3D Bioprinting Techniques and Bioinks for Periodontal Tissues Regeneration—A Literature Review

Abstract

1. Introduction

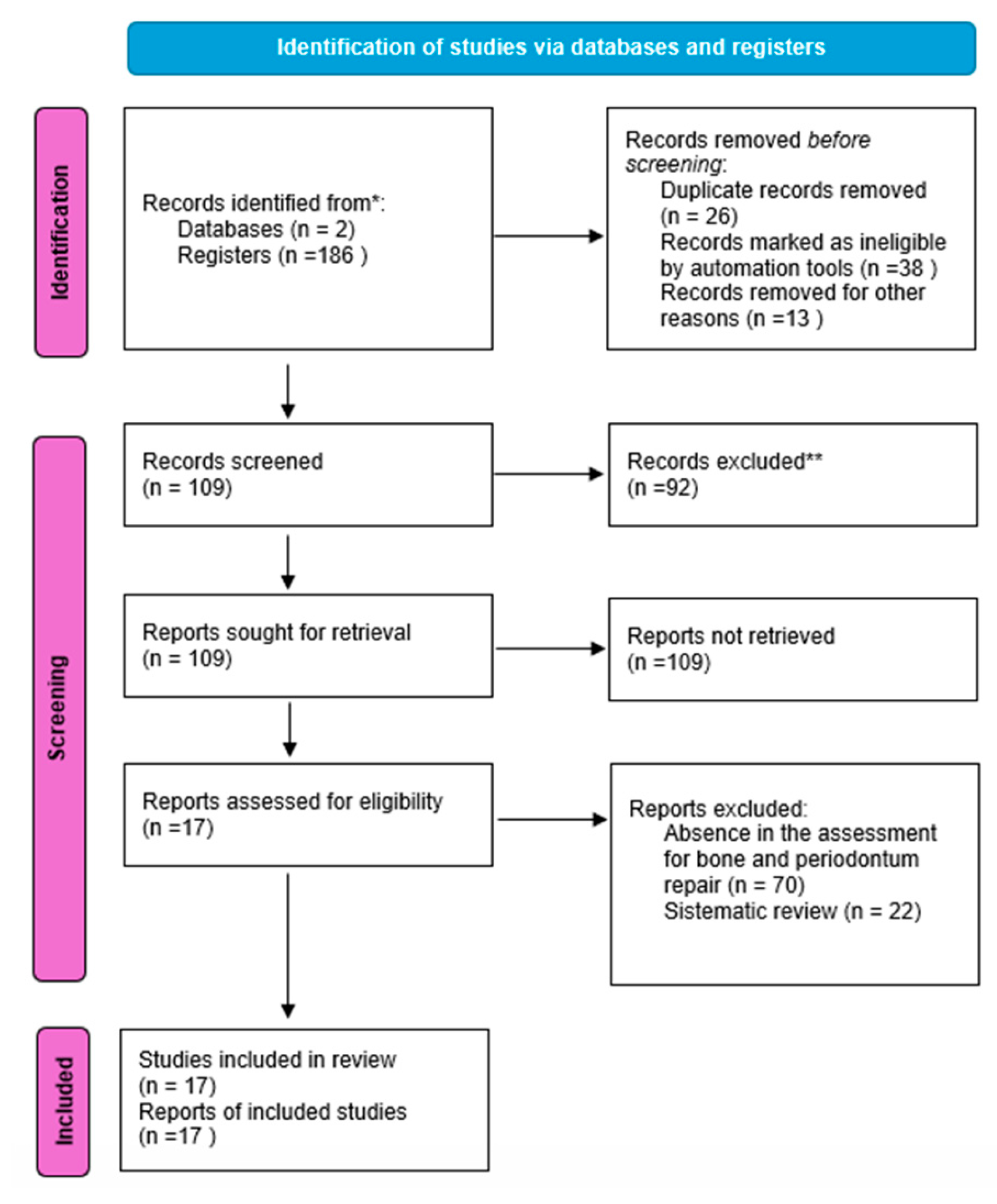

1.1. Methodology and PRISMA Flowchart

1.1.1. Search Strategy

1.1.2. Inclusion Criteria

1.1.3. Exclusion Criteria

1.1.4. Results

2. 3D Bioprinting Techniques

3. Bioink

3.1. Bioink and Alveolar Bone Regeneration

| Application | Biomaterials | Cell Source | Bioprinting | Properties | Reference |

