ratner, A. Experimental Study on Applying Biomass-Derived Syngas in a Microturbine. Appl. Therm. Eng. 2019, 146, 328–337. [Google Scholar] [CrossRef]

- Roy, D.; Samanta, S.; Ghosh, S. Thermo-Economic Assessment of Biomass Gasification-Based Power Generation System Consists of Solid Oxide Fuel Cell, Supercritical Carbon Dioxide Cycle and Indirectly Heated Air Turbine. Clean Technol. Environ. Policy 2019, 21, 827–845. [Google Scholar] [CrossRef]

- Peng, W.; Chen, H.; Liu, J.; Zhao, X.; Xu, G. Techno-Economic Assessment of a Conceptual Waste-to-Energy CHP System Combining Plasma Gasification, SOFC, Gas Turbine and Supercritical CO2 Cycle. Energy Convers. Manag. 2021, 245, 114622. [Google Scholar] [CrossRef]

- Costa, P.; Pinto, F.; André, R.N.; Marques, P. Integration of Gasification and Solid Oxide Fuel Cells (SOFCs) for Combined Heat and Power (CHP). Processes 2021, 9, 254. [Google Scholar] [CrossRef]

- Brynda, J.; Skoblia, S.; Pohořelý, M.; Beňo, Z.; Soukup, K.; Jeremiáš, M.; Moško, J.; Zach, B.; Trakal, L.; Šyc, M.; et al. Wood Chips Gasification in a Fixed-Bed Multi-Stage Gasifier for Decentralized High-Efficiency CHP and Biochar Production: Long-Term Commercial Operation. Fuel 2020, 281, 118637. [Google Scholar] [CrossRef]

- Ma, S.; Dong, C.; Hu, X.; Xue, J.; Zhao, Y.; Wang, X. Techno-Economic Evaluation of a Combined Biomass Gasification-Solid Oxide Fuel Cell System for Ethanol Production via Syngas Fermentation. Fuel 2022, 324, 124395. [Google Scholar] [CrossRef]

- Singh, S.P.; Ohara, B.; Ku, A.Y. Prospects for Cost-Competitive Integrated Gasification Fuel Cell Systems. Appl. Energy 2021, 290, 116753. [Google Scholar] [CrossRef]

- Wei, C.; Liu, Z.; Li, C.; Singh, S.; Lu, H.; Gong, Y.; Li, P.; Wang, H.; Yang, X.; Xu, M.; et al. Status of an MWth Integrated Gasification Fuel Cell Power-Generation System in China. Int. J. Coal Sci. Technol. 2021, 8, 401–411. [Google Scholar] [CrossRef]

- Geis, M.; Herrmann, S.; Fendt, S.; Jeong, H.; Lenser, C.; Menzler, N.H.; Spliethoff, H. Coupling SOFCs to Biomass Gasification—The Influence of Phenol on Cell Degradation in Simulated Bio-Syngas. Part I: Electrochemical Analysis. Int. J. Hydrogen Energy 2018, 43, 20417–20427. [Google Scholar] [CrossRef]

- Qin, Z.; Zhang, Z.; Ma, X. Effects of Sewage Sludge Blending on Techno-Economic Performance of Integrated Gasification Combined Cycle (IGCC) System. Process Saf. Environ. Prot. 2022, 160, 584–593. [Google Scholar] [CrossRef]

- Wu, W.; Wen, F.; Shi, B. Assessing the Commercial Potential of IGCC Polygeneration/Power Plants Integrated with Chemical-Looping Processes. J. Taiwan Inst. Chem. Eng. 2020, 112, 296–305. [Google Scholar] [CrossRef]

- Khoshgoftar Manesh, M.H.; Jadidi, E. Conventional and Advanced Exergy, Exergoeconomic and Exergoenvironmental Analysis of a Biomass Integrated Gasification Combined Cycle Plant. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 7036. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory. Hydrogen Production Cost Estimate Using Biomass Gasification. Available online: https://www.energy.gov/eere/fuelcells/articles/hydrogen-production-cost-estimate-using-biomass-gasification-independent (accessed on 16 May 2023).

