Performance Assessment of One-Part Self-Compacted Geopolymer Concrete Containing Recycled Concrete Aggregate: A Critical Comparison Using Artificial Neural Network (ANN) and Linear Regression Models

Abstract

1. Introduction

2. Results and Discussion

2.1. Linear Regression Model Development

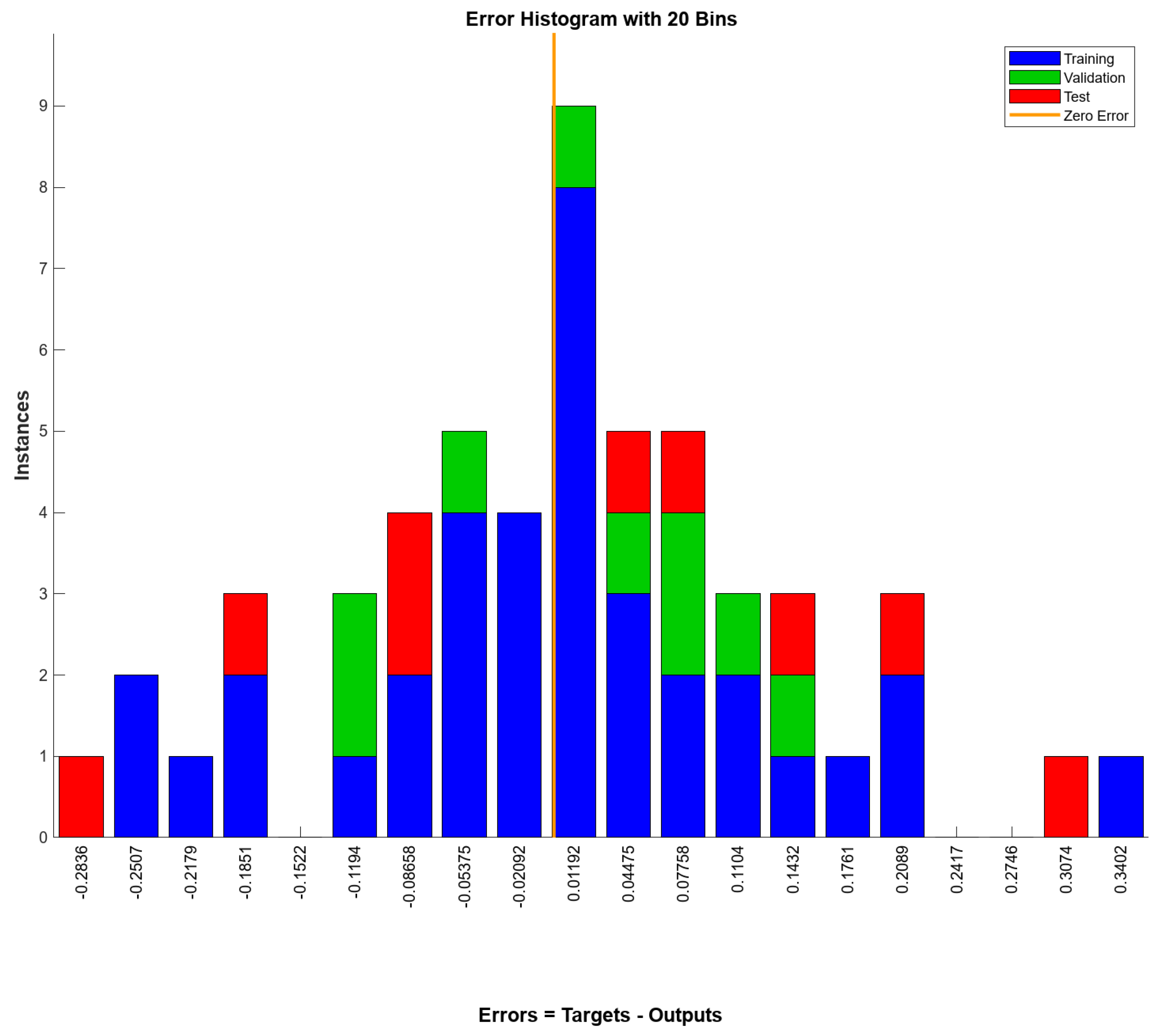

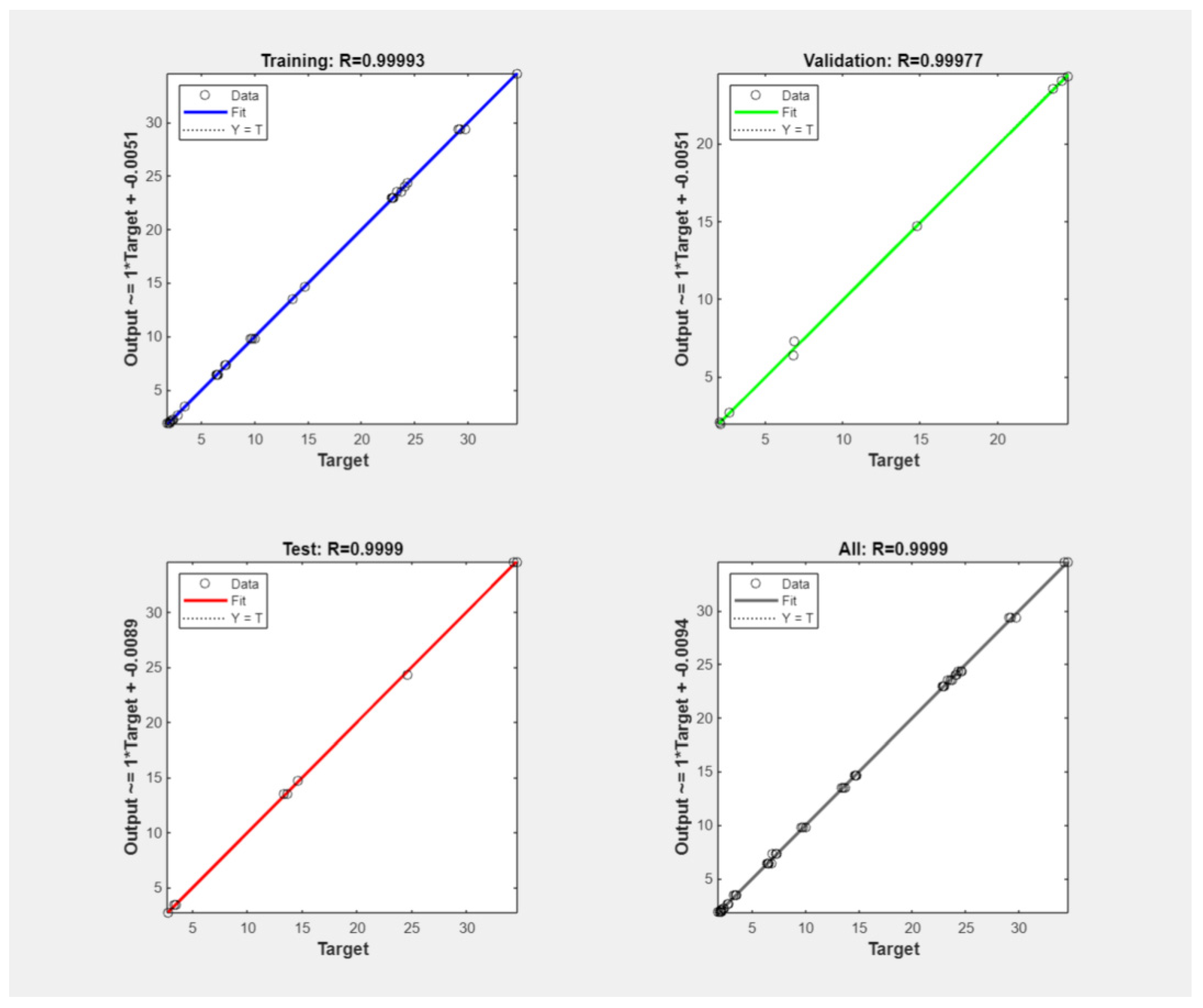

2.2. ANN Model According to the Levenberg–Marquardt (LM) Algorithm