|---|---|---|---|---|---|

| Increase the quality and quantity of keratinized gingiva | Gelatin and sodium alginate | Gingival fibroblasts | 3D printing | Greater promotive effect on soft tissue regeneration | [46] |

| Regeneration of the oral soft tissue | Gelatin, sodium alginate, and platelet-rich fibrin | Multipotent adult stem cells | Extrusion-based 3D printing | Exhibited mechanical and rheological properties; excellent biocompatibility in vitro and in vivo | [47] |

| Formation of cementum | Polycaprolactone, oly)lactic-co-glycolic acids) and connective tissue growth factor | Periodontal ligament stem/progenitor cells | Layer-by-layer 3D printing | Can guide the formation of a fully integrated periodontium-like structure, consisting of cementum/dentin, periodontal ligamen, and alveolar bone in vivo | [48] |

| Guided bone regeneration in peri-implants | Polycaprolactone, poly(lactic-co-glycolic acid), β-tricalcium phosphate, and collagen | Gingival fibroblast | Extrusion-based 3D printing | The 3D-printed PCL/PLGA/β-TCP membrane was confirmed to have substantial efficacy as a resorbable GBR membrane for peri-implant defect treatment | [49] |

| Study | Bioink Composition | Cell Source | Bioprinting | Target Tissue | Antibacterial Results | In Vitro Results | In Vivo Results |

|---|---|---|---|---|---|---|---|

| Yu et al., 2024 [50] | Epsilon-poly-L-lysine hydrogels modified with glycidyl methacrylate | Myeloid-derived suppressor cells and periodontal ligament stem cells | Digital light processing printer | Multifunctional and biomimetic alveolar bone | EPM was shown to effectively kill the periodontopathic bacteria depending on the natural antibacterial properties of the EPL; MDSCs-MV effectively killed the periodontopathic bacteria | 1. Control 2. MDSCs 3. MDSCs-MV MDSCs-MV play an anti-inflammatory and mineralizing role in osteoblast derived from periodontal ligament stem cells.; additionally, could significantly enhance the mineralizing capacity of PDLSCs-derived osteoblast | 1. Control (no scaffold + no bacteria) 2. Scaffold + P.g intervention 3. EPLGMA scaffold + P.g intervention 4. EPLGMA/MDSCs-MV scaffold + P.g intervention 5. EPM scaffold + P.g intervention Micro-CT and histological staining demonstrated that the EPM scaffold similarly had an excellent anti-inflammatory and bone regeneration efficacy |

| Miao et al., 2023 [47] | Gelatin methacryloyl, sodium alginate bioactive glass microsphere | Mouse bone marrow mesenchymal stem cells and growth factors (BMP2 and PDGF) | Extrusion, layer-by-layer application | Bioactive scaffolds for simultaneous repair of periodontal bone and soft tissue | Not mentioned | 1. GelMA/SA 2. GelMA/SA/BGM The incorporating bioactive glass into GelMA/SA hydrogel could improve its bioactivity and showed enhanced osteogenic differentiation and soft tissue repair capabilities in BMP2- and PDGF-loaded scaffolds | 1. Not implanted 2. GelMA/SA/BGM 3. GelMA/SA/BGM 4. Containing cell-laden BMP2 and PDGF BMP2/PDGF 5. GelMA/SA/BGM scaffold containing BMP2 and PDGF Significant regeneration of gingival tissue, periodontal ligament, and alveolar bone was detected |

| Gao et al., 2023 [31] | Polyethylene glycol diacrylate, pluronic F127 diacrylate, and gelatin methacryloyl | Not mentioned | Digital light processing | Scaffold | Not mentioned |

1. Normal medium 2. GPF 3. PF GPF facilitated the adhesion and proliferation of cells and effectively promoted the osteogenic differentiation of mesenchymal stem cells in an osteo-inductive environment |

1. GPF 2. PF 3. Blank GPF possesses a satisfactory porous structure and mechanical properties to promote osteogenic differentiation under osteo-inductive conditions and guides bone |

| Cao et al., 2023 [44] | Methacrylated gelatin, methacrylated alginate, and laponite | Rat platelet-rich plasma | Layer-by-layer | Bone repair scaffold | Both sets of hydrogels containing PRP promoted macrophage M2 polarization | 1. GA 2. PRP-GA 3. PRP-GA@Lap | 1. GA/PCL 2. PRP-GA 3. PRP-GA@Lap/PCL 4. Blank control |

| PRP-GA@Lap promoted the proliferation, migration, and osteogenic differentiation of rat bone marrow mesenchymal stem cells, accelerated the formation of endothelial cell vascular patterns | PRP-GA@Lap promoted vascular inward growth and enhanced bone regeneration at the defect site. | ||||||

| Miau et al., 2016 [51] | Periodontal ligament stem cells (PDLSCs)/methacrylate gelatine (GelMA) hydrogel |