- Sara, H.R.; Enrico, B.; Mauro, V.; Andrea, D.C.; Vincenzo, N. Techno-Economic Analysis of Hydrogen Production Using Biomass Gasification -A Small Scale Power Plant Study. Energy Procedia 2016, 101, 806–813. [Google Scholar] [CrossRef]

- Binder, M.; Kraussler, M.; Kuba, M.; Luisser, M. Hydrogen from Biomass Gasification. Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/01/Wasserstoffstudie_IEA-final.pdf (accessed on 16 May 2023).

- Kim, S.H.; Kumar, G.; Chen, W.H.; Khanal, S.K. Renewable Hydrogen Production from Biomass and Wastes. Bioresour. Technol. 2021, 331, 125024. [Google Scholar] [CrossRef]

- Rönsch, S.; Schneider, J.; Matthischke, S.; Schlüter, M.; Götz, M.; Lefebvre, J.; Prabhakaran, P.; Bajohr, S. Review on Methanation —From Fundamentals to Current Projects. Fuel 2016, 166, 276–296. [Google Scholar] [CrossRef]

- Larsson, A.; Gunnarsson, I.; Tengberg, F. The GoBiGas Project—Demonstration of the Production of Biomethane from Biomass via Gasification. Available online: https://research.chalmers.se/publication/509030/file/509030_Fulltext.pdf (accessed on 16 May 2023).

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A Technological and Economic Review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Batidzirai, B.; Schotman, G.S.; van der Spek, M.W.; Junginger, M.; Faaij, A.P.C. Techno-Economic Performance of Sustainable International Bio-SNG Production and Supply Chains on Short and Longer Term. Biofuels Bioprod. Biorefining 2019, 13, 325–357. [Google Scholar] [CrossRef]

- Prifti, K.; Galeazzi, A.; Manenti, F. Design and Simulation of a Plastic Waste to Methanol Process: Yields and Economics. Ind. Eng. Chem. Res. 2023, 62, 5083–5096. [Google Scholar] [CrossRef]

- Liu, L.; Lin, Z.; Lin, S.; Chen, Y.; Zhang, L.; Chen, S.; Zhang, X.; Lin, J.; Zhang, Z.; Wan, S.; et al. Conversion of Syngas to Methanol and DME on Highly Selective Pd/ZnAl2O4 Catalyst. J. Energy Chem. 2021, 58, 564–572. [Google Scholar] [CrossRef]

- Frazão, C.J.R.; Walther, T. Syngas and Methanol-Based Biorefinery Concepts. Chem. Ing. Tech. 2020, 92, 1680–1699. [Google Scholar] [CrossRef]

- Giuliano, A.; Freda, C.; Catizzone, E. Techno-Economic Assessment of Bio-Syngas Production for Methanol Synthesis: A Focus on the Water–Gas Shift and Carbon Capture Sections. Bioengineering 2020, 7, 70. [Google Scholar] [CrossRef]

- Luk, H.T.; Mondelli, C.; Ferré, D.C.; Stewart, J.A.; Pérez-Ramírez, J. Status and Prospects in Higher Alcohols Synthesis from Syngas. Chem. Soc. Rev. 2017, 46, 1358–1426. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.E.; Maximov, V.V.; Dipheko, T.D.; Sheshko, T.F.; Cherednichenko, A.G.; Nikulshin, P.A.; Kogan, V.M. Synthesis of Higher Alcohols from Syngas over a K-Modified CoMoS Catalyst Supported on Novel Powder and Fiber Commercial Activated Carbons. ACS Omega 2022, 7, 21346–21356. [Google Scholar] [CrossRef]

- Park, T.Y.; Nam, I.S.; Kim, Y.G. Kinetic Analysis of Mixed Alcohol Synthesis from Syngas over K/MoS2 Catalyst. Ind. Eng. Chem. Res. 1997, 36, 5246–5257. [Google Scholar] [CrossRef]

- Nina, L.G.L. Catalytic Conversion of Syngas to Ethanol and Higher Alcohols over Rh and Cu Based Catalysts. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2017. [Google Scholar]

- Nguyen, A.P. The Conversion of Syngas To Mixed Alcohols. Master Thesis, California State University, Sacramento, USA, 2020. [Google Scholar]