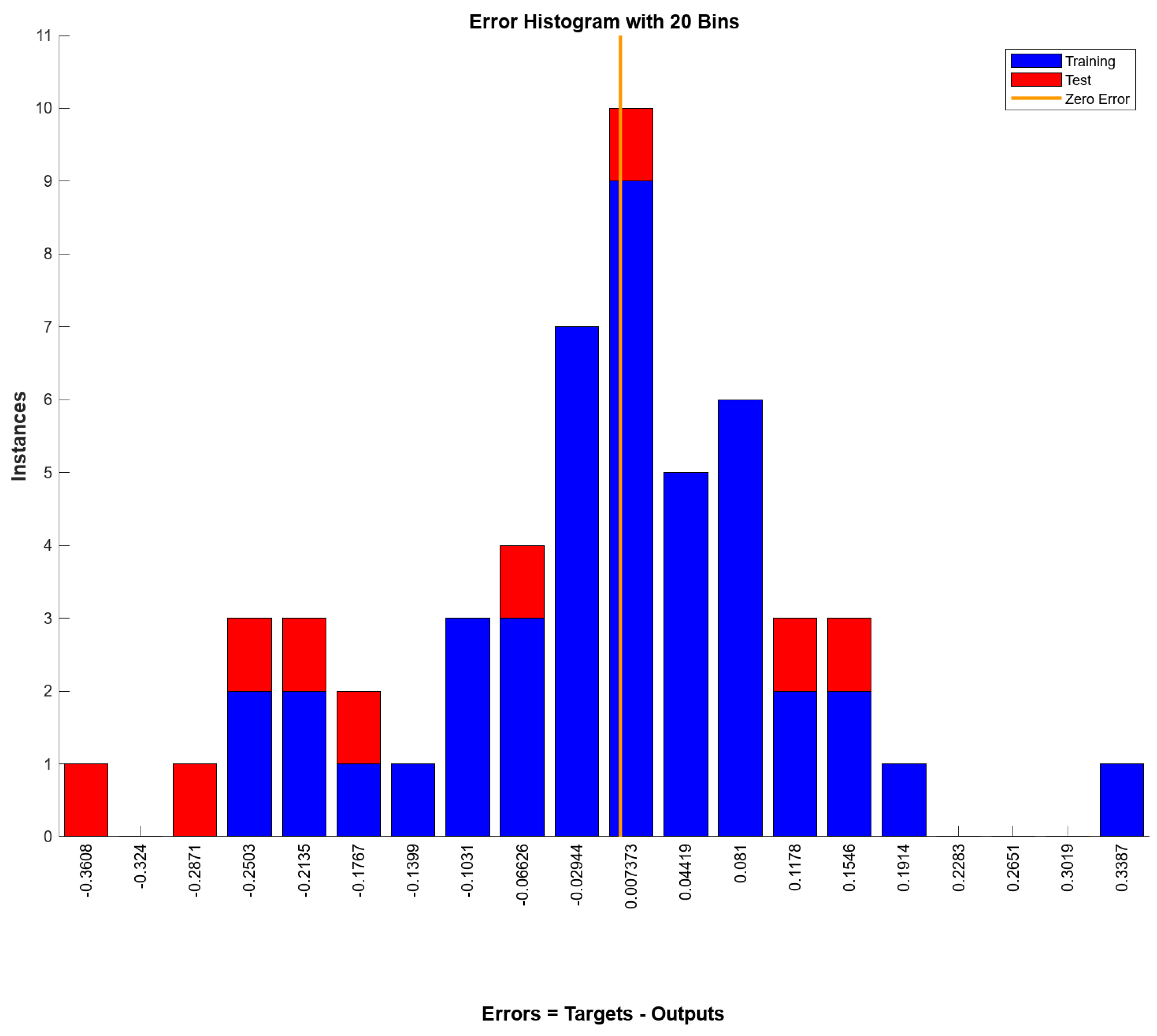

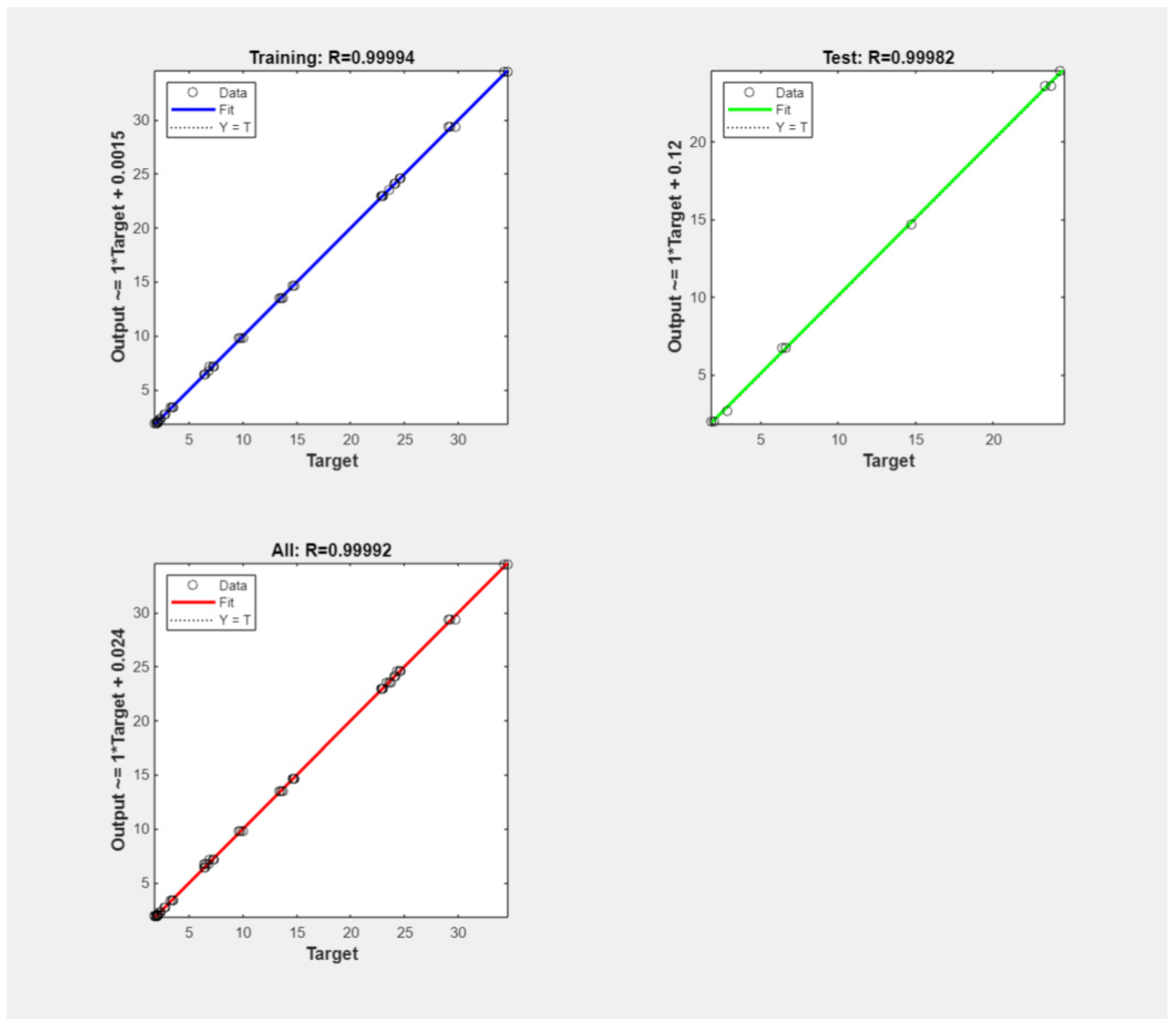

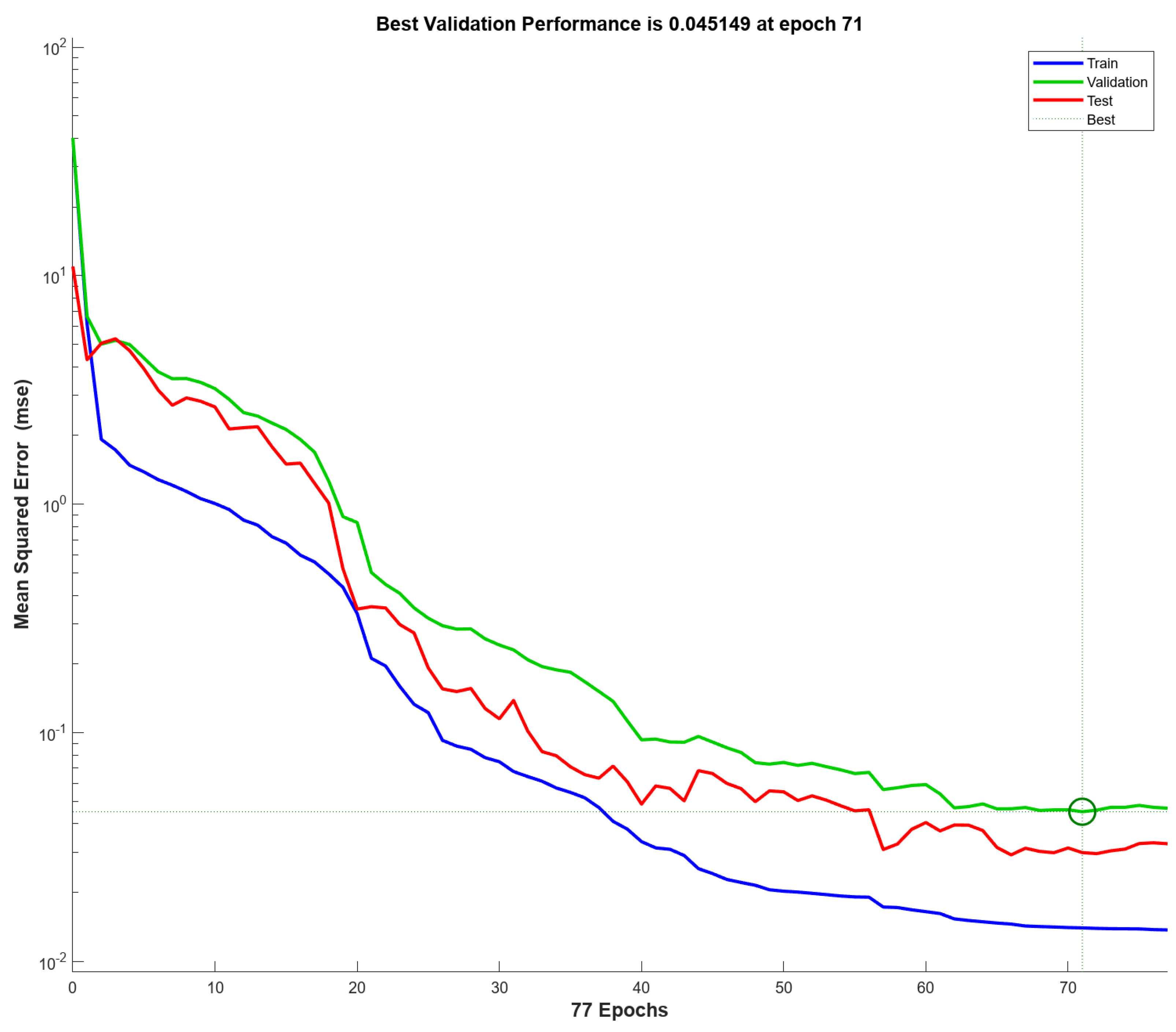

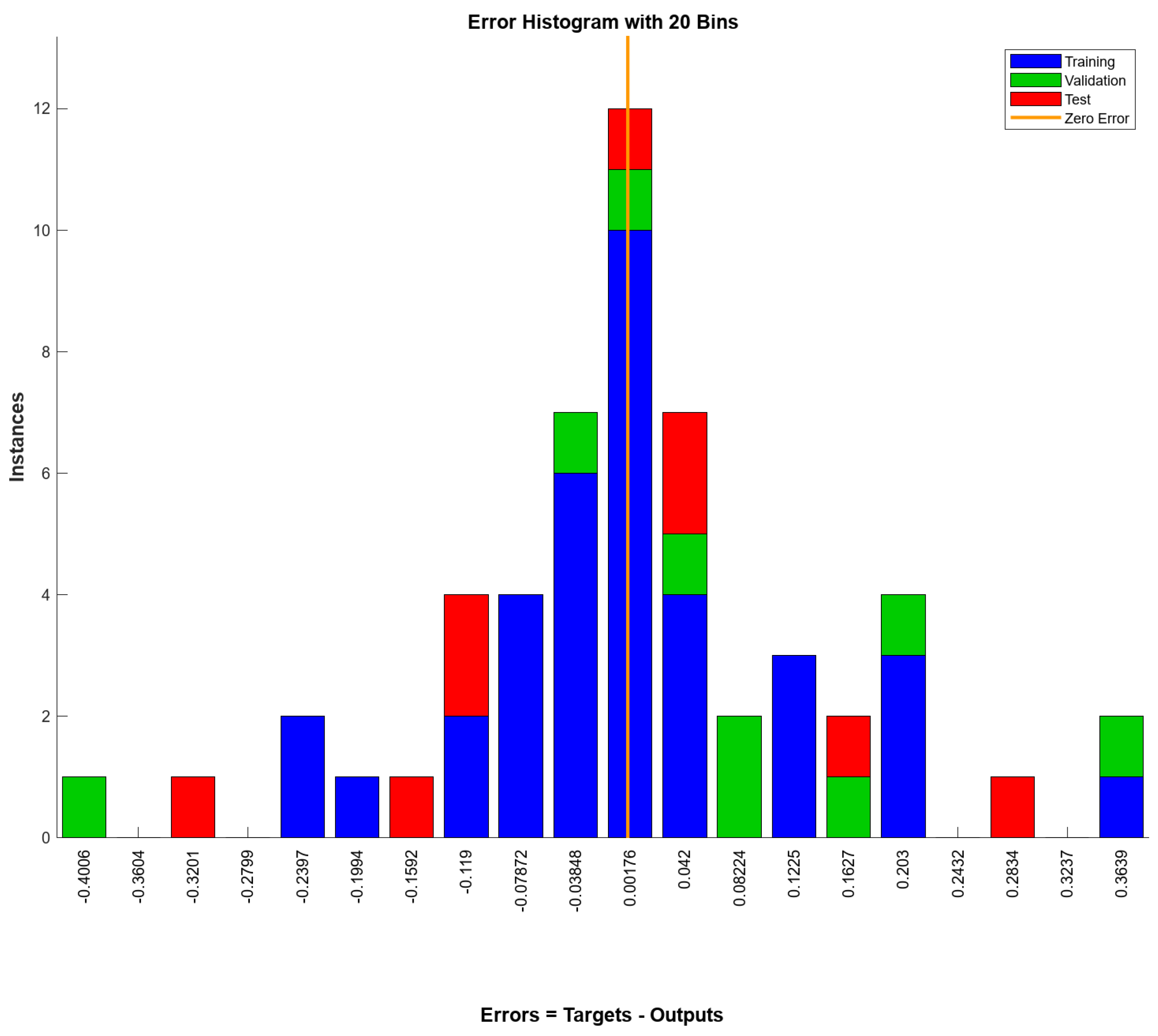

2.3. ANN Model According to Bayesian Regularisation (BR) Algorithm

2.4. ANN Model According to Scaled Conjugate Gradient (SCG) Training

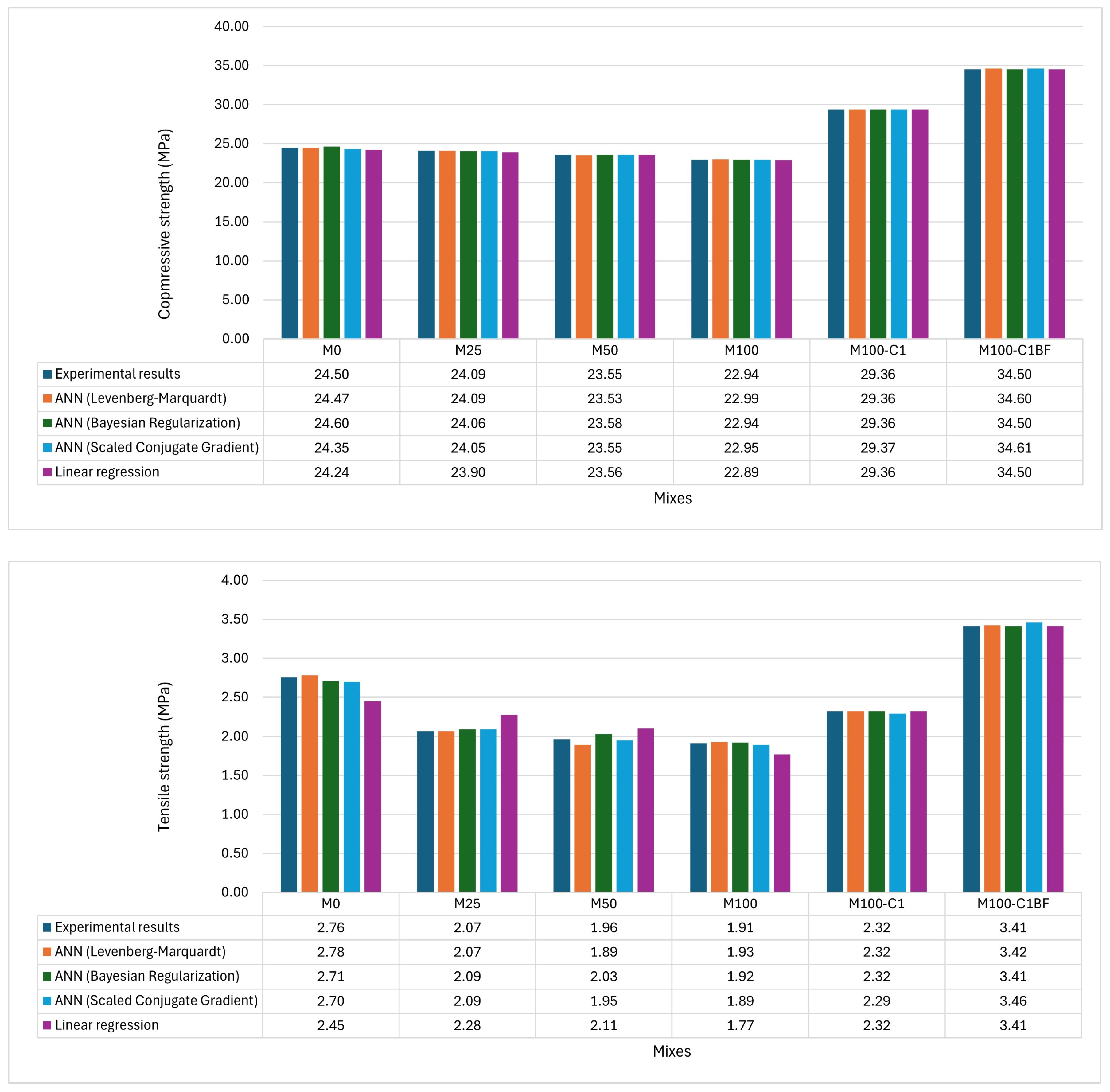

2.5. Performance Comparison of the Models

