Experimental Research on an Afterburner System Fueled with Hydrogen–Methane Mixtures

Abstract

:1. Introduction

2. Materials and Methods

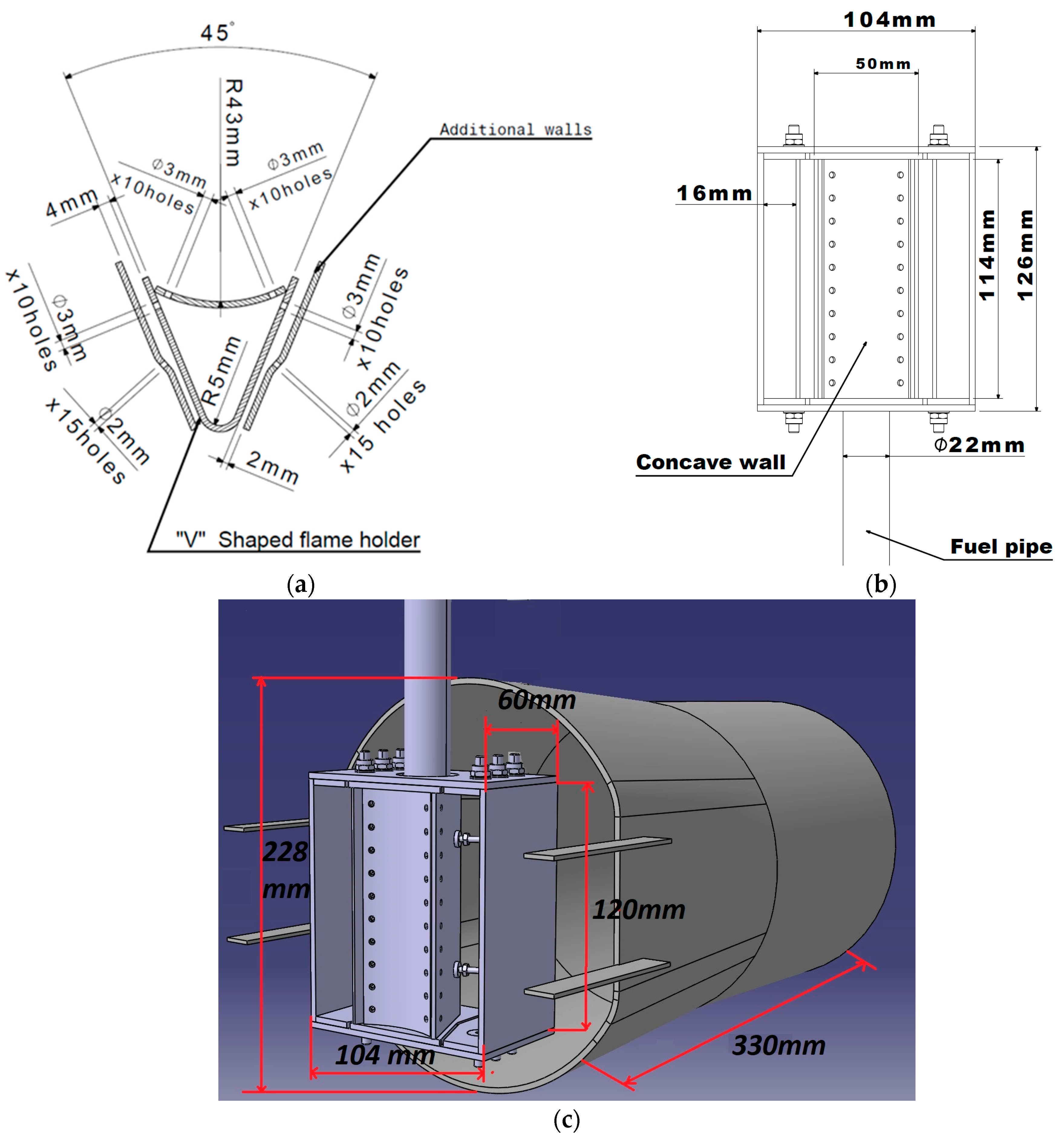

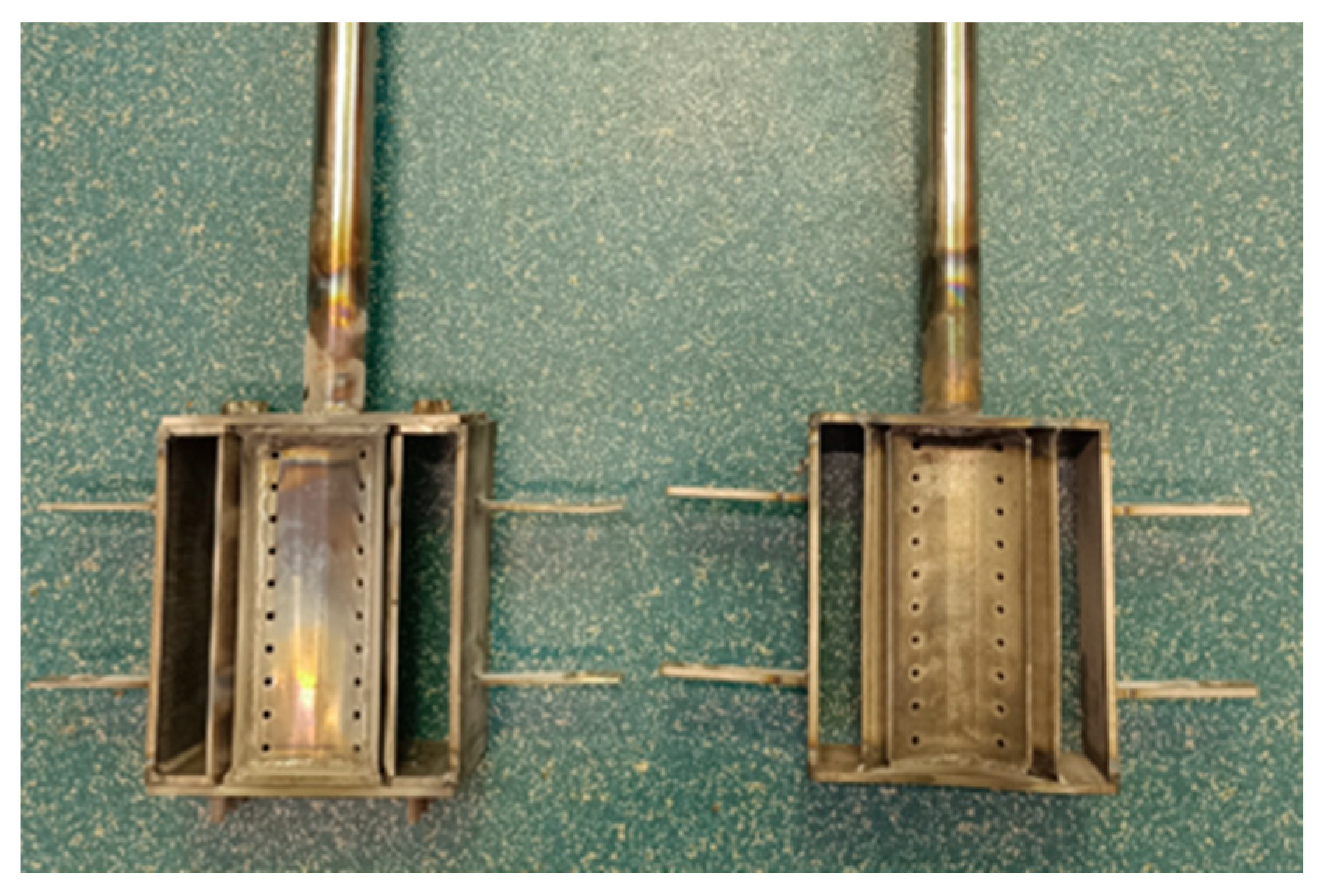

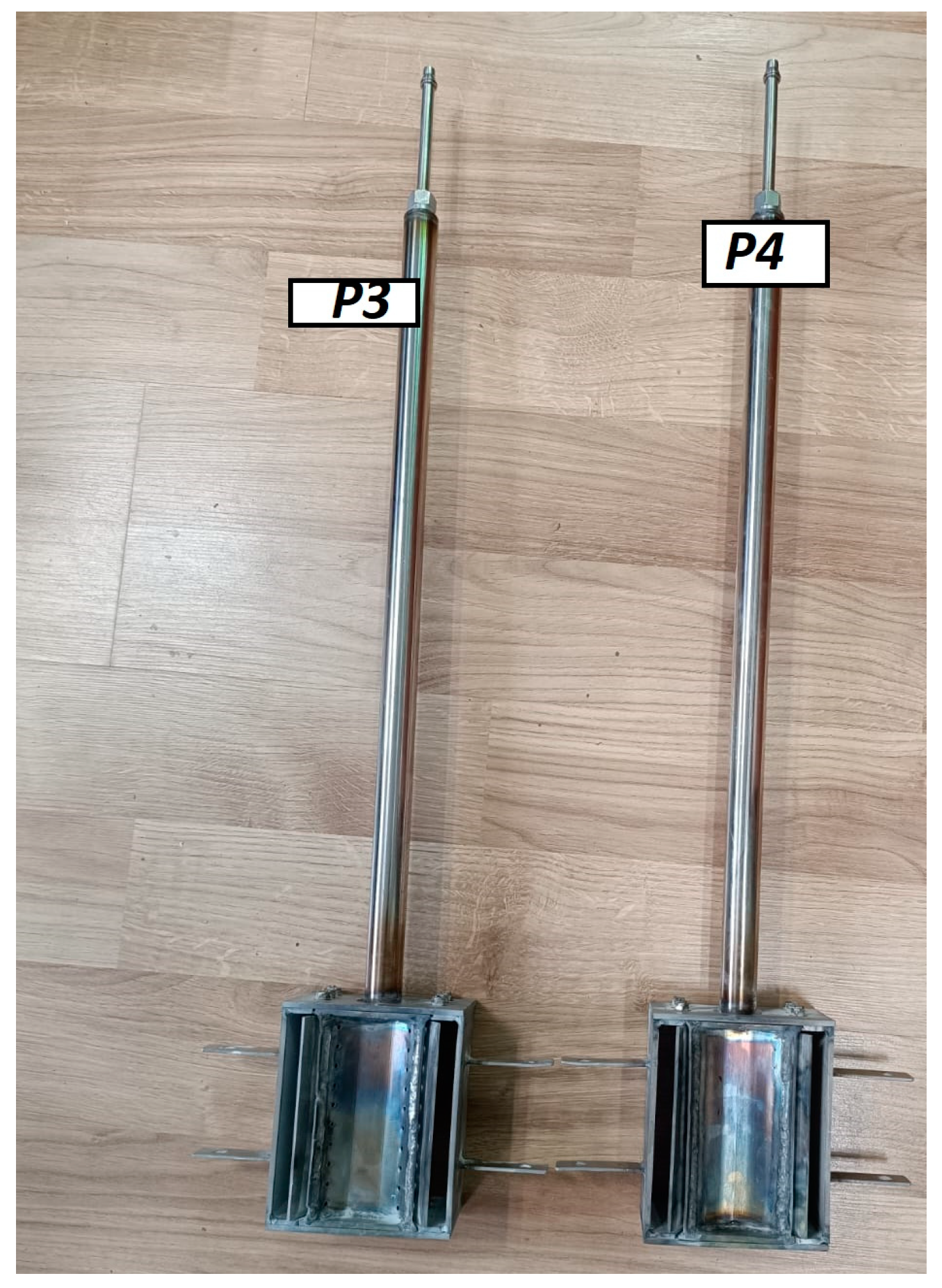

2.1. Afterburner Geometry

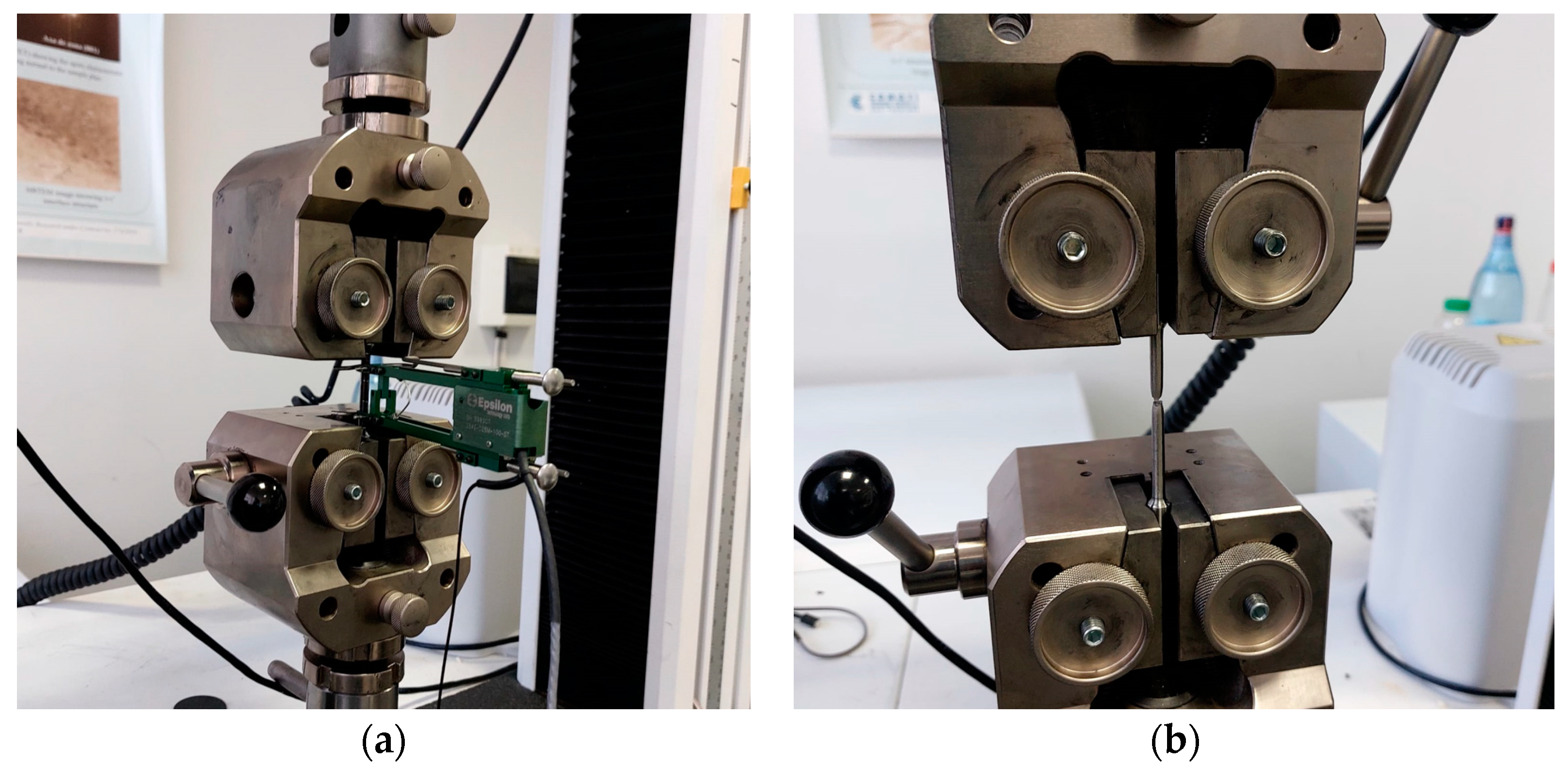

2.2. Material Characterization

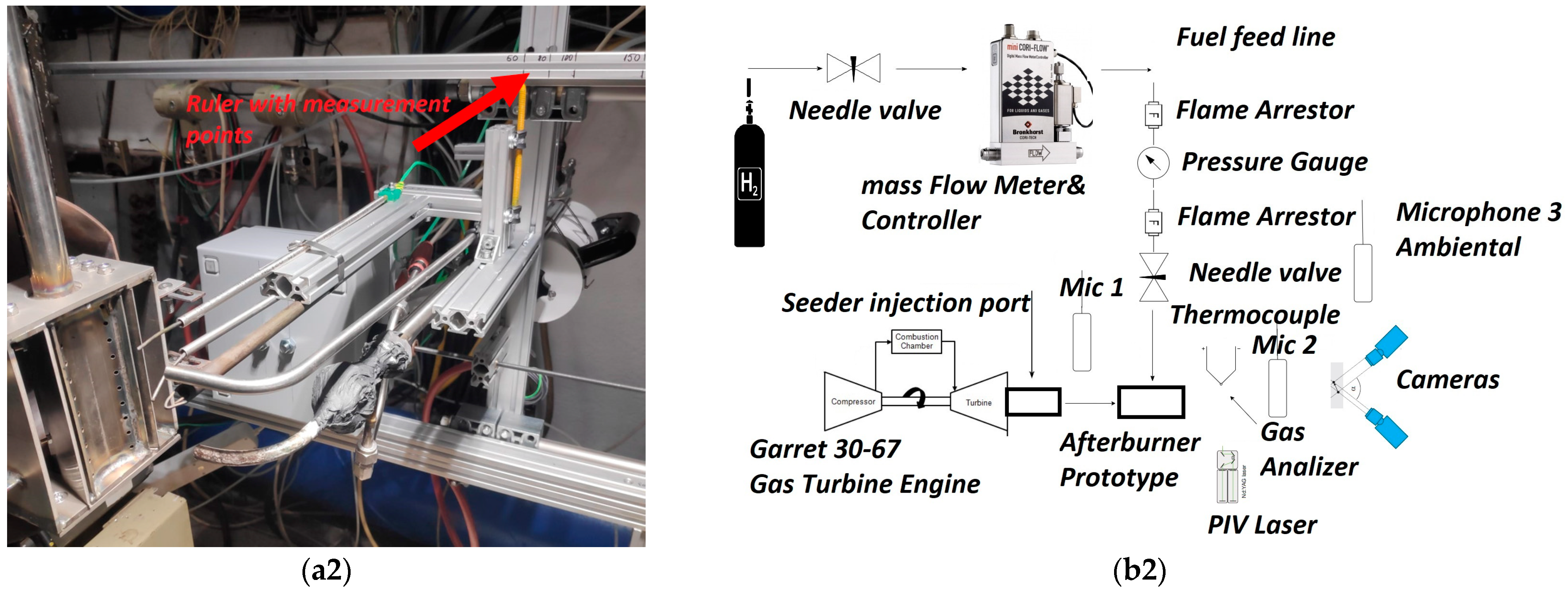

2.3. Experimental Setup

3. Results and Discussion

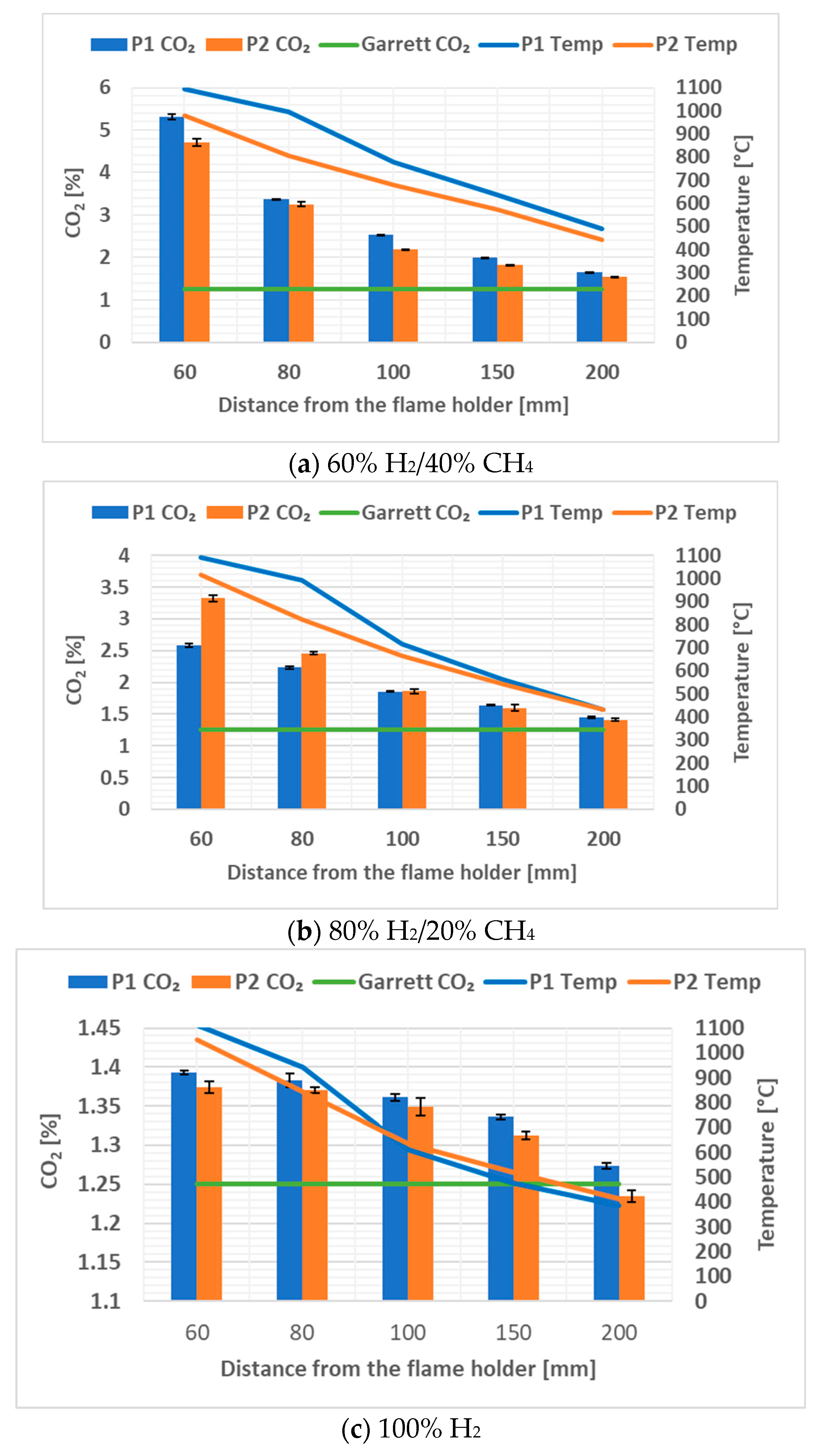

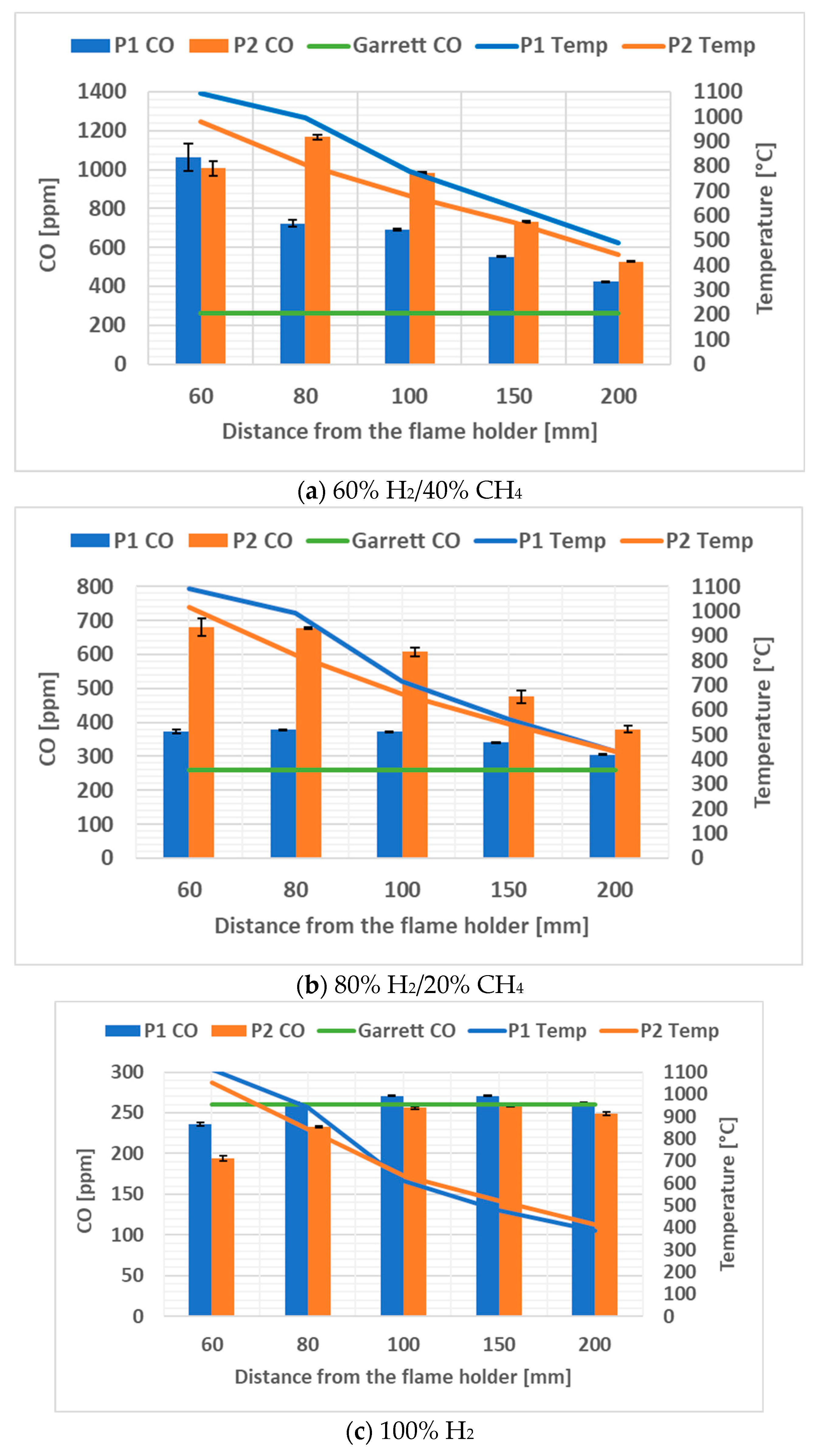

3.1. Comparative Analysis of Flue Gases

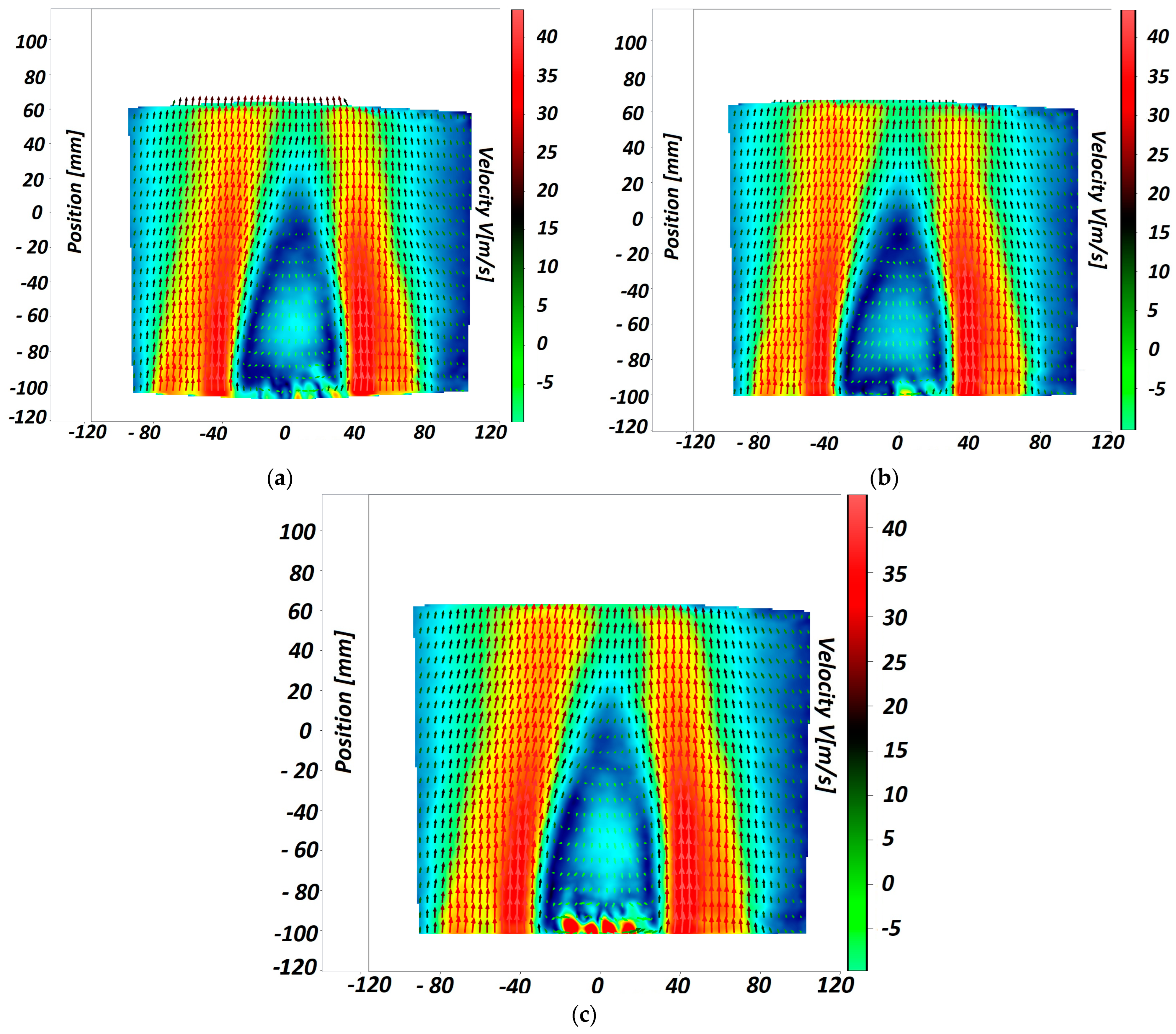

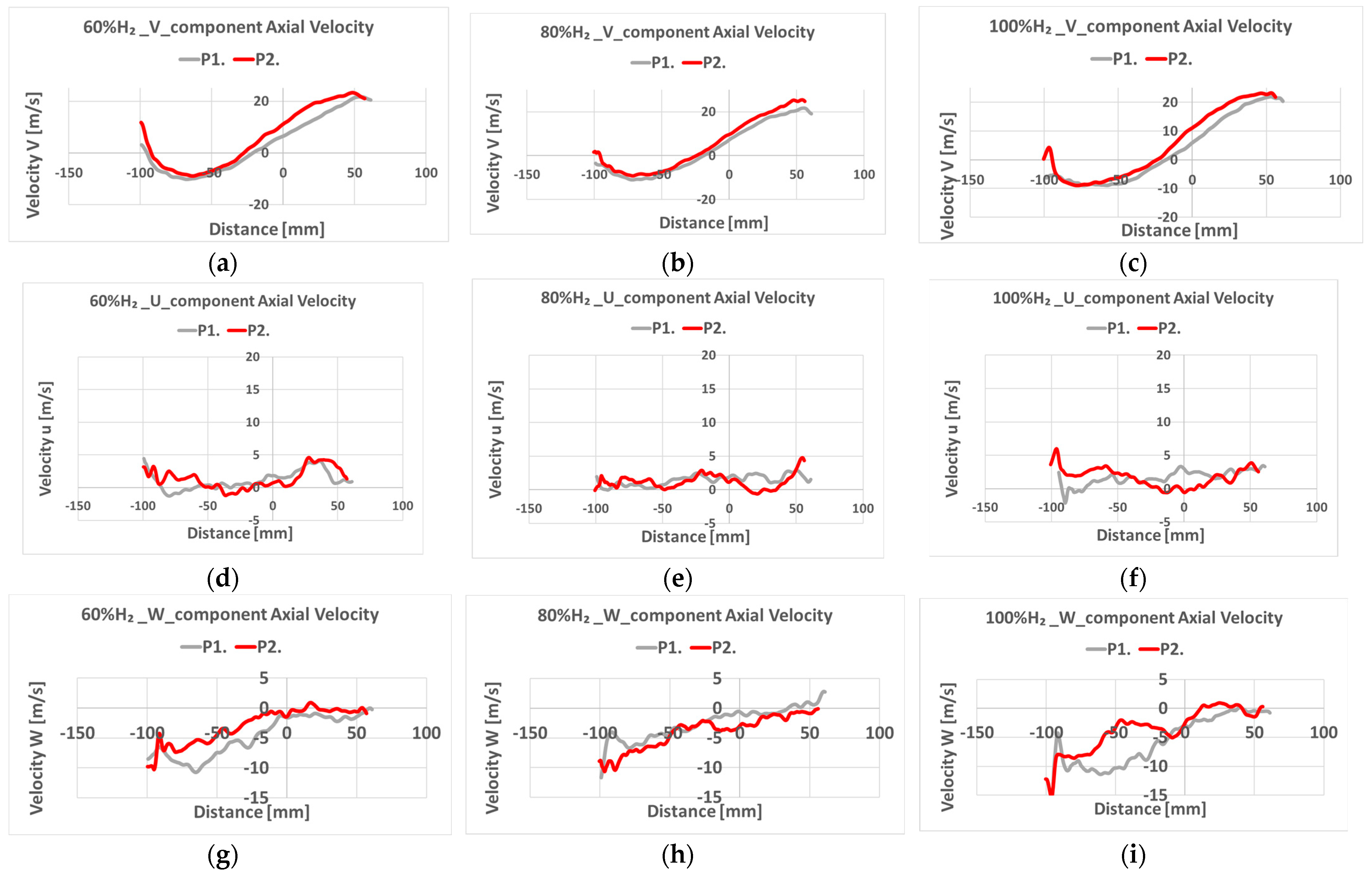

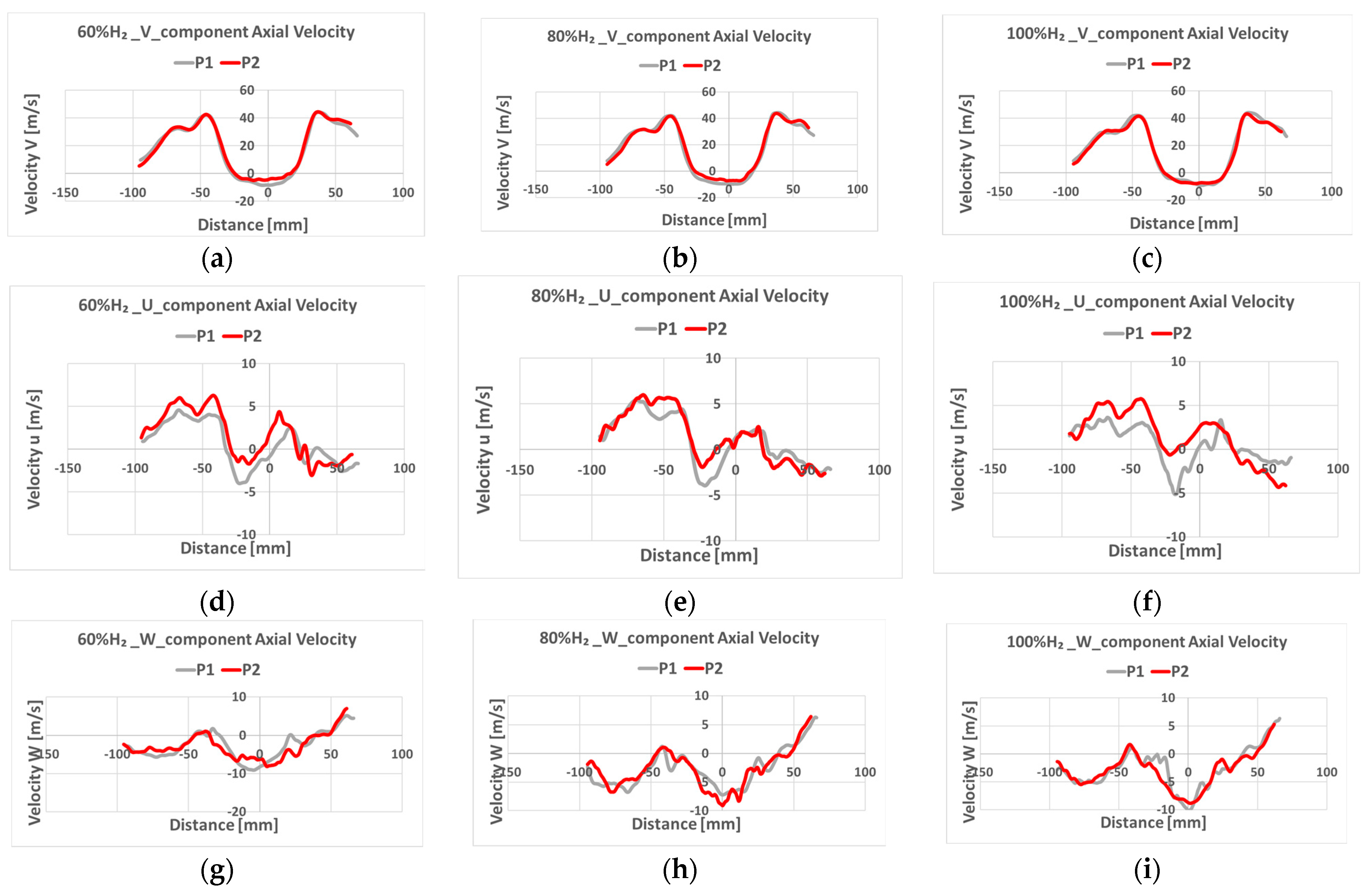

3.2. PIV Experiments

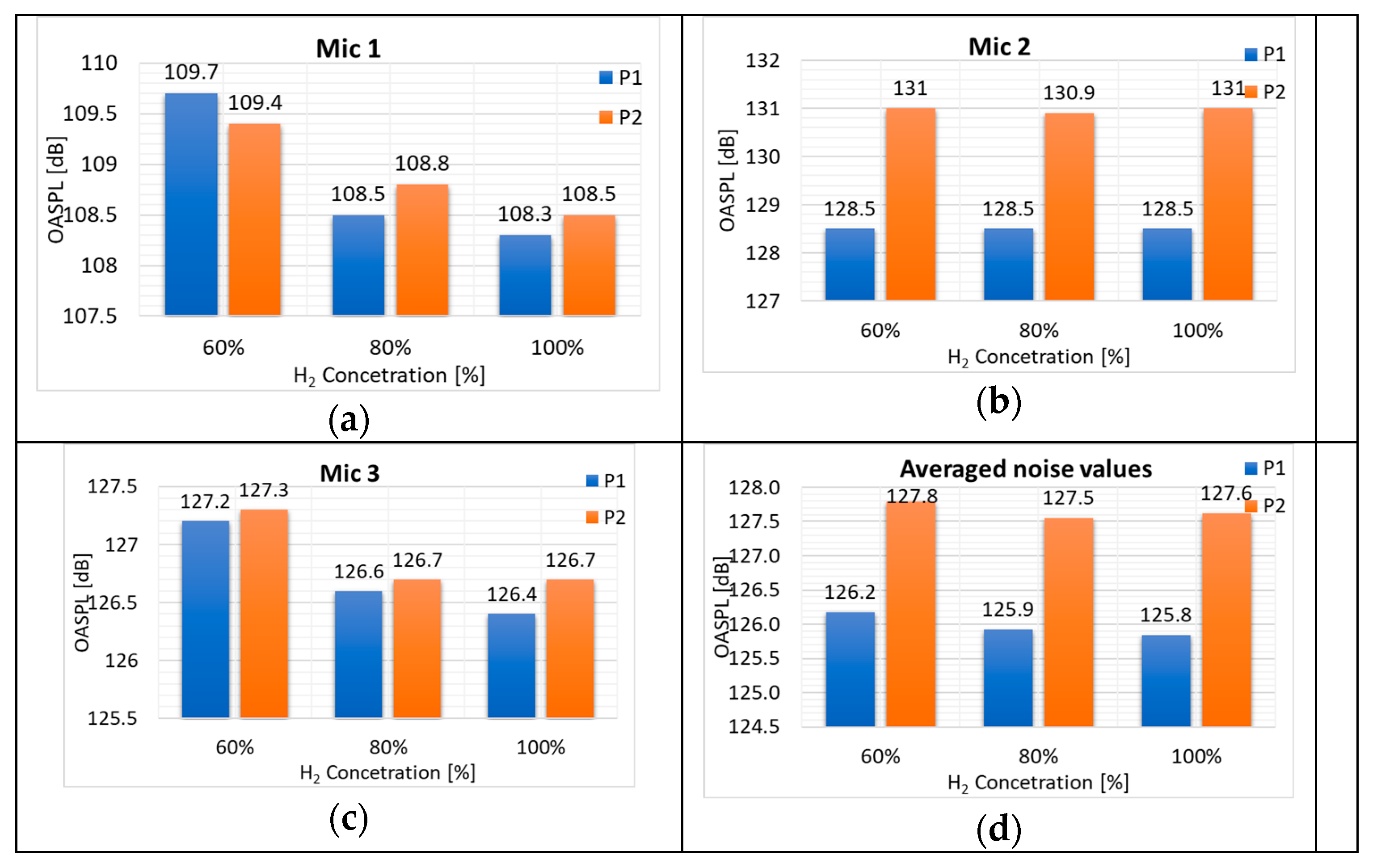

