Clearing the Path: Overcoming Barriers to Prevention through Design (PtD) Utilization in the US Construction Industry

Abstract

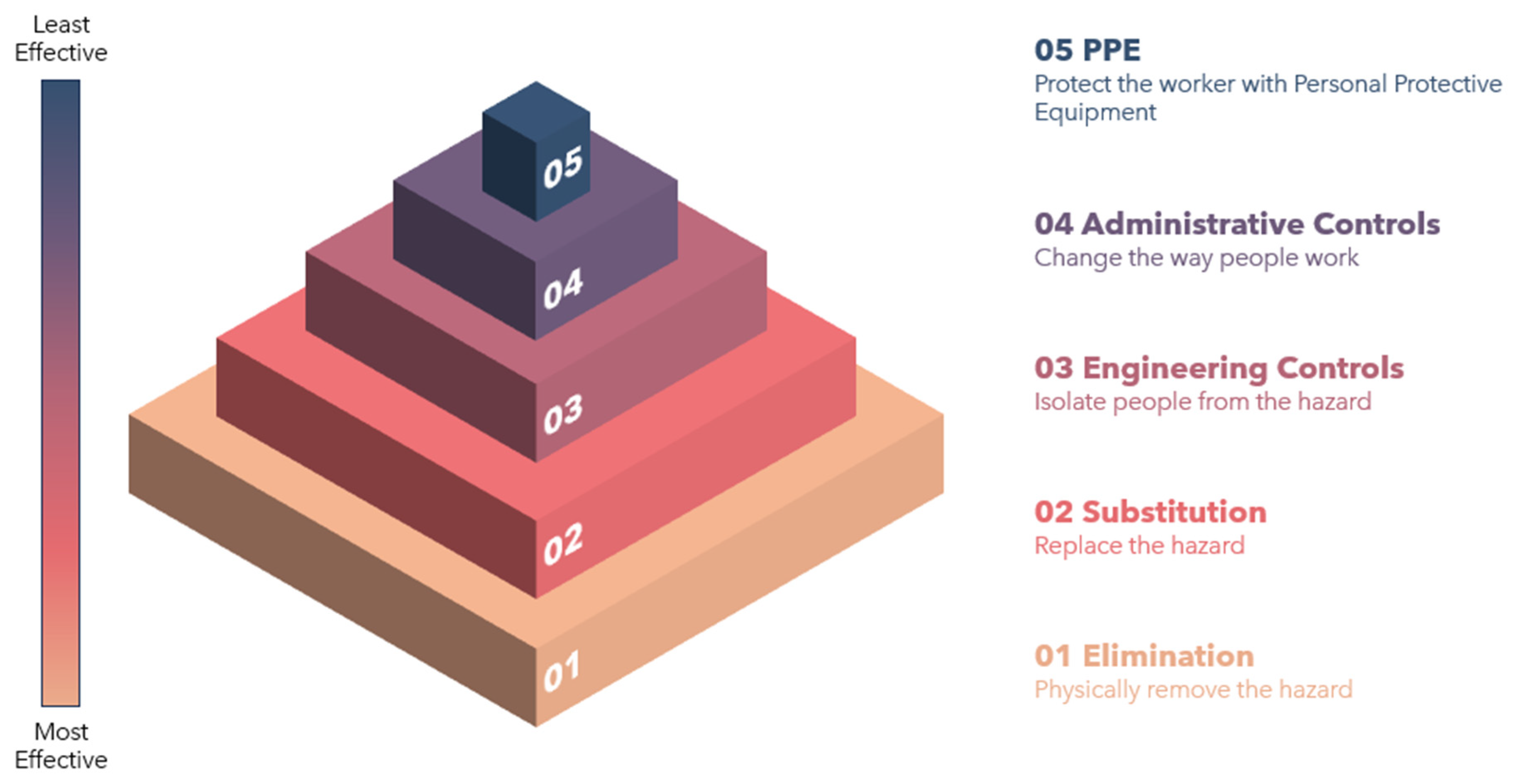

:1. Introduction

- To identify barriers that hinder the utilization of PtD within the construction industry;

- To rank the identified PtD barriers based on their criticality for PtD adoption and implementation.

