Quantitative Evaluation of Soil Structure and Strain in Three Dimensions under Shear Using X-ray Computed Tomography Image Analysis

Abstract

1. Introduction

2. Materials and Method

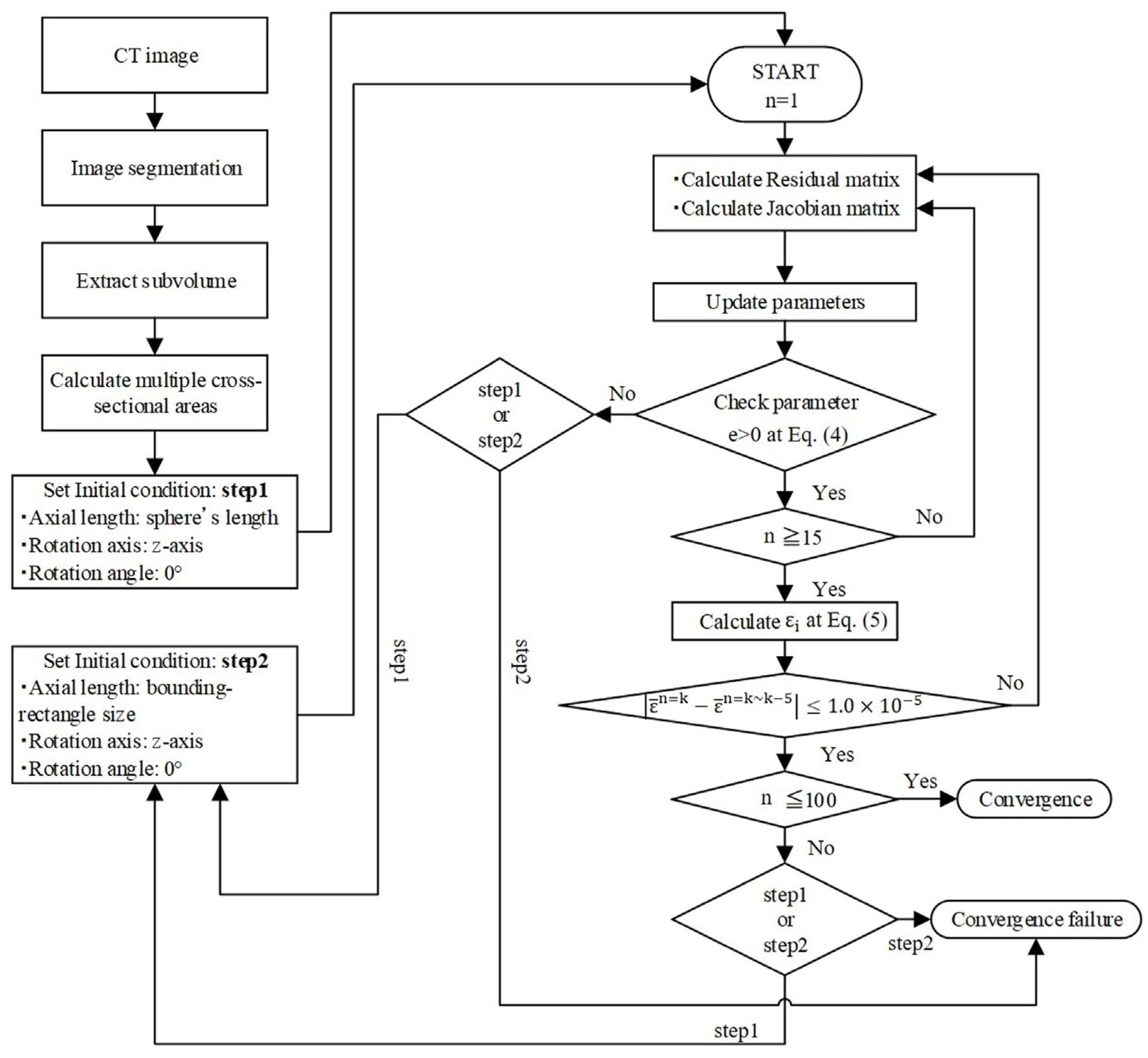

2.1. Ellipsoid Fitting Method

2.2. Materials

2.3. Validation of the Ellipsoid Fitting Method