3. Materials and Methods

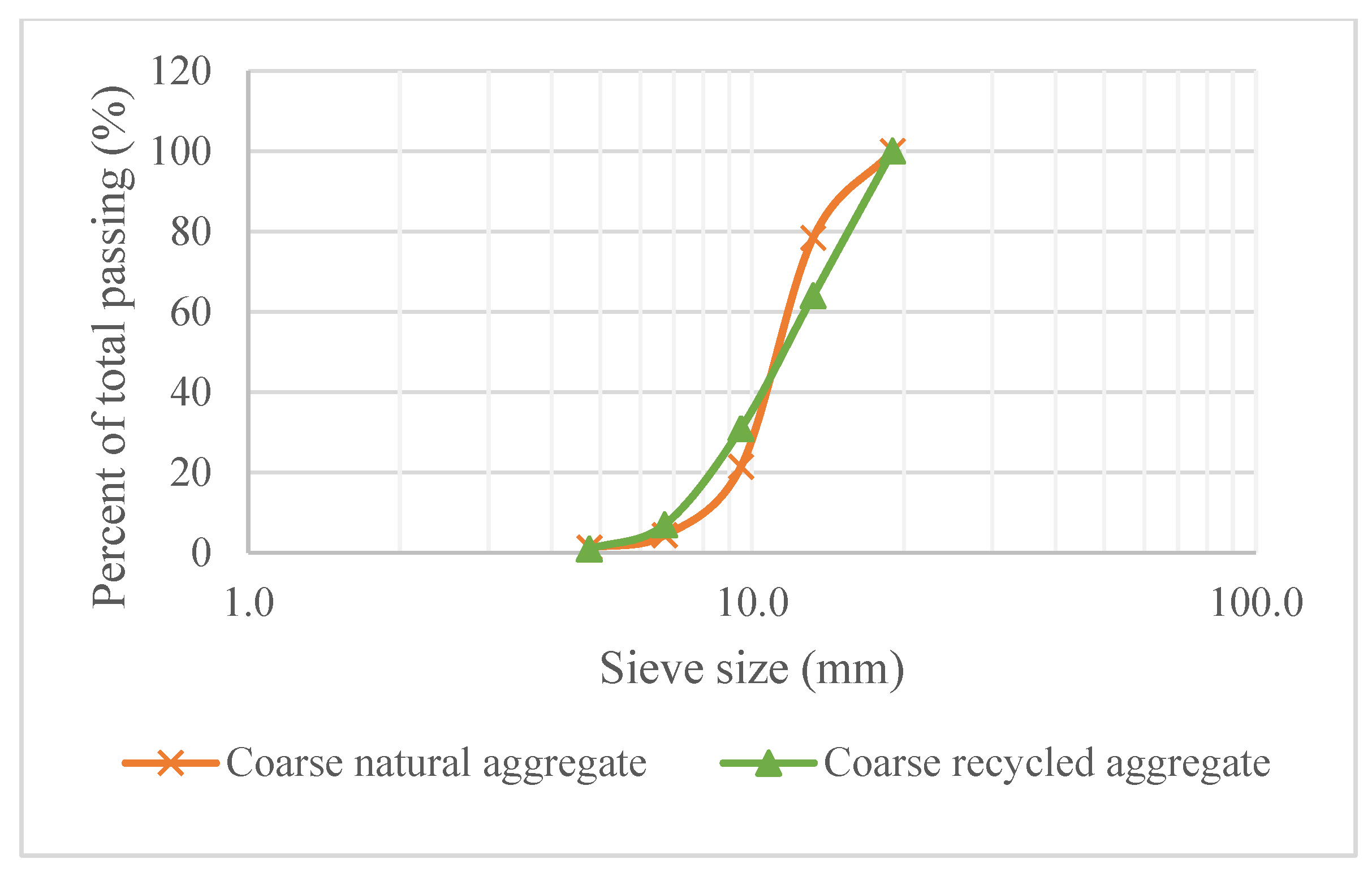

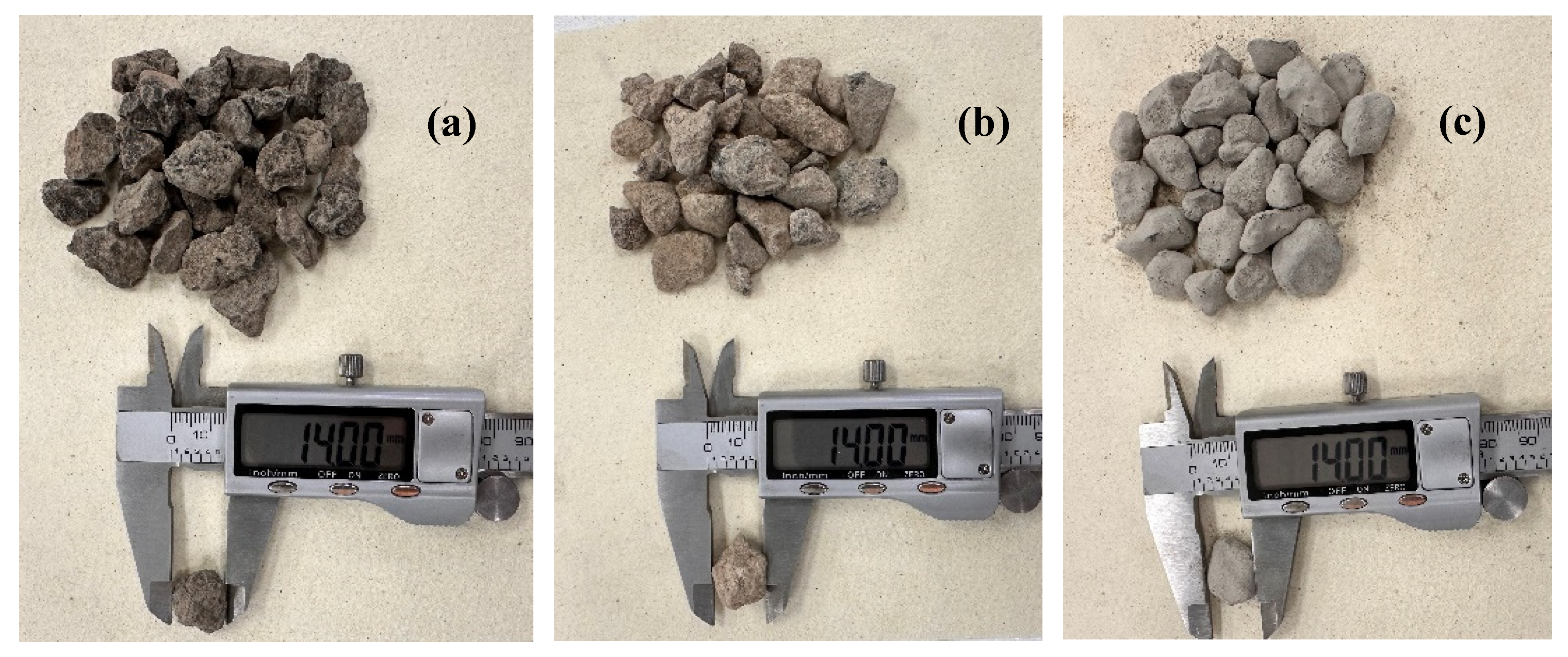

3.1. RCA-Based Self-Compacting Geopolymer Concrete

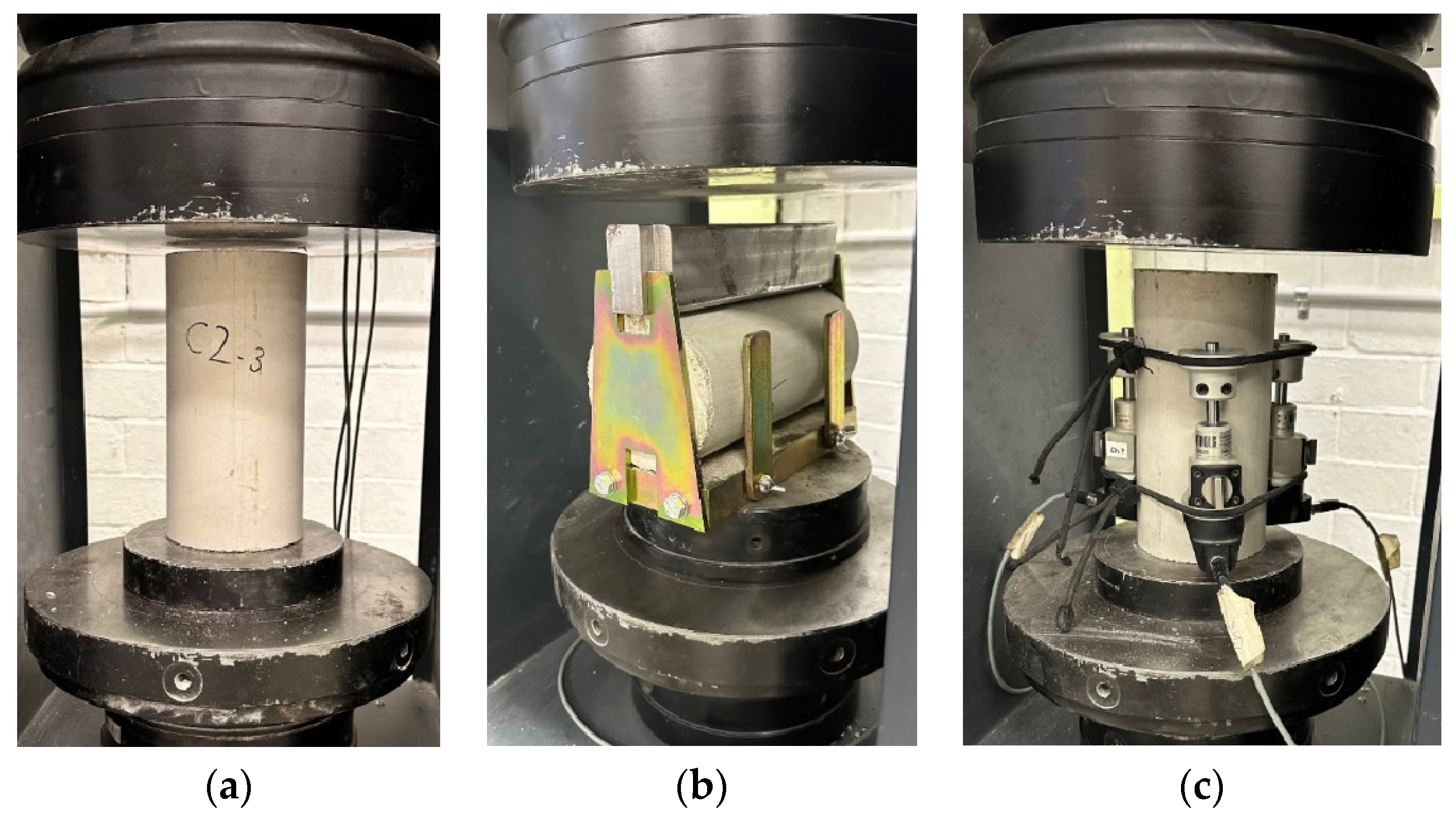

3.2. Experimental Investigation

3.3. Model Development

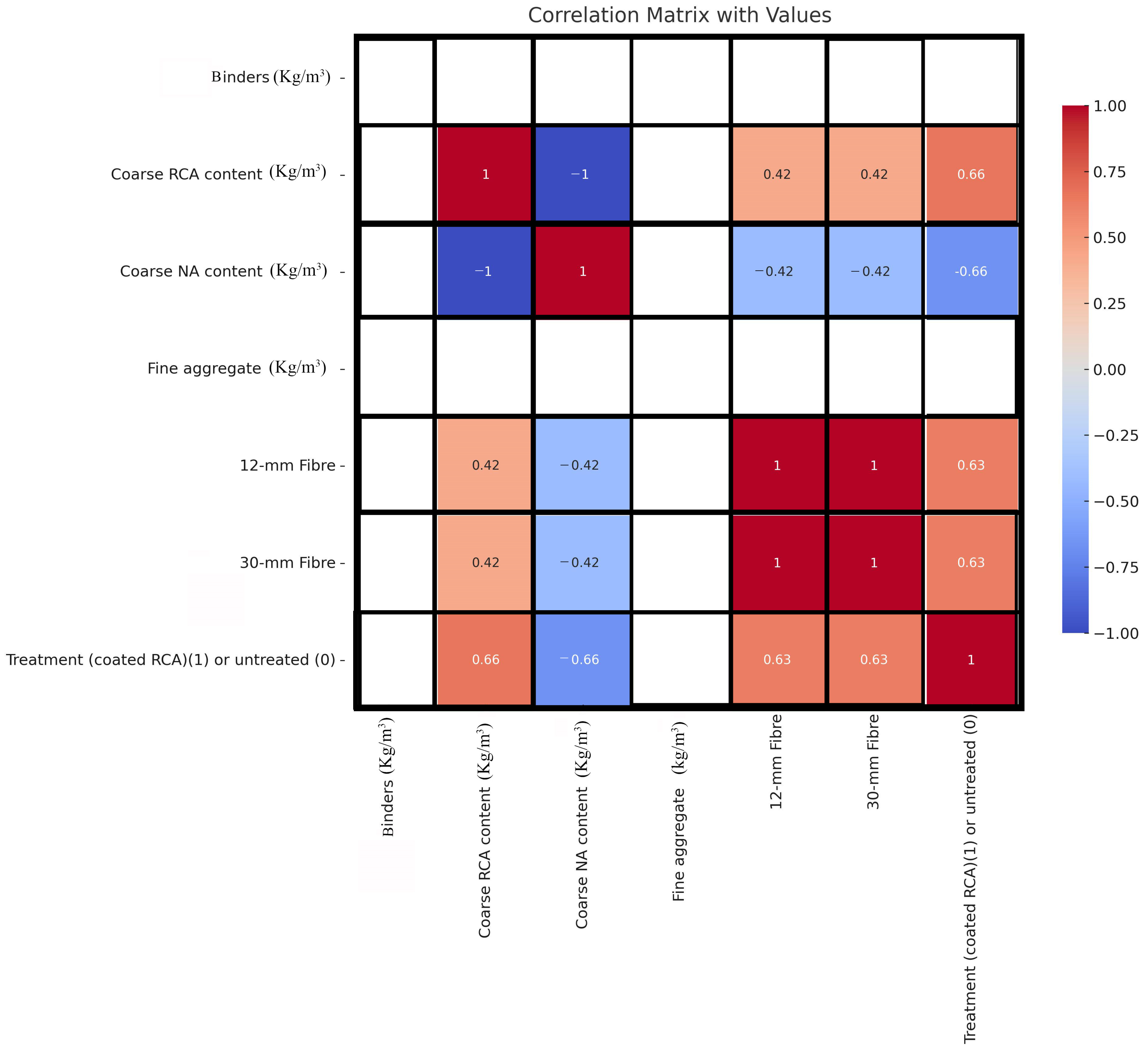

3.4. Sensitivity Analysis

4. Conclusions

- Three ANN-based models demonstrate superior predictions, with R values close to 1, compared to the linear regression model, indicating closer agreement with experimentally reported compressive strength, tensile strength, and modulus of elasticity across various amounts of RCA and treatment incorporations. Hence, ANN models play a crucial role in enhancing the use of recycled concrete aggregate in self-compacted geopolymer concrete, achieving optimal mechanical properties;