2. Research Methodology and Findings

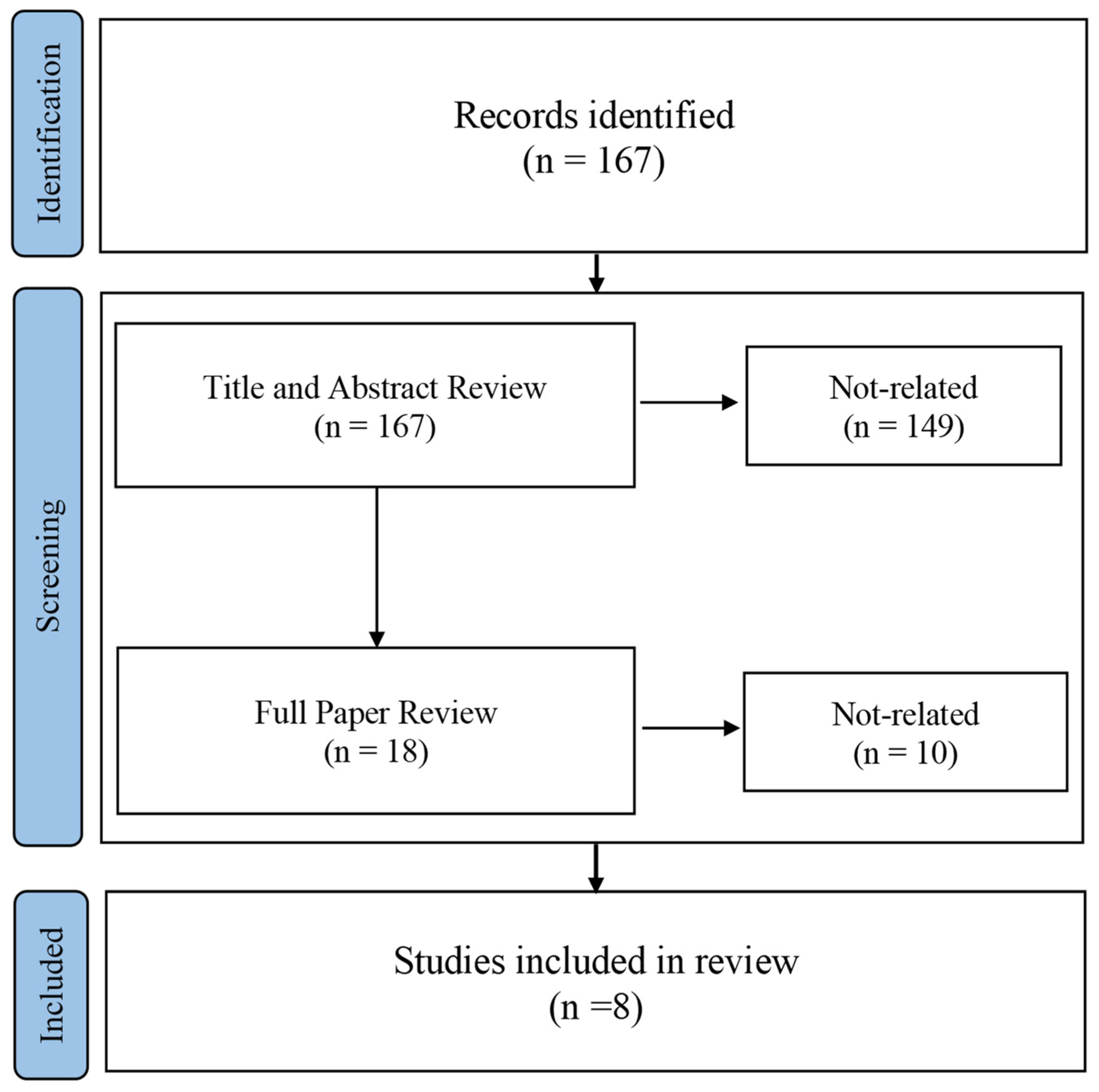

2.1. Phase 1: Literature Review Methodology and Findings

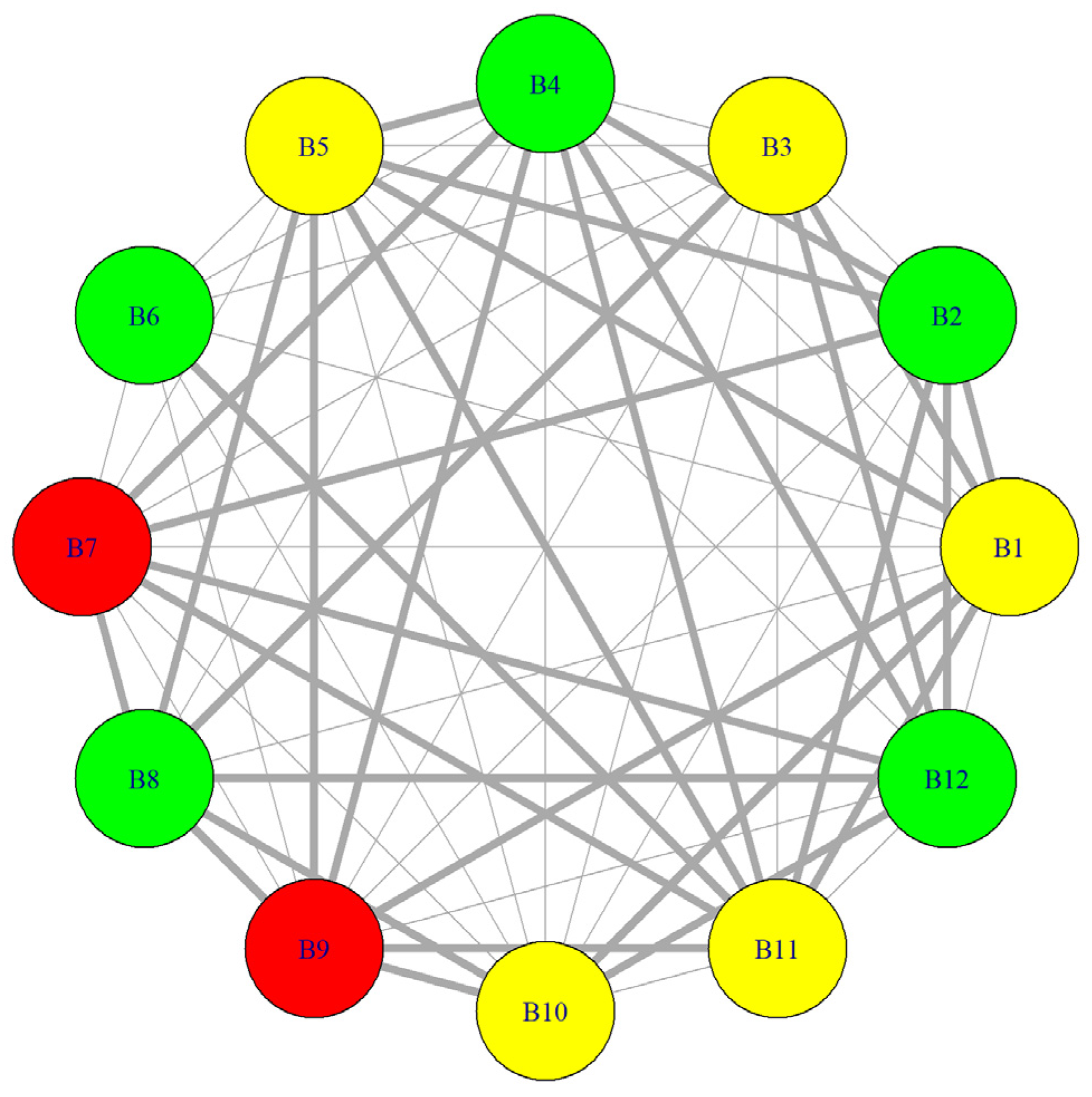

- PtD Utilization Barriers

- Social Network Analysis (SNA) and Clustering

- Red nodes: Barriers with the highest frequency of mentions (most referenced).

- Yellow nodes: Barriers with a moderate frequency of mentions.

- Green nodes: Barriers with the lowest frequency of mentions (least referenced).