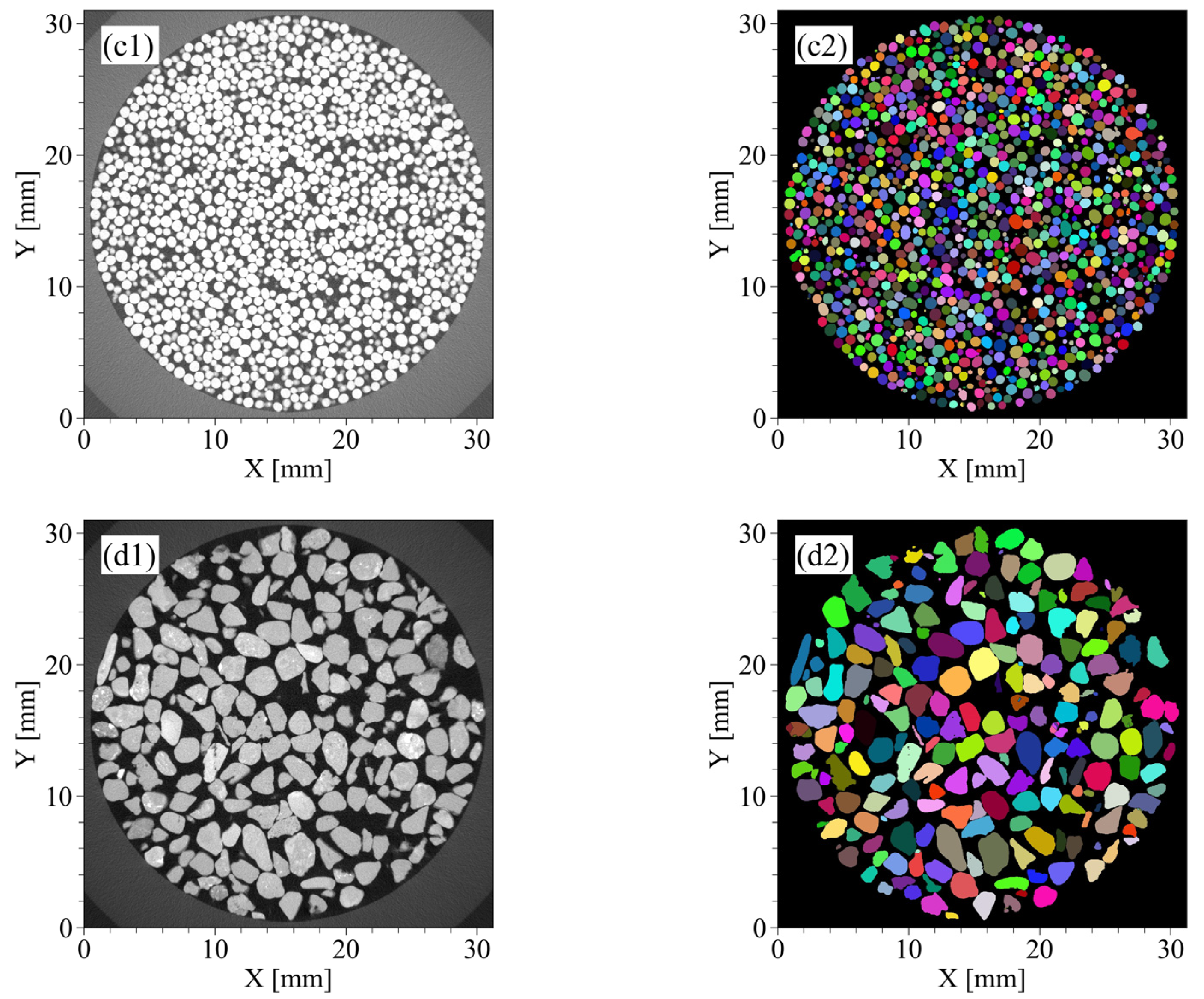

2.3.1. CT Imaging and Particle Shape Evaluation

2.3.2. Particle Measurements Using a Particle Image Analyzer

2.4. Direct Shear Experiment with CT Imaging and Image Analysis

2.4.1. Direct Shear Experiment

2.4.2. Examination of Representative Volume Elements

