Risk Analysis of Underground Tunnel Construction with Tunnel Boring Machine by Using Fault Tree Analysis and Fuzzy Analytic Hierarchy Process

Abstract

:1. Introduction

2. Materials and Methods

- What do you believe is the probability that the “cause” will occur?

- How would you rate the chance of the “cause” occurring in the near future on a scale from 0 to 1?

- On a scale from 0 to 1, how likely is it that the “cause” will happen?

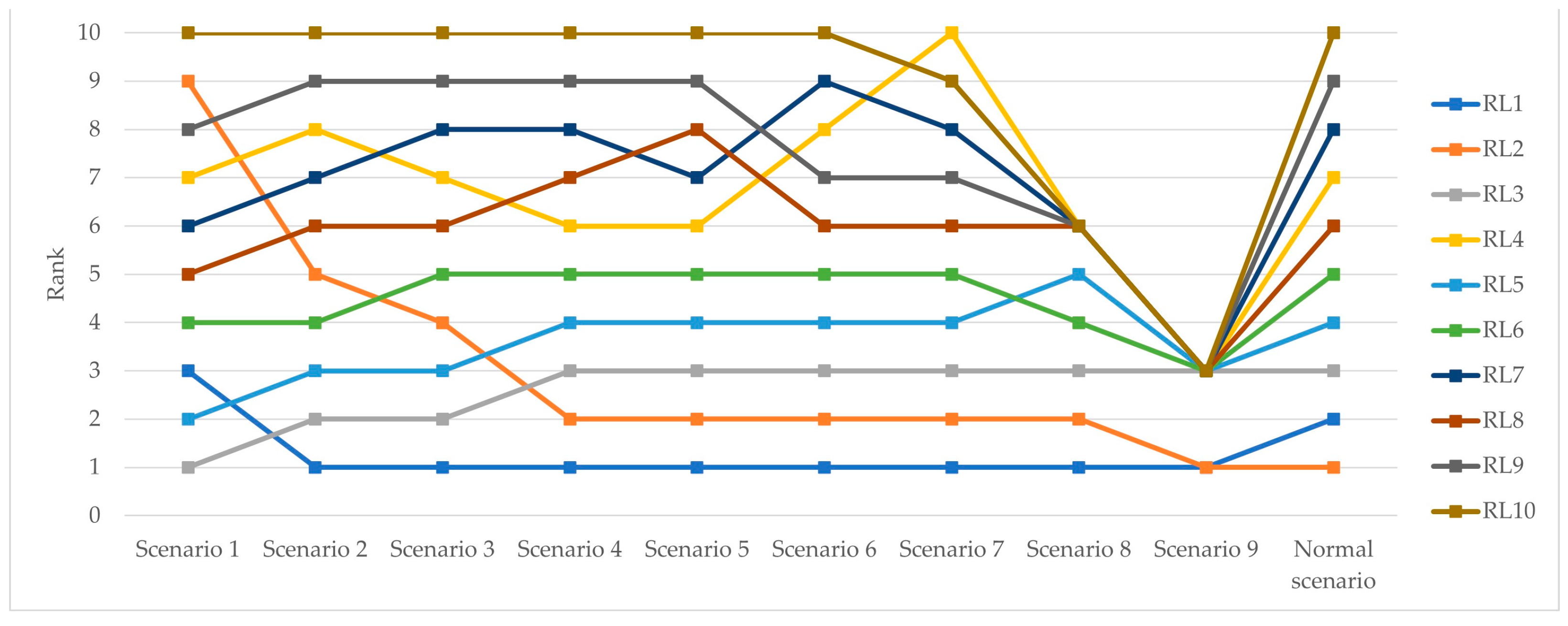