2.2. Phase 2: Survey Methodology and Findings

- Data Analysis Method—Fuzzy Set Theory

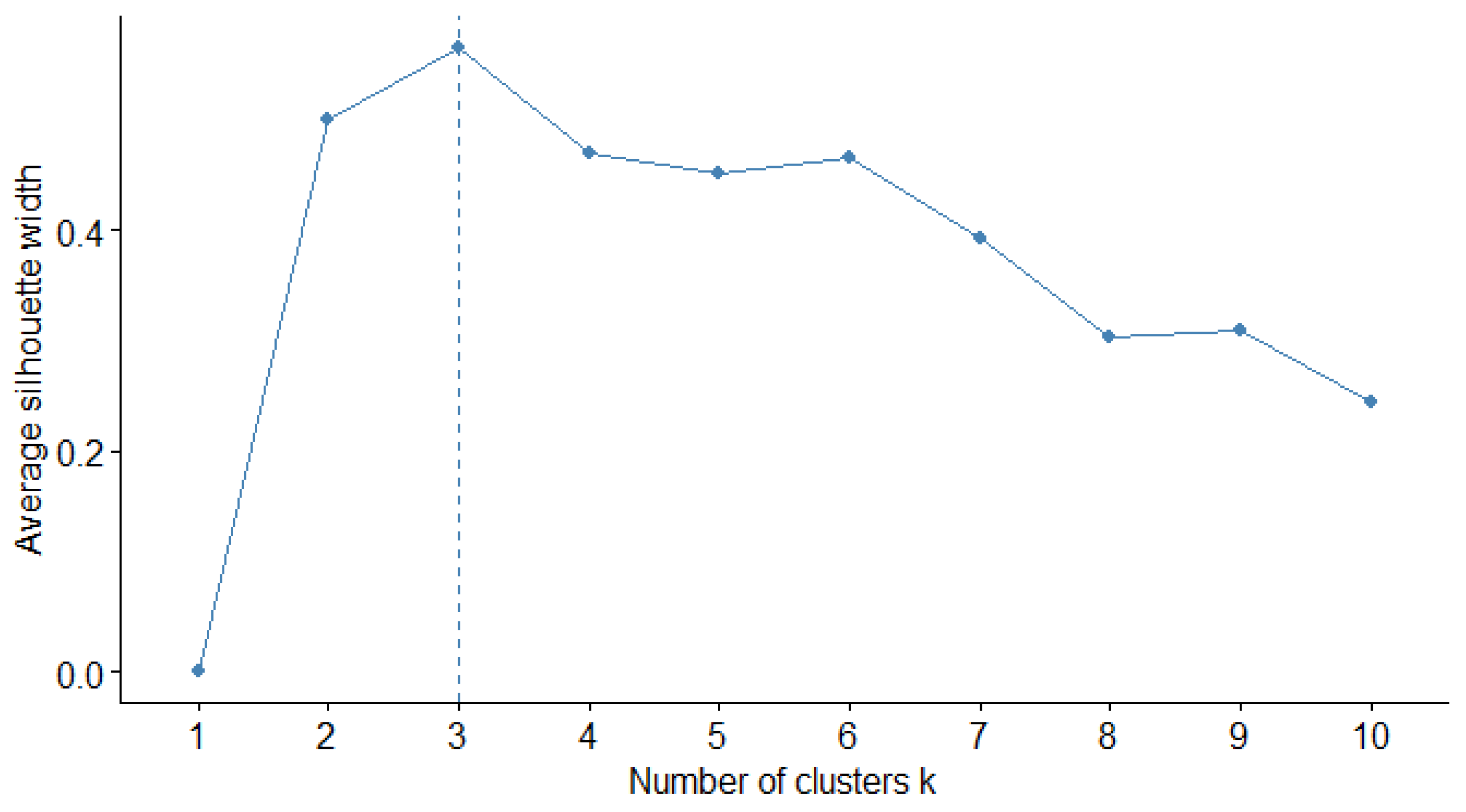

- Barrier Clustering—Prioritizing

3. Discussion

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, C.; McCabe, B.; Jia, G.; Sun, J. Effects of Safety Climate and Safety Behavior on Safety Outcomes between Supervisors and Construction Workers. J. Constr. Eng. Manag. 2020, 146, 04019092. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Goh, Y. A review of construction safety climate: Definitions, factors, relationship with safety behavior and research agenda. Saf. Sci. 2021, 142, 105391. [Google Scholar] [CrossRef]

- Idoro, G.I. Health and safety management efforts as correlates of performance in the Nigerian construction industry. J. Civ. Eng. Manag. 2008, 14, 277–285. [Google Scholar] [CrossRef]

- Williams, O.S.; Hamid, R.A.; Misnan, M.S. Accident causal factors on the building Construction Sites: A review. Int. J. Built Environ. Sustain. 2018, 5, 78–92. [Google Scholar] [CrossRef]