2.4.3. Analysis of Strain Localization by the Digital Image Correlation Method

2.4.4. Evaluation of the Particle Direction

3. Results

3.1. Validation of the Ellipsoid Fitting Method

3.1.1. CT Images and Segmented Images

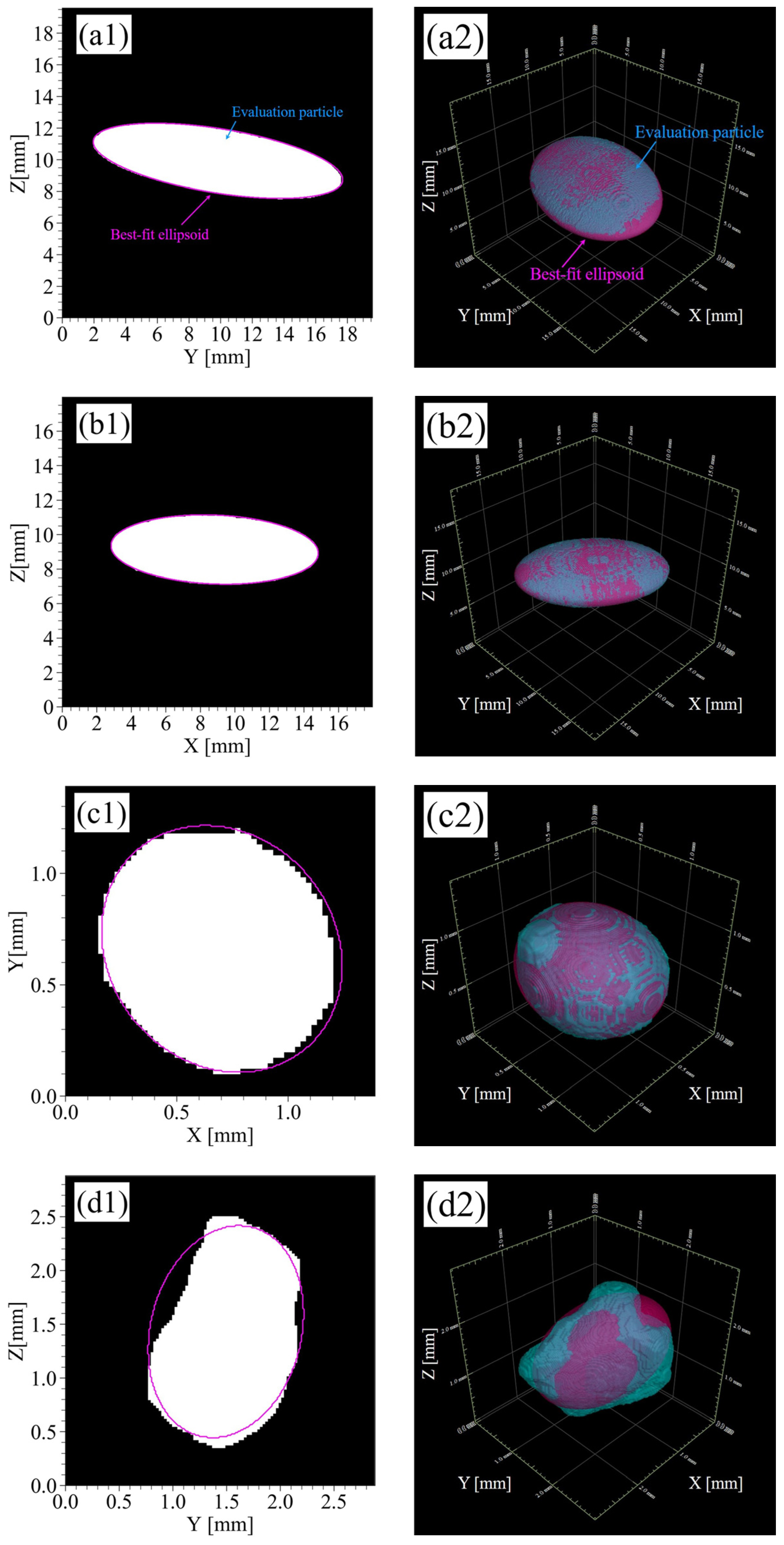

3.1.2. Ellipsoid Fitting