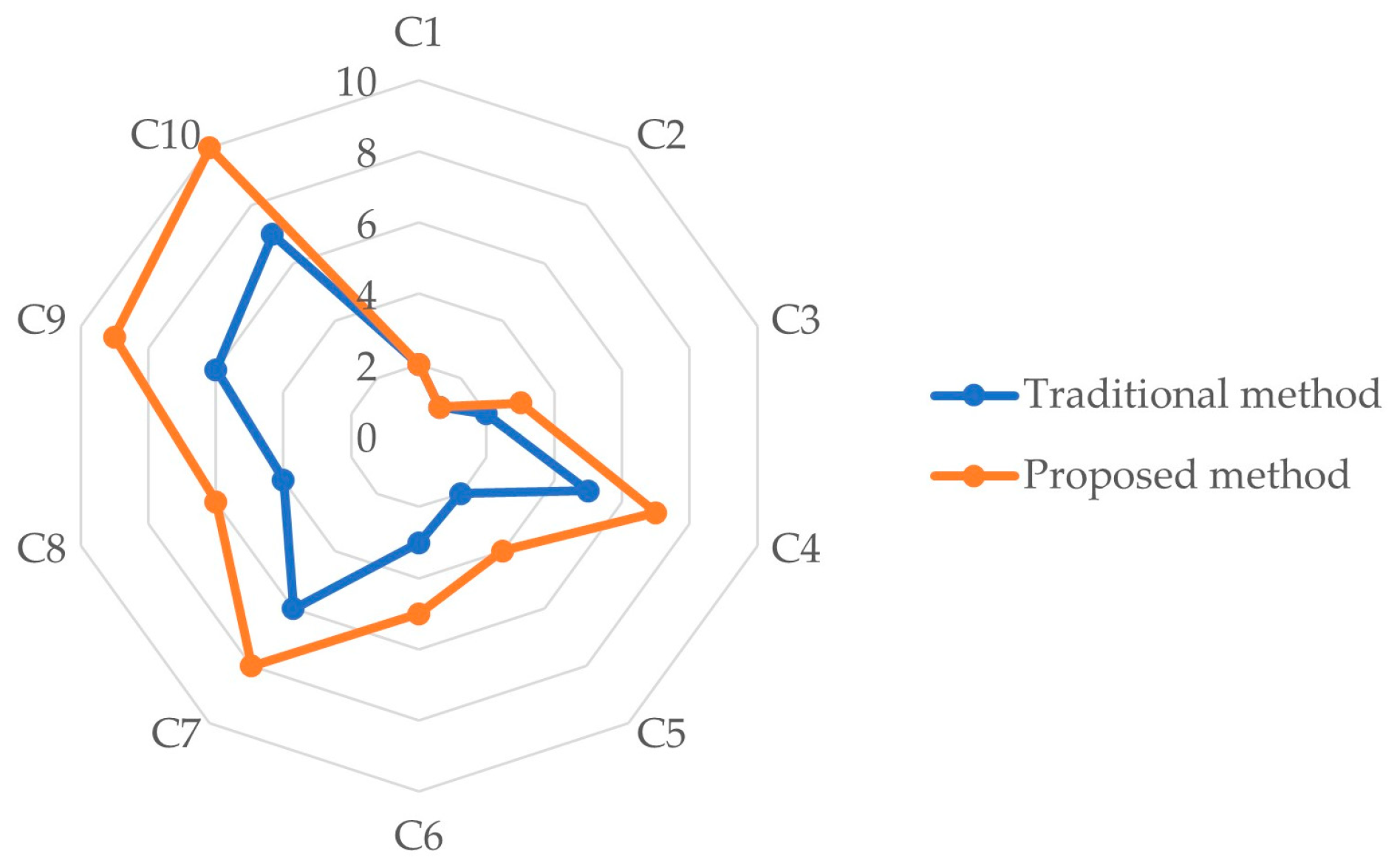

3. Results

4. Discussion

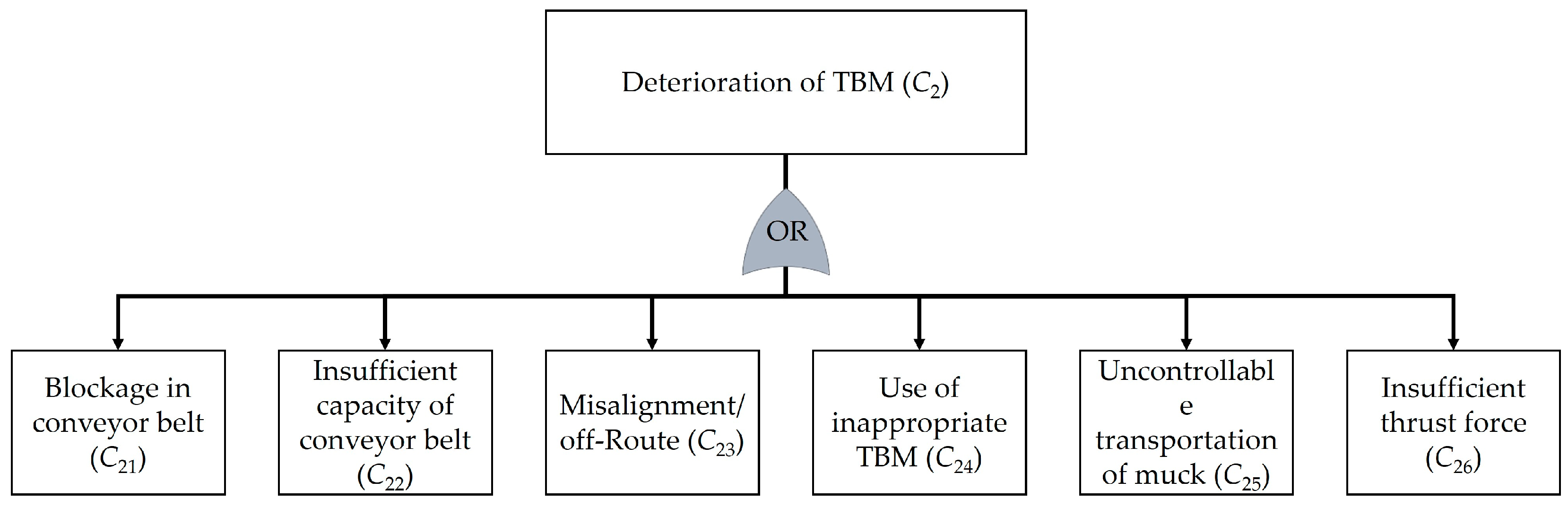

- Inspections should be conducted to identify and remove potential blockages. The size of excavated material should be controlled through the use of rock crushers or grinders. Implementing a strict maintenance schedule to clean and service the conveyor system, along with establishing emergency protocols for addressing blockages, can effectively mitigate this issue.