- He, J.; Zhang, W. Research on Ethanol Synthesis from Syngas. J. Zhejiang Univ. Sci. A 2008, 9, 714–719. [Google Scholar] [CrossRef]

- He, J.; Zhang, W. Techno-Economic Evaluation of Thermo-Chemical Biomass-to-Ethanol. Appl. Energy 2011, 88, 1224–1232. [Google Scholar] [CrossRef]

- Reyes Valle, C.; Villanueva Perales, A.L.; Vidal-Barrero, F.; Gómez-Barea, A. Techno-Economic Assessment of Biomass-to-Ethanol by Indirect Fluidized Bed Gasification: Impact of Reforming Technologies and Comparison with Entrained Flow Gasification. Appl. Energy 2013, 109, 254–266. [Google Scholar] [CrossRef]

- Aui, A.; Wang, Y.; Mba-Wright, M. Evaluating the Economic Feasibility of Cellulosic Ethanol: A Meta-Analysis of Techno-Economic Analysis Studies. Renew. Sustain. Energy Rev. 2021, 145, 111098. [Google Scholar] [CrossRef]

- Regis, F.; Hugo, A.; Monteverde, A.; Fino, D. A Techno-Economic Assessment of Bioethanol Production from Switchgrass through Biomass Gasification and Syngas Fermentation. Energy 2023, 274, 127318. [Google Scholar] [CrossRef]

- Shahriar, M.F.; Khanal, A. The Current Techno-Economic, Environmental, Policy Status and Perspectives of Sustainable Aviation Fuel (SAF). Fuel 2022, 325, 124905. [Google Scholar] [CrossRef]

- Juan Ding, K.Y.A. Fischer-Tropsch Sustainable Aviation Fuel: An Assessment of Pioneer Plants and Canadian Supply. Master Thesis, University of Toronto, Toronto, ON, Canada, 2022. [Google Scholar]

- Petersen, A.M.; Chireshe, F.; Gorgens, J.F.; Van Dyk, J. Flowsheet Analysis of Gasification-Synthesis-Refining for Sustainable Aviation Fuel Production from Invasive Alien Plants. Energy 2022, 245, 123210. [Google Scholar] [CrossRef]

| Product | Plant Company Owner | Technology Description | Product Output | Specific Investment (Updated) | Refs. |

|---|---|---|---|---|---|

| Electricity | Plasco Energy Group | Feedstock: MSW (85 t/d); Conversion pathway: moving grate gasifier + gas engine; TRL: 4. | 4 MWe | 11,800 €/kWe | [47] |

| Taylor Bioenergy * | Feedstock: MSW, wood waste, and construction and demolition waste (900 t/d); conversion pathway: circulating fluidized-bed gasifier + gas turbine. | 20 MWe | 12,991 €/kWe | [47] | |

| Tahoe Regional Power Company | Feedstock: forestry waste; conversion pathway: gasification + internal combustion engine. | 2 MWe | 5240 €/kWe | [54] | |

| PHG Energy | Feedstock: waste wood, scrap tires, and sewage sludge (58 t/d); Conversion pathway: downdraft gasifier. | 300 kWe | 10,031 €/kWe | [54] | |

| M&W Group | Feedstock: refuse-derived fuel (RDF, 40,000 t/y); conversion pathway: fluidized-bed gasifier. | 12.5 MWe | 10,598 €/kWe | [54] | |

| EERC | Conversion pathway: entrained-flow gasifier. | 300 kWe | 2318 €/kWe | [55] | |

| CoGen | Feedstock: waste wood (67,000 t/y, updraft gasifier; 72,000 t/y, updraft gasifier; 157,000 t/y, fluidized-bed gasifier); | 10.3/10.6/26.5 MWe | 7987/6073/5395 €/kWe | [56] | |

| Mitsubishi Materials and Kawasaki Steel | Feedstock: MSW (51,000 t/y); conversion pathway: high-temperature gasification + fusion of waste materials. | 2.4 MWe | 215,211 €/kWe | [56] | |

| Heat | Vicat | Feedstock: wood and RDF (3 t/h); conversion pathway: fixed-bed gasifier + direct burn of gas. | 6.4 MWth | 710 €/kWth | [56] |