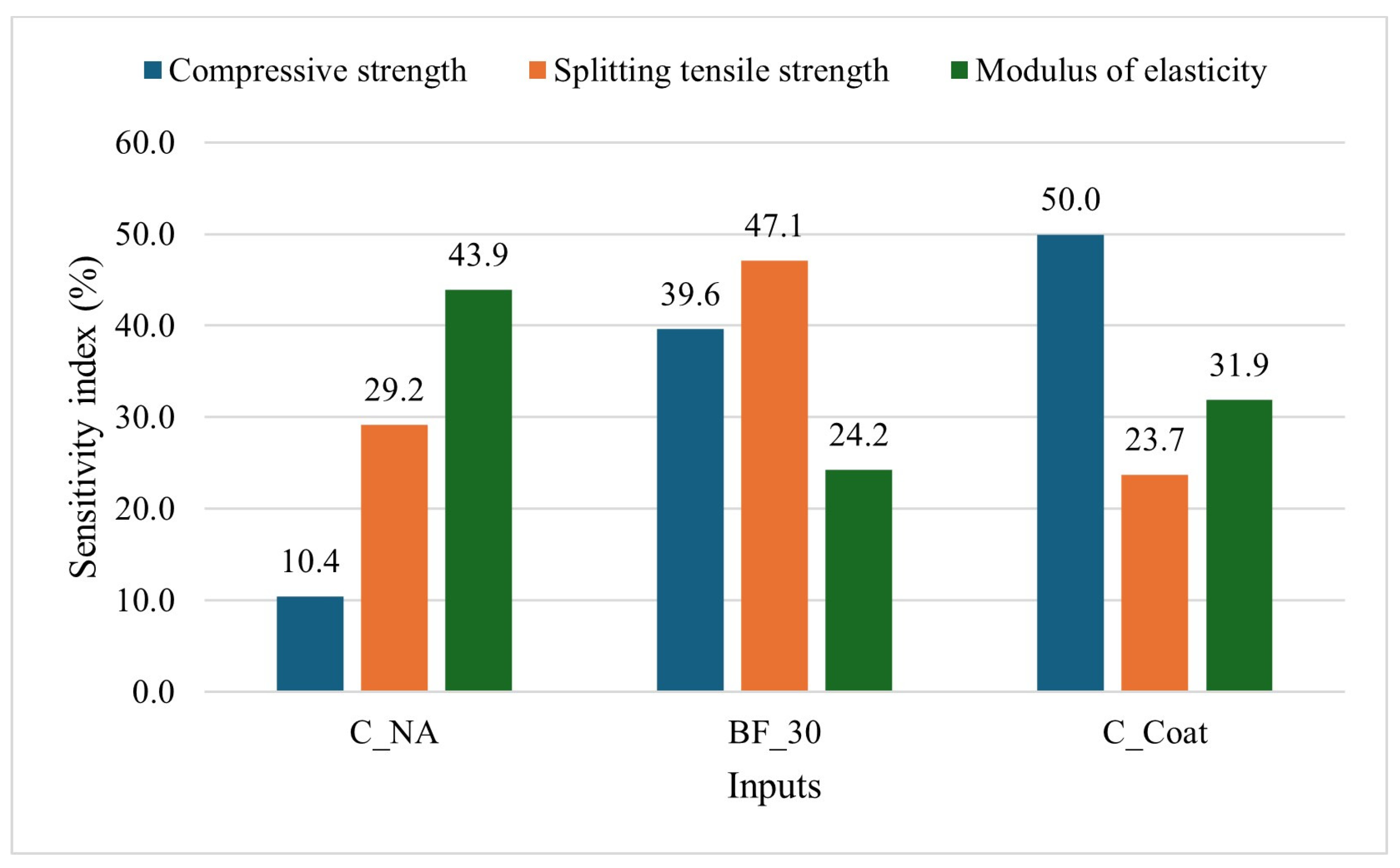

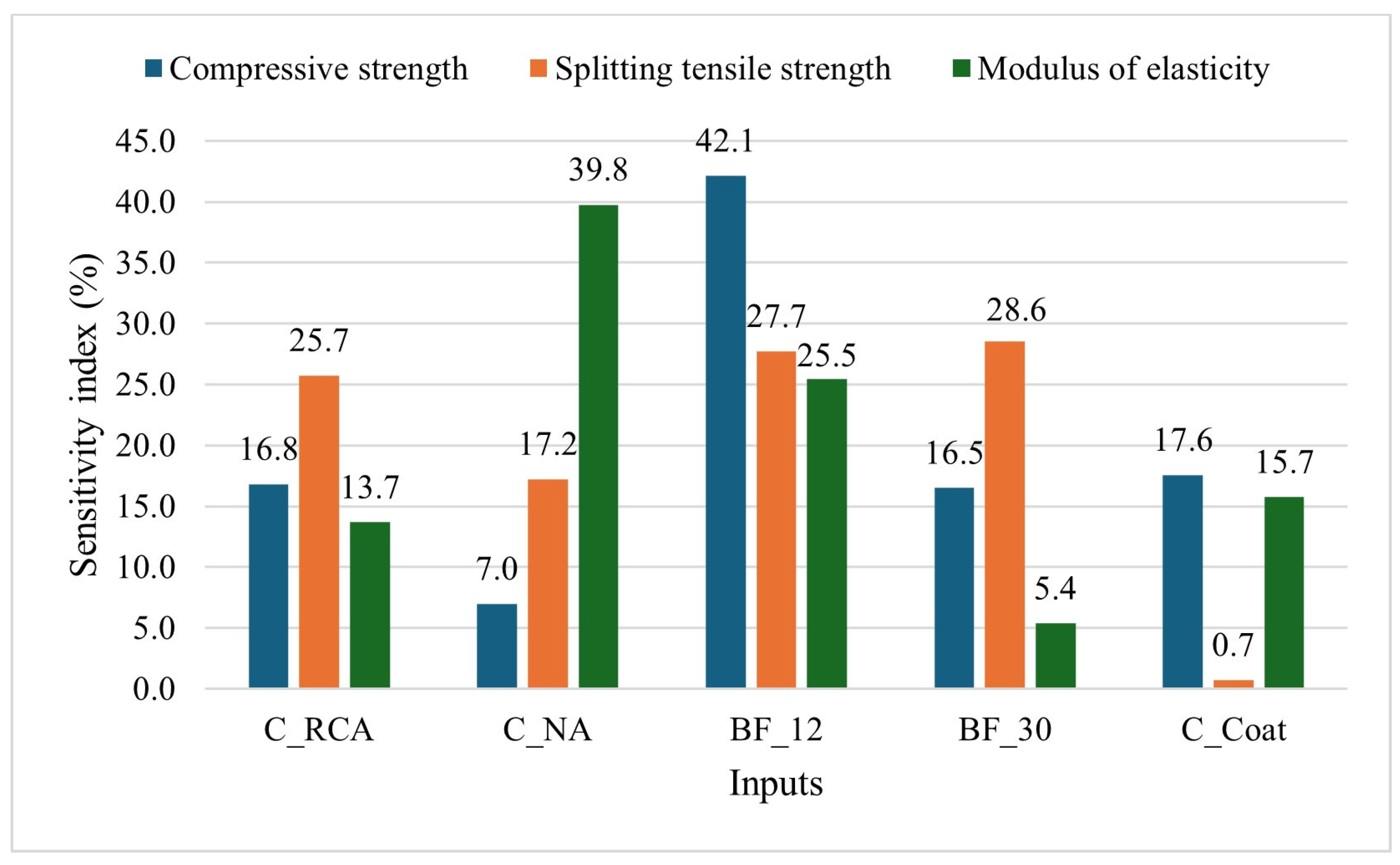

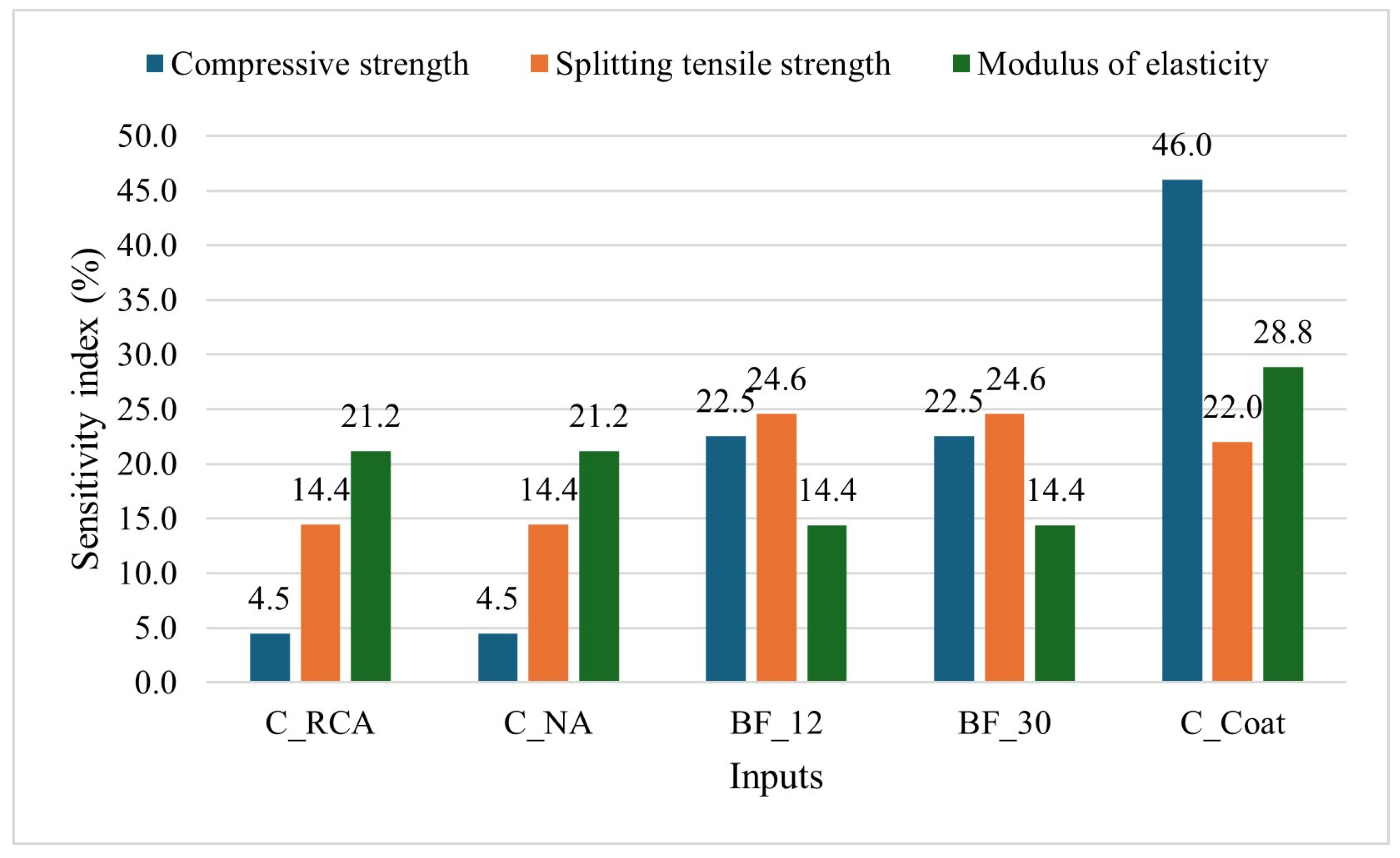

- Sensitivity analysis was performed to study the impact of each input variable on , indicating that the LR-based ANN model for predicting compressive strength, tensile strength, and MoE is 50%, 47.1%, and 43.9% sensitive to , , and , respectively. The ANN model trained with the LM algorithm represents sensitivities of 42.1%, 28.6%, and 39.8% to , and for compressive strength, splitting tensile strength, and modulus of elasticity estimations. The BR-based ANN model is highly sensitive to for compressive strength and modulus of elasticity predictions, with sensitivity indexes of 46% and 28.8%, respectively, while for tensile strength, it is equally sensitive to both and each with a 24.6% sensitivity index. The SCG-based ANN model is sensitive to and by 31.4% and 29.1% for compressive strength and modulus of elasticity predictions, respectively. For tensile strength predictions, it is approximately 36% sensitive to 12-mm and 30-mm basalt fibres;

- The BR-based ANN model outperformed the LM- and SCG-based ANN models in predicting the compressive strength of geopolymer concrete samples with various RCA rates and treatments;

- The BR- and SCG-based ANN models were surpassed by the LM-based ANN model, demonstrating more accurate predictions for the splitting tensile strength and modulus of elasticity of SCGC samples cast with different replacement rates of treated and untreated RCA.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Pickin, J.; Wardle, C.; O’Farrell, K.; Stovell, L.; Nyunt, P.; Guazzo, S.; Lin, Y.; Caggiati-Shortell, G.; Chakma, P.; Edwards, C. National Waste Report 2022. Available online: https://www.dcceew.gov.au/sites/default/files/documents/national-waste-report-2022.pdf (accessed on 27 August 2024).

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- Nikmehr, B.; Hosseini, M.R.; Wang, J.; Chileshe, N.; Rameezdeen, R. BIM-Based Tools for Managing Construction and Demolition Waste (CDW): A Scoping Review. Sustainability 2021, 13, 8427. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Matějková, P.; Matějka, V.; Sabovčík, T.; Gryžbon, L.; Vlček, J. Alkali Activation of Ground Granulated Blast Furnace Slag and Low Calcium Fly Ash Using “One-Part” Approach. J. Sustain. Metall. 2022, 8, 511–521. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Liu, J.C.; Wu, B. Mechanical properties and reaction mechanism of one-part geopolymer mortars. Constr. Build. Mater. 2021, 273, 121973. [Google Scholar] [CrossRef]

- Wan-En, O.; Yun-Ming, L.; Cheng-Yong, H.; Abdullah, M.M.A.B.; Li, L.Y.; Ho, L.N.; Loong, F.K.; Shee-Ween, O.; Hui-Teng, N.; Yong-Sing, N.; et al. Comparative mechanical and microstructural properties of high calcium fly ash one-part geopolymers activated with Na2SiO3-anhydrous and NaAlO2. J. Mater. Res. Technol. 2021, 15, 3850–3866. [Google Scholar] [CrossRef]

- Zhou, S.; Ma, C.; Long, G.; Xie, Y. A novel non-Portland cementitious material: Mechanical properties, durability and characterization. Constr. Build. Mater. 2020, 238, 117671. [Google Scholar] [CrossRef]

- Tesanasin, T.; Suksiripattanapong, C.; Van Duc, B.; Tabyang, W.; Phetchuay, C.; Phoo-ngernkham, T.; Sukontasukkul, P.; Chindaprasirt, P. Engineering properties of marginal lateritic soil stabilized with one-part high calcium fly ash geopolymer as pavement materials. Case Stud. Constr. Mater. 2022, 17, e01328. [Google Scholar] [CrossRef]

- Wan-En, O.; Yun-Ming, L.; Cheng Yong, H.; Li-Ngee, H.; Al Bakri Abdullah, M.M.; Shee-Ween, O.; Sandu, A.V. Effect of Sodium Aluminate on the Fresh and Hardened Properties of Fly Ash-Based One-Part Geopolymer. Arch. Metall. Mater. 2022, 67, 441–445. [Google Scholar] [CrossRef]