- Assessments of capacity requirements are necessary, along with the installation of load monitoring systems to track real-time loads and prevent overloading. Upgrading equipment or adding additional conveyors may be required if the current system consistently reaches its capacity limits.

- Utilizing advanced global positioning and laser guidance systems, frequently calibrating navigation systems, and conducting comprehensive geotechnical surveys can help maintain accurate alignment. Developing protocols for re-aligning the TBM in case of deviation is also important.

- Clear criteria for TBM selection should be established. Consultations with TBM manufacturers and experts should be conducted to ensure a suitable machine is chosen. Leasing or modular TBMs that can adapt to different conditions may also be considered.

- Optimized muck handling systems can be implemented. Muck transportation must be continuously monitored and disposal plans can be developed to address this issue. Training operators and clear protocols for managing transportation issues are necessary.

- Maintenance and checks on hydraulic systems, upgrading hydraulic systems when necessary, and verifying machine setup parameters before operations can ensure that thrust force requirements are met.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, F.; Ren, F.; Yuen, K.F.; Guo, Y.; Zhao, C.; Guo, D. The spatial coupling effect between urban public transport and commercial complexes: A network centrality perspective. Sustain. Cities Soc. 2019, 50, 101645. [Google Scholar] [CrossRef]

- Xu, C.; Liu, X.; Wang, E.; Wang, S. Prediction of tunnel boring machine operating parameters using various machine learning algorithms. Tunn. Undergr. Space Technol. 2021, 109, 103699. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, T.; Zhou, W.; Tang, J. Safety risk factors of metro tunnel construction in China: An integrated study with EFA and SEM. Saf. Sci. 2018, 105, 98–113. [Google Scholar] [CrossRef]

- Hosseini, N.; Givehchi, S.; Maknoon, R. Cost-based fire risk assessment in natural gas industry by means of fuzzy FTA and ETA. J. Loss Prev. Process Ind. 2020, 63, 104025. [Google Scholar] [CrossRef]

- Wang, T.; Cao, J.; Liu, J.; Xu, J.; Zhou, G. Characterizing anisotropic spatial variations of uncertain mechanical parameters for clay layer using incomplete probability data. Probabilistic Eng. Mech. 2024, 76, 103623. [Google Scholar] [CrossRef]

- Cao, J.; Wang, T.; Zhou, G.; Feng, X.; Zhu, C. Parameter estimation of grouting pressure and surface subsidence on the reliability of shield tunnel excavation under incomplete probability information. Comput. Geotech. 2024, 173, 106530. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, Y.; Shen, Q.; Yang, L.; Cai, H. Risk assessment and management via multi-source information fusion for undersea tunnel construction. Autom. Constr. 2020, 111, 103050. [Google Scholar] [CrossRef]

- Yu, J.; Zhong, D.; Ren, B.; Tong, D.; Hong, K. Probabilistic Risk Analysis of Diversion Tunnel Construction Simulation. Comput. Aided Civil Infrastruct. Eng. 2017, 32, 748–771. [Google Scholar] [CrossRef]

- Gangrade, R.; Grasmick, J.; Trainor-Guitton, W.; Mooney, M. Risk-based methodology to optimize geotechnical site investigations in tunnel projects. Tunn. Undergr. Space Technol. 2022, 127, 104589. [Google Scholar] [CrossRef]

- Qin, G.; Zhang, P.; Hou, X.; Wu, S.; Wang, Y. Risk assessment for oil leakage under the common threat of multiple natural hazards. Environ. Sci. Pollut. Res. Int. 2020, 27, 16507–16520. [Google Scholar] [CrossRef]

- Moradi, M.R.; Farsangi, M.A.E. Application of the Risk Matrix Method for Geotechnical Risk Analysis and Prediction of the Advance Rate in Rock TBM Tunneling. Rock Mech. Rock Eng. 2014, 47, 1951–1960. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A. Proposing a New Methodology Based on Fuzzy Logic for Tunnelling Risk Assessment. J. Civ. Eng. Manag. 2014, 20, 82–94. [Google Scholar] [CrossRef]

- Liu, G.-F.; Feng, X.-T.; Feng, G.-L.; Chen, B.-R.; Chen, D.-F.; Duan, S.-Q. A Method for Dynamic Risk Assessment and Management of Rockbursts in Drill and Blast Tunnels. Rock Mech. Rock Eng. 2016, 49, 3257–3279. [Google Scholar] [CrossRef]

- Relkar, A.S. Risk Analysis of Equipment Failure through Failure Mode and Effect Analysis and Fault Tree Analysis. J. Fail. Anal. Prev. 2021, 21, 793–805. [Google Scholar] [CrossRef]

- Sharafat, A.; Latif, K.; Seo, J. Risk analysis of TBM tunneling projects based on generic bow-tie risk analysis approach in difficult ground conditions. Tunn. Undergr. Space Technol. 2021, 111, 103860. [Google Scholar] [CrossRef]