Periodontal ligament | Extrusion | Alveolar bone cells |

Not mentioned |

1. PDLSC with 3% GelMA 2. PDLSC with 5% GelMa 3. PDLSC with 10% GelMA | |

| 10% GelMA bioprinted constructs showed lower cell viability, less cell spreading. | 10% GelMA bioprinted showed lower cell survival, but good bone regeneration | ||||||

| Shokouhimehr et al., 2021 [33] | Hyperelastic bone ink and oxide nanoparticles | Not mentioned | Cylindrical scaffold and disc scaffold | Incorporating 200 µg/mL of SPIONs increased antibacterial activity in comparison to the 60 µg/mL SPION-loaded group |

1. SPION-free 2. SPION-loaded 60 µg/mL 3. SPION-loaded 200 µg/mL 60 µg/mL SPION-loaded group appeared to keep higher viability and exhibited greater potential for osteogenesis and mineralization |

1. Control 2. SPION-loaded 60 µg/mL 60 µg/mL SPION-loaded HB scaffolds grafts show rapid integration with host tissue, ossification, and growth of new bone | |

3.2. Bioink and Periodontal Ligament Regeneration

| Study | Bioink Composition | Cell Source | Bioprinting | Target Tissue | Antibacterial Results | In Vitro Results | In Vivo Results |

|---|---|---|---|---|---|---|---|

| Yang et al., 2023 [48] | Methacrylate gelatin/decellularized extracellular matrix | Porcine dental follicles | Digital light projection |

Periodontal module comprising periodontal ligament and module alveolar bone | Not mentioned | 1. GelMA 2. GelMA + 5dECM 3. GelMA + 10dECM The periodontal module did not give rise to apparent immunological rejection or systemic damage |

GelMA + dECM promoted the regeneration of functional periodontal tissues, higher alveolar bone recovery, more mature periodontal ligament fibers, and a more sophisticated fusion of the interface. GelMA + 5dECM promoted the regeneration of hybrid periodontal tissues, especially the anchoring structures of the bone–ligament interface, well-aligned periodontal fibers, and highly mineralized alveolar bone; GelMA, forming GelMA/dECM cell-laden bioink |

| Zhang et al., 2022 [56] | Alginate/gelatin nanohydroxyapatite | Gingival fibroblast cells and bone-marrow-derived mesenchymal stem cells | Extrusion | Not mentioned | 1. GFs in AG 2. BMSC in AGH The viability of GFs in AG was higher than in BMSC AGH | 1. AG 2. AGH (acellular) 3. AG + GFs/AGH + BMSCs (cell printed) The cellular printed construct displayed a more integrated structure and was better | |

| Lin et al., 2021 [52] | Type 1 collagen-based | Periodontal ligament | Extrusion | Periodontal tissue | Not mentioned |

Collagen-based microfibers were successfully fabricated; exhibited an enhanced tendency to promote healing and regeneration | Not mentioned |

| Raveendran et al., 2019 [60] |

Gelatin methacryloyl and phenyl-2,4,6- trimethylbenzoylphosphinate | Human primary periodontal ligaments cells | Extrusion | Periodontal tissue | Not mentioned | 1. Control casted cellular solution in GelMA 2. Casted cellular solution in GelMA with 0.05% LAP 3. Casted cellular solution in GelMA with a 20 s UV exposure 4. Casted cellular solution in GelMA with 0.05% LAP and with a 20 s UV exposure The bioprinted cellular GelMA (Printed) without LAP or UV irradiation; the cell viability of the 3D-printed PDLCs decreased | |

| Lee et al., 2014 [61] |

Polycarprolactione- hydroxylapatite | From dental stem/progenitor cells | Layer-by-Layer |

Region-specific micro-scaffolds | Not mentioned | 1. PDLSCs 2. DPSCs 3. ABSCs Distinctive tissue phenotypes were formed with collagen I-rich fibers especially by PDLSCs and mineralized tissues by DPSCs, PDLSCs, and ABSCs | 1. Control–DPSC with microspheres 2. DPSC-seeded with amelogenin 3. DPSC-seeded with BMP2 4. DPSC-CTGF DPSC-seeded multiphase Scaffolds upon implantation yielded aligned PDL-like collagen fibers inserted DSPP+, CEMP1+ mineralized matrix on one side and bone-like tissue on another side, which together recapitulated a putative periodontium complex |