- Cong, P.; Mei, L. Using silica fume for improvement of fly ash/slag based geopolymer activated with calcium carbide residue and gypsum. Constr. Build. Mater. 2021, 275, 122171. [Google Scholar] [CrossRef]

- Samarakoon, M.H.; Ranjith, P.G.; Hui Duan, W.; Chen, B.K.; Khandelwal, M. Early age properties of alkali-activated cement and class G cement under different saturation conditions in oil well applications. Constr. Build. Mater. 2021, 271, 121543. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. A newly developed self-compacting geopolymer concrete under ambient condition. Constr. Build. Mater. 2021, 267, 121822. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. Marine Geopolymer Concrete—A Hybrid Curable Self-Compacting Sustainable Concrete for Marine Applications. Appl. Sci. 2022, 12, 3116. [Google Scholar] [CrossRef]

- Pang, L.; Liu, Z.; Wang, D.; An, M. Review on the Application of Supplementary Cementitious Materials in Self-Compacting Concrete. Crystals 2022, 12, 180. [Google Scholar] [CrossRef]

- Okrajnov-Bajić, R.; Vasović, D. Self-compacting concrete and its application in contemporary architectural practice. Spatium 2009, 20, 28–34. [Google Scholar] [CrossRef]

- Nikmehr, B.; Al-Ameri, R.; Kafle, B. Structural Performance of Geopolymer Concrete with Recycled Concrete Aggregate: A review. In Proceedings of the 3rd International Conference on Structural Engineering Research (iCSER-2022), Sydney, Australia, 27–30 November 2022. [Google Scholar]

- Nikmehr, B.; Al-Ameri, R. A State-of-the-Art Review on the Incorporation of Recycled Concrete Aggregates in Geopolymer Concrete. Recycling 2022, 7, 51. [Google Scholar] [CrossRef]

- Salimbahrami, S.R.; Shakeri, R. Experimental investigation and comparative machine-learning prediction of compressive strength of recycled aggregate concrete. Soft Comput. 2021, 25, 919–932. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Salas-Morera, L.; Jiménez, J.R.; García-Hernández, L. A novel artificial neural network to predict compressive strength of recycled aggregate concrete. Appl. Sci. 2021, 11, 11077. [Google Scholar] [CrossRef]

- Amiri, M.; Hatami, F. Prediction of mechanical and durability characteristics of concrete including slag and recycled aggregate concrete with artificial neural networks (ANNs). Constr. Build. Mater. 2022, 325, 126839. [Google Scholar] [CrossRef]

- Rizvon, S.S.; Jayakumar, K. Strength prediction models for recycled aggregate concrete using Random Forests, ANN and LASSO. J. Build. Pathol. Rehabil. 2022, 7, 5. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. Structural assessment of Basalt FRP reinforced self-compacting geopolymer concrete using artificial neural network (ANN) modelling. Constr. Build. Mater. 2023, 397, 132464. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. Experimental and Artificial Neural Network-Based Study on the Sorptivity Characteristics of Geopolymer Concrete with Recycled Cementitious Materials and Basalt Fibres. Recycling 2022, 7, 55. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N.; Silva, L.C.F.D.; Evangelista, A.C.J. A prediction model for compressive strength of CO2 concrete using regression analysis and artificial neural networks. Constr. Build. Mater. 2022, 324, 126689. [Google Scholar] [CrossRef]

- Nunez, I.; Marani, A.; Flah, M.; Nehdi, M.L. Estimating compressive strength of modern concrete mixtures using computational intelligence: A systematic review. Constr. Build. Mater. 2021, 310, 125279. [Google Scholar] [CrossRef]

- Vapnik, V. The Nature of Statistical Learning Theory; Springer: New York, NY, USA, 2013. [Google Scholar]