- Al-Bayati, A.J.; Albert, A.; Ford, G. Construction Safety Culture and Climate: Satisfying the Necessity for an Industry Framework. Pract. Period. Struct. Des. Constr. 2019, 24, 04019028. [Google Scholar] [CrossRef]

- Al-Bayati, A.J.; Rener, A.T.; Listello, M.P.; Mohamed, M. PPE non-compliance among construction workers: An assessment of contributing factors utilizing fuzzy theory. J. Saf. Res. 2023, 85, 242–253. [Google Scholar] [CrossRef]

- Buniya, M.K.; Othman, I.; Sunindijo, R.Y.; Karakhan, A.A.; Kineber, A.F.; Durdyev, S. Contributions of safety critical success factors and safety program elements to overall project success. Int. J. Occup. Saf. Ergon. 2023, 29, 129–140. [Google Scholar] [CrossRef]

- Chen, H.; Chen, C.; Li, H.; Zhang, J.; Yang, Z. A simulation study on the processes of Intra-Group informal interaction affecting workers’ safety behaviors. Int. J. Environ. Res. Public Health 2022, 19, 10048. [Google Scholar] [CrossRef]

- Manuele, F. Risk assessment & hierarchies of control. Prof. Saf. J. 2005, 50, 33–39. [Google Scholar]

- Lyon, B.K.; Popov, G. Risk Treatment Strategies: Harmonizing the Hierarchy of Controls & Inherently Safer Design Concepts. Prof. Saf. J. 2019, 64, 34–43. [Google Scholar]

- Occupational Safety and Health Administration (OSHA). Regulations (Standards—29 CFR), 2023. Available online: https://www.osha.gov/laws-regs/regulations/standardnumber/1926 (accessed on 8 July 2024).

- National Institute for Occupational Safety and Health (NIOSH). Hierarchy of Controls; Centers for Disease Control and Prevention (CDC): Atlanta, GA, USA, 2023. Available online: https://www.cdc.gov/niosh/topics/hierarchy/default.html (accessed on 12 November 2023).

- Ko, C.H.; Abdulmajeed, H.A. Improving Construction Safety: Lessons Learned from COVID-19 in the United States (Special issue: Advances in Construction Safety Management Practices). Sustainability 2022, 14, 7137. [Google Scholar] [CrossRef]

- Karakhan, A.A.; Gambatese, J.A. Safety Innovation and Integration in High-Performance Designs: Benefits, Motivations, and Obstacles. Pract. Period. Struct. Des. Constr. 2017, 22, 04017018. [Google Scholar] [CrossRef]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.F.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef] [PubMed]

- Behm, M. Linking construction fatalities to the design for construction safety concept. Saf. Sci. 2005, 43, 589–611. [Google Scholar] [CrossRef]

- Rajendran, S.; Gambatese, J. Risk and financial impacts of prevention through design solutions. Pract. Period. Struct. Des. Constr. 2013, 18, 67–72. [Google Scholar] [CrossRef]

- Karakhan, A.; Gambatese, J. Hazards and risk in construction and the impact of incentives and rewards on safety outcomes. Pract. Period. Struct. Des. Constr. 2018, 23, 04018005. [Google Scholar] [CrossRef]

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization (ISO): Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/63787.html (accessed on 15 July 2024).

- American National Standards Institute (ANSI); American Society of Safety Professionals (ASSP). Prevention through Design: Guidelines for Addressing Occupational Hazards and Risks in Design and Redesign Processes [ANSI/ASSP Z590.3-2011 (R2016)]; ASSP: Park Ridge, IL, USA, 2016. [Google Scholar]

- Karakhan, A.A.; Gambatese, J.A. Integrating Worker Health and Safety into Sustainable Design and Construction: Designer and Constructor Perspectives. J. Constr. Eng. Manag. 2017, 143, 04017069. [Google Scholar] [CrossRef]

- PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses). 2015. Available online: http://www.prisma-statement.org/ (accessed on 12 November 2023).