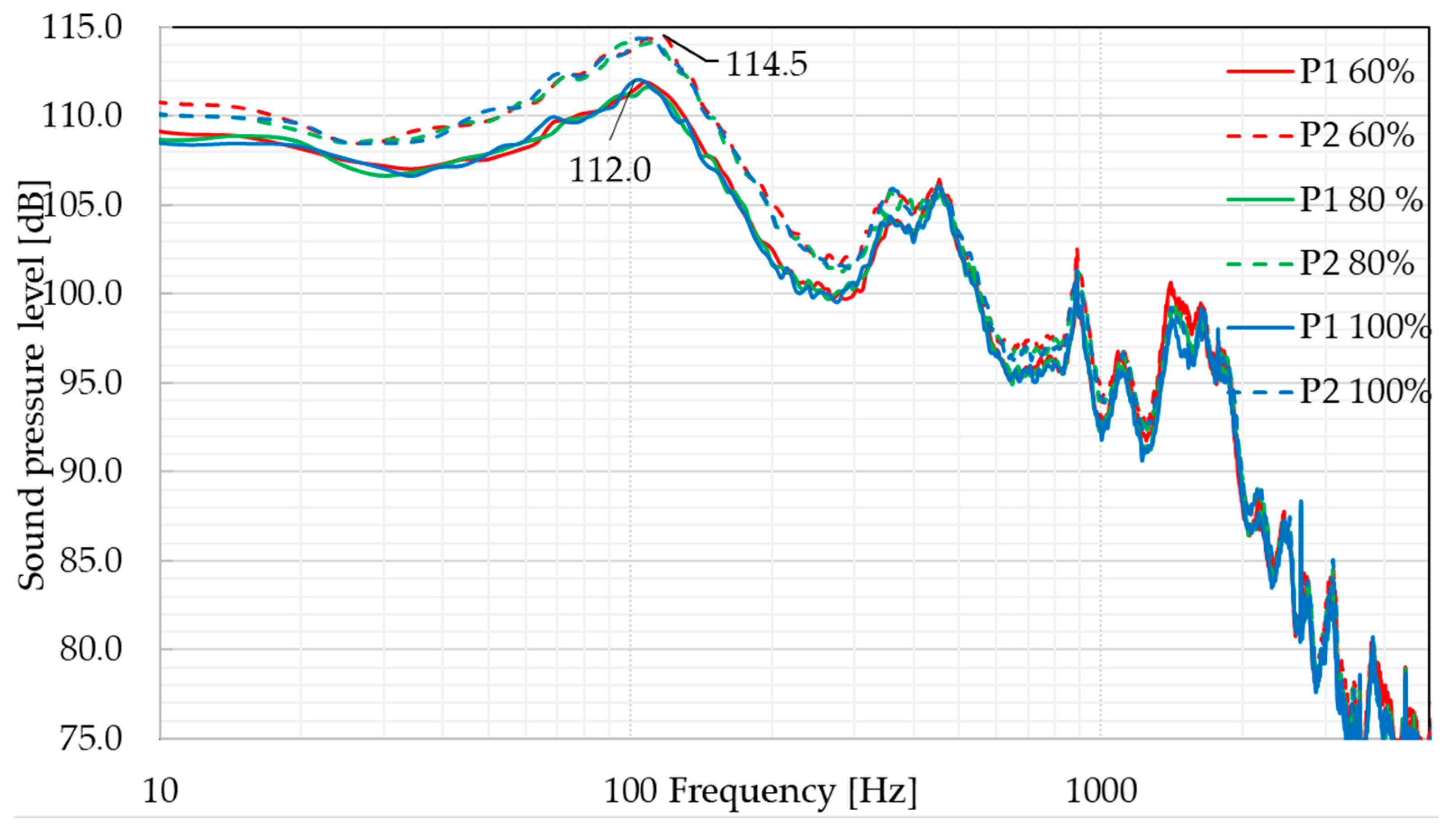

3.3. Noise Measurements

4. Conclusions

- A stable functioning of the afterburner assembly for all used fuels, in the case of both prototypes.

- The CO2 concentration became lower as the percentage of H2 in the fuel mixture increased. This was expected due to the fact that as the H2 percentage in the fuel increased, the presence of carbon atoms in the fuel diminished. Thus, less CO2 was produced as the fuel burned. The behavior of the two tested prototypes was very similar. For all three fuels used, the CO2 concentration levels were slightly lower in the case of the additive-manufactured prototype (P2);

- Similar to the CO2 concentration, the CO levels decreased as the percentage of H2 in the fuel increased. The CO levels