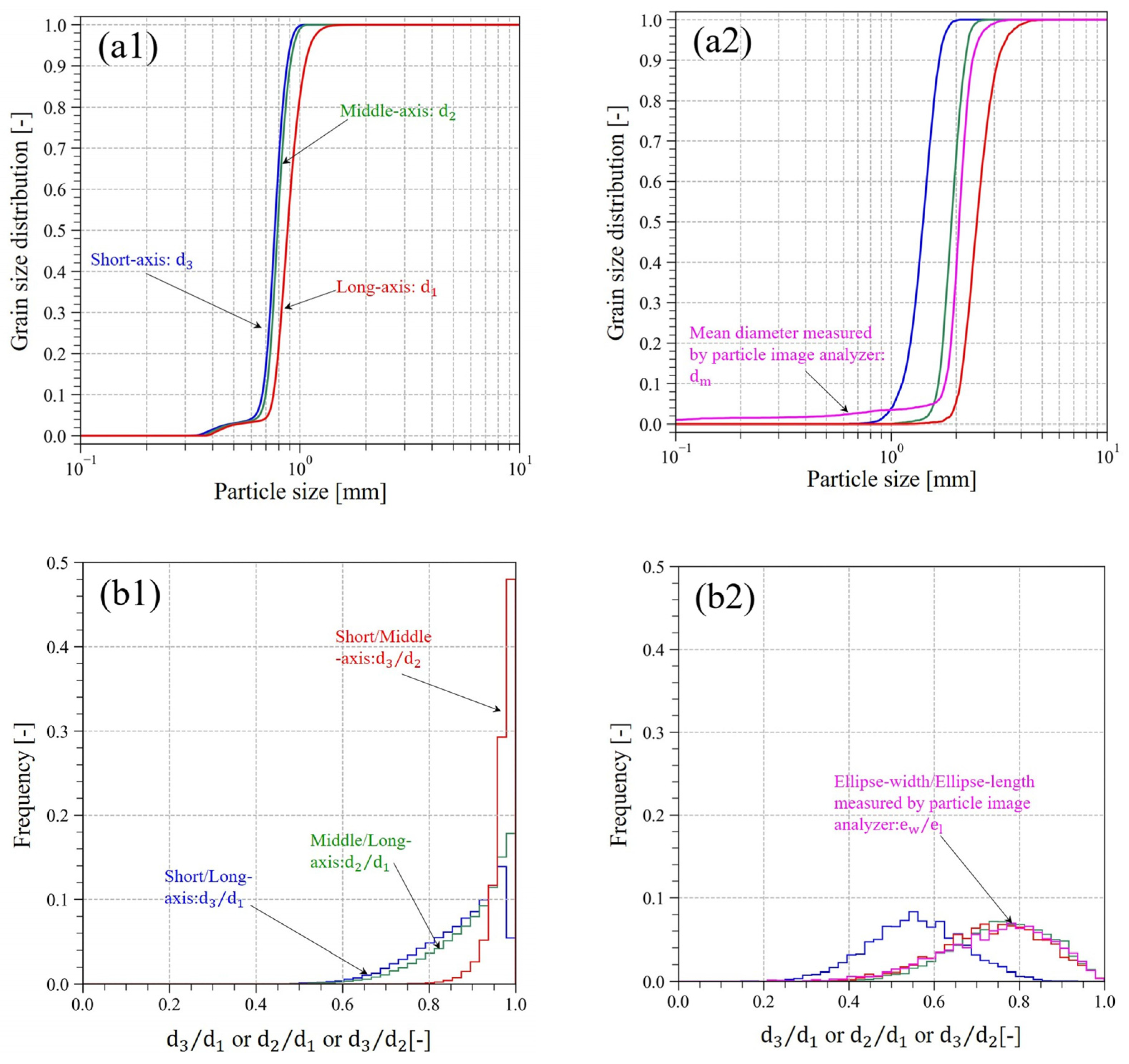

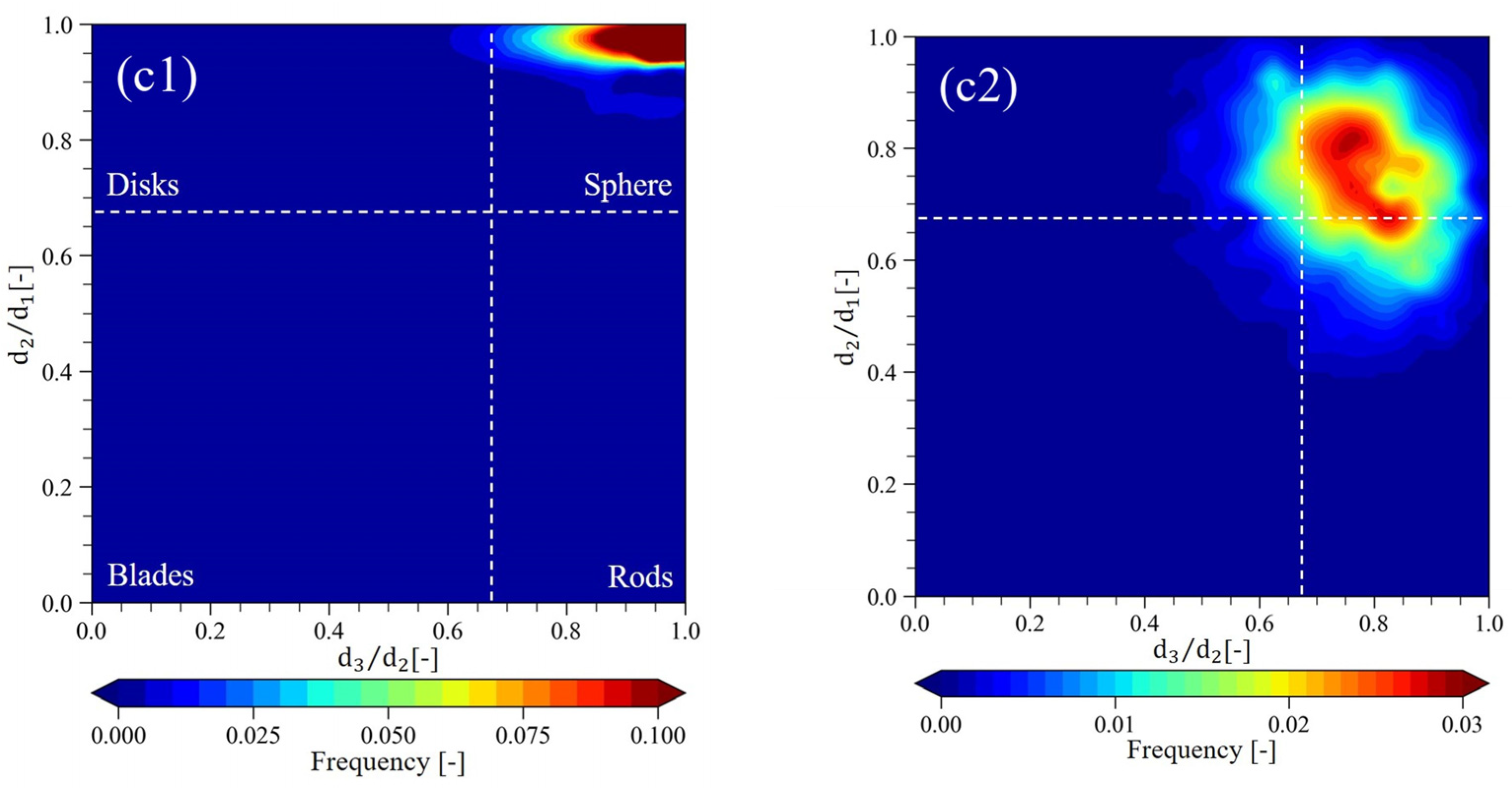

3.1.3. Evaluation of the Particle Shape Characteristics

3.2. Direct Shear Experiment

3.2.1. Experimental Results, CT Images, and Segmented Images

3.2.2. Evaluation of the Porosity and Contact Surface between Particles