- Qie, Z.; Yan, H. A Causation Analysis of Chinese Subway Construction Accidents Based on Fault Tree Analysis-Bayesian Network. Front. Psychol. 2022, 13, 887073. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Deng, Y. Analysis on Security Risks in Tunnel Construction Based on the Fault Tree Analysis. IOP Conf. Ser. Earth Environ. Sci. 2021, 638, 012089. [Google Scholar] [CrossRef]

- Koohathongsumrit, N.; Meethom, W. A fuzzy decision-making framework for route selection in multimodal transportation networks. Eng. Manag. J. 2022, 34, 689–704. [Google Scholar] [CrossRef]

- Koohathongsumrit, N.; Chankham, W. Route selection in multimodal supply chains: A fuzzy risk assessment model-BWM-MARCOS framework. Appl. Soft Comput. 2023, 137, 110167. [Google Scholar] [CrossRef]

- Fouladgar, M.M.; Yazdani-Chamzini, A.; Zavadskas, E.K. Risk evaluation of tunneling projects. Arch. Civil Mech. Eng. 2012, 12, 1–12. [Google Scholar] [CrossRef]

- Ehsanifar, M.; Hemesy, M. A new hybrid multi-criteria decision-making model to prioritize risks in the construction process under fuzzy environment (case study: The Valiasr Street underpass project). Int. J. Constr. Manag. 2021, 21, 508–523. [Google Scholar] [CrossRef]

- Hou, W.-H.; Wang, X.-K.; Zhang, H.-Y.; Wang, J.-Q.; Li, L. Safety risk assessment of metro construction under epistemic uncertainty: An integrated framework using credal networks and the EDAS method. Appl. Soft Comput. 2021, 108, 107436. [Google Scholar] [CrossRef]

- Lin, S.-S.; Zhou, A.; Shen, S.-L. Safety assessment of excavation system via TOPSIS-based MCDM modelling in fuzzy environment. Appl. Soft Comput. 2023, 138, 110206. [Google Scholar] [CrossRef]

- Koohathongsumrit, N.; Meethom, W. Risk analysis in underground tunnel construction with tunnel boring machines using the Best-Worst method and data envelopment analysis. Heliyon 2024, 10, e23486. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhang, Z.-J.; Gong, D.-Q. An improved failure mode and effect analysis method for group decision-making in utility tunnels construction project risk evaluation. Reliab. Eng. Syst. Saf. 2024, 244, 109943. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Saaty, T.L. How to make a decision: The analytic hierarchy process. Interfaces 1994, 24, 19–43. [Google Scholar] [CrossRef]

- Saaty, T.L. A scaling method for priorities in hierarchical structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Koohathongsumrit, N.; Chankham, W. A hybrid approach of fuzzy risk assessment-based incenter of centroid and MCDM methods for multimodal transportation route selection. Cogent Eng. 2022, 9, 2091672. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A.; Yakhchali, S.H.; Mahmoodian, M. Risk ranking of tunnel construction projects by using the ELECTRE technique under a fuzzy environment. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 1–14. [Google Scholar] [CrossRef]

- Gogate, N.G.; Shelake, A.G.; Band, P. Selection of most significant risk factors for Indian tunnel projects: An integrated fuzzy-based MCDM approach. Int. J. Constr. Manag. 2024, 24, 161–176. [Google Scholar] [CrossRef]

- Nezarat, H.; Sereshki, F.; Ataei, M. Ranking of geological risks in mechanized tunneling by using Fuzzy Analytical Hierarchy Process (FAHP). Tunn. Undergr. Space Technol. 2015, 50, 358–364. [Google Scholar] [CrossRef]

- Shaffiee Haghshenas, S.; Shaffiee Haghshenas, S.; Abduelrhman, M.A.; Zare, S.; Mikaeil, R. Identifying and Ranking of Mechanized Tunneling Project’s Risks by Using A Fuzzy Multi-Criteria Decision Making Technique. J. Soft Comput. Civil Eng. 2022, 6, 29–45. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, X.-H.; Wang, Y.-J. Risk analysis for urban excavation: A FAHP-VIKOR hybrid method. Geomat. Nat. Hazards Risk 2023, 14, 2282944. [Google Scholar] [CrossRef]

- Hyun, K.-C.; Min, S.; Choi, H.; Park, J.; Lee, I.-M. Risk analysis using fault-tree analysis (FTA) and analytic hierarchy process (AHP) applicable to shield TBM tunnels. Tunn. Undergr. Space Technol. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Tamošaitienė, J.; Khosravi, M.; Cristofaro, M.; Chan, D.W.M.; Sarvari, H. Identification and Prioritization of Critical Risk Factors of Commercial and Recreational Complex Building Projects: A Delphi Study Using the TOPSIS Method. Appl. Sci. 2021, 11, 7906. [Google Scholar] [CrossRef]

- Meethom, W.; Koohathongsumrit, N. A decision support system for road freight transportation route selection with new fuzzy numbers. Foresight 2020, 22, 505–527. [Google Scholar] [CrossRef]