were significantly higher in the case of the additive-manufactured prototype P2 when 60% H2/40% CH4 and 80% H2/20% CH4 mixtures were used as fuel. When pure H2 was used as fuel, the measured data suggest that no additional CO was produced during the combustion process; the level of CO was similar to that coming from the Garrett micro gas turbine at all five measuring points. This is due to the absence of carbon atoms in the fuel, thus the production of CO as a by-product of the combustion process not being possible.

- The NO emissions gradually decreased as the percentage of H2 in the fuel mixture increased. The NO concentration was significantly lower in the case of the additive-manufactured prototype P2 in comparison with the classic manufactured prototype P1, except for at the 60 mm measuring point.

- Examining the data obtained from PIV experimental measurements of the flow within the mixing region shows that the differences between the tested prototypes are marginal. The highest axial velocity component value on the centerline was measured for the P1 prototype. Downstream of the bluff body, a negative velocity was observed, creating a recirculation region where the axial velocity reached a nadir of approximately 10 m/s, located approximately 25 mm downstream of the flame holder’s trailing edge. The length of the recirculation region spanned about 60 mm. In the transversal direction, the axial velocity profile along the transversal direction was roughly parabolic for all the presented cases. For all cases, the central, high-velocity region of the flow expanded downstream, due to the spreading of the jet. The mean velocity profiles along the transversal direction at distance L = −60, indicate that the negative velocity region measured approximately 80 mm. Downstream, the velocity deficit caused by the flame holder diminished, with the axial gradient influenced by the rate of volumetric expansion due to chemical heat release.

- The acoustic measurements showed that a higher H2 concentration led to a reduction in noise of approximately 1.5 dB for both afterburner prototypes. Also, in the case of prototype P2, the noise level was slightly higher. The noise reduction of prototype P1 compared with prototype P2 occurred in the low-frequency range between 10 and 400 Hz, where the difference between P2 and P1 was up to 2.5 dB at a frequency of 100 Hz.