4. Future Insights into Bioprinting

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ostrovidov, S.; Ramalingam, M.; Bae, H.; Orive, G.; Fujie, T.; Shi, X.; Kaji, H. Bioprinting and biomaterials for dental alveolar tissue regeneration. Front. Bioeng. Biotechnol. 2023, 11, 991821. [Google Scholar] [CrossRef] [PubMed]

- Hirashima, S.; Kanazawa, T.; Ohta, K.; Nakamura, K.I. Three-dimensional ultrastructural imaging and quantitative analysis of the periodontal ligament. Anat. Sci. Int. 2020, 95, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Tonetti, M.S.; Greenwell, H.; Kornman, K.S. Staging and grading of periodontitis: Framework and proposal of a new classification and case definition. J. Periodontol. 2018, 89, 1475, reprinted in J. Periodontol. 2018, 89 (Suppl. 1), S159–S172. [Google Scholar] [CrossRef] [PubMed]

- Muthukrishnan, L. Imminent antimicrobial bioink deploying cellulose, alginate, EPS and synthetic polymers for 3D bioprinting of tissue constructs. Carbohydr. Polym. 2021, 260, 117774. [Google Scholar] [CrossRef] [PubMed]

- Donderwinkel, J.C.; Van Hest, N.R. Cameron. Bio-inks for 3D bioprinting: Recent advances and future prospects. Polym. Chem. 2017, 8, 4451–4471. [Google Scholar] [CrossRef]

- França, R.; Winkler, J.; Hsu, H.H.; Rahimnejad, M.; Abdali, Z. 3D Printing—Additive Manufacturing of Dental Biomaterials. Dental Biomaterials; World Scientific Series: From Biomaterials towards Medical Devices; World Scientific: London, UK, 2018; pp. 421–462. [Google Scholar]

- Ostrovidov, S.; Salehi, S.; Costantini, M.; Suthiwanich, K.; Ebrahimi, M.; Sadeghian, R.B.; Fujie, T.; Shi, X.; Cannata, S.; Gargioli, C.; et al. 3D Bioprinting in Skeletal Muscle Tissue Engineering. Small 2019, 15, e1805530. [Google Scholar] [CrossRef] [PubMed]

- Tayebi, L. Applications of Biomedical Engineering in Dentistry, 1st ed.; Springer Nature: Cham, Switzerland, 2019. [Google Scholar]

- Kumar, K.; Kumar, S.; Singh, R.; Vaibhav, V.; Kedia, N.B.; Singh, A.K. Basal implants-A new era of prosthodontic dentistry. IP Ann. Prosthodont. Restor. Dent. 2020, 6, 1–3. [Google Scholar] [CrossRef]

- Mosaddad, S.A.; Rasoolzade, B.; Namanloo, R.A.; Azarpira, N.; Dortaj, H. Stem cells and common biomaterials in dentistry: A review study. J. Mat. Sci. Mat. Med. 2022, 33, 55. [Google Scholar] [CrossRef] [PubMed]

- Venkatesh, D.; Kumar, K.P.M.; Alur, J.B. Gingival mesenchymal stem cells. J. Oral. Maxillofac. Pathol. 2017, 21, 296–298. [Google Scholar] [CrossRef]

- Yang, H.; Gao, L.-N.; An, Y.; Hu, C.-H.; Jin, F.; Zhou, J.; Jin, Y.; Chen, F.-M. Comparison of mesenchymal stem cells derived from gingival tissue and periodontal ligament in different incubation conditions. Biomaterials 2013, 34, 7033–7047. [Google Scholar] [CrossRef]

- Dwivedi, R.; Mehrotra, D. 3D bioprinting and craniofacial regeneration. J. Oral. Biol. Craniofac. Res. 2020, 10, 650–659. [Google Scholar] [CrossRef] [PubMed]

- Gudupati, H.; Dey, M.; Ozbolat, I. A Comprehensive Review on Droplet-based Bioprinting: Past, Present and Future. Biomaterials 2016, 102, 20–42. [Google Scholar] [CrossRef] [PubMed]