- Kongchasing, N.; Sua-Iam, G. The Major Causes of Construction Delays Identified Using the Delphi Technique: Perspectives of Contractors and Consultants in Thailand. Int. J. Civil Eng. 2021, 19, 319–338. [Google Scholar] [CrossRef]

- Kabir, S.; Aslansefat, K.; Sorokos, I.; Papadopoulos, Y.; Konur, S. A Hybrid Modular Approach for Dynamic Fault Tree Analysis. IEEE Access 2020, 8, 97175–97188. [Google Scholar] [CrossRef]

- Aoun, J.; Quaglietta, E.; Goverde, R.M.P.; Scheidt, M.; Blumenfeld, M.; Jack, A.; Redfern, B. A hybrid Delphi-AHP multi-criteria analysis of Moving Block and Virtual Coupling railway signalling. Transp. Res. Part C Emerg. Technol. 2021, 129, 103250. [Google Scholar] [CrossRef]

- Gupta, S.; Raj, S.; Gupta, S.; Sharma, A. Prioritising crowdfunding benefits: A fuzzy-AHP approach. Qual. Quant. 2023, 57, 379–403. [Google Scholar] [CrossRef] [PubMed]

- Rouyendegh, B.D.; Savalan, Ş. An Integrated Fuzzy MCDM Hybrid Methodology to Analyze Agricultural Production. Sustainability 2022, 14, 4835. [Google Scholar] [CrossRef]

- Thapar, S.S.; Sarangal, H. Quantifying reusability of software components using hybrid fuzzy analytical hierarchy process (FAHP)-Metrics approach. Appl. Soft Comput. 2020, 88, 105991. [Google Scholar] [CrossRef]

- Koohathongsumrit, N.; Luangpaiboon, P. An integrated FAHP–ZODP approach for strategic marketing information system project selection. Manag. Decis. Econ. 2021, 43, 1792–1809. [Google Scholar] [CrossRef]

- Sanni-Anibire, M.O.; Mahmoud, A.S.; Hassanain, M.A.; Salami, B.A. A risk assessment approach for enhancing construction safety performance. Saf. Sci. 2020, 121, 15–29. [Google Scholar] [CrossRef]

- Koohathongsumrit, N.; Luangpaiboon, P. Strategic marketing information system planning: An integrated BWM–ELECTRE approach. Group Decis. Negot. 2024, 33, 267–289. [Google Scholar] [CrossRef]