- Gambatese, J.A.; Gibb, A.G.; Brace, C.; Tymvios, N. Motivation for Prevention through Design: Experiential Perspectives and Practice. Pract. Period. Struct. Des. Constr. 2017, 22, 04017017. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Toole, T.M.; Abowitz, D.A. Owner Perceptions of Barriers to Prevention through Design Diffusion. J. Constr. Eng. Manag. 2017, 143, 04017016. [Google Scholar] [CrossRef]

- Toole, T.M.; Gambatese, J.A.; Abowitz, D.A. Owners’ Role in Facilitating Prevention through Design. J. Prof. Issues Eng. Educ. Pract. 2017, 143, 04016012. [Google Scholar] [CrossRef]

- Jin, Z.; Gambatese, J.; Karakhan, A.; Nnaji, C. Analysis of Prevention through Design Studies in Construction: A Subject Review. J. Saf. Res. 2023, 84, 138–154. [Google Scholar] [CrossRef]

- Toole, T.M.; Erger, K. Prevention through Design: Promising or Perilous? J. Leg. Aff. Disput. Resolut. Eng. Constr. 2019, 11, 04518023. [Google Scholar] [CrossRef]

- Ibrahim, C.K.I.C.; Belayutham, S.; Mohammad, M.Z.; Ismail, S. Development of a Conceptual Designer’s Knowledge, Skills, and Experience Index for Prevention through Design Practice in Construction. J. Constr. Eng. Manag. 2022, 148, 04021199. [Google Scholar] [CrossRef]

- Al-Bayati, A.J. Impact of Construction Safety Culture and Construction Safety Climate on Safety Behavior and Safety Motivation. Safety 2021, 7, 41. [Google Scholar] [CrossRef]

- Li, D.F.; Hong, F.X. Solving constrained matrix games with payoffs of triangular fuzzy numbers. Comput. Math. Appl. 2012, 64, 432–446. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Ho, W. Analytic hierarchy process and fuzzy set theory. In Fuzzy Analytic Hierarchy Process; Chapman and Hall/CRC: Boca Raton, FL, USA, 2017; pp. 1–10. [Google Scholar]

- Saxena, A.; Prasad, M.; Gupta, A.; Bharill, N.; Patel, O.P.; Tiwari, A.; Er, M.J.; Ding, W.; Lin, C.-T. A review of clustering techniques and developments. Neurocomputing 2017, 267, 664–681. [Google Scholar] [CrossRef]

- Na, S.; Xumin, L.; Yong, G. Research on k-means clustering algorithm: An improved k-means clustering algorithm. In Proceedings of the 2010 Third International Symposium on Intelligent Information Technology and Security Informatics, Jian, China, 2–4 April 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 63–67. [Google Scholar]

- Yuan, C.; Yang, H. Research on K-value selection method of K-means clustering algorithm. J 2019, 2, 226–235. [Google Scholar] [CrossRef]

- Toole, M. History and Future of PTD. Prevention through Design. 2017. Available online: https://designforconstructionsafety.org/history-and-future-of-ptd/ (accessed on 12 November 2023).

- Al-Bayati, A.J.; Jensen, E.; Eiris, R.; Abudayyeh, O. Integrating Prevention Through Design (PtD) Into Engineering Curricula. Proc. Int. Struct. Eng. Constr. 2024, 11, CSA-04. [Google Scholar] [CrossRef]

- Al-Bayati, A.J.; Alghamdi, A.; Abydayyeh, O. Improving the Safety Culture and Climate of Smaller Construction Firms: A Necessary Addition to the OSH Intervention Model. J. Civ. Eng. Constr. 2023, 12, 187–196. [Google Scholar] [CrossRef]

- National Safety Council (NSC). 2014 Injury Facts; National Safety Council: Itasca, IL, USA, 2014. [Google Scholar]

- Uğura, L.O.; Leblebicib, N. An examination of the LEED green building certification system in terms of construction costs. Renew. Sustain. Energy Rev. 2018, 81, 1476–1483. [Google Scholar] [CrossRef]

- Bonilla v. Verges Rome Architects. No. 2023-C-00928, Supreme Court of Louisiana. 2024. Available online: https://law.justia.com/cases/louisiana/supreme-court/2024/2023-c-00928.html (accessed on 28 July 2024).