- Mandrycky, C.; Wang, Z.; Kim, K.; Kim, D.H. 3D bioprinting for engineering complex tissues. Biotechnol. Adv. 2016, 34, 422–434. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Gao, G.; Qiu, Y. Accelerated myotube formation using bioprinting technology for biosensor applications. Biotechnol. Lett. 2013, 35, 315–321. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.Q.; Liu, J.C.; Zhang, Z.Y.; Xu, C.X. A review on cell damage, viability, and functionality during 3D bioprinting. Mil. Med. Res. 2022, 9, 70. [Google Scholar] [CrossRef]

- Herzog, J.; Franke, L.; Lai, Y.; Gomez Rossi, P.; Sachtleben, J.; Weuster-Botz, D. 3D bioprinting of microorganisms: Principles and applications. Bioprocess Biosyst. Eng. 2024, 47, 443. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Chen, X.; Shan, M.; Hao, Z.; Zhang, X.; Meng, L.; Zhai, Z.; Zhang, L.; Liu, X.; Wang, X. Convergence of 3D Bioprinting and Nanotechnology in Tissue Engineering Scaffolds. Biomimetics 2023, 8, 94. [Google Scholar] [CrossRef] [PubMed]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Q.; Wang, S.; Tao, J.; Gou, M. Digital Light Processing Based Three-dimensional Printing for Medical Applications. Int. J. Bioprint. 2019, 6, 242. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Sultan, S.; Siqueira, G.; Zimmermann, T.; Mathew, A.P. 3D printing of nano-cellulosic biomaterials for medical applications. Curr. Opin. Biomed. Eng. 2017, 2, 29–34. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, Y.; Zhang, Y.; Zhao, Z.; Xue, T.; Wang, J.; Li, M.; Zhao, S.; Zhang, H.; Ding, Y. 3D bioprinting advanced biomaterials for craniofacial and dental tissue engineering–A review. Mater. Des. 2024, 241, 112886. [Google Scholar] [CrossRef]

- Ozbolat, I.T. Scaffold-Based or Scaffold-Free Bioprinting: Competing or Complementing Approaches? ASME J. Nanotechnol. Eng. Med. 2015, 6, 024701. [Google Scholar] [CrossRef]

- Mohd, N.; Razali, M.; Fauzi, M.B.; Abu Kasim, N.H. In Vitro and In Vivo Biological Assessments of 3D-Bioprinted Scaffolds for Dental Applications. Int. J. Mol. Sci. 2023, 24, 12881. [Google Scholar] [CrossRef]

- Gungor-Ozkerim, P.S.; Inci, I.; Zhang, Y.S.; Khademhosseini, A.; Dokmeci, M.R. Bioinks for 3D bioprinting: An overview. Biomater. Sci. 2018, 6, 915–946. [Google Scholar] [CrossRef] [PubMed]

- Su, C.; Chen, Y.; Tian, S.; Lu, C.; Lv, Q. Natural Materials for 3D Printing and Their Applications. Gels 2022, 8, 748. [Google Scholar] [CrossRef] [PubMed]

- Rahimnejad, M.; Rezvaninejad, R.; Rezvaninejad, R.; Franca, R. Biomaterials in bone and mineralized tissue engineering using 3D printing and bioprinting technologies. Biomed. Phys. Eng. Express 2021, 7, 062001. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Li, M.; Cheng, J.; Liu, X.; Liu, Z.; Liu, J.; Tang, P. 3D-Printed GelMA/PEGDA/F127DA Scaffolds for Bone Regeneration. J. Funct. Biomater. 2023, 14, 96. [Google Scholar] [CrossRef] [PubMed]

- Bajestan, M.N.; Rajan, A.; Edwards, S.P.; Aronovich, S.; Cevidanes, L.H.S.; Polymeri, A.; Travan, S.; Kaigler, D. Stem cell therapy for reconstruction of alveolar cleft and trauma defects in adults: A randomized controlled, clinical trial. Clin. Implant. Dent. Relat. Res. 2017, 19, 793–801. [Google Scholar] [CrossRef] [PubMed]

- Shokouhimehr, M.; Theus, A.S.; Kamalakar, A.; Ning, L.; Cao, C.; Tomov, M.L.; Kaiser, J.M.; Goudy, S.; Willett, N.J.; Jang, H.W.; et al. 3D Bioprinted Bacteriostatic Hyperelastic Bone Scaffold for Damage-Specific Bone Regeneration. Polym. Res. 2021, 13, 1099. [Google Scholar] [CrossRef] [PubMed]

- Zhiwei, J.; Bin, L.; Xiang, S.; Ma, H.; Yu, Y.; Yang, W. 3D printing of HA/PCL composite tissue engineering scaffolds. Adv. Ind. Eng. Polym. Res. 2019, 2, 196–202. [Google Scholar]