- Chopra, P.; Sharma, R.K.; Kumar, M. Prediction of Compressive Strength of Concrete Using Artificial Neural Network and Genetic Programming. Adv. Mater. Sci. Eng. 2016, 2016, 7648467. [Google Scholar] [CrossRef]

- Ayub, T.; Mahmood, W.; Khan, A.-R. Durability performance of SCC and SCGC containing recycled concrete aggregates: A comparative study. Sustainability 2021, 13, 8621. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Danish, A.; Alqurashi, M.; Mosaberpanah, M.A.; Masood, B.; Hussein, E.E. Influence of Bentonite on Mechanical and Durability Properties of High-Calcium Fly Ash Geopolymer Concrete with Natural and Recycled Aggregates. Materials 2021, 14, 7790. [Google Scholar] [CrossRef] [PubMed]

- Al-Jaberi, L.; Al-Saraj, A.-S.K.W.; Al-Serai, A.-S.J.S. Scanning Electron Microscopy of Metakaolin Based Geopolymer Concrete. J. Phys. Conf. Ser. 2021, 2114, 012061. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Pham, T.M. Effective utilisation of ultrafine slag to improve mechanical and durability properties of recycled aggregates geopolymer concrete. Clean. Eng. Technol. 2021, 5, 100330. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Kiran, T.; Anand, N.; Al Jabri, K.; Justin, S. Development and strength assessment of eco-friendly geopolymer concrete made with natural and recycled aggregates. Constr. Innov. 2022, 23, 524–545. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Zhang, X.; Ding, Y.; Xu, P. Mechanical properties and microstructure of basalt fiber-reinforced recycled concrete. J. Clean. Prod. 2021, 278, 123252. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; He, Z. Mechanical and fracture properties of geopolymer concrete with basalt fiber using digital image correlation. Theor. Appl. Fract. Mech. 2021, 112, 102909. [Google Scholar] [CrossRef]

- Heweidak, M.; Kafle, B.; Al-Ameri, R. Influence of Hybrid Basalt Fibres Length on Fresh and Mechanical Properties of Self-Compacted Ambient-Cured Geopolymer Concrete. J. Compos. Sci. 2022, 6, 292. [Google Scholar] [CrossRef]

- Nikmehr, B.; Kafle, B.; Al-Ameri, R. Developing a sustainable self-compacting geopolymer concrete with 100% geopolymer-coated recycled concrete aggregate replacement. Smart Sustain. Built Environ. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Kumar, P. Performance Assessment of Graphene Oxide–Reinforced Sustainable Geopolymer Concrete. J. Mater. Civ. Eng. 2021, 33, 04021322. [Google Scholar] [CrossRef]

- Alserai, S.J.; Alsaraj, W.K.; Abass, Z.W. Effect of iron filings on the mechanical properties of different types of sustainable concrete. Open Civ. Eng. J. 2018, 12, 441–457. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Constr. Build. Mater. 2019, 205, 519–528. [Google Scholar] [CrossRef]

- Dabiri, H.; Clementi, J.; Marini, R.; Mugnozza, G.S.; Bozzano, F.; Mazzanti, P. Machine learning-based analysis of historical towers. Eng. Struct. 2024, 304, 117621. [Google Scholar] [CrossRef]

- AS 1012.8-1986 AMDT 1; Methods of Testing Concrete, Method 8: Method for Making and Curing Concrete Compression, Indirect Tensile and Flexure Test Specimens, in the laboratory or in the Field. Standards Australia Limited: Sydney, NSW, Australia, 1986.

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Nikmehr, B.; Kafle, B.; Al-Ameri, R. A review of the advanced treatment techniques for enriching the recycled concrete aggregates for recycled-based concrete: Economic, environmental and technical analysis. Smart Sustain. Built Environ. 2024, 13, 560–583. [Google Scholar] [CrossRef]

- Gupta, A.; Mandal, S.; Ghosh, S. Durability of geopolymer coated recycled aggregate concrete exposed to Sulphuric acid. Int. J. Appl. Eng. Res. 2012, 7, 91–103. [Google Scholar] [CrossRef]

- AS 1012.8.1:2014; Methods of Testing Concrete. Method 8.1: Method for Making and Curing Concrete-Compression and Indirect Tensile Test Specimens. Standards Australia Limited: Sydney, NSW, Australia, 2014.

- AS 1012.3.5:2015; Methods of Testing Concrete. Method 3.5: Determination of Properties Related to the Consistency of Concrete—Slump Flow, T500 and J-Ring Test. Standards Australia: Sydney, NSW, Australia, 2015.

- VicRoads. Technical Note 73: Self Compacting Concrete (SCC). Melbourne, VIC, Australia. 2006. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.vicroads.vic.gov.au/-/media/files/technical-documents-new/technical-notes/technical-note-tn-073--self-compacting-concrete.ashx&ved=2ahUKEwitpOf5gaOIAxVvna8BHc_cIEgQFnoECBkQAQ&usg=AOvVaw3y4wkbNHn5Cf04GgNE4v7l (accessed on 27 August 2024).

- AS 1012.9: 2014; Methods of Testing Concrete. Method 9: Compressive Strength Tests—Concrete, Mortar and Grout Specimens. Standards Australia Limited: Sydney, NSW, Australia, 2014.

- AS 1012.10-2000Methods of Testing Concrete, Method 10: Determination of Indirect Tensile Strength of Concrete Cylinders (‘Brazil’ or Splitting Test); Standards Australia Limited: Sydney, NSW, Australia, 2000.

- AS 1012.17-1997; Methods of Testing Concrete, Method 17: Determination of the Static Chord Modulus of Elasticity and Poisson’s Ratio of Concrete Specimens. Standards Australia Limited: Sydney, NSW, Australia, 1997.

- Frank, I.E.; Todeschini, R. The Data Analysis Handbook; Elsevier Science: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S. Experimental investigation and modelling the deformation properties of demolition wastes subjected to freeze–thaw cycles using ANN and SVR. Constr. Build. Mater. 2020, 258, 119688. [Google Scholar] [CrossRef]

- MathWorks, Inc. MATLAB, version: 23.2.0.2365128 (R2023b); Natick: Massachusetts, MA, USA, 2023. [Google Scholar]

- Corporation, I. IBM SPSS Statistics for Windows, Version 29.0; IBM Corp.: Armonk, NY, USA, 2022. [Google Scholar]

- Cook, R.; Lapeyre, J.; Ma, H.; Kumar, A. Prediction of Compressive Strength of Concrete: Critical Comparison of Performance of a Hybrid Machine Learning Model with Standalone Models. J. Mater. Civ. Eng. 2019, 31, 04019255. [Google Scholar] [CrossRef]

- Han, T.; Siddique, A.; Khayat, K.; Huang, J.; Kumar, A. An ensemble machine learning approach for prediction and optimization of modulus of elasticity of recycled aggregate concrete. Constr. Build. Mater. 2020, 244, 118271. [Google Scholar] [CrossRef]

- Origin. OriginLab Corporation, 2023b; OriginLab: Northampton, MA, USA, 2023. [Google Scholar]

- Rostami, M.F.; Sadrossadat, E.; Ghorbani, B.; Kazemi, S.M. New empirical formulations for indirect estimation of peak-confined compressive strength and strain of circular RC columns using LGP method. Eng. Comput. 2018, 34, 865–880. [Google Scholar] [CrossRef]

| Study by | Input Variables | Output | R2 |

|---|---|---|---|

| Tam, Butera, Le, Silva, and Evangelista [29] | Chamber time, chamber pressure, cement, water, water to binder ratio (W/C), RCA, and sand content | Compressive strength | 0.95 |

| Rizvon and Jayakumar [26] | Age, W/C, superplasticiser, FA, RCA, and water content | Compressive strength | 0.93 |

| Amiri and Hatami [25] | Age, W/C, slag, RCA content | Compressive strength and chloride migration | 0.99 |

| Suescum-Morales, Salas-Morera, Jiménez, and García-Hernández [24] | Cement, FA, water, superplasticiser, fine and coarse NA or RCA content | Compressive strength | 0.99 |

| Salimbahrami and Shakeri [23] | Coarse and fine NA and RCA, cement, water, superplasticiser content | Compressive strength | 0.98 |

| Model Summary | Linear Regression Coefficients | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | R2 | R2 Adjusted | SEE | Constant | ||||||

| Compressive Strength | 0.999 | 0.998 | 0.998 | 0.18688 | 22.886 | 0 | 0.002 | 0.324 | 0 | 6.477 |

| Tensile Strength | 0.937 | 0.878 | 0.852 | 0.21285 | 1.769 | 0 | 0.001 | 0.069 | 0 | 0.551 |

| Modulus of Elasticity | 0.813 | 0.661 | 0.589 | 2.19700 | 4.887 | 0 | 0.010 | 0.236 | 0 | 4.913 |

| Compressive Strength | Tensile Strength | Modulus of Elasticity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks |

| R | >0.90 | 0.999 | Satisfactory | R | >0.90 | 0.937 | Satisfactory | R | >0.90 | 0.813 | Unsatisfactory |

| MSE | Close to 0 | 0.041 | Satisfactory | MSE | Close to 0 | 0.036 | Satisfactory | MSE | Close to 0 | 3.755 | Unsatisfactory |

| MAE | Close to 0 | 0.172 | Satisfactory | MAE | Close to 0 | 0.155 | Satisfactory | MAE | Close to 0 | 1.555 | Unsatisfactory |

| MAPE | <10% | 0.656% | Satisfactory | MAPE | <10% | 6.812% | Satisfactory | MAPE | <10% | 18.657% | Unsatisfactory |

| RMSE | Close to 0 | 0.204 | Satisfactory | RMSE | Close to 0 | 0.189 | Satisfactory | RMSE | Close to 0 | 1.938 | Unsatisfactory |

| Compressive Strength | Tensile Strength | Modulus of Elasticity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks |

| R | >0.90 | 0.999 | Satisfactory | R | >0.90 | 0.989 | Satisfactory | R | >0.90 | 0.999 | Satisfactory |

| MSE | Close to 0 | 0.026 | Satisfactory | MSE | Close to 0 | 0.006 | Satisfactory | MSE | Close to 0 | 0.021 | Satisfactory |