| ESKA | Feedstock: wastepaper and plastics (3.5 t/h); conversion pathway: circulating fluidized-bed gasifier + steam generation. | 12 MWth | 1231 €/kWth | [57] | |

| Stora Enso | Feedstock: plastics; conversion pathway: fluidized-bed gasifier + steam generation. | 40 MWth | 624 €/kWth | [47] | |

| Lahti Energia Oy | Feedstock: forestry biomass (50–55 truckloads per day); conversion pathway: circulating fluidized-bed gasifier + steam generation. | 190 MWth | 868 €/kWth | [47] | |

| CHP | Dall Energy | Feedstock: wood, garden, and forestry wastes; conversion pathway: updraft gasifier + thermal oil heater + internal combustion engine; TRL: 8. | 800 kWe (electricity) 5000 kWth (heat) | 1528 €/kW | [47] |

| Babcock&Wilcox Volund | Feedstock: woodchips; conversion pathway: updraft gasifier + gas engine; TRL: 9. | 1 MWe (electricity) 3 MWth (heat) | 4501 €/kW | [58] | |

| H. H. Käser GmbH | Feedstock: woodchips, forestry waste, and short rotation plants (133 kg/h); conversion pathway: downdraft gasifier; TRL: 9. | 140 kWe (electricity) 240 kWth (heat) | 1807 €/kW | [59] | |

| Josef Bucher AG | Feedstock: woodchips (15 m3/d); conversion pathway: downdraft gasifier + gas engine; TRL: 9. | 130 kWe (electricity) 260 kWth (heat) | 3658 €/kW | [59] | |

| Energie Oberwart | Feedstock: woodchips; conversion pathway: circulating fluidized-bed gasifier + gas engine; TRL: 9. | 2.8 MWe (electricity) 4.1 MWth (heat) | 2436 €/kW | [59] | |

| Emamejeriet AB | Feedstock: forestry wastes; conversion pathway: gasifier + gas engine; TRL: 8. | 40 kWe (electricity) 100 kWth (heat) | 2184 €/kW | [59] | |

| Lahti Energia Oy | Feedstock: solid recovered fuel (SRF, 250,000 t/y); conversion pathway: circulating fluidized-bed gasifier + steam turbine; TRL: 9. | 50 MWe (electricity) 90 MWth (heat) | 1127 €/kW | [59] | |

| Spanner Re2 | Feedstock: pellets, briquettes, and woodchips; conversion pathway: downdraft gasifier. | 450 kW (electricity + heat) | 4709 €/kW | [59] | |

| Vaskiluodon Voima | Feedstock: biomass + coal; conversion pathway: downdraft gasifier. | 140 MW (electricity + heat) | 289 €/kW | [47,59] | |

| Royal Haskoning DHV | Conversion pathway: bubbling fluidized-bed gasifier. | 10.5 MW (electricity + heat) | 5201 €/kW | [60] | |

| SNG | Go Green Fuels Ltd. | Feedstock: RDF and waste wood; conversion pathway: fluidized-bed gasifier + water-gas shift + methanation; TRL: 8. | 1500 t/y | 18,589 €/(t/y) | [61] |

| Goeteborg Energi | Feedstock: woody biomass; conversion pathway: fluidized-bed gasifier + methanation; TRL: 6–7. | 11,200 t/y | 13,419 €/(t/y) | [62] | |

| Engie | Feedstock: wastes of wood, straw, forest, agriculture, paper industry, and SRF; conversion pathway: fluidized-bed gasifier + catalytic methanation; TRL: 4–5. | 100 kg/y | 606 M€/(t/y) | [59] | |

| Ethanol | Enerkem | Feedstock: MSW; conversion pathway: gasification + methanol synthesis + ethanol conversion; TRL: 8. | 30,000 t/y | 3397 €/(t/y) | |

| Enerkem | Feedstock: MSW; conversion pathway: gasification + methanol synthesis + ethanol conversion. | 35,000 t/y | 1879 €/(t/y) | [63,64] | |

| Woodland Biofuels | Feedstock: wood and crop wastes; conversion pathway: gasification + catalytic synthesis. | 601 t/y | 14,899 €/(t/y) | [65] | |

| Methanol | Varmlands Methanol | Conversion pathway: gasification + alcohol synthesis. | 92,000 t/y | 3384 €/(t/y) | [65] |