- Rastin, H.; Zhang, B.; Mazinani, A.; Hassan, K.; Bi, J.; Tung, T.; Losic, D. 3D Bioprinting of Cell-Laden Electroconductive MXene Nanocomposite Bioinks. Nanoscale 2020, 12, 16069–16080. [Google Scholar] [CrossRef] [PubMed]

- Crowder, S.; Prasai, D.; Rath, R.; Balikov, D.; Bae, H.; Bolotin, K.; Sung, H.-J. Three-dimensional graphene foams promote osteogenic differentiation of human mesenchymal stem cells. Nanoscale 2013, 5, 4171–4176. [Google Scholar] [CrossRef] [PubMed]

- Wei, P.; Xu, Y.; Gu, Y.; Yao, Q.; Li, J.; Wang, L. IGF-1-releasing PLGA nanoparticles modified 3D printed PCL scaffolds for cartilage tissue engineering. Drug Deliv. 2020, 27, 1106–1114. [Google Scholar] [CrossRef] [PubMed]

- Diniz, F.R.; Maia, R.C.A.P.; de Andrade, L.R.M.; Andrade, L.N.; Vinicius Chaud, M.; da Silva, C.F.; Corrêa, C.B.; de Albuquerque Junior, R.L.C.; Pereira da Costa, L.; Shin, S.R.; et al. Silver Nanoparticles-Composing Alginate/Gelatine Hydrogel Improves Wound Healing In Vivo. Nanomaterials 2020, 10, 390. [Google Scholar] [CrossRef] [PubMed]

- Saraiva, A.S.; Ribeiro, I.A.C.; Fernandes, M.H.; Cerdeira, A.C.; Vieira, B.J.C.; Waerenborgh, J.C.; Pereira, L.C.J.; Cláudio, R.; Carmezim, M.J.; Gomes, P.; et al. 3D-printed platform multi-loaded with bioactive, magnetic nanoparticles and an antibiotic for re-growing bone tissue. Int. J. Pharm. 2021, 593, 120097. [Google Scholar] [CrossRef] [PubMed]

- Del Pino, P.; Yang, F.; Pelaz, B.; Zhang, Q.; Kantner, K.; Hartmann, R.; Martinez de Baroja, N.; Gallego, M.; Möller, M.; Manshian, B.B.; et al. Basic Physicochemical Properties of Polyethylene Glycol Coated Gold Nanoparticles that Determine Their Interaction with Cells. Angew. Chem. Int. Ed. Engl. 2016, 55, 5573–5577. [Google Scholar] [CrossRef]

- Fielding, G.; Bandyopadhyay, A.; Bose, S. Effects of Silica and Zinc Oxide Doping on Mechanical and Biological Properties of 3D Printed Tricalcium Phosphate Tissue Engineering Scaffolds. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2012, 28, 113–122. [Google Scholar] [CrossRef] [PubMed]

- Wilson, S.; Cross, L.; Peak, C.; Gaharwar, A. Shear-Thinning and Thermo-Reversible Nanoengineered Inks for 3D Bioprinting. ACS Appl. Mater. Interfaces 2017, 9, 43449–43458. [Google Scholar] [CrossRef] [PubMed]

- Alcala-Orozco, C.R.; Mutreja, I.; Cui, X.; Hooper, G.J.; Lim, K.S.; Woodfield, T.B.F. Hybrid biofabrication of 3D osteoconductive constructs comprising Mg-based nanocomposites and cell-laden bioinks for bone repair. Bone 2022, 154, 116198. [Google Scholar] [CrossRef] [PubMed]

- Cao, B.; Lin, J.; Tan, J.; Li, J.; Ran, Z.; Deng, L.; Hao, Y. 3D-printed vascularized biofunctional scaffold for bone regeneration. Int. J. Bioprint. 2023, 9, 702. [Google Scholar] [CrossRef] [PubMed]

- Hafezi, M.; Khorasani, S.N.; Khalili, S.; Neisiany, R.E. Self-healing interpenetrating network hydrogel based on GelMA/alginate/nano-clay. Int. J. Biol. Macromol. 2023, 242 Pt 2, 124962. [Google Scholar] [CrossRef] [PubMed]

- Han, W.; Singh, N.K.; Kim, J.J.; Kim, H.; Kim, B.S.; Park, J.Y.; Jang, J.; Cho, D.W. Directed differential behaviors of multipotent adult stem cells from decellularized tissue/organ extracellular matrix bioinks. Biomaterials 2019, 224, 119496. [Google Scholar] [CrossRef] [PubMed]