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sustainable Development Goals. Available online: https://www.un.org/development/desa/pd/sites/www.un.org.development.desa.pd/files/undesa_pd_2022_global_population_growth.pdf (accessed on 10 March 2024).

- Nakaya, S.; Omi, K.; Okamoto, T.; Ikeda, Y.; Zhao, C.; Tsue, M.; Taguchi, H. Instability and mode transition analysis of a hydrogen-rich combustion in a model afterburner. Proc. Combust. Inst. 2020, 38, 5933–5942. [Google Scholar] [CrossRef]

- Wu, B.; Zhao, X.; Chowdhury, B.R.; Cetegen, B.M.; Xu, C.; Lu, T. A numerical investigation of the flame structure and blowoff characteristics of a bluff-body stabilized turbulent premixed flame. Combust. Flame 2019, 202, 376–393. [Google Scholar] [CrossRef]

- Guo, S.; Wang, J.; Zhang, W.; Zhang, M.; Huang, Z. Effect of hydrogen enrichment on swirl/bluff-body lean premixed flame stabilization. Int. J. Hydrogen Energy 2020, 45, 10906–10919. [Google Scholar] [CrossRef]

- Pathania, R.; Skiba, A.; Ciardiello, R.; Mastorakos, E. Blow-off mechanisms of turbulent premixed bluff-body stabilised flames operated with vapourised kerosene fuels. Proc. Combust. Inst. 2020, 38, 2957–2965. [Google Scholar] [CrossRef]

- Kore, R.; Patil, S.; Victor, V.; Suresh, S.; Bajaj, D.K.; Jain, S. CFD approach to predict the significance of the shape bluff body on flame stabilisation in lean premixed combustion of hydrogen-air mixtures. Mater. Today Proc. 2023, 72, 1181–1189. [Google Scholar] [CrossRef]