| Gasoline | GTI Gas Technology Institute | Feedstock: woodchips and pellets; conversion pathway: pressurized fluidized-bed gasifier + methanol/dimethyl ether synthesis + gasoline synthesis; TRL: 4–5. | 27.9 t/y | 929,757 €/(t/y) | [63] |

| FTfuels | Total | Feedstock: straw, energy crops, and forestry waste; conversion pathway: gasification + FT synthesis; TRL: 6–7. | 8000 t/y | 23,750 €/(t/y) | [66] |

| Fulcrum | Conversion pathway: gasification + FT synthesis. | 30,360 t/y | 5764 €/(t/y) | [63,67] | |

| CHOREN Fuel Freiberg GmbH | Feedstock: woodchips and residual forestry wood; conversion pathway: gasification + FT synthesis; TRL: 6–7. | 13,500 t/y | 17,684 €/(t/y) | [59] | |

| Red Rock Biofuels | Conversion pathway: gasification + FT synthesis. | 47,270 t/y | 6325 €/(t/y) | [65] | |

| BioTfuel Demo | Feedstock: straw, energy crops, and forestry waste; conversion pathway: gasification + FT synthesis + hydrotreating/hydrocracking; TRL: 6–7. | 8000 t/y | 23,750 €/(t/y) | [59] | |

| Karlsruhe Institute of Technology | Feedstock: straw; conversion pathway: gasification + FT synthesis; TRL: 6–7. | 968 t/y | 57,965 €/(t/y) | [65] | |

| Tubitak | Feedstock: forestry waste; conversion pathway: gasification + gas clean-up and conditioning + FT synthesis; TRL: 4–5. | 250 t/y | 33,702 €/(t/y) | [63] |

| Plant Type | Variation of Specific Costs | Average Specific Cost |

|---|---|---|

| Electricity | 2318–12,991 €/kWe (Output range: 2–26.5 MWe) | 8583 €/kWe |

| Heat | 624–1231 €/kWth (Output range: 6.4–190 MWth) | 858 €/kWth |

| CHP | 289–5201 €/kW (Total output range: 140–140,000 kW) | 2744 €/kW |

| Synthetic natural gas | 13,419–18,589 €/(t/y) (Output range: 1500–11,200 t/y) | 16,004 €/(t/y) |

| Liquid fuels | 1879–33,702 €/(t/y) (Output range: 250–92,000 t/y) | 10,879 €/(t/y) |

| Plant Type | Equation | R2 | Notes |

|---|---|---|---|

| Electricity | SI = −531.01 × Y + 1,077,364.19 | 0.67 | SI—specific investment (k€/kW for electricity and CHP; k€/(t/y) for liquid fuels)Y—year of the plant |

| CHP | SI = −120.03 × Y + 244,214.06 | 0.21 | |

| Liquid fuels | SI = −933.29 × Y + 1,891,578.92 | 0.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lourinho, G.; Alves, O.; Garcia, B.; Rijo, B.; Brito, P.; Nobre, C. Costs of Gasification Technologies for Energy and Fuel Production: Overview, Analysis, and Numerical Estimation. Recycling 2023, 8, 49. https://doi.org/10.3390/recycling8030049

Lourinho G, Alves O, Garcia B, Rijo B, Brito P, Nobre C. Costs of Gasification Technologies for Energy and Fuel Production: Overview, Analysis, and Numerical Estimation. Recycling. 2023; 8(3):49. https://doi.org/10.3390/recycling8030049

Chicago/Turabian StyleLourinho, Gonçalo, Octávio Alves, Bruno Garcia, Bruna Rijo, Paulo Brito, and Catarina Nobre. 2023. "Costs of Gasification Technologies for Energy and Fuel Production: Overview, Analysis, and Numerical Estimation" Recycling 8, no. 3: 49. https://doi.org/10.3390/recycling8030049

APA StyleLourinho, G., Alves, O., Garcia, B., Rijo, B., Brito, P., & Nobre, C. (2023). Costs of Gasification Technologies for Energy and Fuel Production: Overview, Analysis, and Numerical Estimation. Recycling, 8(3), 49. https://doi.org/10.3390/recycling8030049