- Miao, G.; Liang, L.; Li, W.; Ma, C.; Pan, Y.; Zhao, H.; Zhang, Q.; Xiao, Y.; Yang, X. 3D Bioprinting of a Bioactive Composite Scaffold for Cell Delivery in Periodontal Tissue Regeneration. Biomolecules 2023, 13, 1062. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Ma, Y.; Wang, X.; Yuan, S.; Huo, F.; Yi, G.; Zhang, J.; Yang, B.; Tian, W. A 3D-Bioprinted Functional Module Based on Decellularized Extracellular Matrix Bioink for Periodontal Regeneration. Adv. Sci. 2023, 10, e2205041. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Li, Q.; Yang, Q.; Zhang, S.; Yi, K.; Zhang, G.; Tang, Z. Evaluation of the effect of 3D-bioprinted gingival fibroblast-encapsulated ADM scaffolds on keratinized gingival augmentation. J. Periodontal. Res. 2023, 58, 564–574. [Google Scholar] [CrossRef] [PubMed]

- Yu, G.T.; Zhu, W.X.; Zhao, Y.Y.; Cui, H.; Chen, H.; Chen, Y.; Ning, T.-T.; Rong, M.-D.; Rao, L.; Ma, D.-D. 3D-printed bioink loading with stem cells and cellular vesicles for periodontitis-derived bone defect repair. Biofabrication 2024, 16, 025007. [Google Scholar] [CrossRef] [PubMed]

- Miao, S.; Zhu, W.; Castro, N.J.; Nowicki, M.; Zhou, X.; Cui, H.; Fisher, J.P.; Zhang, L.G. 4D printing smart biomedical scaffolds with novel soybean oil epoxidized acrylate. Sci. Rep. 2016, 6, 27226. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.-H.; Chao, P.-H.G.; Tai, W.-C.; Chang, P.-C. 3D-Printed Collagen-BasedWaveform Microfibrous Scaffold for Periodontal Ligament Reconstruction. Int. J. Mol. Sci. 2021, 22, 7725. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Liu, M.; Liu, Y. The performance of 3D bioscaffolding based on a human periodontal ligamentstem cell printing technique. J. Biomed. Mater. Res. A 2021, 109, 1209–1219. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Wang, W.; Chen, Q.; Ren, T. Bioprinted PDLSCs with high-concentration GelMA hydrogels exhibit enhanced osteogenic differentiation in vitro and promote bone regeneration in vivo. Clin. Oral. Investig. 2023, 27, 5153–5170. [Google Scholar] [CrossRef]

- Vurat, M.T.; Seker, S.; Lalegul-Ulker, O.; Parmaksiz, M.; Elçin, A.E.; Elçin, Y.M. Development of a multicellular 3D-bioprinted microtissue model of human periodontal ligament-alveolar bone biointerface: Towards a pre-clinical model of periodontal diseases and personalized periodontal tissue engineering. Genes Dis. 2020, 9, 1008–1023. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, Q.; Liu, P.; Lin, C.; Tang, Z.; Wang, H.L. Three-Dimensional Cell Printed Lock-Key Structure for Oral Soft and Hard Tissue Regeneration. Tissue Eng. Part A 2022, 28, 13–26. [Google Scholar] [CrossRef] [PubMed]

- Yi, K.; Li, Q.; Lian, X.; Wang, Y.; Tang, Z. Utilizing 3D bioprinted platelet-rich fibrin-based materials to promote the regeneration of oral soft tissue. Regen. Biomater. 2022, 9, rbac021. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Tarafder, S.; Fogge, M.; Kao, K.; Lee, C.H. Periodontal ligament stem/progenitor cells with protein-releasing scaffolds for cementum formation and integration on dentin surface. Connect Tissue Res. 2016, 57, 488–495. [Google Scholar] [CrossRef] [PubMed]

- Won, J.Y.; Park, C.Y.; Bae, J.H.; Ahn, G.; Kim, C.; Lim, D.H.; Huh, J.B. Evaluation of 3D printed PCL/PLGA/β-TCP versus collagen membranes for guided bone regeneration in a beagle implant model. Biomed. Mater. 2016, 11, 055013. [Google Scholar] [CrossRef] [PubMed]