3.2.3. The Change of the Porosity and the Contact Surface between Particles

3.2.4. Evaluation of the Volumetric Strain and the Shear Strain

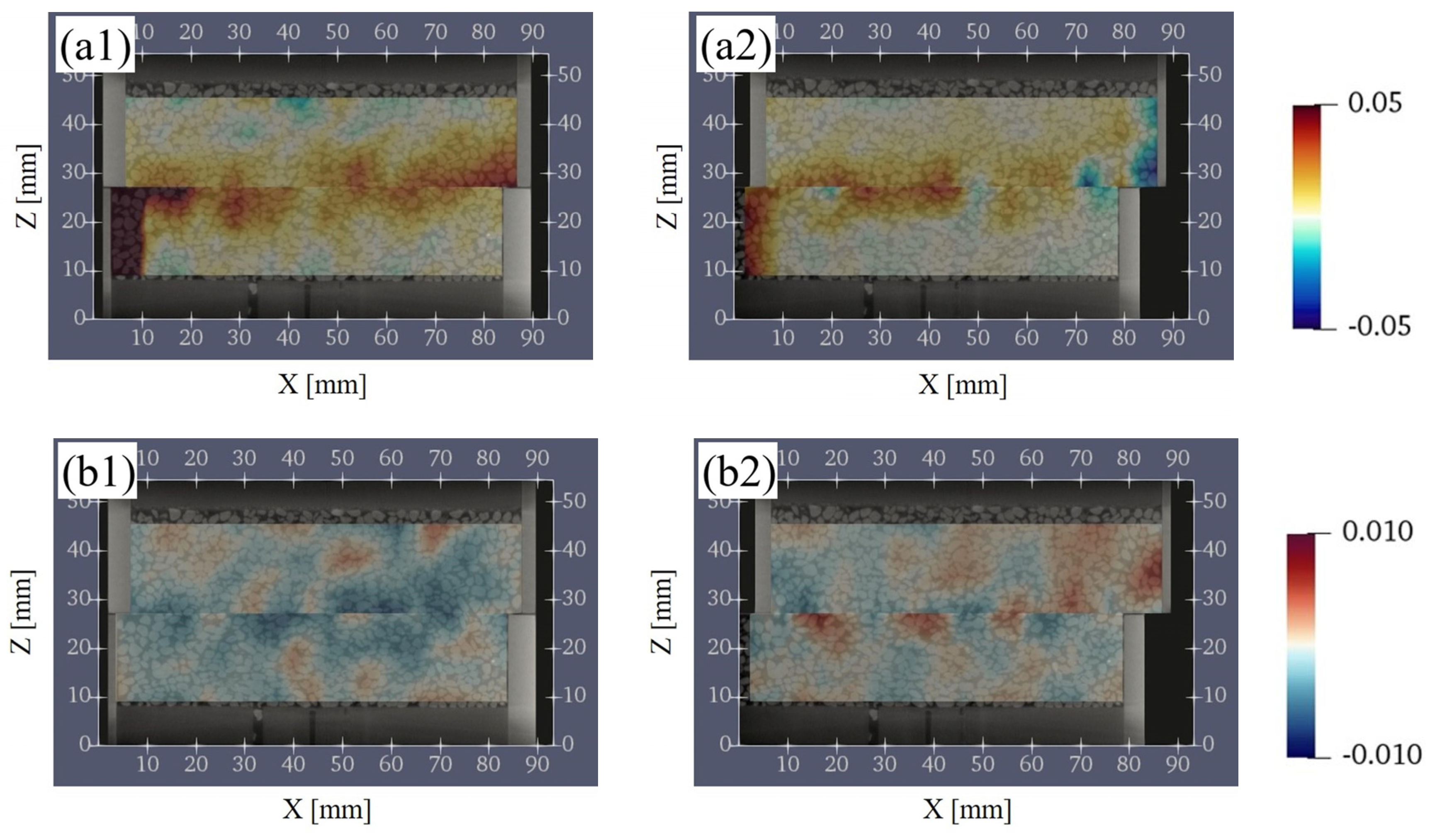

3.2.5. Comparison of the Porosity, the Contact Surface Ratio, the Volumetric Strain, and the Shear Strain versus Distance from the Shear Plane