| MAE | Close to 0 | 0.121 | Satisfactory | MAE | Close to 0 | 0.063 | Satisfactory | MAE | Close to 0 | 0.118 | Satisfactory |

| MAPE | <10% | 0.454% | Satisfactory | MAPE | <10% | 2.777% | Satisfactory | MAPE | <10% | 1.389% | Satisfactory |

| RMSE | Close to 0 | 0.161 | Satisfactory | RMSE | Close to 0 | 0.081 | Satisfactory | RMSE | Close to 0 | 0.145 | Satisfactory |

| Compressive Strength | Tensile Strength | Modulus of Elasticity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks |

| R | >0.90 | 0.999 | Satisfactory | R | >0.90 | 0.989 | Satisfactory | R | >0.90 | 0.999 | Satisfactory |

| MSE | Close to 0 | 0.026 | Satisfactory | MSE | Close to 0 | 0.007 | Satisfactory | MSE | Close to 0 | 0.024 | Satisfactory |

| MAE | Close to 0 | 0.121 | Satisfactory | MAE | Close to 0 | 0.064 | Satisfactory | MAE | Close to 0 | 0.117 | Satisfactory |

| MAPE | <10% | 0.447% | Satisfactory | MAPE | <10% | 2.887% | Satisfactory | MAPE | <10% | 1.410% | Satisfactory |

| RMSE | Close to 0 | 0.161 | Satisfactory | RMSE | Close to 0 | 0.082 | Satisfactory | RMSE | Close to 0 | 0.154 | Satisfactory |

| Compressive Strength | Tensile Strength | Modulus of Elasticity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks | Statistical Values | Condition | Outcome Achieved | Remarks |

| R | >0.90 | 0.999 | Satisfactory | R | >0.90 | 0.989 | Satisfactory | R | >0.90 | 0.999 | Satisfactory |

| MSE | Close to 0 | 0.030 | Satisfactory | MSE | Close to 0 | 0.007 | Satisfactory | MSE | Close to 0 | 0.027 | Satisfactory |

| MAE | Close to 0 | 0.127 | Satisfactory | MAE | Close to 0 | 0.064 | Satisfactory | MAE | Close to 0 | 0.125 | Satisfactory |

| MAPE | <10% | 0.475% | Satisfactory | MAPE | <10% | 2.814% | Satisfactory | MAPE | <10% | 1.507% | Satisfactory |

| RMSE | Close to 0 | 0.172 | Satisfactory | RMSE | Close to 0 | 0.082 | Satisfactory | RMSE | Close to 0 | 0.164 | Satisfactory |

| Developed Model | Model Types | MSE (MPa2) | MAE (MPa) | MAPE (%) | RMSE (MPa) | CPI (Unitless) | Rank in Each Category |

|---|---|---|---|---|---|---|---|

| Compressive strength | ANN (Levenberg–Marquardt) | 0.026 | 0.121 | 0.454 | 0.161 | 0.008 | 2 |

| ANN (Bayesian regularisation) | 0.026 | 0.121 | 0.447 | 0.161 | 0.000 | 1 | |

| ANN (Scaled Conjugate Gradient) | 0.030 | 0.127 | 0.475 | 0.172 | 0.194 | 3 | |

| Linear Regression | 0.041 | 0.172 | 0.656 | 0.204 | 1.000 | 4 | |

| Tensile strength | ANN (Levenberg–Marquardt) | 0.006 | 0.063 | 2.777 | 0.081 | 0.000 | 1 |

| ANN (Bayesian regularisation) | 0.007 | 0.064 | 2.887 | 0.082 | 0.020 | 3 | |

| ANN (Scaled Conjugate Gradient) | 0.007 | 0.064 | 2.814 | 0.082 | 0.016 | 2 | |

| Linear Regression | 0.036 | 0.155 | 6.812 | 0.189 | 1.000 | 4 | |

| Modulus of elasticity | ANN (Levenberg–Marquardt) | 0.021 | 0.118 | 1.389 | 0.145 | 0.000 | 1 |

| ANN (Bayesian regularisation) | 0.024 | 0.117 | 1.410 | 0.154 | 0.002 | 2 | |

| ANN (Scaled Conjugate Gradient) | 0.027 | 0.125 | 1.507 | 0.164 | 0.006 | 3 | |

| Linear Regression | 3.755 | 1.555 | 18.657 | 1.938 | 1.000 | 4 |

| Mixes | Coarse Aggregates (kg/m3) | Fine Aggregates (kg/m3) | Fly Ash * (kg/m3) | Micro Fly Ash (kg/m3) | GGBS (kg/m3) | Sodium Metasilicate Activator (kg/m3) | Water/Binder Ratio | Basalt Fibre (% Total Mass of Binders) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NA | RCA | Coated RCA | 12 mm | 30 mm | |||||||

| M0 | 677 | - | - | 763 | 480 | 120 | 360 | 96 | 0.45 | - | - |

| M25 | 169 | 508 | - | 763 | 480 | 120 | 360 | 96 | 0.45 | - | - |

| M50 | 338.5 | 338.5 | - | 763 | 480 | 120 | 360 | 96 | 0.45 | - | - |

| M100 | - | 677 | - | 763 | 480 | 120 | 360 | 96 | 0.45 | - | - |

| M100-C1 | - | - | 677 | 763 | 480 | 120 | 360 | 96 | 0.45 | - | - |

| M100-C1BF | - | - | 677 | 763 | 480 | 120 | 360 | 96 | 0.45 | 0.5 | 1.5 |

| Geopolymer slurry | - | - | - | - | 240 | 60 | 180 | 48 | 0.45 | - | - |

| Length (mm) | Diameter (μm) | Density (g/cm3) | Modulus of Elasticity (GPa) | Moisture Absorption | Melt Temperature (°C) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 12 | 13 | 2.6–2.8 | 70 | <0.1% T | 1450 | 1000 |

| 30 | 13 | 2.6–2.8 | 70 | <0.1% T | 1450 | 1000 |

| Chemical Composition (Mass%) | SiO2 | CaO | Al2O3 | MgO | K2O | MnO | SO3 | V2O5 | TiO2 | Na2O | P2O5 | FeO | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Binders | |||||||||||||

| Fly ash | 65.75 | - | 32.87 | - | - | - | - | - | 1.38 | - | - | - | |

| GGBS | 35.19 | 41.47 | 13.66 | 6.32 | - | - | 2.43 | 0.20 | 0.73 | - | - | - | |

| Micro fly ash | 63.09 | - | 32.26 | - | 0.83 | - | - | - | 1.67 | 0.41 | 0.62 | 1.12 | |

| Anhydrous Sodium Metasilicate | 50 | - | - | - | - | - | - | - | - | 50 | - | - | |

| Aggregate | Nominal Size | Water Absorption (%) | Moisture Content (%) |

|---|---|---|---|

| Coarse natural aggregate | 14 mm | 3.3 | 2.05 |

| Recycled concrete aggregate | 14 mm | 6.6 | 3 |

| Mix | Slump Flow (mm) | T500 (s) | J-Ring (mm) |

|---|---|---|---|

| M0 | 700 | 2 | 2 |

| M25 | 690 | 2.3 | 2 |

| M50 | 680 | 2.5 | 2 |

| M100 | 660 | 3.1 | 3 |

| M100-C1 | 550 | 4.5 | 8 |

| M100-C1BF | 580 | 3.5 | 10 |

| Input/Output Variables | Mean | Standard Error of the Mean (SEM) | Sample Standard Deviation (SSD) | Sample Variance (SV) | Range | Min | Max |

|---|---|---|---|---|---|---|---|

| 423.125 | 65.97729 | 279.9179 | 78,354.04 | 677 | 0 | 677 | |

| 253.875 | 65.97729 | 279.9179 | 78,354.04 | 677 | 0 | 677 | |

| 0.88 | 0.477247 | 2.024788 | 4.099765 | 5.28 | 0 | 5.28 | |

| 2.64 | 1.431741 | 6.074363 | 36.89788 | 15.84 | 0 | 15.84 | |

| 0.333333 | 0.114332 | 0.485071 | 0.235294 | 1 | 0 | 1 | |

| CS | 26.49111 | 1.007696 | 4.27529 | 18.2781 | 11.73 | 22.88 | 34.61 |

| TS | 2.405556 | 0.130297 | 0.552803 | 0.305591 | 1.7 | 1.8 | 3.5 |

| MoE | 9.705556 | 0.807378 | 3.425416 | 11.73347 | 8.4 | 6.4 | 14.8 |

| Item | Formula |

|---|---|

| Linear coefficient correlation (R) | |

| Adjusted R2 | ) |

| Mean Squared Error (MSE) | |

| Mean Absolute Error (MAE) | |

| Mean Absolute Percentage Error (MAPE) | |

| Root Mean Square Error (RMSE) | |

| Sample Variance (SV) | |

| Sample Standard Deviation (SSD) | |

| Standard Error of the Mean (SEM) | |

| Standard Error of the Estimate (SEE) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikmehr, B.; Kafle, B.; Al-Ameri, R. Performance Assessment of One-Part Self-Compacted Geopolymer Concrete Containing Recycled Concrete Aggregate: A Critical Comparison Using Artificial Neural Network (ANN) and Linear Regression Models. Recycling 2024, 9, 73. https://doi.org/10.3390/recycling9050073

Nikmehr B, Kafle B, Al-Ameri R. Performance Assessment of One-Part Self-Compacted Geopolymer Concrete Containing Recycled Concrete Aggregate: A Critical Comparison Using Artificial Neural Network (ANN) and Linear Regression Models. Recycling. 2024; 9(5):73. https://doi.org/10.3390/recycling9050073

Chicago/Turabian StyleNikmehr, Bahareh, Bidur Kafle, and Riyadh Al-Ameri. 2024. "Performance Assessment of One-Part Self-Compacted Geopolymer Concrete Containing Recycled Concrete Aggregate: A Critical Comparison Using Artificial Neural Network (ANN) and Linear Regression Models" Recycling 9, no. 5: 73. https://doi.org/10.3390/recycling9050073

APA StyleNikmehr, B., Kafle, B., & Al-Ameri, R. (2024). Performance Assessment of One-Part Self-Compacted Geopolymer Concrete Containing Recycled Concrete Aggregate: A Critical Comparison Using Artificial Neural Network (ANN) and Linear Regression Models. Recycling, 9(5), 73. https://doi.org/10.3390/recycling9050073