| Probability Level | Definition | Probability |

|---|---|---|

| Greater than 4.20 | Very likely | Greater than 0.68 |

| 3.41–4.20 | Likely | 0.54–0.68 |

| 2.61–3.40 | Possible | 0.40–0.53 |

| 1.81–2.60 | Unlikely | 0.25–0.39 |

| Less than 1.81 | Very unlikely | Less than 0.25 |

| Linguistic Variables | Importance Level |

|---|---|

| Equally preferred | (1, 1, 1) |

| Equally to moderately preferred | (1, 2, 3) |

| Moderately preferred | (2, 3, 4) |

| Moderately to Strongly preferred | (3, 4, 5) |

| Strongly preferred | (4, 5, 6) |

| Strongly to very strongly preferred | (5, 6, 7) |

| Very strongly preferred | (6, 7, 8) |

| Very strongly to extremely preferred | (7, 8, 9) |

| Extremely preferred | (8, 9, 9) |

| Consequence Level | Definition | Weights |

|---|---|---|

| Greater than 4.20 | Very high impact | Greater than 0.14 |

| 3.41–4.20 | High impact | 0.12–0.14 |

| 2.61–3.40 | Moderate impact | 0.10–0.11 |

| 1.81–2.60 | Low impact | 0.07–0.09 |

| Less than 1.81 | Very low impact | Less than 0.07 |

| Cause | Probability | ≥ 3.50 | IQR ≤ 1.00 | |Med − Mod| ≤ 1.00 | SD ≤ 1.50 |

|---|---|---|---|---|---|

| C11 | 0.07 | 4.15 | 1.00 | 0.00 | 0.76 |

| C12 | 0.08 | 3.73 | 1.00 | 0.00 | 1.06 |

| C13 | 0.08 | 3.53 | 1.00 | 0.00 | 1.16 |

| C14 | 0.08 | 4.10 | 1.00 | 0.00 | 0.90 |

| C15 | 0.09 | 4.05 | 1.00 | 1.00 | 1.02 |

| C16 | 0.08 | 4.27 | 1.00 | 1.00 | 0.80 |

| C21 | 0.08 | 3.53 | 1.00 | 0.00 | 1.14 |

| C22 | 0.09 | 3.55 | 1.00 | 0.00 | 1.11 |

| C23 | 0.08 | 3.52 | 1.00 | 0.00 | 1.00 |

| C24 | 0.08 | 3.58 | 1.00 | 0.00 | 1.11 |

| C25 | 0.09 | 3.68 | 1.00 | 0.00 | 1.03 |

| C26 | 0.09 | 3.57 | 1.00 | 0.00 | 1.09 |

| C31 | 0.08 | 3.62 | 1.00 | 0.0 | 1.12 |

| C32 | 0.08 | 3.63 | 1.00 | 1.00 | 1.04 |

| C33 | 0.09 | 3.52 | 1.00 | 0.00 | 1.16 |

| C34 | 0.09 | 3.57 | 1.00 | 0.00 | 1.13 |

| C35 | 0.09 | 3.62 | 1.00 | 0.00 | 1.14 |

| C41 | 0.08 | 3.52 | 1.00 | 0.00 | 1.08 |

| C42 | 0.09 | 3.60 | 1.00 | 0.00 | 1.14 |

| C51 | 0.08 | 3.65 | 1.00 | 1.00 | 1.12 |

| C52 | 0.08 | 3.58 | 1.00 | 1.00 | 1.05 |

| C53 | 0.08 | 3.55 | 1.00 | 0.00 | 1.14 |

| C54 | 0.08 | 3.53 | 1.00 | 0.00 | 1.20 |

| C55 | 0.08 | 3.58 | 1.00 | 0.00 | 1.06 |

| C61 | 0.08 | 3.62 | 1.00 | 0.00 | 1.15 |

| C62 | 0.08 | 3.65 | 1.00 | 0.00 | 1.16 |

| C63 | 0.08 | 3.67 | 1.00 | 0.00 | 1.11 |

| C64 | 0.09 | 3.55 | 1.00 | 0.00 | 1.19 |

| C65 | 0.07 | 3.63 | 1.00 | 0.00 | 1.15 |

| C71 | 0.08 | 3.52 | 1.00 | 0.00 | 1.03 |

| C72 | 0.09 | 3.70 | 1.00 | 0.00 | 1.11 |