3.2.6. Evaluation for the Particle Direction

4. Discussion

4.1. Validation of the Ellipsoid Fitting Method

4.2. Relationship between the Changes in Soil Structure and Strain Due to Shearing

5. Conclusions

- The ellipsoid fitting method proposed in this study is less affected by the irregularities on the particle surface and local shape changes; thus, it can fit particles with complex shapes such as average ellipsoids. The proposed method can accurately fit ellipsoids not only for spherical or ellipsoidal particles produced by glass beads or 3D printers, but also for natural soil particles with surface roughness and complex shapes without changing the calculation method.

- The specimen of direct shear experiment used in this study was filled by free fall into a shear box placed on a horizontal table, so that the long axis of most of the particles were directed in the horizontal direction and the short axis in the vertical direction in the initial state. Even if shearing occurred, the overall tendency in the direction of the particles is sustained. However, it was clarified that the direction of the particles partially changed when the volume expansion inside the shear zone exceeded the peak. The ratio of both the horizontally directed long axes and vertically directed short axes of the particles decreased by 6~8%. On the other hand, the ratio of both the vertical long axes and horizontal short axes of the particles increased by ~4%. Since no such change was observed in the region away from the shear plane, it was suggested that the change is characteristic of the soil structure near the shear plane.

- The porosity, contact–surface ratio, volumetric strain, and shear strain changed significantly in the range of ~7.1 times the median grain size of the sand used in this study. On the other hand, it is obvious that the change in particle direction occurs within an even narrower range than the change in porosity, contact–surface ratio, volumetric strain, and shear strain, and is restricted to the vicinity of the shear plane.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CSR | ratio of contact surface between particles on RVE |

| CT | computed tomography |

| DEM | distinct element method |

| Dh | horizontal displacement of lower box of direct shear experiment’s apparatus |

| DIC | digital image correlation |

| GBs | glass beads |

| KS | Kashima–Keisa sand |

| PIA | particle image analyzer |

| RP | resin particles |

| RVE | representative volume element |

Appendix A

Appendix B

References

- Oda, M.; Kazama, H. Microstructure of shear bands and its relation to the mechanisms of dilatancy and failure of dense granular soils. Geotechnique 1998, 48, 465–481. [Google Scholar] [CrossRef]

- Matsuoka, H. A microscopic study on shear mechanism of granular materials. Soils Found. 1974, 14, 29–43. [Google Scholar] [CrossRef]

- Drescher, A. An Experimental Investigation of Flow Rules for Granular Materials Using Optically Sensitive Glass Particles. Geotechnique 1976, 26, 591–601. [Google Scholar] [CrossRef]

- Kanatani, K. A theory of contact force distribution in granular materials. Powder Technol. 1981, 28, 167–172. [Google Scholar] [CrossRef]

- Maeda, K.; Hirabayashi, H. Influence of Grain Properties on Macro Mechanical Behaviors of Granular Media by DEM. J. Appl. Mech. 2006, 9, 623–630. [Google Scholar] [CrossRef]

- Oda, M. Initial fabrics and their relations to mechanical properties of granular material. Soils Found. 1972, 12, 17–36. [Google Scholar] [CrossRef]

- Oda, M. The mechanism of fabric changes during compressional deformation of sand. Soils Found. 1972, 12, 1–18. [Google Scholar] [CrossRef]

- Yang, Z.X.; Lit, X.S.; Yang, J. Quantifying and modelling fabric anisotropy of granular soils. Geotechnique 2008, 58, 237–248. [Google Scholar] [CrossRef]

- Zhao, C.; Koseki, J. An image-based method for evaluating local deformations of saturated sand in undrained torsional shear tests. Soils Found. 2020, 60, 608–620. [Google Scholar] [CrossRef]

- Ketcham, R.A.; Carlson, W.D. Acquisition, optimization and interpretation of x-ray computed tomographic imagery: Applications to the geosciences. Comput. Geosci. 2001, 27, 381–400. [Google Scholar] [CrossRef]

- Mees, F.; Swennen, R.; Van Geet, M.; Jacobs, P. Applications of X-ray computed tomography in the geosciences. Geol. Soc. Spec. Publ. 2003, 215, 1–6. [Google Scholar] [CrossRef]

- Otani, J.; Obara, Y. X-ray CT for Geomaterials Soils, Concrete, Rocks; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Desrues, J.; Viggiani, G.; Besuelle, P. Advances in X-ray Tomography for Geomaterials; Wiley-ISTE: London, UK, 2010. [Google Scholar]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef]

- Plessis, A.; Roux, S.G.; Guelpa, A. Comparison of medical and industrial X-ray computed tomography for non-destructive testing. Case Stud. Nondestruct. Test. Eval. 2016, 6, 17–25. [Google Scholar] [CrossRef]