| Category | Barrier | References |

|---|---|---|

| Industry | B1: Lack of PtD regulations and industry standards | [14,21,24,25,26] |

| B2: Absence of contractual clauses to arrange PtD application | [21,26,27] | |

| B3: Absence of PtD professional development training | [21,23,24,26] | |

| B4: Absence of PtD education on a college level | [14,26,28] | |

| Project | B5: Potential increased costs and time required for design work | [21,23,24,26,27] |

| B6: Project delivery methods not supporting PtD application | [14,28] | |

| Designer | B7: Lack of PtD knowledge among designers | [14,21,24,25,26,27,28] |

| B8: Absence of PtD training and education for designers | [14,21] | |

| B9: Designers’ fear of liability and lack of insurance coverage | [14,21,23,24,27,28] | |

| B10: Absence of motivation and incentives for designers | [14,21,23,24,26] | |

| Client | B11: Lack of understanding of PtD among project owners/clients | [24,25,26,28] |

| B12: Lack of encouragement from clients for PtD implementation | [14,26] |

| Barrier | Average Fuzzy Score |

|---|---|

| B7: Lack of PtD knowledge among designers | 0.6414 |

| B11: Lack of understanding of PtD among project owners/clients | 0.6276 |

| B5: Potential increased costs and time required for design work | 0.6172 |

| B8: Absence of PtD training and education for designers | 0.6103 |

| B9: Designers’ fear of liability and lack of insurance coverage | 0.5897 |

| B3: Absence of PtD professional development training | 0.5793 |

| B1: Lack of PtD regulation and industry standards | 0.5793 |

| B10: Absence of motivation and incentives for designers | 0.5655 |

| B4: Absence of PtD education on a college level | 0.5586 |

| B2: Absence of contractual clauses to arrange PtD application | 0.5448 |

| B6: Project delivery methods not supporting PtD application | 0.5241 |

| B12: Lack of encouragement from clients for PtD implementation | 0.5069 |

| Barrier | K-Cluster | Influential Level |

|---|---|---|

| B7: Lack of PtD knowledge among designers | 1 | High |

| B11: Lack of understanding of PtD among project owners/clients | ||

| B5: Potential increased costs and time required for design work | ||

| B8: Absence of PtD training and education for designers | ||

| B9: Designers’ fear of liability and lack of insurance coverage | 2 | Moderate |

| B3: Absence of PtD professional development training | ||

| B1: Lack of PtD regulation and industry standards | ||

| B10: Absence of motivation and incentives for designers | ||

| B4: Absence of PtD education on a college level | ||

| B2: Absence of contractual clauses to arrange PtD application | 3 | Low |

| B6: Project delivery methods not supporting PtD application | ||

| B12: Lack of encouragement from clients for PtD implementation |

| Barrier | Experts Ranking | Literature Focus |

|---|---|---|

| B1: Lack of PtD regulation and industry standards | Moderate | Moderate |

| B2: Absence of contractual clauses to arrange PtD application | Low | Least |

| B3: Absence of PtD professional development training | Moderate | Moderate |

| B4: Absence of PtD education on a college level | Moderate | Least |

| B5: Potential increased costs and time of design work | High | Moderate |

| B6: Project delivery methods not supporting PtD application | Low | Least |

| B7: Lack of PtD knowledge among designers | High | Most |

| B8: Absence of PtD training and education for designers | High | Least |

| B9: Designers’ fear of liability and lack of insurance coverage | Moderate | Most |

| B10: Absence of motivation and incentives for designers | Moderate | Moderate |

| B11: Lack of understanding of PtD among project owners/clients | High | Moderate |

| B12: Lack of encouragement from clients for PtD implementation | Low | Least |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Bayati, A.J.; Bazzi, K.; Karakhan, A.A.; Jensen, E. Clearing the Path: Overcoming Barriers to Prevention through Design (PtD) Utilization in the US Construction Industry. Safety 2024, 10, 74. https://doi.org/10.3390/safety10030074

Al-Bayati AJ, Bazzi K, Karakhan AA, Jensen E. Clearing the Path: Overcoming Barriers to Prevention through Design (PtD) Utilization in the US Construction Industry. Safety. 2024; 10(3):74. https://doi.org/10.3390/safety10030074

Chicago/Turabian StyleAl-Bayati, Ahmed Jalil, Karim Bazzi, Ali A. Karakhan, and Elin Jensen. 2024. "Clearing the Path: Overcoming Barriers to Prevention through Design (PtD) Utilization in the US Construction Industry" Safety 10, no. 3: 74. https://doi.org/10.3390/safety10030074

APA StyleAl-Bayati, A. J., Bazzi, K., Karakhan, A. A., & Jensen, E. (2024). Clearing the Path: Overcoming Barriers to Prevention through Design (PtD) Utilization in the US Construction Industry. Safety, 10(3), 74. https://doi.org/10.3390/safety10030074