| C73 | 0.08 | 3.70 | 1.00 | 1.00 | 0.96 |

| C81 | 0.09 | 3.62 | 1.00 | 0.00 | 1.12 |

| C82 | 0.08 | 3.52 | 1.00 | 0.00 | 1.13 |

| C83 | 0.08 | 3.95 | 0.25 | 0.00 | 0.77 |

| C84 | 0.08 | 3.62 | 1.00 | 1.00 | 0.96 |

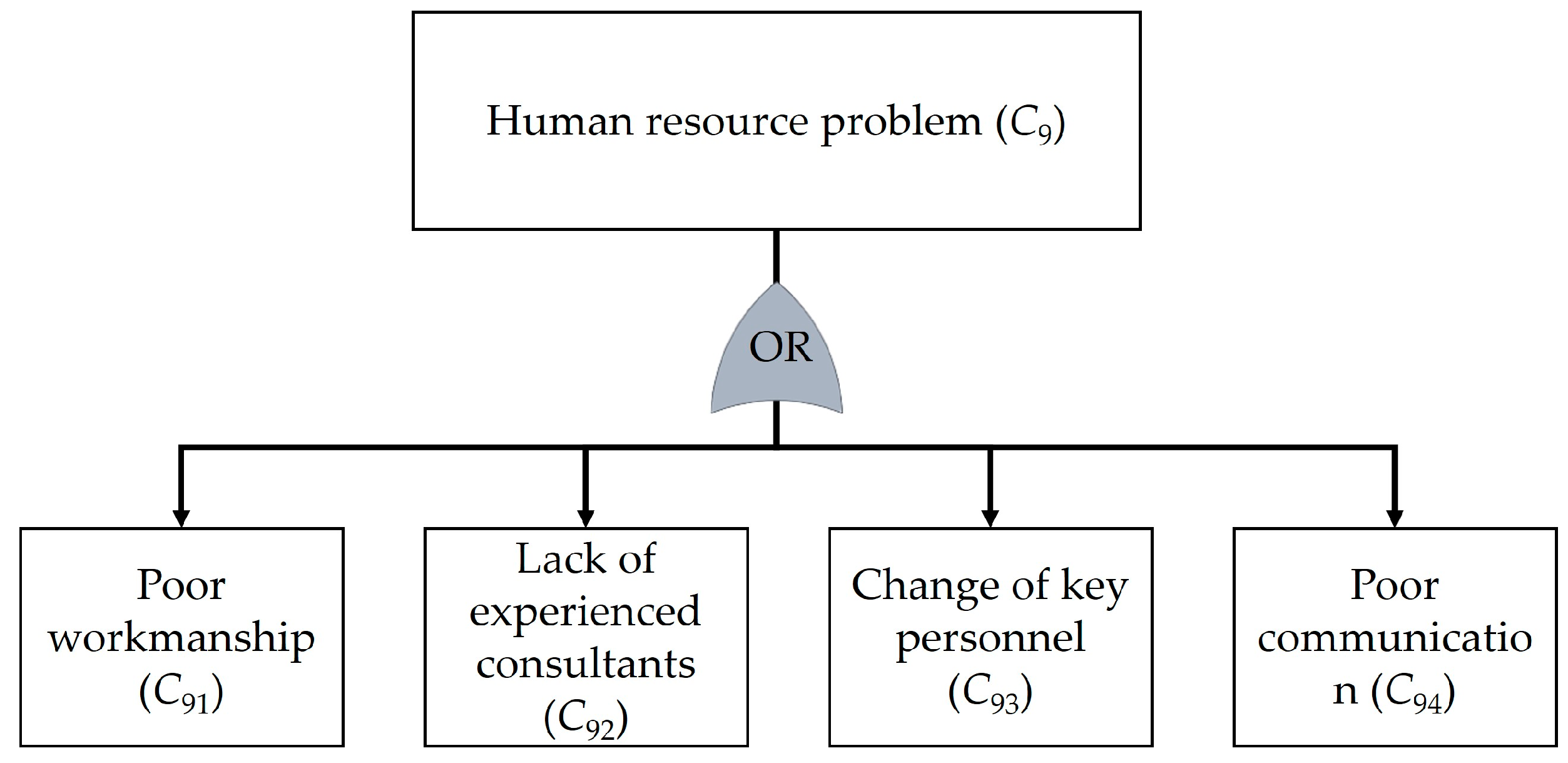

| C91 | 0.08 | 4.40 | 1.00 | 0.00 | 0.83 |

| C92 | 0.08 | 3.52 | 1.00 | 0.00 | 1.19 |

| C93 | 0.08 | 3.73 | 1.00 | 0.00 | 1.09 |

| C94 | 0.08 | 4.10 | 1.00 | 1.00 | 1.02 |

| C101 | 0.07 | 3.90 | 1.00 | 0.00 | 0.84 |

| C102 | 0.07 | 3.60 | 1.00 | 0.00 | 1.11 |

| C103 | 0.08 | 3.52 | 1.00 | 0.50 | 1.03 |

| RP | Probability | PL |

|---|---|---|

| 1 | 1 − ((1 − 0.07) × (1 − 0.08) × (1 − 0.08) × (1 − 0.08) × (1 − 0.09) × (1 − 0.08)) = 0.39 | 2.61 |

| 2 | 1 − ((1 − 0.08) × (1 − 0.09) × (1 − 0.08) × (1 − 0.08) × (1 − 0.09) × (1 − 0.09)) = 0.41 | 2.72 |

| 3 | 1 − ((1 − 0.08) − (1 − 0.08) − (1 − 0.09) − (1 − 0.09) − (1 − 0.09)) = 0.36 | 2.46 |

| 4 | 1 − ((1 − 0.08) − (1 − 0.09)) = 0.16 | 1.34 |

| 5 | 1 − ((1 − 0.08) − (1 − 0.08) − (1 − 0.08) − (1 − 0.08) − (1 − 0.08)) = 0.34 | 2.30 |

| 6 | 1 − ((1 − 0.08) − (1 − 0.08) − (1 − 0.08) − (1 − 0.09) − (1 − 0.08)) = 0.34 | 2.33 |

| 7 | 1 − ((1 − 0.08) − (1 − 0.09) − (1 − 0.08)) = 0.22 | 1.69 |

| 8 | 1 − ((1 − 0.09) − (1 − 0.08) − (1 − 0.08) − (1 − 0.08)) = 0.29 | 2.05 |

| 9 | 1 − ((1 − 0.08) − (1 − 0.08) − (1 − 0.08) − (1 − 0.08)) = 0.29 | 2.20 |

| 10 | 1 − ((1 − 0.08) − (1 − 0.07) − (1 − 0.08)) = 0.21 | 1.62 |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | (1,1,1) | (0.91, 1.30, 1.79) | (0.85, 1.30, 1.85) | (1.18, 1.72, 2.28) | (0.69, 0.99, 1.37) | (0.92, 1.40, 1.95) | (0.94, 1.42, 1.97) | (1.15, 1.72, 2.31) | (1.33, 1.85, 2.35) | (1.52, 2.31, 3.08) |

| C2 | (0.56, 0.77, 1.10) | (1,1,1) | (1.03, 1.56, 2.17) | (1.02, 1.50, 2.05) | (0.85, 1.25, 1.72) | (1.01, 1.50, 2.03) | (1.08, 1.54, 1.99) | (1.09, 1.58, 2.08) | (1.26, 1.92, 2.53) | (1.35, 2.12, 2.83) |

| C3 | (0.54, 0.77, 1.17) | (0.46, 0.64, 0.98) | (1,1,1) | (1.02, 1.47, 1.92) | (0.73, 1.06, 1.49) | (1.18, 1.62, 2.03) | (1.06, 1.57, 2.07) | (1.12, 1.67, 2.25) | (1.46, 2.12, 2.70) | (1.18, 1.69, 2.15) |

| C4 | (0.44, 0.58, 0.85) | (0.49, 0.66, 0.98) | (0.52, 0.68, 0.98) | (1,1,1) | (0.88, 1.26, 1.69) | (0.98, 1.45, 1.99) | (1.10, 1.55, 1.96) | (1.07, 1.60, 2.16) | (1.35, 1.93, 2.44) | (1.29, 1.83, 2.30) |

| C5 | (0.73, 1.01, 1.44) | (0.58, 0.80, 1.18) | (0.67, 0.94, 1.36) | (0.59, 0.79, 1.14) | (1,1,1) | (1.26, 1.77, 2.20) | (1.11, 1.70, 2.26) | (1.18, 1.80, 2.39) | (1.24, 1.87, 2.45) | (1.25, 1.86, 2.39) |