- Bultreys, T.; De Boever, W.; Cnudde, V. Imaging and image-based fluid transport modeling at the pore scale in geological materials: A practical introduction to the current state-of-the-art. Earth Sci. Rev. 2016, 155, 93–128. [Google Scholar] [CrossRef]

- Fonseca, J.; O’Sullivan, C.; Coop, M.R.; Lee, P.D. Non-invasive characterization of particle morphology of natural sands. Soils Found. 2012, 52, 712–722. [Google Scholar] [CrossRef]

- Fonseca, J.; O’Sullivan, C.; Coop, M.R.; Lee, P.D. Quantifying the evolution of soil fabric during shearing using directional parameters. Geotechnique 2013, 63, 487–499. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J. Experimental investigation of inter-particle contact evolution of sheared granular materials using X-ray micro-tomography. Soils Found. 2018, 58, 1492–1510. [Google Scholar] [CrossRef]

- Imseeh, W.H.; Druckrey, A.M.; Alshibli, K.A. 3D experimental quantification of fabric and fabric evolution of sheared granular materials using synchrotron micro-computed tomography. Granul. Matter 2018, 20, 24. [Google Scholar] [CrossRef]

- Hall, S.A.; Bornert, M.; Desrues, J.; Pannier, Y.; Lenoir, N.; Viggiani, G.; Besuelle, P. Discrete and continuum analysis of localised deformation in sand using X-ray μCT and volumetric digital image correlation. Geotechnique 2010, 60, 315–322. [Google Scholar] [CrossRef]

- Watanabe, Y.; Lenoir, N.; Otani, J.; Nakai, T. Displacement in sand under triaxial compression by tracking soil particles on X-ray CT data. Soils Found. 2012, 52, 312–320. [Google Scholar] [CrossRef]

- Takano, D.; Lenoir, N.; Otani, J.; Hall, S.A. Localised deformation in a wide-grained sand under triaxial compression revealed by X-ray tomography and digital image correlation. Soils Found. 2015, 55, 906–915. [Google Scholar] [CrossRef]

- Lin, X.; Ng, T.-T. A three-dimensional discrete element model using arrays of ellipsoids. Geotechnique 1997, 47, 319–329. [Google Scholar] [CrossRef]

- Ng, T. Discrete Element Method Simulations of the Critical State of a Granular Material. Int. J. Geomech. 2009, 9, 209–216. [Google Scholar] [CrossRef]

- Yan, B.; Regueiro, R.A.; Sture, S. Three-dimensional ellipsoidal discrete element modeling of granular materials and its coupling with finite element facets. Eng. Comput. 2009, 27. [Google Scholar] [CrossRef]

- Ketcham, R.A. Three-dimensional grain fabric measurements using high-resolution X-ray computed tomography. J. Struct. Geol. 2005, 27, 1217–1228. [Google Scholar] [CrossRef]

- Takemura, T.; Takahashi, M.; Oda, M.; Hirai, H.; Murakoshi, A.; Miura, M. Three-dimensional fabric analysis for anisotropic material using multi-directional scanning line-Application to X-ray CT image. Mater. Trans. 2007, 48, 1173–1178. [Google Scholar] [CrossRef]

- Phillion, A.B.; Lee, P.D.; Maire, E.; Cockcroft, S.L. Quantitative assessment of deformation-induced damage in a semisolid aluminum alloy via X-ray microtomography. Metall. Mater. Trans. A 2008, 39, 2459–2469. [Google Scholar] [CrossRef]

- Bektas, S. Orthogonal distance from an ellipsoid. Bol. de Cienc. Geod. 2014, 20, 970–983. [Google Scholar] [CrossRef][Green Version]

- Bektas, S. Least squares fitting of ellipsoid using orthogonal distances. Bol. de Cienc. Geod. 2015, 21, 329–339. [Google Scholar] [CrossRef]

- Ferguson, C.C. Intersections of ellipsoids and planes of arbitrary orientation and position. IAMG 1979, 11, 329–336. [Google Scholar] [CrossRef]

- Klein, P. On the Ellipsoid and Plane Intersection Equation. Appl. Math. 2012, 3, 1634–1640. [Google Scholar] [CrossRef][Green Version]

- Bektas, S. Intersection of an Ellipsoid and a Plane. Int. J. Appl. Eng. Res. 2016, 6, 273–283. [Google Scholar]

- Harris, C.R.; Millman, K.J.; van der Walt, S.J.; Gommers, R.; Virtanen, P.; Cournapeau, D.; Wieser, E.; Taylor, J.; Berg, S.; Smith, N.J.; et al. Array programming with NumPy. Nature 2020, 585, 357–362. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef]

- Van der Walt, S.; Schönberger, J.L.; Nunez-Iglesias, J.; Boulogne, F.; Warner, J.D.; Yager, N.; Gouillart, E.; Yu, T. Scikit-image: Image processing in Python. PeerJ 2014, 2, e453. [Google Scholar] [CrossRef]