- Thattaruparambil Raveendran, N.; Vaquette, C.; Meinert, C.; Samuel Ipe, D.; Ivanovski, S. Optimization of 3D bioprinting of periodontal ligament cells. Dent. Mater. 2019, 35, 1683–1694. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Hajibandeh, J.; Suzuki, T.; Fan, A.; Shang, P.; Mao, J.J. Three-dimensional printed multiphase scaffolds for regeneration of periodontium complex. Tissue Eng. Part A 2014, 20, 1342–1351. [Google Scholar] [CrossRef] [PubMed]

- Soleymani, S.; Naghib, S.M. 3D and 4D printing hydroxyapatite-based scaffolds for bone tissue engineering and regeneration. Heliyon 2023, 9, e19363. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Tibbits, S. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Chen, X.; Han, S.; Wu, W.; Wu, Z.; Yuan, Y.; Wu, J.; Liu, C. Harnessing 4D Printing Bioscaffolds for Advanced Orthopedics. Small 2022, 18, e2106824. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Qiao, Z.; Nazarzadeh Zare, E.; Huang, J.; Zheng, X.; Sun, X.; Shao, M.; Wang, H.; Wang, X.; Chen, D.; et al. 4D-Printed Dynamic Materials in Biomedical Applications: Chemistry, Challenges, and Their Future Perspectives in the Clinical Sector. J. Med. Chem. 2020, 63, 8003–8024. [Google Scholar] [CrossRef]

- Gillaspie, E.A.; Matsumoto, J.S.; Morris, N.E.; Downey, R.J.; Shen, K.R.; Allen, M.S.; Blackmon, S.H. From 3-Dimensional Printing to 5-Dimensional Printing: Enhancing Thoracic Surgical Planning and Resection of Complex Tumors. Ann. Thorac. Surg. 2016, 101, 1958–1962. [Google Scholar] [CrossRef] [PubMed]

- Verykokou, S.; Ioannidis, C.; Soile, S.; Angelopoulos, C.; Theodoridis, K.; Arampatzis, A.S.; Assimopoulou, A.N.; Christofilos, D.; Kapourani, A.; Pantazos, I.; et al. The Role of Cone Beam Computed Tomography in Periodontology: From 3D Models of Periodontal Defects to 3D-Printed Scaffolds. J. Pers. Med. 2024, 14, 207. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.H.; Chen, J.Y.; Suo, W.H.; Shao, W.R.; Huang, C.Y.; Li, M.T.; Li, Y.-Y.; Li, Y.-H.; Liang, E.-L.; Lee, I.T.; et al. Unlocking the Future of Periodontal Regeneration: An Interdisciplinary Approach to Tissue Engineering and Advanced Therapeutics. Biomedicines 2024, 12, 1090. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Saiding, Q.; Cai, X.; Xiao, Y.; Wang, P.; Cai, Z.; Gong, X.; Gong, W.; Zhang, X.; Cui, W. Intelligent Vascularized 3D/4D/5D/6D-Printed Tissue Scaffolds. Nanomicro Lett. 2023, 15, 239. [Google Scholar] [CrossRef] [PubMed]

- Vasiliadis, A.V.; Koukoulias, N.; Katakalos, K. From Three-Dimensional (3D)- to 6D-Printing Technology in Orthopedics: Science Fiction or Scientific Reality? J. Funct. Biomater. 2022, 13, 101. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almeida, N.D.; Carneiro, C.A.; de Marco, A.C.; Porto, V.C.; França, R. 3D Bioprinting Techniques and Bioinks for Periodontal Tissues Regeneration—A Literature Review. Biomimetics 2024, 9, 480. https://doi.org/10.3390/biomimetics9080480

Almeida ND, Carneiro CA, de Marco AC, Porto VC, França R. 3D Bioprinting Techniques and Bioinks for Periodontal Tissues Regeneration—A Literature Review. Biomimetics. 2024; 9(8):480. https://doi.org/10.3390/biomimetics9080480

Chicago/Turabian StyleAlmeida, Nátaly Domingues, Camila Alves Carneiro, Andrea Carvalho de Marco, Vinicius Carvalho Porto, and Rodrigo França. 2024. "3D Bioprinting Techniques and Bioinks for Periodontal Tissues Regeneration—A Literature Review" Biomimetics 9, no. 8: 480. https://doi.org/10.3390/biomimetics9080480

APA StyleAlmeida, N. D., Carneiro, C. A., de Marco, A. C., Porto, V. C., & França, R. (2024). 3D Bioprinting Techniques and Bioinks for Periodontal Tissues Regeneration—A Literature Review. Biomimetics, 9(8), 480. https://doi.org/10.3390/biomimetics9080480