- Huang, Z.; Peng, Q.; Shi, Z.; Fu, G.; Xiao, H.; Huang, C. Numerical and experimental investigation of H2/CH4/Air combustion characteristics and thermal performance in the combustor with multi-bluff-body. Fuel 2024, 367, 131435. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, Y.; Li, L.; Cui, Y.; Zhang, L.; Yang, Z.; Zhang, Z. Numerical comparison of H2/air catalytic combustion characteristic of micro–combustors with a conventional, slotted or controllable slotted bluff body. Energy 2019, 189, 116242. [Google Scholar] [CrossRef]

- Jha, V.; Velidi, G.; Emani, S. Optimization of flame stabilization methods in the premixed microcombustion of hydrogen–air mixture. Heat Transf. 2022, 51, 5896–5918. [Google Scholar] [CrossRef]

- Kim, Y.J.; Song, W.; Pérez, F.E.H.; Im, H.G. Explosive dynamics of bluff-body-stabilized lean premixed hydrogen flames at blow-off. Proc. Combust. Inst. 2021, 38, 2265–2274. [Google Scholar] [CrossRef]

- Kwak, S.; Choi, J.; Ahn, M.; Yoon, Y. Effects of hydrogen addition on the forced response of H2/CH4 flames in a dual-nozzle swirl-stabilized combustor. Int. J. Hydrogen Energy 2022, 47, 28139–28151. [Google Scholar] [CrossRef]

- Ge, B.; Ji, Y.; Zhang, Z.; Zang, S.; Tian, Y.; Yu, H.; Chen, M.; Jiao, G.; Zhang, D. Experiment study on the combustion performance of hydrogen-enriched natural gas in a DLE burner. Int. J. Hydrogen Energy 2019, 44, 14023–14031. [Google Scholar] [CrossRef]

- Nam, J.; Lee, Y.; Joo, S.; Yoon, Y.; Yoh, J.J. Numerical analysis of the effect of the hydrogen composition on a partially premixed gas turbine combustor. Int. J. Hydrogen Energy 2019, 44, 6278–6286. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, M.; Peng, S.; Wang, J.; Huang, Z. Large Eddy Simulation of the Effect of Hydrogen Ratio on the Flame Stabilization and Blow-Off Dynamics of a Lean CH4/H2/Air Bluff-Body Flame. Appl. Sci. 2024, 14, 1846. [Google Scholar] [CrossRef]

- Ceglie, V.; Stefanizzi, M.; Capurso, T.; Fornarelli, F.; Camporeale, S.M. Thermoacoustic Combustion Stability Analysis of a Bluff Body-Stabilized Burner Fueled by Methane–Air and Hydrogen–Air Mixtures. Energies 2023, 16, 3272. [Google Scholar] [CrossRef]

- Vance, F.H.; Shoshin, Y.; de Goey, P.; van Oijen, J. Flame Stabilization and Blow-Off of Ultra-Lean H2-Air Premixed Flames. Energies 2021, 14, 1977. [Google Scholar] [CrossRef]

- Wan, J.; Fan, A. Recent progress in flame stabilization technologies for combustion-based micro energy and power systems. Fuel 2020, 286, 119391. [Google Scholar] [CrossRef]

- Stefanizzi, M.; Capurso, T.; Filomeno, G.; Torresi, M.; Pascazio, G. Recent Combustion Strategies in Gas Turbines for Propulsion and Power Generation toward a Zero-Emissions Future: Fuels, Burners, and Combustion Techniques. Energies 2021, 14, 6694. [Google Scholar] [CrossRef]

- Ahn, B.; Indlekofer, T.; Dawson, J.; Worth, N. Transient Thermo-Acoustic Responses of Methane/Hydrogen Flames in a Pressurized Annular Combustor. J. Eng. Gas Turbines Power 2022, 144, 011018. [Google Scholar] [CrossRef]

- Florean, F.G.; Petcu, A.C.; Carlanescu, R.; Porumbel, I.; Sandu, C.; Carlanescu, C. “Instalaţie de Postcombustie, Multietajată în Skyd Turbomotor Autoventilat” [Buletinul Oficial de Propietate Industrial nr. 7/2016]. RO128845B1/2016. Available online: http://pub.osim.ro/publication-server/pdf-document?PN=RO128845%20RO%20128845&iDocId=8631&iepatch=.pdf (accessed on 28 March 2024).

- Florean, F.; Mangra, A.; Enache, M.; Carlanescu, R.; Kuncser, R. Design and numerical investigations of an afterburner system using methane-hydrogen blends. Int. J. Mod. Manuf. Technol. 2023, 15, 39–46. [Google Scholar] [CrossRef]

- RR1047 Injecting Hydrogen into the Gas Network—A Literature Search. Available online: https://www.hse.gov.uk/research/rrhtm/rr1047.htm (accessed on 28 March 2024).

- Romania’s Recovery and Resilience Plan. Available online: https://mfe.gov.ro/wp-content/uploads/2021/06/0c2887df42dd06420c54c1b4304c5edf.pdf (accessed on 28 March 2024).

- Lefebvre, A.H.; Ballal, D.R. Gas Turbine Combustion—Alternative Fuels and Emissions, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9780429141041. [Google Scholar] [CrossRef]

- ISO 3744: 2010; Acoustics—Determination of Sound Power Levels and Sound Energy Levels of Noise Sources Using Sound Pressure—Engineering Methods for an Essentially Free Field over a Reflecting Plane. International Organization for Standardization: Geneva, Switzerland, 2010.

| Prototype P1 | Prototype P2 | ||

|---|---|---|---|

| Ultimate tensile strength (UTS) | 992.8 | 867 | MPa |

| Yield strength (0.2% offset) | 528.8 | 591 | MPa |

| Elongation at fracture (α) | 34 | 37 | % |

| Modulus of elasticity (E) | 147.5 | 145 | GPa |

| Mean roughness value (Ra) | 0.616 | 8.442 | µm |

| Peak-to-valley roughness depth (Rz) | 4.996 | 56.571 | µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Florean, F.G.; Mangra, A.; Enache, M.; Deaconu, M.; Ciobanu, R.; Carlanescu, R. Experimental Research on an Afterburner System Fueled with Hydrogen–Methane Mixtures. Inventions 2024, 9, 46. https://doi.org/10.3390/inventions9030046

Florean FG, Mangra A, Enache M, Deaconu M, Ciobanu R, Carlanescu R. Experimental Research on an Afterburner System Fueled with Hydrogen–Methane Mixtures. Inventions. 2024; 9(3):46. https://doi.org/10.3390/inventions9030046

Chicago/Turabian StyleFlorean, Florin Gabriel, Andreea Mangra, Marius Enache, Marius Deaconu, Razvan Ciobanu, and Razvan Carlanescu. 2024. "Experimental Research on an Afterburner System Fueled with Hydrogen–Methane Mixtures" Inventions 9, no. 3: 46. https://doi.org/10.3390/inventions9030046

APA StyleFlorean, F. G., Mangra, A., Enache, M., Deaconu, M., Ciobanu, R., & Carlanescu, R. (2024). Experimental Research on an Afterburner System Fueled with Hydrogen–Methane Mixtures. Inventions, 9(3), 46. https://doi.org/10.3390/inventions9030046