- Krumbein, W.C. Measurement and geological significance of shape and roundness of sedimentary particles. J. Sediment. Res. 1941, 11, 64–72. [Google Scholar] [CrossRef]

- Zingg, T. Beitrag zur schotteranalyse, Schweizerische Mineralogische and Petrographische Mitteilungen. Band 1935, 15, 39–140. [Google Scholar] [CrossRef]

- Chevalier, B.; Tsutsumi, Y.; Otani, J. Direct shear behavior of a mixture of sand and tire chips using X-ray computed tomography and discrete element method. Int. J. Geosynth. Ground Eng. 2019, 5, 7. [Google Scholar] [CrossRef]

- Lenoir, N.; Bornert, M.; Desrues, J.; Bésuelle, P.; Viggiani, G. Volumetric Digital Image Correlation Applied to X-ray Microtomography Images from Triaxial Compression Tests on Argillaceous Rock. Strain 2007, 43, 193–205. [Google Scholar] [CrossRef]

- Utsugawa, T.; Shirai, M. A Review of Roundness, a Fundamental Shape Parameter of Detrital Particles: History of Analysis and Analytic Prospects. Geogr. Rev. Jpn. 2016, 89, 329–346. (In Japanese) [Google Scholar] [CrossRef]

- Katagiri, J.; Matsushima, T.; Saomoto, H. Quantitative characterization of three-dimensional grain shapes by X-ray micro CT at SPRING-8. J. JSCE Ser. C 2014, 70, 265–274. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Iwashita, K.; Oda, M. Micro-deformation mechanism of shear banding process based on modified distinct element method. Powder Technol. 2000, 109, 192–205. [Google Scholar] [CrossRef]

- Sakakibara, T.; Kato, S.; Yoshimura, Y.; Shibuya, S. Effects of grain shape on mechanical behaviors and shear band of granular materials in dem analysis. J. JSCE Ser. C 2008, 64, 456–472. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Noumeir, R. Detecting three-dimensional rotation of an ellipsoid from its orthographic projections. Pattern Recognit. Lett. 1999, 20, 585–590. [Google Scholar] [CrossRef]

| Material | Parameter | Unit | Mean | Std | Q25 | Q50 | Q75 |

|---|---|---|---|---|---|---|---|

| RP1 | [mm] | 15.63 | 0.58 | 15.67 | 15.87 | 15.94 | |

| 11.72 | 0.42 | 11.79 | 11.85 | 11.90 | |||

| 3.91 | 0.13 | 3.84 | 3.88 | 3.90 | |||

| [-] | 0.57 | 0.015 | 0.57 | 0.57 | 0.57 | ||

| RP2 | [mm] | 15.52 | 0.71 | 15.47 | 15.84 | 15.90 | |

| 7.85 | 0.24 | 7.83 | 7.93 | 7.97 | |||

| 3.87 | 0.13 | 3.82 | 3.83 | 3.85 | |||

| [-] | 0.50 | 0.017 | 0.49 | 0.50 | 0.50 | ||

| GBs | [mm] | 0.88 | 0.14 | 0.81 | 0.87 | 0.96 | |

| 0.78 | 0.10 | 0.74 | 0.79 | 0.84 | |||

| 0.76 | 0.10 | 0.72 | 0.76 | 0.82 | |||

| [-] | 0.92 | 0.06 | 0.89 | 0.94 | 0.97 | ||

| KS | [mm] | 2.55 | 0.45 | 2.24 | 2.48 | 2.78 | |

| 1.90 | 0.22 | 1.75 | 1.89 | 2.05 | |||

| 1.39 | 0.21 | 1.26 | 1.39 | 1.54 | |||

| 2.02 | 0.40 | 1.91 | 2.05 | 2.20 | |||

| [-] | 0.75 | 0.08 | 0.70 | 0.75 | 0.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nohara, S.; Mukunoki, T. Quantitative Evaluation of Soil Structure and Strain in Three Dimensions under Shear Using X-ray Computed Tomography Image Analysis. J. Imaging 2021, 7, 230. https://doi.org/10.3390/jimaging7110230

Nohara S, Mukunoki T. Quantitative Evaluation of Soil Structure and Strain in Three Dimensions under Shear Using X-ray Computed Tomography Image Analysis. Journal of Imaging. 2021; 7(11):230. https://doi.org/10.3390/jimaging7110230

Chicago/Turabian StyleNohara, Shintaro, and Toshifumi Mukunoki. 2021. "Quantitative Evaluation of Soil Structure and Strain in Three Dimensions under Shear Using X-ray Computed Tomography Image Analysis" Journal of Imaging 7, no. 11: 230. https://doi.org/10.3390/jimaging7110230

APA StyleNohara, S., & Mukunoki, T. (2021). Quantitative Evaluation of Soil Structure and Strain in Three Dimensions under Shear Using X-ray Computed Tomography Image Analysis. Journal of Imaging, 7(11), 230. https://doi.org/10.3390/jimaging7110230