| C6 | (0.51, 0.71, 1.09) | (0.49, 0.67, 0.99) | (0.49, 0.62, 0.84) | (0.50, 0.69, 1.02) | (0.45, 0.57, 0.79) | (1,1,1) | (1.23, 1.74, 2.24) | (1.14, 1.70, 2.19) | (1.15, 1.62, 2.01) | (1.36, 1.98, 2.53) |

| C7 | (0.51, 0.70, 1.07) | (0.50, 0.65, 0.93) | (0.48, 0.64, 0.94) | (0.51, 0.64, 0.91) | (0.44, 0.59, 0.90) | (0.45, 0.57, 0.81) | (1,1,1) | (1.20, 1.72, 2.19) | (1.25, 1.92, 2.55) | (1.19, 1.66, 2.15) |

| C8 | (0.43, 0.58, 0.87) | (0.48, 0.63, 0.91) | (0.44, 0.60, 0.89) | (0.46, 0.63, 0.94) | (0.42, 0.56, 0.84) | (0.46, 0.59, 0.88) | (0.46, 0.58, 0.83) | (1,1,1) | (1.17, 1.72, 2.22) | (1.04, 1.51, 1.95) |

| C9 | (0.43, 0.54, 0.75) | (0.39, 0.52, 0.79) | (0.37, 0.47, 0.69) | (0.41, 0.52, 0.74) | (0.41, 0.54, 0.81) | (0.50, 0.62, 0.87) | (0.39, 0.52, 0.80) | (0.45, 0.58, 0.85) | (1,1,1) | (1.09, 1.40, 1.68) |

| C10 | (0.32, 0.43, 0.66) | (0.35, 0.47, 0.74) | (0.47, 0.59, 0.85) | (0.43, 0.55, 0.78) | (0.42, 0.54, 0.80) | (0.39, 0.51, 0.73) | (0.46, 0.60, 0.84) | (0.51, 0.66, 0.96) | (0.59, 0.72, 0.92) | (1,1,1) |

| w | Weight | CL |

|---|---|---|

| 1 | 0.15/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.14 | 4.23 |

| 2 | 0.15/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.13 | 4.12 |

| 3 | 0.14/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.12 | 3.69 |

| 4 | 0.12/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.11 | 3.31 |

| 5 | 0.14/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.12 | 3.69 |

| 6 | 0.11/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.10 | 2.88 |

| 7 | 0.10/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.09 | 2.57 |

| 8 | 0.08/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.07 | 2.16 |

| 9 | 0.08/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.06 | 1.73 |

| 10 | 0.08/(0.15 + 0.15 + 0.14 + 0.12 + 0.14 + 0.11 + … + 0.07) = 0.06 | 1.61 |

| Risk | PL | CL | RL | Rank | Classification |

|---|---|---|---|---|---|

| Insufficient tunneling (C1) | 2.61 | 4.23 | 11.06 | 2 | High |

| Deterioration of TBM (C2) | 2.72 | 4.12 | 11.18 | 1 | High |

| Soil or rock movement (C3) | 2.46 | 3.69 | 9.06 | 3 | Moderate |

| Flooding in work area (C4) | 1.34 | 3.31 | 4.43 | 7 | Low |

| Tunnel segment deterioration (C5) | 2.30 | 3.69 | 8.50 | 4 | Moderate |

| Inappropriate working conditions (C6) | 2.33 | 2.88 | 6.70 | 5 | Moderate |

| Community complaints (C7) | 1.69 | 2.57 | 4.35 | 8 | Low |

| Economic fluctuations (C8) | 2.05 | 2.16 | 4.43 | 6 | Low |

| Human resource problem (C9) | 2.20 | 1.73 | 3.51 | 9 | Low |

| Unforeseen event (C10) | 1.62 | 1.61 | 2.61 | 10 | Low |

| Discrete Probability Level | Probability | Discrete Consequence Level | Weight |

|---|---|---|---|

| 5 | Greater than 0.68 | 5 | Greater than 0.14 |

| 4 | 0.54–0.68 | 4 | 0.12–0.14 |

| 3 | 0.40–0.53 | 3 | 0.10–0.11 |

| 2 | 0.25–0.39 | 2 | 0.07–0.09 |

| 1 | Less than 0.25 | 1 | Less than 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koohathongsumrit, N.; Chankham, W. Risk Analysis of Underground Tunnel Construction with Tunnel Boring Machine by Using Fault Tree Analysis and Fuzzy Analytic Hierarchy Process. Safety 2024, 10, 68. https://doi.org/10.3390/safety10030068

Koohathongsumrit N, Chankham W. Risk Analysis of Underground Tunnel Construction with Tunnel Boring Machine by Using Fault Tree Analysis and Fuzzy Analytic Hierarchy Process. Safety. 2024; 10(3):68. https://doi.org/10.3390/safety10030068

Chicago/Turabian StyleKoohathongsumrit, Nitidetch, and Wasana Chankham. 2024. "Risk Analysis of Underground Tunnel Construction with Tunnel Boring Machine by Using Fault Tree Analysis and Fuzzy Analytic Hierarchy Process" Safety 10, no. 3: 68. https://doi.org/10.3390/safety10030068